The Influence of Ultraviolet Radiation on the Surface Roughness of Prints Made on Papers with Natural and Bleached Hemp Fibers

Abstract

1. Introduction

2. Materials and Methods

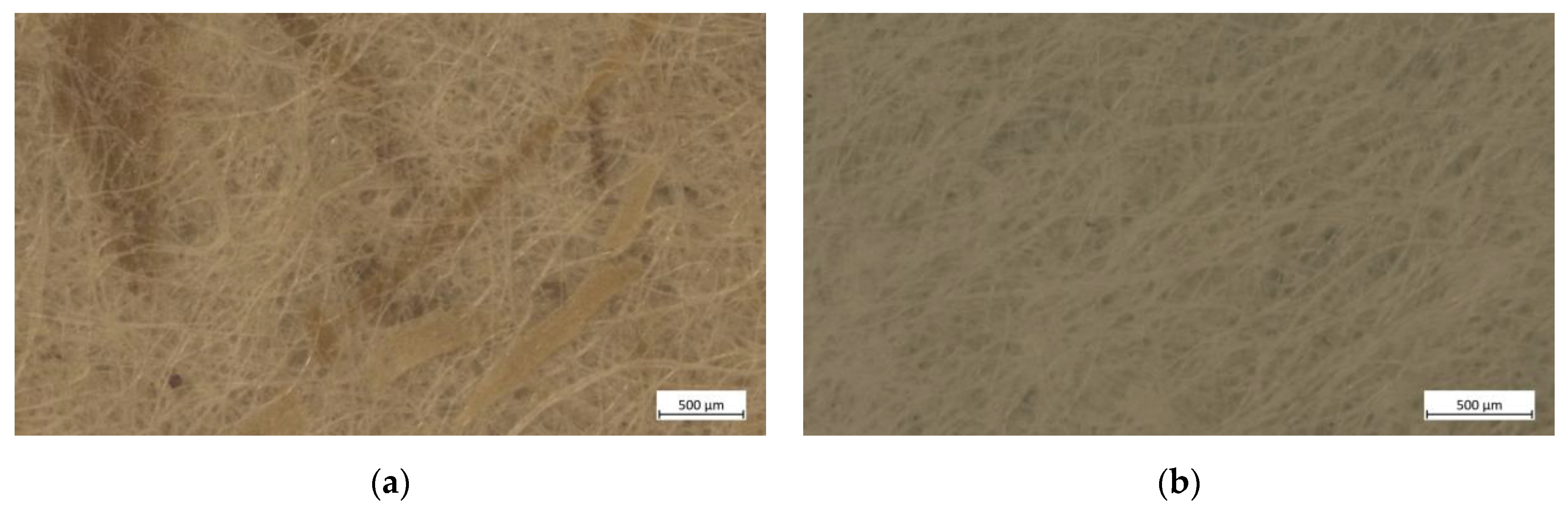

2.1. Printing Substrate

2.2. Printing of Analyzed Substrates

2.3. UV Radiation Treatment

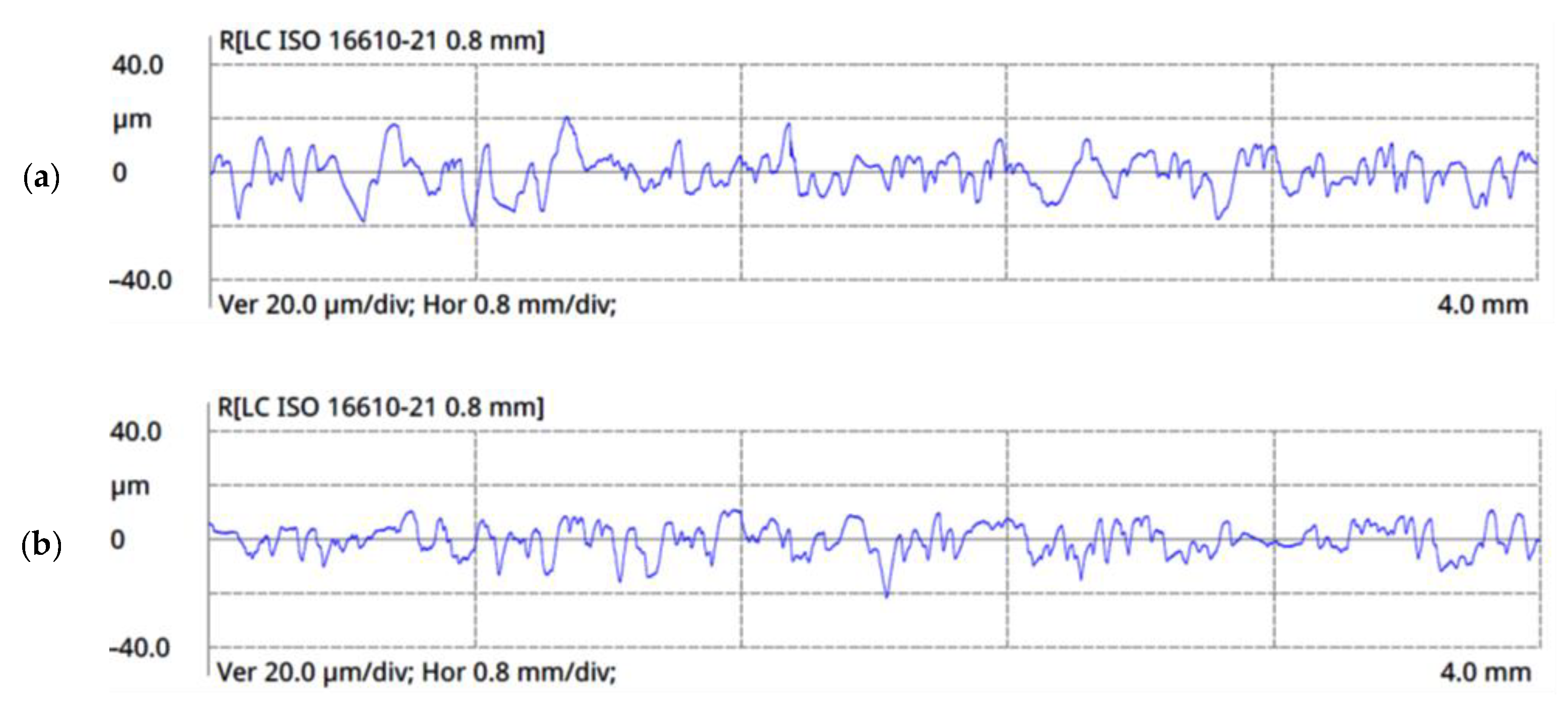

2.4. Roughness Analysis

2.5. Graininess Analysis

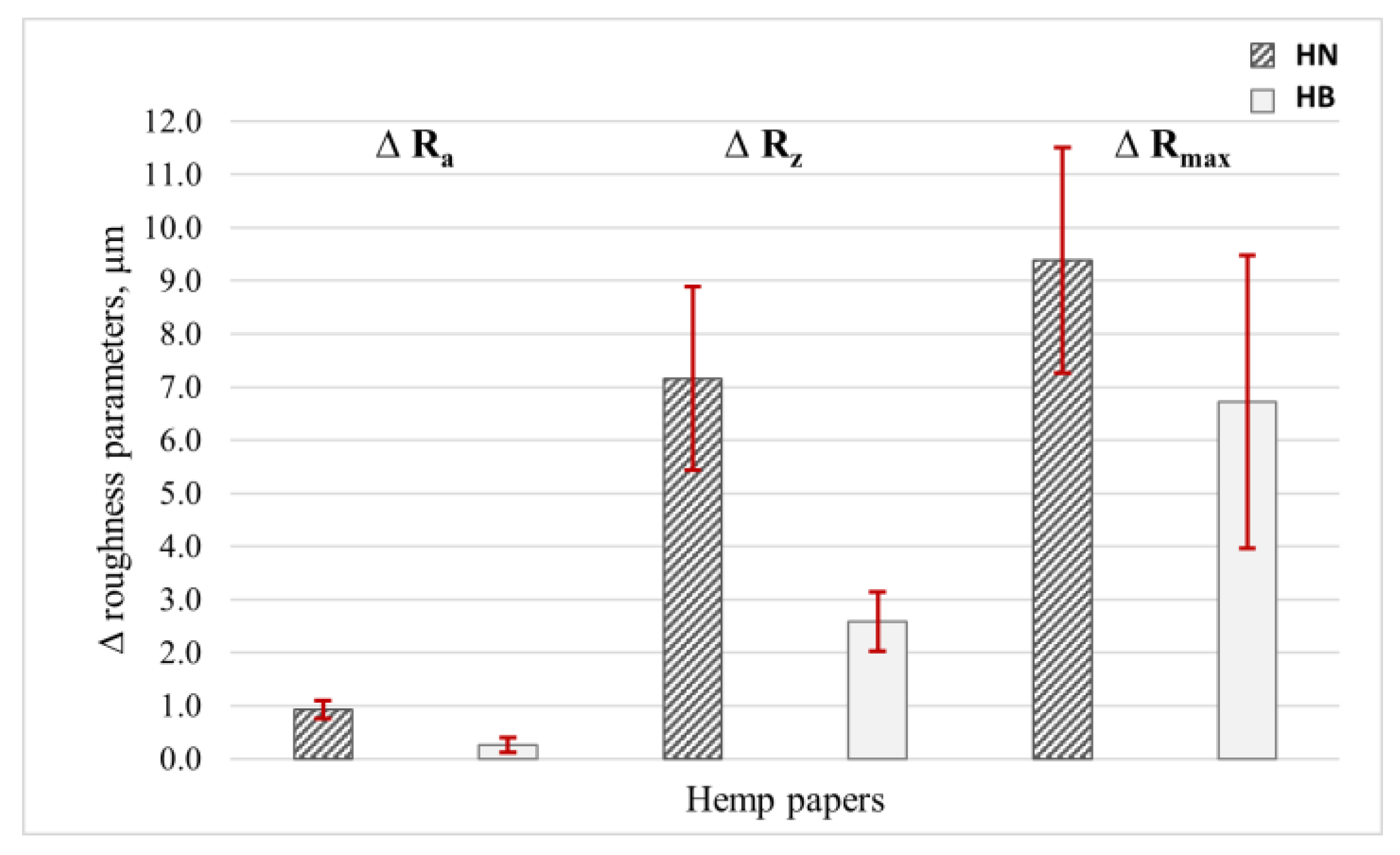

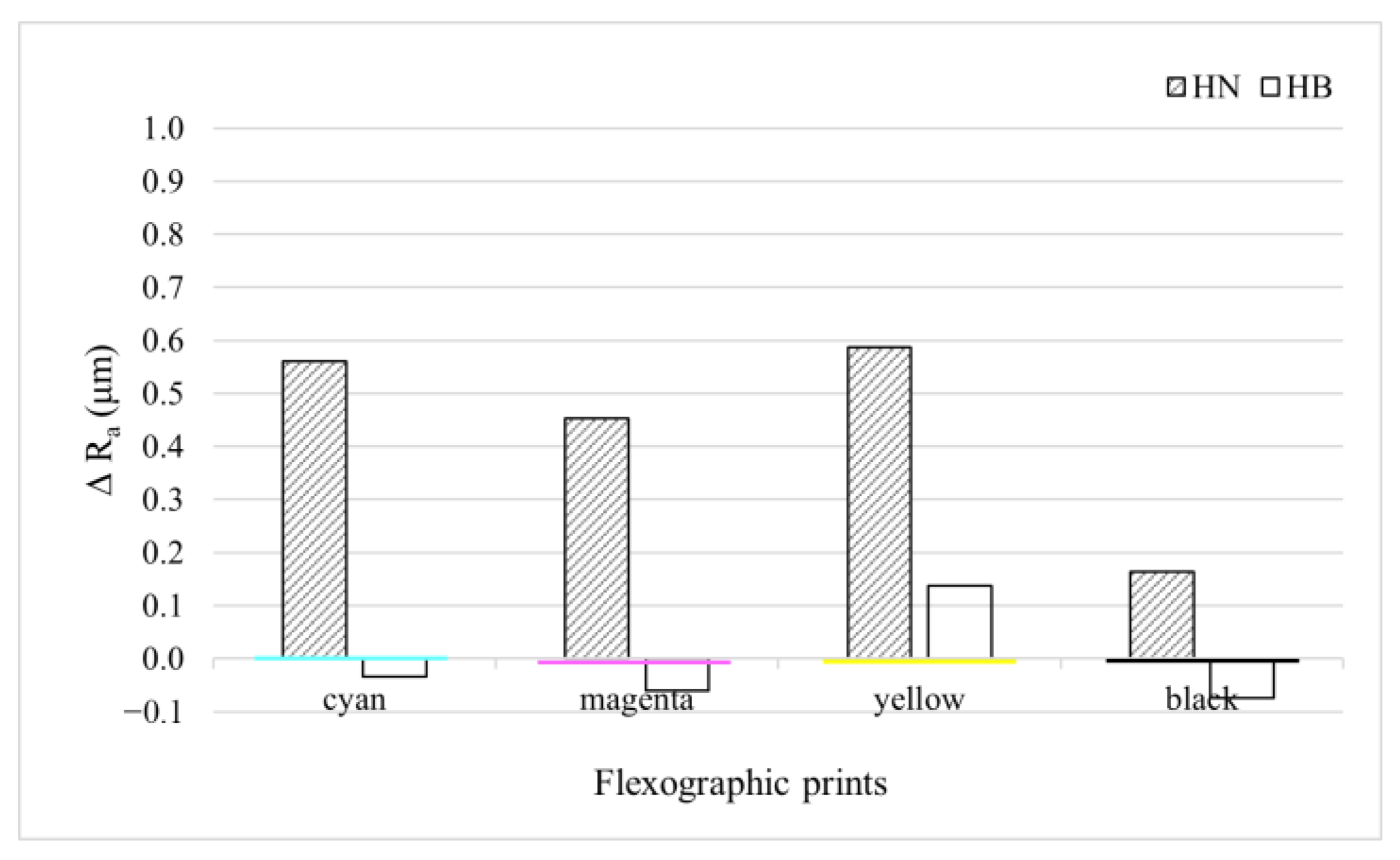

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- McCarthy, P.; Lei, L. Regional demands for pulp and paper products. J. For. Econ. 2010, 16, 127–144. [Google Scholar] [CrossRef]

- Danielewicz, D. Industrial Hemp as a Potential Nonwood Source of Fibres for European Industrial-Scale Papermaking—A Review. Materials 2023, 16, 6548. [Google Scholar] [CrossRef]

- Global Production of Paper and Paperboard 1961–2022. Published by Statista Research Department. 2024. Available online: https://www.statista.com/statistics/270314/global-paper-and-cardboard-production/ (accessed on 13 September 2024).

- Worku, L.A.; Bachheti, A.; Bachheti, R.K.; Rodrigues Reis, C.E.; Chandel, A.K. Agricultural Residues as Raw Materials for Pulp and Paper Production: Overview and Applications on Membrane Fabrication. Membranes 2023, 13, 228. [Google Scholar] [CrossRef] [PubMed]

- Baptista, C.; Santos, N.; Rosa, M. Portuguese Hemp Plant as Raw Material for Papermaking. Athens J. Sci. 2020, 7, 15–28. [Google Scholar] [CrossRef]

- Preston, J. Review: The surface analysis of paper. In Advances in Pulp and Paper Research, Oxford 2009; Anson, S.J.I., Ed.; FRC: Manchester, UK, 2018; pp. 749–838. [Google Scholar] [CrossRef]

- Stančić, M.; Ružičić, b.; Pelkić, S. Influence of substrate roughness on print quality parameters of digitally printed paper substrates. J. Chem. Technol. Environ. 2022, 3, 38–46. Available online: https://doisrpska.nub.rs/index.php/ghters/article/view/9672 (accessed on 17 May 2024).

- Petric Maretić, K.; Rudolf, M.; Bates, I.; Plazonić, I. The comparison of topographic paper surface characteristics based on roughness and smoothness. In Proceedings of the Printing & Design 2018, Zagreb, Croatia, 16–17 March 2018. [Google Scholar]

- Pino, A.O.; Pladellorens Mallofre, J.; Aregay, J.C.; Cusola, O. Roughness measurement of paper using speckle. Opt. Eng. 2011, 50, 093605-1–093605-5. [Google Scholar] [CrossRef][Green Version]

- Pino, A.; Pladellorens, J. Measure of roughness of paper using speckle. In Optical Inspection and Metrology for Non-Optics Industries; SPIE: Bellingham, WA, USA, 2009; pp. 74320E-1–74320E-9. [Google Scholar]

- Angélico, D.; Reis, M.; Costa, R.; Saraiva, P.; Ataíde, J. Profilometry: A Technique to Characterize Paper Surface. Available online: https://www.tecnicelpa.com/files/Profilometry.pdf (accessed on 17 May 2024).

- Fischer, W.J.; Mayr, M.; Spirk, S.; Reishofer, D.; Jagiello, L.A.; Schmiedt, R.; Colson, J.; Zankel, A.; Bauer, W. Pulp Fines—Characterization, Sheet Formation, and Comparison to Microfibrillated Cellulose. Polymers 2017, 9, 366. [Google Scholar] [CrossRef]

- Pydimalla, M.; Reddy, K. Effect of Pulping, Bleaching and Refining Process on Fibers for Paper Making—A Review. Int. J. Eng. Res. Technol. 2020, 9, 310–316. [Google Scholar]

- Bucher, W. Bleaching 101: The Basics. Frontline Focus 2006, 87, 36–37. [Google Scholar]

- Esteves, C.V.; Sevastyanova, O.; Östlund, S.; Brännvall, E. The impact of bleaching on the yield of softwood kraft pulps obtained by high alkali impregnation. Nord. Pulp Pap. Res. J. 2022, 37, 593–608. [Google Scholar] [CrossRef]

- Environmental, Health, and Safety Guidelines Pulp and Paper Mills. IFC. 2007, pp. 1–30. Available online: https://www.ifc.org/content/dam/ifc/doc/2000/2007-pulp-and-paper-mills-ehs-guidelines-en.pdf (accessed on 20 July 2024).

- Kline, L.M.; Hayes, D.G.; Womac, A.R.; Labbé, N. Simplified determination of lignin content in hard and soft woods via UV-spectrophotometric analysis of biomass dissolved in ionic liquids. BioResources 2010, 5, 1366–1383. [Google Scholar] [CrossRef]

- Plazonić, I.; Džimbeg-Malčić, V.; Bates, I.; Barbarić-Mikočević, Ž. Effects of Photo-oxidation on the Properties of Hemp Office Papers. Int. J. Technol. 2020, 11, 215–224. [Google Scholar] [CrossRef]

- Teacă, C.-A.; Roşu, D.; Bodîrlău, R.; Roşu, L. Structural changes in wood under artificial UV light irradiation determined by FTIR spectroscopy and color measurements—A brief review. BioResources 2013, 8, 478–1507. [Google Scholar] [CrossRef]

- Geffertova, J.; Geffert, A.; Deliiski, N. The Effect of Light on the Changes of White Office Paper. Key Eng. Mater. 2016, 688, 104–111. [Google Scholar] [CrossRef]

- Plazonić, I.; Barbarić-Mikočević, Ž.; Bates, I.; Malnar, L. Chemical stability of prints made on hemp fibrebased papers. Acta Graph. Znan. Časopis Za Tisk. I Graf. Komun. 2016, 27, 25–30. [Google Scholar]

- ISO 5637; Paper, Board and Pulps—Determination of Water Absorption after Immersion in Water. International Organization for Standardization: Geneva, Switzerland, 1989.

- Leach, R.H.; Pierce, R.J. The Printing Ink Manual, 5th ed.; Springer: Dordrecht, The Netherlands, 2008; pp. 562–563. [Google Scholar]

- ASTM D 6789-02; Paper—Standard Test Method for Accelerated Light Aging of Prints and Writing Paper by Xenon-Arc Exposure Apparatus. ASTM International: West Conshohocken, PA, USA, 2017.

- Plazonić, I.; Džimbeg-Malčić, V.; Bates, I.; Žilić, G. The effect of electromagnetic radiation on the reflectance spectra of prints on hemp papers. J. Graph. Eng. Des. 2021, 12, 21–28. [Google Scholar] [CrossRef]

- Kyrychok, T.; Klymenko, T.; Talimonova, N.; Svezhentsova, K. Determining special features in the topography of paper with water marks at the micro- and nanolevels. East. Eur. J. Enterp. Technol. 2019, 2, 28–35. [Google Scholar] [CrossRef]

- ISO/IEC 13660; Information Technology—Office Equipment—Measurement of Image Quality Attributes—Binary Monochrome Text and Graphic Images. ISO: Geneva, Switzerland, 2001.

- Bates, I.; Plazonić, I.; Radić Seleš, V.; Petric Maretić, K.; Rudolf, M. Usability of Discarded Lignocellulosic Fibers in Paper for Secondary Green Packaging and Labeling. Sustainability 2023, 15, 5378. [Google Scholar] [CrossRef]

- Arnata, I.W.; Suprihatin;Fahma, F.; Richana, N.; Sunarti, T.C. Cellulose Production from Sago Frond with Alkaline Delignification and Bleaching on Various Types of Bleach Agents. Orient. J. Chem. 2019, 35, 8–19. [Google Scholar] [CrossRef]

- Tomić, I.; Karlović, I.; Jurič, I.; Szentgyörgyvölgyi, R. An influence of accelerated ageing on distinctness of image for coated offset prints. In Proceedings of the 11th Symposium on Graphic Arts, Pardubice, The Czech Republic, 17–18 June 2013. [Google Scholar]

- Karlovits, M.; Gregor-Svetec, D. Durability of Cellulose and Synthetic Papers Exposed to Various Methods of Accelerated Ageing. Acta Polytech. Hung. 2012, 9, 81–100. [Google Scholar] [CrossRef]

| Characteristics | Printing Substrates | |

|---|---|---|

| HN | HB | |

| Composition | 100% hemp plant fiber | |

| Production | handmade | |

| Coating | uncoated | |

| Bleaching | natural, unbleached | non-chlorine bleached |

| ISO Brightness | 37.70 ± 0.21 | 70.79 ± 0.77 |

| Thickness, mm | 0.18 ± 0.01 | 0.20 ± 0.01 |

| Ash900 [%] | 1.34 | 1.72 |

| Moisture [%] | 4.95 ± 0.39 | 5.17 ± 0.37 |

| Tensile index [Nmg−1] | 55.52 ± 5.43 | 58.64 ± 3.94 |

| Elongation at break [%] | 2.04 | 2.48 |

| Tear index [mNm2g−1] | 24.96 ± 1.57 | 15.15 ± 1.25 |

| Roughness (Bendtsen method) [mL min−1] | 920.50 ± 204.28 | 646.50 ± 139.58 |

| Smoothness (Bekk method) [s 10 mL−1] | 1.98 ± 0.13 | 3.24 ± 0.21 |

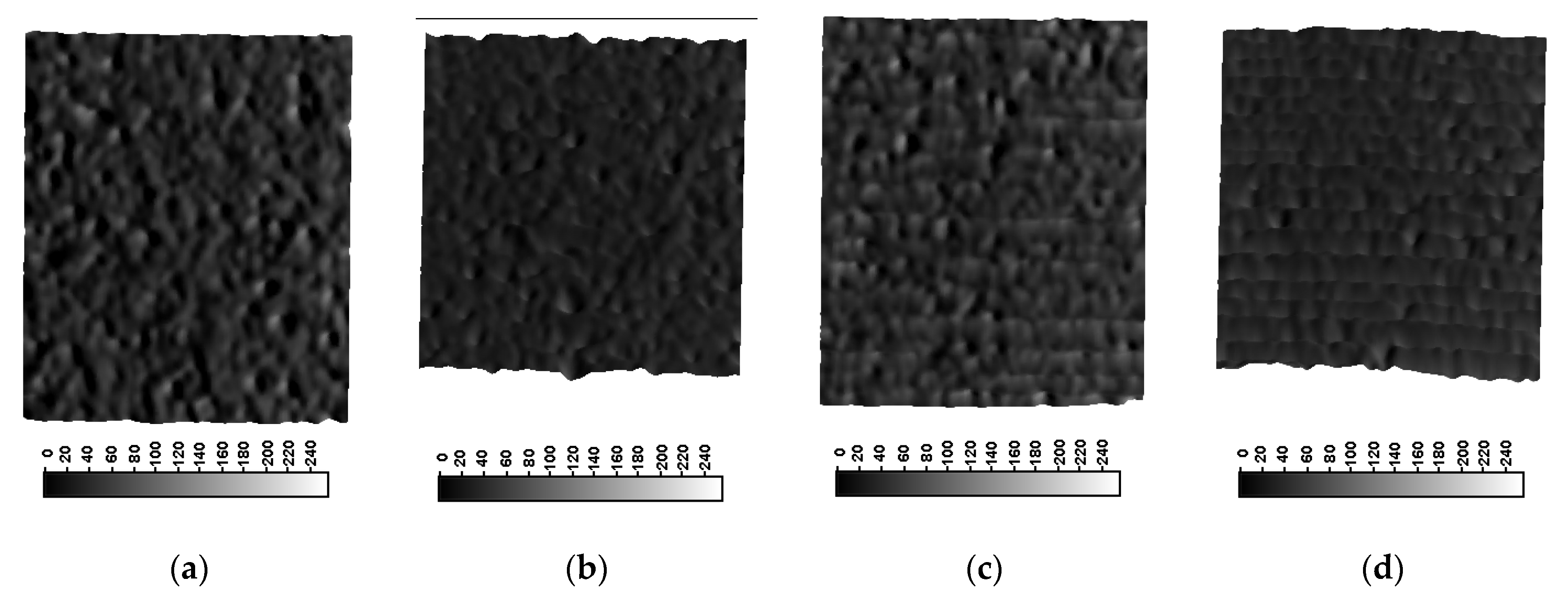

| Flexographic Prints | Printing Substrates | |

|---|---|---|

| HN | HB | |

| Cyan |  |  |

| Magenta |  |  |

| Yellow |  |  |

| Black |  |  |

| Paper | Relative Water Absorption (%) |

|---|---|

| HN | 340.72 ± 5.10 |

| HB | 280.77 ± 10.33 |

| Parameters of Surface Roughness (μm) | |||

|---|---|---|---|

| Ra | Rz | Rmax | |

| HN | 5.575 ± 0.402 a | 31.081 ± 1.966 a | 39.461 ± 4.645 a |

| HB | 4.302 ± 0.233 b | 24.529 ± 1.328 b | 29.878 ± 2.427 b |

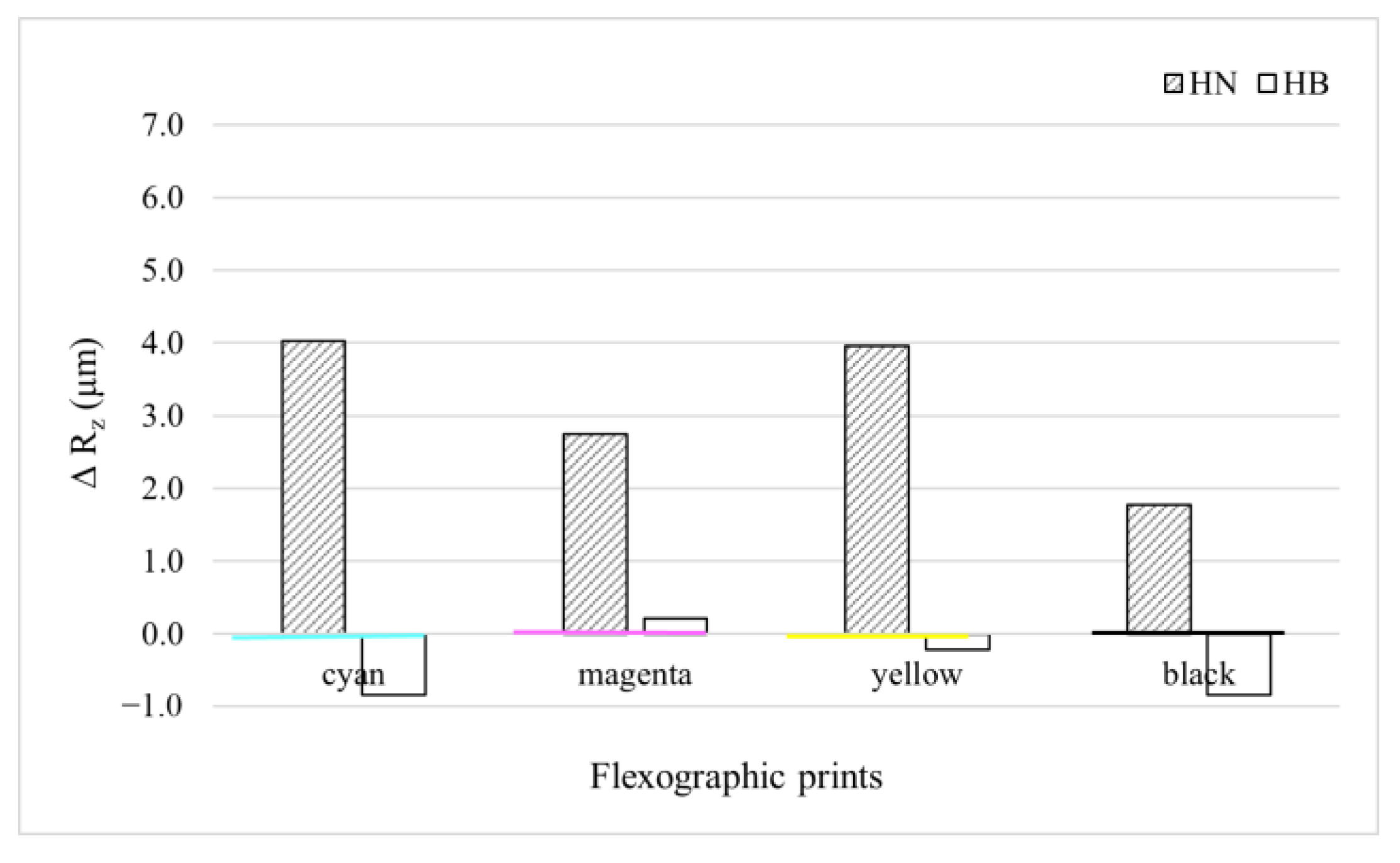

| Flexographic Prints | Ra (μm) | Rz (μm) | Rmax (μm) | |

|---|---|---|---|---|

| Cyan | HN | 5.782 ± 0.385 a | 30.876 ± 2.130 b | 38.010 ± 3.388 b |

| HB | 4.110 ± 0.299 c | 24.653 ± 1.739 e | 30.585 ± 2.582 d | |

| Magenta | HN | 5.519 ± 0.299 a | 30.260 ± 2.113 c | 36.100 ± 2.675 b |

| HB | 4.208 ± 0.298 c | 23.219 ± 2.241 e | 29.054 ± 5.415 e | |

| Yellow | HN | 5.506 ± 0.342 a | 29.405 ± 3.272 c | 36.932 ± 5.467 b |

| HB | 4.483 ± 0.205 b | 26.623 ± 2.115 d | 32.464 ± 3.878 c | |

| Black | HN | 5.808 ± 0.532 a | 33.816 ± 3.860 a | 43.350 ± 7.051 a |

| HB | 4.101 ± 0.213 c | 23.686 ± 1.632 e | 30.397 ± 6.703 e | |

| Flexographic Prints | Graininess (%) | ||

|---|---|---|---|

| HN | HB | ||

| Cyan | BUV | 2.3 | 1.8 |

| AUV | 1.8 | 1.5 | |

| Magenta | BUV | 1.6 | 0.6 |

| AUV | 1.6 | 0.6 | |

| Yellow | BUV | 2.0 | 1.3 |

| AUV | 2.1 | 2.8 | |

| Black | BUV | 2.0 | 0.7 |

| AUV | 2.1 | 0.7 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barbarić-Mikočević, Ž.; Bates, I.; Rudolf, M.; Plazonić, I. The Influence of Ultraviolet Radiation on the Surface Roughness of Prints Made on Papers with Natural and Bleached Hemp Fibers. Fibers 2024, 12, 112. https://doi.org/10.3390/fib12120112

Barbarić-Mikočević Ž, Bates I, Rudolf M, Plazonić I. The Influence of Ultraviolet Radiation on the Surface Roughness of Prints Made on Papers with Natural and Bleached Hemp Fibers. Fibers. 2024; 12(12):112. https://doi.org/10.3390/fib12120112

Chicago/Turabian StyleBarbarić-Mikočević, Željka, Irena Bates, Maja Rudolf, and Ivana Plazonić. 2024. "The Influence of Ultraviolet Radiation on the Surface Roughness of Prints Made on Papers with Natural and Bleached Hemp Fibers" Fibers 12, no. 12: 112. https://doi.org/10.3390/fib12120112

APA StyleBarbarić-Mikočević, Ž., Bates, I., Rudolf, M., & Plazonić, I. (2024). The Influence of Ultraviolet Radiation on the Surface Roughness of Prints Made on Papers with Natural and Bleached Hemp Fibers. Fibers, 12(12), 112. https://doi.org/10.3390/fib12120112