An Electromechanical Impedance-Based Application of Realtime Monitoring for the Load-Induced Flexural Stress and Damage in Fiber-Reinforced Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Properties

2.2. Specimens Manufacturing

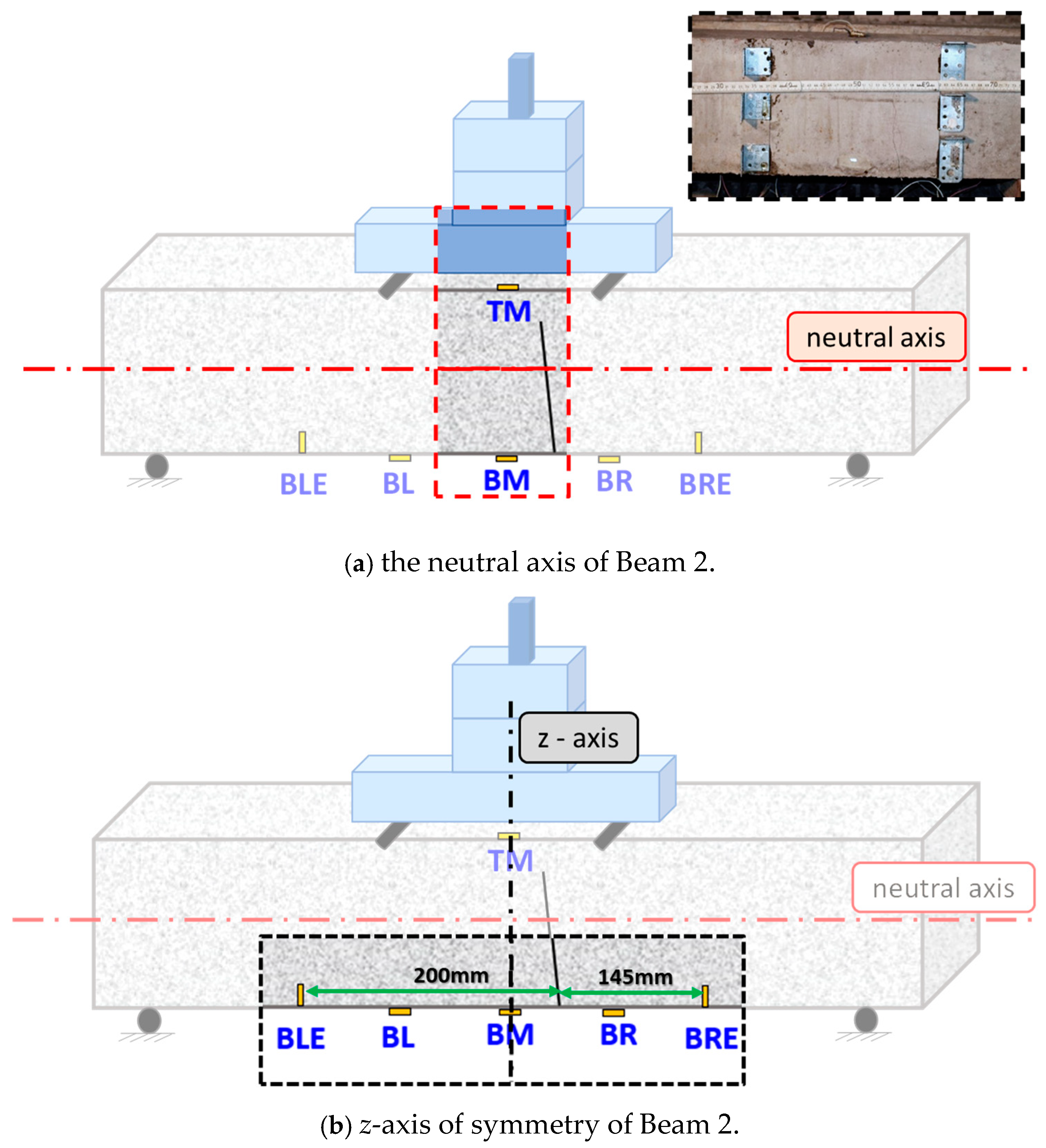

2.3. Set Up and Tested Specimens

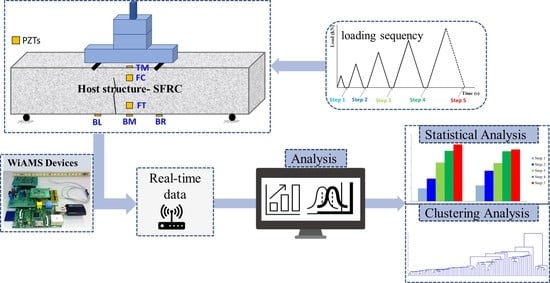

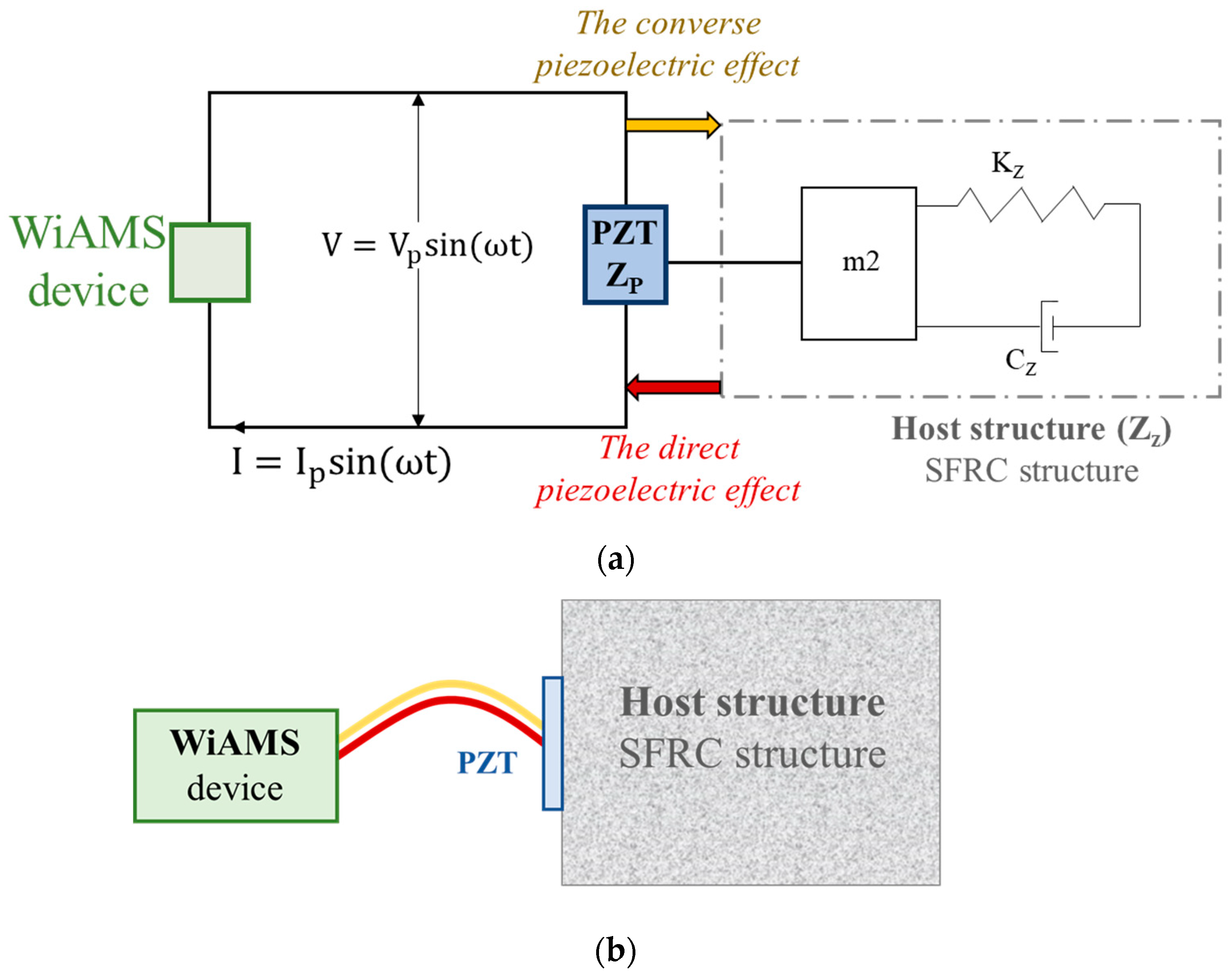

2.4. Development of Monitoring

- (A)

- damage evaluation caused on SFRC beams subjected to a four-point bending test

- (B)

- the influence of the induced load on the acquired EMI measurements

- (C)

- the impact of the angle created between the direction of the formed crack and the direction of the PZT’s polarization

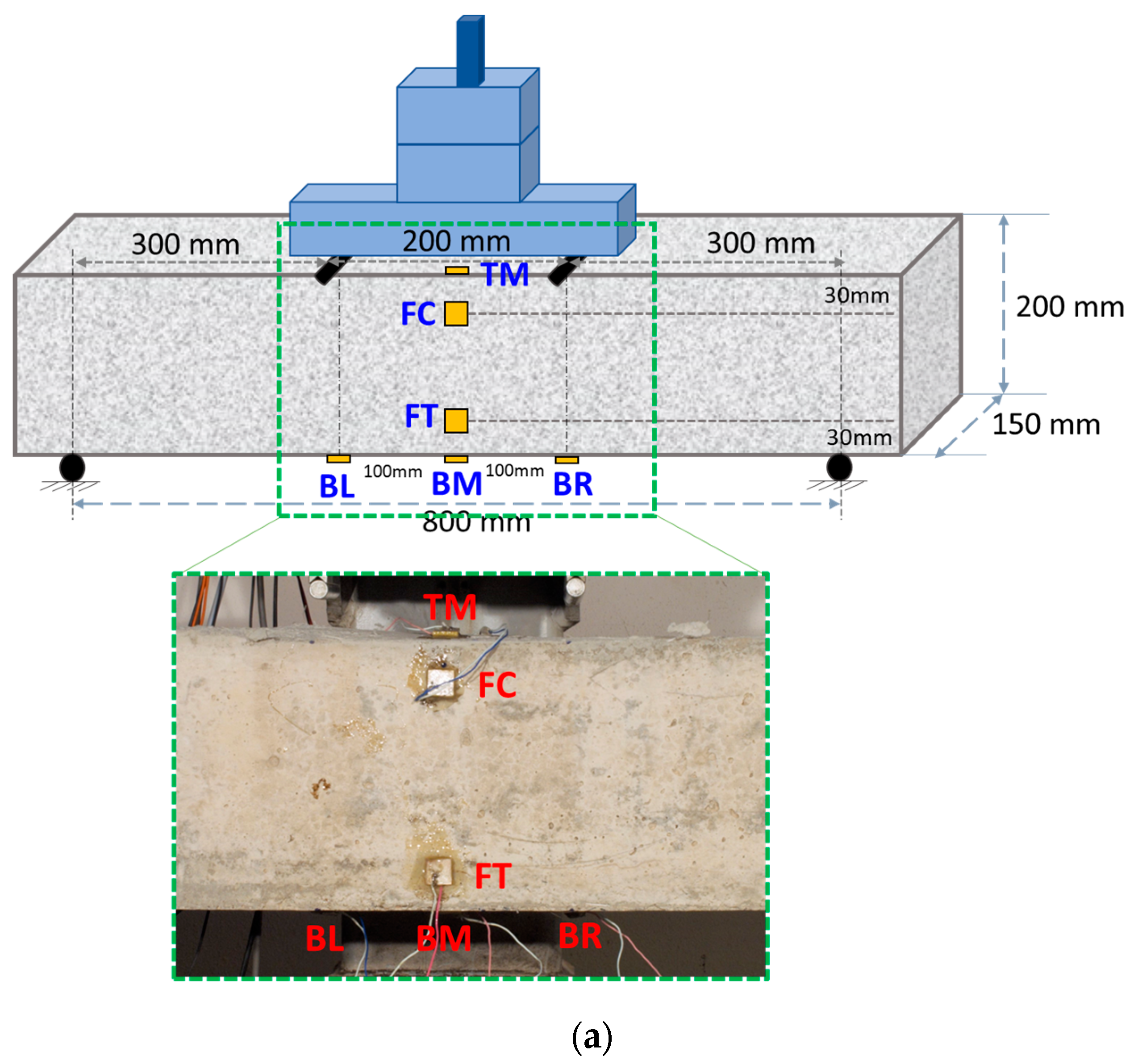

- -

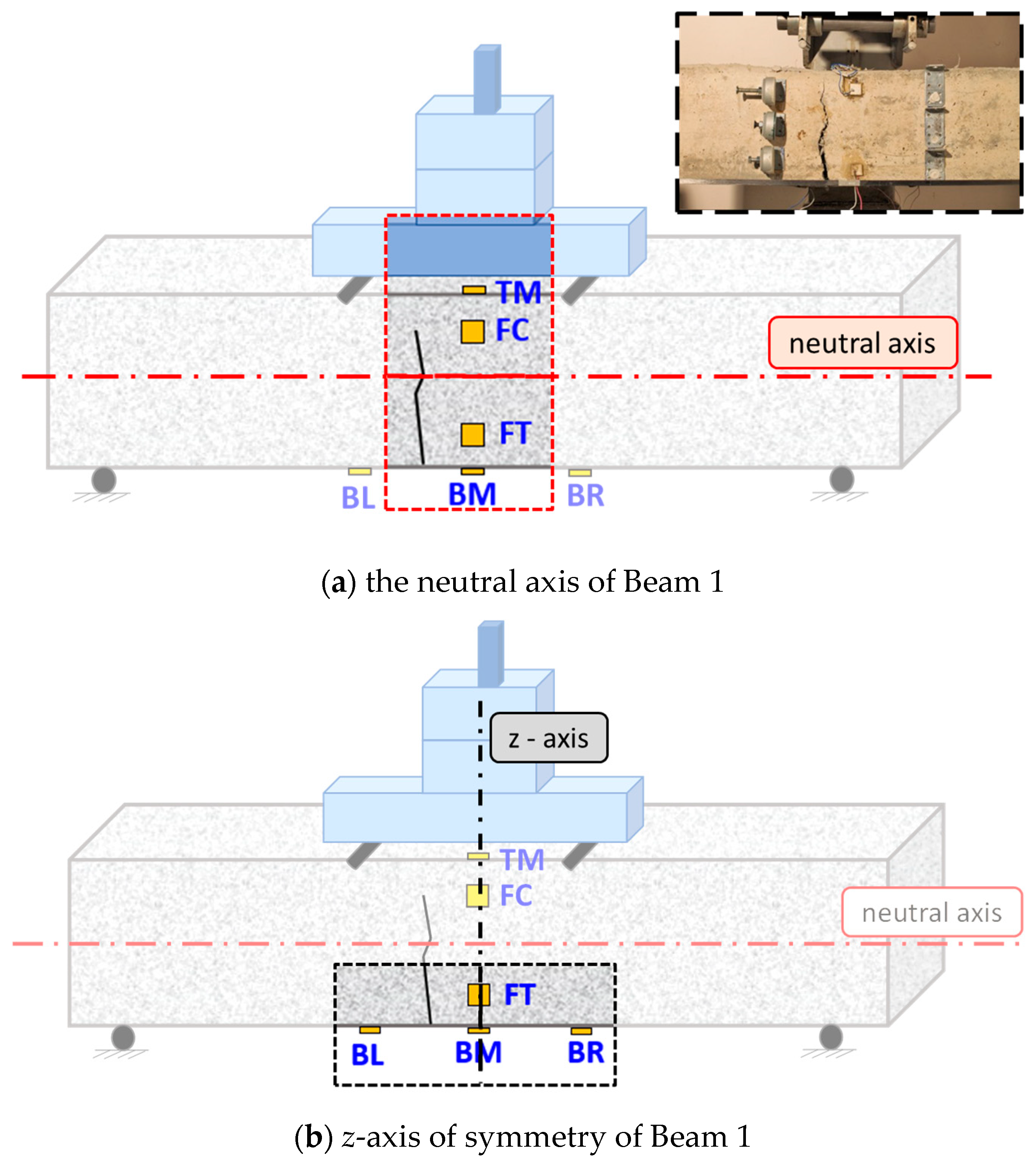

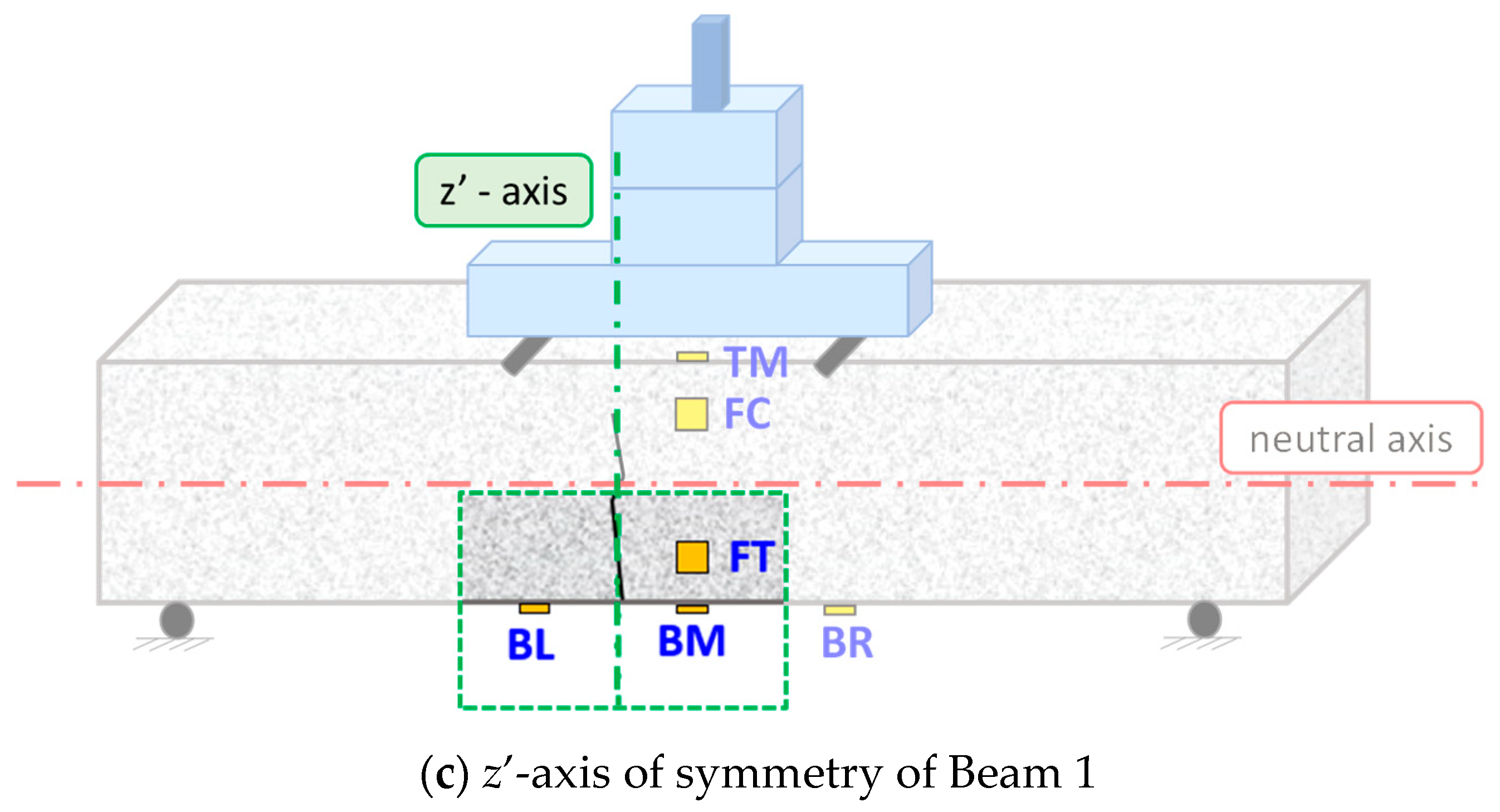

- FT—Facade Tension: The PZT patch was bonded in the middle of the façade surface at around 30 mm from the lower extreme fiber of the beam.

- -

- FC—Facade Compression: The PZT patch was bonded in the middle of the façade surface at around 30 mm from the extreme upper fiber of the beam.

- -

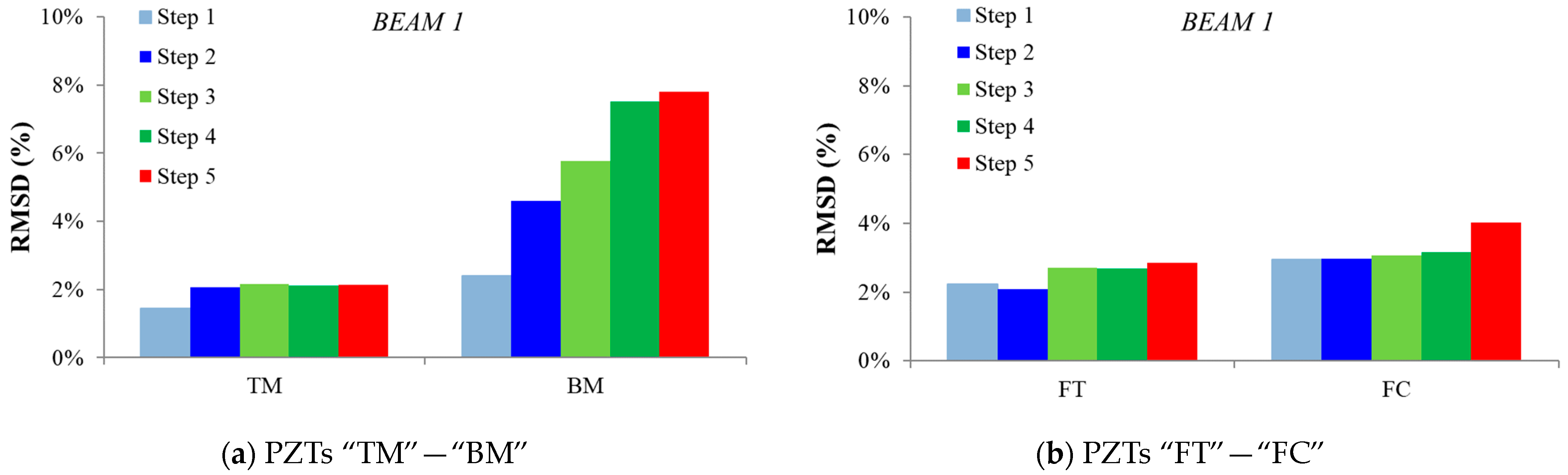

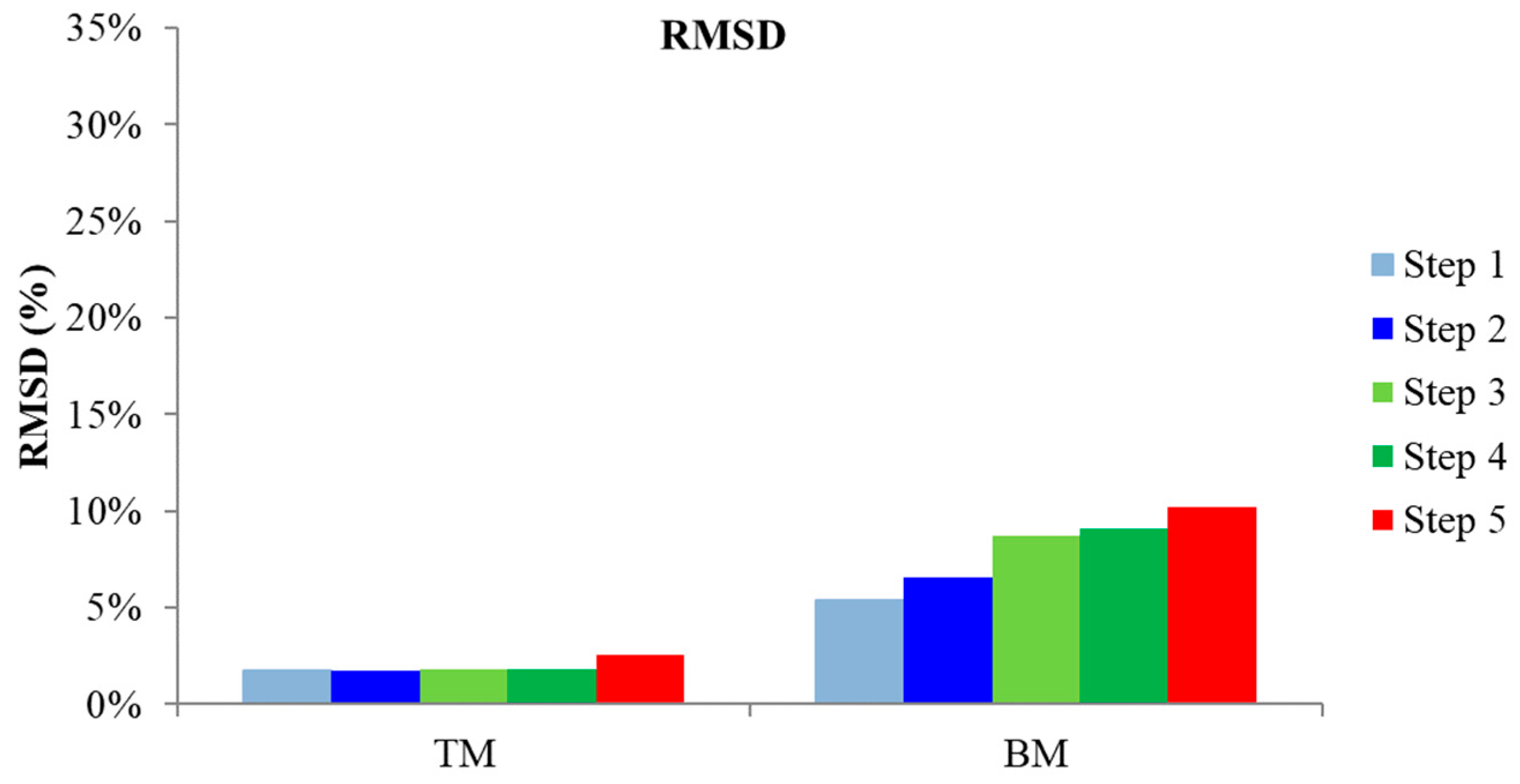

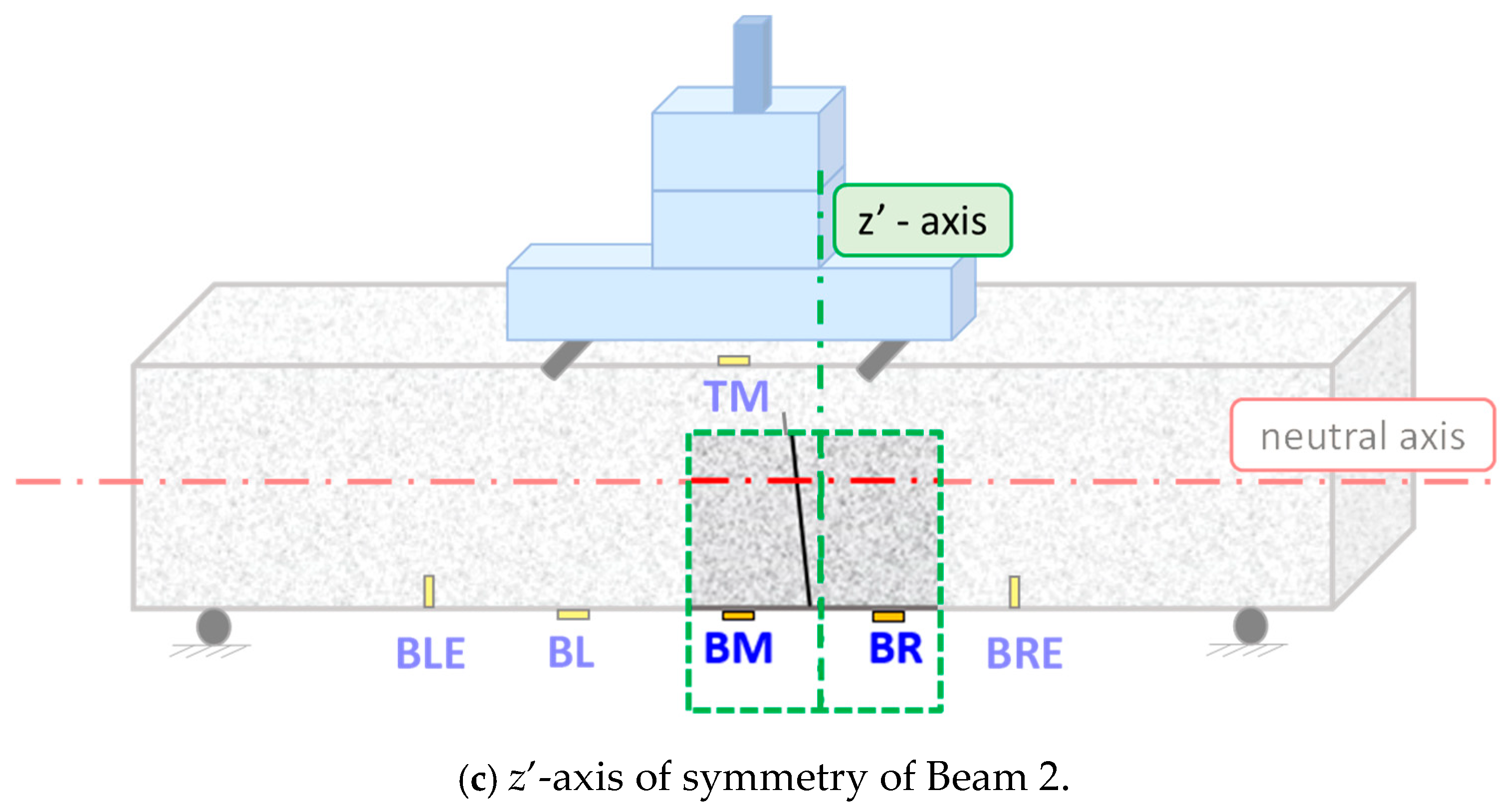

- TM—Top Mid: The PZT patch was bonded in the middle of the top surface at an equal distance of 100 mm apart from the loading points.

- -

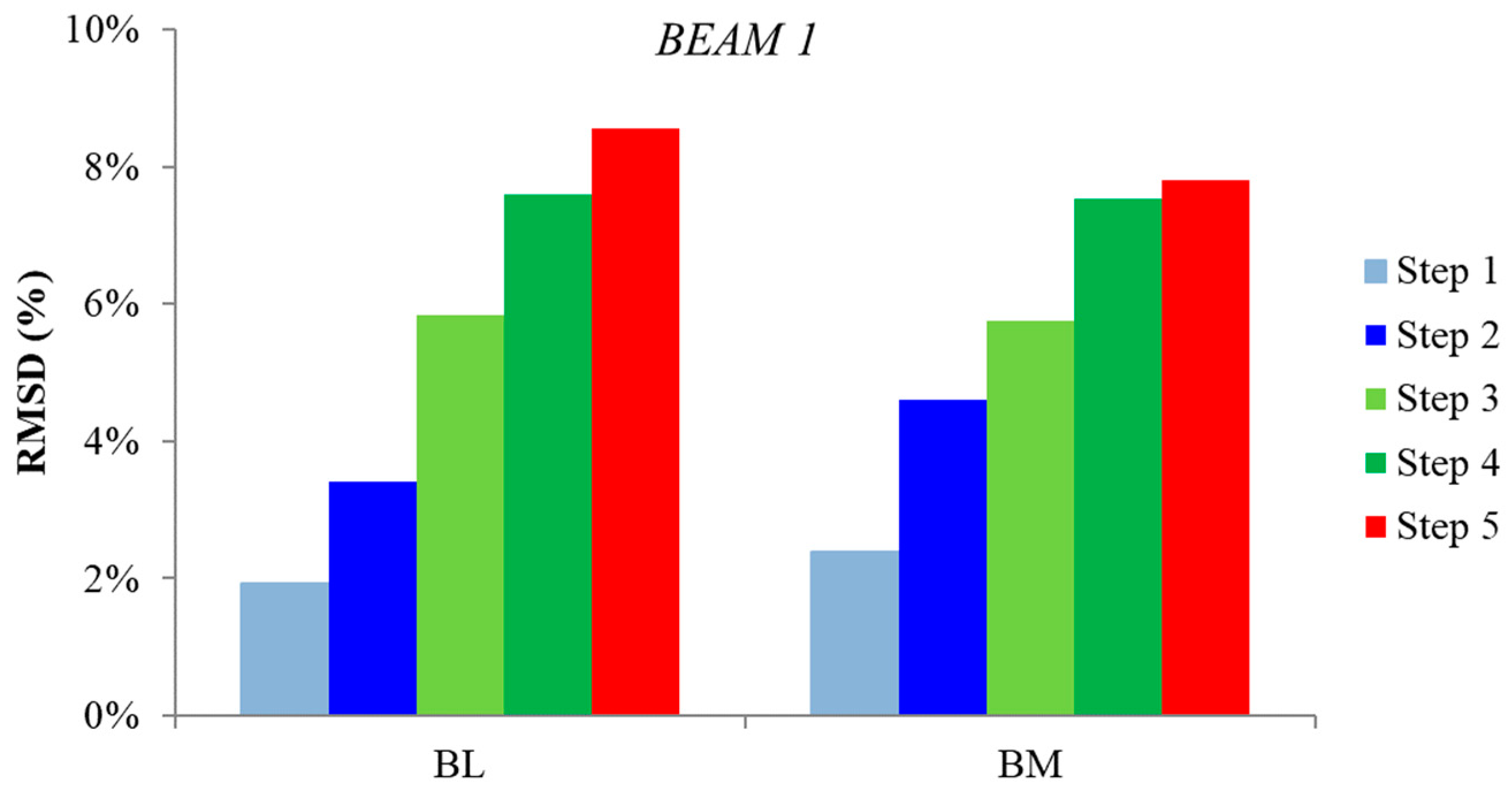

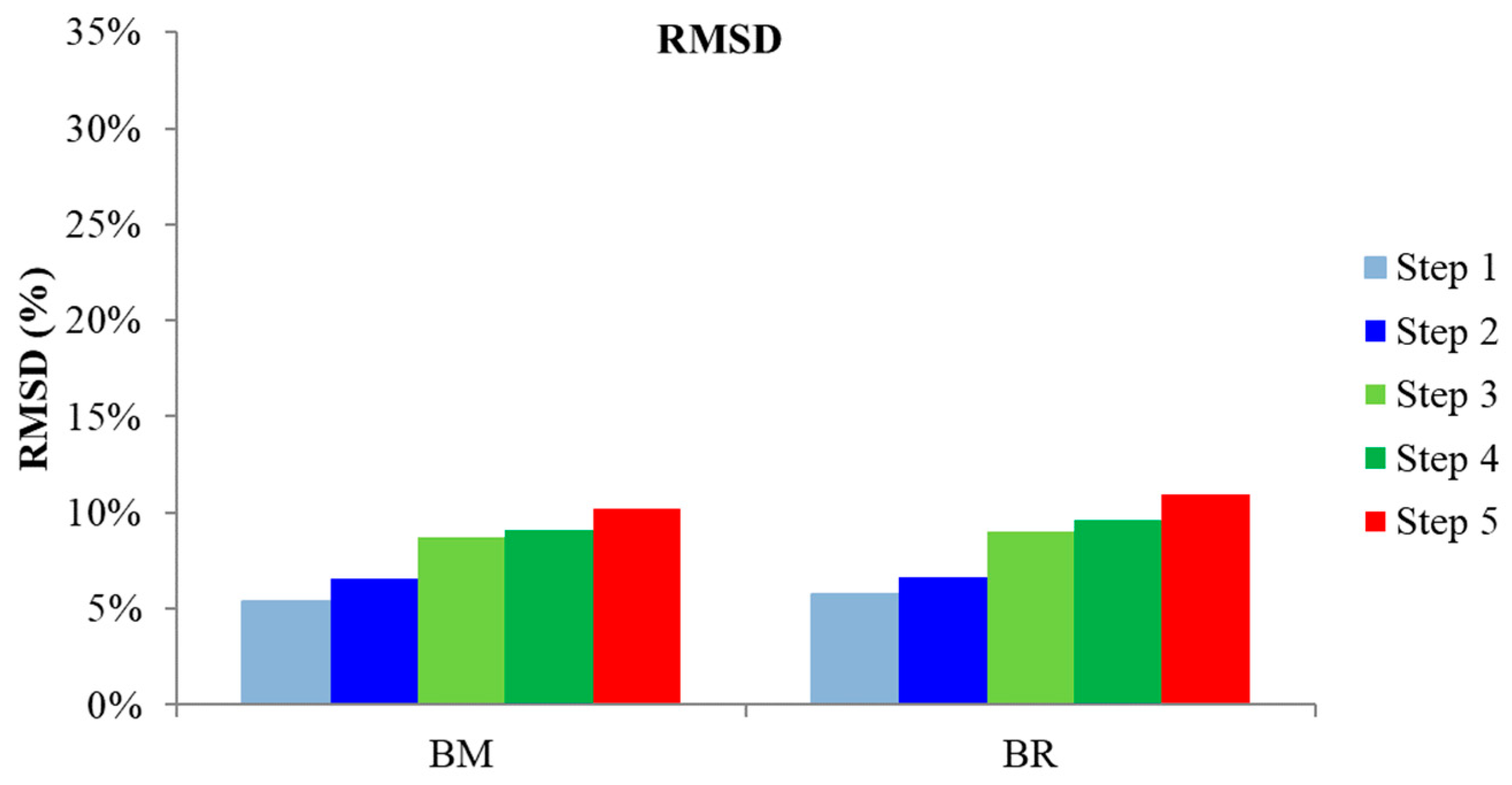

- BM—Bottom Mid: The PZT patch was bonded in the middle of the bottom surface directly opposite to the TM patch.

- -

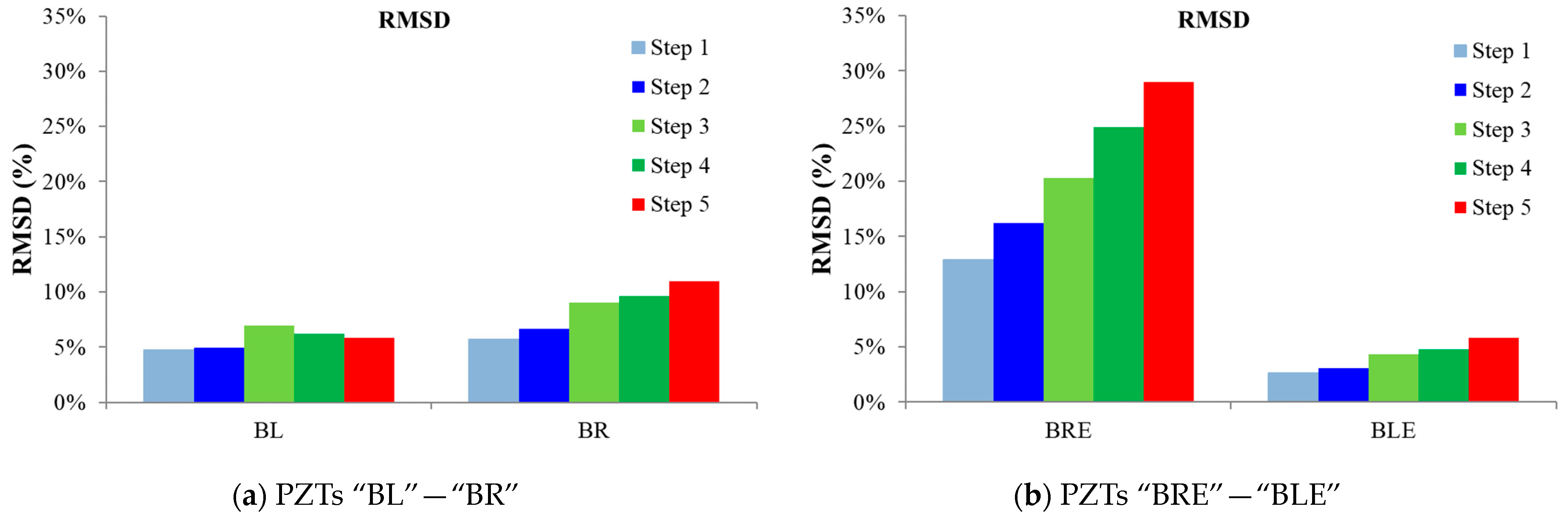

- BL—Bottom Left: The PZT patch was bonded 100 mm to the left direction from the middle of the lower extreme fiber surface directly opposite to the left loading point.

- -

- BR—Bottom Right: The PZT patch was bonded 100 mm to the right direction from the middle of the lower extreme fiber surface directly opposite to the right loading point.

- -

- BLE—Bottom Left External: The NeeS PZT patch was vertically epoxy-embedded to a grooved notch with a depth of 22 mm and at a distance of 200 mm to the left direction from the middle of the lower extreme fiber surface.

- -

- BRE—Bottom Right External: The NeeS PZT patch was vertically epoxy-embedded to a grooved notch with a depth of 22 mm and at a distance of 200 mm to the right direction from the middle of the lower extreme fiber surface.

2.5. Damage Quantification Process

- RMSD: Root Mean Square Deviation

- MAPD: Mean Absolute Percentage Deviation

- CC: Coefficient of Correlation

- insertion of all the desired measurements into the system

- allocation of the measurements to a cluster. The algorithm starts with all the measurements, initially consisting of a cluster.

- creating the first clusters by merging some single measurements with best-fit similarity

- recomputation of the metric distances between the newly formed clusters and the initial ones

- The algorithm stops whenever all the measurements are assigned to a cluster or until the formation of the clusters’ designed number occurs.

3. Results

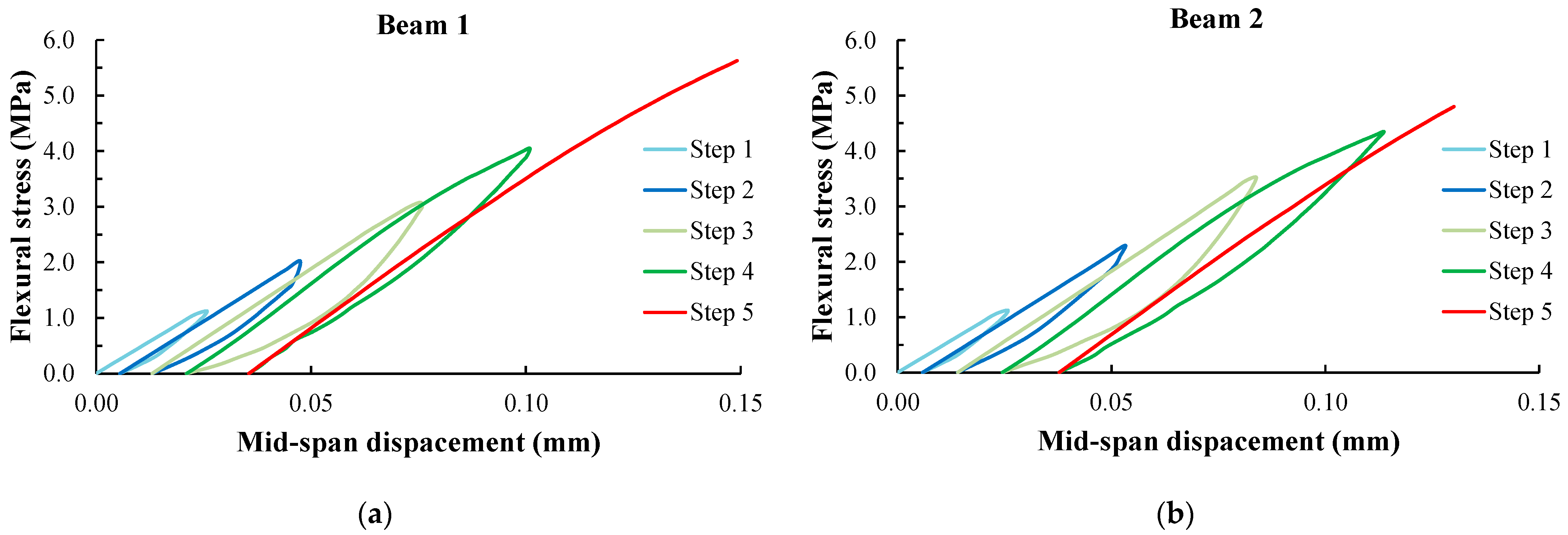

3.1. Flexural Behavior of Beams

3.2. Structural Health Monitoring Results

3.2.1. Analysis through Statistic Metrics in the Beams’ Released Condition

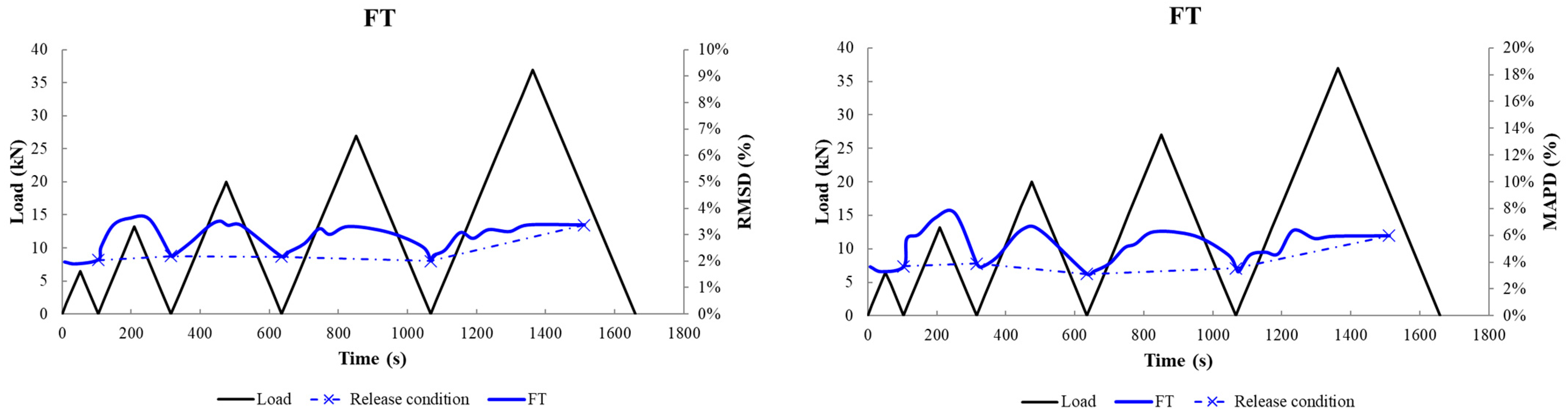

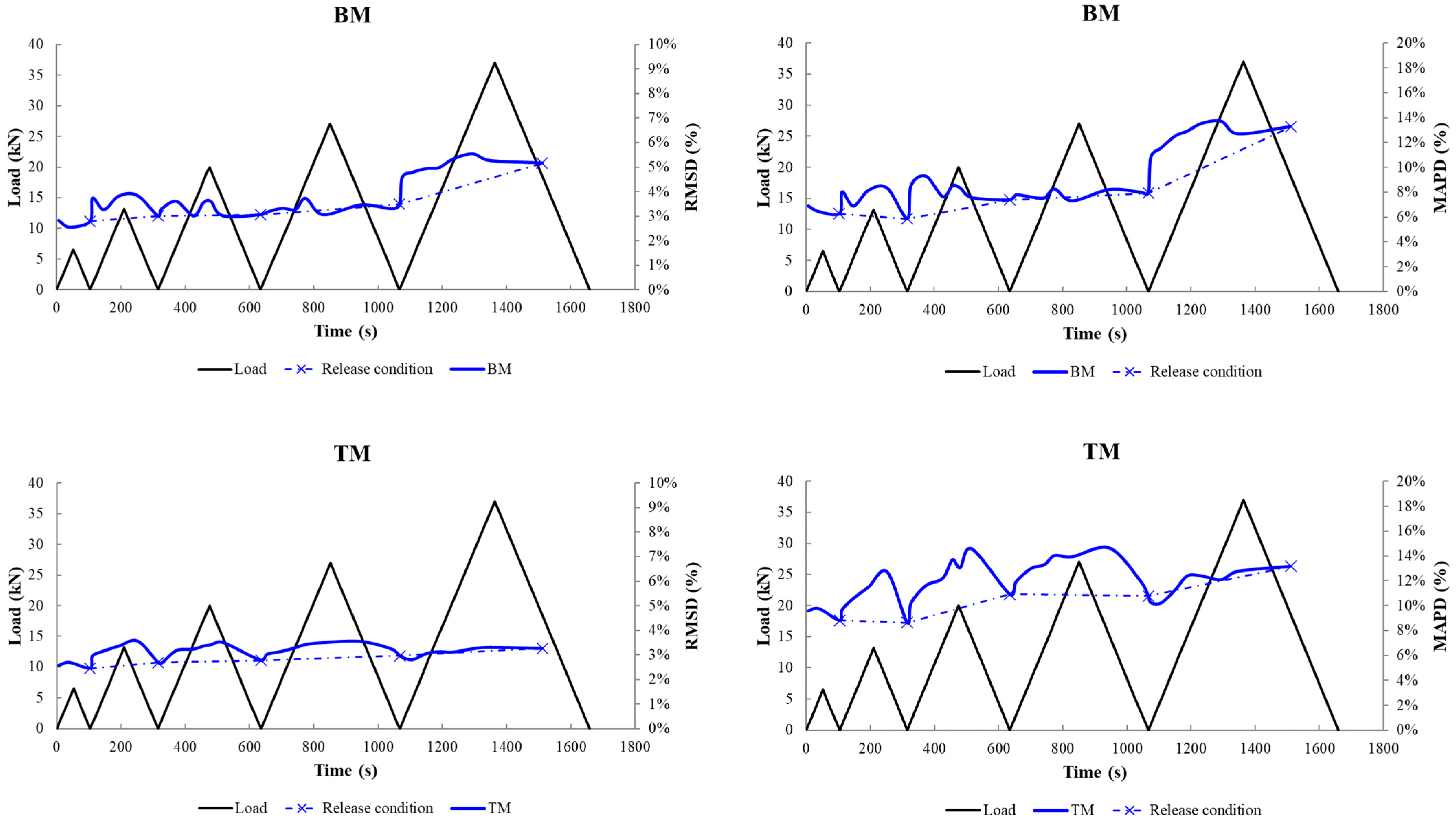

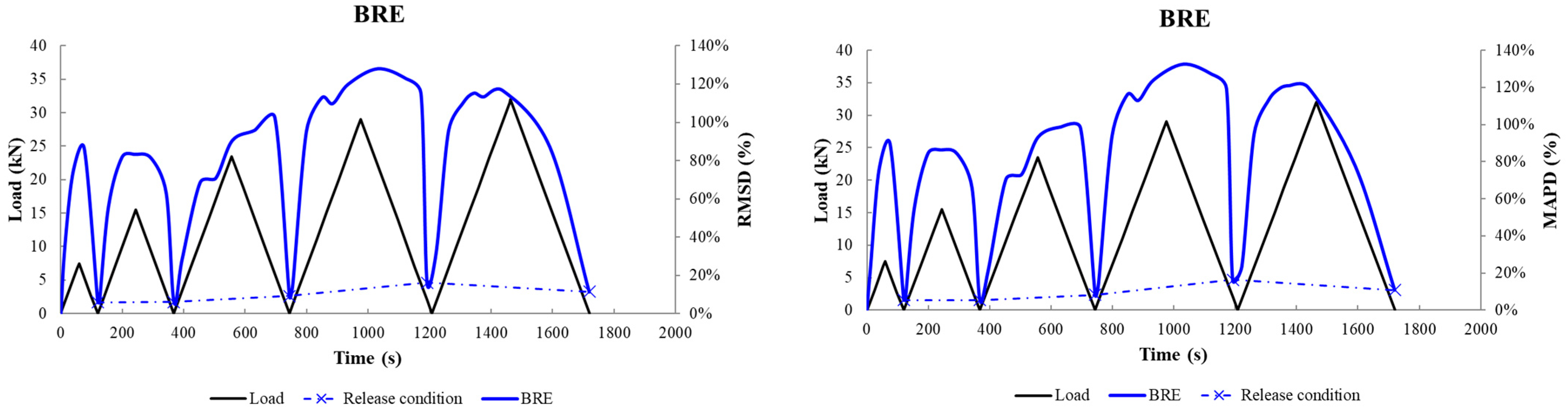

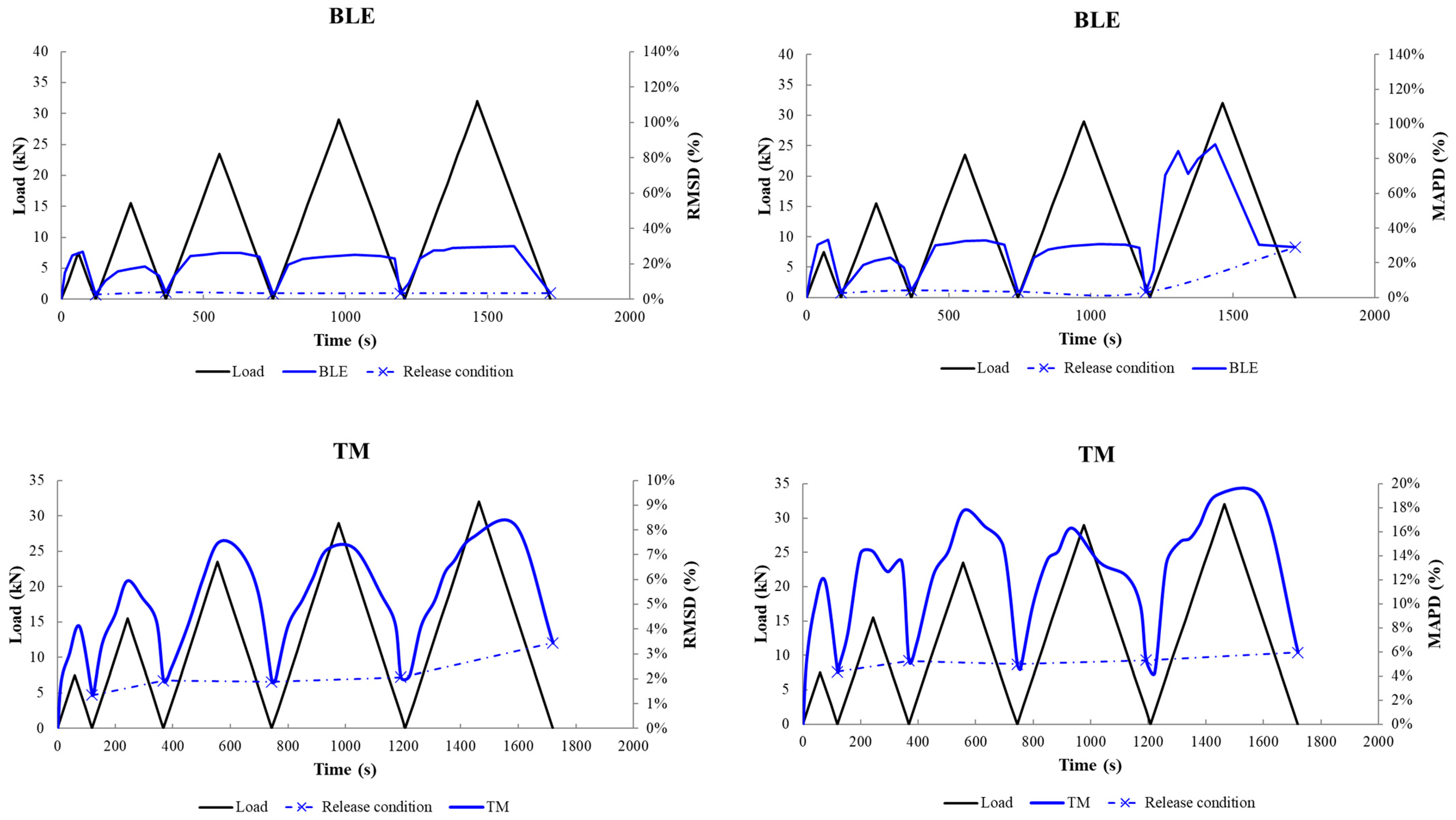

3.2.2. Analysis through Statistic Metrics during the Loading Sequence

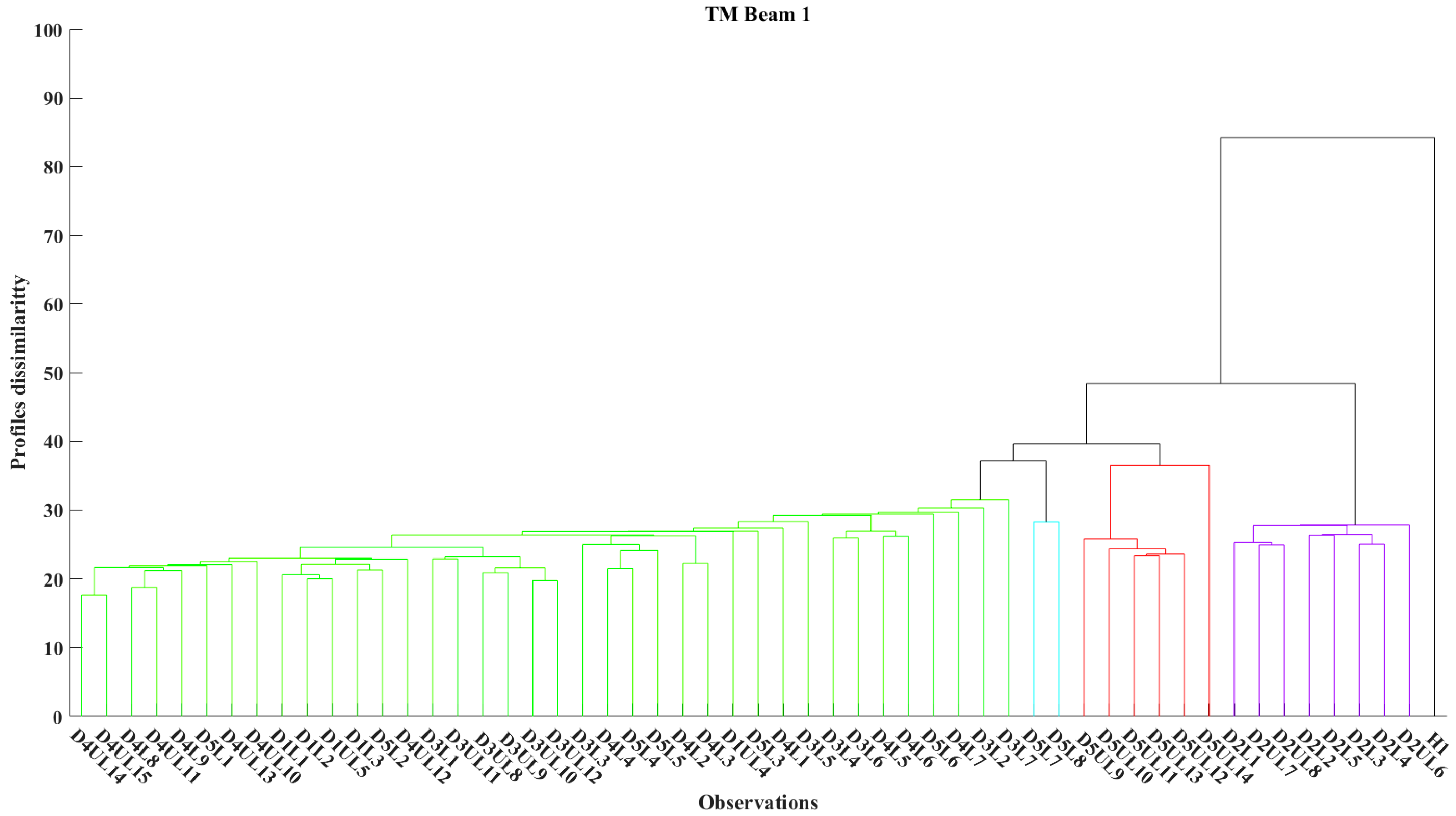

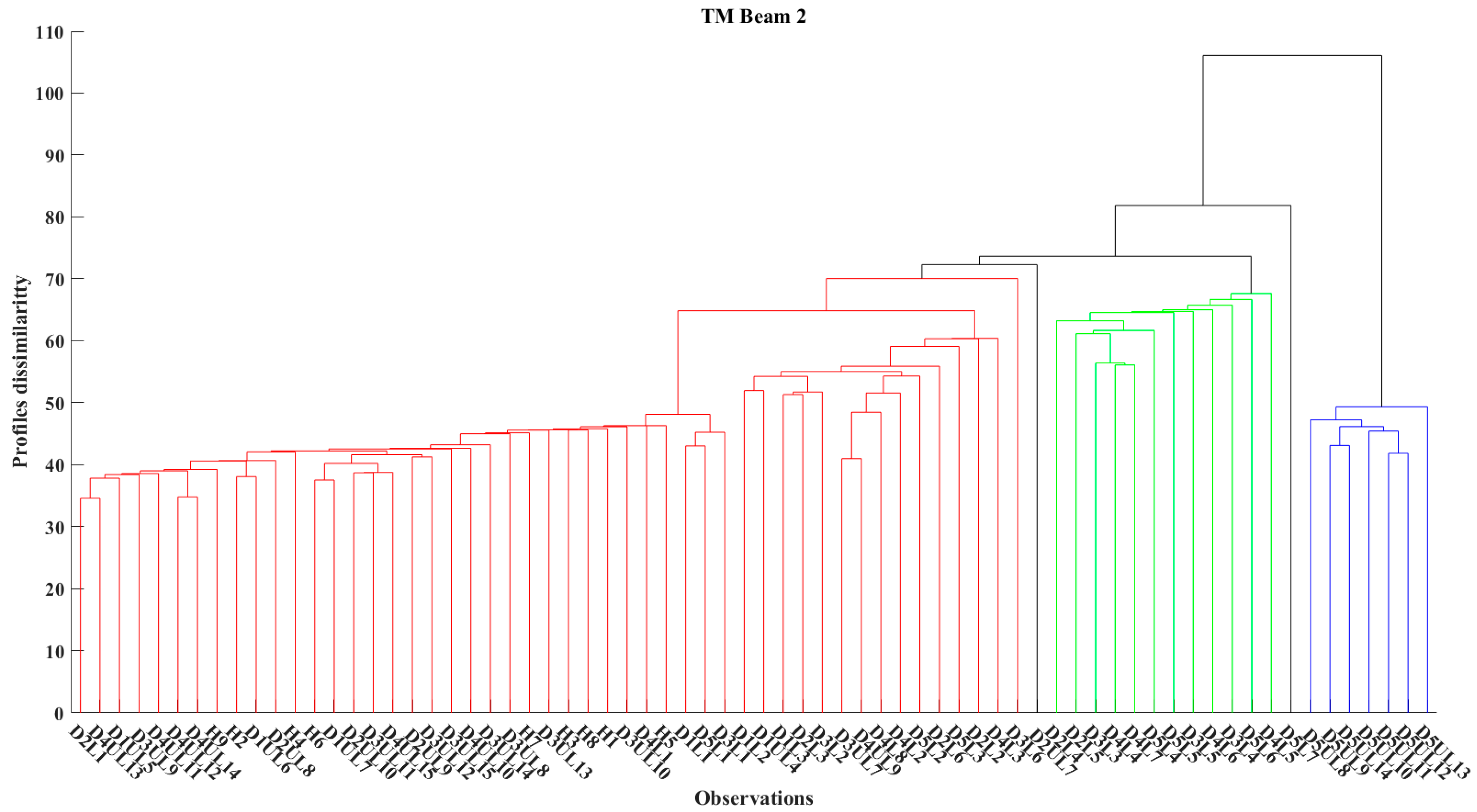

3.2.3. Analysis through Hierarchical Clustering Approach

4. Conclusions

- In both beams, proximate to the failure, external epoxy-bonded PZT transducers have effectively detected the damage development by applying the RMSD scalar index in the released condition.

- Furthermore, the values of the indices are slightly higher for the proximate to the failure PZT compared to its symmetric one (BL, BR).

- The introduction of NeeS configuration applied for the EMI measurements.

- The NeeS BRE showed remarkable performance, even if it was positioned 145 mm far from the final failure formation; it detected the forthcoming failure even at earlier loading steps, owing to the vertical polarization placement into the concrete mass.

- In beam 1, PZT transducers BM and BL, and, in Beam 2, PZTs BM, BR, and BRE, seemed to detect the forthcoming failure at earlier damage states.

- In beam 1, PZT transducers FT, BM, and TM, according to their indices (RMSD, MAPD), and in beam 2, PZT transducers TM, BRE, and BLE, according to their indices (RMSD, MAPD) values, seemed to be affected by the subjection of the loading.

- The MAPD statistical index seems more sensitive to the elaboration of the acquired data, performing higher volume ratios.

- The HCA (a) could distinguish, with excellent accuracy, the measurements affected by the induced load and those in the release condition, (b) could efficiently distinguish and sort the acquired transitional measurements, and (c) could achieve three out of four to distinguish the failure measurement in the external epoxy-bonded PZT transducers; two out of four were used to distinguish an earlier detection of the failure in the external epoxy-bonded PZT transducers; and further, four out of four distinguished the post-failure measurements and (d) achieved the distinguishment of the failure measurement related to the NeeS BRE. While, for NeeS BLE, there was no indication concerning which factor was evaluated as correct due to the remote position of the PZT.

- A further experimental investigation is required to enhance the determination of the localization of the crack and to evaluate the efficiency of the HCA; Moreover, the efficiency of the applied HCA by applying multiple distance metrics and increasing the correlation of the representation should be further extended.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lessly, S.H.; Kumar, S.L.; Jawahar, R.R.; Prabhu, L. Durability Properties of Modified Ultra-High Performance Concrete with Varying Cement Content and Curing Regime. Mater. Today Proc. 2020, 45, 6426–6432. [Google Scholar] [CrossRef]

- Sideris, K.K.; Anagnostopoulos, N.S. Durability of Normal Strength Self-Compacting Concretes and Their Impact on Service Life of Reinforced Concrete Structures. Constr. Build. Mater. 2013, 41, 491–497. [Google Scholar] [CrossRef]

- Torres, J.A.; Lantsoght, E.O.L. Influence of Fiber Content on Shear Capacity of Steel Fiber-Reinforced Concrete Beams. Fibers 2019, 7, 102. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. The Effects of Silica Fume and Polypropylene Fibers on the Impact Resistance and Mechanical Properties of Concrete. Constr. Build. Mater. 2010, 24, 927–933. [Google Scholar] [CrossRef]

- Signorini, C.; Volpini, V. Mechanical Performance of Fiber-reinforced Cement Composites Including Fully-Recycled Plastic Fibers. Fibers 2021, 9, 16. [Google Scholar] [CrossRef]

- Nobili, A.L.; Tarantino, A.M. Performance Evaluation of a Polypropylene-Based Draw-Wired Fibre for Concrete Structures. Constr. Build. Mater. 2012, 28, 798–806. [Google Scholar] [CrossRef]

- Khaloo, A.R.; Kim, N. Influence of Concrete and Fiber Characteristics on Behavior of Steel Fiber-reinforced Concrete under Direct Shear. ACI Mater. J. 1997, 94, 592–601. [Google Scholar]

- Abbas, A.M.; Hussain, H.K.; Ojaimi, M.F. Shear and Flexural Behavior of Flat Slabs Casted with Polyolefin Fiber-Reinforced Concrete. Fibers 2022, 10, 34. [Google Scholar] [CrossRef]

- Kytinou, V.K.; Chalioris, C.E.; Karayannis, C.G. Analysis of Residual Flexural Stiffness of Steel Fiber-Reinforced Concrete Beams with Steel Reinforcement. Materials 2020, 13, 2698. [Google Scholar] [CrossRef]

- Narayanan, A.; Subramaniam, K.V.L. Sensing of Damage and Substrate Stress in Concrete Using Electromechanical Impedance Measurements of Bonded PZT Patches. Smart Mater. Struct. 2016, 25, 095011. [Google Scholar] [CrossRef]

- Papadopoulos, N.A.; Naoum, M.C.; Sapidis, G.M.; Chalioris, C.E. Cracking and Fiber Debonding Identification of Concrete Deep Beams Reinforced with C-FRP Ropes against Shear Using a Real-Time Monitoring System. Polymers 2023, 15, 473. [Google Scholar] [CrossRef]

- Na, W.S.; Baek, J. A Review of the Piezoelectric Electromechanical Impedance Based Structural Health Monitoring Technique for Engineering Structures. Sensors 2018, 18, 1307. [Google Scholar] [CrossRef] [PubMed]

- Sam-Daliri, O.; Faller, L.M.; Farahani, M.; Roshanghias, A.; Araee, A.; Baniassadi, M.; Oberlercher, H.; Zangl, H. Impedance analysis for condition monitoring of single lap CNT-epoxy adhesive joint. Int. J. Adhes. Adhes. 2019, 88, 59–65. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Faller, L.M.; Farahani, M.; Zangl, H. Structural health monitoring of adhesive joints under pure mode I loading using the electrical impedance measurement. Eng. Fract. Mech. 2021, 245, 107585. [Google Scholar] [CrossRef]

- Casini, M. Smart Buildings, Advanced Materials and Nanotechnology to Improve Energy-Efficiency and Environmental Performance; Woodhead Publishing: Sawston, CA, USA, 2016; pp. 55–104. [Google Scholar]

- Providakis, C.P.; Stefanaki, S.D.; Voutetaki, M.E.; Tsompanakis, Y.; Stavroulaki, M. Damage detection in concrete structures using a simultaneously activated multi-mode PZT active sensing system: Numerical modelling. Struct. Infrastruct. Eng. 2014, 10, 1451–1468. [Google Scholar] [CrossRef]

- Ai, D.; Luo, H.; Wang, C.; Zhu, H. Monitoring of the Load-Induced RC Beam Structural Tension/Compression Stress and Damage Using Piezoelectric Transducers. Eng. Struct. 2018, 154, 38–51. [Google Scholar] [CrossRef]

- Ai, D.; Cheng, J. A Deep Learning Approach for Electromechanical Impedance Based Concrete Structural Damage Quantification Using Two-Dimensional Convolutional Neural Network. Mech. Syst. Signal Process. 2023, 183, 109634. [Google Scholar] [CrossRef]

- Ai, D.; Du, L.; Li, H.; Zhu, H. Corrosion Damage Identification for Reinforced Concrete Beam Using Embedded Piezoelectric Transducer: Numerical Simulation. Meas. J. Int. Meas. Confed. 2022, 192, 110925. [Google Scholar] [CrossRef]

- Ai, D.; Yang, Z.; Li, H.; Zhu, H. Heating-Time Effect on Electromechanical Admittance of Surface-Bonded PZT Sensor for Concrete Structural Monitoring. Meas. J. Int. Meas. Confed. 2021, 184, 109992. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Karayannis, C.G.; Angeli, G.M.; Papadopoulos, N.A.; Favvata, M.J.; Providakis, C.P. Applications of Smart Piezoelectric Materials in a Wireless Admittance Monitoring System (WiAMS) to Structures-Tests in RC Elements. Case Stud. Constr. Mater. 2016, 5, 1–18. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Papadopoulos, N.A.; Angeli, G.M.; Karayannis, C.G.; Liolios, A.A.; Providakis, C.P. Damage Evaluation in Shear-Critical Reinforced Concrete Beam Using Piezoelectric Transducers as Smart Aggregates. Open Eng. 2015, 5, 373–384. [Google Scholar] [CrossRef]

- Voutetaki, M.E.; Papadopoulos, N.A.; Angeli, G.M.; Providakis, C.P. Investigation of a New Experimental Method for Damage Assessment of RC Beams Failing in Shear Using Piezoelectric Transducers. Eng. Struct. 2016, 114, 226–240. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Voutetaki, M.E.; Liolios, A.A. Structural health monitoring of seismically vulnerable RC frames under lateral cyclic loading. Earthq. Struct. 2020, 19, 29–44. [Google Scholar]

- Karayannis, C.G.; Golias, E.; Naoum, M.C.; Chalioris, C.E. Efficacy and Damage Diagnosis of Reinforced Concrete Columns and Joints Strengthened with FRP Ropes Using Piezoelectric Transducers. Sensors 2022, 22, 8294. [Google Scholar] [CrossRef] [PubMed]

- Voutetaki, M.E.; Naoum, M.C.; Papadopoulos, N.A.; Chalioris, C.E. Cracking Diagnosis in Fiber-Reinforced Concrete with Synthetic Fibers Using Piezoelectric Transducers. Fibers 2022, 10, 5. [Google Scholar] [CrossRef]

- Kocherla, A.; Subramaniam, K.V.L. Embedded Smart PZT-Based Sensor for Internal Damage Detection in Concrete under Applied Compression. Meas. J. Int. Meas. Confed. 2020, 163, 108018. [Google Scholar] [CrossRef]

- Narayanan, A.; Subramaniam, K.V.L. Experimental Evaluation of Load-Induced Damage in Concrete from Distributed Microcracks to Localized Cracking on Electromechanical Impedance Response of Bonded PZT. Constr. Build. Mater. 2016, 105, 536–544. [Google Scholar] [CrossRef]

- Perera, R.; Torres, L.; Ruiz, A.; Barris, C.; Baena, M. An EMI-based clustering for structural health monitoring of NSM FRP strengthening systems. Sensors 2019, 19, 3775. [Google Scholar] [CrossRef]

- Sevillano, E.; Sun, R.; Gil, A.; Perera, R. Interfacial crack-induced debonding identification in FRP-strengthened RC beams from PZT signatures using hierarchical clustering analysis. Compos. Part B Eng. 2016, 87, 322–335. [Google Scholar] [CrossRef]

- Voutetaki, M.E.; Naoum, M.C.; Papadopoulos, N.A.; Sapidis, G.; Chalioris, C.E. Cracking Diagnosis in Fibre Reinforced Concrete Cubes and Cylinders with Synthetic Fibres Using a PZT-Based Health Monitoring System. Sch. J. Eng. Technol. 2021, 9, 140–151. [Google Scholar] [CrossRef]

- Zhang, C.; Yan, Q.; Panda, G.P.; Wu, W.; Song, G.; Vipulanandan, C. Real-Time Monitoring Stiffness Degradation of Hardened Cement Paste under Uniaxial Compression Loading through Piezoceramic-Based Electromechanical Impedance Method. Constr. Build. Mater. 2020, 256, 119395. [Google Scholar] [CrossRef]

- Providakis, C.P.; Tsistrakis, S.; Voutetaki, M.E.; Tsompanakis, J.; Stavroulaki, M.; Agadakos, J.; Kampianakis, E.; Pentes, G.; Liarakos, E. An Innovative Active Sensing Platform for Wireless Damage Monitoring of Concrete Structures. Curr. Smart Mater. 2016, 1, 49–62. [Google Scholar] [CrossRef]

- Cleven, S.; Raupach, M.; Matschei, T. A New Method to Determine the Steel Fibre Content of Existing Structures-Test Setup and Numerical Simulation. Appl. Sci. 2022, 12, 561. [Google Scholar] [CrossRef]

- Naoum, M.C.; Voutetaki, M.E.; Papadopoulos, N.A.; Chalioris, C.E. Detection of damage in fiber-reinforced concrete using piezoceramic transducers and electromechanical impedance (EMI) method. In Proceedings of the 11th International Conference on Advanced Materials Research (ICAMR 2021), Association for Computing Machinery (ACM), Singapore, 21–24 January 2021. [Google Scholar]

- ASTM C192; Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM: West Conshohocken, PA, USA, 2004.

- ASTM 127; Test Method for Specific Gravity and Absorption of Coarse Aggregate. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM 128; Test Method for Specific Gravity and Absorption of Fine Aggregate. ASTM: West Conshohocken, PA, USA, 2015.

- EN 197-1; Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements. CEN: Brussels, Belgium, 2000.

- ASTM C143/C143M-12; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM C138; Standard Test Method for Unit Weight, Yield, and Air Content (Gravimetric) of Concrete. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM C 78–94; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM: West Conshohocken, PA, USA, 2002.

- Liang, C.; Sun, F.P.; Rogers, C.A. Coupled Electro-Mechanical Analysis of Adaptive Material Systems-Determination of the Actuator Power Consumption and System Energy Transfer. J. Intell. Mater. Syst. Struct. 1997, 8, 335–343. [Google Scholar] [CrossRef]

- Wang, T.; Tan, B.; Lu, M.; Zhang, Z.; Lu, G. Piezoelectric Electro-Mechanical Impedance (EMI) Based Structural Crack Monitoring. Appl. Sci. 2020, 10, 4648. [Google Scholar] [CrossRef]

- Tsintotas, K.A.; Bampis, L.; Gasteratos, A. Assigning Visual Words to Places for Loop Closure Detection. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation, Brisbane, Australia, 21–25 May 2018. [Google Scholar] [CrossRef]

- Tsintotas, K.A.; Sevetlidis, V.; Papapetros, I.T.; Balaska, V.; Psomoulis, A.; Gasteratos, A. BK Tree Indexing for Active Vision-Based Loop-Closure Detection in Autonomous Navigation, 30th ed.; Institute of Electrical and Electronics Engineers: Manhattan, NY, USA, 2022. [Google Scholar]

| Mix Proportion (Cement: Water: Fine Aggregate: Coarse Aggregate) | Proportion of Fiber/m3 Concrete (kg) | Density (kg/m3) | Compressive Strength (MPa) | Young’s Modulus (GPa) | Modulus of Rupture (MPa) |

|---|---|---|---|---|---|

| 1:2:2.4:0.52 | 5 | 2350 | 38.5 | 32.8 | 3.9 |

| Equivalent Diameter (mm) | Length (mm) | Tensile Strength (MPa) | Young’s Modulus (GPa) |

|---|---|---|---|

| 0.715 | 50 | 430 | 6.0 |

| Load Level | Flexural Strength (MPa) | Ratio of the Maximum Flexural Strength | |

|---|---|---|---|

| Beam 1 | Step 1 | 1.0 MPa | 17.9% |

| Step 2 | 2.0 MPa | 35.7% | |

| Step 3 | 3.0 MPa | 53.6% | |

| Step 4 | 4.0 MPa | 71.4% | |

| Step 5 | 5.6 MPa | Failure | |

| Beam 2 | Step 1 | 1.0 MPa | 22.2% |

| Step 2 | 2.0 MPa | 41.7% | |

| Step 3 | 3.0 MPa | 62.5% | |

| Step 4 | 4.0 MPa | 83.8% | |

| Step 5 | 4.8 MPa | Failure |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naoum, M.C.; Sapidis, G.M.; Papadopoulos, N.A.; Voutetaki, M.E. An Electromechanical Impedance-Based Application of Realtime Monitoring for the Load-Induced Flexural Stress and Damage in Fiber-Reinforced Concrete. Fibers 2023, 11, 34. https://doi.org/10.3390/fib11040034

Naoum MC, Sapidis GM, Papadopoulos NA, Voutetaki ME. An Electromechanical Impedance-Based Application of Realtime Monitoring for the Load-Induced Flexural Stress and Damage in Fiber-Reinforced Concrete. Fibers. 2023; 11(4):34. https://doi.org/10.3390/fib11040034

Chicago/Turabian StyleNaoum, Maria C., George M. Sapidis, Nikos A. Papadopoulos, and Maristella E. Voutetaki. 2023. "An Electromechanical Impedance-Based Application of Realtime Monitoring for the Load-Induced Flexural Stress and Damage in Fiber-Reinforced Concrete" Fibers 11, no. 4: 34. https://doi.org/10.3390/fib11040034

APA StyleNaoum, M. C., Sapidis, G. M., Papadopoulos, N. A., & Voutetaki, M. E. (2023). An Electromechanical Impedance-Based Application of Realtime Monitoring for the Load-Induced Flexural Stress and Damage in Fiber-Reinforced Concrete. Fibers, 11(4), 34. https://doi.org/10.3390/fib11040034