Mechanical, Durability and Corrosion Properties of Basalt Fiber Concrete

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials Used

2.2. Mixture Proportions

2.3. Mixing, Casting, and Testing

2.3.1. Fresh Properties Testing

2.3.2. Mechanical Properties Testing

2.3.3. Durability Properties Testing

2.3.4. Corrosion Properties Testing

- Anode macrocell: 18.81 g KOH, 17.87 g NaOH, 974.8 g distilled water, 45.6 g NaCl;

- Cathode macrocell: 18.81 g KOH, 17.87 g NaOH, 974.8 g distilled water;

- All solutions were per 1L of solution with anode containers having a 1.6 M NaCl solution and were made to fill the containers to a height of 3.72 inches. Alongside the pore solutions, the scrubbed air was also set-up with the following set-up and solutions:

- Container: length of 330 mm (13 inch) × height of 150 mm (6 inch);

- Bubbler: 127 mm (5 inch) air bubble stone disc bubble diffuser;

- Connections: plastic tubing, between cathodes about 25.4 mm (1 inch) connections;

- Solution: 1 M NaOH (40 g NaOH per 1000 g distilled water);

- Air Supply: pressurized air at 40–60 KPa (10–15 psi).

- A 100 mm long u-shaped glass tube

- 4.5 g of agar (used to create semisolid gel);

- 30 g of KCL (potassium chloride);

- 100 g distilled water

3. Experimental Results and Discussions

3.1. Fresh Properties

3.1.1. Workability

3.1.2. Unit Weights

3.2. Mechanical Properties

3.2.1. Compressive Strength

3.2.2. Split Tensile Strength

3.2.3. Modulus of Rupture

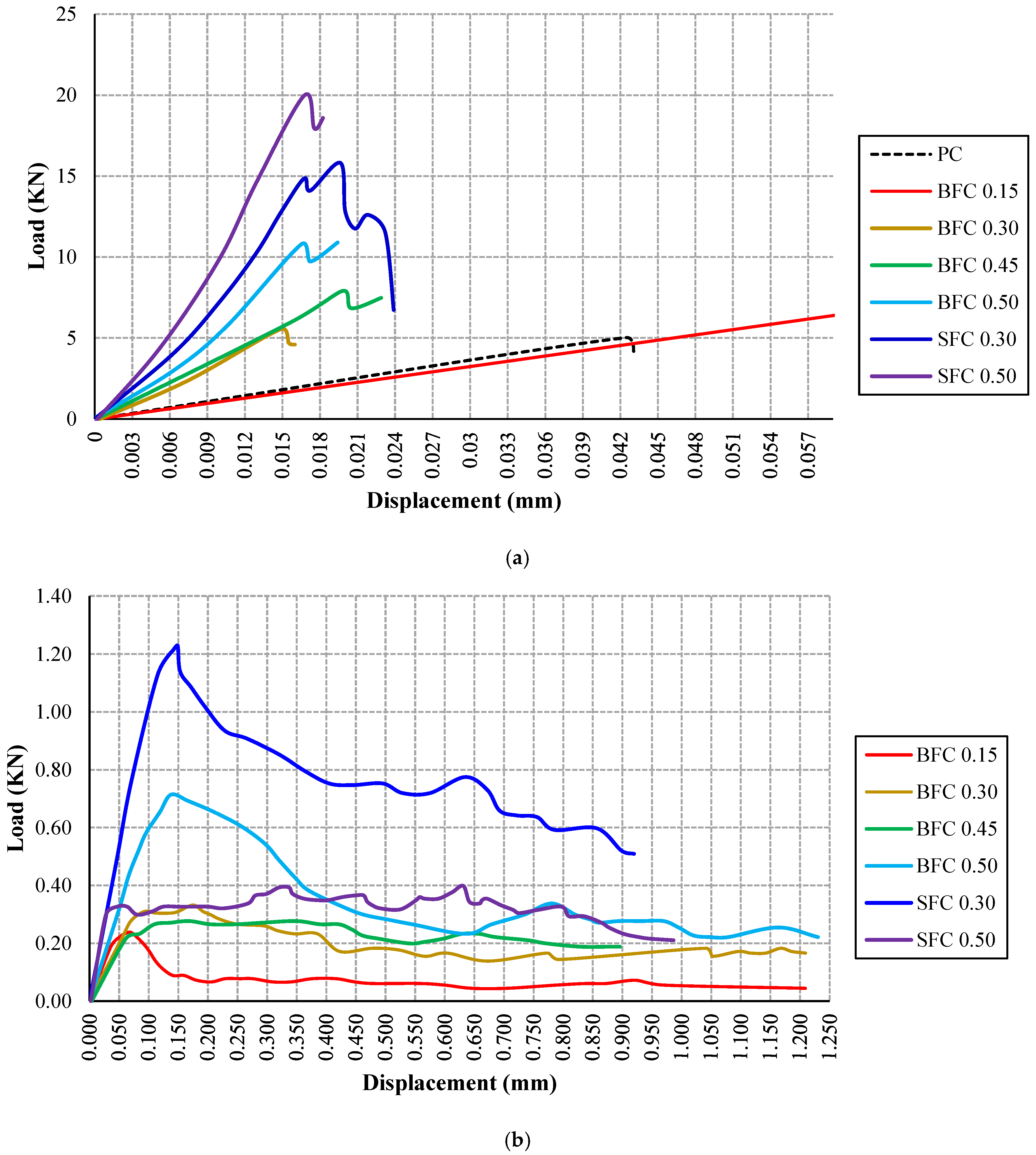

3.2.4. Average Residual Strength

3.3. Durability Properties

3.3.1. Unrestrained Shrinkage

3.3.2. Surface Resistivity

3.4. Corrosion Properties

Rapid Macrocell Corrosion Evaluation Test

4. Conclusions

- The use of fibers increases the cohesion of concrete mixtures, and this reduces its workability and thus high range water admixture has to be added to the mix in order to achieve the desired slump.

- Due to the rough surface of basalt fibers compared to steel fibers, interparticle friction increases and this reduces the BFC workability compared to SFC.

- The unit weight increases with the increase in fibers, due to the higher density of fibers. In addition, basalt fiber mixes provide lighter concrete compared to steel fiber mixes.

- The addition of fibers bridges the microcracks of concrete at early ages and this increases its overall stiffness, which increases the compressive strength. In addition, due to the lower specific gravity of basalt fibers compared to steel fibers, the fibers tend to move upward during compacting process and this non-uniformity could cause a reduction in the strength. However, we tried to overcome this by minimizing the use of vibrator and using the temping rod instead.

- It was found that increasing basalt fiber volume by 0.15%, 0.30%, 0.45%, and 0.50% increased the compressive strength by 5%, 9%, 11%, and 12%, respectively; increased the splitting tensile strength by 18%, 21%, 25%, and 29%, respectively; and increased the flexural strength by 6%, 25%, 17%, and 12%, respectively, compared to the control mix PC.

- Utilizing a 0.30% fibers volume fraction is the optimum ratio with an overall acceptable performance with respect to mechanical and corrosion properties.

- Increasing w/c from 0.35 to 0.40 decreased the compressive strength by around 8–11%, decreased the split tensile strength by around 8–20%, and decreased the flexural strength by around 5–12%.

- Unrestrained shrinkage decreased with the increase in fiber content. However, steel fibers show lower shrinkage compared to basalt fibers. Moreover, the addition of fibers up to 0.30% shows a decrease in chloride-ion penetrability.

- Steel fibers concrete showed better performance compared to the same basalt fibers volume, except for corrosion properties. However, the other results obtained for BFC are still competitive.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yakhlaf, M. Fresh and Mechanical Properties of Basalt Fiber Reinforced Concrete; University of Tripoli: Tripoli, Libya, 2015. [Google Scholar]

- Torrents, J.M.; Blanco, A.; Pujadas, P.; Aguado, A.; Juan-García, P.; Sánchez-Moragues, M. Inductive method for assessing the amount and orientation of steel fibers in concrete. Mater. Struc. 2012, 45, 1577–1592. [Google Scholar] [CrossRef] [Green Version]

- Oh, B.H. Flexural analysis of reinforced concrete beams containing steel fibers. J. Struc. Eng. 1992, 118, 2821–2835. [Google Scholar] [CrossRef]

- Guerini, V.; Conforti, A.; Plizzari, G.; Kawashima, S. Influence of steel and macro-synthetic fibers on concrete properties. Fibers 2018, 6, 47. [Google Scholar] [CrossRef] [Green Version]

- Naaman, A.E.; Najm, H. Bond-slip mechanisms of steel fibers in concrete. Mater. J. 1991, 88, 135–145. [Google Scholar]

- Di Ludovico, M.; Prota, A.; Manfredi, G. Structural upgrade using basalt fibers for concrete confinement. J. Compos. Constr. 2010, 14, 541–552. [Google Scholar] [CrossRef]

- Pelisser, F.; Montedo, O.R.K.; Gleize, P.; Roman, H.R. Mechanical properties of recycled PET fibers in concrete. Mater. Res. 2012, 15, 679–686. [Google Scholar] [CrossRef]

- Naaman, A.E.; Shah, S.P.; Throne, J.L. Some developments in polypropylene fibers for concrete. Spec. Publ. 1984, 81, 375–396. [Google Scholar]

- Eisa, A.S.; Elshazli, M.T.; Nawar, M.T. Experimental investigation on the effect of using crumb rubber and steel fibers on the structural behavior of reinforced concrete beams. Constr. Build. Mater. 2020, 252, 119078. [Google Scholar] [CrossRef]

- Sim, J.; Park, C.; Moon, D.Y. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Iyer, P.; Kenno, S.Y.; Das, S. Mechanical Properties of Fiber-Reinforced Concrete Made with Basalt Filament Fibers. J. Mater. Civ. Eng. 2015, 27, 04015015. [Google Scholar] [CrossRef]

- Yang, Y.X.; Lian, J. Basalt fiber reinforced concrete. Adv. Materi. Res. 2011, 194–196, 1103–1108. [Google Scholar] [CrossRef]

- Yao, W.; Li, J.; Wu, K. Mechanical properties of hybrid fiber-reinforced concrete at low fiber volume fraction. Cem. Concr. Res. 2003, 33, 27–30. [Google Scholar] [CrossRef]

- Abbas, U. Materials Development of Steel-and Basalt Fiber-Reinforced Concretes; Institutt for Konstruksjonsteknikk: Oslo, Norway, 2013. [Google Scholar]

- Halvaei, M.; Jamshidi, M.; Latifi, M. Effect of fiber geometry and tenacity on the mechanical properties of fine aggregates concrete. J. Ind. Text. 2014, 45, 1083–1099. [Google Scholar] [CrossRef]

- Gettu, R.; Gardner, D.R.; Saldivar, H.; Barragan, B.E. Study of the distribution and orientation of fibers in SFRC specimens. Mater. Struc. 2005, 38, 31–37. [Google Scholar] [CrossRef]

- Kılınç, A.Ç.; Durmuşkahya, C.; Seydibeyoğlu, M.Ö. Natural fibers. In Fiber Technology for Fiber-Reinforced Composites; Elsevier: Amsterdam, The Netherlands, 2017; pp. 209–235. [Google Scholar]

- Zīle, E.; Zīle, O. Effect of the fiber geometry on the pullout response of mechanically deformed steel fibers. Cem. Concr. Res. 2013, 44, 18–24. [Google Scholar] [CrossRef]

- Khamees, S.S.; Kadhum, M.M.; Nameer, A.A. Effects of Steel Fibers Geometry on the Mechanical Properties of SIFCON Concrete. Civ. Eng. J. 2020, 6, 21–33. [Google Scholar] [CrossRef]

- Yazıcı, Ş.; İnan, G.; Tabak, V. Effect of aspect ratio and volume fraction of steel fiber on the mechanical properties of SFRC. Constr. Build. Mater. 2007, 21, 1250–1253. [Google Scholar] [CrossRef]

- Kang, S.-T.; Choi, J.-I.; Koh, K.-T.; Lee, K.S.; Lee, B.Y. Hybrid effects of steel fiber and microfiber on the tensile behavior of ultra-high performance concrete. Compos. Struct. 2016, 145, 37–42. [Google Scholar] [CrossRef]

- Soliman, A.; Nehdi, M. Effects of shrinkage reducing admixture and wollastonite microfiber on early-age behavior of ultra-high performance concrete. Cem. Concr. Compos. 2013, 46, 81–89. [Google Scholar] [CrossRef]

- Branston, J.; Das, S.; Kenno, S.; Taylor, C. Influence of basalt fibres on free and restrained plastic shrinkage. Cem. Concr. Compos. 2016, 74, 182–190. [Google Scholar] [CrossRef]

- Gali, S.; Subramaniam, K.V. Evaluation of Crack Propagation and Post-cracking Hinge-type Behavior in the Flexural Response of Steel Fiber Reinforced Concrete. Int. J. Concr. Struct. Mater. 2017, 11, 365–375. [Google Scholar] [CrossRef] [Green Version]

- Barluenga, G.; Hernández-Olivares, F. Cracking control of concretes modified with short AR-glass fibers at early age. Experimental results on standard concrete and SCC. Cem. Concr. Res. 2007, 37, 1624–1638. [Google Scholar] [CrossRef]

- Ramakrishnan, V.; Wu, G.Y.; Hosalli, G. Flexural behavior and toughness of fiber reinforced concretes. Transp. Res. Rec. 1989, 1226, 69–77. [Google Scholar]

- Hao, Y.; Hao, H. Dynamic compressive behaviour of spiral steel fibre reinforced concrete in split Hopkinson pressure bar tests. Constr. Build. Mater. 2013, 48, 521–532. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Maalej, M.; Hashida, T.; Li, V.C. Effect of Fiber Volume Fraction on the Off-Crack-Plane Fracture Energy in Strain -Hardening Engineered Cementitious Composites. J. Am. Ceram. Soc. 1995, 78, 3369–3375. [Google Scholar] [CrossRef] [Green Version]

- Aydin, A.C. Self compactability of high volume hybrid fiber reinforced concrete. Constr. Build. Mater. 2007, 21, 1149–1154. [Google Scholar] [CrossRef]

- Atiş, C.D.; Karahan, O. Properties of steel fiber reinforced fly ash concrete. Constr. Build. Mater. 2007, 23, 392–399. [Google Scholar] [CrossRef]

- Thomas, J.; Ramaswamy, A. Mechanical Properties of Steel Fiber-Reinforced Concrete. J. Mater. Civ. Eng. 2007, 19, 385–392. [Google Scholar] [CrossRef]

- High, C.; Seliem, H.M.; El-Safty, A.; Rizkalla, S.H. Use of basalt fibers for concrete structures. Constr. Build. Mater. 2015, 96, 37–46. [Google Scholar] [CrossRef]

- Ross, A. Basalt fibers: Alternative to glass? Compos. Technol. 2006, 12, 44–48. [Google Scholar]

- Deák, T.; Czigány, T. Chemical Composition and Mechanical Properties of Basalt and Glass Fibers: A Comparison. Text. Res. J. 2009, 79, 645–651. [Google Scholar] [CrossRef]

- Greco, A.; Maffezzoli, A.; Casciaro, G.; Caretto, F. Mechanical properties of basalt fibers and their adhesion to polypropylene matrices. Compos. Part B Eng. 2014, 67, 233–238. [Google Scholar] [CrossRef]

- Wu, G.; Wang, X.; Wu, Z.; Dong, Z.; Zhang, G. Durability of basalt fibers and composites in corrosive environments. J. Compos. Mater. 2014, 49, 873–887. [Google Scholar] [CrossRef]

- Rabiaa, E.; Mohamed, R.A.S.; Sofi, W.H.; Tawfik, T.A. Developing Geopolymer Concrete Properties by Using Nanomaterials and Steel Fibers. Adv. Mater. Sci. Eng. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Ganesh, A.C.; Sowmiya, K.; Muthukannan, M. Investigation on the effect of steel fibers in geopolymer concrete. IOP Conf. Series: Mater. Sci. Eng. 2020, 872, 012156. [Google Scholar] [CrossRef]

- Pareek, K.; Saha, P. Basalt fiber and its composites: An overview. In Advances in Structural Technologies (CoAST-2019); Adhikari, S., Dutta, A., Choudhury, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; Volume 1. [Google Scholar]

- Ralph, C.; Lemoine, P.; Summerscales, J.; Archer, E.; McIlhagger, A. The relationship between the chemical, mechanical and geometrical properties of basalt fibre. Tex. Res. J. 2019, 89, 3056–3066. [Google Scholar] [CrossRef]

- Kumbhar, V.P. An overview: Basalt rock fibers-new construction material. Acta Eng. Int. 2014, 2, 11–18. [Google Scholar]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Ma, W.; Qin, Y.; Li, Y.; Chai, J.; Zhang, X.; Ma, Y.; Liu, H. Mechanical properties and engineering application of cellulose fiber-reinforced concrete. Mater. Today Commun. 2019, 22, 100818. [Google Scholar] [CrossRef]

- Patil, R.K.; Kulkarni, D. Comparative study of effect of basalt, glass and steel fiber on compressive and flexural strength of concrete. Int. J. Res. Eng. Technol. 2014, 3, 436–438. [Google Scholar]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- Kirthika, S.; Singh, S. Experimental Investigations on Basalt Fibre-Reinforced Concrete. J. Inst. Eng. Ser. A 2018, 99, 661–670. [Google Scholar] [CrossRef]

- Kirthika, S.; Singh, S.; Surya, M. Durability studies on basalt fiber reinforced concrete. Indian Concr. 2018, 92, 45–55. [Google Scholar]

- Hung, C.C.; Lee, H.S.; Chan, S.N. Tension-stiffening effect in steel-reinforced UHPC composites: Constitutive model and effects of steel fibers, loading patterns, and rebar sizes. Compos. Part B Eng. 2019, 158, 269–278. [Google Scholar] [CrossRef]

- Kytinou, V.K.; Chalioris, C.E.; Karayannis, C.G. Analysis of residual flexural stiffness of steel fiber-reinforced concrete beams with steel reinforcement. Materials 2020, 13, 2698. [Google Scholar] [CrossRef]

- ASTM C127-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C128-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C150/C150M-21; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C494/C494M-19; Standard Specification for Chemical Admixtures for Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C33/C33M-18; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2018.

- ACI Committee 544. State-of-the-Art Report on Fiber Reinforced Concrete (ACI 544.1R-96); American Concrete Institute: Farmington Hills, MI, USA, 2002; p. 66. [Google Scholar]

- ACI Committee 544. Guide to Design with Fiber-Reinforced Concrete (ACI 544.4R-18); American Concrete Institute: Farmington Hills, MI, USA, 2018; p. 44. [Google Scholar]

- ASTM C192/C192M-19; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C138/C138M-17a; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C496/C496M-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C78/C78M-21; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C1399/C1399M-10(2015); Standard Test Method for Obtaining Average Residual-Strength of Fiber-Reinforced Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C490/C490M-17; Standard Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- AASHTO T358-19; Method of Test for Surface Resistivity Indication of Concrete’s Ability to Resist Chloride Ion Penetration. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- ASTM G109-07(2013); Standard Test Method for Determining Effects of Chemical Admixtures on Corrosion of Embedded Steel Reinforcement in Concrete Exposed to Chloride Environments. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM C305-20; Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency. ASTM International: West Conshohocken, PA, USA, 2020.

- Kachouh, N.; El-Hassan, H.; El Maaddawy, T. The use of steel fibers to enhance the performance of concrete made with recycled aggregate. In Proceedings of the Fifth International Conference on Sustainable Construction Materials and Technologies (SCMT5), London, UK, 14 July 2019; pp. 15–17. [Google Scholar]

- Liu, J.; Chen, M.; Yang, J.; Wu, Z. Study on Mechanical Properties of Basalt Fibers Superior to E-glass Fibers. J. Nat. Fibers 2020, 1–13. [Google Scholar] [CrossRef]

- Asadi, A.; Baaij, F.; Mainka, H.; Rademacher, M.; Thompson, J.; Kalaitzidou, K. Basalt fibers as a sustainable and cost-effective alternative to glass fibers in sheet molding compound (SMC). Compos. Part B Eng. 2017, 123, 210–218. [Google Scholar] [CrossRef]

- Wang, X.; Shi, J.; Liu, J.; Yang, L.; Wu, Z. Creep behavior of basalt fiber reinforced polymer tendons for prestressing application. Mater. Des. 2014, 59, 558–564. [Google Scholar] [CrossRef]

- Jalasutram, S.; Sahoo, D.R.; Matsagar, V. Experimental investigation of the mechanical properties of basalt fiber-reinforced concrete. Struct. Concr. 2017, 18, 292–302. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Al Hawat, W. Influence of Fly Ash and Basalt Fibers on Strength and Chloride Penetration Resistance of Self-Consolidating Concrete. Mater. Sci. Forum 2016, 866, 3–8. [Google Scholar] [CrossRef]

- Huang, Q.; Shi, X.S.; Wang, Q.Y.; Tang, L.; Zhang, H.E. The influence of fiber on the resistance to chloride-ion penetration of concrete under the environment of carbonation. Mater Rev. 2015, 2, 546–549. [Google Scholar]

- Guo, Y.; Hu, X.; Lv, J. Experimental study on the resistance of basalt fibre-reinforced concrete to chloride penetration. Constr. Build. Mater. 2019, 223, 142–155. [Google Scholar] [CrossRef]

- Weige, C.; Zhu, H.; He, Z.; Yang, L.; Zhao, L.; Wen, C. Experimental investigation on chloride-ion penetration resistance of slag containing fiber-reinforced concrete under drying-wetting cycles. Constr. Build. Mater. 2020, 274, 121829. [Google Scholar] [CrossRef]

- Lövgren, I. Fibre-Reinforced Concrete for Industrial Construction–A fracture Mechanics Approach to Material Testing and Structural Analysis; Chalmers Tekniska Hogskola: Stockholm, Sweden, 2005. [Google Scholar]

| Fiber Type | Specific Gravity (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (Gpa) | Elongation at Break (%) |

|---|---|---|---|---|

| Steel | 7.86 | 280–2800 | 210 | 0.5–35 |

| E-Glass | 2.56 | 1400–2500 | 76 | 1.8–3.2 |

| AR-Glass | 2.68 | 3700 | 74 | 2.5 |

| PAN-based Carbon | 1.77–1.79 | 5500–5800 | 354–375 | NA |

| Pitch-based Carbon | 2.20 | 3100 | 965 | NA |

| Polypropylene | 0.91 | 628–760 | 3.5–8 | 25 |

| Polyethylene | 0.97 | 2588–2900 | 117 | 10 |

| Basalt | 2.8 | 2800 | 89 | 3.15 |

| Cellulose | 1.10–1.50 | 600–1000 | 10–50 | 3.5 |

| Material | Properties | |

|---|---|---|

| Portland Cement | Relative Density | 3.15 |

| Basalt Coarse Aggregate (CA) | Maximum Aggregate Size | 19 mm (3/4″) |

| Specific Gravity | 2.729 | |

| % Absorption | 2.73 | |

| Graded in Accordance with ASTM C33 [55] | ||

| Natural Sand (FA) | Specific Gravity | 2.683 |

| % Absorption | 4.03 | |

| Fineness Modulus | 2.93 | |

| Graded in Accordance with ASTM C33 [55] | ||

| Basalt Fibers (BF) | Specific Gravity | 2.70 |

| Fiber Length | 24.13 mm (0.950″) | |

| Diameter | 0.60 mm (0.0235″) | |

| Aspect Ratio (L/D) | 40 | |

| Steel Fiber (SF) | Specific Gravity | 7.85 |

| Fiber length | 38 mm (1.5″) | |

| Diameter | 1.14 mm (0.045″) | |

| Aspect Ratio (L/D) | 34 | |

| Tensile Strength | 966–1242 Mpa (140–180 ksi) | |

| Elastic Modulus | 205 Gpa (29,700 ksi) | |

| High-Range Water Admixture | Specific Gravity | 1.08 |

| Normal Tap Water | Density at 24 °C (75.2 °F): 997.28 kg/m3 (62.3 lb./ft3) | |

| Group | No. | Mix | Cement kg/m3 (lbs/yd3) | Water L/m3 (lbs/yd3) | Fine Agg. kg/m3 (lbs/yd3) | Coarse Agg. kg/m3 (lbs/yd3) | Basalt F. kg/m3 (lbs/yd3) | Steel F. kg/m3 (lbs/yd3) | HRWA L/m3 (gal./yd3) |

|---|---|---|---|---|---|---|---|---|---|

| MA (w/c = 0.35) | 1 | PC | 371 (625) | 130 (219) | 804 (1355) | 985 (1660) | 0.00 | 0.00 | 0.00 |

| 2 | BFC 0.15% | 371 (625) | 130 (219) | 804 (1355) | 985 (1660) | 4.05 (6.83) | 0.00 | 0.60 (0.12) | |

| 3 | BFC 0.30% | 371 (625) | 130 (219) | 804 (1355) | 985 (1660) | 8.10 (13.65) | 0.00 | 0.60 (0.12) | |

| 4 | BFC 0.45% | 371 (625) | 130 (219) | 804 (1355) | 985 (1660) | 12.15 (20.48) | 0.00 | 0.60 (0.12) | |

| 5 | BFC 0.50% | 371 (625) | 130 (219) | 804 (1355) | 985 (1660) | 13.50 (22.75) | 0.00 | 0.62 (0.13) | |

| 6 | SFC 0.30% | 371 (625) | 130 (219) | 804 (1355) | 985 (1660) | 0.00 | 23.55 (39.69) | 1.04 (0.21) | |

| 7 | SFC 0.50% | 371 (625) | 130 (219) | 804 (1355) | 985 (1660) | 0.00 | 39.25 (66.15) | 0.83 (0.17) | |

| MB (w/c = 0.40) | 8 | PC | 371 (625) | 148 (250) | 804 (1355) | 985 (1660) | 0.00 | 0.00 | 0.00 |

| 9 | BFC 0.15% | 371 (625) | 148 (250) | 804 (1355) | 985 (1660) | 4.05 (6.83) | 0.00 | 0.50 (0.10) | |

| 10 | BFC 0.30% | 371 (625) | 148 (250) | 804 (1355) | 985 (1660) | 8.10 (13.65) | 0.00 | 0.50 (0.10) | |

| 11 | BFC 0.45% | 371 (625) | 148 (250) | 804 (1355) | 985 (1660) | 12.15 (20.48) | 0.00 | 0.50 (0.10) | |

| 12 | BFC 0.50% | 371 (625) | 148 (250) | 804 (1355) | 985 (1660) | 13.50 (22.75) | 0.00 | 0.62 (0.13) | |

| 13 | SFC 0.30% | 371 (625) | 148 (250) | 804 (1355) | 985 (1660) | 0.00 | 23.55 (39.69) | 0.73 (0.15) | |

| 14 | SFC 0.50% | 371 (625) | 148 (250) | 804 (1355) | 985 (1660) | 0.00 | 39.25 (66.15) | 0.52 (0.11) |

| Property | Test | Standard | Specimen Dimensions | Number of Specimens |

|---|---|---|---|---|

| Fresh Properties | Concrete Slump (Workability) | ASTM C143 [59] | N/A | N/A |

| Fresh Density | ASTM C138 [60] | N/A | N/A | |

| Mechanical Properties | Compressive Strength | ASTM C39 [61] | 100Ø × 200 mm (4Ø × 8″) | 126 |

| Splitting Tensile Strength | ASTM C496 [62] | 150Ø × 300 mm (6Ø × 12″) | 42 | |

| Flexural Strength (MOR) | ASTM C78 [63] | 150 × 150 × 500 mm (6 × 6 × 20″) | 42 | |

| Average Residual Strength (ARS) | ASTM C1399 [64] | 50 × 50 × 300 mm (2 × 2 × 12″) | 42 | |

| Durability Properties | Unrestrained Drying Shrinkage | ASTM C490 [65] | 50 × 50 × 300 mm (2 × 2 × 10″) | 42 |

| Surface Resistivity | AASHTO TP-95 [66] | 100Ø × 200 mm (4Ø × 8″) | 42 |

| Fresh Properties | 28 Days Mechanical Properties | |||||||

|---|---|---|---|---|---|---|---|---|

| No. | Mix | Slump mm (inch) | Unit Weight kg/m3 (Ib/ft3) | Compressive Strength MPa (Psi) | Split-Tensile Strength MPa (Psi) | MR MPa (Psi) | ARS MPa (Psi) | |

| MA (W/C = 0.35) | 1 | PC | 152 (6.0) | 2286.38 (142.73) | 47.0 (6815.00) | 3.41 (494.45) | 4.01 (581.45) | N/A |

| 2 | BFC 15% | 152 (6.0) | 2322.90 (145.01) | 49.0 (7105.00) | 4.02 (582.90) | 4.22 (611.90) | 0.29 (42.1) | |

| 3 | BFC 30% | 140 (5.5) | 2423.62 (151.30) | 51.0 (7395.00) | 4.10 (594.50) | 4.99 (723.55) | 0.57 (82.7) | |

| 4 | BFC 45% | 127 (5.0) | 2480.85 (154.87) | 52.0 (7540.00) | 4.23 (613.35) | 4.69 (680.05) | 0.76 (110.2) | |

| 5 | BFC 50% | 114 (4.5) | 2499.40 (156.03) | 52.5 (7613.00) | 4.39 (636.55) | 4.49 (651.05) | 1.03 (149.4) | |

| 6 | SFC 30% | 152 (6.0) | 2502.00 (156.19) | 53.0 (7685.00) | 4.52 (655.40) | 5.12 (742.40) | 0.90 (130.5) | |

| 7 | SFC 50% | 140 (5.5) | 2560.00 (159.82) | 54.0 (7830.00) | 4.41 (639.45) | 4.95 (717.75) | 1.14 (165.3) | |

| MB (W/C = 0.40) | 8 | PC | 165 (6.5) | 2325.00 (145.15) | 43.2 (6269.80) | 3.23 (468.35) | 3.52 (510.40) | N/A |

| 9 | BFC 15% | 152 (6.0) | 2355.00 (147.01) | 44.1 (6394.50) | 3.38 (490.10) | 3.86 (559.70) | 0.10 (14.5) | |

| 10 | BFC 30% | 140 (5.5) | 2455.42 (153.29) | 46.4 (6729.45) | 3.83 (555.35) | 4.54 (658.30) | 0.35 (50.8) | |

| 11 | BFC 45% | 140 (5.5) | 2490.00 (155.45) | 46.3 (6710.60) | 3.91 (566.95) | 4.6 (667.00) | 0.43 (62.4) | |

| 12 | BFC 50% | 127 (5.0) | 2520.00 (157.32) | 47.3 (6851.70) | 3.99 (578.55) | 4.3 (623.50) | 0.66 (95.7) | |

| 13 | SFC 30% | 152 (6.0) | 2525.00 (157.63) | 49.3 (7147.05) | 4.24 (614.80) | 4.85 (703.25) | 0.61 (88.5) | |

| 14 | SFC 50% | 140 (5.5) | 2573.00 (160.63) | 49.4 (7164.45) | 4.12 (597.40) | 4.78 (693.10) | 1.06 (153.7) | |

| No. | Mix | Compressive Test | Split-Tensile Test | Flexural Test | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | S2 | S | Mean | S2 | S | Mean | S2 | S | |||

| MA (W/C = 0.35) | 1 | PC | 47.0 (6815.00) | 2.00 | 1.42 | 3.41 (494.45) | 1.67 | 1.30 | 4.01 (581.45) | 1.25 | 1.12 |

| 2 | BFC 15% | 49.0 (7105.00) | 2.67 | 1.64 | 4.02 (582.90) | 2.21 | 1.49 | 4.22 (611.90) | 0.99 | 1.00 | |

| 3 | BFC 30% | 51.0 (7395.00) | 0.67 | 0.82 | 4.10 (594.50) | 1.25 | 1.12 | 4.99 (723.55) | 1.12 | 1.06 | |

| 4 | BFC 45% | 52.0 (7540.00) | 2.00 | 1.42 | 4.23 (613.35) | 2.00 | 1.42 | 4.69 (680.05) | 2.30 | 1.52 | |

| 5 | BFC 50% | 52.5 (7613.00) | 1.59 | 1.27 | 4.39 (636.55) | 0.82 | 0.91 | 4.49 (651.05) | 1.28 | 1.14 | |

| 6 | SFC 30% | 53.0 (7685.00) | 2.00 | 1.42 | 4.52 (655.40) | 1.12 | 1.06 | 5.12 (742.40) | 0.87 | 0.94 | |

| 7 | SFC 50% | 54.0 (7830.00) | 2.00 | 1.42 | 4.41 (639.45) | 2.00 | 1.42 | 4.95 (717.75) | 1.12 | 1.06 | |

| MB (W/C = 0.40) | 8 | PC | 43.2 (6269.80) | 0.91 | 0.96 | 3.23 (468.35) | 2.00 | 1.42 | 3.52 (510.40) | 0.95 | 0.98 |

| 9 | BFC 15% | 44.1 (6394.50) | 2.95 | 1.72 | 3.38 (490.10) | 2.23 | 1.50 | 3.86 (559.70) | 1.35 | 1.17 | |

| 10 | BFC 30% | 46.4 (6729.45) | 1.63 | 1.28 | 3.83 (555.35) | 1.35 | 1.17 | 4.54 (658.30) | 1.2 | 1.10 | |

| 11 | BFC 45% | 46.3 (6710.60) | 0.89 | 0.95 | 3.91 (566.95) | 1.12 | 1.06 | 4.6 (667.00) | 1.89 | 1.38 | |

| 12 | BFC 50% | 47.3 (6851.70) | 0.89 | 0.95 | 3.99 (578.55) | 0.87 | 0.94 | 4.3 (623.50) | 2.00 | 1.42 | |

| 13 | SFC 30% | 49.3 (7147.05) | 2.89 | 1.7 | 4.24 (614.80) | 1.30 | 1.15 | 4.8 (703.25) | 2.87 | 1.70 | |

| 14 | SFC 50% | 49.4 (7164.45) | 1.63 | 1.28 | 4.12 (597.40) | 2.50 | 1.59 | 4.78 (693.10) | 1.59 | 1.27 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elshazli, M.T.; Ramirez, K.; Ibrahim, A.; Badran, M. Mechanical, Durability and Corrosion Properties of Basalt Fiber Concrete. Fibers 2022, 10, 10. https://doi.org/10.3390/fib10020010

Elshazli MT, Ramirez K, Ibrahim A, Badran M. Mechanical, Durability and Corrosion Properties of Basalt Fiber Concrete. Fibers. 2022; 10(2):10. https://doi.org/10.3390/fib10020010

Chicago/Turabian StyleElshazli, Mohamed T., Kevin Ramirez, Ahmed Ibrahim, and Mohamed Badran. 2022. "Mechanical, Durability and Corrosion Properties of Basalt Fiber Concrete" Fibers 10, no. 2: 10. https://doi.org/10.3390/fib10020010

APA StyleElshazli, M. T., Ramirez, K., Ibrahim, A., & Badran, M. (2022). Mechanical, Durability and Corrosion Properties of Basalt Fiber Concrete. Fibers, 10(2), 10. https://doi.org/10.3390/fib10020010