Shear Strengthening of Reinforced Concrete Beams Using Engineered Cementitious Composites and Carbon Fiber-Reinforced Polymer Sheets

Abstract

:1. Introduction

2. Experimental Program

2.1. Material Properties and Mix Proportions

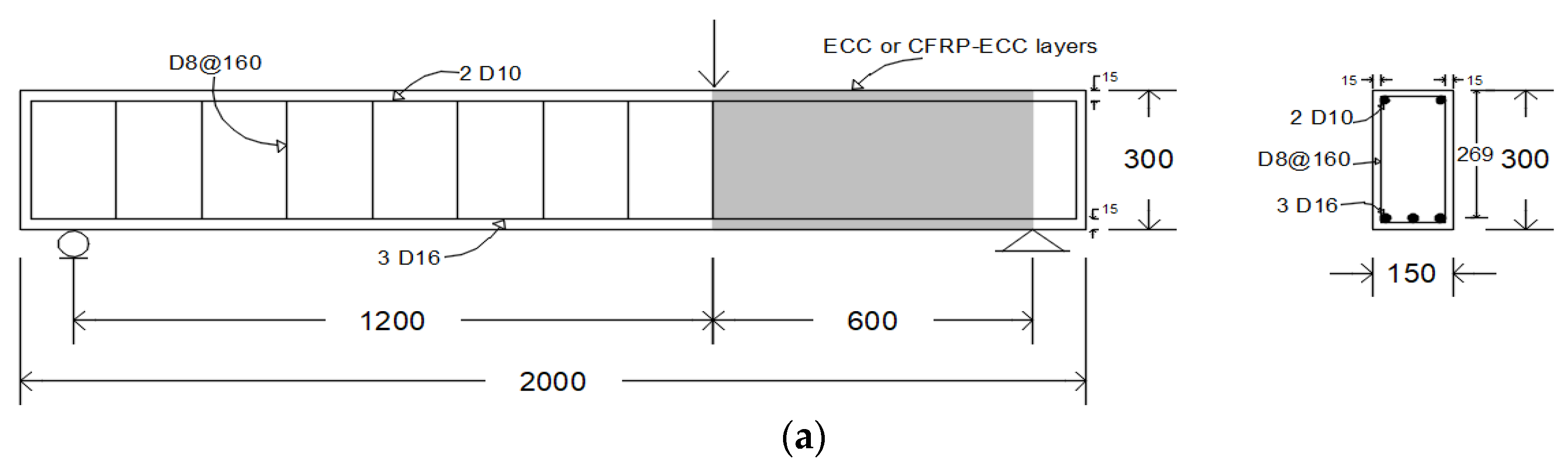

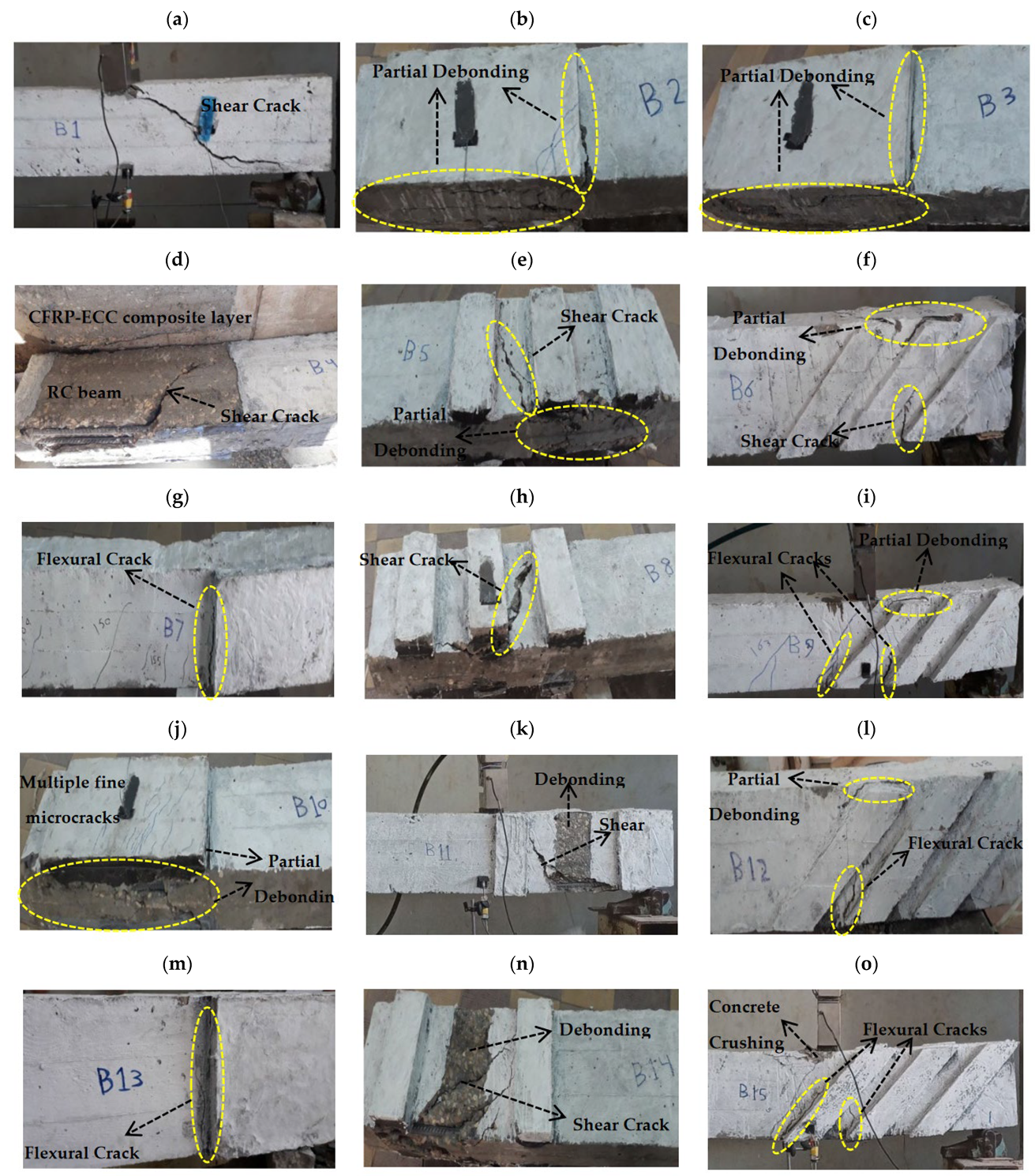

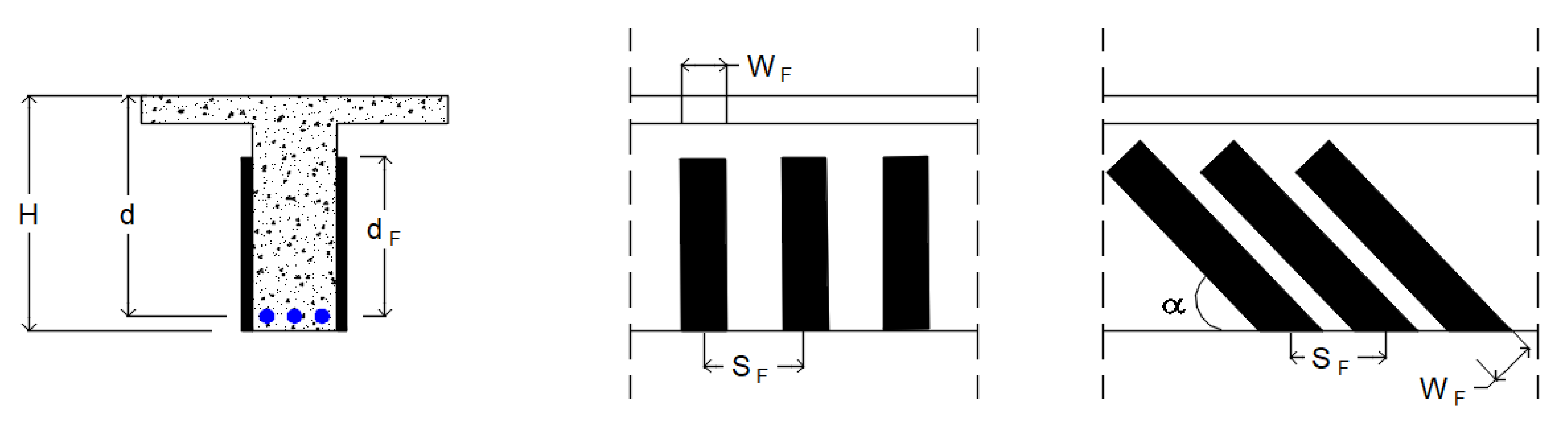

2.2. Details of the Tested Specimens and Investigated Parameters

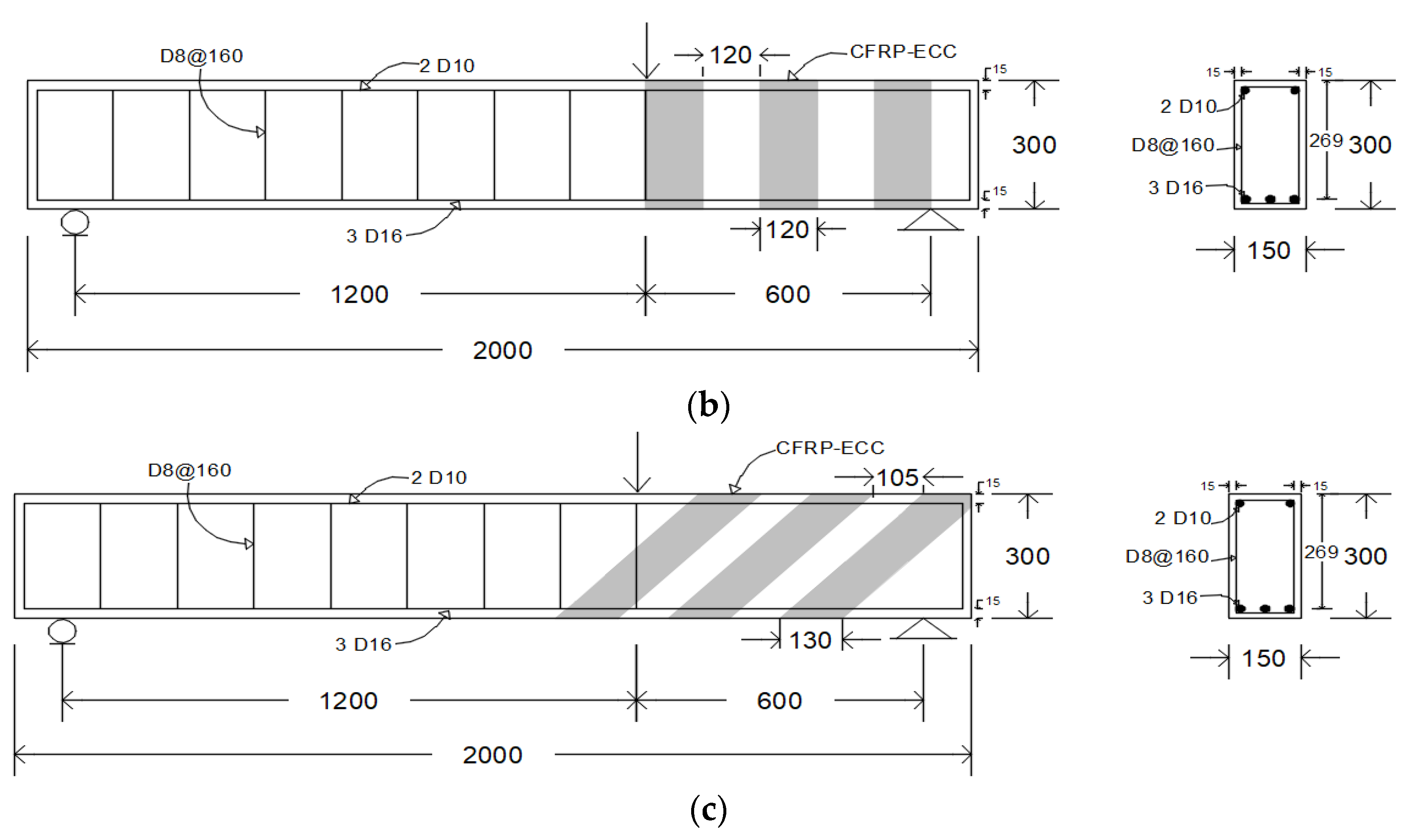

2.3. Strengthening Procedures

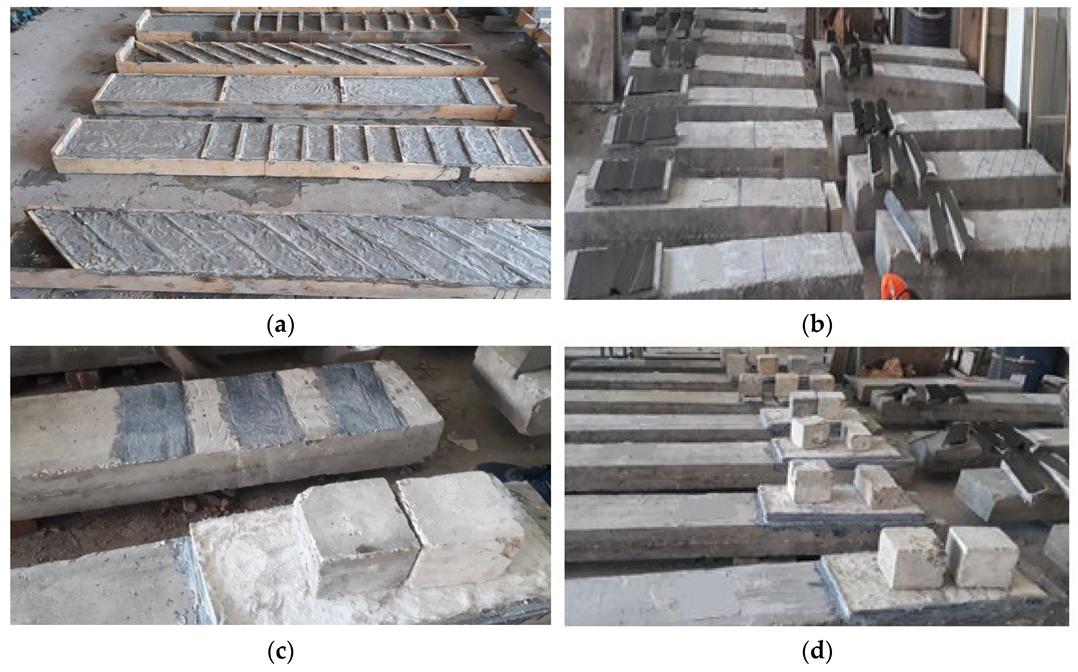

2.4. Test Setup and Instrumentation

3. Test Results and Discussion

3.1. Load Capacities

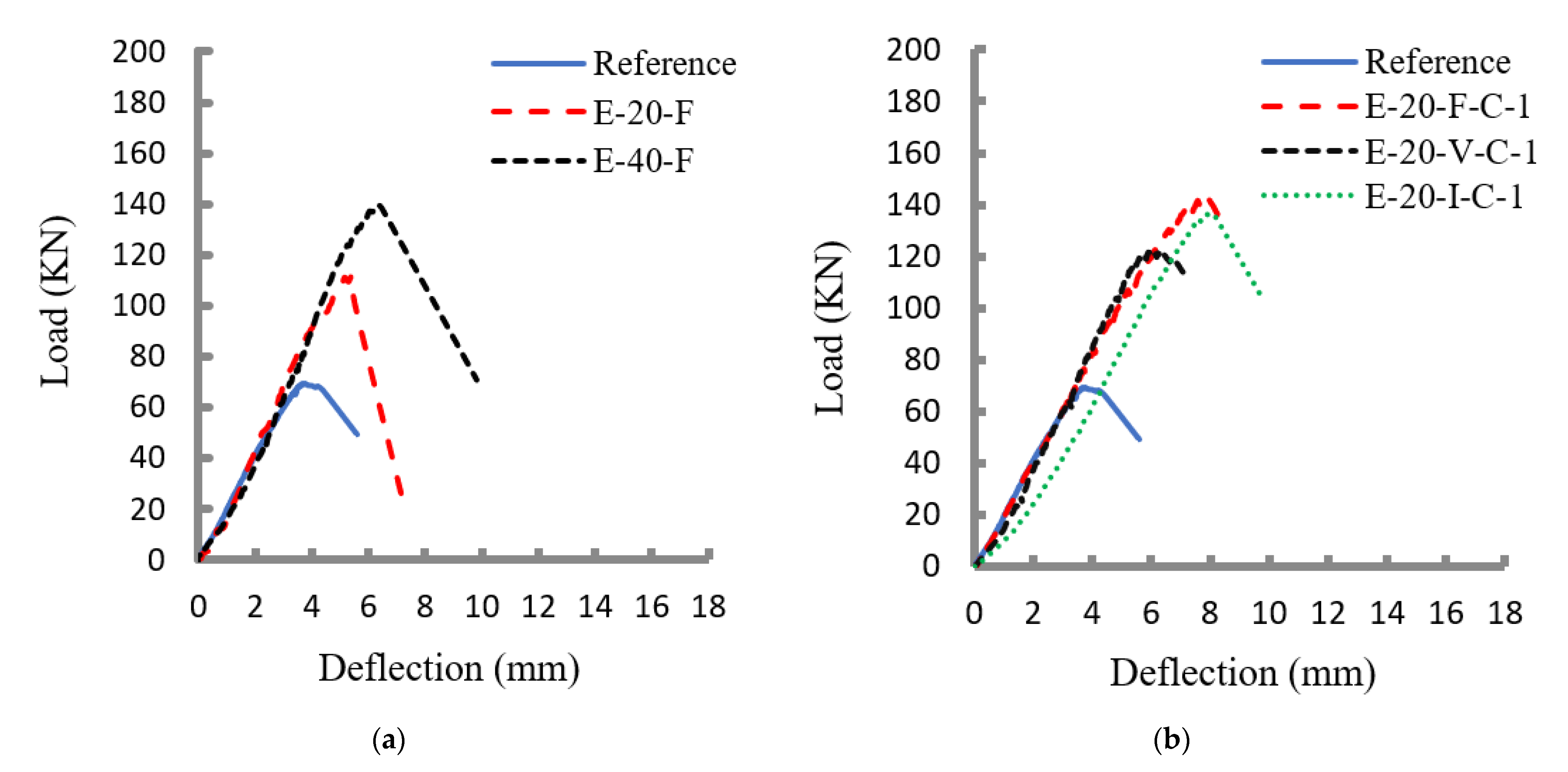

3.2. Load–Deflection Relationships

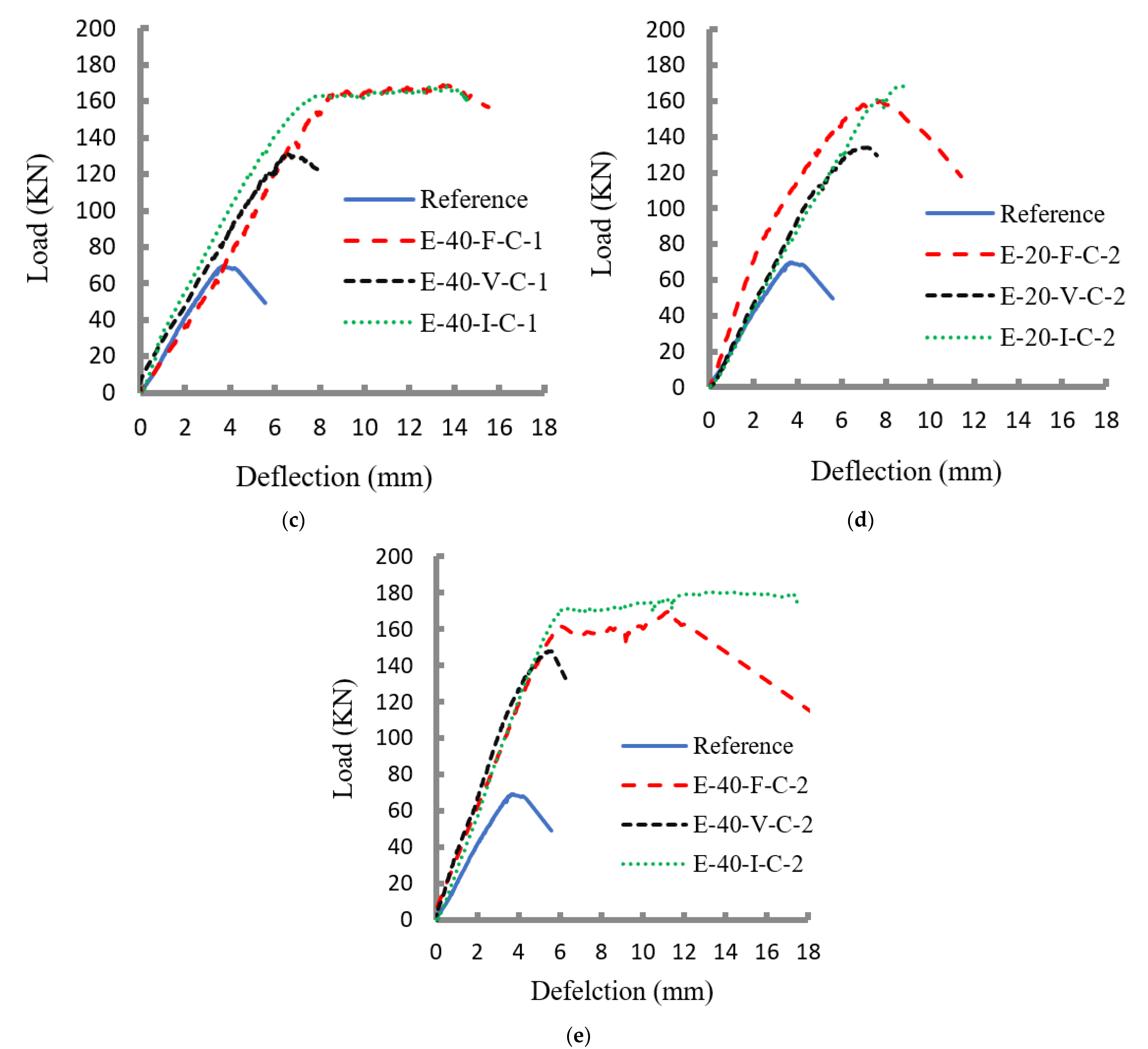

3.3. Modes of Failure

3.4. Ductility

4. Theoretical Code Formulation

4.1. According to ACI 549

4.2. According to ACI 440.2R-17

5. Conclusions

- The CFRP-ECC composites improved the shear capacity of the RC beams with a value ranging from 61.1% to 160.1% compared to the reference specimen.

- The deformation of the strengthened beams was 2.31 times that of the control beam, which demonstrates the higher ductile performance of these beams.

- The common type of failure mode for the strengthened beams was debonding or partial debonding of the strengthening layers ended with shear or flexural cracks. However, for reference one, a clear shear crack failure occurred.

- The fully strengthened configuration for beams in groups G2 and G3 showed more improvements in terms of load capacity with respect to the vertical or inclined schemes. However, the inclined scheme showed the highest values for beams of groups G4 and G5.

- Theoretical analysis using the two code provisions (ACI 549 and ACI 440.2R-17) was recommended to calculate the ultimate load capacity for the tested beams.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jahani, Y.; Baena, M.; Gómez, J.; Barris, C.; Torres, L. Experimental study of the effect of high service temperature on the flexural performance of near-surface mounted (NSM) carbon fiber-reinforced polymer (CFRP)-strengthened concrete beams. Polymers 2021, 13, 920. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Ren, Y.; Li, M.; Hu, P.; Du, M.; Zhang, R. Experimental study on flexural shear strengthening effect on low-strength RC beams by using FRP grid and ECC. Eng. Struct. 2021, 227, 111434. [Google Scholar] [CrossRef]

- Tahmouresi, B.; Momeninejad, K.; Mohseni, E. Flexural response of FRP-strengthened lightweight RC beams: Hybrid bond efficiency of L-shape ribbed bars and NSM technique. Arch. Civ. Mech. Eng. 2022, 22, 95. [Google Scholar] [CrossRef]

- Gao, W.; Dai, J.-G.; Teng, J. Three-level fire resistance design of FRP-strengthened RC beams. J. Compos. Constr. 2018, 22, 05018001. [Google Scholar] [CrossRef]

- Dai, J.-G.; Yokota, H.; Iwanami, M.; Kato, E. Experimental investigation of the influence of moisture on the bond behavior of FRP to concrete interfaces. J. Compos. Constr. 2010, 14, 834–844. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Gao, W.-Y.; Duan, Z.-J.; Bai, Y.-L.; Guo, Y.-C.; Ouyang, L.-J. Axial compressive behavior of polyethylene terephthalate/carbon FRP-confined seawater sea-sand concrete in circular columns. Constr. Build. Mater. 2020, 234, 117383. [Google Scholar] [CrossRef]

- Bournas, D.A.; Pavese, A.; Tizani, W. Tensile capacity of FRP anchors in connecting FRP and TRM sheets to concrete. Eng. Struct. 2015, 82, 72–81. [Google Scholar] [CrossRef]

- Tetta, Z.C.; Bournas, D.A. TRM vs. FRP jacketing in shear strengthening of concrete members subjected to high temperatures. Compos. Part B Eng. 2016, 106, 190–205. [Google Scholar] [CrossRef]

- Wang, X.; Ghiassi, B.; Oliveira, D.V.; Lam, C. Modelling the nonlinear behaviour of masonry walls strengthened with textile reinforced mortars. Eng. Struct. 2017, 134, 11–24. [Google Scholar] [CrossRef]

- Dong, Z.; Dai, J.; Deng, M.; Wu, Z. Experimental study on the mechanical properties of textile reinforced mortar (TRM) composites with different yarn shapes subjected to uniaxial tension. Arch. Civ. Mech. Eng. 2022, 22, 185. [Google Scholar] [CrossRef]

- Truong, B.; Bui, T.; Limam, A.; Larbi, A.S.; Le Nguyen, K.; Michel, M. Experimental investigations of reinforced concrete beams repaired/reinforced by TRC composites. Compos. Struct. 2017, 168, 826–839. [Google Scholar] [CrossRef]

- Yu, Y.-L.; Yin, S.-P.; Na, M.-W. Bending performance of TRC-strengthened RC beams with secondary load under chloride erosion. J. Cent. South Univ. 2019, 26, 196–206. [Google Scholar] [CrossRef]

- Si, Z.; Liu, F.; Pan, J.; Dong, H. Research on Impact Resistance of Reinforced Concrete Beams Strengthened with Carbon Fiber Reinforced Polymer Grid and Engineered Cementitious Composites. Polymers 2022, 14, 1951. [Google Scholar] [CrossRef] [PubMed]

- Wakjira, T.G.; Ebead, U. Hybrid NSE/EB technique for shear strengthening of reinforced concrete beams using FRCM: Experimental study. Constr. Build. Mater. 2018, 164, 164–177. [Google Scholar] [CrossRef]

- Ge, W.; Tang, R.; Wang, Y.; Zhang, Z.; Sun, C.; Yao, S.; Lu, W. Flexural performance of ECC-concrete composite beams strengthened with carbon fiber sheet. Results Eng. 2022, 13, 100334. [Google Scholar] [CrossRef]

- Bournas, D.; Triantafillou, T.; Zygouris, K.; Stavropoulos, F. Textile-reinforced mortar (TRM) versus FRP jacketing in seismic retrofitting of RC columns with continuous or lap-spliced deformed bars. J. Compos. Constr. 2009, 13, 360–371. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Almusallam, T.H.; Alsayed, S.H.; Al-Salloum, Y.A. Flexural strengthening of RC beams using textile reinforced mortar–Experimental and numerical study. Compos. Struct. 2013, 97, 40–55. [Google Scholar] [CrossRef]

- Harajli, M.; ElKhatib, H.; San-Jose, J.T. Static and cyclic out-of-plane response of masonry walls strengthened using textile-mortar system. J. Mater. Civ. Eng. 2010, 22, 1171–1180. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Papanicolaou, C.G. Shear strengthening of reinforced concrete members with textile reinforced mortar (TRM) jackets. Mater. Struct. 2006, 39, 93–103. [Google Scholar] [CrossRef]

- Brückner, A.; Ortlepp, R.; Curbach, M. Anchoring of shear strengthening for T-beams made of textile reinforced concrete (TRC). Mater. Struct. 2008, 41, 407–418. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; Elsanadedy, H.M.; Alsayed, S.H.; Iqbal, R.A. Experimental and numerical study for the shear strengthening of reinforced concrete beams using textile-reinforced mortar. J. Compos. Constr. 2012, 16, 74–90. [Google Scholar] [CrossRef]

- Azam, R.; Soudki, K. FRCM strengthening of shear-critical RC beams. J. Compos. Constr. 2014, 18, 04014012. [Google Scholar] [CrossRef]

- Tzoura, E.; Triantafillou, T. Shear strengthening of reinforced concrete T-beams under cyclic loading with TRM or FRP jackets. Mater. Struct. 2016, 49, 17–28. [Google Scholar] [CrossRef]

- ACI Committee. ACI 549.4 R-13: Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) Systems for Repair and Strengthening Concrete and Masonry Structures. In Proceedings of the American Concrete Institute, Phoenix, AZ, USA, 20–24 October 2013. [Google Scholar]

- Elsanadedy, H.M.; Abbas, H.; Almusallam, T.H.; Al-Salloum, Y.A. Organic versus inorganic matrix composites for bond-critical strengthening applications of RC structures–State-of-the-art review. Compos. Part B Eng. 2019, 174, 106947. [Google Scholar] [CrossRef]

- Dai, J.-G.; Munir, S.; Ding, Z. Comparative study of different cement-based inorganic pastes towards the development of FRIP strengthening technology. J. Compos. Constr. 2014, 18, A4013011. [Google Scholar] [CrossRef]

- Ding, Z.; Dai, J.-G.; Muner, S. Study on an improved phosphate cement binder for the development of fiber-reinforced inorganic polymer composites. Polymers 2014, 6, 2819–2831. [Google Scholar] [CrossRef]

- Zhang, D.; Ueda, T.; Furuuchi, H. Average crack spacing of overlay-strengthened RC beams. J. Mater. Civ. Eng. 2011, 23, 1460–1472. [Google Scholar] [CrossRef]

- Mansur, M.A.; Ong, K.C.G. Shear strength of ferrocement beams. Am. Concr. Inst. Struct. J. 1987, 84, 10–17. [Google Scholar]

- Li, V.C.; Mishra, D.K.; Naaman, A.E.; Wight, J.K.; LaFave, J.M.; Wu, H.-C.; Inada, Y. On the shear behavior of engineered cementitious composites. Adv. Cem. Based Mater. 1994, 1, 142–149. [Google Scholar] [CrossRef]

- Yu, K.-Q.; Yu, J.-T.; Dai, J.-G.; Lu, Z.-D.; Shah, S.P. Development of ultra-high performance engineered cementitious composites using polyethylene (PE) fibers. Constr. Build. Mater. 2018, 158, 217–227. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q. Matrix tailoring of Engineered Cementitious Composites (ECC) with non-oil-coated, low tensile strength PVA fiber. Constr. Build. Mater. 2018, 161, 420–431. [Google Scholar] [CrossRef]

- Zhang, R.; Matsumoto, K.; Hirata, T.; Ishizeki, Y.; Niwa, J. Shear behavior of polypropylene fiber reinforced ECC beams with varying shear reinforcement ratios. J. JSCE 2014, 2, 39–53. [Google Scholar] [CrossRef]

- Emara, M.; Mohamed, H.A.; Rizk, M.S.; Hu, J.W. Behavior of ECC columns confined using steel wire mesh under axial loading. J. Build. Eng. 2021, 43, 102809. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, M.; Tian, T.; Dong, Z.; Sun, Y.; Zhang, W. Influence of textile grid forms on tensile mechanical behaviors of carbon textile-reinforced composites with polyethylene (PE) short fibers. Arch. Civ. Mech. Eng. 2023, 23, 103. [Google Scholar] [CrossRef]

- Pyo, S.; El-Tawil, S. Capturing the strain hardening and softening responses of cementitious composites subjected to impact loading. Constr. Build. Mater. 2015, 81, 276–283. [Google Scholar] [CrossRef]

- Ranade, R.; Li, V.C.; Stults, M.D.; Heard, W.F.; Rushing, T.S. Composite Properties of High-Strength, High-Ductility Concrete. ACI Mater. J. 2013, 110, 413–422. [Google Scholar] [CrossRef]

- Ranade, R.; Li, V.C.; Stults, M.D.; Rushing, T.S.; Roth, J.; Heard, W.F. Micromechanics of high-strength, high-ductility concrete. ACI Mater. J. 2013, 110, 375. [Google Scholar]

- Yang, X.; Gao, W.-Y.; Dai, J.-G.; Lu, Z.-D.; Yu, K.-Q. Flexural strengthening of RC beams with CFRP grid-reinforced ECC matrix. Compos. Struct. 2018, 189, 9–26. [Google Scholar] [CrossRef]

- Ranade, R.; Li, V.C.; Heard, W.F. Tensile rate effects in high strength-high ductility concrete. Cem. Concr. Res. 2015, 68, 94–104. [Google Scholar] [CrossRef]

- Cheung, Y.N. Investigation of Concrete Components with a Pseudo-Ductile Layer. Ph.D. Thesis, Hong Kong University of Science and Technology, Hong Kong, China, 2004. [Google Scholar]

- Li, Q.; Xu, S. Experimental investigation and analysis on flexural performance of functionally graded composite beam crack-controlled by ultrahigh toughness cementitious composites. Sci. China Ser. E Technol. Sci. 2009, 52, 1648–1664. [Google Scholar] [CrossRef]

- Ge, W.-J.; Ashour, A.F.; Ji, X.; Cai, C.; Cao, D.-F. Flexural behavior of ECC-concrete composite beams reinforced with steel bars. Constr. Build. Mater. 2018, 159, 175–188. [Google Scholar] [CrossRef]

- Wang, G.; Zhu, F.; Yang, C. Experimental study on Shear behaviors of RC beams strengthened with ECC layers. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Chengdu, China, 13–15 December 2019; p. 042024. [Google Scholar]

- Yang, X.; Gao, W.-Y.; Dai, J.-G.; Lu, Z.-D. Shear strengthening of RC beams with FRP grid-reinforced ECC matrix. Compos. Struct. 2020, 241, 112120. [Google Scholar] [CrossRef]

- 6892-1; Metallic Materials-Tensile Testing—Part 1: Method of Test at Room Temperature. International Organization for Standardization: Geneva, Switzerland, 2009.

- SikaWrap®-300 C | FRP Fabrics. Available online: https://egy.sika.com/en/construction/structural-bonding/structural-strengthening/frp-fabrics/sikawrap-300-c.html (accessed on 20 June 2022).

- Sikadur®-330 | FRP Fabrics. Available online: https://egy.sika.com/en/construction/structural-bonding/structural-strengthening/frp-fabrics/sikadur-330.html (accessed on 20 June 2022).

- ACI-ASCE Committee. Recent Approaches to Shear Design of Structural Concrete. J. Struct. Eng. 1998, 124, 1375–1417. [Google Scholar] [CrossRef]

- Sharaky, I.; Mohamed, H.A.; Torres, L.; Emara, M. Flexural behavior of rubberized concrete beams strengthened in shear using welded wire mesh. Compos. Struct. 2020, 247, 112485. [Google Scholar] [CrossRef]

- Bakis, C.; Ganjehlou, A.; Kachlakev, D.; Schupack, M.; Balaguru, P.N.; Gee, D.; Karbhari, V.; Scott, D.; Ballinger, C.; Gentry, R. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. In Reported by ACI Committee; ACI: Farmington Hills, MI, USA, 2002; Volume 440. [Google Scholar]

- Younis, A.; Ebead, U.; Shrestha, K.C. Different FRCM systems for shear-strengthening of reinforced concrete beams. Constr. Build. Mater. 2017, 153, 514–526. [Google Scholar] [CrossRef]

- ACI Committee. Building Code Requirements for Structural Concrete (ACI 318-08) and Commentary; ACI: Farmington Hills, MI, USA, 2008. [Google Scholar]

| Material | Cement | Fly Ash | Fine Aggregate | Coarse Aggregate | Water | HRWR * | PP Fibers | W/C |

|---|---|---|---|---|---|---|---|---|

| RC | 360 | ---- | 670 | 1277 | 151 | ---- | ---- | 0.42 |

| ECC | 877 | 598 | ---- | ---- | 420 | 12 | 16.5 | 0.48 |

| Specimen | Compressive Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

| 1 | 67.5 | 7.16 |

| 2 | 67 | 5.57 |

| 3 | 62.5 | 5.73 |

| Mean | 65.67 | 6.15 |

| Steel | Yield Strength Fy (MPa) | Ultimate Strength Fu (MPa) | Ultimate/Yield Strength | Modulus of Elasticity Es (GPa) |

|---|---|---|---|---|

| Stirrups | 299 | 458 | 1.53 | 196 |

| Main reinforcement | 509 | 688 | 1.35 | 200 |

| Material | Area Density (Kg/m2) | Nominal Thickness (mm) | Tensile Strength (MPa) | Elongation (%) | Elasticity Modulus (GPa) |

|---|---|---|---|---|---|

| SikaWrap®-300 C | 0.304 | 0.167 | 4000 | 1.7% | 230 |

| Group | Specimen | ECC Thickness (mm) | Matrix | CFRP Layers | Strengthening Scheme |

|---|---|---|---|---|---|

| Control | Reference | ---- | ---- | ---- | ---- |

| G1 | E-20-F | 20 | ECC | ---- | Full |

| E-40-F | 40 | ECC | ---- | Full | |

| G2 | E-20-F-C-1 | 20 | CFRP-ECC | 1 | Full |

| E-20-V-C-1 | 20 | CFRP-ECC | 1 | Vertical strips | |

| E-20-I-C-1 | 20 | CFRP-ECC | 1 | Inclined strips | |

| G3 | E-40-F-C-1 | 40 | CFRP-ECC | 1 | Full |

| E-40-V-C-1 | 40 | CFRP-ECC | 1 | Vertical strips | |

| E-40-I-C-1 | 40 | CFRP-ECC | 1 | Inclined strips | |

| G4 | E-20-F-C-2 | 20 | CFRP-ECC | 2 | Full |

| E-20-V-C-2 | 20 | CFRP-ECC | 2 | Vertical strips | |

| E-20-I-C-2 | 20 | CFRP-ECC | 2 | Inclined strips | |

| G5 | E-40-F-C-2 | 40 | CFRP-ECC | 2 | Full |

| E-40-V-C-2 | 40 | CFRP-ECC | 2 | Vertical strips | |

| E-40-I-C-2 | 40 | CFRP-ECC | 2 | Inclined strips |

| Group | Specimen | Pcr (kN) | Δcr (mm) | Py (kN) | Δy (mm) | Pu (kN) | Δu (mm) | DI | Mode of Failure |

|---|---|---|---|---|---|---|---|---|---|

| Control | Reference | 47.90 | 2.36 | 65.00 | 3.40 | 69.48 | 3.76 | 1.10 | Shear |

| G1 | E-20-F | 53.60 | 2.51 | 96.47 | 4.46 | 111.90 | 5.40 | 1.21 | P. D |

| E-40-F | 69.77 | 3.23 | 116.00 | 4.90 | 139.70 | 6.30 | 1.28 | P. D + Shear | |

| G2 | E-20-F-C-1 | 62.25 | 3.09 | 127.80 | 6.43 | 143.00 | 7.90 | 1.23 | D + Shear |

| E-20-V-C-1 | 62.48 | 3.11 | 112.50 | 5.21 | 122.50 | 6.31 | 1.21 | P. D in strips + Shear | |

| E-20-I-C-1 | 61.07 | 3.98 | 105.40 | 5.97 | 136.80 | 7.96 | 1.33 | P. D in strips + Shear | |

| G3 | E-40-F-C-1 | 83.20 | 4.34 | 135.00 | 6.63 | 168.80 | 13.50 | 2.04 | Flexural under the load |

| E-40-V-C-1 | 80.61 | 3.61 | 112.80 | 5.20 | 131.20 | 6.56 | 1.26 | P. D in strips + Shear | |

| E-40-I-C-1 | 75.42 | 2.82 | 127.30 | 5.24 | 168.20 | 13.48 | 2.57 | P. D in strips + Flexural | |

| G4 | E-20-F-C-2 | 83.55 | 2.48 | 139.50 | 5.37 | 159.90 | 7.73 | 1.44 | P. D + Shear |

| E-20-V-C-2 | 70.66 | 3.04 | 112.50 | 4.95 | 134.20 | 6.91 | 1.40 | D in strips + Shear | |

| E-20-I-C-2 | 75.97 | 3.40 | 126.80 | 5.77 | 168.60 | 8.70 | 1.51 | P. D in strips + Flexural | |

| G5 | E-40-F-C-2 | 99.67 | 3.33 | 132.80 | 4.61 | 170.30 | 11.43 | 2.48 | Flexural under the load |

| E-40-V-C-2 | 85.34 | 2.53 | 122.30 | 3.76 | 148.20 | 5.41 | 1.44 | D in strips + Shear | |

| E-40-I-C-2 | 81.40 | 2.70 | 140.70 | 4.66 | 180.70 | 13.87 | 2.98 | C.C + P. D in strips + Flexural |

| Group | Specimen | Experimental (Pu) | Theoretical (Pu) ACI 549 [24] | Theoretical (Pu) ACI 440 [51] | ACI 549 [24] | ACI 440 [51] |

|---|---|---|---|---|---|---|

| Control | Reference | 69.48 | ---- | --- | ---- | --- |

| G1 | E-20-F | 111.90 | 91.72 | 91.71 | 1.220 | 1.220 |

| E-40-F | 139.70 | 113.96 | 113.95 | 1.226 | 1.226 | |

| G2 | E-20-F-C-1 | 143.00 | 154.965 | 160.47 | 0.923 | 0.891 |

| E-20-V-C-1 | 122.50 | 120.80 | 117.20 | 1.014 | 1.045 | |

| E-20-I-C-1 | 136.80 | 128.32 | 134.99 | 1.066 | 1.013 | |

| G3 | E-40-F-C-1 | 168.80 | 177.20 | 182.71 | 0.953 | 0.924 |

| E-40-V-C-1 | 131.20 | 134.10 | 130.54 | 0.978 | 1.005 | |

| E-40-I-C-1 | 168.20 | 140.00 | 146.71 | 1.200 | 1.146 | |

| G4 | E-20-F-C-2 | 159.90 | 218.20 | 183.39 | 0.733 | 0.872 |

| E-20-V-C-2 | 134.20 | 158.70 | 128.66 | 0.846 | 1.043 | |

| E-20-I-C-2 | 168.6 | 175.41 | 152.92 | 0.961 | 1.103 | |

| G5 | E-40-F-C-2 | 170.30 | 240.40 | 205.63 | 0.710 | 0.828 |

| E-40-V-C-2 | 148.20 | 172.00 | 142.00 | 0.862 | 1.044 | |

| E-40-I-C-2 | 180.70 | 187.14 | 164.64 | 0.966 | 1.098 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Emara, M.; Salem, M.A.; Mohamed, H.A.; Shehab, H.A.; El-Zohairy, A. Shear Strengthening of Reinforced Concrete Beams Using Engineered Cementitious Composites and Carbon Fiber-Reinforced Polymer Sheets. Fibers 2023, 11, 98. https://doi.org/10.3390/fib11110098

Emara M, Salem MA, Mohamed HA, Shehab HA, El-Zohairy A. Shear Strengthening of Reinforced Concrete Beams Using Engineered Cementitious Composites and Carbon Fiber-Reinforced Polymer Sheets. Fibers. 2023; 11(11):98. https://doi.org/10.3390/fib11110098

Chicago/Turabian StyleEmara, Mohamed, Mohamed A. Salem, Heba A. Mohamed, Hamdy A. Shehab, and Ayman El-Zohairy. 2023. "Shear Strengthening of Reinforced Concrete Beams Using Engineered Cementitious Composites and Carbon Fiber-Reinforced Polymer Sheets" Fibers 11, no. 11: 98. https://doi.org/10.3390/fib11110098

APA StyleEmara, M., Salem, M. A., Mohamed, H. A., Shehab, H. A., & El-Zohairy, A. (2023). Shear Strengthening of Reinforced Concrete Beams Using Engineered Cementitious Composites and Carbon Fiber-Reinforced Polymer Sheets. Fibers, 11(11), 98. https://doi.org/10.3390/fib11110098