Concrete Reinforced by Hybrid Mix of Short Fibers under Bending

Abstract

1. Introduction

2. Materials

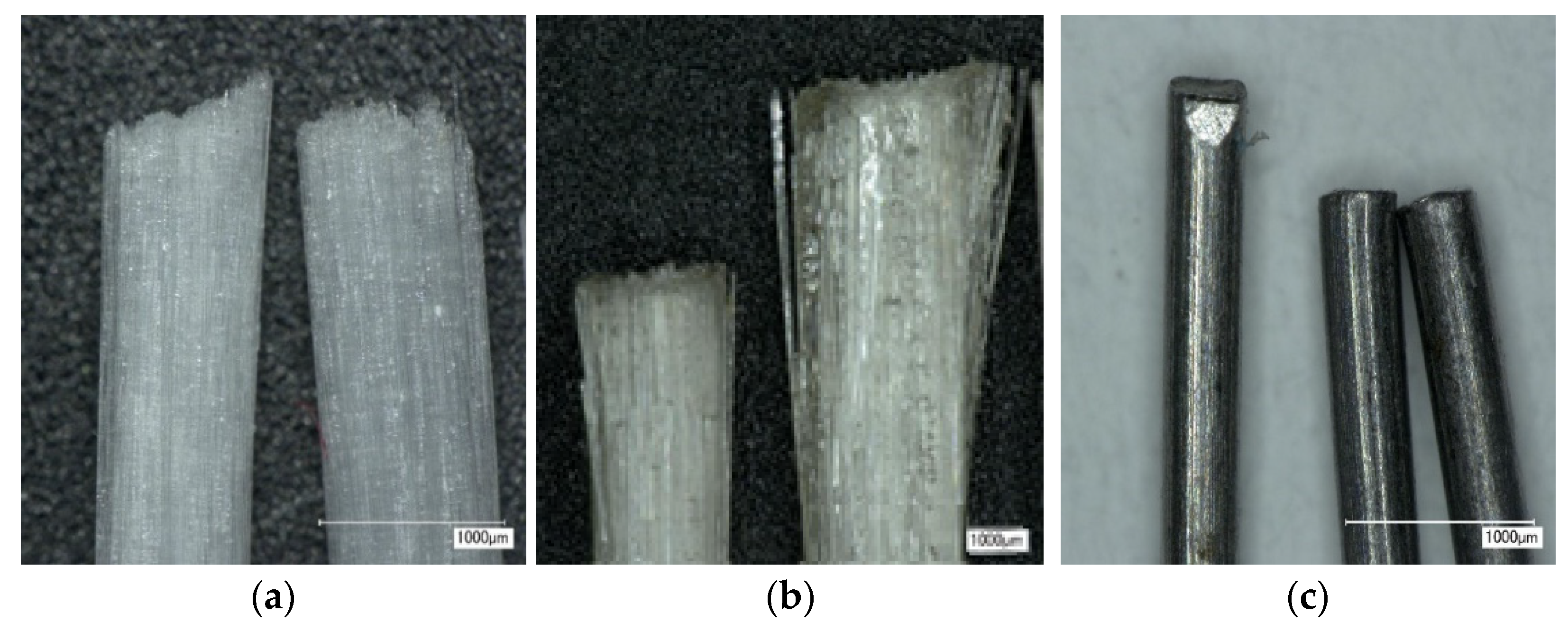

Fibers

3. Preparation of Samples with the Hybrid Mix of Fibers

3.1. Mixing Concrete with Fibers

3.2. Materials and Mix Proportions

4. Experimental Setup

4.1. Technological Properties’ Tests

Sieve Segregation Test

4.2. Structural Properties’ Tests

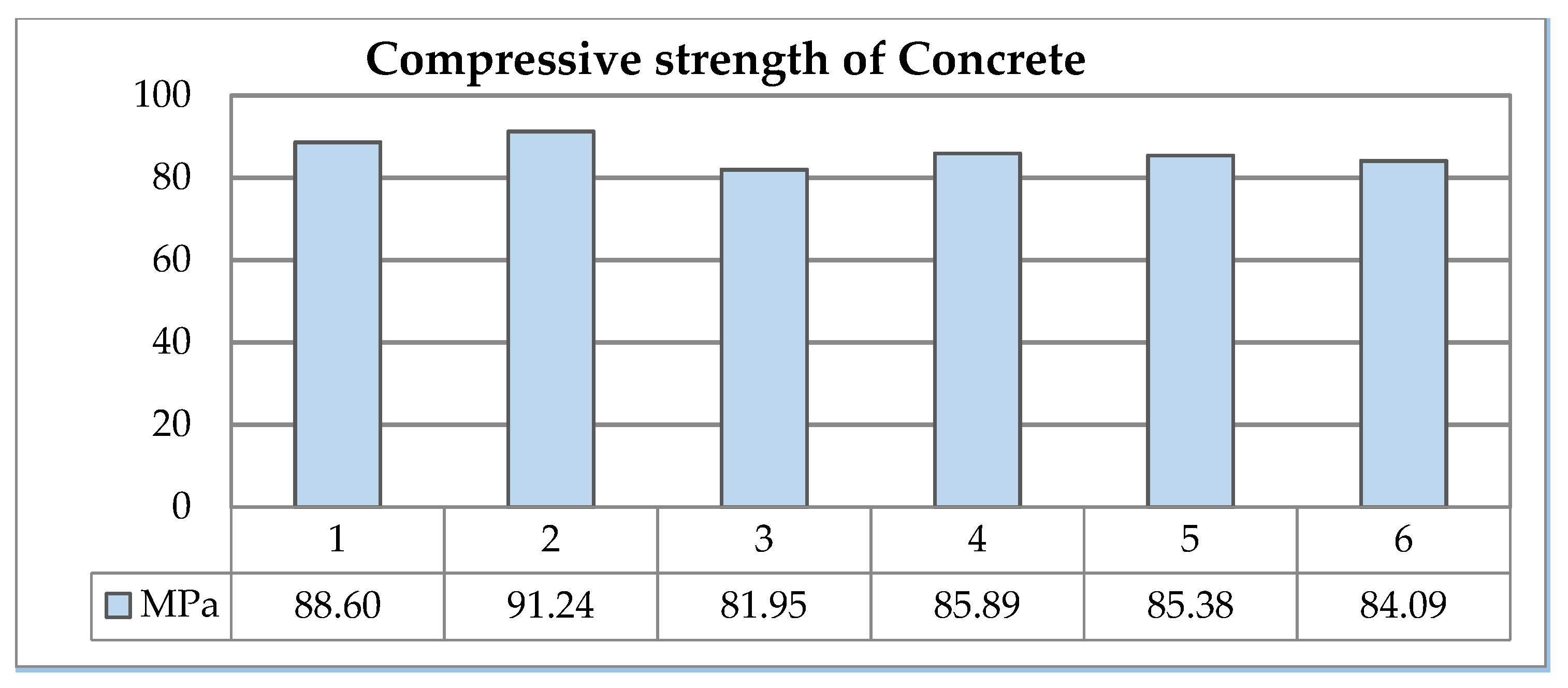

4.2.1. Compressive Strength (Concrete Cube Test)

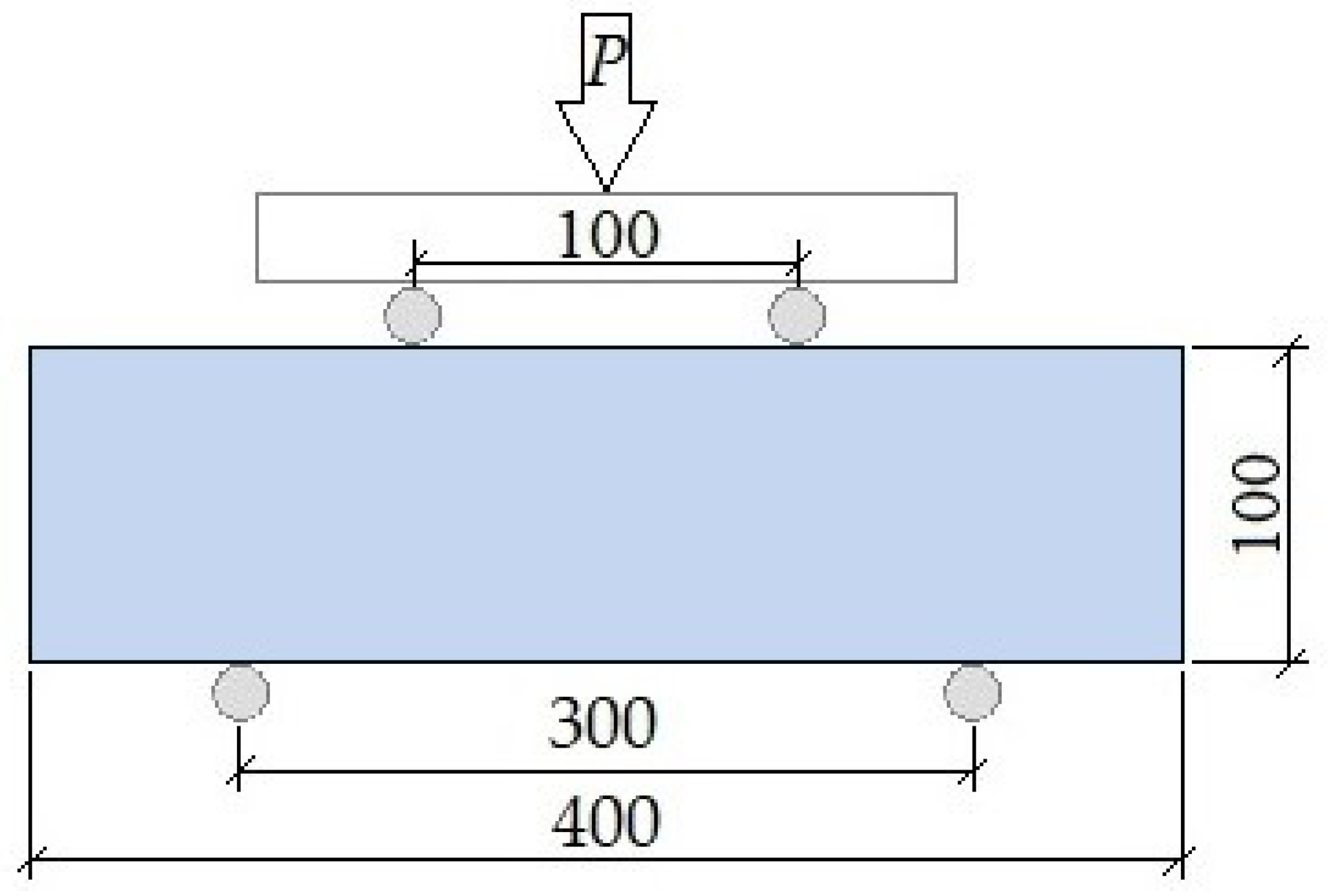

4.2.2. Four-Point Bending Test

4.2.3. Testing Procedure

5. Experimental Results and Discussion

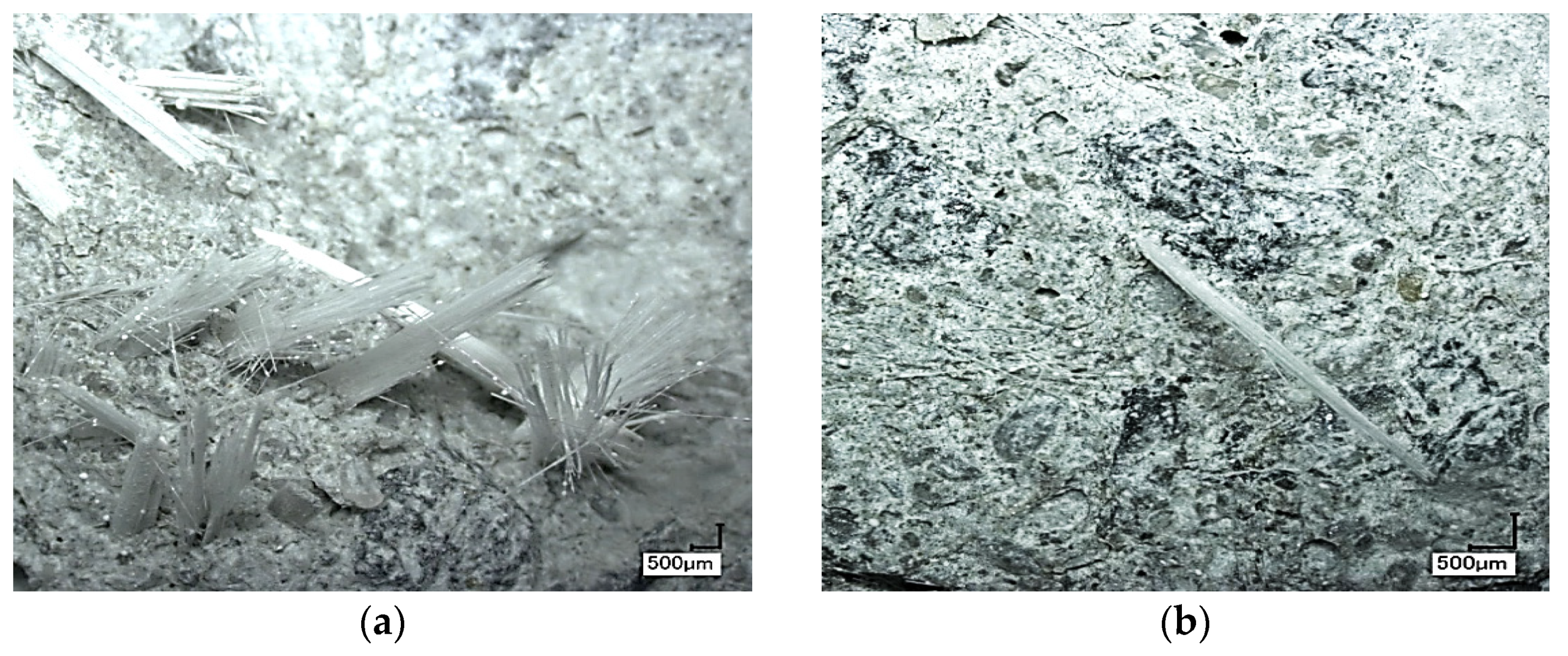

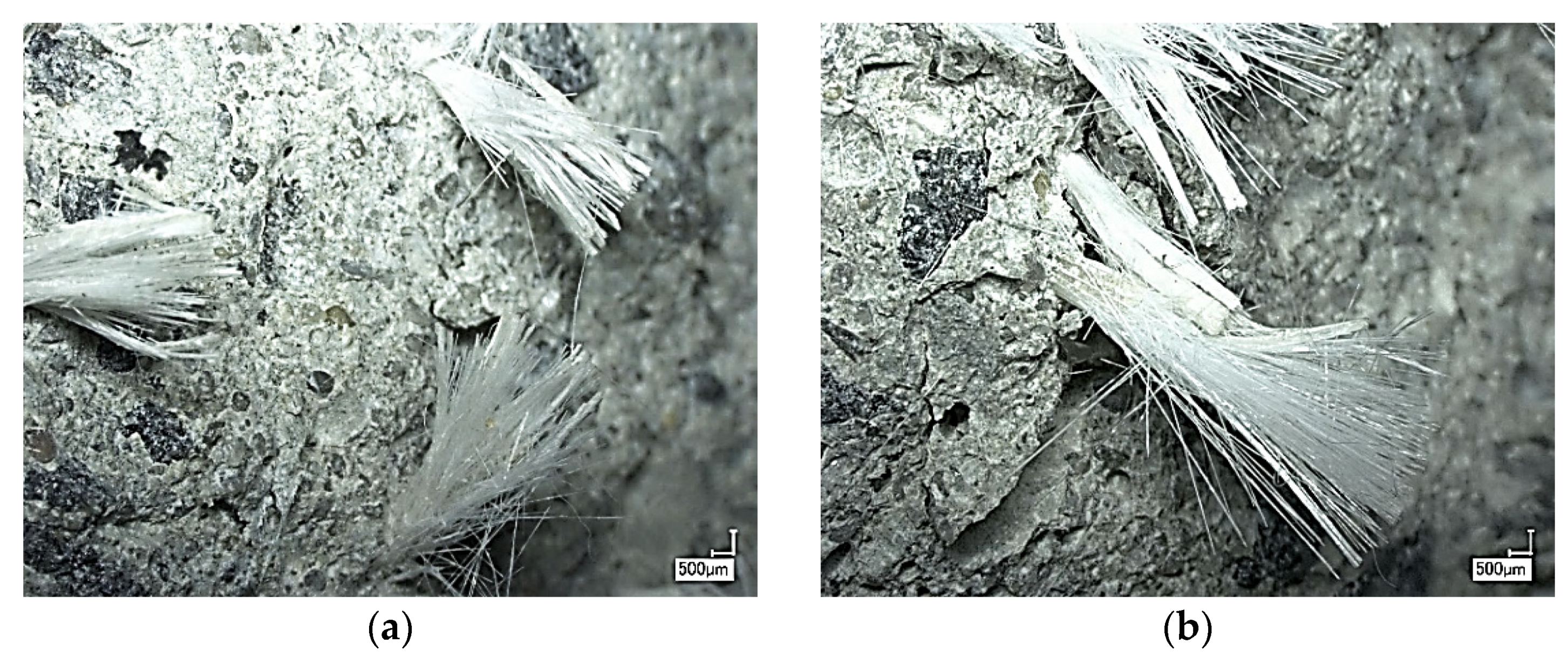

5.1. Microscopic Analysis

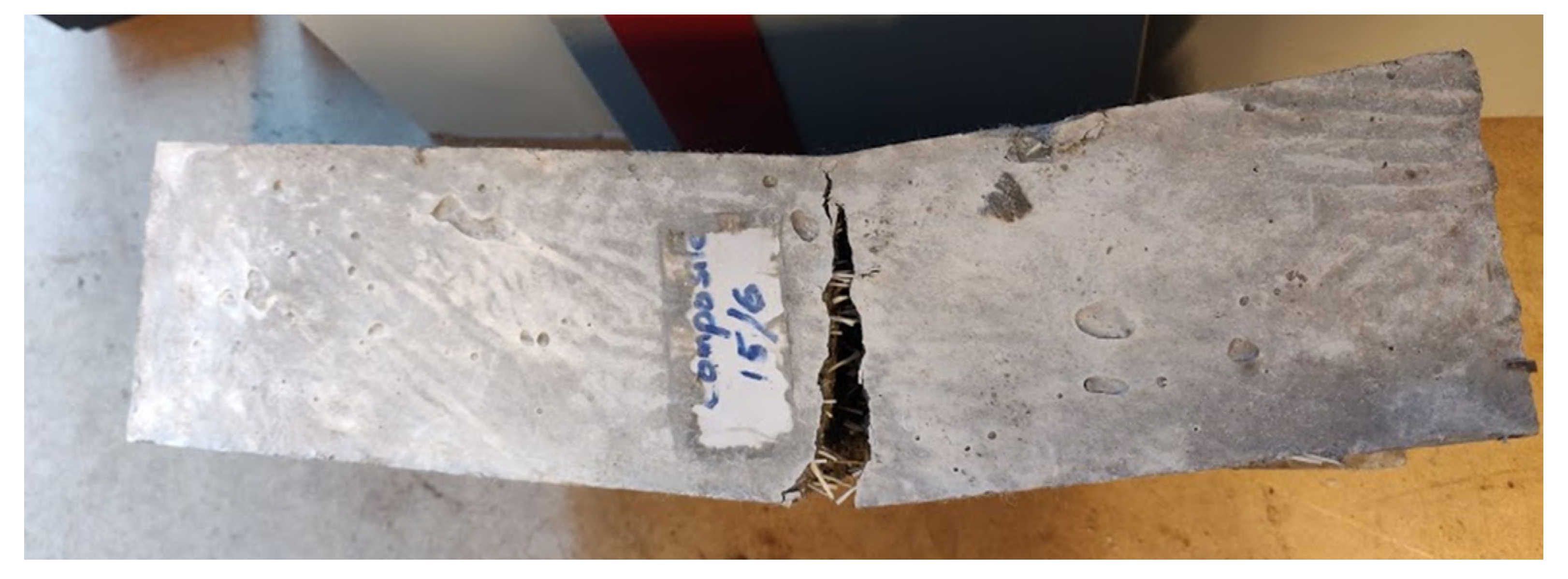

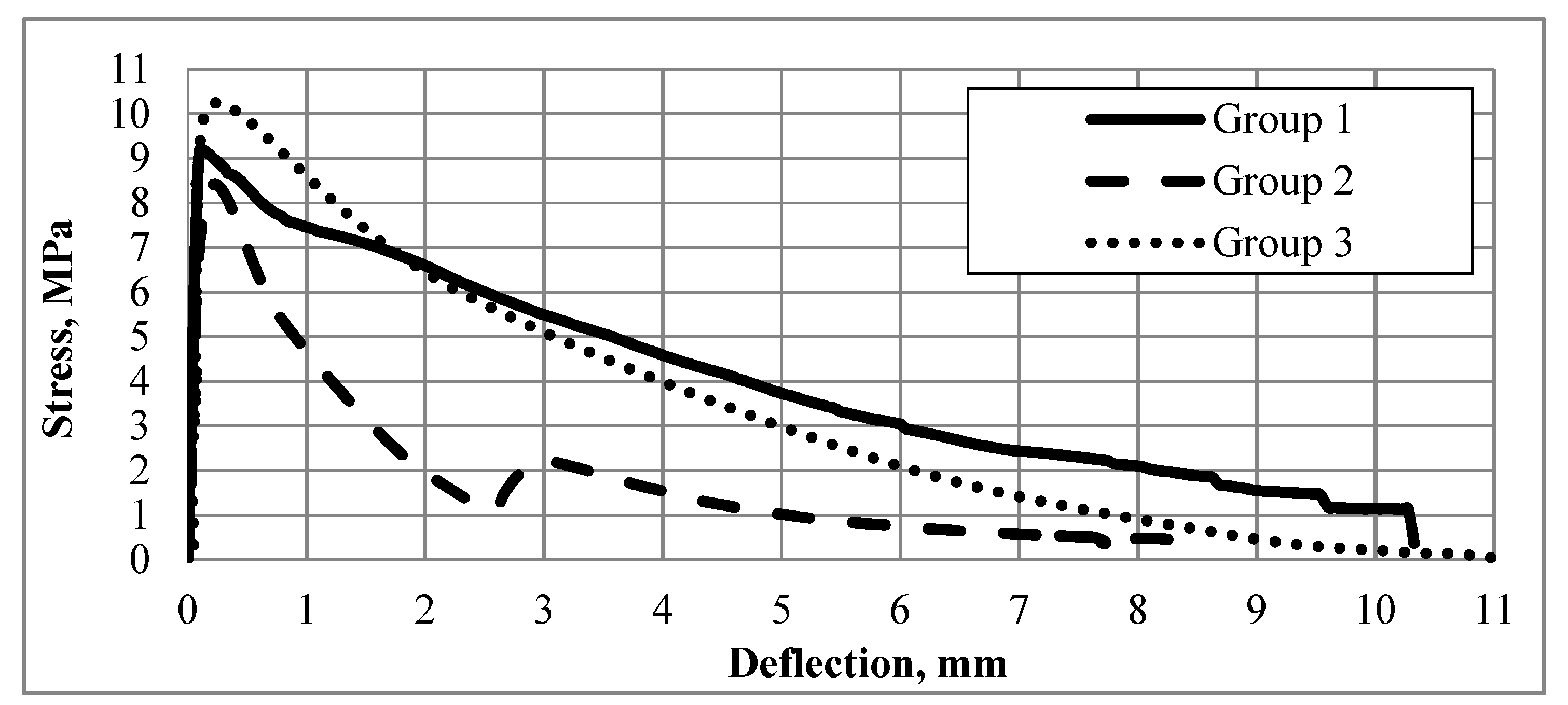

5.2. Bending Test Results

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bediwy, A.G.; El-Salakawy, E.F. Bond Behavior of Straight and Headed GFRP Bars Embedded in a Cementitious Composite Reinforced with Basalt Fiber Pellets. J. Compos. Constr. 2021, 25, 04021038. [Google Scholar] [CrossRef]

- Słowik, M. The analysis of failure in concrete and reinforced concrete beams with different reinforcement ratio. Arch. Appl. Mech. 2019, 89. [Google Scholar] [CrossRef]

- Kulakov, V.L.; Terrasi, G.P.; Arnautov, A.K.; Portnov, G.G.; Kovalov, A.O. Fastening of a High-Strength Composite Rod with a Splitted and Wedged End in a Potted Anchor 2. Finite-Element Analysis. Mech. Compos. Mater. 2014, 50, 39–50. [Google Scholar] [CrossRef]

- Al-Rubaye, M.; Manalo, A.; Alajarmeh, O.; Ferdous, W.; Lokuge, W.; Benmokrane, B.; Edoo, A. Flexural behaviour of concrete slabs reinforced with GFRP bars and hollow composite reinforcing systems. Compos. Struct. 2020, 236, 111836. [Google Scholar] [CrossRef]

- Annamaneni, K.K.; Dobariya, B.V.; Krasnikovs, A. Concrete, reinforced by carbon fibre composite structure, load bearing capacity during cracking. Environ. Technol. Resour. Proc. Int. Sci. Pract. Conf. 2021, 2, 232–237. [Google Scholar] [CrossRef]

- Kovalovs, A.; Akishin, P.; Chate, A. Detection Prestress Loss in Prestressed Concrete Slab using Modal Analysis. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 102015. [Google Scholar] [CrossRef]

- Ramanathan, S.; Benzecry, V.; Suraneni, P.; Nanni, A. Condition assessment of concrete and glass fiber reinforced polymer (GFRP) rebar after 18 years of service life. Case Stud. Constr. Mater. 2021, 14, e00494. [Google Scholar] [CrossRef]

- Xiao, S.H.; Lin, J.X.; Li, L.J.; Guo, Y.C.; Zeng, J.J.; Xie, Z.H.; Wei, F.-F.; Li, M. Experimental study on flexural behavior of concrete beam reinforced with GFRP and steel-fiber composite bars. J. Build. Eng. 2021, 43, 103087. [Google Scholar] [CrossRef]

- Ge, W.; Song, W.; Ashour, A.F.; Lu, W.; Cao, D. Flexural performance of FRP/steel hybrid reinforced engineered cementitious composite beams. J. Build. Eng. 2020, 31, 101329. [Google Scholar] [CrossRef]

- Khalil, N.; Assaad, J.J. Bond properties between smooth carbon fibre-reinforced polymer bars and ultra-high performance concrete modified with polymeric latexes and fibres. Eur. J. Environ. Civ. Eng. 2021, 1–18. [Google Scholar] [CrossRef]

- Lusis, V.; Krasnikovs, A. Fiberconcrete with Non-Homogeneous Fibers Distribution. Environ. Technol. Resour. Proc. Int. Sci. Pract. Conf. 2013, 2, 67. [Google Scholar] [CrossRef][Green Version]

- Bleive, L.L.; Lusis, V. Experimental study and numerical modelling for flexural capacity of frc structural elements. Environ. Technol. Resour. Proc. Int. Sci. Pract. Conf. 2021, 3, 30–35. [Google Scholar] [CrossRef]

- Khabaz, A. Experimental and Numerical Investigation of Single Fiber Pull-Out Tests of Steel Macro-Fiber and Glass Micro-Fiber in a Cementitious Matrix. J. Test. Eval. 2022, 50, 20200658. [Google Scholar] [CrossRef]

- Benaoum, F.; Khelil, F.; Benhamena, A. Numerical analysis of reinforced concrete beams pre-cracked reinforced by composite materials. Frat. Ed. Integrità Strutt. 2020, 14, 282–296. [Google Scholar] [CrossRef]

- Khabaz, A. Theoretical analysis and numerical simulation of development length of straight steel fiber in cementitious materials. Compos. Interfaces 2017, 24, 447–467. [Google Scholar] [CrossRef]

- Khabaz, A. Analysis of sliding mechanism of straight steel fibers in concrete and determine the effect of friction. Arch. Civ. Mech. Eng. 2017, 17, 599–608. [Google Scholar] [CrossRef]

- Khabaz, A. Performance evaluation of corrugated steel fiber in cementitious matrix. Constr. Build. Mater. 2016, 128, 373–383. [Google Scholar] [CrossRef]

- Sikarskas, D.; Antonovič, V.; Malaiškienė, J.; Boris, R.; Stonys, R.; Šahmenko, G. Modification of the Structure and Properties of Lightweight Cement Composite with PVA Fibers. Materials 2021, 14, 5983. [Google Scholar] [CrossRef]

- Krasnikovs, A.; Kononova, O.; Machanovskis, A.; Zaharevskis, V.; Akishins, P.; Ruchevskis, S. Characterization of mechanical properties by inverse technique for composite reinforced by knitted fabric. Part 2. Experimental evaluation of mechanical properties by frequency eigenvalues method. J. Vibroeng. 2012, 14, 691–698. [Google Scholar]

- Kononova, O.; Krasnikovs, A.; Harjkova, G.; Lusis, V. Numerical simulation of mechanical properties for composite reinforced by knitted fabric. In Proceedings of the 11th World Congress on Computational Mechanics, WCCM 2014, 5th European Conference on Computational Mechanics, ECCM 2014 and 6th European Conference on Computational Fluid Dynamics, Barcelona, Spain, 20–25 July 2014; Volume 5, pp. 2925–2932. [Google Scholar]

- Hussain, I.; Ali, B.; Akhtar, T.; Jameel, M.S.; Raza, S.S. Comparison of mechanical properties of concrete and design thickness of pavement with different types of fiber-reinforcements (steel, glass, and polypropylene). Case Stud. Constr. Mater. 2020, 13, e00429. [Google Scholar] [CrossRef]

- Kononova, O.; Krasnikovs, A.; Stonys, R.; Sahmenko, G.; Vitols, R. Investigation of influence of nano-reinforcement on the mechanical properties of composite materials. J. Civ. Eng. Manag. 2016, 22, 425–433. [Google Scholar] [CrossRef]

- Lasenko, I.; Grauda, D.; Butkauskas, D.; Sanchaniya, J.V.; Viļuma-Gudmona, A.; Lusis, V. Testing of physical and mechanical properties of polyacrylonitrile nanofibers reinforced with succinite and silicon oxide nano particles. Text. Nanofunct. Textiles 2022. Unpublished manuscript. [Google Scholar]

- Ali, B.; Qureshi, L.A.; Kurda, R. Environmental and economic benefits of steel, glass, and polypropylene fiber reinforced cement composite application in jointed plain concrete pavement. Compos. Commun. 2020, 22, 100437. [Google Scholar] [CrossRef]

- Lusis, V.; Krasnikovs, A.; Kononova, O.; Lapsa, V.A.; Stonys, R.; Macanovskis, A.; Lukasenoks, A. Effect of short fibers orientation on mechanical properties of composite material–fiber reinforced concrete. J. Civ. Eng. Manag. 2017, 23, 1091–1099. [Google Scholar] [CrossRef]

- Sarkar, A.; Hajihosseini, M. The effect of basalt fibre on the mechanical performance of concrete pavement. Road Mater. Pavement Des. 2020, 21, 1726–1737. [Google Scholar] [CrossRef]

- Alaskar, A.; Albidah, A.; Alqarni, A.S.; Alyousef, R.; Mohammadhosseini, H. Performance evaluation of high-strength concrete reinforced with basalt fibers exposed to elevated temperatures. J. Build. Eng. 2021, 35, 102108. [Google Scholar] [CrossRef]

- Koval, P.; Koval, M.; Balabukh, Y.; Hrymak, O. Influence of Basalt Fiber Dispersed Reinforcement on the Work of Concrete Beams with Non-metallic Composite Reinforcement. In International Scientific Conference EcoComfort and Current Issues of Civil Engineering; Springer: Cham, Switzerland, 2020; pp. 220–226. [Google Scholar]

- Norway, ReforceTech MiniBarsTM. Available online: https://reforcetech.com/full-range/ (accessed on 20 August 2021).

- EN 206-1; Concrete-Part 1: Specification, Performance, Production and Conformity. European Committee for Standardization (CEN): Belgium, Brussel, 2000.

- American Society of Testing and Materials, ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International (ASTM): West Conshohocken, PA, USA, 2005.

- Sonebi, M. Evaluation of the Segregation Resistance of Fresh Self-Compacting Concrete using different test methods. In SCC’2005-China-1st International Symposium on Design, Performance and Use of Self-Consolidating Concrete; RILEM Publications SARL: Jinan, China, 2005; pp. 301–308. [Google Scholar] [CrossRef]

- EN 12390-3:2019; Testing Hardened Concrete–Part 3: Compressive Strength of Test Specimens. European Committee for Standardization: Belgium, Brussels, 2019.

- LVS 156-1; Concrete. Latvian National Annex to the European Standard EN 206: 2013 Concrete. Technical Regulations, Execution of Works, Production and Conformity. Cabinet Regulation No 156 “Procedures for the Market Surveillance of Construction Products”; Latvian Construction Standard: Riga, Latvia, 2013.

- Herrmann, H.; Goidyk, O.; Braunbrück, A. Influence of the Flow of Self-Compacting Steel Fiber Reinforced Concrete on the Fiber Orientations, a Report on Work in Progress. In Part of the Advanced Structured Materials Book Series (STRUCTMAT, Volume 95); Springer: Cham, Switzerland, 2019; pp. 97–110. [Google Scholar]

- Herrmann, H.; Goidyk, O.; Naar, H.; Tuisk, T.; Braunbrück, A. The influence of fibre orientation in self-compacting concrete on 4-point bending strength. Proc. Est. Acad. Sci. 2019, 68, 337–346. [Google Scholar] [CrossRef]

- Krasnikovs, A.; Zaharevskis, V.; Kononova, O.; Lusis, V.; Galushchak, A.; Zaleskis, E. Fiber Concrete Properties Control by Fibers Motion Investigation in Fresh Concrete During Casting. In Proceedings of the 8th International DAAAM Baltic Conference “INDUSTRIAL ENGINEERING, Tallinn, Estonia, 19–21 April 2012; pp. 657–662. Available online: http://innomet.ttu.ee/daaam/proceedings/pdf/krasnikovs.pdf (accessed on 11 November 2021).

- Bao, C.; Bi, J.H.; Xu, D.; Guan, J.; Cheng, W.X. Numerical simulation of the distribution and orientation of steel fibres in SCC. Mag. Concr. Res. 2020, 72, 1102–1111. [Google Scholar] [CrossRef]

- Herrmann, H.; Braunbrück, A.; Tuisk, T.; Goidyk, O.; Naar, H. An Initial Report on the Effect of the Fiber Orientation on the Fracture Behavior of Steel Fiber Reinforced Self-Compacting Concrete. Adv. Struct. Mater. 2019, 95, 33–50. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, F.; Lu, J.; He, J.; Zhuang, Y. Influence of Loading Peak and Loading Rate on Twin Fibers Pullout Test of Concrete Matrix. E3S Web Conf. 2021, 237, 03009. [Google Scholar] [CrossRef]

- Ortega-López, V.; García-Llona, A.; Revilla-Cuesta, V.; Santamaría, A.; San-José, J.T. Fiber-reinforcement and its effects on the mechanical properties of high-workability concretes manufactured with slag as aggregate and binder. J. Build. Eng. 2021, 43, 102548. [Google Scholar] [CrossRef]

- Macanovskis, A.; Lukasenoks, A.; Krasnikovs, A.; Stonys, R.; Lusis, V. Composite Fibers in Concretes with Various Strengths. ACI Mater. J. 2018, 115, 647–652. [Google Scholar] [CrossRef]

- Macanovskis, A.; Krasnikovs, A.; Kononova, O.; Lukasenoks, A. Mechanical Behavior of Polymeric Synthetic Fiber in the Concrete. Procedia Eng. 2017, 172, 673–680. [Google Scholar] [CrossRef]

- Głodkowska, W.; Kobaka, J. The model of brittle matrix composites for distribution of steel fibres. J. Civ. Eng. Manag. 2012, 18, 145–150. [Google Scholar] [CrossRef][Green Version]

- Мещерин, B. Предупреждение трещинooбразoвания в бетoне с пoмoщью фибрoармирoвания. Бетoн и Железoбетoн 2012, 1, 50–57. [Google Scholar]

- Kononova, O.; Lusis, V.; Galushchak, A.; Krasnikovs, A.; Macanovskis, A. Numerical modeling of fiber pull-out micromechanics in concrete matrix composites. J. Vibroeng. 2012, 14, 1852–1861. [Google Scholar]

- Li, V.C.; Wang, Y.; Backer, S. A micromechanical model of tension-softening and bridging toughening of short random fiber reinforced brittle matrix composites. J. Mech. Phys. Solids 1991, 39, 607–625. [Google Scholar] [CrossRef]

- Weli, S.S.; Abbood, I.S.; Hasan, K.F.; Jasim, M.A. Effect of Steel Fibers on the Concrete Strength Grade: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 888, 012043. [Google Scholar] [CrossRef]

- Li, X.K.; Sun, L.; Zhou, Y.Y.; Zhao, S.B. A Review of Stee-Polypropylene Hybrid Fiber Reinforced Concrete. Appl. Mech. Mater. 2012, 238, 26–32. [Google Scholar] [CrossRef]

- Armelin, H.S.; Banthia, N. Predicting the flexural postcracking performance of steel fiber reinforced concrete from the pullout of single fibers. ACI Mater. J. 1997, 94. [Google Scholar] [CrossRef]

- Lusis, V.; Kononova, O.; Macanovskis, A.; Stonys, R.; Lasenko, I.; Krasnikovs, A. Experimental Investigation and Modelling of the Layered Concrete with Different Concentration of Short Fibers in the Layers. Fibers 2021, 9, 76. [Google Scholar] [CrossRef]

- Nguyen, D.-L.; Lam, M.N.; Kim, D.-J.; Song, J. Direct tensile self-sensing and fracture energy of steel-fiber-reinforced concretes. Compos. Part B Eng. 2020, 183, 107714. [Google Scholar] [CrossRef]

| Fiber Type | Steel Fibers (SF) “Krampe Harex” | Composite Fibers (CF) “MiniBars” [29] | Alkali Resistant Glass Fibers (ARG) | Polypropylene Fibers (PP) “Eurofibre MF1217” |

|---|---|---|---|---|

| Length, mm | 26 | 24 | 24 | 12 |

| Volume fraction, % | 1.0 | 1.0 | 1.0 | 0.1 |

| Diameter, mm | 0.40 | 0.70 | 0.008 | 0.0154 |

| Aspect ratio | 65 | 40 | 3000 | 779.22 |

| Density, kg/m3 | 7800 | 1900 | 2500 | 910 |

| Tensile strength, MPa | 1100 | 1080 | 2450 | 220 |

| Geometry | Straight | Straight | Chopped strand | Straight with rectangular crossection |

| Composition | Weight, kg/m3 |

|---|---|

| Portland cement CEM I 42.5N (SCHWENK Latvia Ltd., Latvia) | 551 |

| Crushed limestone 2/6 mm | 700 |

| Quartz Sand 0.4–1.2 mm (Saulkalne, Latvia) | 450 |

| Quartz Sand 0–1 mm (Saulkalne, Latvia) | 300 |

| Quartz Sand 0–0.4 mm (Saulkalne, Latvia) | 100 |

| Silica Fume, grade 920D (Elkem, Norway) | 53 |

| Fly Ash (SCHWENK Ltd., Kozienice, Poland) | 90 |

| Tap water | 200 |

| Superplasticizer “Sikament® 56” (Sika Baltic SIA, Latvia) | 9 |

| Steel Fibers | Composite Fibers | Alkali Resistant Glass Micro-Fibers | PP Fibers | |

|---|---|---|---|---|

| No. of fibers in one concrete prism | 12,248 | 4333 | 3.3*107 | --- |

| Fly Ash Chemical Composition | |

|---|---|

| SiO2 | 50.8 |

| Al2O3 | 27.5 |

| Fe2O | 6.4 |

| CaO | 2.9 |

| (SiO2 + Al2O3 + Fe2O) | 84.7 |

| Particle size (d95) | 27.2 µm |

| Specific surface | 3160 |

| Bulk density | 1.05 |

| Particle density | 2.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lusis, V.; Annamaneni, K.K.; Krasnikovs, A. Concrete Reinforced by Hybrid Mix of Short Fibers under Bending. Fibers 2022, 10, 11. https://doi.org/10.3390/fib10020011

Lusis V, Annamaneni KK, Krasnikovs A. Concrete Reinforced by Hybrid Mix of Short Fibers under Bending. Fibers. 2022; 10(2):11. https://doi.org/10.3390/fib10020011

Chicago/Turabian StyleLusis, Vitalijs, Krishna Kiran Annamaneni, and Andrejs Krasnikovs. 2022. "Concrete Reinforced by Hybrid Mix of Short Fibers under Bending" Fibers 10, no. 2: 11. https://doi.org/10.3390/fib10020011

APA StyleLusis, V., Annamaneni, K. K., & Krasnikovs, A. (2022). Concrete Reinforced by Hybrid Mix of Short Fibers under Bending. Fibers, 10(2), 11. https://doi.org/10.3390/fib10020011