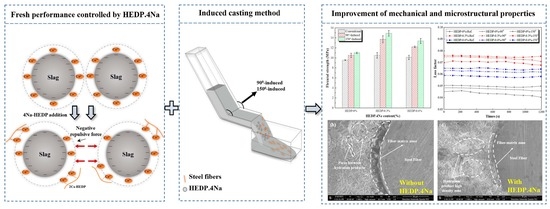

Synergistic Effect of HEDP.4Na and Different Induced Pouring Angles on Mechanical Properties of Fiber-Reinforced Alkali-Activated Slag Composites

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Raw Materials

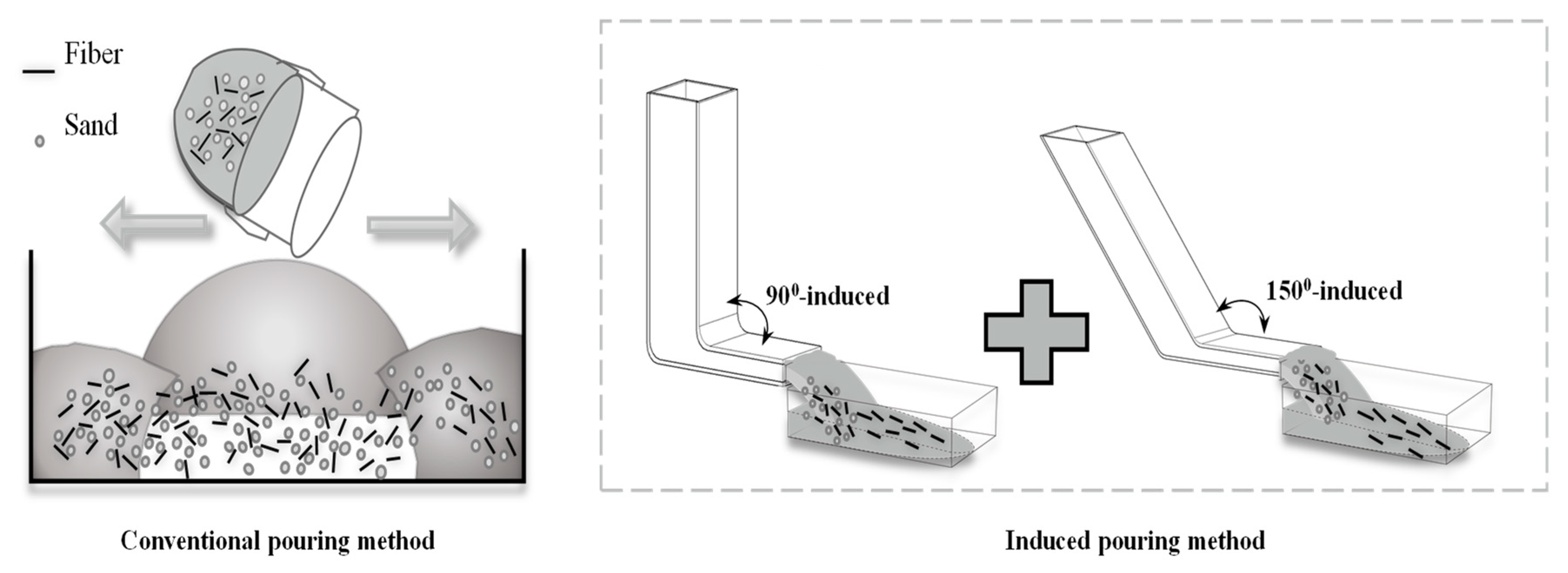

2.2. Mixture Design and Specimen Preparation

2.3. Test Method

2.3.1. Mini-Slump Flow and Setting Time

2.3.2. Compressive and Flexural Strength Test

2.3.3. Dynamic Mechanical Properties Test

2.3.4. Phase Analysis

2.3.5. Heat of Hydration Analysis

2.3.6. Pore Structure Analysis

2.3.7. Scanning Electron Microscopy (SEM) Analysis

3. Results and Discussion

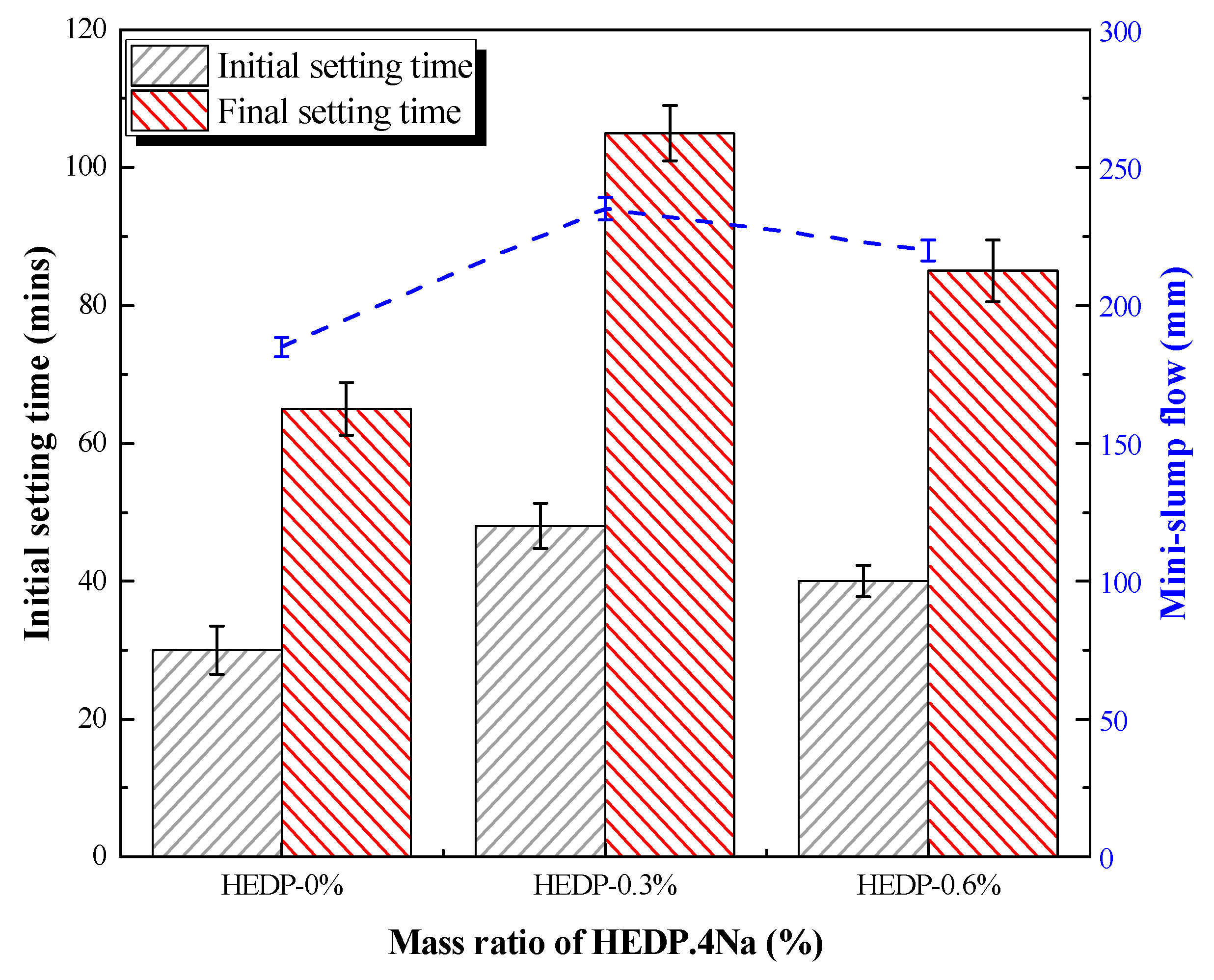

3.1. Setting Time and Mini-Slump Flow of FR-AASC

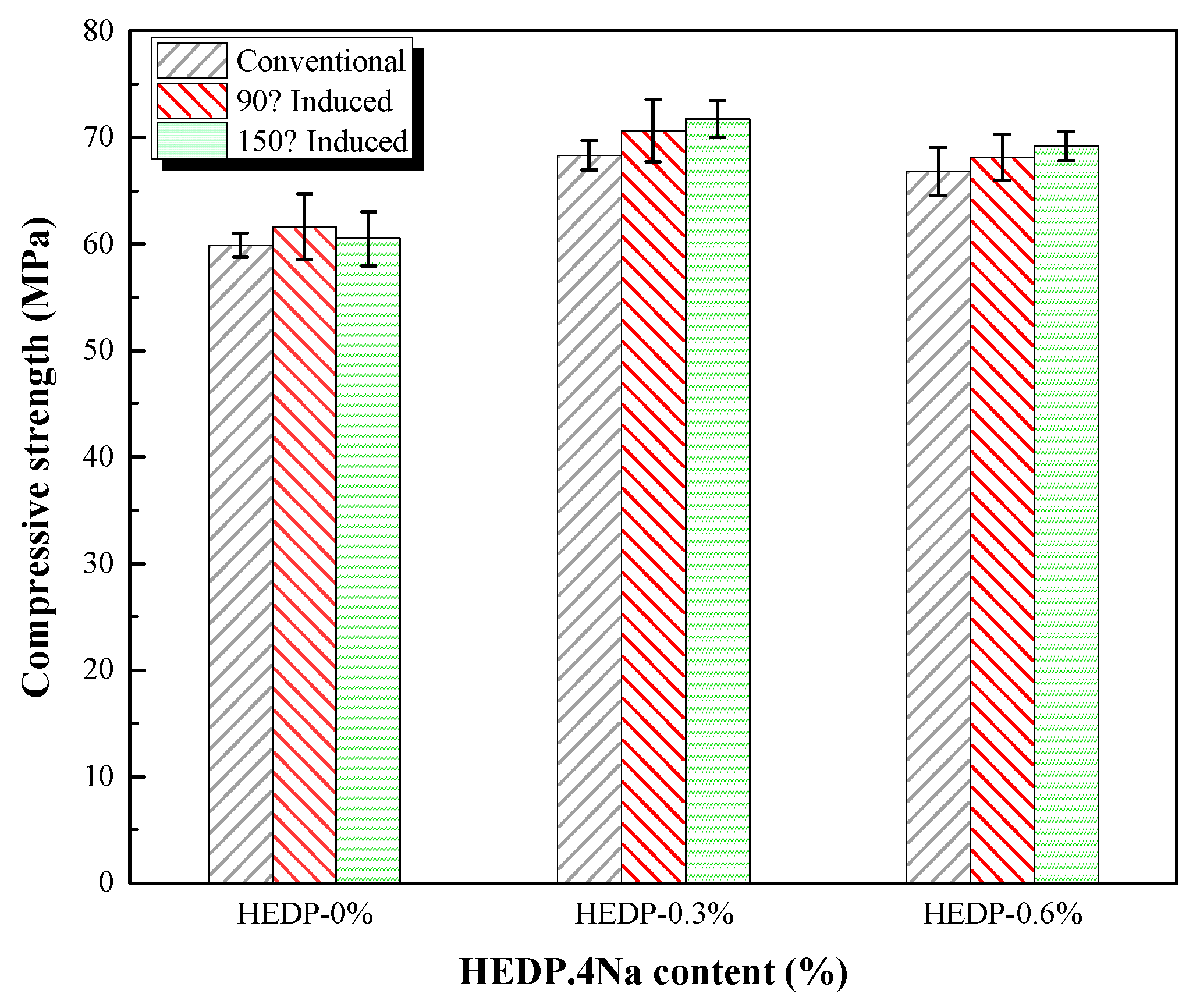

3.2. Compressive Strength of FR-AASC

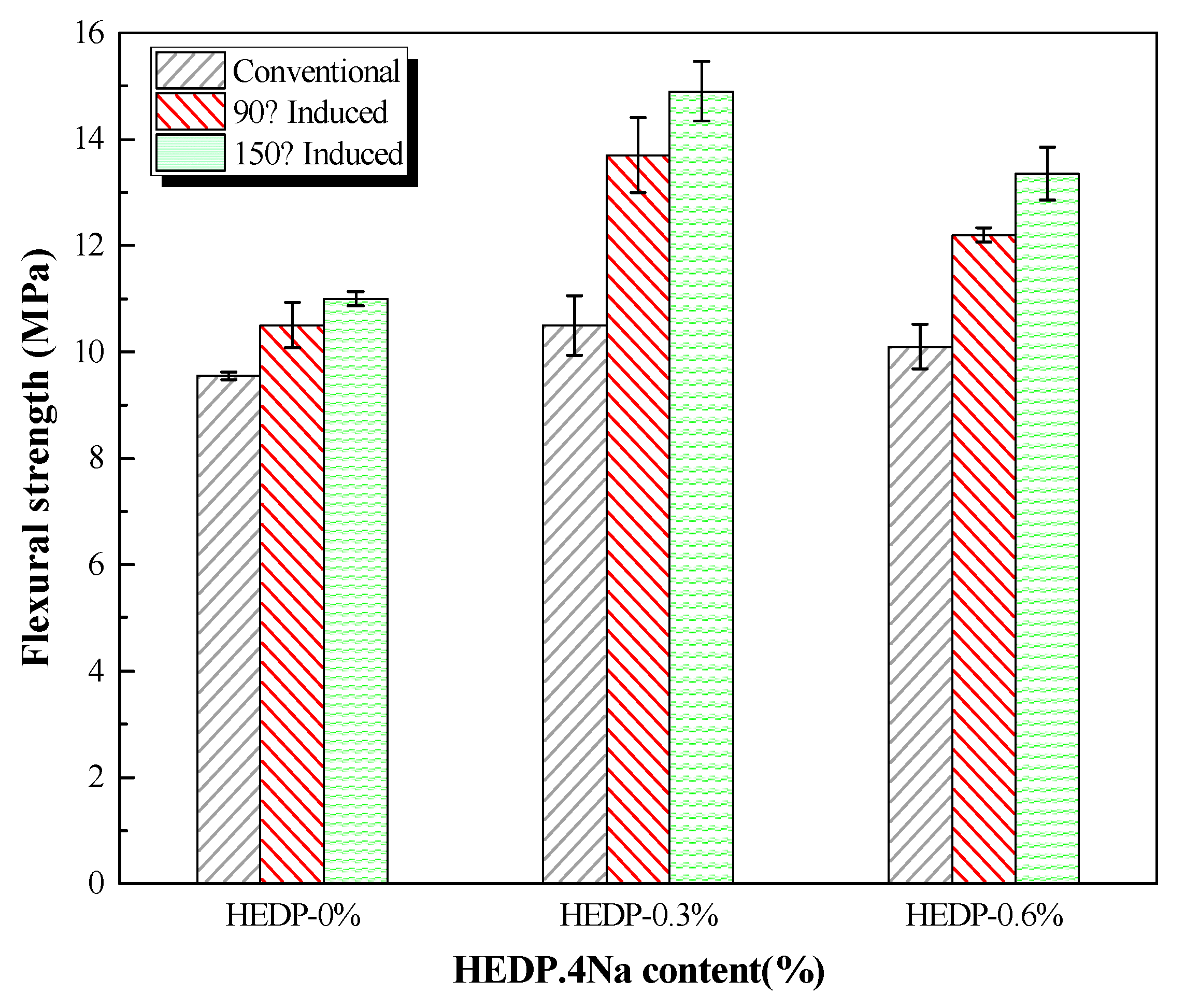

3.3. Flexural Strength of FR-AASC

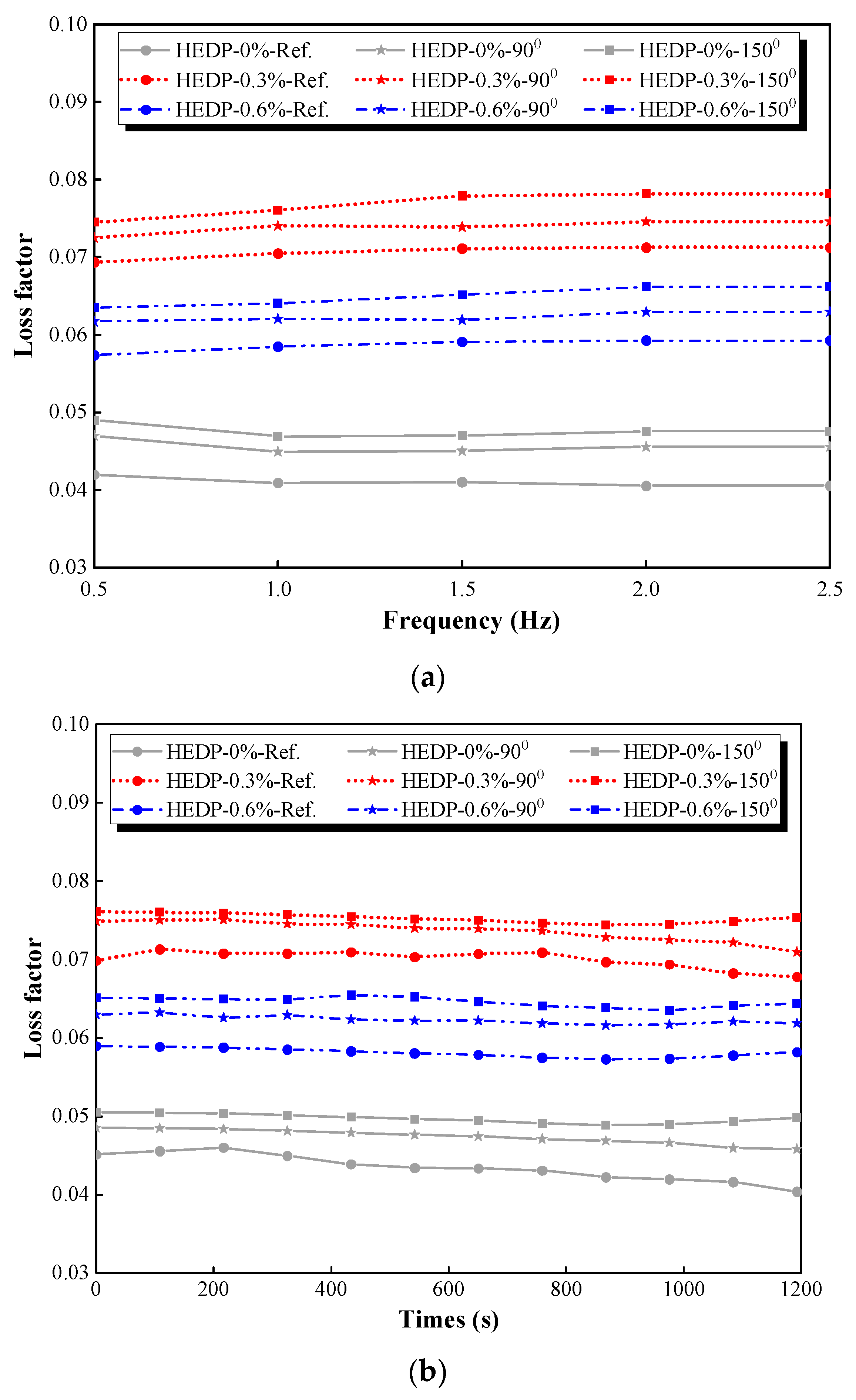

3.4. Loss Factor of FR-AASC

3.5. Storage Modulus of FR-AASC

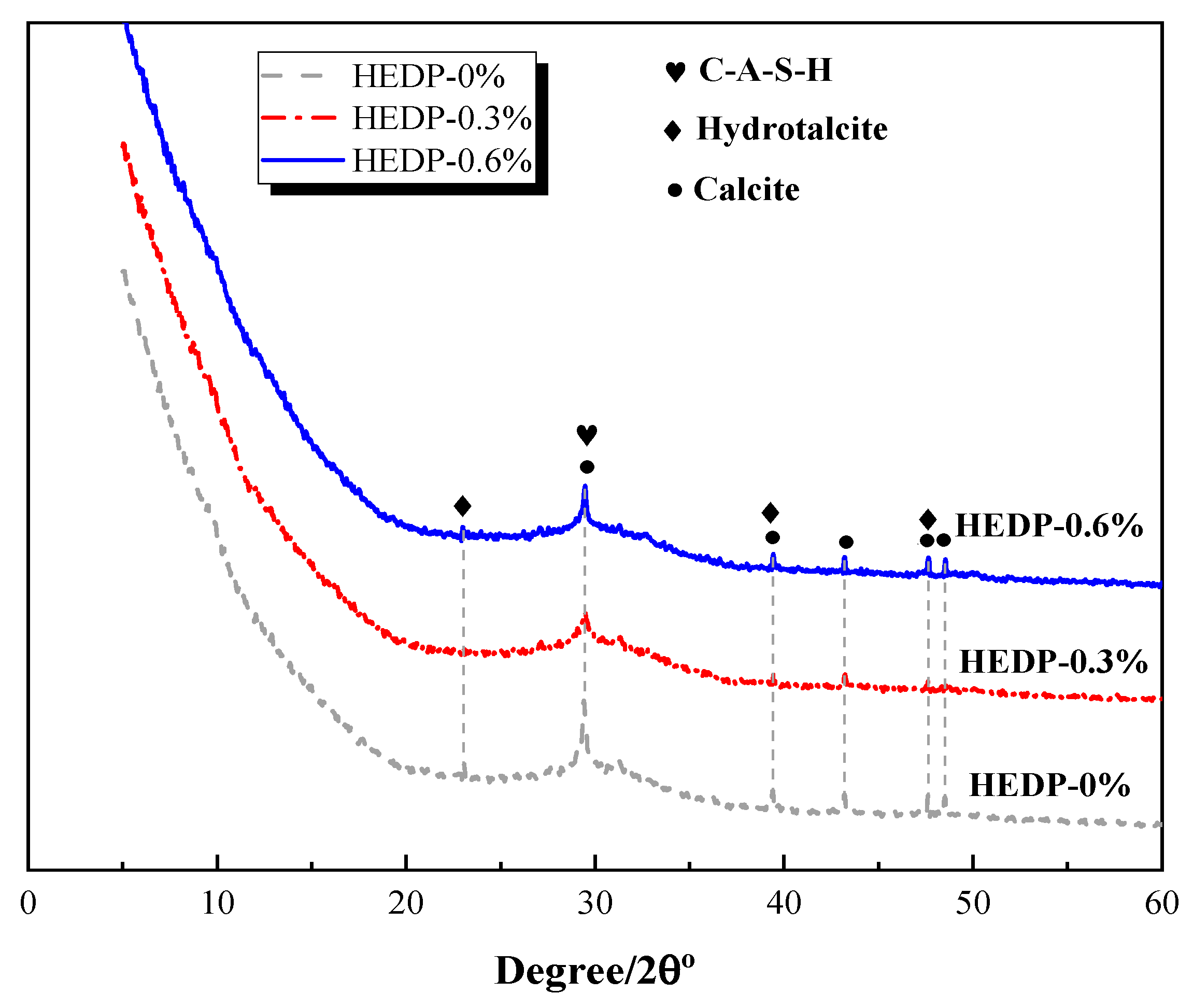

3.6. Phase Analysis

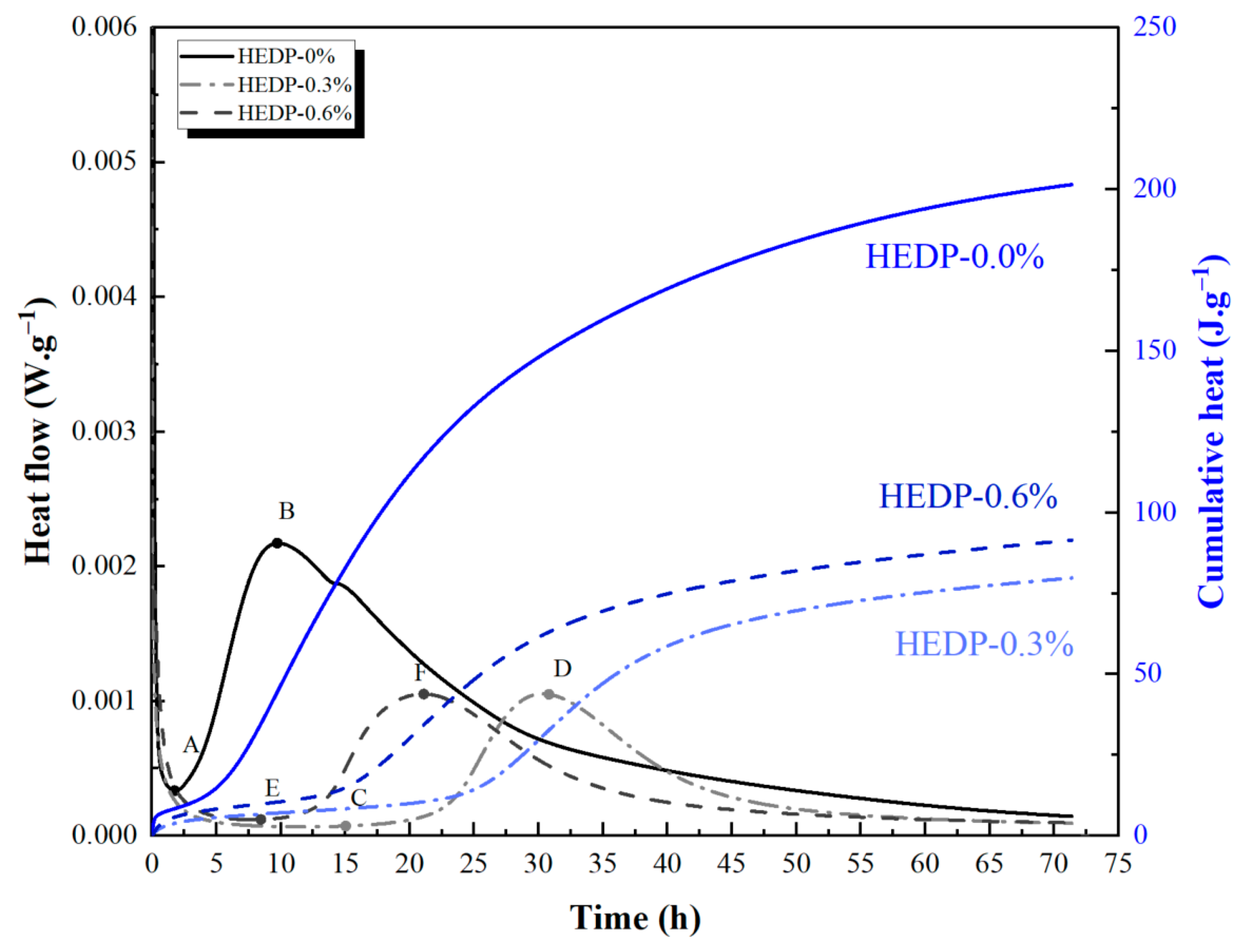

3.7. Heat of Hydration Analysis

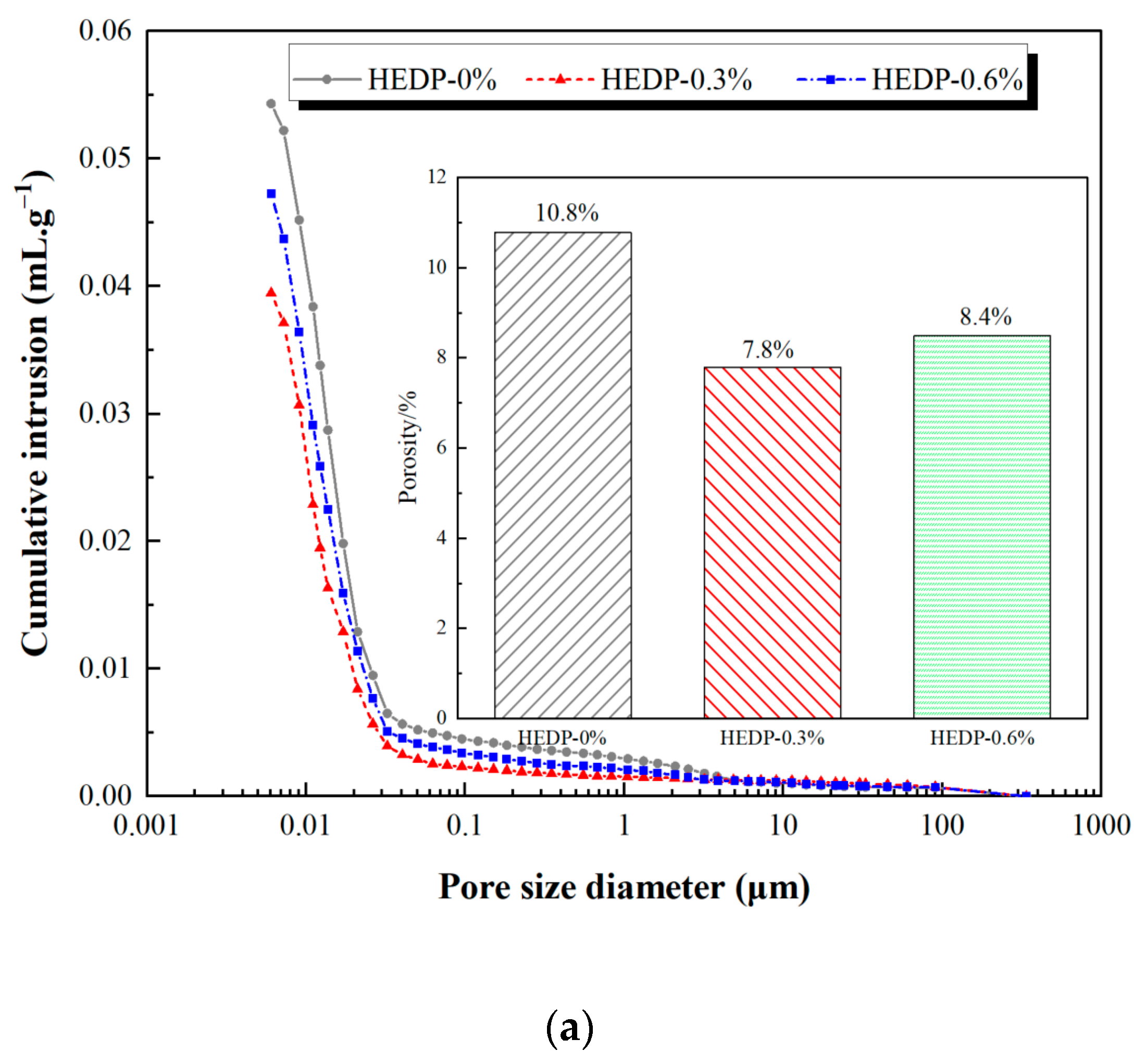

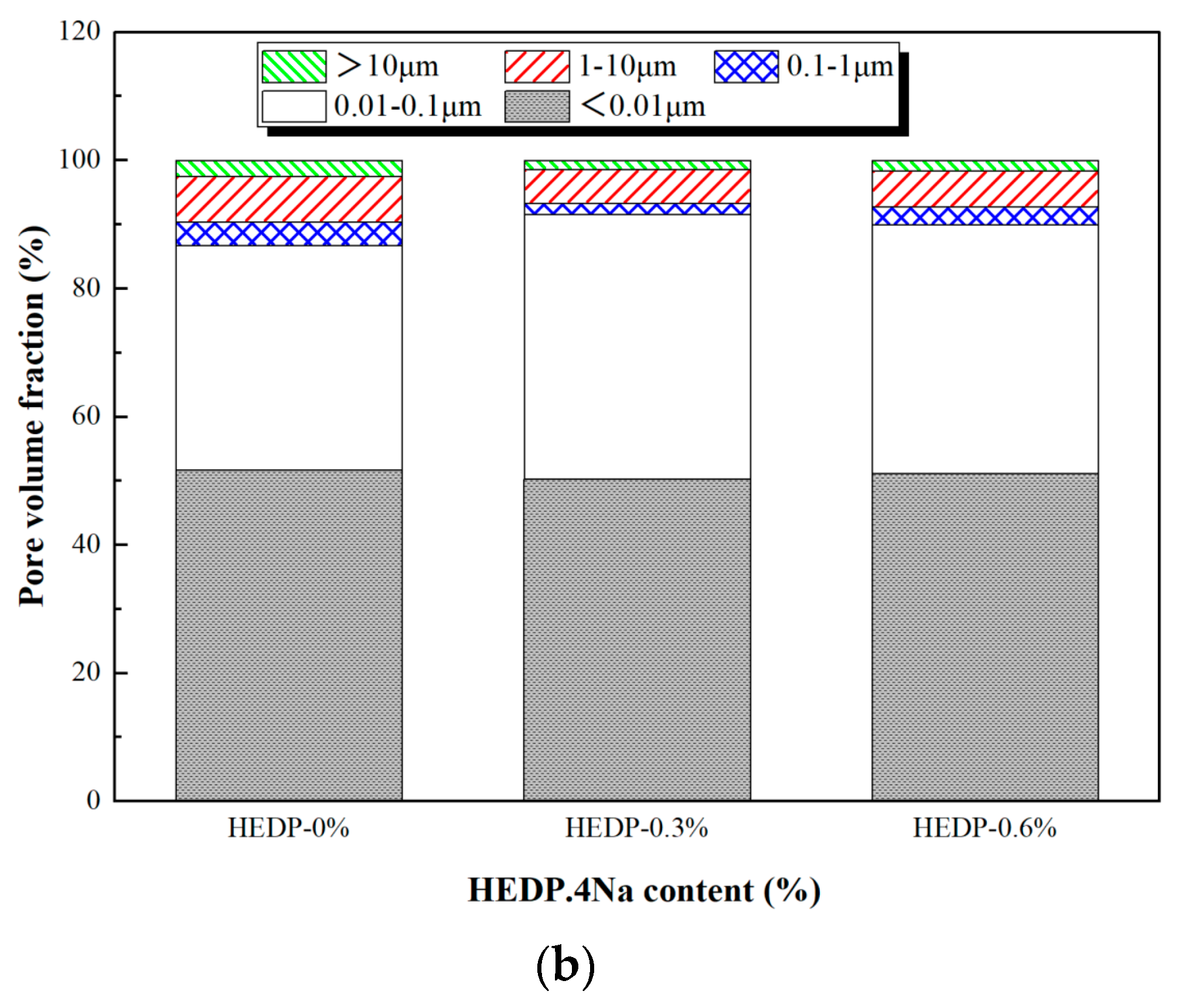

3.8. Pore Structure Analysis

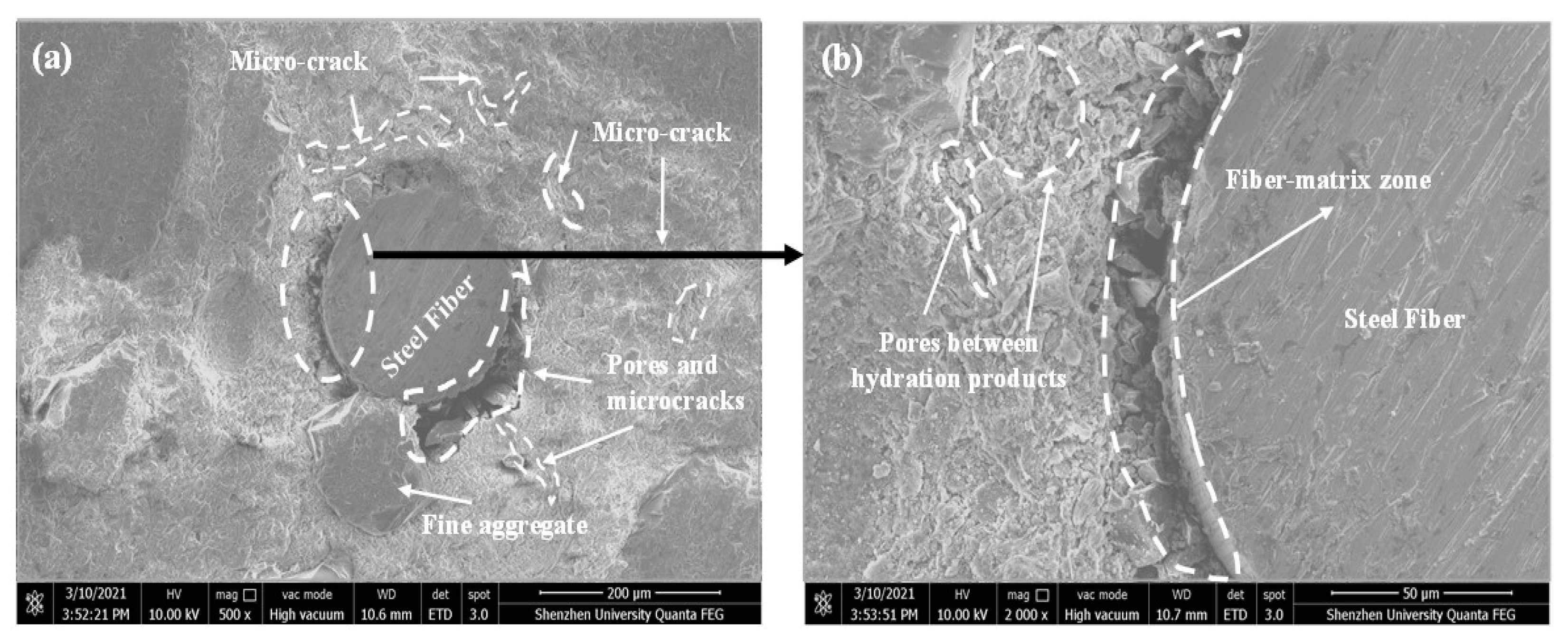

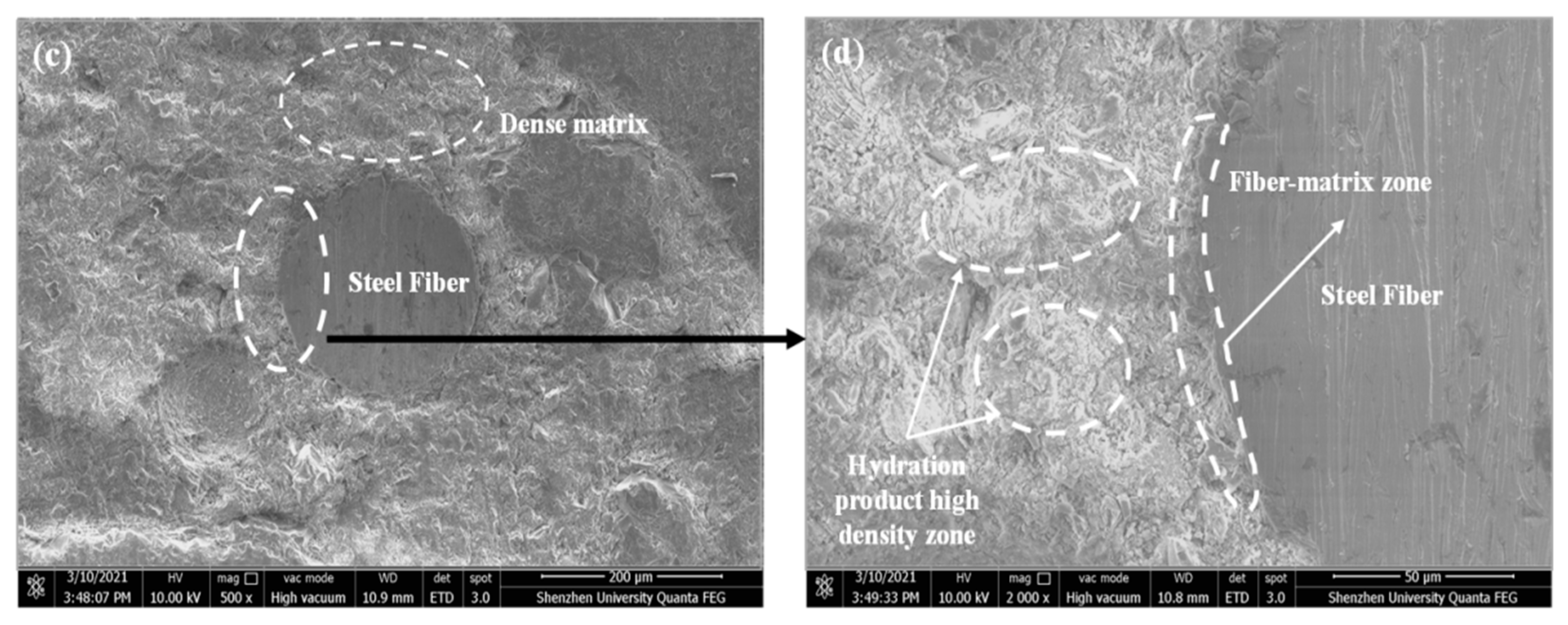

3.9. Scanning Electron Microscopy (SEM) Analysis

4. Conclusions

- (1)

- The FR-AASC sample with HEDP.4Na increased the 28-day compressive and flexural strength by 19% and 17% compared with the control sample. The FR-AASC sample cast by the induced pouring method increased 28-day flexural strength by 42% compared to the sample cast by the conventional method. The synergistic effect of HEDP.4Na and the induced pouring method significantly improved the 28-day flexural strength by 60%.

- (2)

- For a given frequency, the FR-AASC sample with 0.3% and 0.6% HEDP.4Na increased the loss factor by 53% and 30%, respectively, compared to the control group. It was attributed to that HEDP.4Na can modify the fiber–matrix interface transition zone and improve the sliding friction energy dissipation capacity of steel fibers. Compared to the control sample cast by the conventional method, the loss factor of the sample cast by 150°-induced pouring methods increased by 17%. The FR-AASC sample with 0.3% HEDP.4Na cast by the 150°-induced pouring method increased the loss factor by 78% compared with the reference sample prepared with the conventional methodology.

- (3)

- The incorporation of HEDP.4Na and the induced pouring method increased the storage modulus of the FR-AASC matrix. The incorporation of 0.3% HEDP.4Na into samples increased the storage modulus by up to 29% compared with the control sample. Compared to the control sample cast by the conventional method, the storage modulus of FR-AASC samples with HEDP.4Na cast by the 150°-induced pouring method increased by 5.0%.

- (4)

- The use of HEDP.4Na delayed the leaching time of Ca2+ and the growth of C-A-S-H, thereby inhibiting the exothermic reaction of hydration in the first 72 h. The total porosity of the sample with HEDP.4Na slightly decreased, which was attributed to the reduction in the size of the hydration products modified by HEDP.4Na. The high-density region of hydration products near ITZ resulted in an improvement in internal frictional energy dissipation under the external dynamic load.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Prasanna, P.; Srinivasu, K.; Murthy, A.R. Strength and durability of fiber reinforced concrete with partial replacement of cement by ground granulated blast furnace slag. Mater. Today Proc. 2021, 47, 5416–5425. [Google Scholar] [CrossRef]

- Kajaste, R.; Hurme, M. Cement industry greenhouse gas emissions—Management options and abatement cost. J. Clean. Prod. 2016, 112, 4041–4052. [Google Scholar] [CrossRef]

- Lehne, J.; Preston, F. Making Concrete Change Innovation in Low-Carbon Cement and Concrete, Chatham House. Available online: https://policycommons.net/artifacts/1423241/making-concrete-change/2037504/ (accessed on 14 February 2023).

- Staff, G.C. Forty Cement and Concrete Companies Commit to the Global Cement and Concrete Association’s Roadmap to Net Zero. 2021. Available online: https://www.globalcement.com/news/item/13119-forty-cement-and-concrete-companies-commit-to-the-global-cement-and-concrete-association-s-roadmap-to-net-zero (accessed on 14 February 2023).

- American Society of Civil Engineers (ASCE). 2021 Report Card for a Comprehensive Assessment of America’s Infrastructure. 2021. Available online: https://www.infrastructurereportcard.org/wp-content/uploads/2020/12/2021-IRC-Executive-Summary.pdf (accessed on 14 February 2023).

- P.E.C.C. Group. Capturing Value in the U.S. Cement Industry with a Grinding Plant Utilizing Imported Clinker. 2021. Available online: https://www.penta.net/wp-content/uploads/2021/01/PENTA-Cement-Industry-WhitePaper_Jan2021.pdf (accessed on 14 February 2023).

- Rashad, A.; Bai, Y.; Basheer, P.; Collier, N.; Milestone, N. Chemical and mechanical stability of sodium sulfate activated slag after exposure to elevated temperature. Cem. Concr. Res. 2012, 42, 333–343. [Google Scholar] [CrossRef]

- Yang, K.-H.; Song, J.-K.; Song, K.-I. Assessment of CO2 reduction of alkali-activated concrete. J. Clean. Prod. 2013, 39, 265–272. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Chougan, M.; Ghaffar, S.H. Reducing the emission of climate-altering substances in cementitious materials: A comparison between alkali-activated materials and Portland cement-based composites incorporating recycled tire rubber. J. Clean. Prod. 2022, 333, 130013. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Adesina, A.; Sivakrishna, A.; Gobinath, R.; Kumar, K.R.; Srinivas, A. Alkali activated binders: Challenges and opportunities. Mater. Today Proc. 2020, 27, 40–43. [Google Scholar] [CrossRef]

- Wu, Y.; Lu, B.; Bai, T.; Wang, H.; Du, F.; Zhang, Y.; Cai, L.; Jiang, C.; Wang, W. Geopolymer, green alkali activated cementitious material: Synthesis, applications and challenges. Constr. Build. Mater. 2019, 224, 930–949. [Google Scholar] [CrossRef]

- Fang, S.; Lam, E.S.S.; Li, B.; Wu, B. Effect of alkali contents, moduli and curing time on engineering properties of alkali activated slag. Constr. Build. Mater. 2020, 249, 118799. [Google Scholar] [CrossRef]

- Long, W.-J.; Wu, Z.; Khayat, K.H.; Wei, J.; Dong, B.; Xing, F.; Zhang, J. Design, dynamic performance and ecological efficiency of fiber-reinforced mortars with different binder systems: Ordinary Portland cement, limestone calcined clay cement and alkali-activated slag. J. Clean. Prod. 2022, 337, 130478. [Google Scholar] [CrossRef]

- Long, W.-J.; Wei, J.-J.; Gu, Y.-C.; Xing, F. Research on dynamic mechanical properties of alkali activated slag concrete under temperature-loads coupling effects. Constr. Build. Mater. 2017, 154, 687–696. [Google Scholar] [CrossRef]

- Zhu, P.; Kai, G.; Kenan, F.; Sanjayan, J.G.; Wenhui, D.; Collins, F. Damping capacity of fly ash-based geopolymer. In Proceedings of the 18th International Conference on Composite Materials (ICCM18), Jeju Island, South Korea, 21–26 August 2011; The Korean Society for Composite Materials: Jeju Island, South Korea, 2011; pp. 1–5. Available online: http://handle.uws.edu.au:8081/1959.7/547489 (accessed on 14 February 2023).

- Wei, J.; Long, W.-J.; Khayat, K.H.; Dong, B.; Mei, L.; Xing, F. Dynamical properties of environmental high-performance composites with calcined clay. J. Clean. Prod. 2021, 335, 130226. [Google Scholar] [CrossRef]

- Golewski, G.L. A novel specific requirements for materials used in reinforced concrete composites subjected to dynamic loads. Compos. Struct. 2019, 223, 110939. [Google Scholar] [CrossRef]

- Wei, J.; Cheng, B.; Li, L.; Long, W.-J.; Khayat, K.H. Prediction of dynamic mechanical behaviors of coral concrete under different corrosive environments and its enhancement mechanism. J. Build. Eng. 2023, 63, 105507. [Google Scholar] [CrossRef]

- Jinhua, H.; Xing, Z.; Yuanjun, C.; Baisong, Y.; Jian, Z.; Xuemin, W.; Wei, L.; Zhansheng, W.; Ruizhi, Z. Preparation, characterization and application of environment-friendly high density and low damage solid free completion fluids for completing HTHP oil and gas wells. Geoenergy Sci. Eng. 2023, 221, 211351. [Google Scholar] [CrossRef]

- Chi, L.; Lu, S.; Yao, Y. Damping additives used in cement-matrix composites: A review. Compos. Part B Eng. 2019, 164, 26–36. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Abdelgader, H.S.; Murali, G.; Ozbakkaloglu, T.; Lee, Y.H. Fiber-reinforced alkali-activated concrete: A review. J. Build. Eng. 2021, 45, 103638. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Li, L.; Wang, H. Improvement effect of steel fiber orientation control on mechanical performance of UHPC. Constr. Build. Mater. 2018, 188, 709–721. [Google Scholar] [CrossRef]

- Jang, S.-J.; Yun, H.-D. Combined effects of steel fiber and coarse aggregate size on the compressive and flexural toughness of high-strength concrete. Compos. Struct. 2018, 185, 203–211. [Google Scholar] [CrossRef]

- Lee, J.-H.; Cho, B.; Choi, E. Flexural capacity of fiber reinforced concrete with a consideration of concrete strength and fiber content. Constr. Build. Mater. 2017, 138, 222–231. [Google Scholar] [CrossRef]

- Swamy, R.N. Fibre reinforcement of cement and concrete. Mater. Struct. 1975, 8, 235–254. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Teng, L. Fiber alignment and its effect on mechanical properties of UHPC: An overview. Constr. Build. Mater. 2021, 296, 123741. [Google Scholar] [CrossRef]

- Wang, C.; Wei, J.; Long, W.-J.; Dong, B. Review on the effect of fiber orientation distribution on mechanical performance of cement-based composites and its evaluated methods. Mater. Rep. 2022, 36, 20120133. Available online: http://www.mater-rep.com/EN/10.11896/cldb.20120133 (accessed on 14 February 2023).

- Ferrara, L.; Ozyurt, N.; di Prisco, M. High mechanical performance of fibre reinforced cementitious composites: The role of “casting-flow induced” fibre orientation. Mater. Struct. 2011, 44, 109–128. [Google Scholar] [CrossRef]

- Teng, L.; Huang, H.; Khayat, K.H.; Gao, X. Simplified analytical model to assess key factors influenced by fiber alignment and their effect on tensile performance of UHPC. Cem. Concr. Compos. 2021, 127, 104395. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, Y.; Qu, S.; Kumar, A.; Shao, X. Improvement of flexural and tensile strength of layered-casting UHPC with aligned steel fibers. Constr. Build. Mater. 2020, 251, 118893. [Google Scholar] [CrossRef]

- Gou, H.; Zhu, H.; Zhou, H.; Yang, Z. Reinforcement mechanism of orientally distributed steel fibers on ultra-high-performance concrete. Constr. Build. Mater. 2021, 281, 122646. [Google Scholar] [CrossRef]

- Teng, L.; Huang, H.; Du, J.; Khayat, K.H. Prediction of fiber orientation and flexural performance of UHPC based on suspending mortar rheology and casting method. Cem. Concr. Compos. 2021, 122, 104142. [Google Scholar] [CrossRef]

- Zeng, B.; Li, M.; Zhu, Z.; Zhao, J.; Zhang, H. Application of 1-hydroxyethylidene-1, 1-diphosphonic acid in boiler water for industrial boilers. Water Sci. Tech. 2013, 67, 1544–1550. [Google Scholar] [CrossRef]

- Liang, H.; Liu, J.; Kang, B.; Zhang, Y.; He, Y.; Yang, H. Optimizing 1-hydroxyethylidene-1,1-diphosphonic acid and mechanically-activated iron ore tailings to prepare low-cost and retarded magnesium oxysulfate cement. Case Stud. Constr. Mater. 2022, 17, e01631. [Google Scholar] [CrossRef]

- Hurnaus, T.; Plank, J. Synthesis, characterization and performance of a novel phosphate-modified fluid loss additive useful in oil well cementing. J. Nat. Gas Sci. Eng. 2016, 36, 165–174. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Wang, Y.-S.; Dai, J.-G. Effect of mixing method on the performance of alkali-activated fly ash/slag pastes along with polycarboxylate admixture. Cem. Concr. Compos. 2021, 117, 103917. [Google Scholar] [CrossRef]

- Raza, A.; El Ouni, M.H.; Azab, M.; Ali, K.; Haider, H.; Rashedi, A. A scientometric review on mechanical and durability performance of geopolymer Paste: Effect of various raw materials. Constr. Build. Mater. 2022, 345, 128297. [Google Scholar] [CrossRef]

- ASTM C230; Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. ASTM West Conshohocken: Conshohocken, PA, USA, 2010.

- ASTM C403/403M; Standard Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance. ASTM West Conshohocken: Conshohocken, PA, USA, 2016.

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens). ASTM West Conshohocken: Conshohocken, PA, USA, 2021.

- ASTM C 1609; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM West Conshohocken: Conshohocken, PA, USA, 2019.

- Long, W.; Fang, C.; Wei, J.; Xu, Z. Study on dynamic properties of alkali-activated cementing materials at different temperatures. In Proceedings of the 2016 7th International Conference on Mechatronics, Control and Materials (ICMCM 2016), Changsha, China, 29–30 October 2016; Atlantis Press: Paris, France, 2016; Volume 104, pp. 75–79. [Google Scholar] [CrossRef]

- Long, W.; Wei, J.; Fang, C.; Xiao, B. Analysis on dynamic mechanical properties and surface micro-topography of alkali-activated concrete under different temperatures. In Proceedings of the 2016 International Conference on Materials Science, Resource and Environmental Engineering, Xi’an, China, 6 January 2017; AIP Publishing LLC: Beijing, China, 2017; Volume 1794, p. 020014. [Google Scholar] [CrossRef]

- Liu, T.; Song, W.; Zou, D.; Li, L. Dynamic mechanical analysis of cement mortar prepared with recycled cathode ray tube (CRT) glass as fine aggregate. J. Clean. Prod. 2017, 174, 1436–1443. [Google Scholar] [CrossRef]

- Liang, C.; Liu, T.; Xiao, J.; Zou, D.; Yang, Q. The damping property of recycled aggregate concrete. Constr. Build. Mater. 2016, 102, 834–842. [Google Scholar] [CrossRef]

- Sasaki, K.; Kurumisawa, K.; Ibayashi, K. Effect of retarders on flow and strength development of alkali-activated fly ash/blast furnace slag composite. Constr. Build. Mater. 2019, 216, 337–346. [Google Scholar] [CrossRef]

- Ramachandran, V.S.; Lowery, M.S.; Wise, T.; Polomark, G.M. The role of phosphonates in the hydration of Portland cement. Mater. Struct. 1993, 26, 425–432. [Google Scholar] [CrossRef]

- Kiiashko, A.; Chaouche, M.; Frouin, L. Effect of phosphonate addition on sodium carbonate activated slag properties. Cem. Concr. Compos. 2021, 119, 103986. [Google Scholar] [CrossRef]

- Browning, F.H.; Fogler, H.S. Effect of precipitating conditions on the formation of calcium−HEDP precipitates. Langmuir 1996, 12, 5231–5238. [Google Scholar] [CrossRef]

- Teng, L.; Meng, W.; Khayat, K.H. Rheology control of ultra-high-performance concrete made with different fiber contents. Cem. Concr. Res. 2020, 138, 106222. [Google Scholar] [CrossRef]

- Zou, D.; Liu, T.; Teng, J. Improving the damping ability by the addition of Nano SiO2 to the concrete materials. In Proceedings of the Second International Conference on Smart Materials and Nanotechnology in Engineering, SPEI, Weihai, China, 20 October 2009; pp. 918–926. [Google Scholar] [CrossRef]

- Wei, J.-J.; Long, W.-J.; Fang, C.-L.; Li, H.-D.; Guo, Y.-G. Effect of graphene oxide on the damping capability of recycled mortar. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 4th International Conference on Advanced Engineering and Technology, Shanghai, China, 1 March 2018; IOP Publishing: Beijing, China, 2018; Volume 317, p. 012001. [Google Scholar] [CrossRef]

- Giner, V.T.; Baeza, F.J.; Ivorra, S.; Zornoza, E.; Galao, Ó. Effect of steel and carbon fiber additions on the dynamic properties of concrete containing silica fume. Mater. Des. 2012, 34, 332–339. [Google Scholar] [CrossRef]

- Lv, S.; Ting, S.; Liu, J.; Zhou, Q. Use of graphene oxide nanosheets to regulate the microstructure of hardened cement paste to increase its strength and toughness. CrystEngComm 2014, 16, 8508–8516. [Google Scholar] [CrossRef]

- Sun, J.; Chen, Z. Effect of silicate modulus of water glass on the hydration of alkali-activated converter steel slag. J. Therm. Anal. Calorim. 2019, 138, 47–56. [Google Scholar] [CrossRef]

- Xyla, A.G.; Koutsoukos, P.G. Effect of diphosphonates on the precipitation of calcium carbonate in aqueous solutions. J. Chem. Soc. Faraday Trans. 1 Phys. Chem. Condens. Phases 1987, 83, 1477–1484. [Google Scholar] [CrossRef]

- Tong, S.; Yuqi, Z.; Qiang, W. Recent advances in chemical admixtures for improving the workability of alkali-activated slag-based material systems. Constr. Build. Mater. 2021, 272, 121647. [Google Scholar] [CrossRef]

| Property | Morphology | HEDP Content/wt% | Purity/wt% | Density/g.m2 | pH |

|---|---|---|---|---|---|

| HEDP.4Na | White powder | ≥65.0 | ≥90.0 | 1.26–1.36 | 11.0–12.0 |

| Specimen | GGBFS kg·m−3 | Sand kg·m−3 | NaOH kg·m−3 | Na2CO3 kg·m−3 | Water kg·m−3 | Steel Fiber vol.% | HEDP.4Na Mass% | Induced Pouring Angle (°) |

|---|---|---|---|---|---|---|---|---|

| HEDP-0-Ref. | 1000 | 1500 | 19.27 | 77.05 | 400 | 1 | 0 | Ref. |

| HEDP-0-90° | 1000 | 1500 | 19.27 | 77.05 | 400 | 1 | 0 | 90° |

| HEDP-0-150° | 1000 | 1500 | 19.27 | 77.05 | 400 | 1 | 0 | 150° |

| HEDP-0.3%-Ref. | 1000 | 1500 | 19.27 | 77.05 | 400 | 1 | 0.3 | Ref. |

| HEDP-0.3%-90° | 1000 | 1500 | 19.27 | 77.05 | 400 | 1 | 0.3 | 90° |

| HEDP-0.3%-150° | 1000 | 1500 | 19.27 | 77.05 | 400 | 1 | 0.3 | 150° |

| HEDP-0.6%-Ref. | 1000 | 1500 | 19.27 | 77.05 | 400 | 1 | 0.6 | Ref. |

| HEDP-0.6%-90° | 1000 | 1500 | 19.27 | 77.05 | 400 | 1 | 0.6 | 90° |

| HEDP-0.6%-150° | 1000 | 1500 | 19.27 | 77.05 | 400 | 1 | 0.6 | 150° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, J.; Liu, J.; Khayat, K.H.; Long, W.-J. Synergistic Effect of HEDP.4Na and Different Induced Pouring Angles on Mechanical Properties of Fiber-Reinforced Alkali-Activated Slag Composites. Fibers 2023, 11, 23. https://doi.org/10.3390/fib11030023

Wei J, Liu J, Khayat KH, Long W-J. Synergistic Effect of HEDP.4Na and Different Induced Pouring Angles on Mechanical Properties of Fiber-Reinforced Alkali-Activated Slag Composites. Fibers. 2023; 11(3):23. https://doi.org/10.3390/fib11030023

Chicago/Turabian StyleWei, Jingjie, Jianwei Liu, Kamal H. Khayat, and Wu-Jian Long. 2023. "Synergistic Effect of HEDP.4Na and Different Induced Pouring Angles on Mechanical Properties of Fiber-Reinforced Alkali-Activated Slag Composites" Fibers 11, no. 3: 23. https://doi.org/10.3390/fib11030023

APA StyleWei, J., Liu, J., Khayat, K. H., & Long, W.-J. (2023). Synergistic Effect of HEDP.4Na and Different Induced Pouring Angles on Mechanical Properties of Fiber-Reinforced Alkali-Activated Slag Composites. Fibers, 11(3), 23. https://doi.org/10.3390/fib11030023