The Feasibility of Producing Particleboards with Waste Wood from Civil Construction and Epoxidized Waste Cooking Oils

Abstract

:1. Introduction

2. Material and Methods

2.1. Material

2.2. Methods

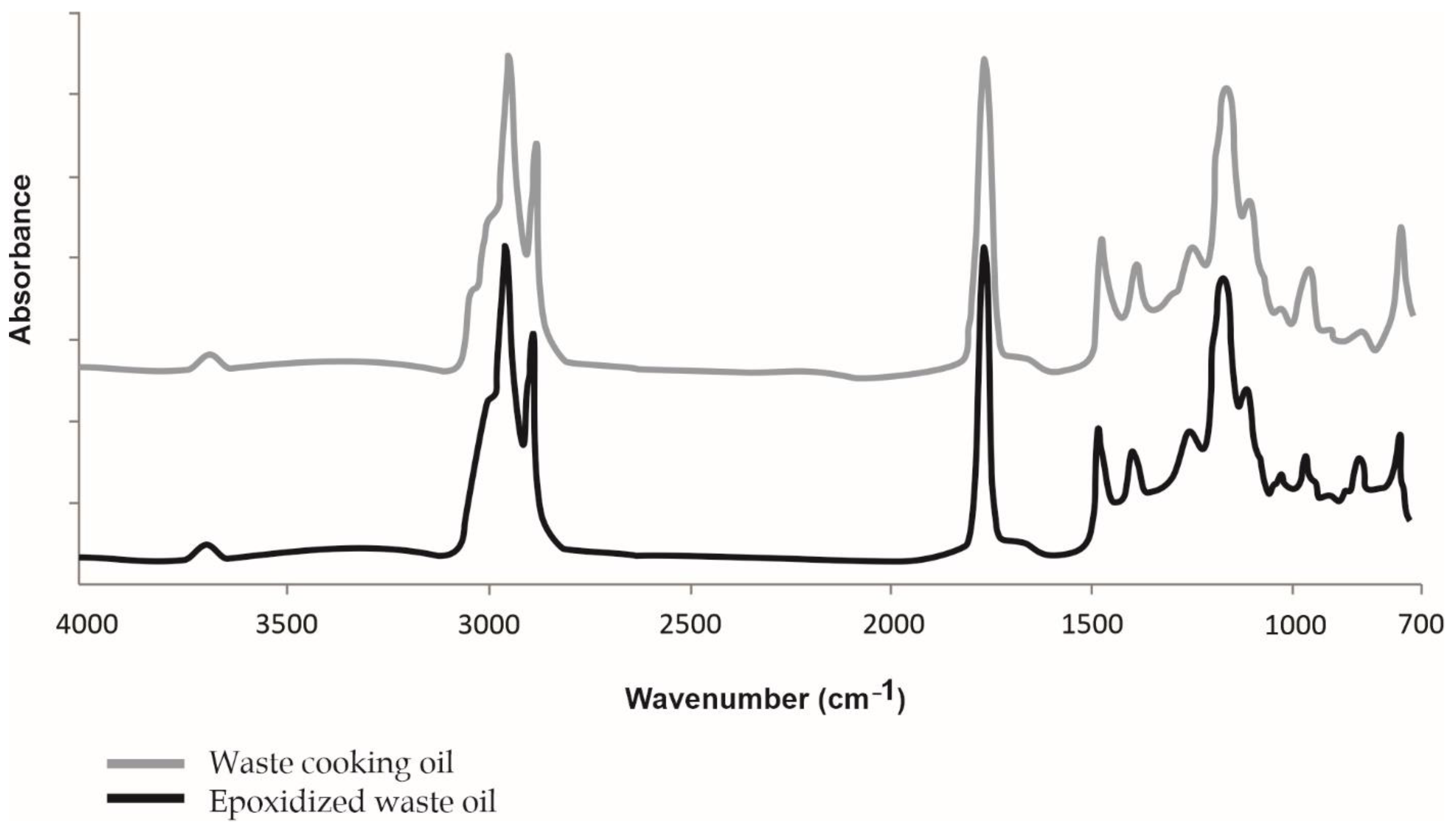

2.2.1. Epoxidation of Waste Cooking Oil and Characterization of the Epoxidized Oil

2.2.2. Preparation and Characterization of Waste Wood Particles

2.2.3. Preparation and Characterization of Particleboards

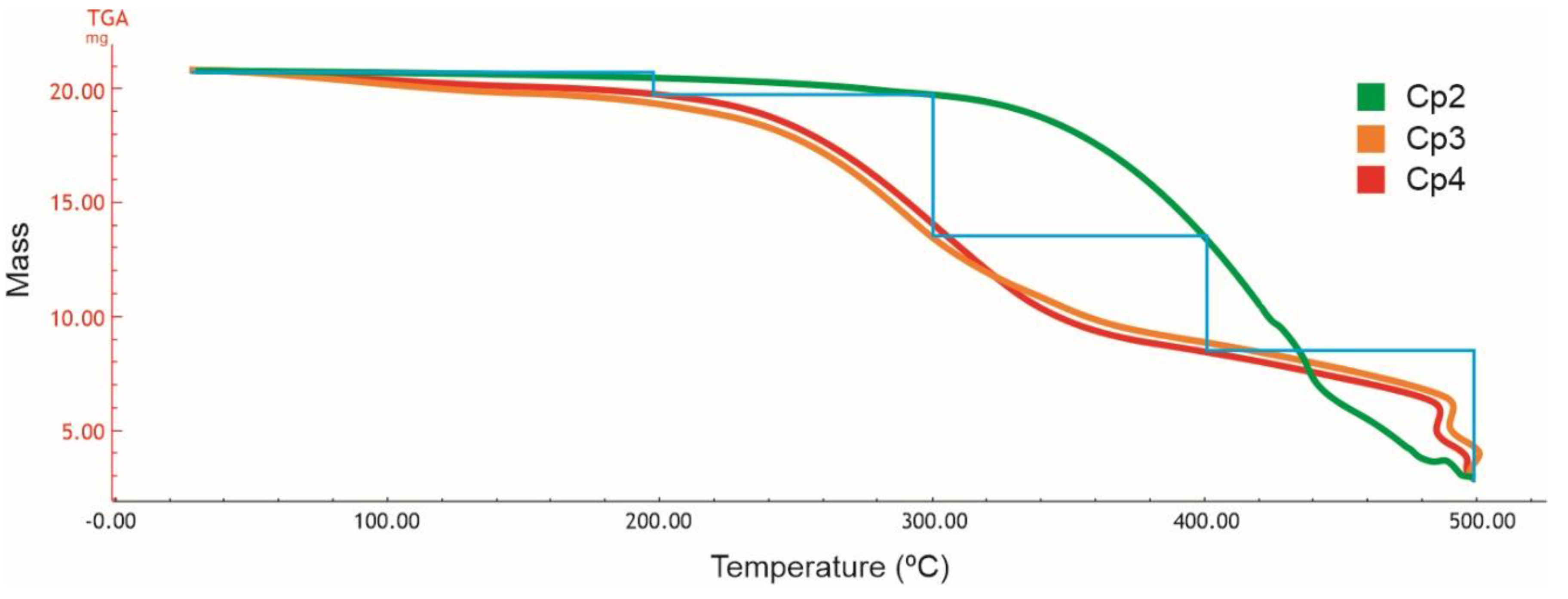

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Silva, V.U.; Nascimento, M.F.; Oliveira, P.R.; Panzera, T.H.; Rezende, M.O.; Silva, D.A.L.; Aquino, V.B.M.; Lahr, F.A.R.; Christoforo, A.L. Circular vs. linear economy of building materials: A case study for particleboards made of recycled wood and biopolymer vs. conventional particleboards. Constr. Build. Mater. 2021, 285, 122906. [Google Scholar] [CrossRef]

- Besserer, A.; Troilo, S.; Girods, P.; Rogaume, Y.; Brosse, N. Cascading Recycling of Wood Waste: A Review. Polymers 2021, 13, 1752. [Google Scholar]

- Kern, A.P.; Amor, L.V.; Angulo, S.C.; Montelongo, A. Factors influencing temporary wood waste generation in high-rise building construction. Waste Manag. 2018, 78, 446–455. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Solomon, S.D., Qin, M., Manning, Z., Chen, M., Marquis, K.B., Averyt, T.M., Miller, H.L., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007; 996p. [Google Scholar]

- Tsai, W.-T.; Wu, P.-H. Environmental Concerns About Carcinogenic Air Toxics Produced from Waste Woods as Alternative Energy Sources. Energy Sources Part A Recovery Util. Environ. Eff. 2013, 35, 725–732. [Google Scholar] [CrossRef]

- Hossain, U.; Poon, C.S. Comparative LCA of wood waste management strategies generated from building construction activities. J. Clean. Prod. 2018, 177, 387–397. [Google Scholar] [CrossRef]

- Pędzik, M.; Auriga, R.; Kristak, L.; Antov, P.; Rogozínski, T. Physical and Mechanical Properties of Particleboard Produced with Addition of Walnut (Juglans regia L.) Wood Residues. Materials 2022, 15, 1280. [Google Scholar] [CrossRef]

- Yang, T.H.; Lin, C.J.; Wang, S.Y.; Tsai, M.J. Characteristics of particleboard made from recycled wood-waste chips impregnated with phenol formaldehyde resin. Build. Environ. 2007, 42, 189–195. [Google Scholar] [CrossRef]

- Felix, A.L.; Narciso, C.R.P.; Lima, F.S.; Mendes, R.F.; Mendes, L.M.; Scolforo, J.R.S. Use of Waste Wood for Particleboard Production. Key Eng. Mater. 2015, 668, 375–380. [Google Scholar] [CrossRef]

- Wang, L.; Chen, S.S.; Tsang, D.C.W.; Poon, C.S.; Shih, K. Value-added recycling of construction waste wood into noise and thermal insulating cement-bonded particleboards. Constr. Build. Mater. 2016, 125, 316–325. [Google Scholar] [CrossRef]

- Astari, L.; Prasetiyo, K.W.; Suryanegara, L. Properties of Particleboard Made from Wood Waste with Various Size. IOP Conf. Ser. Earth Environ. Sci. 2018, 166, 012004. [Google Scholar] [CrossRef] [Green Version]

- Azambuja, R.R.; Castro, V.G.; Trianoski, R.; Iwakiri, S. Recycling wood waste from construction and demolition to produce particleboards. Maderas Cienc. Tecnol. 2018, 20, 681–690. [Google Scholar] [CrossRef]

- Azambuja, R.R.; Castro, V.G.; Trianoski, R.; Iwakiri, S. Utilization of construction and demolition waste for particleboard production. J. Build. Eng. 2018, 20, 488–492. [Google Scholar] [CrossRef]

- Laskowska, A.; Mamiński, M. Properties of particleboard produced from post-industrial UF- and PF-bonded plywood. Eur. J. Wood Prod. 2018, 76, 427–435. [Google Scholar] [CrossRef] [Green Version]

- Souza, A.M.; Nascimento, M.F.; Almeida, D.H.; Lopes Silva, D.A.L.; Almeida, T.H.; Christoforo, A.L.; Lahr, F.A.R. Wood-based composite made of wood waste and epoxy based ink-waste as adhesive: A cleaner production alternative. J. Clean. Prod. 2018, 193, 549–562. [Google Scholar] [CrossRef]

- Iždinský, J.; Vidholdová, Z.; Reinprecht, L. Particleboards from Recycled Wood. Forests 2020, 11, 1166. [Google Scholar] [CrossRef]

- Khan, M.U.; Abas, M.; Noor, S.; Salah, B.; Saleem, W.; Khan, R. Experimental and Statistical Analysis of Saw Mill Wood Waste Composite Properties for Practical Applications. Polymers 2021, 13, 4038. [Google Scholar] [CrossRef]

- Mandal, M.; Begum, P.; Deka, R.C.; Maji, T.K. Wood flour thermoset composites using chemically modified epoxidized soybean oil. Eur. J. Wood Prod. 2019, 77, 569–580. [Google Scholar] [CrossRef]

- Uppal, N.; Pappu, A.; Gowri, V.K.S.; Thakur, V.K. Cellulosic fibres-based epoxy composites: From bioresources to a circular economy. Ind. Crops Prod. 2022, 182, 114895. [Google Scholar] [CrossRef]

- Di Mauro, C.; Malburet, S.; Genua, A.; Graillot, A.; Mija, A. Sustainable Series of New Epoxidized Vegetable Oil-Based Thermosets with Chemical Recycling Properties. Biomacromolecules 2020, 21, 3923–3935. [Google Scholar] [CrossRef]

- Landi, F.F.A.; Fabiani, C.; Castellani, B.; Cotana, F.; Pisello, A.L. Environmental assessment of four waste cooking oil valorization pathways. Waste Manag. 2022, 138, 219–233. [Google Scholar] [CrossRef]

- Orjuela, A.; Clark, J. Green chemicals from used cooking oils: Trends, challenges, and opportunities. Curr. Opin. Green Sustain. Chem. 2020, 26, 100369. [Google Scholar] [CrossRef] [PubMed]

- Foo, W.H.; Koay, S.S.N.; Chia, S.R.; Chia, W.Y.; Tang, D.Y.Y.; Nomanbhay, S.; Chew, K.W. Recent advances in the conversion of waste cooking oil into value-added products: A review. Fuel 2022, 324, 124539. [Google Scholar] [CrossRef]

- Silviana, S.; Anggoro, D.D. Use of Epoxidized Waste Cooking Oil as Bioplasticizer of Sago Starch-Based Biocomposite Reinforced Microfibrillated Cellulose of Bamboo. Adv. Sci. Lett. 2017, 23, 2591–2594. [Google Scholar] [CrossRef]

- Tarazona, E.R.T.; Oliveira, L.S.; Rubio, J.C.; Franca, A.S. Preparation, preliminary characterization and mechanical properties of epoxy composites reinforced with spent coffee grounds. In Proceedings of the 8th International Conference on Mechanical and Aerospace Engineering (ICMAE), Prague, Czech Republic, 22–25 July 2017. [Google Scholar]

- Suzuki, A.H.; Botelho, B.G.; Oliveira, L.S.; Franca, A.S. Sustainable synthesis of epoxidized waste cooking oil and its application as a plasticizer for polyvinyl chloride films. Eur. Polym. J. 2018, 99, 142–149. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Khandelwal, V.; Manik, G. Influence of epoxidized linseed oil and sisal fibers on structure–property relationship of epoxy biocomposite. Polym. Compos. 2018, 39, E2595–E2605. [Google Scholar] [CrossRef]

- Fernandes, F.C.; Kirwan, K.; Lehane, D.; Coles, S.R. Epoxy resin blends and composites from waste vegetable oil. Eur. Polym. J. 2017, 89, 449–460. [Google Scholar] [CrossRef] [Green Version]

- Lage, F.C.; Suzuki, A.H.; Oliveira, L.S. Comparative evaluation of conventional and microwave assisted epoxidation of soybean oil with citric acid, acetic acid using homogeneous and heterogeneous catalysis. Braz. J. Chem. Eng. 2021, 38, 327–340. [Google Scholar] [CrossRef]

- ASTM. D5554-95 Standard Test for Determination of Iodine Value of Fats and Oils; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM. E1252-98 Standard Practice for General Techniques for Obtaining Infrared Spectra for Qualitative Analysis; ASTM International: West Conshohocken, PA, USA, 2021. [Google Scholar]

- ASTM. D 792-8 Standard Test Method for Density and Specific Gravity (Relative Density) of Plastics by Displacement; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ASTM. D3039/D3039M-08 Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Dominguez-Candela, I.; Lerma-Canto, A.; Cardona, S.C.; Lora, J.; Fombuena, V. Physicochemical Characterization of Novel Epoxidized Vegetable Oil from Chia Seed Oil. Materials 2022, 15, 3250. [Google Scholar] [CrossRef]

- Donev, E.; Gandla, M.L.; Jönsson, L.J.; Mellerowicz, E.J. Engineering Non-cellulosic Polysaccharides of Wood for the Biorefinery. Front. Plant Sci. 2018, 9, 1537. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Renard, C.M.G.C.; Bureau, S.; Le Bourvellec, C. Revisiting the contribution of ATR-FTIR spectroscopy to characterize plant cell wall polysaccharides. Carbohydr. Polym. 2021, 262, 117935. [Google Scholar] [CrossRef]

- Coimbra, M.A.; Barros, A.; Rutledge, D.N.; Delgadillo, I. FTIR spectroscopy as a tool for the analysis of olive pulp cell-wall polysaccharide extracts. Carbohydr. Res. 1999, 317, 145–154. [Google Scholar] [CrossRef]

- Deka, H.; Wang, T.; Mohanty, A.K.; Misra, M. Novel Biocomposites from Biobased Epoxy and Corn-Based Distillers Dried Grains (DDG). J. Polym. Environ. 2015, 23, 425–436. [Google Scholar] [CrossRef] [Green Version]

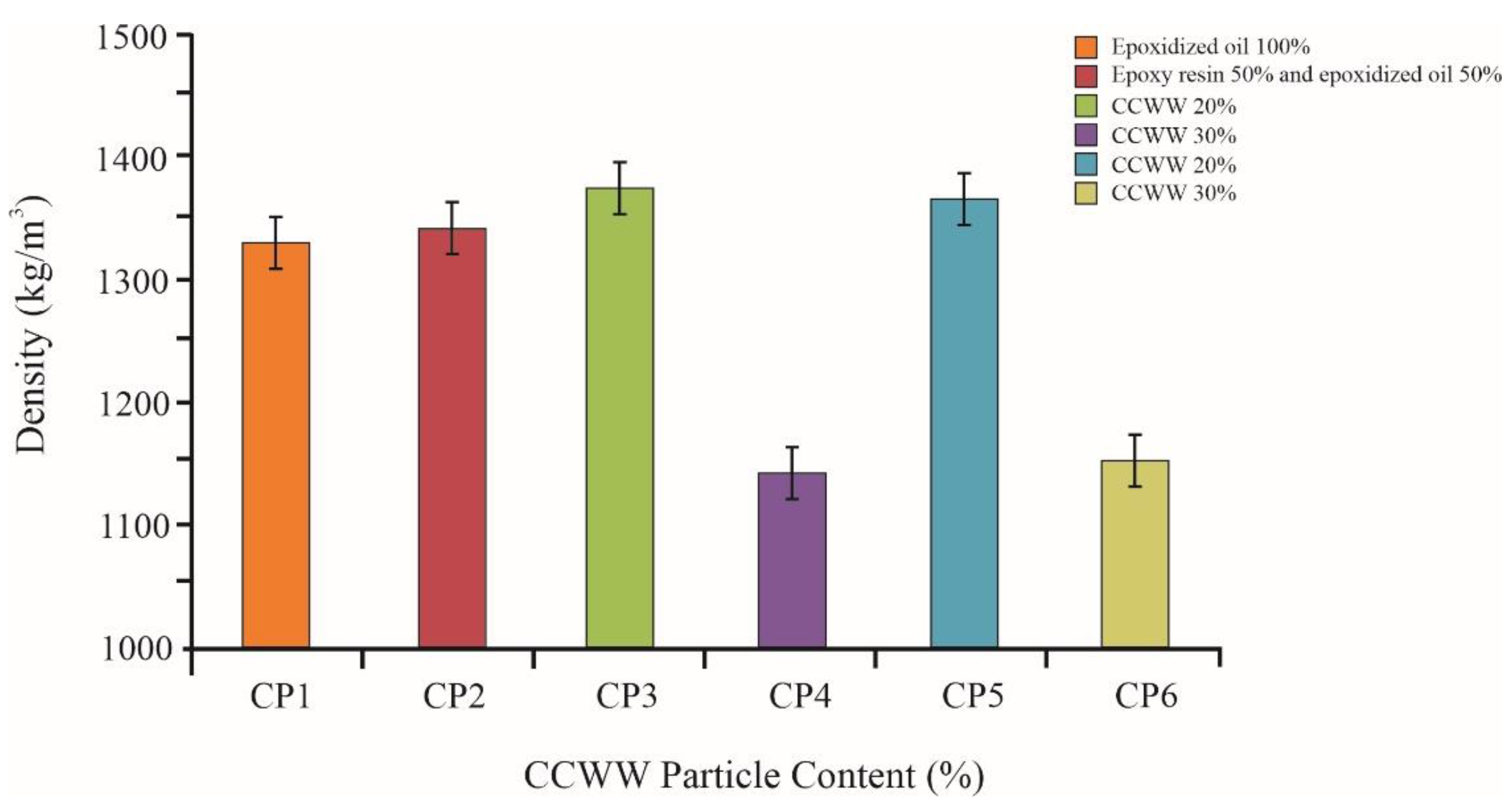

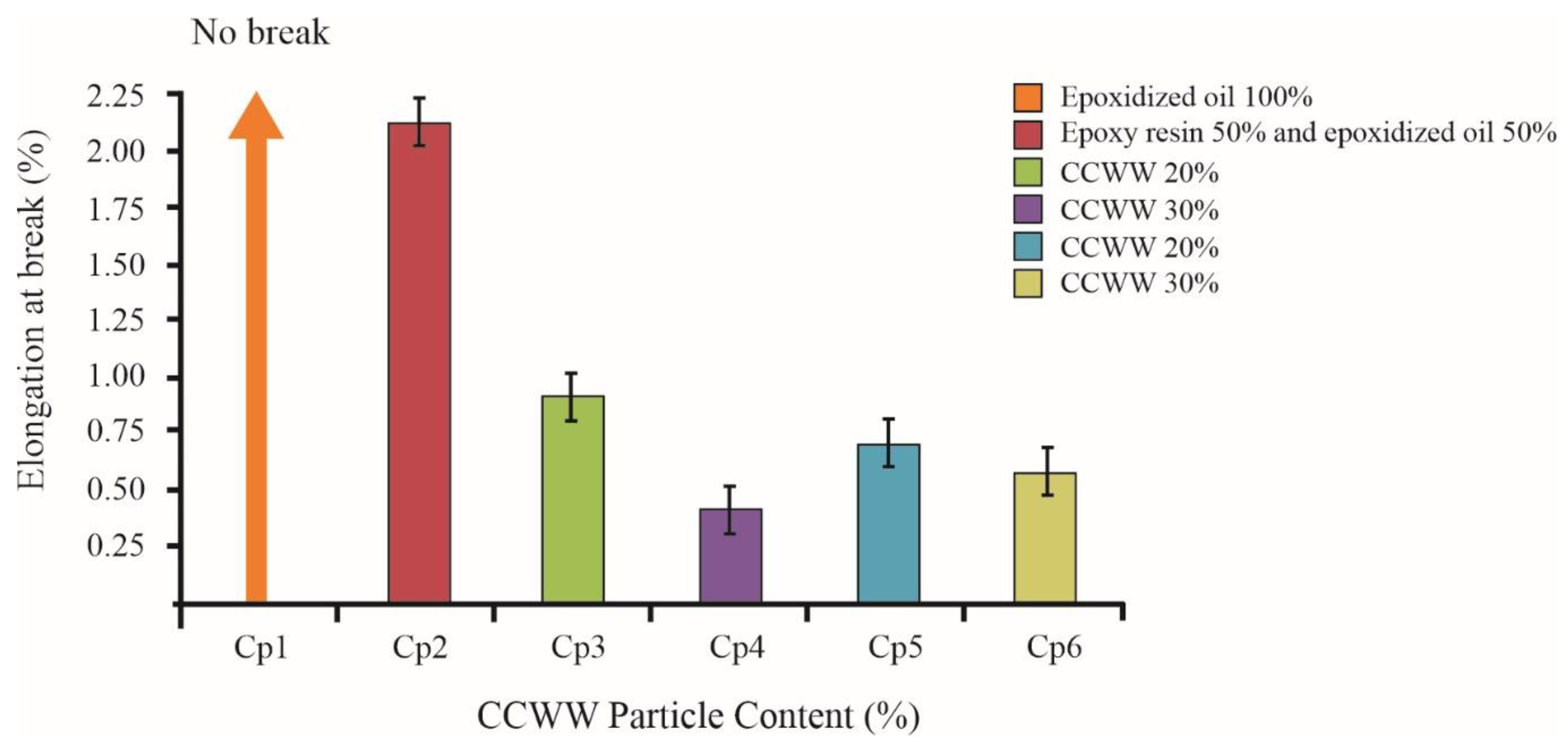

| Specimen | Composition | Content of Epoxidized Oil (%)—DGEBA (%) | Content of CCWW (%) | Particle Diameter ϕ (mm) |

|---|---|---|---|---|

| CP1 | Epoxidized oil | 100–0 | 0 | - |

| CP2 | Epoxy resin and epoxidized oil | 50–50 | 0 | - |

| CP3 | Epoxy resin and epoxidized oil | 50–50 | 20 | >1.0 |

| CP4 | Epoxy resin and epoxidized oil | 50–50 | 30 | >1.0 |

| CP5 | Epoxy resin and epoxidized oil | 50–50 | 20 | 1.0 > ϕ > 0.5 |

| CP6 | Epoxy resin and epoxidized oil | 50–50 | 30 | 1.0 > ϕ > 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cavalcanti, W.M.; de Oliveira, L.S.; Maziero, R.; Campos Rubio, J.C. The Feasibility of Producing Particleboards with Waste Wood from Civil Construction and Epoxidized Waste Cooking Oils. Fibers 2022, 10, 62. https://doi.org/10.3390/fib10080062

Cavalcanti WM, de Oliveira LS, Maziero R, Campos Rubio JC. The Feasibility of Producing Particleboards with Waste Wood from Civil Construction and Epoxidized Waste Cooking Oils. Fibers. 2022; 10(8):62. https://doi.org/10.3390/fib10080062

Chicago/Turabian StyleCavalcanti, Washington Moreira, Leandro Soares de Oliveira, Rômulo Maziero, and Juan Carlos Campos Rubio. 2022. "The Feasibility of Producing Particleboards with Waste Wood from Civil Construction and Epoxidized Waste Cooking Oils" Fibers 10, no. 8: 62. https://doi.org/10.3390/fib10080062

APA StyleCavalcanti, W. M., de Oliveira, L. S., Maziero, R., & Campos Rubio, J. C. (2022). The Feasibility of Producing Particleboards with Waste Wood from Civil Construction and Epoxidized Waste Cooking Oils. Fibers, 10(8), 62. https://doi.org/10.3390/fib10080062