Performance of Rice Straw Fibers on Hardened Concrete Properties under Effect of Impact Load and Gamma Radiation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Test Procedures

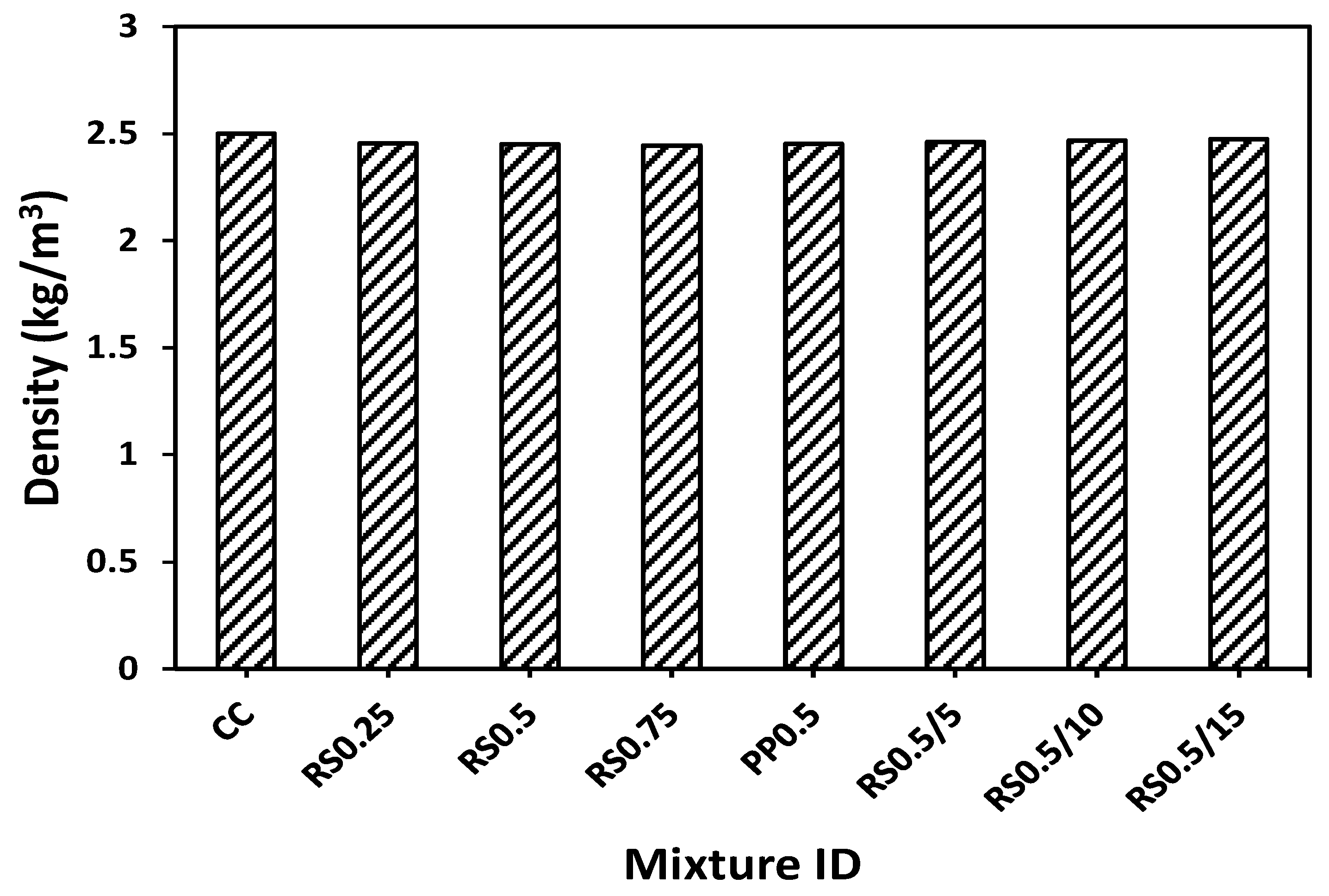

2.2.1. Unit Weight Measurement

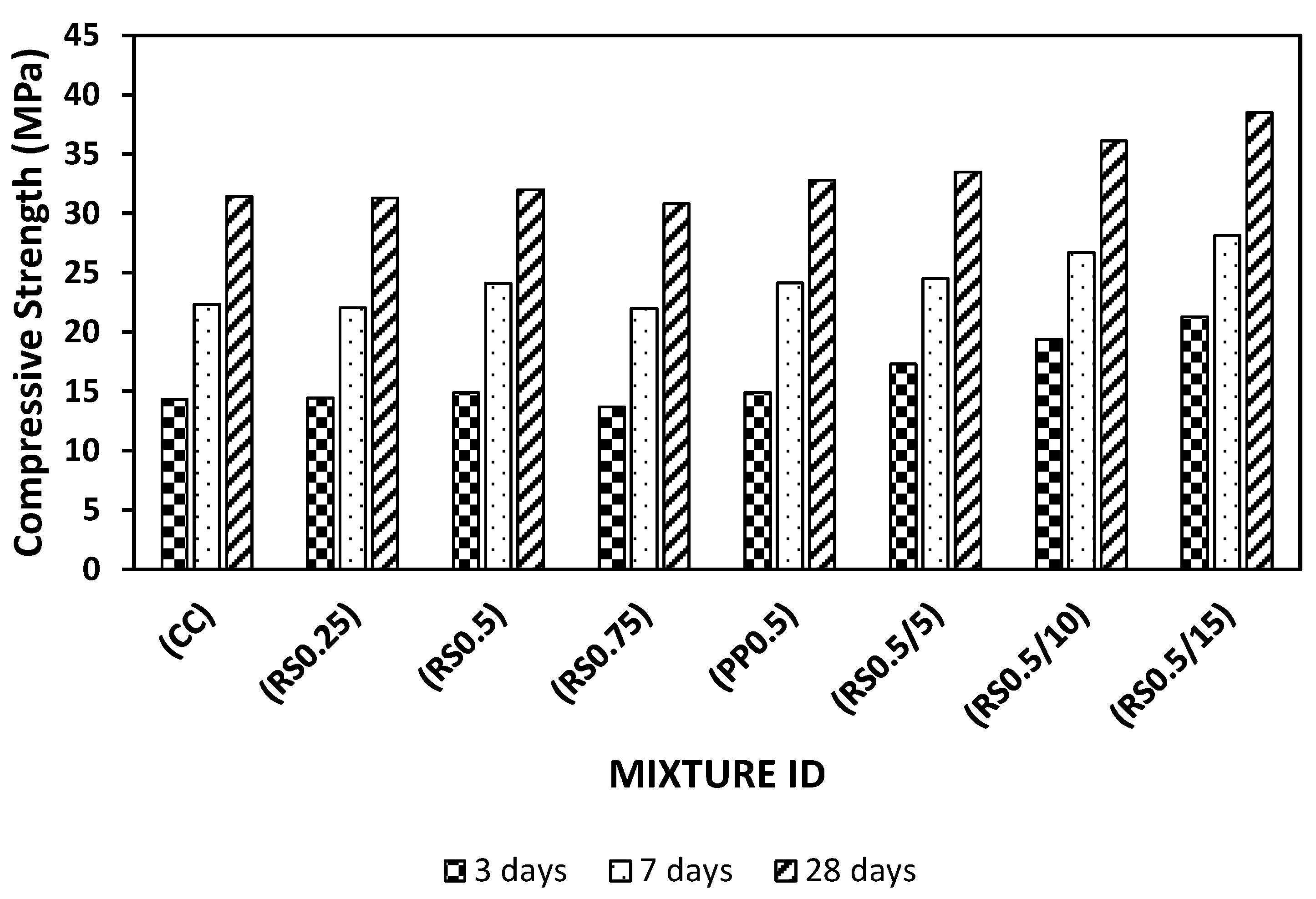

2.2.2. Compressive Strength Test

2.2.3. Splitting Tensile Strength Test

2.2.4. Flexural Strength Test

2.2.5. Impact Resistance Test

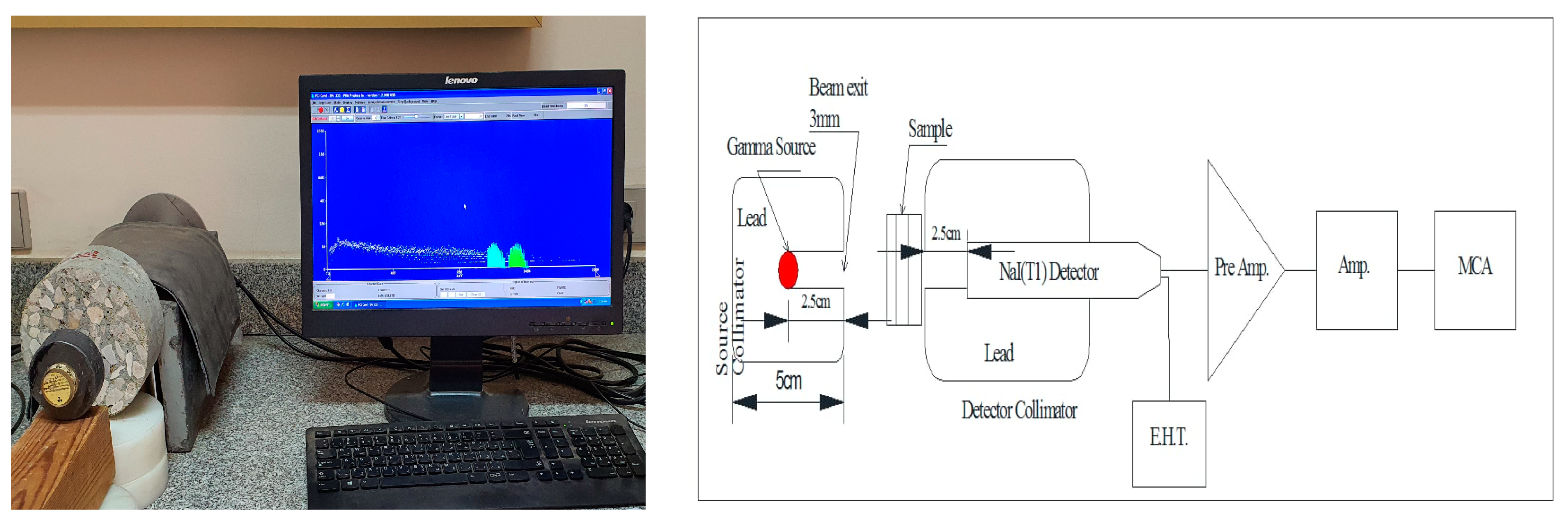

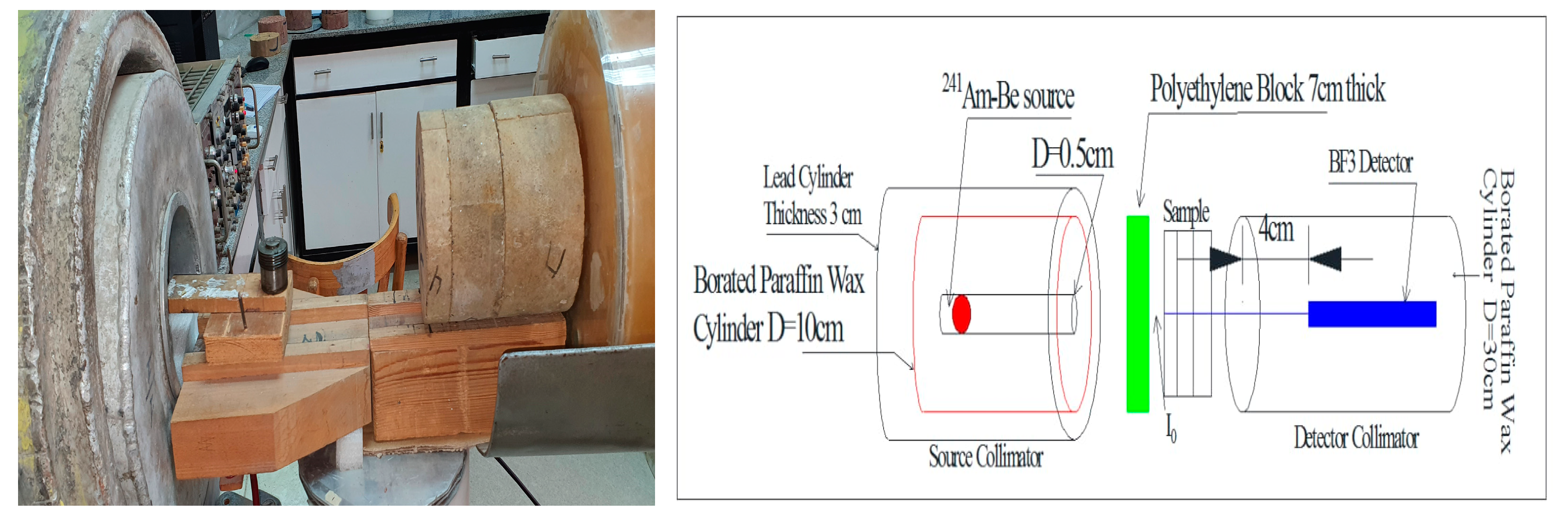

2.2.6. Linear Attenuation Test

3. Results and Discussion

3.1. Unit Weight Measurement

3.2. Compressive Strength

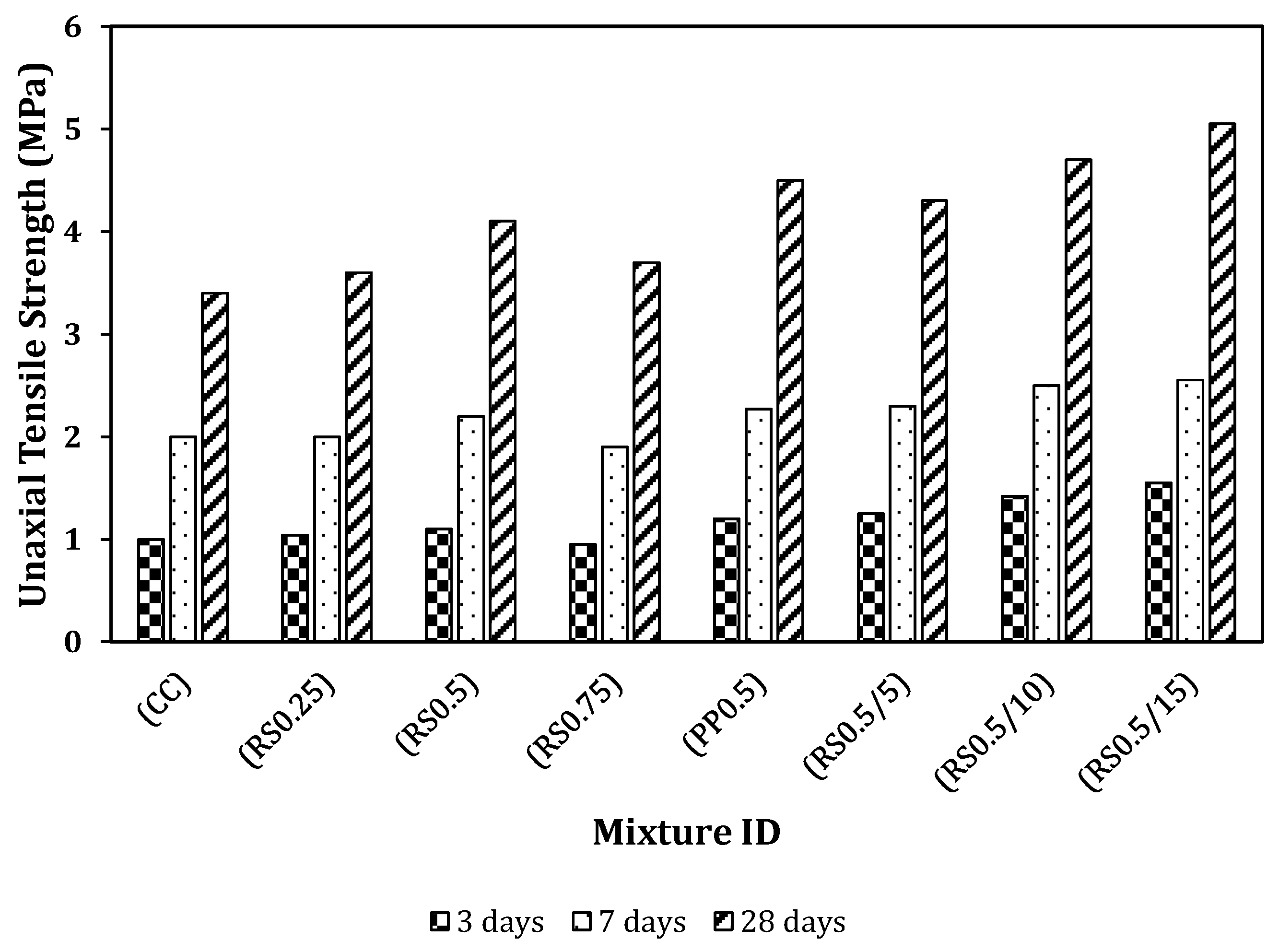

3.3. Splitting Tensile Strength

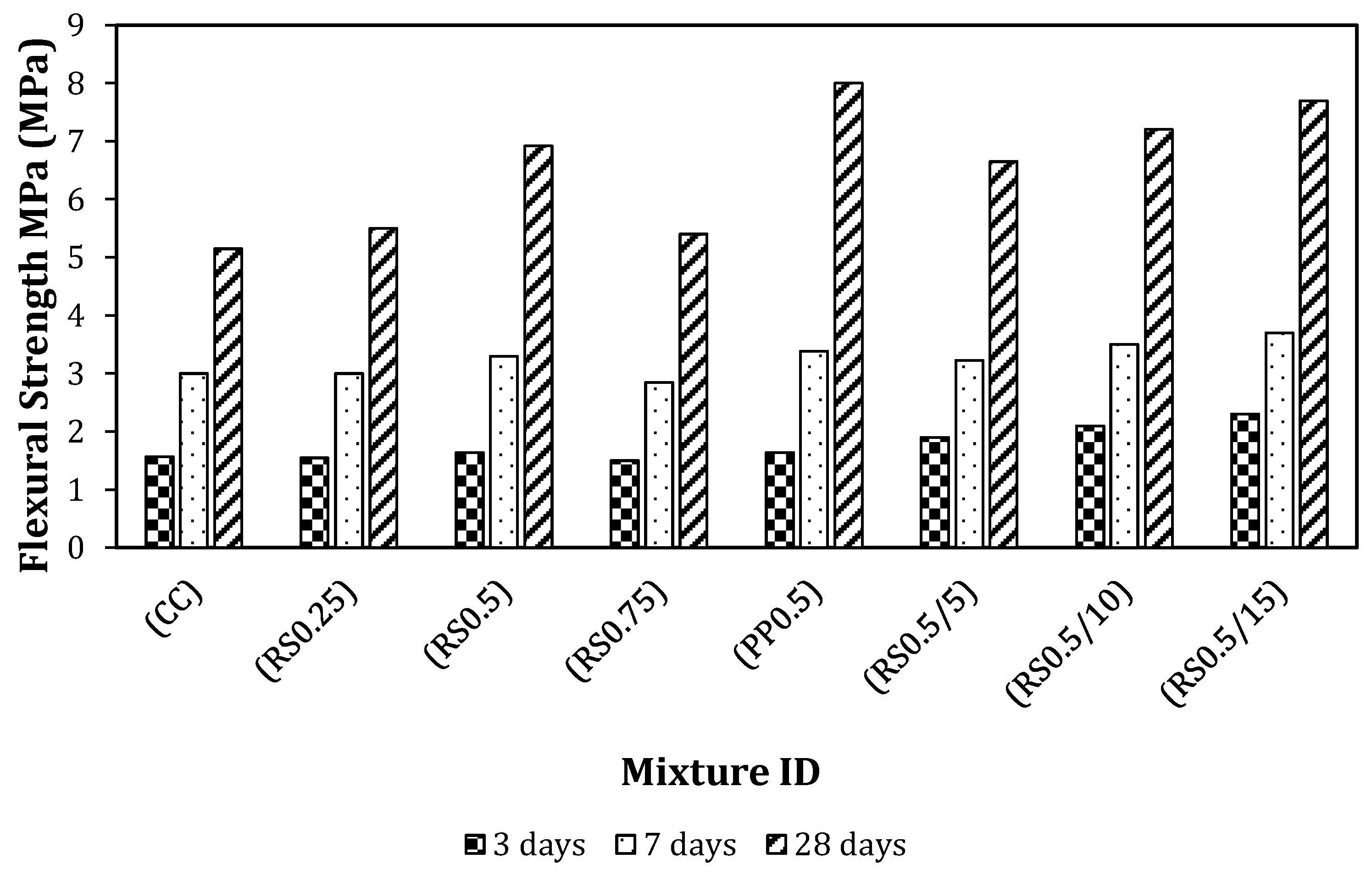

3.4. Flexural Strength

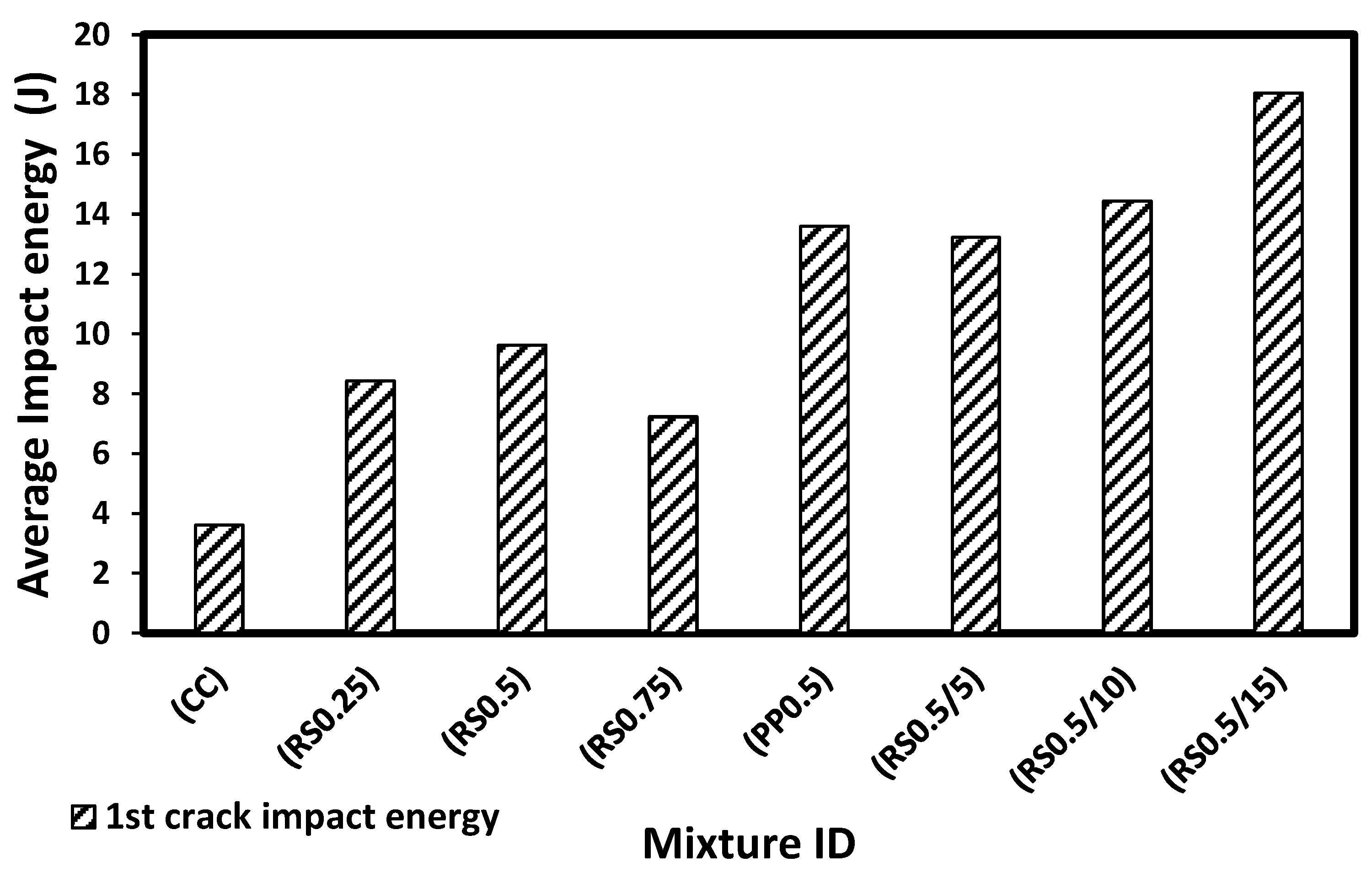

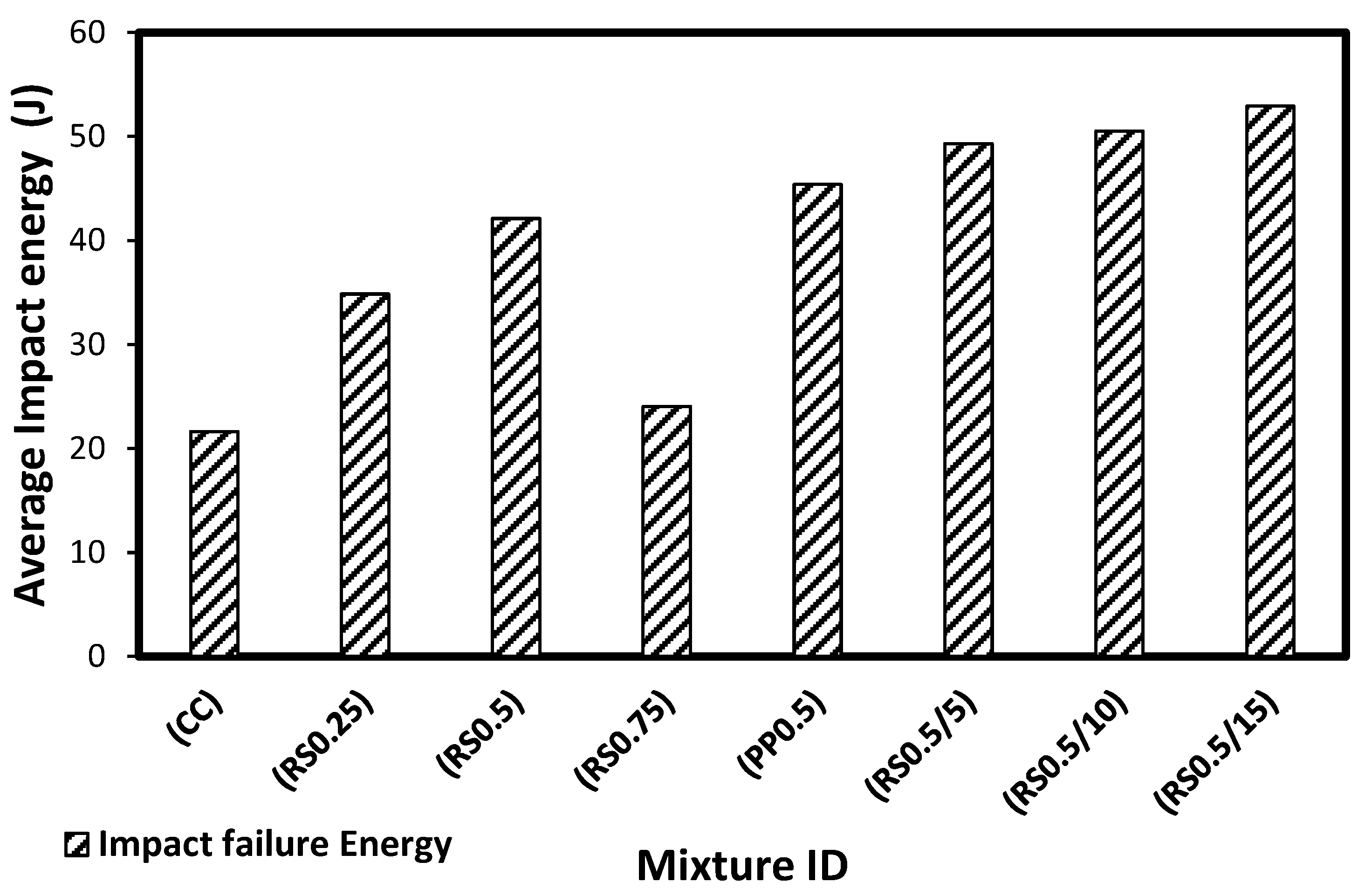

3.5. Impact Resistance Test

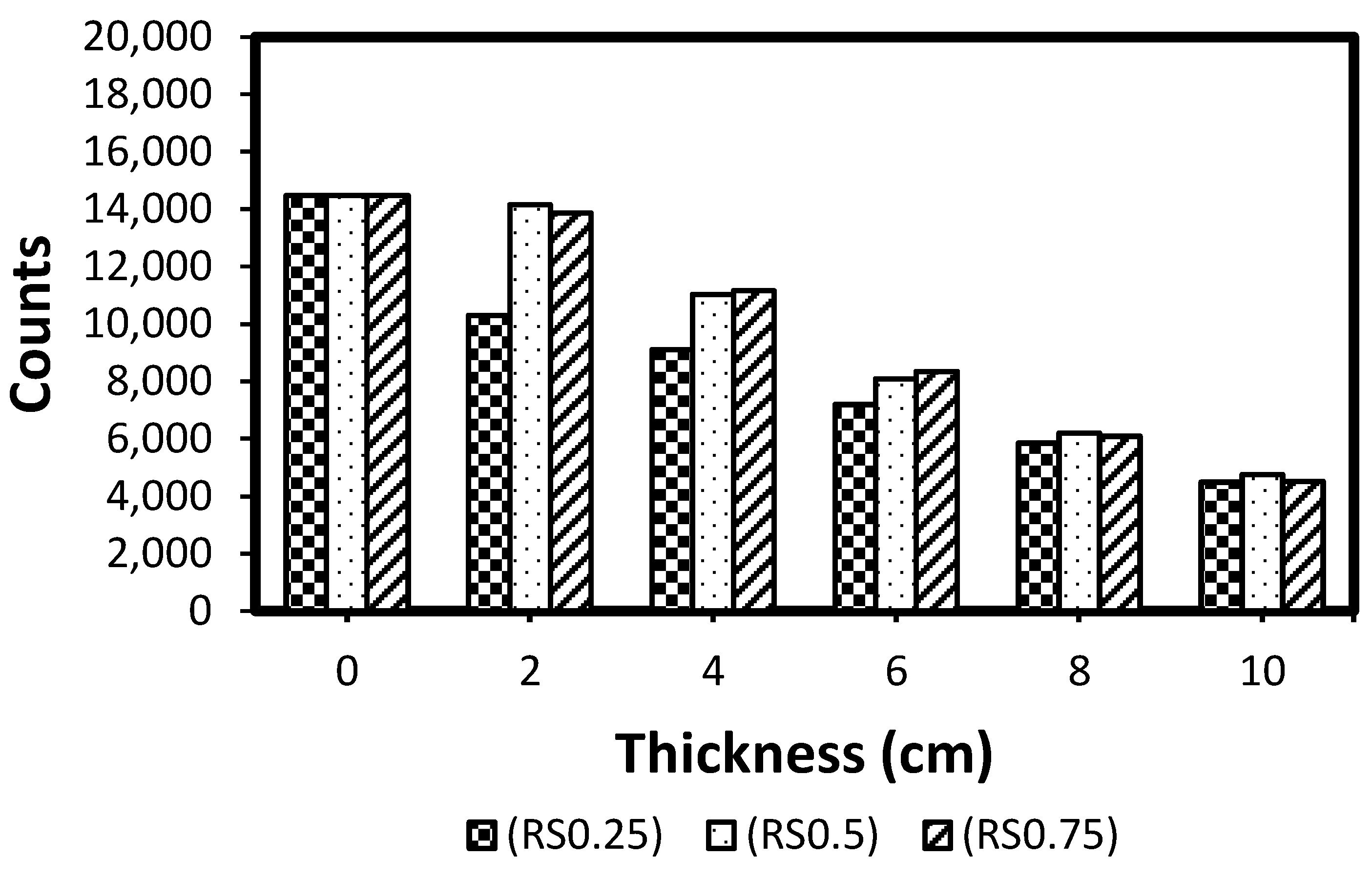

3.6. Linear Attenuation Test

3.6.1. Gamma Ray Results Analysis

3.6.2. Neutron Radiation Results Analysis

4. Conclusions

- Replacing heavyweight concrete constituents with lightweight rice straw fibers led to a slight reduction in the unit weight of tested specimens of up to 1.8%, while incorporating silica fume in concrete manufacturing generally increased the concrete’s unit weight by up to 0.98% compared to normal concrete.

- A slight to non-existent increase of up to 7% in compressive strength was observed due to rice straw and PP fiber addition; however, silica fume addition led to enhanced compressive properties of up to 30% at the rate of 15% addition by cement weight.

- Enhanced tensile and flexural properties of up to 17.1% and 25.8% were achieved, respectively, owing to rice straw fiber addition, which was attributed to the crack control capability of the utilized fiber.

- A superior dynamic performance was achieved by incorporating rice straw fiber in concrete production. The sustained impact energy up to first crack and failure were enhanced by about 62.5% and 48.6%, respectively, relative to conventional concrete due to the fiber–matrix interfacial bond, which improved the load transfer across cracks, thus enhancing the overall impact load-carrying capacity of rice straw concrete.

- Although the usage of polypropylene fiber improved the performance of concrete statically and dynamically compared to rice straw fiber, the latter generally achieved superior performance compared to normal concrete, which reflects the applicability of utilizing such natural waste materials as a contender with PP fiber in concrete manufacturing.

- The attenuation test demonstrated the effectiveness of using rice straw fiber concrete as radiation shields against gamma rays. The gamma ray attenuation capability was enhanced by about 7.9% owing to rice straw fiber incorporation compared to normal concrete shields at different energy levels.

- Generally, the rice straw fiber addition in concrete did not show a significant effect on the neutron attenuation capability of such shields.

- Among all tested specimens, the concrete shield which incorporated rice straw fiber of 0.5% by volume fraction and 10% silica fume by cement weight acquired the best performance under different loading regimes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ravikumar, C.S.; Ramasamy, V.; Thandavamoorthy, T.S. Effect of Fibers in Concrete Composites. Int. J. Appl. Eng. Res. 2015, 10, 419–430. [Google Scholar]

- Bahnsawy, A.H.I.; Yehia, T.H.; Ashour, M.H.; Khalil; Orabi, M.A. Physico Mechanical Properties of Concrete Mixes Containing Recycled Rice Straw and Blast-Furnace Slag. In Proceedings of the 7th International Conference on Nano-Technology in Construction, Sharm El-Sheikh, Egypt, 20–24 March 2015; HBRC Publisher: Cairo, Egypt, 2015. [Google Scholar]

- Kamal, I. Experimental Investigation on Blast Furnace Slag HPC. Master’s Thesis, Arab Academy for Science and Technology and Maritime Transport, Cairo, Egypt, 2020. [Google Scholar]

- Al-Masoodi, A.H.H.; Kawan, A.; Kasmuri, M.; Hamid, R.; Khan, M.N.N. Static and dynamic properties of concrete with different types and shapes of fibrous reinforcement. Constr. Build. Mater. 2016, 104, 247–262. [Google Scholar] [CrossRef]

- Song, P.; Hwang, S.; Sheu, B. Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Li, W.; Xu, J. Mechanical properties of basalt fiber reinforced geopolymeric concrete under impact loading. Mater. Sci. Eng. A 2009, 505, 178–186. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N.; Kim, S.-W.; Yoon, Y.-S. Response of ultra-high-performance fiber-reinforced concrete beams with continuous steel reinforcement subjected to low-velocity impact loading. Compos. Struct. 2015, 126, 233–245. [Google Scholar] [CrossRef]

- Soe, K.T.; Zhang, Y.; Zhang, L. Impact resistance of hybrid-fiber engineered cementitious composite panels. Compos. Struct. 2013, 104, 320–330. [Google Scholar] [CrossRef]

- Nehdi, M.; Duquette, J. Fibre synergy in hybrid fibre-reinforced self-consolidating concrete. ACI Mater. J. 2004, 101, 508–517. [Google Scholar]

- Nia, A.A.; Hedayatian, M.; Nili, M.; Sabet, V.A. An experimental and numerical study on how steel and polypropylene fibers affect the impact resistance in fiber-reinforced concrete. Int. J. Impact Eng. 2012, 46, 62–73. [Google Scholar]

- Sivaraja, M.; Kandasamy, S. Potential Reuse of Waste Rice Husk as Fibre Composites in Concrete. Asian J. Civ. Eng. 2011, 12, 205–217. [Google Scholar]

- Shetty, M.S. Concrete Technology: Theory and Practice; S. Chand & Compavy Pvt. Ltd.: New Delhi, India, 2008. [Google Scholar]

- Moraes, C.A.; Fernandes, I.J.; Calheiro, D.; Kieling, A.G.; Brehm, F.A.; Rigon, M.R.; Berwanger Filho, J.A.; Schneider, I.A.; Osorio, E. Review Of The Rice Production Cycle: By-Products And The Main Applications Focusing On Rice Husk Combustion And Ash Recycling. Waste Manag. Res. J. A Sustain. Circ. Econ. 2014, 32, 1034–1048. [Google Scholar] [CrossRef]

- Morsy, M.I.N. Properties of Rice Straw Cementitious Composite. Ph.D. Thesis, Universitäts-und Landesbibliothek Darmstadt, Alexandria, Egypt, 2011. [Google Scholar]

- Ramakrishna, G.; Sundararajan, T. Impact Strength of a Few Natural Fiber Reinforced Cement Mortar Slabs: A Comparative Study. Cem. Concr. Compos. 2005, 27, 547–553. [Google Scholar] [CrossRef]

- Bahari, I.; Sumarni, S.; Murtiono, E.S. Mechanical Property of Straw Concrete Brick with Additives Viscocrete. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2019; Volume 2114, p. 030017. [Google Scholar]

- Allam, M.; Garas, G. Recycled Chopped Rice Straw–Cement Bricks: An Analytical and Economical Study. WIT Trans. Ecol. Environ. 2010, 140, 79–86. [Google Scholar]

- Ibrahim, M.T.; Hamdy, G.A.; Abdel-Naby, R.M.; El-Sayed, T.A. Study of Properties of Concrete Containing Recycled Rice Straw and Rice Husk. Eng. Res. J. 2019, 1, 87–101. [Google Scholar]

- Chin, C.S.; Nepal, B. Material Properties of Agriculture Straw Fibre-Reinforced Concrete. In Ecological Wisdom Inspired Restoration Engineering; Springer: Singapore, 2019; pp. 109–120. [Google Scholar]

- Ataie, F. Influence of Rice Straw Fibers on Concrete Strength and Drying Shrinkage, Sustainable Cementitious Materials for the Construction Industry. Sustainability 2018, 10, 2445. [Google Scholar] [CrossRef]

- Van Nguyen, C.; Mangat, P.S. Properties of Rice Straw Reinforced Alkali Activated Cementitious Composites. Constr. Build. Mater. 2020, 261, 120536. [Google Scholar] [CrossRef]

- El-Samrah, M.G.; Tawfic, A.F.; Chidiac, S.E. Spent nuclear fuel interim dry storage; design requirements, most common methods, and evolution: A review. Ann. Nucl. Energy 2021, 160, 108408. [Google Scholar] [CrossRef]

- Chilton, A.B.; Shultis, J.K.; Faw, R.E. Principles of Radiation Shielding; International Nuclear Information System, Prentice Hall Inc.: Old Tappan, NJ, USA, 1984. [Google Scholar]

- Baalamurugan, J.; Kumar, V.G.; Chandrasekaran, S.; Balasundar, S.; Venkatraman, B.; Padmapriya, R.; Raja, V.B. Recycling of steel slag aggregates for the development of high density concrete: Alternative & environment-friendly radiation shielding composite. Compos. Part B Eng. 2021, 216, 108885. [Google Scholar]

- Beaucour, A.-L.; Pliya, P.; Faleschini, F.; Njinwoua, R.; Pellegrino, C.; Noumowé, A. Influence of elevated temperature on properties of radiation shielding concrete with electric arc furnace slag as coarse aggregate. Constr. Build. Mater. 2020, 256, 119385. [Google Scholar] [CrossRef]

- Abdel-Rahman, M.A.; Ali, M.A.; El-Mongy, S.A. Penetrability of γ/n and static behavior of newly developed concrete using different passive assay techniques. Nucl. Technol. 2020, 206, 766–778. [Google Scholar] [CrossRef]

- Ali, M.A.; Tawfic, A.; Abdelgawad, M.A.; Mahdy, M.; Omar, A. Gamma and neutrons shielding using innovative fiber reinforced concrete. Prog. Nucl. Energy 2022, 145, 104133. [Google Scholar] [CrossRef]

- Ali, S.; Lublóy, É. Radiation shielding structures: Concepts, behavior and the role of the heavyweight concrete as a shielding material—Review. Concr. Struct. 2020, 21, 24–30. [Google Scholar] [CrossRef]

- Sensoy, A.; Gökçe, H. Simulation and optimization of gamma-ray linear attenuation coefficients of barite concrete shields. Constr. Build. Mater. 2020, 253, 119218. [Google Scholar] [CrossRef]

- Pomaro, B.; Gramegna, F.; Cherubini, R.; De Nadal, V.; Salomoni, V.; Faleschini, F. Gamma-ray shielding properties of heavyweight concrete with Electric Arc Furnace slag as aggregate: An experimental and numerical study. Constr. Build. Mater. 2018, 200, 188–197. [Google Scholar] [CrossRef]

- Alhajali, S.; Yousef, S.; Naoum, B. Appropriate concrete for nuclear reactor shielding. Appl. Radiat. Isot. 2016, 107, 29–32. [Google Scholar] [CrossRef] [PubMed]

- Ravikumar, H.; Dattatreya, J.K.; Shivananda, K.P. Experimental investigation on replacement of steel slag as coarse aggregate in concrete. J. Civ. Eng. Environ. Technol. 2015, 2, 58–63. [Google Scholar]

- Beigi, M.H.; Berenjian, J.; Omran, O.L.; Nik, A.S.; Nikbin, I.M. An experimental survey on combined effects of fibers and nanosilica on the mechanical, rheological, and durability properties of self-compacting concrete. Mater. Des. 2013, 50, 1019–1029. [Google Scholar] [CrossRef]

- Abdel-Rahman, M.A.E.; Fouda, A.A.; El-Mongy, S.A. Study of γ-Fast Neutron Attenuation and Mechanical Characteristics of Modified Concretes for Shielding and Sheltering Purposes. Z. Anorg. Allg. Chem. 2019, 645, 649–655. [Google Scholar] [CrossRef]

- Demir, I.; Gümüş, M.; Gökçe, H.S. Gamma-ray and neutron shielding characteristics of polypropylene fiber-reinforced heavyweight concrete exposed to high temperatures. Constr. Build. Mater. 2020, 257, 119596. [Google Scholar] [CrossRef]

- ASTM C150; Standard Specification for Portland Cement. American Society for Testing and Materials. ASTM International: West Conshohocken, PA, USA, 2018; 9p.

- ASTM C 1240; Standard Specification for Silica Fumes in the Cementitious Mixtures. American Society for Testing and Materials. ASTM International: West Conshohocken, PA, USA, 2005; 7p.

- ASTM C33/C33M; Standard Specification for Concrete Aggregates. American Society for Testing and Materials. ASTM International: West Conshohocken, PA, USA, 2018; 8p.

- ASTM C494/C494M; Standard Specification for Chemical Admixtures for Concrete. American Society for Testing and Materials. ASTM International: West Conshohocken, PA, USA, 2015; 10p.

- ASTM C138; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. American Society for Testing and Materials. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM C 39/C 39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. American Society for Testing and Materials. ASTM International: West Conshohocken, PA, USA, 2015; 7p.

- ASTM C78; Standard Test Method for Flexural Strength on third point loading. American Society for Testing and Materials. ASTM International: West Conshohocken, PA, USA, 2002; 7p.

- ASTM C31/C31M; Standard Practice for Making and Curing Concrete Test Specimens in the Field. American Society for Testing and Materials. ASTM International: West Conshohocken, PA, USA, 2019; 6p.

| Characteristic | Dolomite | Silica Sand |

|---|---|---|

| Bulk-Specific Gravity (SSD) | 2.64 | 2.63 |

| Apparent Specific Gravity | 2.69 | 2.67 |

| Water Absorption | 0.66% | 0.91% |

| Compounds | Percentage |

|---|---|

| SiO2 | 75% |

| K2O | 10% |

| P2O5 | 3% |

| F2O3 | 3% |

| CaO | 1.3% |

| Mg and Na | Minimal percentage |

| Characteristic | Polypropylene Fibers | Rice Straw Fibers |

|---|---|---|

| Length | 8 mm | 8 mm |

| Diameter | 20 µm | 16 µm |

| Tensile strength (MPa) | 520 | 450 |

| Specific gravity | 0.9 | 1.1 |

| Color | White | Greenish Yellow |

| Constituent | Pure Homopolymer Polypropylene | Cellulose, lignin, hemicellulose |

| Moisture content | - | 12–17% |

| Mixture ID | Silica Sand (kg) | Coarse Aggregate (kg) | Cement (kg) | Water (kg) | Silica Fume (kg) | PP (%Vf) | Rice Straw Fiber (%Vf) | HRWRA (kg) |

|---|---|---|---|---|---|---|---|---|

| CC | 760.75 | 1145.471 | 350 | 140 | - | - | - | 7.0 |

| RS0.25 | 0.25% | |||||||

| RS0.5 | 0.5% | |||||||

| RS0.75 | 0.75% | |||||||

| PP0.5 | 0.5 | - | ||||||

| RS0.5/5 | 766.6 | 1154.28 | 332.5 | 17.5 | - | 0.5% | ||

| RS0.5/10 | 772.44 | 1163.07 | 315 | 35 | ||||

| RS0.5/15 | 778.29 | 1171.87 | 297.5 | 52.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahdy, M.M.; Mahfouz, S.Y.; Tawfic, A.F.; Ali, M.A.E.M. Performance of Rice Straw Fibers on Hardened Concrete Properties under Effect of Impact Load and Gamma Radiation. Fibers 2023, 11, 42. https://doi.org/10.3390/fib11050042

Mahdy MM, Mahfouz SY, Tawfic AF, Ali MAEM. Performance of Rice Straw Fibers on Hardened Concrete Properties under Effect of Impact Load and Gamma Radiation. Fibers. 2023; 11(5):42. https://doi.org/10.3390/fib11050042

Chicago/Turabian StyleMahdy, Mohamed M., Sameh Y. Mahfouz, Ahmed F. Tawfic, and Mohamed A. E. M. Ali. 2023. "Performance of Rice Straw Fibers on Hardened Concrete Properties under Effect of Impact Load and Gamma Radiation" Fibers 11, no. 5: 42. https://doi.org/10.3390/fib11050042

APA StyleMahdy, M. M., Mahfouz, S. Y., Tawfic, A. F., & Ali, M. A. E. M. (2023). Performance of Rice Straw Fibers on Hardened Concrete Properties under Effect of Impact Load and Gamma Radiation. Fibers, 11(5), 42. https://doi.org/10.3390/fib11050042