Abstract

Textiles have been at the heart of human technological progress for thousands of years, with textile developments closely tied to key inventions that have shaped societies. The relatively recent invention of electronic textiles is set to push boundaries again and has already opened up the potential for garments relevant to defense, sports, medicine, and health monitoring. The aim of this review is to provide an overview of the key innovative pathways in the development of electronic textiles to date using sources available in the public domain regarding electronic textiles (E-textiles); this includes academic literature, commercialized products, and published patents. The literature shows that electronics can be integrated into textiles, where integration is achieved by either attaching the electronics onto the surface of a textile, electronics are added at the textile manufacturing stage, or electronics are incorporated at the yarn stage. Methods of integration can have an influence on the textiles properties such as the drapability of the textile.

1. Introduction

This historical review will provide the reader with an insight into the development and employment of electronic textiles. While some academic sources have been used, a strong focus has been placed upon patented technology and commercialized products, which are often neglected in reviews of the literature.

The innovation of textiles 27,000 years ago could be contested as humanity’s invention of the first material [1]. The passing of the millennia has consolidated humanity’s need of textiles either to be protected from the environment, or desire to outwardly convey a message about themselves; whether that be artistic, stylistic, or wealth-related. The creation of textiles has therefore been coupled closely with key inventions that have shaped society; the knitting frame by William Lee in 1589 [2], the flying shuttle by John Kay in 1733 and the spinning jenny by James Hargreaves around 1765 [3], and set the foundation for the first industrial revolution.

A new revolution is now underway where the most widely used material by humankind has gained new functionality with the incorporation of electronic components. The first examples of electronic textiles date back to the use of illuminated headbands in the ballet La Farandole in 1883 [4]. More recently advances have appeared due to the reducing size and cost of electronic components, as well as an increased complexity of small-scale electronics, and have begun to show the true scope of possibilities for integrating electronics with clothing.

The growth of E-textiles in the later part of the 20th Century was due to a series of developments in material science and electronics further expanding the potential scope for embedding electronics within clothing. The conductive polymer was a key innovation; invented by Heeger et al. in 1977 [5] this led to a Nobel Prize thirty-three years later [6]. A patent for this type of technology for use with textiles was granted shortly after its creation [7]. Another critical development were advancements in transistor technology, with the creation of the first MOS (metal–oxide–semiconductor field-effect transistor) in 1960 [8]. The use of transistor-based electronics were outlined in a patent describing illuminated clothing from 1979 [9].

For a greater adoption of E-textiles a better level of integration of the electronic components was required. Key patents from 2005, 2016 and 2017 described the encapsulation of semi-conductor devices within the fibers of yarns [10,11,12]. This represented the start of the work on electronically functional yarns.

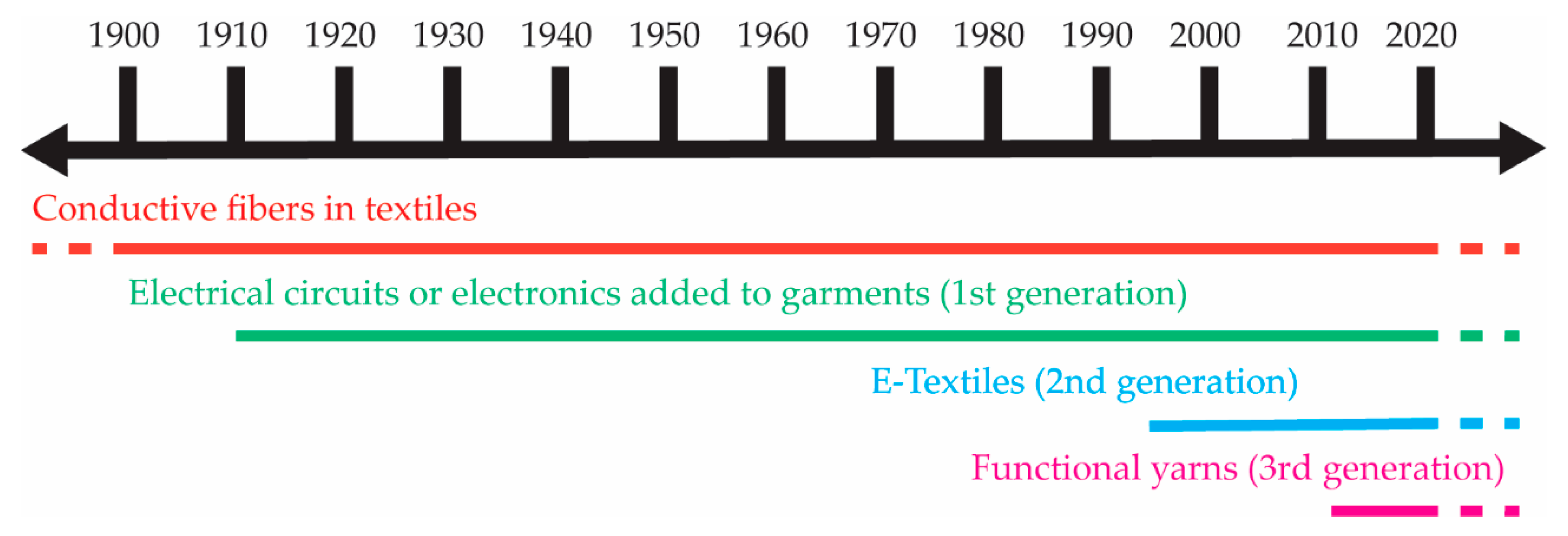

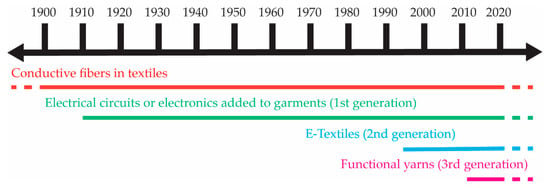

Three different pathways have been used to integrate electronics into textiles. These three distinct generations of electronic textiles are adding electronics or circuitry to a garment (first generation), functional fabrics such as sensors and switches (second generation), and functional yarns (third generation). Prior to the creation of E-textiles there are also many examples of the use of conductive fibers in textile fabrication, going back as far as the second century [13]. A timeline showing the evolution of E-textiles is given by Figure 1.

Figure 1.

A timeline of the different generations of electronic textiles. This timeline shows when significant interest in the technology began, and not earlier, isolated instances.

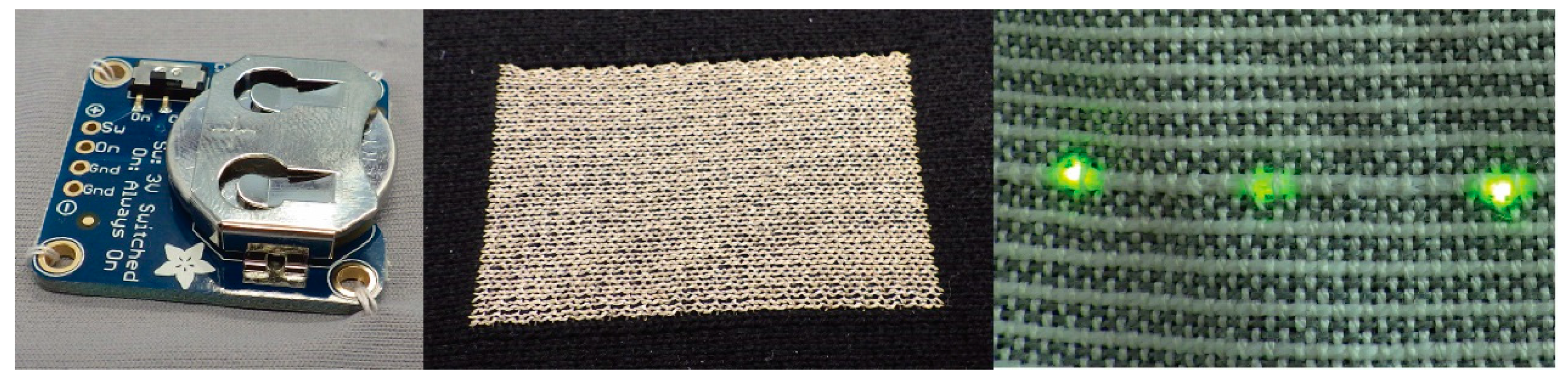

Each method of integration will have an influence on the textile properties such as the shear properties of the textile, or its flexibility, both of which effect the drapability. Figure 2 shows examples of each generation of electronic textiles.

Figure 2.

Photographs showing contemporary examples of each generation of electronic textile. (Left) An Adafruit coin cell battery holder. The first generation saw devices affixed to textiles. (Middle) A knitted electrode. The second generation of electronic textiles describes functional fabrics where conductive elements are integrated into a textile. (Right) An example of functional yarns (in this case LED yarns). The third generation of electronic textiles describe electronics embedded into textiles at a yarn level.

For the purposes of this review it is important to disentangle the various terms used loosely in the field of advanced textiles. Electronic textiles will be discussed; the strict definition of electronic textiles are where electronically conductive fibers or components are incorporated into a textile (electronic textiles will be referred to as ‘E-textiles’ in the subsequent text). Here, the term smart textiles, often anachronistically used as a synonym for electronic or E-textiles, will not be employed unless the textile has some kind of intelligence.

Critically, this historical review of the literature has a strong focus on innovation including patented technology and commercialized products, making heavy use of patents and internet sources. Non-internet sources have been referenced wherever possible; however, in many cases, particularly for products, only websites exist. These are areas that are typically neglected and this review serves as a complimentary piece to other more traditional reviews with the academic literature as the focus.

As a historic review this work will principally focus on research prior to 2010. Interest in electronic textiles has increased significantly since 2010. A search of the literature using the term ‘electronic textiles’ yields 310,000 results of which 254,000 are between 2010 and 2018. For completeness some more contemporary resources will be examined, for example in the area of textile energy solutions, which has largely evolved since 2010. There are several excellent reviews covering more recent developments in electronic textiles [14,15,16] and recent books on this subject [17,18].

The aim of this review is to overview the key pathways to the development of electronic textiles. The review is structured over ten sections, with the seven sections covering examples from a specific types of E-textile or application, such as sensors or illumination. Each section covers a major area of research in the literature, for example, temperature control textiles. In some cases two areas of interest have been grouped together such as E-textile pressure sensors and textile switches as one of these technologies led to the other. Three final sections discuss market trends, possible future developments for E-textiles, and a brief conclusion.

2. Temperature Control Textiles

It is unsurprising that the use of embedded conductive fibers was employed in one of the first true E-textiles, the electrically heated glove patented in 1910 [19]. This invention used ohmic heating (Joule heating, or resistive heating [20]), where an electric current was run through the conductive fibers and the electric resistance in the wires led to a heating effect. This type of heating was the core application of many early E-textiles. Other patents refining the heated gloves were filed [21,22], and variations on the theme appeared such as the heated boot [23], and full heated garments including a jacket element [24,25]. The knitted heater was patented in 1910 [26]. Heated gloves and jackets based on these core concepts are still available today showing the relevance of these early innovations.

Other devices utilizing heating elements were created between the 1930s and 1970s included the heated blanket [27], a heated baby carriage blanket [28], and electrically heated socks [29]. The year 1968 is often seen as the birth of modern E-textiles, when the Museum of Contemporary Craft in New York City held an exhibition, Body Covering, exploring a series of electric garments with functions such as heating and cooling [30].

Interest in developing new heated textiles remained well into the 21st Century with a patent from 2008 describing the incorporation of inductive heating elements into footwear and apparel [31]. Commercially, EXO Technologies have produced heated gloves that can be used by militaries or for a variety of outdoor activities such as skiing or motorcycling [32]. Marktek also make conductive textiles [33] that include heating products. WarmX produce heated clothing [34]. In addition to heating, a paper in 2012 described a wearable textile-based cooling system using thermoelectric modules and refrigerant channels [35].

3. Materials Developments and Wearable Computing

Wearable computing is a type of wearable that contains information technology, and is able to store, manipulate, or transmit data. The inclusion of wearable computing is what makes an E-textile a smart textile. The 1990s and early 2000s saw patents for devices either integrated onto the surface of garments or contained within pockets beginning to emerge [36,37,38,39,40,41,42]. These are generally regarded as the first generation E-textiles, where an electrical circuit or electronic components were attached to a garment. The initial commercialized ‘first generation E-textile’ garments began to appear on the market with the Industrial Clothing Division plus-jacket in 2000 [43]. This jacket attached electronic devices into pockets.

An important component towards the successful development of wearable computing included methods of creating electronic circuits within textiles. Post et al. filed a patent in the late 1990s describing how to integrate devices and circuits into textiles [44]. Another patent described using electrically insulating and electrically conductive yarns woven into a garment to create an electronic circuit [45]. A later patent further built on the use of knitting techniques to create electrical circuits and pathways [46]. In 2006 Ghosh et al. described an in-depth means of forming electrical circuits within textile structures [47]. Textilma were granted a patent describing an elastic compound thread with electrical conductivity [48]. A patent two years later from Seoul National University described a system for power transmission using conductive sewing thread [49]. An E-textile patents published in 2006 discussed the inclusion of devices such as Bluetooth and the electrical connections required between components [50]. With the concept of wearable computing existing for a number of years, in 2006 Frost and Sullivan provided an excellent review of wearable computing at that time [51].

A variety of other developments linked to wearable computing appeared in the 2000s. WearIT@work [52] was a project funded by the European Commission (€14.6 million) to investigate wearable computing. A particular focus was user acceptance. The European Space Agency (ESA) iGarment project was developed to create an Integrated System for Management of Civil Protection Units. The project was targeted to make a full-body smart garment. This would have incorporated sensors for monitoring vital signs and position. The garment was also to have included a communications unit and GPS [53].

Some recent developments in wearable computing have veered away from textiles including the Google Glass [54]. Despite these devices being wearables and not textiles, textile computing has still made significant strides in recent years.

Graphene technology may be a key contributor to the further development of wearable computing. The US Army Research Laboratory discussed the potential of graphene-based nano-electronics for applications in wearable electronics in a report produced in 2012 [55]. Interfacing with E-textiles is also of importance for future developments: A recent Microsoft patent described an interface system for using muscle movements to control a computer or other device [56].

The use of organic conductive polymers may also improve the potential for wearable computing. Hamedi et al. have developed a fiber-level electrochemical transistor, opening up the potential to create larger circuits using a weave of these fibers [57].

4. Sensors

The development of E-textiles in an academic setting first gained traction in the late 1990s with a series of publications from the Massachusetts Institute of Technology (MIT) and the Georgia Institute of Technology [58]. The ‘The Wearable MotherboardTM’ proposed a smart-shirt capable of un-obstructively monitoring human life signs [59].

Work by Farringdon et al. described a functional fabric in the form of a woven stretch sensors later 1990s. They produced a fabric stretch sensors for the monitoring of body movement [60].

A master’s thesis from the US Naval Postgraduate School in 2006 identified a further potential use of wearable sensors, suggesting that they may prove beneficial to locate sniper fire in combat situations [61].

Health and wellbeing applications also gained interest in the 2000s, with Cooseman et al. [62] describing a garment with an embedded patient monitoring system, which included wireless communication and inductive powering. In this instance, the garment was designed for infants. A paper in 2008 described a process for transforming cotton thread for use in E-textiles by applying carbon nanotubes [63]. It was claimed that the technology could be used for bio-sensing with a key result of the paper being that the carbon nano-tube cotton threads could be used to detect albumin, which is an important protein in the blood.

Work has investigated the use of textile electrodes for heart rate monitoring or ECG (Electrocardiogram). MyHeart was an EU (FP 6) funded project to develop smart fabrics for both ECG and respiration [64], with the project concluding in 2009. Another EU FP 6 project, CONTEXT, also investigated the use of textile electrodes, in this case to measure muscle and heart electric signals [65].

A paper from 2009 described an integrated temperature sensor [66]. Also in 2009, a report described the development of a knitted biomedical sensor for the monitoring body temperature [67]. A patent was granted for a linear electronic transducer for strain measurement in 2011 [68].

A proliferation of sensor embedded garments began to emerge on the market with the company Clothing+ producing both the Sensor Belt [69] and the Pure Lime sensor bra. Both devices focused on the active-wear market. At the time of writing it is unclear whether the Pure Lime sensor bra is still in production. Other active-ware devices have included the Adidas MiCoach heartrate monitoring bra. Despite interest by a number of media outlets [70], at the time of writing it appears that this product is no longer sold by Adidas.

The incorporation of sensors into garments has also continued to generate interest in the literature and from companies. A 2011 paper from described the development of a socks with integrated strain sensors for monitoring foot movement. Such systems could have had applications in stroke rehabilitation [71]. There have also been other example of incorporating temperature-sensing elements into textiles [72,73,74,75].

A variety of textile-based sensors and sensing garments have also appeared on the market. Nypro (formerly Clothing+) produces textile-based sensor systems [76]. Ohmatex [77] has created textile conductors and sensors. Polar [78] sell wearable monitoring equipment, including heartrate monitors. SmartLife [79] produce knitted physiological measurement devices for healthcare, sports and military applications. The Zephyr BioHarness [80] takes physiological meassurements from the wearer. The recorded data can then be transmitted. Under Armour have produced a shirt that monitors biometric data [81].

5. E-Textile Pressure Sensors and Textile Switches

Many early functional fabrics took the form of textile switches [82] and this area of research was expanded upon heavily by academia. The work of Post et al. included the development of a textile-based keyboard using embroidered electrodes with a silk and twisted gold spacer fabric [83]. This technology was the first step forwards pressure sensitive fabrics.

Further developments into textile transducers came in a paper from 2004 which described knitted transducers for motion and gesture capture together with ECG (electrocardiogram) measurement [84], which was also patented [85]. A related paper from 2005 described knitted capacitive transducers for touch and proximity sensing [86].

Sergio et al. initially proposed a textile based capacitive pressure sensor where a three-layer structure was implemented with a layer of rows of conductive fibers, an elastic spacer foam, and then another layer of conductive fibers orientated perpendicular to the top layer [87]. Their work described four methods for producing the conductive tracks; weaving in a mix of conductive and insulating fibers, embroidering the circuit using conductive thread, textile electrodes separated by conducting strips (called bundle routing in the paper), and the use of conductive paint. A follow-up paper described a measurement system in combination with their E-textile that was capable of producing pressure images [88]. Other researchers also developed this type of technology. Mannsfeld et al. developed a highly flexible and inexpensive capacitive pressure sensor using a micro-structured thin film as the capacitors dielectric layer [89]. Takamatsu et al. fabricated a pressure sensitive textile using a perfluoropolymer spacer, and rows of woven, die-coated yarns to make conductive rows [90]. Meyer et al. have contributed to the development of textile pressure sensors. Their general pressure sensor design consisted of three parts, an embroidered set of 2 cm × 2 cm electrodes, a 3D-knitted spacer fabric, and a woven back electrode [91,92]. Hoffmann et al. used a similar principle for a system to measure respiratory rate, where two conductive fabrics were placed on either side of a 3D-spacer textile [93]. A different proposal to monitor respiratory rate has used the change in induction of two knitted coils as the coils moved [94].

Holleczek et al. created a sensor using a pair of textile electrodes and a proprietary resin spacer material, integrating the sensor into socks [95]. Other capacitive textile designs have included a capacitive fiber by Gu et al. [96]. The capacitive fiber consisted of a conducting copper wire (0.12 mm diameter) embedded within a fiber. A similar design was employed by Lee et al. where a conductive coating was applied to a Kevlar fiber, which was then coated in a Polydimethylsiloxane (dielectric) layer. Capacitive junctions seen where the two fibers intersected [97]. Other copper wires were wrapped around the fibers surface acting as the second electrode.

Pressure sensing textiles have not been limited to a research environment. Commercially, Novel sell a number of pressure sensing products including insoles, seating covers, and gloves [98]. The XSENSOR® Technology Corporation have focused on seating sensors (in particular for the automotive industry), health care monitoring, and sleep solutions using pressure sensitive mats to aid in mattresses selection [99]. Their technology has been implemented in a variety of medical studies, with a particular focus of managing pressure ulcers [100,101,102,103]. Pressure Profile Systems continue to sell capacitive pressure sensors as of mid-2016 for a variety of applications, including gloves, robotics, pressure mats, and medical applications [104]. LG have recently announced the release of a flexible textile sensor based on capacitive technology [105]. It is difficult to ascertain the exact make-up of many of these sensors and they may not be true E-textiles. Certainly, Peterson et al. stated that the XSENSOR® devices use proprietary capacitive technology, and described the sensor as a flexible thin pad [100].

The simpler textile switch also found its way into commercial products. In 2006 an intelligent push-button system was described in a patent [106]. Beyond this a patent in 2006 [107], followed by an article [108] described a fully integrated textile switch. Other patents by France Telecom (Now Orange S.A., Paris, France)) [109], Daimler Chrysler (Auburn Hills, MI, USA) [110] and Sentrix (New York, NY, USA) [111] also describe alternative textile switch technologies.

The Burton Amp snowboarding jacket saw integrated textile switches on the arm of the jacket used to control an Apple iPod in 2002 [112]. Nike + iPod Sports Kit was another example of Apple engaging with sports apparel companies to create an E-textile device. In this case a sensor was incorporated into the shoe which communicated with an Apple product (such as an iPhone) or other Nike wearables (such as the Nike + Sportband) to track activity [113]. The recent Google and Levi’s Jacquard jacket also included textile switches [114].

6. Textile Energy Solutions

By the early 2000s the first patent for textile-based energy harvesting appeared in the form of a mechanical generator scavenging energy through motion [115]. A paper by Qin et al. in 2007 described a technique for energy scavenging using piezoelectric zinc oxide nanowires grown radially around textile fibers [116]; this being one of the earlier examples of energy scavenging within textiles.

The further development of energy storage and scavenging within textiles became a key area of interest in the 2010s as the viability of many of E-textile products and concepts are dependent on a suitable power supply. Existing textile energy scavenging (or energy harvesting) devices exploit either thermoelectrics, kinetics, or photovoltaics. Each system possesses different advantages or disadvantages, with many modern systems incorporated into textiles providing flexibility but lacking other textile properties such as bend or shear. In all cases the harvested power was minimal, with the most promising generators capable of producing sustained power on the order of milliwatts. Both thermoelectric and kinetic systems draw energy from the wearer while photovoltaic energy harvesting draws energy from light sources, such as the sun. Photovoltaics have also shown significant promise concerning the power that can be generated (~30 mW/m2) [117].

The use of carbon-nano tube based systems have gained significant popularity for both energy harvesting and storage [117,118,119,120,121]. For an energy storage device the textile can be used as a substrate for flexible films, or a carbon nano-tube infused film can be used to produce yarns [120]. Storage technology is either capacitive (normally supercapacitors) or chemical in nature. The use of carbon nano-tubes has caused some worry due to safety concerns [122], which would possibly impede future commercialization.

Another popular storage method has seen flexible, solid electrolyte-based batteries [123] woven into a garment as thin strips, however at present these batteries are still large relative to a normal yarn (width = 10 mm).

Triboelectric nano-generators are also viewed as a potential source of energy for wearables given their very small size, high peak power densities, and good energy conversion efficiencies [124]. Triboelectric generators convert mechanical energy and therefore could be powered by human motion or vibration. Despite high energy densities, the converted energy has a small current and the generators energy output over time is unpredictable, requiring complex supporting power management electronics. Cui et al. have demonstrated a cloth-based triboelectric generator where frictional forces between the forearm of the wearer and their body was used to generate energy [125].

Comprehensive reviews of energy harvesting and storage in textiles are available elsewhere [14,120].

7. Communication Devices

A textile-based antenna fabricated from polymer (polypyrrole) strips has been described in the literature [126]. Two conference papers from 2010 have also describe conformable antennas for space suits [127,128]. The production of flexible embroidered antennas has been reported as suitable for megahertz frequency communications [129,130]. This type of antenna is highly sensitive and has been employed for unilateral magnetic resonance measurements [131].

Incorporating radio frequency identification (commonly known as RFID) tags into textiles has also been investigated by a number of entities. Textilma were granted a patent describing an RFID module textile tag [132]. Another patent described a method of attaching RFID chips to a textile substrate [133] however, full integration within yarns was not proposed. A patent from 2007 also described a RFID device, this time focusing on clothing [134]. In 2005 a patent described the incorporation of RFID devices within epoxy resin for use in laundries [135]. A patent from 2010 described an RFID tag with integrated antenna [136] whilst another patent from the same year described a method of incorporating a RFID device into a textile tag [137].

8. Illumination

Interest in illuminated textiles continued into the mid-2000s with a patent from Daimler Chrysler in 2005 describing a textile-based lighting system for automotive applications [138]. A patent described creating a flat-panel video display by weaving electronically conductive fibers, such as dielectrics [139]. This led to patents being filed for other textile-based flexible displays in later years [140,141]. Other patents granted described a lighting system that used light leakage from optical fibers in specific locations [142] to create illumination.

A patent from 2011 described a method of producing an illuminated pattern using light conducting fibres [143]. Another illuminated textile using optical fibres was described in a patent from the same year [144]. The company Sensing Tex Sl have used optical fibers to illuminate textiles [145].

In contrast, Philips have produced illuminated textiles using LED technology [146]. Philips have previously patented a flexible electro-optic filament [147]. There are a variety of companies that produce illuminated clothing for fashion applications, as well as use in performance (i.e. theatre), these include Cutecircuit [148] and LUcentury [149] which create garments by sewing LEDs onto existing clothing. Given advances in LED technology, reducing their size, LEDs can easily be incorporated into yarns using functional electronic yarns technology, and subsequently into garments [75]. Electroluminescent yarn was also developed on 2010 [150] with the technology fully described in a 2012 paper [151]. Another form of lighting used for E-textiles was by attaching lasers to a garment, as shown by Bono in 2009 [152]. This technology is not practical for a mass produced garment for a variety of reasons including cost and the weight of the final garment.

9. Market Trends

According to IMS Research (Wellingborough, UK), 14 million wearable devices were shipped in 2011 [153]. This clear market coupled with the significant scientific advances in E-textiles led to a proliferation of devices entering the market in the early 2010’s, and an increased interest in the technology from academia. More recently the Fung Global Retail and Technology report on wearables in 2016 [154] identified a significant increase in the wearable market between 2015 and 2016, a 18.4% climb to $28.7 billion. This is far higher than the predictions of the IMS, expecting that the revenue for wearable technology would be $6 billion in 2016. Forbes currently predict that the wearable market will reach $34 billion by 2020 [155]. It is of interest to note that the Fung report also states that the top wearable brands of 2016 were Fitbit, Xiaomi, and Apple based on the number of units shipped: These company’s products are not textile based. The principal wearable device sold by each company are smart watches. It is unclear whether the growing market for wearables will become more focused on textile-based devices in the coming years, but the advantages offered, such as comfort to the wearer, will likely be an influential factor. The current market for E-textiles generates sales of around $100 million per year, with some sources predicting a $5 billion market by 2027 [156].

Current commercially available E-textiles include soft textile switches produced by International Fashion Machines (Seattle, WA, USA) [157] and systems for incorporating wires into clothing by the Technology Enabled Clothing [158]. Additionally, Fibretronic [159] have created a varied range of products including (but not limited to) flexible switches, textile cables for signal or power transport, and textile sensors, however as of 2018 it is unclear whether they are still trading. As discussed earlier some sportswear E-textile products are no longer available, presumably due to poor market demand. An important thing to note is that a significant number of website sources have been using in this review, particularly regarding commercial products, as information was not available from other sources. This is another possible indicator of poor uptake of certain products.

10. Potential Future Developments

While this review is focused on the history and evolution of E-textiles, it is of interest to consider the direction that E-textile research will take in upcoming years. Originally, the vision of those working in the field of E-textiles was to incorporate all of the required electronic systems within the textile. More recently however some claim that the best approach is to use mobile phones as an interface [160]; which has been aided in part by the substantial advancement in mobile phone technology in recent years. Others claim that this approach is a temporary diversion and there are many advantages for fully embedded systems, and that as developments progress, the mobile phone itself will be integrated into textiles. A complete integration of the electronics may also be unfavorable for sustainability reasons as it makes the electronics more difficult to remove at the end of the life of a product [161].

It is expected that there will be a far greater uptake of wearable electronics when battery technology is improved or alternative energy sources, such as energy scavenging, become more viable. This is of particular importance to E-textiles over wearables more generally, as most conventional power sources are not well suited to textile integration due to size, inflexibility, and lack of washability. The reductions in size and cost of components will promote further development and uptake. A review paper from 2012 discussed the subject [162] and a BBC news item outlined on-going UK research in the area [163].

Ultimately, the adoption of E-textiles will depend on the cost. This will reduce with material costs and improvements to the manufacturing processes. It is also possible that developments in graphene technology will be improve the potential of what can be achieved with electronic textiles. Many major companies including Samsung, Nokia, and IBM have made significant investments into graphene technology [164]. There is the potential that graphene’s physical properties, including its strength and electrical conductivity, will allow it to replace silicon in many devices, possibly by the late 2020s after the technology has matured. In addition, work on carbon nanotubes is beginning to show some promise, especially for energy-based applications (such as energy harvesting and scavenging) [117,119,120,121]. Both technologies offer potential for further miniaturization of embedded electronics.

With an enhancement of how much can be fit within a textile, and suitable energy solutions, E-textiles could move towards true wearable computing, with the textile managing and processing data on its own depending upon requirements. The decreasing size of microprocessors makes embedding this kind of intelligence within a textile likely in the immediate future.

11. Conclusions

This review of the literature has clearly shown that the three pathways of integrating electronics into textiles have been applied in different ways. The methods of integrating electronics offer different advantages and disadvantages. The first generation E-textiles will always interfere with the textile properties of a garment, even thin film devices (while flexible), will not possess the shear properties of a normal textile. The second generation textiles may retain a textile feel but are limited in their applications; such as the creation of electronic pathways, and electrode-based sensing.

The third generation of E-textiles, where electronics are contained within the yarn structure, do not interfere with the textile properties of a fabric. As this technology is principally limited by the size of the incorporated electronics (i.e., the electronic chip dimensions) the potential of this area will grow as smaller electronic chips become available.

While the history of E-textiles has shown the development of new techniques to integrate electronics within a textile it is likely that the existing three methods will remain in use into the future. The attachment of electronics onto a garment is still common, in particular for illuminated textiles, despite this technology first being demonstrated in 1883.

Author Contributions

T.H.-R., C.C. and T.D. located the reference material used in the review. T.H.-R. and T.D. reviewed all of the reference material used in this review. T.H.-R. prepared the final manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Adovasio, J.M.; Soffer, O.; Klíma, B. Upper Palaeolithic fibre technology: Interlaced woven finds from Pavlov I, Czech Republic, c. 26,000 years ago. Antiquity 1996, 70, 526–534. [Google Scholar] [CrossRef]

- Lewis, P. William Lee’s stocking frame: Technical evolution and economic viability 1589–1750. Text. Hist. 1986, 17, 129–147. [Google Scholar] [CrossRef]

- Thackeray, F.W.; Findling, J.E. (Eds.) Events that Changed Great Britain Since 1689; Greenwood Publishing Group: Westport, CT, USA, 2002. [Google Scholar]

- Guler, S.D.; Gannon, M.; Sicchio, K. A Brief History of Wearables. In Crafting Wearables; Apress: New York, NY, USA, 2016; pp. 3–10. [Google Scholar]

- Shirakawa, H.; Louis, E.J.; MacDiarmid, A.G.; Chiang, C.K.; Heeger, A.J. Synthesis of electrically conducting organic polymers: Halogen derivatives of polyacetylene,(CH)x. J. Chem. Soc. Chem. Commun. 1977, 16, 578–580. [Google Scholar] [CrossRef]

- The Nobel Prize in Chemistry 2000. Available online: https://www.nobelprize.org/nobel_prizes/chemistry/laureates/2000/ (accessed on 21 August 2017).

- Paton, G.A.; Sterling, M.N.; Sanders, J.H. Integral, Electrically-Conductive Textile Filament. U.S. Patent 4,045,949, 6 September 1977. [Google Scholar]

- 1960: Metal Oxide Semiconductor (MOS) Transistor Demonstrated, The Silicon Engine, Computer History Museum. Available online: http://www.computerhistory.org/siliconengine/metal-oxide-semiconductor-mos-transistor-demonstrated/ (accessed on 21 August 2017).

- Miller, G.E.; Dalke, M. Illuminated Article of Clothing. U.S. Patent 4,164,008, 7 August 1979. [Google Scholar]

- Dias, T.; Fernando, A. Operative Devices Installed in Yarns. GB0509963B1, 9 May 2005. [Google Scholar]

- Dias, T. Electronic strip yarn. WO2017/1150873 A1, 6 July 2017. [Google Scholar]

- Dias, T.K.; Rathnayake, A. Electronically Functional Yarns. GB2529900, 9 March 2016. [Google Scholar]

- Conroy, D.W.; García, A. A golden garment from ancient Cyprus? Identifying new ways of looking at the past through a preliminary report of textile fragments from the Pafos ‘Erotes’ Sarcophagus. In The SInet 2010 eBook; University of Wollongong: Wollongong, Australia, 2010; p. 36. [Google Scholar]

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.M. Fiber-based wearable electronics: A review of materials, fabrication, devices, and applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef] [PubMed]

- Weng, W.; Chen, P.; He, S.; Sun, X.; Peng, H. Smart electronic textiles. Angew. Chem. Int. Ed. 2016, 55, 6140–6169. [Google Scholar] [CrossRef] [PubMed]

- Tao, X. (Ed.) Handbook of Smart Textiles; Springer: Singapore, 2015; ISBN 9789814451468. [Google Scholar]

- Dias, T. (Ed.) Electronic Textiles: Smart Fabrics and Wearable Technology; Woodhead Publishing: Cambridge, UK, 2015; ISBN 9780081002018. [Google Scholar]

- Carron, A.L. Electric-Heated Glove. U.S. Patent 1,011,574, 9 September 1911. [Google Scholar]

- Joule, J.P. On the Production of Heat by Voltaic Electricity. Proc. R. Soc. 1840, 1, 59–60. [Google Scholar] [CrossRef]

- Pollak, A. Electrically-Heated Garment. U.S. Patent 1,073,926, 23 September 1913. [Google Scholar]

- Lemercier, A.A. Electrically-Heated Clothing. U.S. Patent 1,284,378, 12 November 1918. [Google Scholar]

- Heinemann, O. Electrically-Heated Boot. U.S. Patent 1,761,829, 3 June 1930. [Google Scholar]

- Benjamin, B. Electrically-Heated Garment. U.S. Patent 1,358,509, 9 November 1920. [Google Scholar]

- Graham, W.D.; Uhlig, C.M. Electrically-Heated Garment. U.S. Patent 1,691,472, 13 November 1928. [Google Scholar]

- Hefter, M. Knitted Electric Heating-Body. U.S. Patent 975,359, 8 November 1910. [Google Scholar]

- Grisley, F. Improvements in Blankets, Pads, Quilts, Clothing, Fabric, or the Like, Embodying Electrical Conductors. GB445195(A), 30 March 1936. [Google Scholar]

- Ellis, H.G. Heated Baby Carriage Blanket. U.S. Patent 2,993,979, 25 July 1961. [Google Scholar]

- Balz, C.F.; Murphy, D.J. Electrically Heated Sock with Battery Supporting Pouch. U.S. Patent 3,396,264, 6 August 1968. [Google Scholar]

- Pavitt, J. Fear and Fashion in the Cold War; V&A Publishing: London, UK, 2008. [Google Scholar]

- Bourke, M.J.; Clothier, B.L. Inductively Heated Clothing. WO2008101203, 21 August 2008. [Google Scholar]

- EXO². Available online: http://www.exo2.co.uk/ (accessed on 22 August 2017).

- Marktek Inc. EMI Shielding, Conductive, Resistive and Radar Absorptive Materials. Available online: http://www.marktek-inc.com/ (accessed on 22 August 2017).

- Beheizbare Unterwäsche als Alltagslösung von. warmx.de. Available online: http://www.warmx.de/index.php (accessed on 22 August 2017).

- Delkumburewattea, G.B.; Dias, T. Wearable cooling system to manage heat in protective clothing. J. Text. Inst. 2012, 103, 483–489. [Google Scholar] [CrossRef]

- Carroll, D.W. Wearable Personal Computer System. U.S. Patent 5,555,490, 10 September 1996. [Google Scholar]

- Egan, E.; Amon, C.H. Cooling strategies for embedded electronic components of wearable computers fabricated by shape deposition manufacturing. In Proceedings of the I-THERM V., Inter-Society Conference on Thermal Phenomena in Electronic Systems, Orlando, FL, USA, 29 May–1 June 1996; pp. 13–20. [Google Scholar]

- Baudhuin, E.S. Telemaintenance applications for the Wearable/sup TM/PC. In Proceedings of the 15th AIAA/IEEE, Digital Avionics Systems Conference, Atlanta, GA, USA, 31 October 1996; pp. 407–413. [Google Scholar]

- Janik, C.M. Flexible Wearable Computer. U.S. Patent 6,108,197, 22 August 2000. [Google Scholar]

- Tento, H.; Nasu, R. Base for Wearable Computer. JP2000357025, 26 December 2000. [Google Scholar]

- Dale, C.A. Wearable Computer Apparatus. U.S. Patent 6,167,413, 26 December 2000. [Google Scholar]

- Jenkins, M.D. Convertible Wearable Computer. HK1024069, 22 September 2006. [Google Scholar]

- The ICD+ jacket: Slip into My Office, Please. The Independent. 4 September 2000. Available online: http://www.independent.co.uk/news/business/analysis-and-features/the-icd-jacket-slip-into-my-office-please-694074.html (accessed on 17 November 2017).

- Post, E.R.; Orth, M.; Cooper, E.; Smith, J.R. Electrically Active Textiles and Articles Made Therefrom. U.S. Patent 6,210,771, 3 April 2001. [Google Scholar]

- Hill, I.G.; Trotz, S.; Riddle, G.H.N.; Brookstein, D.S.; Govindaraj, M. Plural Layer Woven Electronic Textile, Article and Method. U.S. Patent 7,144,830, 5 December 2006. [Google Scholar]

- Dias, T.K.; Mitcham, K.; Hurley, W. Knitting Techniques. U.S. Patent 7,779,656, 24 August 2010. [Google Scholar]

- Ghosh, T.K.; Dhawan, A.; Muth, J.F. Formation of electrical circuits in textile structures. In Intelligent Textiles and Clothing; North Carolina State University: Raleigh, NC, USA, 2006. [Google Scholar]

- Speich, F. Electrically Conductive, Elastic Compound Thread, Particularly for RFID Textile Labels, the Use Thereof, and the Production of a Woven Fabric, Knitted Fabric, or Meshwork Therewith. TW200840891, 16 October 2008. [Google Scholar]

- Kang, T.J.; Kim, B.D. Electrically Conductive Sewing Thread for Power and Data Transmission Line of Smart Interactive Textile Systems. KR20090012769, 4 February 2009. [Google Scholar]

- Klaus, P.; Jochen, D.; Horst, T. Article of Clothing for Attaching e.g., ID Systems and Blue Tooth Modules Comprises Electrical Internal and External Components Arranged on the Surface of the Article so that Electrical Lines Extend between the External Components. DE102004039765, 9 March 2006. [Google Scholar]

- Wearable Computing (Technical Insights). Available online: http://www.frost.com/sublib/display-report.do?id=D626-01-00-00-00 (accessed on 21 August 2017).

- WearIT@Work Project-Customer Cases-Xsens 3D Motion Tracking. Available online: https://www.xsens.com/customer-cases/wearitwork-project/ (accessed on 21 August 2017).

- Final Presentation of the I-GARMENT Project. Available online: http://www.esa.int/Our_Activities/Preparing_for_the_Future/Space_for_Earth/Space_for_health/Final_presentation_of_the_I-GARMENT_project (accessed on 21 August 2017).

- Google’s Project Glass Made Available to Developers. Available online: https://www.theguardian.com/technology/2012/jun/28/google-project-glass-available-to-developers (accessed on 21 August 2017).

- Dubey, M.; Nambaru, R.; Ulrich, M.; Ervin, M.; Nichols, B.; Zakar, E.; Nayfeh, O.M.; Chin, M.; Birdwell, G.; O’Regan, T. Graphene-Based Nanoelectronics; U.S. Army Research Laboratory: Adelphi, MD, USA, 2012. [Google Scholar]

- Tan, D.; Saponas, T.S.; Morris, D.; Turner, J. Wearable Electromyography-Based Human-Computer Interface. US2012188158, 26 July 2012. [Google Scholar]

- Hamedi, M.; Forchheimer, R.; Inganäs, O. Towards woven logic from organic electronic fibres. Nat. Mater. 2007, 6, 57–362. [Google Scholar] [CrossRef] [PubMed]

- Post, E.R.; Orth, M. Smart Fabric, or Washable Computing. In Proceedings of the First IEEE International Symposium on Wearable Computers, Cambridge, MA, USA, 13–14 October 1997. [Google Scholar]

- Gopalsamy, C.; Park, S.; Rajamanickam, R.; Jayaraman, S. The Wearable Motherboard™: The first generation of adaptive and responsive textile structures (ARTS) for medical applications. Virtual Real. 1999, 4, 152–168. [Google Scholar] [CrossRef]

- Farringdon, J.; Moore, A.J.; Tilbury, N.; Church, J.; Biemon, P.D. Wearable sensor badge and sensor jacket for context awareness. In Proceedings of the Third International Symposium on Wearable Computers, Digest of Papers, San Francisco, CA, USA, 18–19 October 1999; pp. 107–113. [Google Scholar]

- Stephen, T.K.S. Source Localization Using Wireless Sensor Networks. Thesis for Master of Science in Electrical Engineering, Naval Postgraduate School Monterey, Monterey, CA, USA, 2006. Available online: https://calhoun.nps.edu/bitstream/handle/10945/2689/06_Jun_Tan.pdf?sequence=1 (accessed on 15 May 2018).

- Coosemans, J.; Hermans, B.; Puers, R. Integrating wireless ECG monitoring in textiles. Sens. Actuators A Phys. 2006, 130, 48–53. [Google Scholar] [CrossRef]

- Shim, B.S.; Chen, W.; Doty, C.; Xu, C.; Kotov, N.A. Smart Electronic Yarns and Wearable Fabrics for Human Biomonitoring made by Carbon Nanotube Coating with Polyelectrolytes. Nano Lett. 2008, 8, 4151–4157. [Google Scholar] [CrossRef] [PubMed]

- European Commission: CORDIS: Projects and Results: MyHeart. Available online: https://www.cordis.europa.eu/project/rcn/71193_en.html (accessed on 25 April 2018).

- European Commission: CORDIS: Projects and Results: Contactless Sensors for Body Monitoring Incorporated in Textiles. Available online: https://cordis.europa.eu/project/rcn/80730_en.html (accessed on 25 April 2018).

- Kinkeldei, T.; Zysset, C.; Cherenack, K.; Troester, G. Development and evaluation of temperature sensors for textile integration. In Proceedings of the IEEE Sensors, Christchurch, New Zealand, 25–28 October 2009. [Google Scholar]

- Husain, M.D.; Dias, T. Development of Knitted Temperature Sensor (KTS). Available online: http://www.systex.eu/sites/default/files/Systex_award_2009_Dawood_03Sept09.pdf (accessed on 15 May 2018).

- Challis, S.; Fernando, A.; Dias, T.; Cooke, W.; Chaudhury, N.H.; Geraghty, J.; Smith, S. Precision Delivery System. US2003110812, 19 June 2003. [Google Scholar]

- Reho, A. Clothing+. In Proceedings of the Smart Fabrics Conference, Miami, FL, USA, 17–19 April 2012. [Google Scholar]

- Best Heart Rate Monitor Sports Bra that’s actually Smart and Comfortable. Available online: http://notsealed.com/heart-rate-monitor-sports-bra-smart-comfortable.html (accessed on 17 November 2017).

- Preece, S.J.; Kenney, L.P.J.; Major, M.J.; Dias, T.; Lay, E.; Fernandes, B.T. Automatic identification of gait events using an instrumented sock. J. NeuroEng. Rehabil. 2011, 8, 32. [Google Scholar] [CrossRef] [PubMed]

- Hughes-Riley, T.; Lugoda, P.; Dias, T.; Trabi, C.L.; Morris, R. A study of thermistor performance within a textile structure. Sensors 2017, 17, 1804. [Google Scholar] [CrossRef] [PubMed]

- Cherenack, K.; Zysset, C.; Kinkeldei, T.; Münzenrieder, N.; Tröster, G. Woven electronic fibers with sensing and display functions for smart textiles. Adv. Mater. 2010, 22, 5178–5182. [Google Scholar] [CrossRef] [PubMed]

- Lugoda, P.; Dias, T.; Morris, R. Electronic temperature sensing yarn. J. Multidiscip. Eng. Sci. Stud. 2015, 1, 100–103. [Google Scholar]

- Dias, T.; Hughes-Riley, T. Electronically Functional Yarns Transform Wearable Device Industry. Read. Res. Dev. Commun. 2017, 59, 19–21. [Google Scholar]

- Consumer Health. Available online: https://www.jabil.com/solutions/by-industry/healthcare/consumer-health.html (accessed on 22 August 2017).

- Ohmatex. Available online: http://www.ohmatex.dk/ (accessed on 22 August 2017).

- Heart Rate Monitors, Activity Trackers and Bike Computers. Available online: https://www.polar.com/en (accessed on 22 August 2017).

- Smartlife. Available online: https://www.smartlifeinc.com/ (accessed on 22 August 2017).

- Zephyr™ Performance Systems. Performance Monitoring Technology. Available online: https://www.zephyranywhere.com/ (accessed on 22 August 2017).

- Under Armour-Sportswear, Sport Shoes, & Accessories. Available online: http://www.underarmour.co.uk/ (accessed on 22 August 2017).

- Schwabe, D. Electrical Switch for Automotive or Clothing Use is Integrated into a Flexible Textile Material and is Actuated by Applied Force. DE102005038988 (A1), 22 February 2007. [Google Scholar]

- Post, E.R.; Orth, M.; Russo, P.R.; Gershenfeld, N. E-broidery: Design and fabrication of textile-based computing. IBM Syst. J. 2000, 39, 840–860. [Google Scholar] [CrossRef]

- Wijesiriwardana, R.; Mitcham, K.; Dias, T. Fibre-meshed transducers based real time wearable physiological information monitoring system. In Proceedings of the ISWC 2004. Eighth International Symposium on Wearable Computers, Arlington, VA, USA, 31 October–3 November 2004; Volume 1, pp. 40–47. [Google Scholar]

- Tilak, D.; Beatty, P.C.W.; Cooke, W.; Wijesiriwardana, R.; Mitcham, K.; Mukhopadhyay, S.; Hurley, W. Knitted Transducer Devices. U.S. Patent Application 10/557,074, 19 May 2004. [Google Scholar]

- Wijesiriwardana, R.; Mitcham, K.; Hurley, W.; Dias, T. Capacitive fiber-meshed transducers for touch and proximity-sensing applications. IEEE Sens. J. 2005, 5, 989–994. [Google Scholar] [CrossRef]

- Sergio, M.; Manaresi, N.; Tartagni, M.; Guerrieri, R.; Canegallo, R. A textile based capacitive pressure sensor. In Proceedings of the IEEE Sensors, Orlando, FL, USA, 12–14 June 2002; Volume 2, pp. 1625–1630. [Google Scholar]

- Sergio, M.; Manaresi, N.; Campi, F.; Canegallo, R.; Tartagni, M.; Guerrieri, R. A dynamically reconfigurable monolithic CMOS pressure sensor for smart fabric. IEEE J. Solid-State Circuits 2003, 38, 966–975. [Google Scholar] [CrossRef]

- Mannsfeld, S.C.; Tee, B.C.; Stoltenberg, R.M.; Chen, C.V.H.; Barman, S.; Muir, B.V.; Sokolov, A.N.; Reese, C.; Bao, Z. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 2010, 9, 859–864. [Google Scholar] [CrossRef] [PubMed]

- Takamatsu, S.; Kobayashi, T.; Shibayama, N.; Miyake, K.; Itoh, T. Fabric pressure sensor array fabricated with die-coating and weaving techniques. Sens. Actuators A Phys. 2012, 184, 57–63. [Google Scholar] [CrossRef]

- Meyer, J.; Lukowicz, P.; Troster, G. Textile pressure sensor for muscle activity and motion detection. In Proceedings of the 10th IEEE International Symposium on Wearable Computers, Montreux, Switzerland, 11–14 October 2006; pp. 69–72. [Google Scholar]

- Meyer, J.; Arnrich, B.; Schumm, J.; Troster, G. Design and modeling of a textile pressure sensor for sitting posture classification. IEEE Sens. J. 2010, 10, 1391–1398. [Google Scholar] [CrossRef]

- Hoffmann, T.; Eilebrecht, B.; Leonhardt, S. Respiratory monitoring system on the basis of capacitive textile force sensors. IEEE Sens. J. 2011, 11, 1112–1119. [Google Scholar] [CrossRef]

- Wijesiriwardana, R. Inductive fiber-meshed strain and displacement transducers for respiratory measuring systems and motion capturing systems. IEEE Sens. J. 2006, 6, 571–579. [Google Scholar] [CrossRef]

- Holleczek, T.; Rüegg, A.; Harms, H.; Tröster, G. Textile pressure sensors for sports applications. In Proceedings of the IEEE Sensors, Kona, HI, USA, 1–4 November 2010; pp. 732–737. [Google Scholar]

- Gu, J.F.; Gorgutsa, S.; Skorobogatiy, M. A Fully Woven Touchpad Sensor Based on Soft Capacitor Fibers. Unpublished. 2011. Available online: https://www.researchgate.net/profile/Maksim_Skorobogatiy/publication/51912313_A_fully_woven_touchpad_sensor_based_on_soft_capacitor_fibers/links/00b4951cad5dfa7912000000.pdf (accessed on 4 May 2016).

- Lee, J.; Kwon, H.; Seo, J.; Shin, S.; Koo, J.H.; Pang, C.; Son, S.; Kim, J.H.; Jang, Y.H.; Kim, D.E.; et al. Conductive Fiber-Based Ultrasensitive Textile Pressure Sensor for Wearable Electronics. Adv. Mater. 2015, 27, 2433–2439. [Google Scholar] [CrossRef] [PubMed]

- Sensors. Available online: http://www.novel.de/novelcontent/sensors (accessed on 21 August 2017).

- Xsensor Technology. Available online: http://www.xsensor.com (accessed on 21 August 2017).

- Peterson, M.J.; Gravenstein, N.; Schwab, W.K.; van Oostrom, J.H.; Caruso, L.J. Patient repositioning and pressure ulcer risk-monitoring interface pressures of at-risk patients. J. Rehabil. Res. Dev. 2013, 50, 477. [Google Scholar] [CrossRef] [PubMed]

- Kahn, J.A.; Kerrigan, M.V.; Gutmann, J.M.; Harrow, J.J. Pressure ulcer risk of patient handling sling use. J. Rehabil. Res. Dev. 2015, 52, 291. [Google Scholar]

- Wong, H.; Kaufman, J.; Baylis, B.; Conly, J.M.; Hogan, D.B.; Stelfox, H.T.; Southern, D.A.; Ghali, W.A.; Ho, C.H. Efficacy of a pressure-sensing mattress cover system for reducing interface pressure: Study protocol for a randomized controlled trial. Trials 2015, 16, 1. [Google Scholar] [CrossRef] [PubMed]

- Higer, S.; James, T. Interface pressure mapping pilot study to select surfaces that effectively redistribute pediatric occipital pressure. J. Tissue Viability 2016, 25, 41–49. [Google Scholar] [CrossRef] [PubMed]

- Capacitive Tactile Pressure Sensors. Available online: http://www.pressureprofile.com/capacitive-sensors (accessed on 21 August 2017).

- LG Innotek Unveils Flexible Textile Pressure Sensors. Available online: http://m.phys.org/news/2016-07-lg-innotek-unveils-flexible-textile.html?utm_source=nwletter&utm_medium=email&utm_campaign=daily-nwletter (accessed on 21 August 2017).

- Schedukat, N.; Gries, T. Intelligent Push-Button System for Use in Smart Textile, Has Upper and Lower Push-Button Halves with Two Electric Contacts Connected with One Another Electro-Conductively for Data, Signal and Power Transmission, While Closing Connection. DE102004026554, 16 March 2006. [Google Scholar]

- Dias, T.; Hurley, W.; Wijesiriwardana, R. Switches in Textile Structures. WO2006045988, 4 May 2006. [Google Scholar]

- Dias, T.; Hurley, W.; Monaragala, R.; Wijeyesiriwardana, R. Development of Electrically Active Textiles. In Advances in Science and Technology; Trans Tech Publications: Zürich, Switzerland, 2008; Volume 60. [Google Scholar]

- Deflin, E.; Weill, A.; Bonfiglio, J.; Athimon-Pillard, B. Flexible Textile Structure for Producing Electric Switches. WO03050832, 19 June 2003. [Google Scholar]

- Kuebler, S.; Seidel, F.-P. Textile with Built-in Electrical Switches is Used as Internal Lining or Seat Covering in Vehicles. DE102004009189, 15 September 2005. [Google Scholar]

- Leftly, S.A. Switches and Devices for Textile Articles. WO2006030230, 23 March 2006. [Google Scholar]

- Greenfield, A. Readings from Everyware: The dawning age of Ubiquitous Computing; New Rider: San Francisco, CA, USA, 2006. [Google Scholar]

- Nike + iPod Sensor. Available online: https://manuals.info.apple.com/MANUALS/1000/MA1139/en_US/nike_plus_ipod_sensor.pdf (accessed on 8 August 2017).

- Jacquard by Google. Available online: https://atap.google.com/jacquard/ (accessed on 17 November 2017).

- Muglia, H.A.; Refeld, J.; Eiselt, H. Generator Device for Converting Motion Energy of Person’s Respiration into Electrical Energy is Integrated into Clothing Item Normally Arranged at One or More Positions on Person that Undergoes Change in Dimensions during Respiration. DE10340873, 28 April 2005. [Google Scholar]

- Qin, Y.; Wang, X.; Wang, Z.L. Microfibre-nanowire hybrid structure for energy scavenging. Nature 2008, 451, 809–813. [Google Scholar] [CrossRef] [PubMed]

- Velten, J.; Kuanyshbekova, Z.; Göktepe, Ö.; Göktepe, F.; Zakhidov, A. Weavable dye sensitized solar cells exploiting carbon nanotube yarns. Appl. Phys. Lett. 2013, 102, 203902. [Google Scholar] [CrossRef]

- Uddin, M.J.; Davies, B.; Dickens, T.J.; Okoli, O.I. Self-aligned carbon nanotubes yarns (CNY) with efficient optoelectronic interface for microyarn shaped 3D photovoltaic cells. Solar Energy Mater. Solar Cells 2013, 115, 166–171. [Google Scholar] [CrossRef]

- Meng, Y.; Zhao, Y.; Hu, C.; Cheng, H.; Hu, Y.; Zhang, Z.; Shi, G.; Qu, L. All-graphene core-sheath microfibers for all-solid-state, stretchable fibriform supercapacitors and wearable electronic textiles. Adv. Mater. 2013, 25, 2326–2331. [Google Scholar] [CrossRef] [PubMed]

- Jost, K.; Dion, G.; Gogotsi, Y. Textile energy storage in perspective. J. Mater. Chem. A 2014, 2, 10776–10787. [Google Scholar] [CrossRef]

- Zhang, D.; Miao, M.; Niu, H.; Wie, Z. Core-spun carbon nanotube yarn supercapacitors for wearable electronic textiles. Acs Nano 2014, 8, 4571–4579. [Google Scholar] [CrossRef] [PubMed]

- Greenemeier, L. Study says carbon nanotubes as dangerous as asbestos. Sci. Am. 2008, 20. Available online: https://www.scientificamerican.com/article/carbon-nanotube-danger/ (accessed on 8 August 2017).

- Liu, Y.; Gorgutsa, S.; Santato, C.; Skorobogatiy, M. Flexible, solid electrolyte-based lithium battery composed of LiFePO4 cathode and Li4Ti5O12 anode for applications in smart textiles. J. Electrochem. Soc. 2012, 159, A349–A356. [Google Scholar] [CrossRef]

- Fan, F.R.; Tian, Z.Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Cui, N.; Liu, J.; Gu, L.; Bai, S.; Chen, X.; Qin, Y. Wearable triboelectric generator for powering the portable electronic devices. ACS Appl. Mater. Interfaces 2015, 7, 18225–18230. [Google Scholar] [CrossRef] [PubMed]

- Pillai, P.; Paster, E.; Montemayor, L.; Benson, C.; Hunter, I.W. Development of Soldier Conformable Antennae Using Conducting Polymers; Massachusetts Inst of Tech Cambridge Institute for Soldier Nanotechnologies (ISN): Cambridge, MA, USA, 2010. [Google Scholar]

- Campbell, T.G.; Hearn, C.W.; Reddy, C.J.; Boyd, R.C.; Yang, T.; Davis, W.A.; Persans, A.; Scarborough, S. Development of Conformal Space Suit Antennas for Enhanced EVA Communications and Wearable Computer Applications. In Proceedings of the 2010 Antenna Applications Symposium Volume II of II, Tangshan, China, 15–18 October 2010. [Google Scholar]

- Yang, T.; Davis, W.A.; Campbell, T.G.; Reddy, C.J. A Low-Profile Antenna Design Approach for Conformal Space Suit and Other Wearable Applications. In Proceedings of the 2010 Antenna Applications Symposium Volume II of II, Monticello, IL, USA, 21–23 September 2010. [Google Scholar]

- Acti, T.; Zhang, S.; Chauraya, A.; Whittow, W.; Seager, R.; Dias, T.; Vardaxoglou, Y. High performance flexible fabric electronics for megahertz frequency communications. In Proceedings of the Antennas and Propagation Conference (LAPC), 2011 Loughborough, Loughborough, UK, 14–15 November 2011; pp. 1–4. [Google Scholar]

- Chauraya, A.; Zhang, S.; Whittow, W.; Acti, T.; Seager, R.; Dias, T.; Vardaxoglou, Y.C. Addressing the challenges of fabricating microwave antennas using conductive threads. In Proceedings of the 6th European Conference on Antennas and Propagation (EUCAP), Prague, Czech Republic, 26–30 March 2012; pp. 1365–1367. [Google Scholar]

- Morris, R.H.; McHale, G.; Dias, T.; Newton, M.I. Embroidered coils for magnetic resonance sensors. Electronics 2013, 2, 168–177. [Google Scholar] [CrossRef]

- Speich, F. RFID Transponder Chip Module with Connecting Means for an Antenna, Textile Tag with an RFID Transponder Chip Module, and Use of an RFID Transponder Chip Module. TW200905574, 1 February 2009. [Google Scholar]

- Muehlbauer, A.G. Method for Attaching and Contacting RFID Chip Modules to Produce Transponders Comprising a Textile Substrate, and Transponder for Fabrics. WO2007104634, 20 September 2007. [Google Scholar]

- Corbett, B.G. Textile Identification System with RFID Tracking. US2005183990, 25 August 2005. [Google Scholar]

- Gravina, D. Method Using RFID Technology for Surveillance of Textile Goods in Laundries. EP1528504, 4 May 2005. [Google Scholar]

- Shpajkh, F. Textile RFID Label. RU2009114415, 27 October 2010. [Google Scholar]

- Speich, F. Method for the Production of a Textile Label Having an RFID Transponder Chip and Interlaced Information Carrier, and System for Carrying out the Method. US2010085166, 8 April 2010. [Google Scholar]

- Boll, W. Illumination System for Automobile Passenger Compartment e.g., for Cabriolet Automobile, Using Flexible Light Conductors or Electrical Lighting Devices Incorporated in Textile Material Forming Automobile Roof. DE10345002, 21 April 2005. [Google Scholar]

- Christensen, A.O. Woven Polymer Fiber Video Displays with Improved Efficiency and Economy of Manufacture. U.S. Patent US 6,229,259, 8 May 2001. [Google Scholar]

- Murasko, M.; Kinlen, P.J. Illuminated Display System and Process. U.S. Patent US 6,811,895, 2 November 2004. [Google Scholar]

- De-Flin, E.; Mourot, E.; Remy, M. Textile Display. WO 2004/100111 A2, 18 November 2004. [Google Scholar]

- DO UK HO. Self-Lighting Textile Using Optical Fiber. KR20080040815, 9 May 2008. [Google Scholar]

- Peng, C.-T.; Wang, C.-T. Textile with Pattern-Lighting Effect. US2011309768, 22 December 2011. [Google Scholar]

- Yu, Z. Lighting Textile Fabric. CN201873891, 22 June 2011. [Google Scholar]

- Ridao, M. Self Illuminating Spaces. In Proceedings of the Smart Fabrics Conference, Miami, FL, USA, 17–19 April 2012. [Google Scholar]

- Van De Pas, L. Bring Spaces Alive. In Proceedings of the Smart Fabrics Conference, Miami, FL, USA, 17–19 April 2012. [Google Scholar]

- Eves, D.A.; Chapman, J.A.; Bechtel, H.-H.; Wagner, P.C.; Martynov, Y. Electro-Optic Filament or Fibre. WO/2004/055576, 1 July 2004. [Google Scholar]

- Cutecircuit. Available online: http://cutecircuit.com/ (accessed on 22 August 2017).

- Lucentury. Available online: http://www.lucentury.com/ (accessed on 22 August 2017).

- Dias, T.; Monaragala, R.M. Electro-luminant Fabric Structures. US2010003496, 7 January 2010. [Google Scholar]

- Dias, T.; Monaragala, R. Development and analysis of novel electroluminescent yarns and fabrics for localized automotive interior illumination. Text. Res. J. 2012, 82, 1164–1176. [Google Scholar] [CrossRef]

- Bono’s Laser Stage Suit by Moritz Waldemeyer. Available online: https://www.dezeen.com/2010/02/28/bonos-laser-stage-suit-by-moritz-waldemeyer/ (accessed on 14 November 2017).

- World Market for Wearable Technology—A Quantitative Market Assessment—2012; IMS Research of Wellingborough: Wellingborough, UK, 2012.

- The Wearables Report 2016: Reviewing a Fast-Changing Market. Available online: https://www.fbicgroup.com/sites/default/files/The%20Wearables%20Report%202016%20by%20FBIC%20Global%20Retail%20and%20Technology%20June%2021%202016.pdf (accessed on 22 August 2017).

- Wearable Tech Market to be Worth $34 Billion By 2020. Available online: https://www.forbes.com/sites/paullamkin/2016/02/17/wearable-tech-market-to-be-worth-34-billion-by-2020/#5f690ca83cb5 (accessed on 22 August 2017).

- Hayward, J. E-Textiles 2017–2027: Technologies, Markets, Players. Available online: https://www.idtechex.com/research/reports/e-textiles-2017-2027-technologies-markets-players-000522.asp (accessed on 17 November 2017).

- International Fashion Machines. Available online: http://www.ifmachines.com/ (accessed on 21 August 2017).

- ScotteVest. Available online: https://www.scottevest.com/ (accessed on 21 August 2017).

- Fibretronic. Wearable Tech. CrunchWear. Available online: http://crunchwear.com/category/companies/fibretronic/ (accessed on 21 August 2017).

- Russell, B. Smart Fabrics for Consumer Health. In Proceedings of the Smart Fabrics Conference, Miami, FL, USA, 17–19 April 2012. [Google Scholar]

- Köhler, A.R.; Hilty, L.M.; Bakker, C. Prospective impacts of electronic textiles on recycling and disposal. J. Ind. Ecol. 2011, 15, 496–511. [Google Scholar] [CrossRef]

- Sun, C.H.; Shang, G.Q.; Tao, Y.Y.; Li, Z.R. A review on application of piezoelectric energy harvesting technology. Adv. Mater. Res. 2012, 516, 1481–1484. [Google Scholar] [CrossRef]

- Can Electricity from the Human Body Replace Batteries? BBC News. Available online: http://www.bbc.co.uk/news/science-environment-19470850 (accessed on 22 August 2017).

- Burns, M.L. Medical Trauma Assessment through the Use of Smart Textiles; Final Technical Report 7/14/94–2/28/95; Science, Math & Engineering, Inc.: Billerica, MA, USA, 1995. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).