Targeted Pre-Treatment of Hemp Fibers and the Effect on Mechanical Properties of Polymer Composites

Abstract

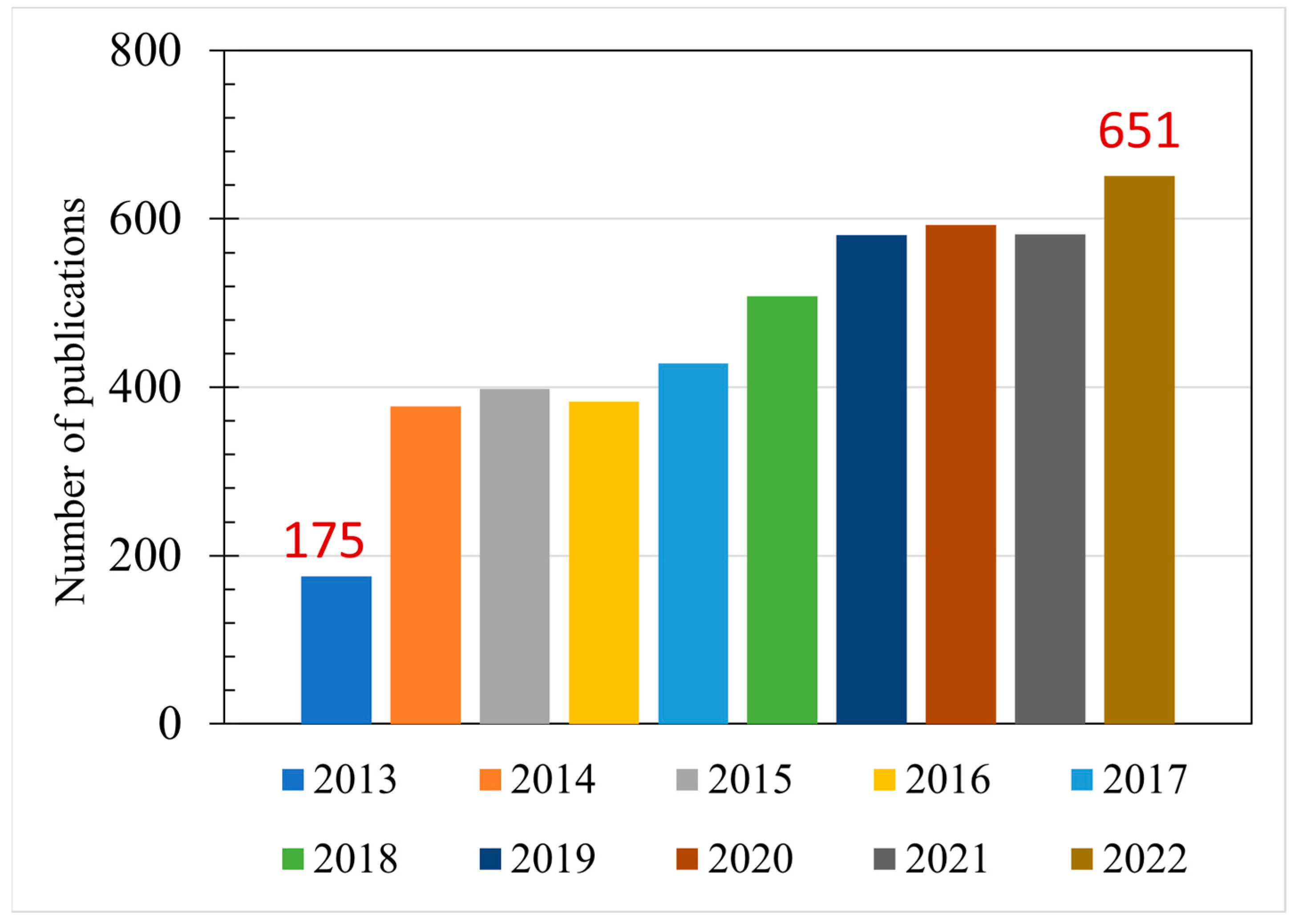

1. Introduction

2. Processing and Targeted Pre-Treatment

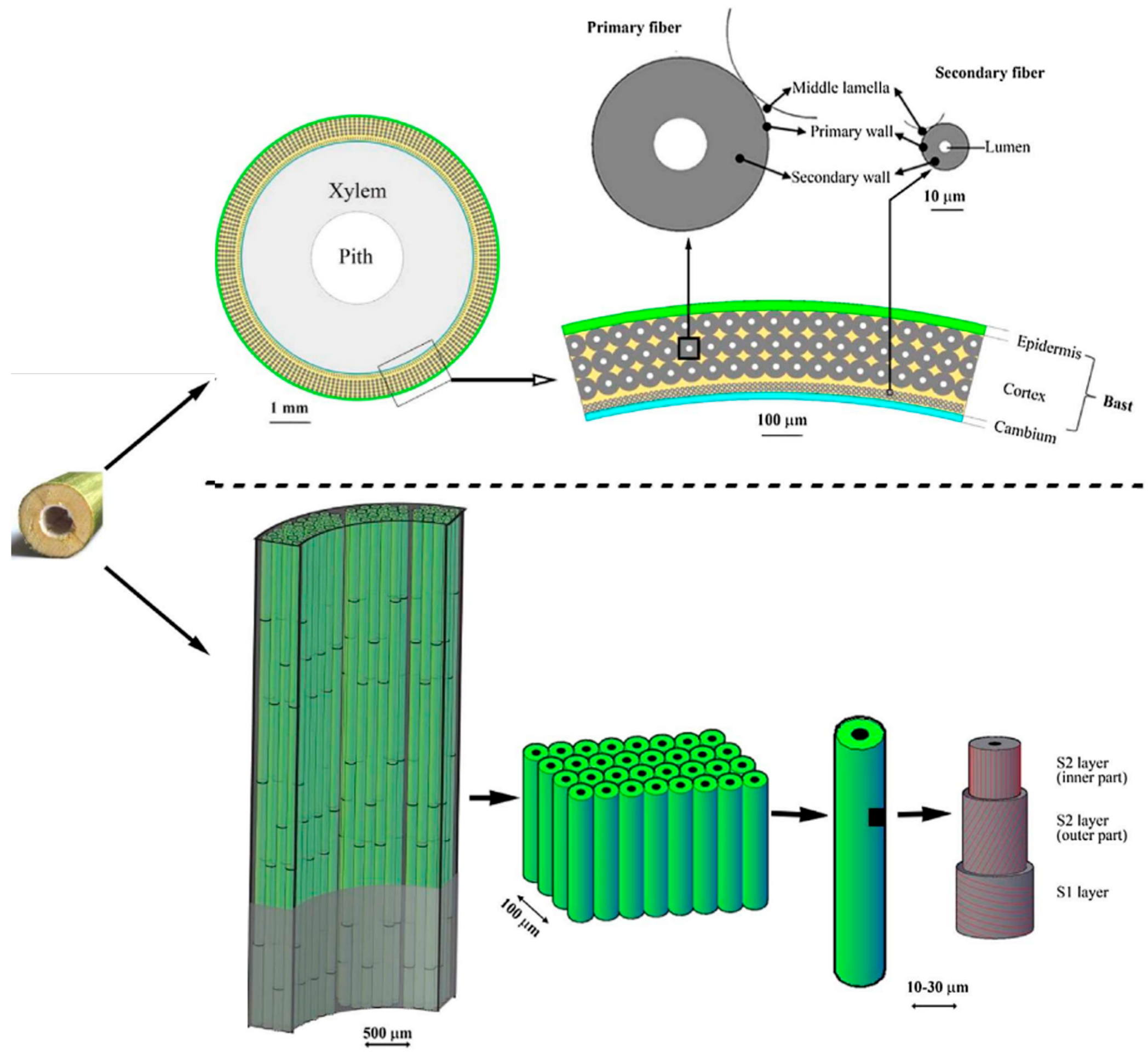

2.1. General Characteristics and Cultivation Hemp Fiber

2.2. Pre-Treatment of Hemp Fiber

- Defibration (traditional retting, controlled microbiological retting, mechanical treatment, steam explosion, chemical treatment and enzyme treatment);

- Surface modification (alkali treatment, graft co-polymerization, physical treatment and esterification);

- Antimicrobial degradation.

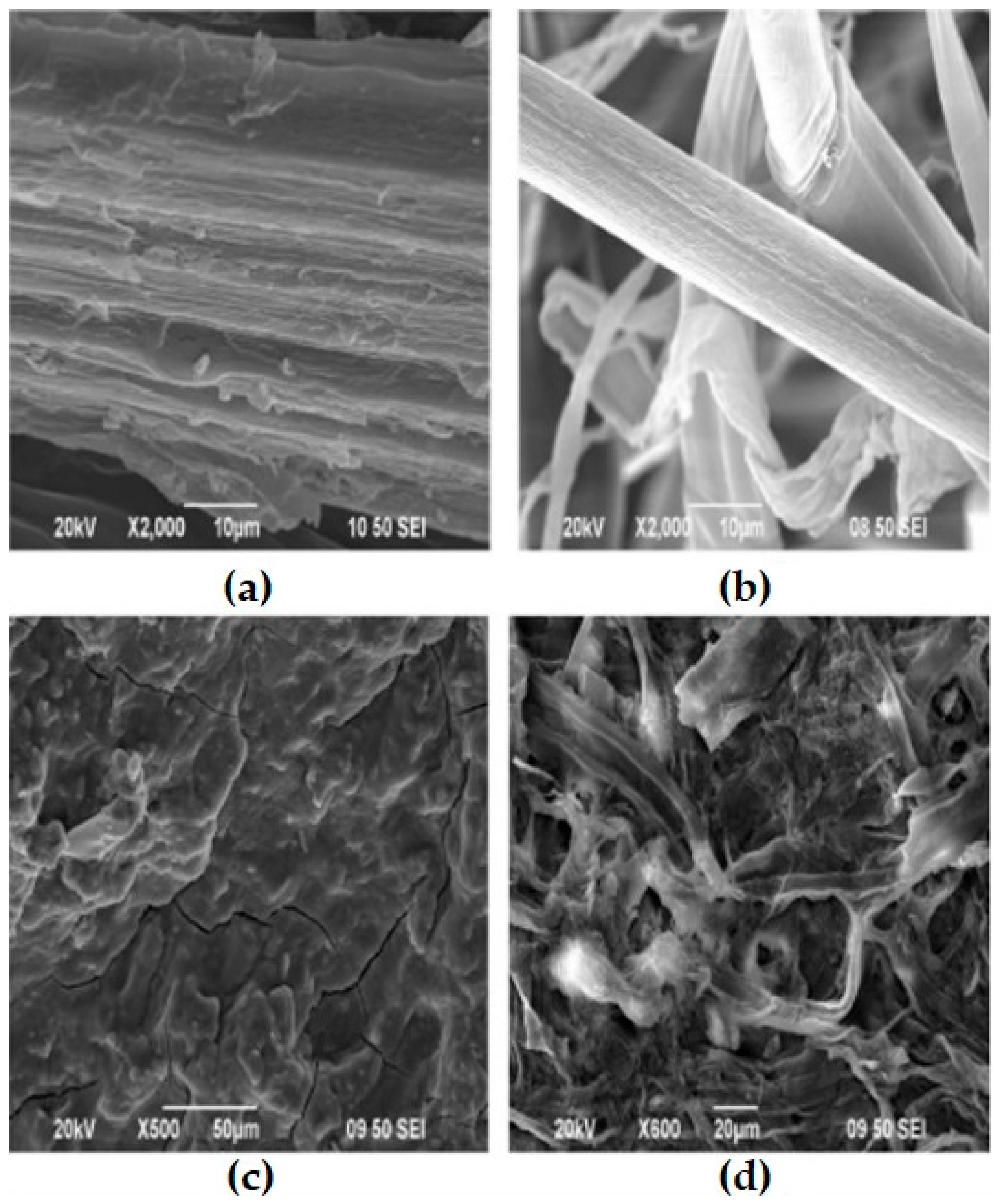

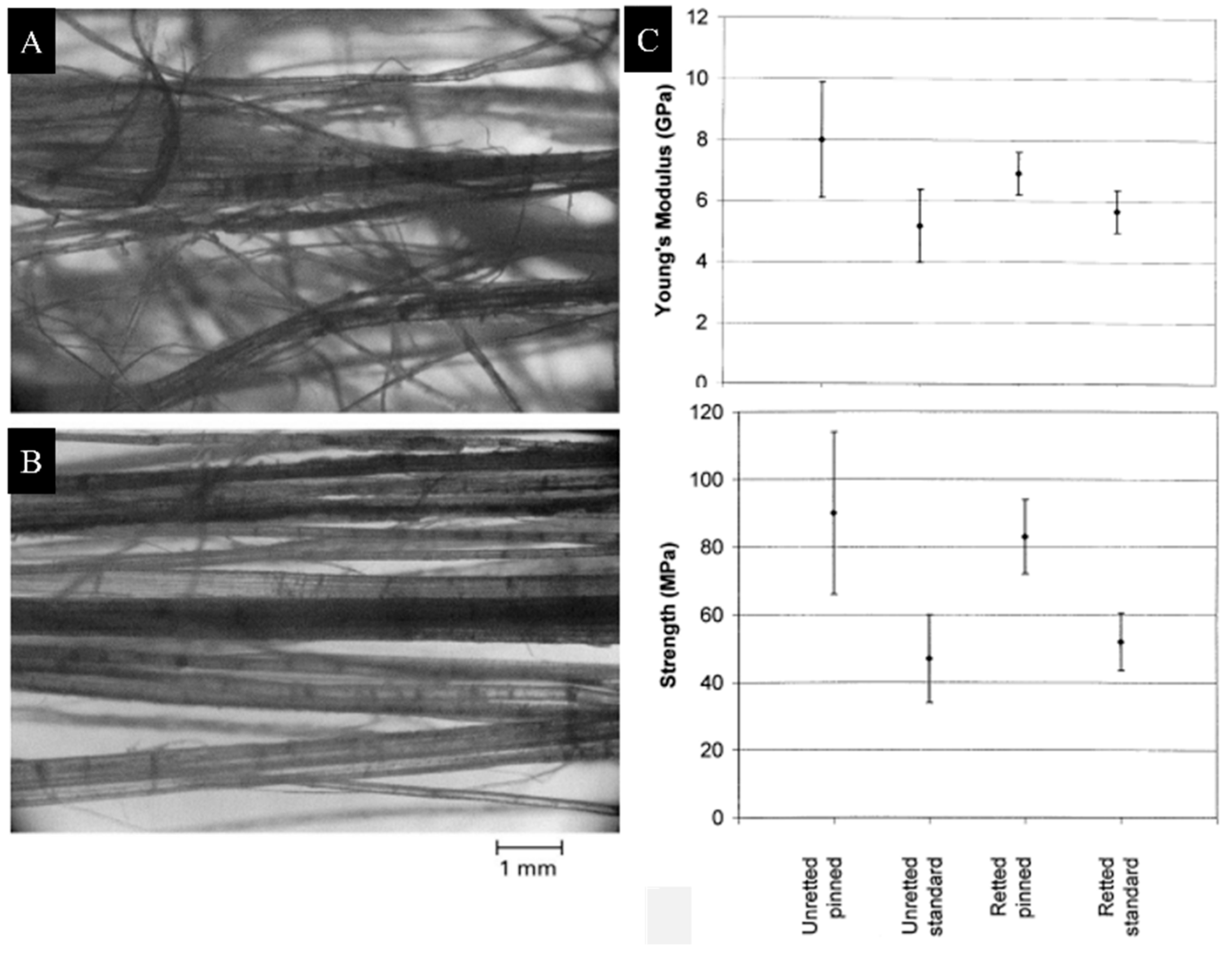

2.2.1. Defibration

2.2.2. Surface Modification

2.2.3. Antimicrobial Degradation

3. Mechanical Properties of Hemp-Fiber-Reinforced Composites

3.1. Effects of Pre-Treatment

3.2. Effects of Fiber Alignment

3.3. Toughening Mechanisms

4. Application Perspectives of Hemp Fiber Reinforced Composites

5. Conclusions and Perspectives

- The effects of hemp-fiber alignment on the mechanical properties of the composite have not been well investigated. Techniques to achieve fiber alignment can be explored to attain excellent properties in a specific direction;

- Research can also be intensified on additive manufacturing of hemp-fiber-reinforced composites. This provides the opportunity to fabricate structures with complex geometry and near complete design freedom at a lower cost and with fast turnaround time. Moreover, exploring 3D printing for fabrication of hemp-fiber-reinforced composites minimizes material wastage since the technique only adds the material required for fabricating a structure;

- Studies have commonly reported the deterioration of mechanical properties at very high fiber loading. As such, it is important to investigate the fundamental idea of stress transfer and interfacial bond strength that influences properties of the composites (e.g., theoretical analysis).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, N.; Oza, S. Thermal stability and thermo-mechanical properties of hemp-high density polyethylene composites: Effect of two different chemical modifications. Compos. Part B Eng. 2013, 44, 484–490. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Plant fibre based bio-composites: Sustainable and renewable green materials. Renew. Sustain. Energy Rev. 2017, 79, 558–584. [Google Scholar] [CrossRef]

- Palani Kumar, K.; Keshavan, D.; Natarajan, E.; Narayan, A.; Ashok Kumar, K.; Deepak, M.; Freitas, L.I. Evaluation of mechanical properties of coconut flower cover fibre-reinforced polymer composites for industrial applications. Prog. Rubber Plast. Recycl. Technol. 2021, 37, 3–18. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Mechanical properties of alkali treated plant fibres and their potential as reinforcement materials. I. hemp fibres. J. Mater. Sci. 2006, 41, 2483–2496. [Google Scholar] [CrossRef]

- Vilaseca, F.; López, A.; Llauró, X.; Pèlach, M.A.; Mutjé, P. Hemp strands as reinforcement of polystyrene composites. Chem. Eng. Res. Des. 2004, 82, 1425–1431. [Google Scholar] [CrossRef]

- Boppana, S.B.; Palani Kumar, K.; Ponshanmugakumar, A.; Dayanand, S. Different natural fiber reinforced composites and its potential industrial and domestic applications: A review. In Bio-Fiber Reinforced Composite Materials: Mechanical, Thermal and Tribological Properties; Springer: Berlin/Heidelberg, Germany, 2022; pp. 51–73. ISBN 9789811688997. [Google Scholar]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Comparative evaluation on properties of hybrid glass fiber-sisal/jute reinforced epoxy composites. Procedia Eng. 2013, 51, 745–750. [Google Scholar] [CrossRef]

- Ahmed, A.T.M.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a potential raw material toward a sustainable world: A review. Heliyon 2022, 8, e08753. [Google Scholar] [CrossRef]

- Tutek, K.; Masek, A. Hemp and Its Derivatives as a Universal Industrial Raw Material (with Particular Emphasis on the Polymer Industry)—A Review. Materials 2022, 15, 2565. [Google Scholar] [CrossRef]

- Kabir, M.M.; Alhaik, M.Y.; Aldajah, S.H.; Lau, K.T.; Wang, H.; Islam, M.M. Effect of Hemp Fibre Surface Treatment on the Fibre-Matrix Interface and the Influence of Cellulose, Hemicellulose, and Lignin Contents on Composite Strength Properties. Adv. Mater. Sci. Eng. 2021, 2021, 9753779. [Google Scholar] [CrossRef]

- Singh, S.K.; Karloopia, J.; Khan, S.; Mishra, R.K. Processing and characterization of hemp nanofiber thermoset polymer composite. Mater. Today Proc. 2021, 46, 1341–1348. [Google Scholar] [CrossRef]

- Alao, P.F.; Marrot, L.; Burnard, M.D.; Lavrič, G.; Saarna, M.; Kers, J. Impact of Alkali and silane treatment on hemp/PLA composites’ performance: From micro to macro scale. Polymers 2021, 13, 851. [Google Scholar] [CrossRef] [PubMed]

- Vijayakumar, S.; Palanikumar, K.; Natarajan, E. Mechanical and resonance properties of sustainable polymer composite reinforced with unidirectional Bio Palm Fiber. In Bio-Fiber Reinforced Composite Materials: Mechanical, Thermal and Tribological Properties; Springer Nature: Singapore, 2022; pp. 205–219. [Google Scholar]

- Alao, P.F.; Marrot, L.; Kallakas, H.; Just, A.; Poltimäe, T.; Kers, J. Effect of hemp fiber surface treatment on the moisture/water resistance and reaction to fire of reinforced pla composites. Materials 2021, 14, 4332. [Google Scholar] [CrossRef] [PubMed]

- Kumar, B.R.; Hariharan, S.S. Comparative investigation on fatigue and moisture absorption behavior of hemp and Jute fibre polymer composites. Struct. Eng. Mech. 2022, 81, 729–736. [Google Scholar] [CrossRef]

- Manich, A.M.; Lis, M.J.; Perez-Rentero, S.; Algaba, I.; Marti, M.; Cayuela, D. Influence of alkaline delignification on moisture uptake behavior and bonding enthalpies of hemp. J. Appl. Polym. Sci. 2021, 138, 50990. [Google Scholar] [CrossRef]

- Dolza, C.; Gonga, E.; Fages, E.; Tejada-Oliveros, R.; Balart, R.; Quiles-Carrillo, L. Green Composites from Partially Bio-Based Poly(butylene succinate-co-adipate)-PBSA and Short Hemp Fibers with Itaconic Acid-Derived Compatibilizers and Plasticizers. Polymers 2022, 14, 1968. [Google Scholar] [CrossRef]

- Han, H.C.; Gong, X.L.; Zhou, M.; Li, C.; Yang, H.B. A study about silane modification and interfacial ultraviolet aging of hemp fiber reinforced polypropylene composites. Polym. Compos. 2021, 42, 2544–2555. [Google Scholar] [CrossRef]

- Manaia, J.P.; Manaia, A. Interface modification, water absorption behaviour and mechanical properties of injection moulded short hemp fiber-reinforced thermoplastic composites. Polymers 2021, 13, 1638. [Google Scholar] [CrossRef]

- Niu, P.; Liu, B.; Wei, X.; Wang, X.; Yang, J. Study on mechanical properties and thermal stability of polypropylene/hemp fiber composites. J. Reinf. Plast. Compos. 2011, 30, 36–44. [Google Scholar] [CrossRef]

- Sebestyén, Z.; May, Z.; Réczey, K.; Jakab, E. The effect of alkaline pretreatment on the thermal decomposition of hemp. J. Therm. Anal. Calorim. 2011, 105, 1061–1069. [Google Scholar] [CrossRef]

- Kalia, S.; Kumar, A. Surface Modification of Sunn Hemp Fibers Using Acrylation, Peroxide and Permanganate Treatments: A Study of Morphology, Thermal Stability and Crystallinity. Polym. Plast. Technol. Eng. 2013, 52, 24–29. [Google Scholar] [CrossRef]

- Liu, M.; Thygesen, A.; Summerscales, J.; Meyer, A.S. Targeted pre-treatment of hemp bast fibres for optimal performance in biocomposite materials: A review. Ind. Crop. Prod. 2017, 108, 660–683. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Effects of chemical treatments on hemp fibre structure. Appl. Surf. Sci. 2013, 276, 13–23. [Google Scholar] [CrossRef]

- Zhang, H.; Zhong, Z.; Feng, L. Advances in the performance and application of hemp fiber. Int. J. Simul. Syst. Sci. Technol. 2016, 17, 18.1–18.5. [Google Scholar] [CrossRef]

- Ouajai, S.; Shanks, R.A. Composition, structure and thermal degradation of hemp cellulose after chemical treatments. Polym. Degrad. Stab. 2005, 89, 327–335. [Google Scholar] [CrossRef]

- Liu, M.; Fernando, D.; Daniel, G.; Madsen, B.; Meyer, A.S.; Ale, M.T.; Thygesen, A. Effect of harvest time and field retting duration on the chemical composition, morphology and mechanical properties of hemp fibers. Ind. Crop. Prod. 2015, 69, 29–39. [Google Scholar] [CrossRef]

- Vera, C.L.; Malhi, S.S.; Phelps, S.M.; May, W.E.; Johnson, E.N. N, P, and S fertilization effects on industrial hemp in Saskatchewan. Can. J. Plant Sci. 2010, 90, 179–184. [Google Scholar] [CrossRef]

- Abdul-Baki, A.A.; Bryan, H.H.; Zinati, G.M.; Klassen, W.; Codallo, M.; Heckert, N. Biomass yield and flower production in sunn hemp: Effect of cutting the main stem. J. Veg. Crop. Prod. 2001, 7, 83–104. [Google Scholar] [CrossRef]

- Jankauskiene, Z.; Butkute, B.; Gruzdeviene, E.; Cesevičiene, J.; Fernando, A.L. Chemical composition and physical properties of dew- and water-retted hemp fibers. Ind. Crop. Prod. 2015, 75, 206–211. [Google Scholar] [CrossRef]

- Bonatti, P.M.; Ferrari, C.; Focher, B.; Grippo, C.; Torri, G.; Cosentino, C. Histochemical and supramolecular studies in determining quality of hemp fibres for textile applications. Euphytica 2004, 140, 55–64. [Google Scholar] [CrossRef]

- Crônier, D.; Monties, B.; Chabbert, B. Structure and chemical composition of bast fibers isolated from developing hemp stem. J. Agric. Food Chem. 2005, 53, 8279–8289. [Google Scholar] [CrossRef]

- van der Werf, H.M.G.; Harsveld van der Veen, J.E.; Bouma, A.T.M.; ten Cate, M. Quality of hemp (Cannabis sativa L.) stems as a raw material for paper. Ind. Crop. Prod. 1994, 2, 219–227. [Google Scholar] [CrossRef]

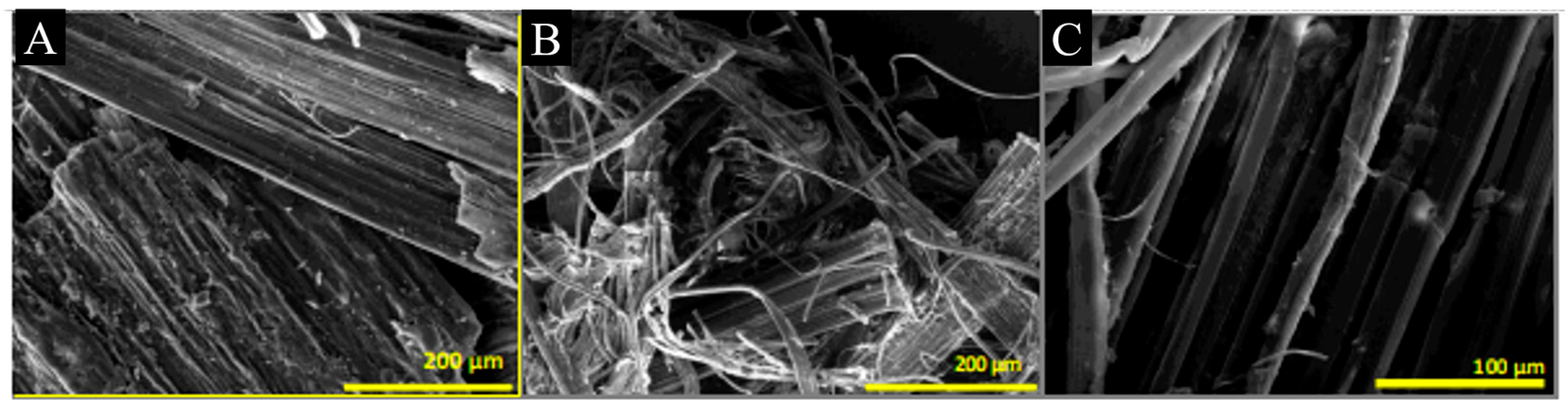

- Thygesen, A.; Daniel, G.; Lilholt, H.; Thomsen, A.B. Hemp fiber microstructure and use of fungal defibration to obtain fibers for composite materials. J. Nat. Fibers 2006, 2, 19–37. [Google Scholar] [CrossRef]

- Kumar, K.P.; Sekaran, A.S.J. Some natural fibers used in polymer composites and their extraction processes: A review. J. Reinf. Plast. Compos. 2014, 33, 1879–1892. [Google Scholar] [CrossRef]

- Jankauskienė, Z.; Gruzdevienė, E. Physical parameters of dew retted and water retted hemp (Cannabis sativa L.) fibres. Zemdirbyste-Agriculture 2013, 100, 71–80. [Google Scholar] [CrossRef]

- Di Candilo, M.; Bonatti, P.M.; Guidetti, C.; Focher, B.; Grippo, C.; Tamburini, E.; Mastromei, G. Effects of selected pectinolytic bacterial strains on water-retting of hemp and fibre properties. J. Appl. Microbiol. 2010, 108, 194–203. [Google Scholar] [CrossRef]

- Thygesen, A.; Lui, M.; Meyer, A.S.; Daniel, G. Hemp fibres: Enzymatic effect of microbial processing on fibre bundle structure. Proc. Risø Int. Symp. Mater. Sci. 2013, 34, 373–380. [Google Scholar]

- Thygesen, A.; Thomsen, A.B.; Daniel, G.; Lilholt, H. Comparison of composites made from fungal defibrated hemp with composites of traditional hemp yarn. Ind. Crop. Prod. 2007, 25, 147–159. [Google Scholar] [CrossRef]

- Li, Y.; Pickering, K.L.; Farrell, R.L. Determination of interfacial shear strength of white rot fungi treated hemp fibre reinforced polypropylene. Compos. Sci. Technol. 2009, 69, 1165–1171. [Google Scholar] [CrossRef]

- George, M.; Mussone, P.G.; Alemaskin, K.; Chae, M.; Wolodko, J.; Bressler, D.C. Enzymatically treated natural fibres as reinforcing agents for biocomposite material: Mechanical, thermal, and moisture absorption characterization. J. Mater. Sci. 2016, 51, 2677–2686. [Google Scholar] [CrossRef]

- Li, X.; Xiao, R.; Morrell, J.J.; Zhou, X.; Du, G. Improving the performance of hemp hurd/polypropylene composites using pectinase pre-treatments. Ind. Crop. Prod. 2017, 97, 465–468. [Google Scholar] [CrossRef]

- Baker, M.L.; Chen, Y.; Laguî, C.; Landry, H.; Peng, Q.; Zhong, W.; Wang, J. Hemp fibre decortications using a planetary ball mill. Can. Biosyst. Eng. J. 2010, 52, 260–264. [Google Scholar] [CrossRef]

- Hepworth, D.G.; Hobson, R.N.; Bruce, D.M.; Farrent, J.W. Use of unretted hemp fibre in composite manufacture. Compos. Part A Appl. Sci. Manuf. 2000, 31, 1279–1283. [Google Scholar] [CrossRef]

- Kukle, S.; Grāvītis, J.; Putniņa, A.; Stikute, A. The Effect of Steam Explosion Treatment on Technical Hemp Fibres. Environ. Technol. Resour. Proc. Int. Sci. Pract. Conf. 2015, 1, 230. [Google Scholar] [CrossRef]

- Moussa, M.; El Hage, R.; Sonnier, R.; Chrusciel, L.; Ziegler-Devin, I.; Brosse, N. Toward the cottonization of hemp fibers by steam explosion. Flame-retardant fibers. Ind. Crop. Prod. 2020, 151, 112242. [Google Scholar] [CrossRef]

- Sauvageon, T.; Lavoie, J.M.; Segovia, C.; Brosse, N. Toward the cottonization of hemp fibers by steam explosion—Part 1: Defibration and morphological characterization. Text. Res. J. 2018, 88, 1047–1055. [Google Scholar] [CrossRef]

- Keller, A. Compounding and mechanical properties of biodegradable hemp fibre composites. Compos. Sci. Technol. 2003, 63, 1307–1316. [Google Scholar] [CrossRef]

- Sutka, A.; Kukle, S.; Gravitis, J.; Berzins, A. Chemical and physical modification of hemp fibres by steam explosion technology. IOP Conf. Ser. Mater. Sci. Eng. 2013, 49, 012053. [Google Scholar] [CrossRef]

- Bacci, L.; Di Lonardo, S.; Albanese, L.; Mastromei, G.; Perito, B. Effect of different extraction methods on fiber quality of nettle (Urtica dioica L.). Text. Res. J. 2011, 81, 827–837. [Google Scholar] [CrossRef]

- Korte, S.; Staiger, M.P. Effect of Processing Route on the Composition and Properties of Hemp Fibre. Fibers Polym. 2008, 9, 593–603. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Effect of various chemical treatments on the fibre structure and tensile properties of industrial hemp fibres. Compos. Part A Appl. Sci. Manuf. 2011, 42, 888–895. [Google Scholar] [CrossRef]

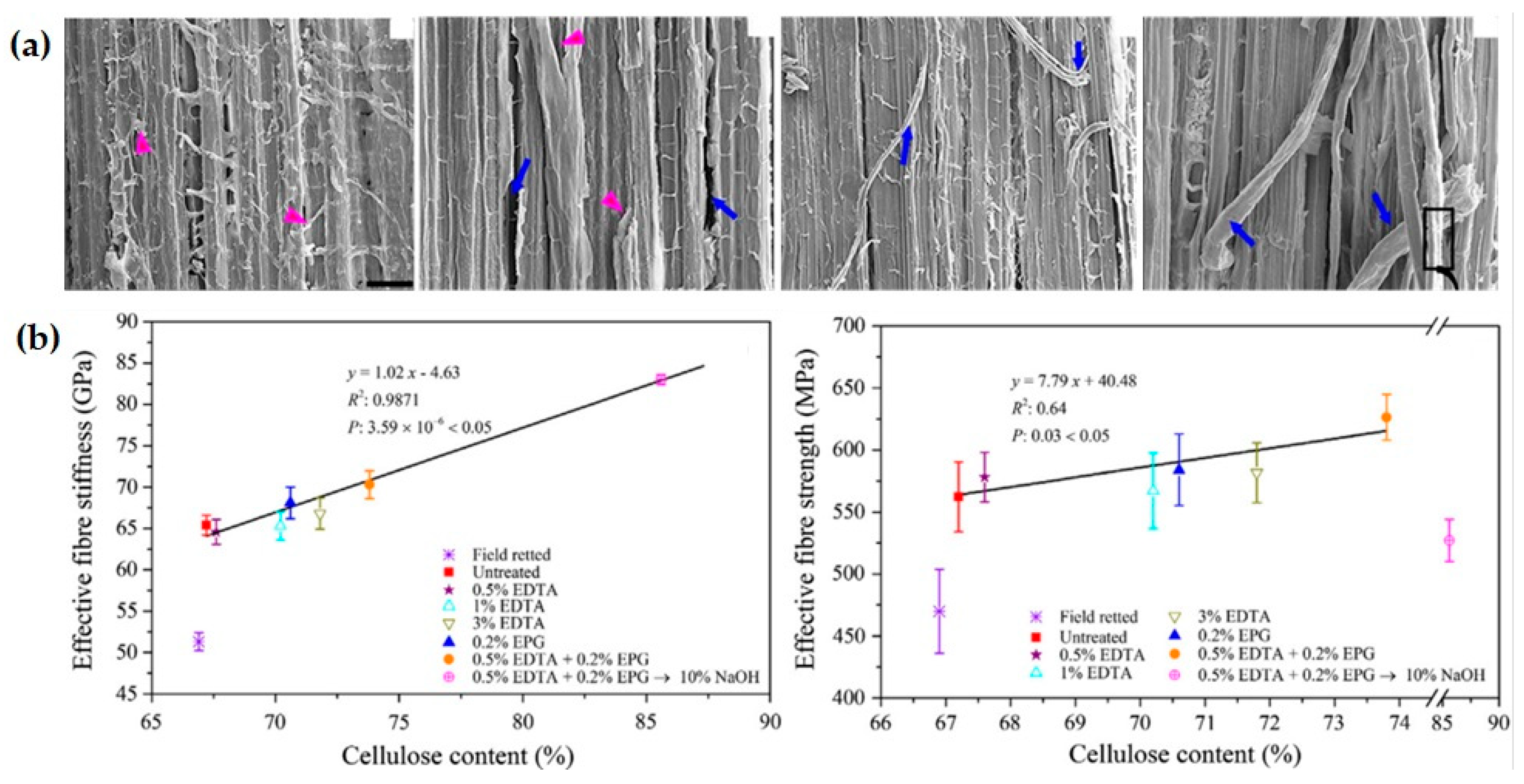

- Liu, M.; Meyer, A.S.; Fernando, D.; Silva, D.A.S.; Daniel, G.; Thygesen, A. Effect of pectin and hemicellulose removal from hemp fibres on the mechanical properties of unidirectional hemp/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 724–735. [Google Scholar] [CrossRef]

- Le Troëdec, M.; Peyratout, C.S.; Smith, A.; Chotard, T. Influence of various chemical treatments on the interactions between hemp fibres and a lime matrix. J. Eur. Ceram. Soc. 2009, 29, 1861–1868. [Google Scholar] [CrossRef]

- Graupner, N.; Weber, D.E.; Bell, E.G.; Lehmann, K.H.; Hilgers, H.W.; Randerath, H.; Gries, T.; Walenta, I.; Joulian, M.; Müssig, J. Hemp From Disordered Lines for New Staple Fibre Yarns and High-Performance Composite Applications. Front. Mater. 2022, 8, 627. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Jawaid, M. A review on the characterisation of natural fibres and their composites after alkali treatment and water absorption. Plast. Rubber Compos. 2017, 46, 119–136. [Google Scholar] [CrossRef]

- Yeping, X.; Jianyong, Y.; Liu, L.; Ruiyun, Z.; Yongshuai, Q.; Miaolei, J. The chemo-enzymatic modification and degumming of hemp fiber by the laccase-2,2,6,6-tetramethylpiperidine-1-oxyl radical-hemicellulase system and physico-chemical properties of the products. Text. Res. J. 2019, 89, 2433–2443. [Google Scholar] [CrossRef]

- Pickering, K.L.; Beckermann, G.W.; Alam, S.N.; Foreman, N.J. Optimising industrial hemp fibre for composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 461–468. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Sunny, T.; Pickering, K.L.; Lim, S.H. Alkali treatment of hemp fibres for the production of aligned hemp fibre mats for composite reinforcement. Cellulose 2020, 27, 2569–2582. [Google Scholar] [CrossRef]

- Moonart, U.; Utara, S. Effect of surface treatments and filler loading on the properties of hemp fiber/natural rubber composites. Cellulose 2019, 26, 7271–7295. [Google Scholar] [CrossRef]

- Islam, M.S.; Pickering, K.L.; Foreman, N.J. Influence of alkali fiber treatment and fiber processing on the mechanical properties of hemp/epoxy composites. J. Appl. Polym. Sci. 2011, 119, 3696–3707. [Google Scholar] [CrossRef]

- Singh, R.; Shukla, A.; Tiwari, S.; Srivastava, M. A review on delignification of lignocellulosic biomass for enhancement of ethanol production potential. Renew. Sustain. Energy Rev. 2014, 32, 713–728. [Google Scholar] [CrossRef]

- Oza, S.; Ning, H.; Ferguson, I.; Lu, N. Effect of surface treatment on thermal stability of the hemp-PLA composites: Correlation of activation energy with thermal degradation. Compos. Part B Eng. 2014, 67, 227–232. [Google Scholar] [CrossRef]

- Pickering, K.L.; Sunny, T. Effect of stearic acid treatment on the properties of aligned short hemp fibre mats and their potential use as reinforcement in polypropylene matrix composites. Cellulose 2021, 28, 5611–5624. [Google Scholar] [CrossRef]

- Rachini, A.; Mougin, G.; Delalande, S.; Charmeau, J.Y.; Barrés, C.; Fleury, E. Hemp fibers/polypropylene composites by reactive compounding: Improvement of physical properties promoted by selective coupling chemistry. Polym. Degrad. Stab. 2012, 97, 1988–1995. [Google Scholar] [CrossRef]

- Gassan, J.; Gutowski, V.S. Effects of corona discharge and UV treatment on the properties of jute-fibre expoxy composites. Compos. Sci. Technol. 2000, 60, 2857–2863. [Google Scholar] [CrossRef]

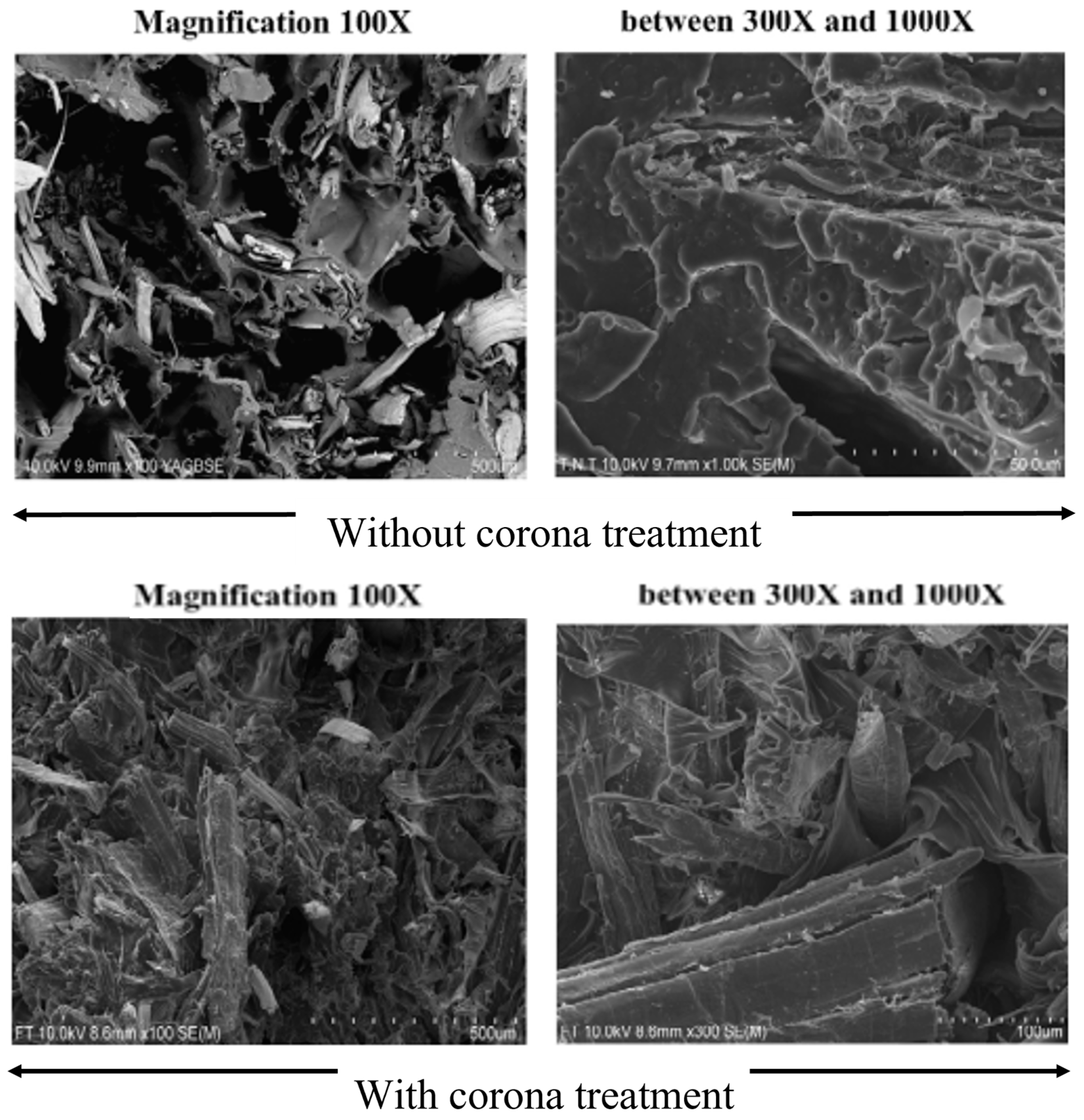

- Ragoubi, M.; Bienaimé, D.; Molina, S.; George, B.; Merlin, A. Impact of corona treated hemp fibres onto mechanical properties of polypropylene composites made thereof. Ind. Crop. Prod. 2010, 31, 344–349. [Google Scholar] [CrossRef]

- Bilal, M.; Vinod, B. Study on effect of Gamma radiation on tensile behavior of hemp and glass fiber reinforced epoxy polymer composite. AIP Conf. Proc. 2020, 2274, 030022. [Google Scholar] [CrossRef]

- Naik, J.B.; Mishra, S. Esterification effect of maleic anhydride on surface and volume resistivity of natural fiber/polystyrene composites. Polym. Plast. Technol. Eng. 2007, 46, 537–540. [Google Scholar] [CrossRef]

- Naik, J.B.; Mishra, S. Esterification effect of maleic anhydride on swelling properties of natural fiber/high density polyethylene composites. J. Appl. Polym. Sci. 2007, 106, 2571–2574. [Google Scholar] [CrossRef]

- Jiang, Y.; Lawrence, M.; Hussain, A.; Ansell, M.; Walker, P. Comparative moisture and heat sorption properties of fibre and shiv derived from hemp and flax. Cellulose 2019, 26, 823–843. [Google Scholar] [CrossRef]

- Tyagi, P.; Gutierrez, J.N.; Lucia, L.A.; Hubbe, M.A.; Pal, L. Evidence for antimicrobial activity in hemp hurds and lignin-containing nanofibrillated cellulose materials. Cellulose 2022, 29, 5151–5162. [Google Scholar] [CrossRef]

- Borsa, J. Antimicrobial Natural Fibres; Woodhead Publishing Limited: Sawston, UK, 2012. [Google Scholar]

- Kostic, M.M.; Milanovic, J.Z.; Baljak, M.V.; Mihajlovski, K.; Kramar, A.D. Preparation and characterization of silver-loaded hemp fibers with antimicrobial activity. Fibers Polym. 2014, 15, 57–64. [Google Scholar] [CrossRef]

- Milanović, J.; Mihailović, T.; Popović, K.; Kostić, M. Antimicrobial oxidized hemp fibers with incorporated silver particles. J. Serbian Chem. Soc. 2012, 77, 1759–1773. [Google Scholar] [CrossRef]

- Kalia, S.; Thakur, K.; Celli, A.; Kiechel, M.A.; Schauer, C.L. Surface modification of plant fibers using environment friendly methods for their application in polymer composites, textile industry and antimicrobial activities: A review. J. Environ. Chem. Eng. 2013, 1, 97–112. [Google Scholar] [CrossRef]

- Fu, J.; Nyanhongo, G.S.; Gbitz, G.M.; Cavaco-Paulo, A.; Kim, S. Enzymatic colouration with laccase and peroxidases: Recent progress. Biocatal. Biotransform. 2012, 30, 125–140. [Google Scholar] [CrossRef]

- Singh, G.; Arya, S.K. Utility of laccase in pulp and paper industry: A progressive step towards the green technology. Int. J. Biol. Macromol. 2019, 134, 1070–1084. [Google Scholar] [CrossRef] [PubMed]

- Viscusi, G.; Barra, G.; Gorrasi, G. Modification of hemp fibers through alkaline attack assisted by mechanical milling: Effect of processing time on the morphology of the system. Cellulose 2020, 27, 8653–8665. [Google Scholar] [CrossRef]

- Maichin, P.; Suwan, T.; Jitsangiam, P.; Chindaprasirt, P. Hemp fiber reinforced geopolymer composites: Effects of NaOH concentration on fiber pre-treatment process. Key Eng. Mater. 2020, 841, 166–170. [Google Scholar] [CrossRef]

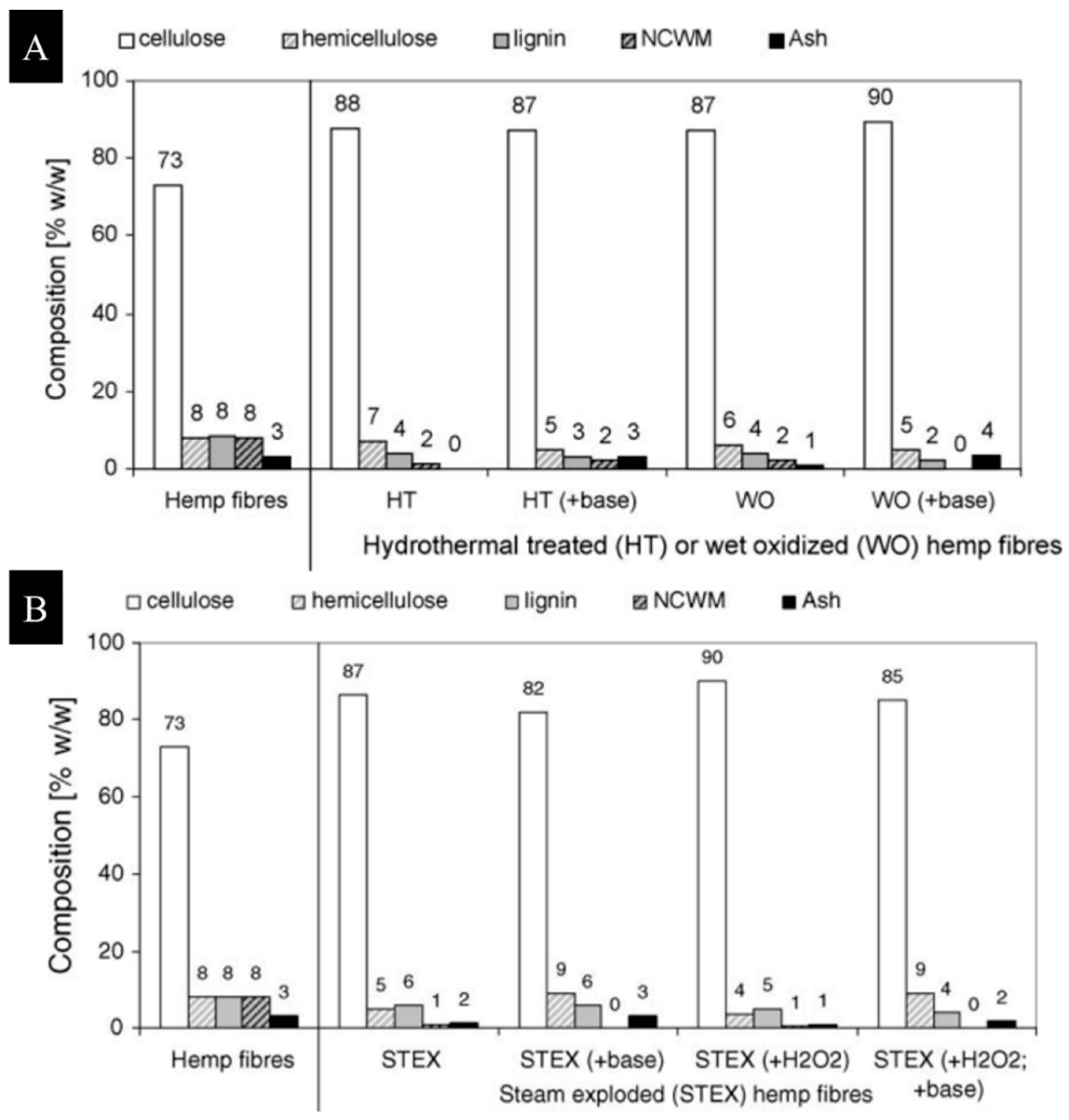

- Thomsen, A.B.; Thygesen, A.; Bohn, V.; Nielsen, K.V.; Pallesen, B.; Jørgensen, M.S. Effects of chemical-physical pre-treatment processes on hemp fibres for reinforcement of composites and for textiles. Ind. Crop. Prod. 2006, 24, 113–118. [Google Scholar] [CrossRef]

- Zhang, B.; Li, H.; Chen, L.; Fu, T.; Tang, B.; Hao, Y.; Li, J.; Li, Z.; Zhang, B.; Chen, Q.; et al. Recent Advances in the Bioconversion of Waste Straw Biomass with Steam Explosion Technique: A Comprehensive Review. Processes 2022, 10, 1959. [Google Scholar] [CrossRef]

- Hassan, S.S.; Williams, G.A.; Jaiswal, A.K. Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour. Technol. 2018, 262, 310–318. [Google Scholar] [CrossRef] [PubMed]

- Dai, L.; He, C.; Wang, Y.; Liu, Y.; Yu, Z.; Zhou, Y.; Fan, L.; Duan, D.; Ruan, R. Comparative study on microwave and conventional hydrothermal pretreatment of bamboo sawdust: Hydrochar properties and its pyrolysis behaviors. Energy Convers. Manag. 2017, 146, 1–7. [Google Scholar] [CrossRef]

- Sun, J.X.; Sun, R.C.; Sun, X.F.; Su, Y.Q. Fractional and physico-chemical characterization of hemicelluloses from ultrasonic irradiated sugarcane bagasse. Carbohydr. Res. 2004, 339, 291–300. [Google Scholar] [CrossRef] [PubMed]

- Mante, O.D.; Amidon, T.E.; Stipanovic, A.; Babu, S.P. Integration of biomass pretreatment with fast pyrolysis: An evaluation of electron beam (EB) irradiation and hot-water extraction (HWE). J. Anal. Appl. Pyrolysis 2014, 110, 44–54. [Google Scholar] [CrossRef]

- Hargitai, H.; Rácz, I.; Anandjiwala, R.D. Development of HEMP fiber reinforced polypropylene composites. J. Thermoplast. Compos. Mater. 2008, 21, 165–174. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Salehi, M.; Bashir, T.; Rissanen, M.; Nousiainen, P. Novel aligned hemp fibre reinforcement for structural biocomposites: Porosity, water absorption, mechanical performances and viscoelastic behaviour. Compos. Part A Appl. Sci. Manuf. 2014, 61, 1–12. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Influence of fiber orientation and fiber content on properties of sisal-jute-glass fiber-reinforced polyester composites. J. Appl. Polym. Sci. 2016, 133, 42968. [Google Scholar] [CrossRef]

- Markandan, K.; Seetoh, I.P.; Lai, C.Q. Mechanical anisotropy of graphene nanocomposites induced by graphene alignment during stereolithography 3D printing. J. Mater. Res. 2021, 36, 4262–4274. [Google Scholar] [CrossRef]

- Markandan, K.; Kanaujia, P.K.; Abhineet, J.P.; Yap, X.Y.; Gan, C.L.; Lai, C.Q. Improvements in the modulus and strength of multi-dimensional hybrid composites through synergistic reinforcement between 1D fiber and 0D particle fillers. J. Mater. Sci. 2021, 56, 15162–15179. [Google Scholar] [CrossRef]

- Zhou, P.; Li, C.; Bai, Y.; Dong, S.; Xian, G.; Vedernikov, A.; Akhatov, I.; Safonov, A.; Yue, Q. Durability study on the interlaminar shear behavior of glass-fibre reinforced polypropylene (GFRPP) bars for marine applications. Constr. Build. Mater. 2022, 349, 128694. [Google Scholar] [CrossRef]

- Vedernikov, A.; Safonov, A.; Tucci, F.; Carlone, P.; Akhatov, I. Analysis of Spring-in Deformation in L-shaped Profiles Pultruded at Different Pulling Speeds: Mathematical Simulation and Experimental Results. ESAFORM 2021 2021. [Google Scholar] [CrossRef]

- Markandan, K.; Tan, M.T.T.; Chin, J.; Lim, S.S. A novel synthesis route and mechanical properties of Si–O–C cured Yytria stabilised zirconia (YSZ)–graphene composite. Ceram. Int. 2015, 41, 3518–3525. Available online: http://linkinghub.elsevier.com/retrieve/pii/S0272884214017416 (accessed on 28 January 2015). [CrossRef]

- Prabhudass, J.M.; Palanikumar, K.; Natarajan, E.; Markandan, K. Enhanced Thermal Stability, Mechanical Properties and Structural Integrity of MWCNT Filled Bamboo/Kenaf Hybrid Polymer Nanocomposites. Materials 2022, 15, 506. [Google Scholar] [CrossRef] [PubMed]

- Palanikumar, K.; Ramesh, M.; Hemachandra Reddy, K. Experimental investigation on the mechanical properties of green hybrid sisal and glass fiber reinforced polymer composites. J. Nat. Fibers 2016, 13, 321–331. [Google Scholar] [CrossRef]

- Hu, R.; Lim, J.K. Fabrication and mechanical properties of completely biodegradable hemp fiber reinforced polylactic acid composites. J. Compos. Mater. 2007, 41, 1655–1669. [Google Scholar] [CrossRef]

- Oushabi, A. The pull-out behavior of chemically treated lignocellulosic fibers/polymeric matrix interface (LF/PM): A review. Compos. Part B Eng. 2019, 174, 107059. [Google Scholar] [CrossRef]

- Lu, N.; Oza, S. A comparative study of the mechanical properties of hemp fiber with virgin and recycled high density polyethylene matrix. Compos. Part B Eng. 2013, 45, 1651–1656. [Google Scholar] [CrossRef]

- Chaudhary, V.; Bajpai, P.K.; Maheshwari, S. Studies on Mechanical and Morphological Characterization of Developed Jute/Hemp/Flax Reinforced Hybrid Composites for Structural Applications. J. Nat. Fibers 2018, 15, 80–97. [Google Scholar] [CrossRef]

- Neves, A.C.C.; Rohen, L.A.; Mantovani, D.P.; Carvalho, J.P.R.G.; Vieira, C.M.F.; Lopes, F.P.D.; Simonassi, N.T.; Luz, F.S.D.; Monteiro, S.N. Comparative mechanical properties between biocomposites of Epoxy and polyester matrices reinforced by hemp fiber. J. Mater. Res. Technol. 2020, 9, 1296–1304. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Oza, S.; Wang, R.; Lu, N. Thermal and mechanical properties of recycled high density polyethylene/hemp fiber composites. Int. J. Appl. Sci. Technol. 2011, 1, 31–36. [Google Scholar]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F.; Aravinthan, T. Mechanical properties of chemically-treated hemp fibre reinforced sandwich composites. Compos. Part B Eng. 2012, 43, 159–169. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Suardana, N.P.G.; Piao, Y.; Lim, J.K. Mechanical properties of HEMP fibers and HEMP/PP composites: Effects of chemical surface treatment. Mater. Phys. Mech. 2011, 11, 1–8. [Google Scholar]

- Haghighatnia, T.; Abbasian, A.; Morshedian, J. Hemp fiber reinforced thermoplastic polyurethane composite: An investigation in mechanical properties. Ind. Crop. Prod. 2017, 108, 853–863. [Google Scholar] [CrossRef]

- Caprino, G.; Carrino, L.; Durante, M.; Langella, A.; Lopresto, V. Low impact behaviour of hemp fibre reinforced epoxy composites. Compos. Struct. 2015, 133, 892–901. [Google Scholar] [CrossRef]

- Kymäläinen, H.R.; Sjöberg, A.M. Flax and hemp fibres as raw materials for thermal insulations. Build. Environ. 2008, 43, 1261–1269. [Google Scholar] [CrossRef]

- Scarponi, C.; Messano, M. Comparative evaluation between E-Glass and hemp fiber composites application in rotorcraft interiors. Compos. Part B Eng. 2015, 69, 542–549. [Google Scholar] [CrossRef]

- Bitar, R.; Saad, G.; Awwad, E.; El Khatib, H.; Mabsout, M. Strengthening unreinforced masonry walls using natural hemp fibers. J. Build. Eng. 2020, 30, 101253. [Google Scholar] [CrossRef]

- Kosiński, P.; Brzyski, P.; Szewczyk, A.; Motacki, W. Thermal Properties of Raw Hemp Fiber as a Loose-Fill Insulation Material. J. Nat. Fibers 2018, 15, 717–730. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, H.; Wang, X.; Zhang, M. An environment friendly hemp fiber modified with phytic acid for enhancing fire safety of automobile parts. J. Polym. Eng. 2022, 42, 535–543. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, H.; Wang, X.; Zhang, M. Modified hemp fiber combined with melamine cyanurate for enhancing fire safety and mechanical properties of unsaturated polyester resins for automobile parts. AIP Adv. 2021, 11, 125329. [Google Scholar] [CrossRef]

- Sathish, T.; Palani, K.; Natrayan, L.; Merneedi, A.; de Poures, M.V.; Singaravelu, D.K. Synthesis and characterization of polypropylene/ramie fiber with hemp fiber and coir fiber natural biopolymer composite for biomedical application. Int. J. Polym. Sci. 2021, 2021, 2462873. [Google Scholar] [CrossRef]

- Yang, Y.; Hao, X.; Hao, X.; Li, H.; Feng, X. Investigate on moisture absorption/desorption of shoe material containing hemp fiber. Adv. Mater. Res. 2013, 627, 49–52. [Google Scholar] [CrossRef]

- Boyko, G.; Holovenko, T.; Yageluk, S.; Dombrovskaya, O.; Kuzmina, T.; Evtushenko, V. Methods for improving the qualitative indicators of fabric on the basis of hemp cotonine for the top of footwear. Vlak. Text. 2021, 28, 3–8. [Google Scholar]

- Hao, X.M.; Yang, Y.; Chen, X.; Huang, J.; Hao, X. Study on moisture comfort of different fiber materials in sport shoes. Adv. Mater. Res. 2013, 821–822, 313–316. [Google Scholar] [CrossRef]

| Cultivar | Cellulose [wt.%] | Hemicellulose [wt.%] | Pectin [wt.%] | Lignin [wt.%] | Ref. |

|---|---|---|---|---|---|

| USO 31 | 78.4–81.7 | 5.7–6.4 | n/a | 10.0–13.0 | [30] |

| Fedora | 55.0 | 16.0 | 8.0 | 4.0 | [31] |

| Fedora 17 | 65.6–84.9 | 6.0–8.1 | 9.4–25.0 | 2.7–4.5 | [32] |

| Fedora 19 | 58.6 | 9.3 | n/a | 5.0 | [33] |

| Felina 34 | 57.1–61.8 | 8.3–14.3 | 2.8–8.6 | 1.2–7.3 | [34] |

| Fibrimon 56 | 53.2 | 6.9 | n/a | 5.0 | [33] |

| Kompolti Sargaszaru | 68.2–69.2 | 6.7–8.5 | n/a | 3.5–5.5 | [33] |

| Kompolti Hybrid TC | 60.2–74.3 | 7.1–7.9 | n/a | 3.3–4.4 | [33] |

| Pre-Treatment Purpose | Technique | Requirements | Advantages | Limitations |

|---|---|---|---|---|

| Defibration Fiber extraction | Traditional retting | Water |

|

|

| Controlled microbiological retting | Sterilization of equipment Microorganisms |

|

| |

| Mechanical treatment | Electricity Decortication equipment |

|

| |

| Steam explosion | Electricity High-pressure equipment |

|

| |

| Chemical treatment | Alkali Chelators Sodium sulphite |

|

| |

| Enzyme treatment | Pectinolytic enzymes |

|

| |

| Surface modification | Alkali treatment | Alkali |

|

|

| Increased moisture resistance Antimicrobial degradation activity | Graft co-polymerization | Phenol/phenol derivatives, oxidase enzymes as catalyst |

|

|

| Physical treatment | Equipment for UV, plasma or gamma radiation |

|

| |

| Esterification | Glacial acetic acid/vinyl acetate |

|

|

| Matrix | Filler Composition [wt.%] | Tensile Strength [MPa] | Tensile Modulus [GPa] | Flexural Strength [MPa] | Flexural Modulus [GPa] | Ref. |

|---|---|---|---|---|---|---|

| Epoxy | 0.00 | 30.00 | 1.10 | 34.69 | 0.60 | [101] |

| 9.00 | 36.48 | 1.43 | 85.59 | 1.78 | ||

| Epoxy | 0.00 | 38.11 | 1.38 | 40.30 | 1.32 | [102] |

| 37.50 a | 50.46 | 1.72 | 76.69 | 3.79 | ||

| Epoxy | 42.20 | 71.55 | 5.85 | 124.52 | 4.15 | [103] |

| HDPE | 0.00 | 18.70 | 0.34 | 17.10 | 0.60 | [100] |

| 50.00 a | 60.20 | 2.31 | 44.60 | 2.42 | ||

| HDPE | 0.00 | n/a | n/a | 17.80 | 0.47 | [104] |

| 50.00 a | n/a | n/a | 44.6 | 1.49 | ||

| Polyester | 10.00 | 111.05 | 2.65 | 60.01 | 4.37 | [105] |

| Polyester | 0.00 | 30.00 | 0.60 | 42.00 | 5.81 | [106] |

| 32.50 a | 65.00 | 0.68 | 84.00 | 8.05 | ||

| Polyester | 0.00 | 23.19 | 0.42 | 50.31 | 1.46 | [102] |

| 25.00 a | 31.46 | 0.51 | 60.06 | 1.86 | ||

| Polyactic acid (PLA) | 0.00 | 35.00 | 3.50 | n/a | n/a | [98] |

| 50.00 a | 54.60 | 8.49 | 112.70 | n/a | ||

| Polypropylene (PP) | 0.00 | 25.00 | n/a | 57.50 | n/a | [107] |

| 37.50 a | 32.50 | n/a | 62.00 | n/a | ||

| Polypropylene (PP) | 0.00 | 27.10 | 0.67 | n/a | n/a | [68] |

| 20.00 | 37.80 | 1.22 | n/a | n/a | ||

| Polyurethane (PU) | 0.00 | 26.52 | 0.04 | 7.55 | 0.157 | [108] |

| 50.00 a | 27.23 | 0.54 | 22.14 | 0.587 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palanikumar, K.; Natarajan, E.; Markandan, K.; Ang, C.K.; Franz, G. Targeted Pre-Treatment of Hemp Fibers and the Effect on Mechanical Properties of Polymer Composites. Fibers 2023, 11, 43. https://doi.org/10.3390/fib11050043

Palanikumar K, Natarajan E, Markandan K, Ang CK, Franz G. Targeted Pre-Treatment of Hemp Fibers and the Effect on Mechanical Properties of Polymer Composites. Fibers. 2023; 11(5):43. https://doi.org/10.3390/fib11050043

Chicago/Turabian StylePalanikumar, K., Elango Natarajan, Kalaimani Markandan, Chun Kit Ang, and Gérald Franz. 2023. "Targeted Pre-Treatment of Hemp Fibers and the Effect on Mechanical Properties of Polymer Composites" Fibers 11, no. 5: 43. https://doi.org/10.3390/fib11050043

APA StylePalanikumar, K., Natarajan, E., Markandan, K., Ang, C. K., & Franz, G. (2023). Targeted Pre-Treatment of Hemp Fibers and the Effect on Mechanical Properties of Polymer Composites. Fibers, 11(5), 43. https://doi.org/10.3390/fib11050043