Phase Selectivity in Cr and N Co-Doped TiO2 Films by Modulated Sputter Growth and Post-Deposition Flash-Lamp-Annealing

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Sample Characterization

3. Results and Discussion

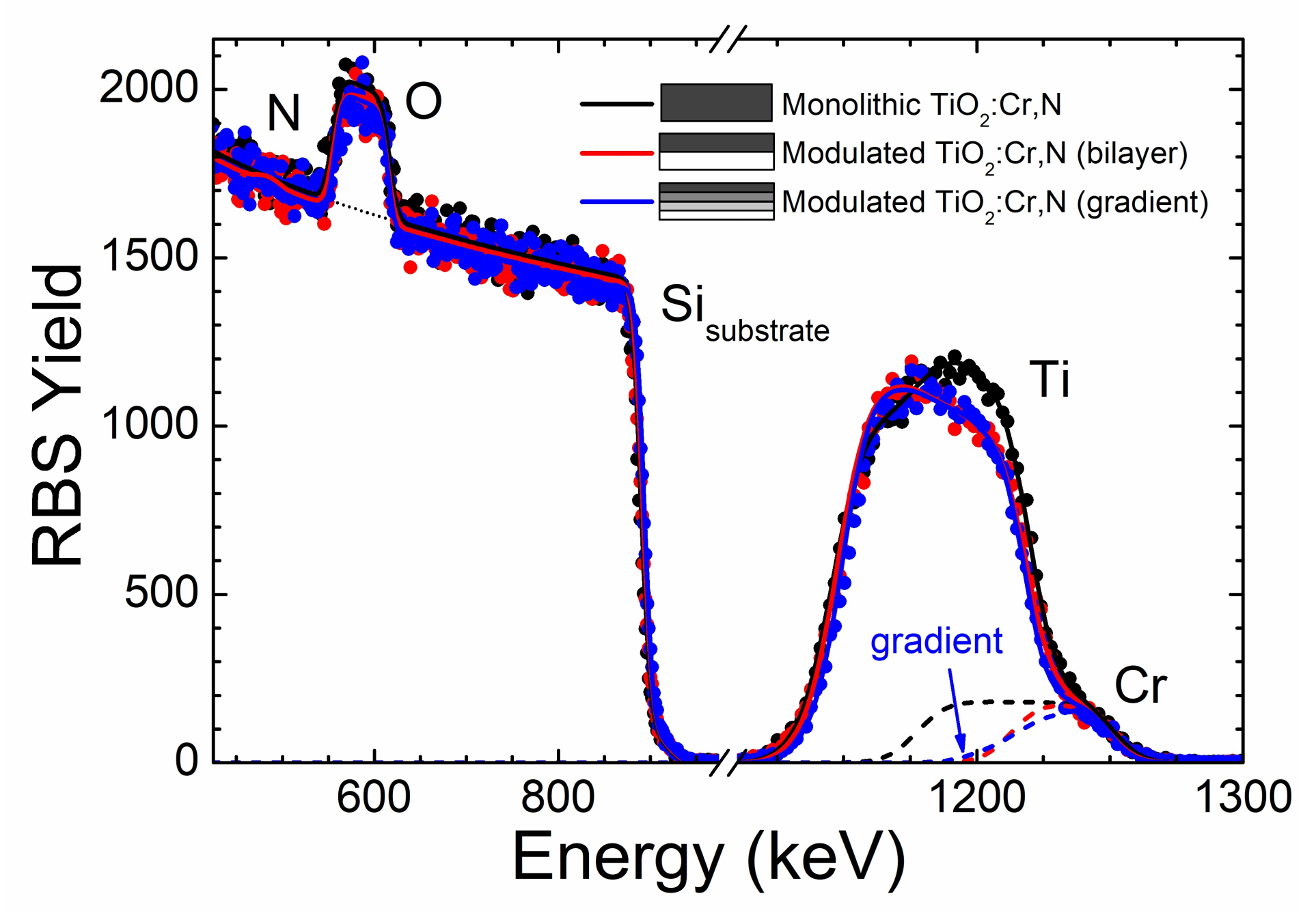

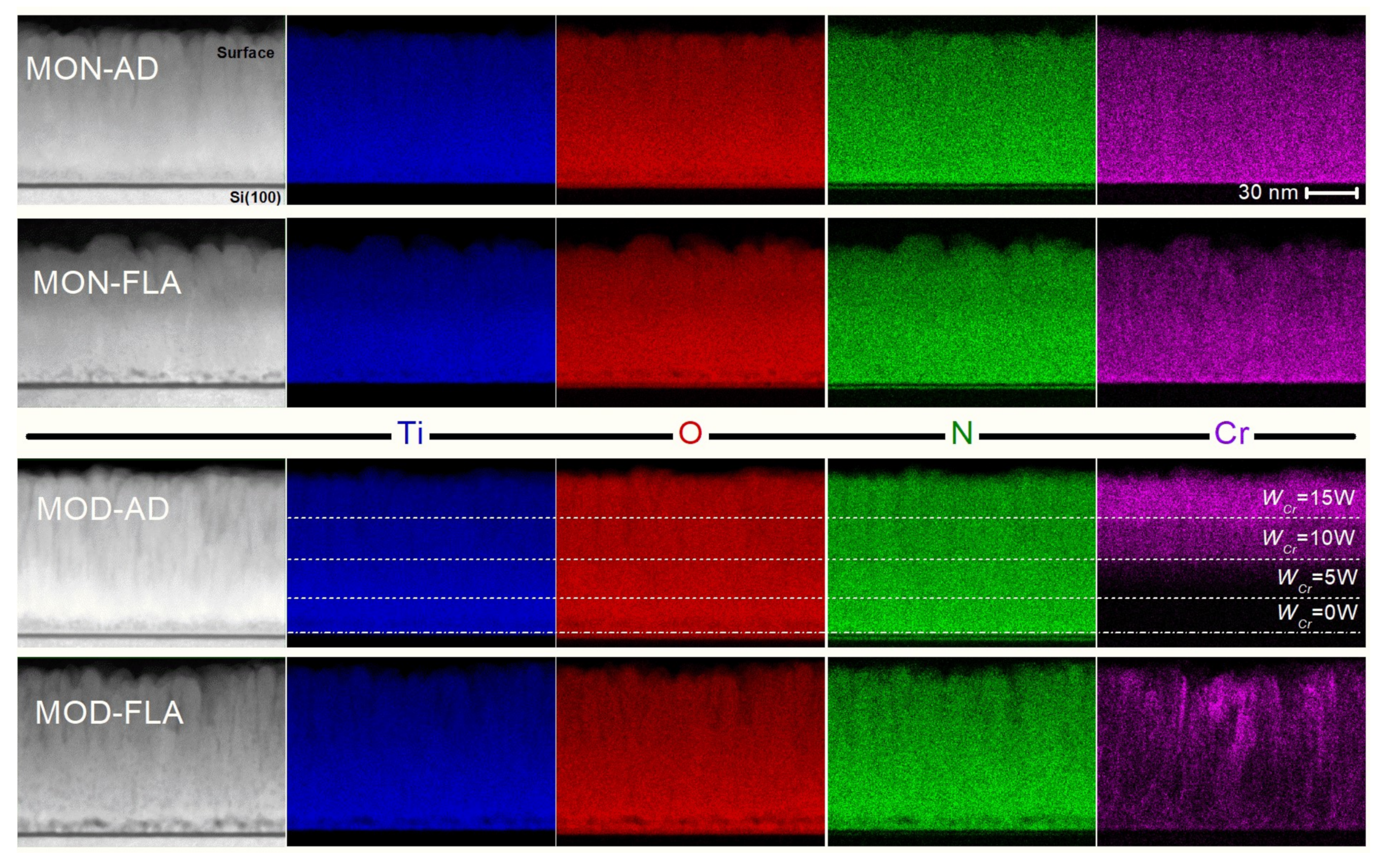

3.1. Compositional Profile in Monolithic and Modulated Films

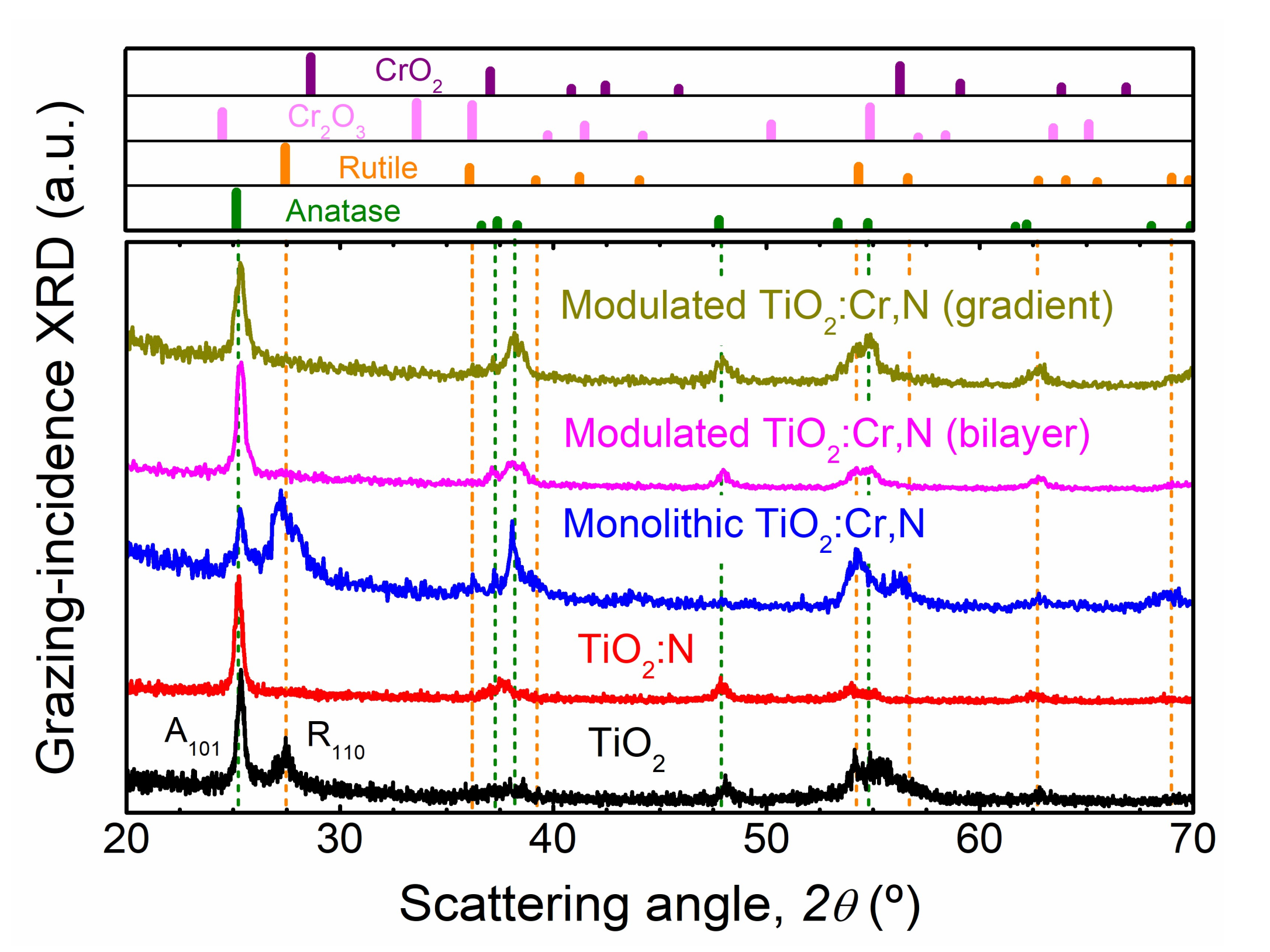

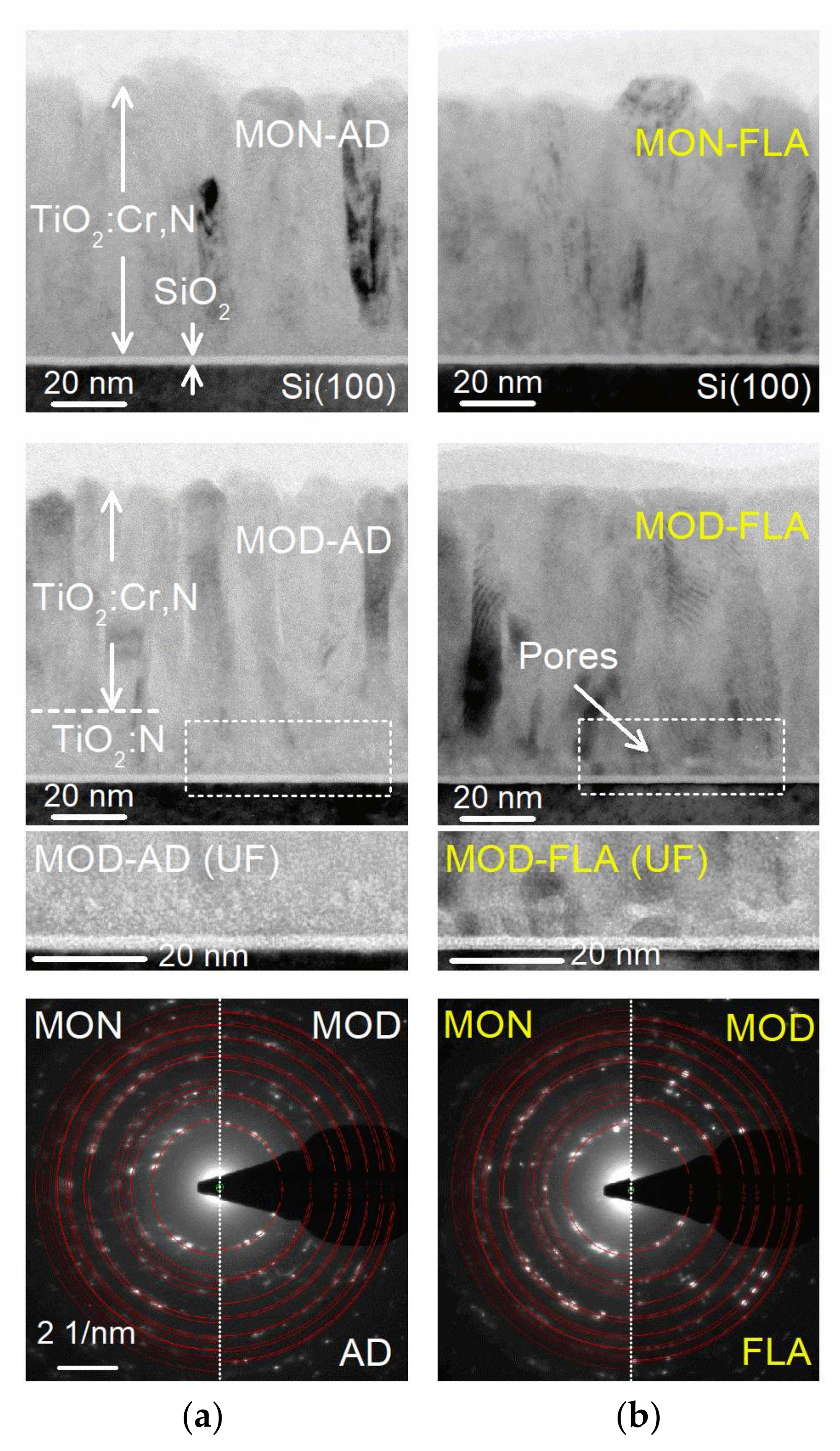

3.2. Structural Investigations of Monolithic and Modulated Films

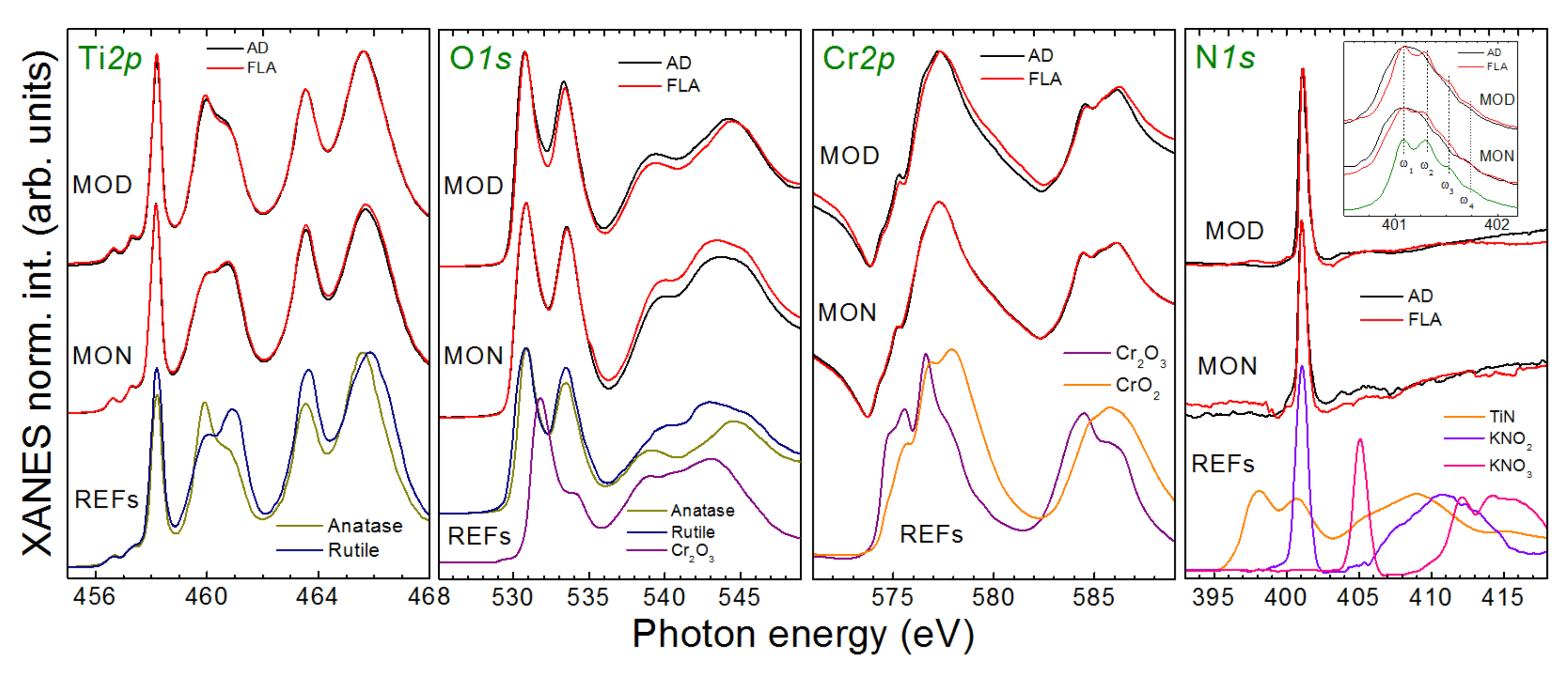

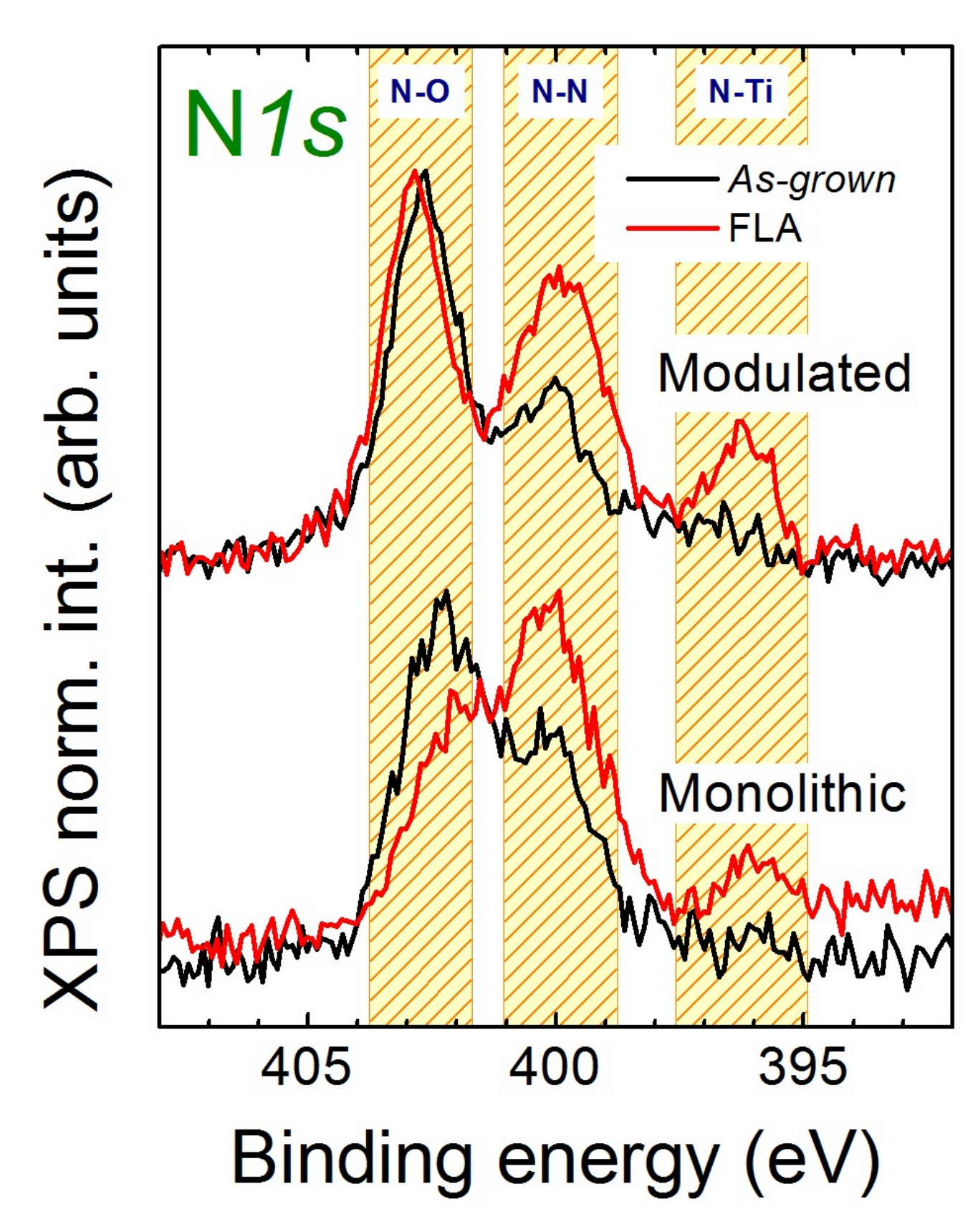

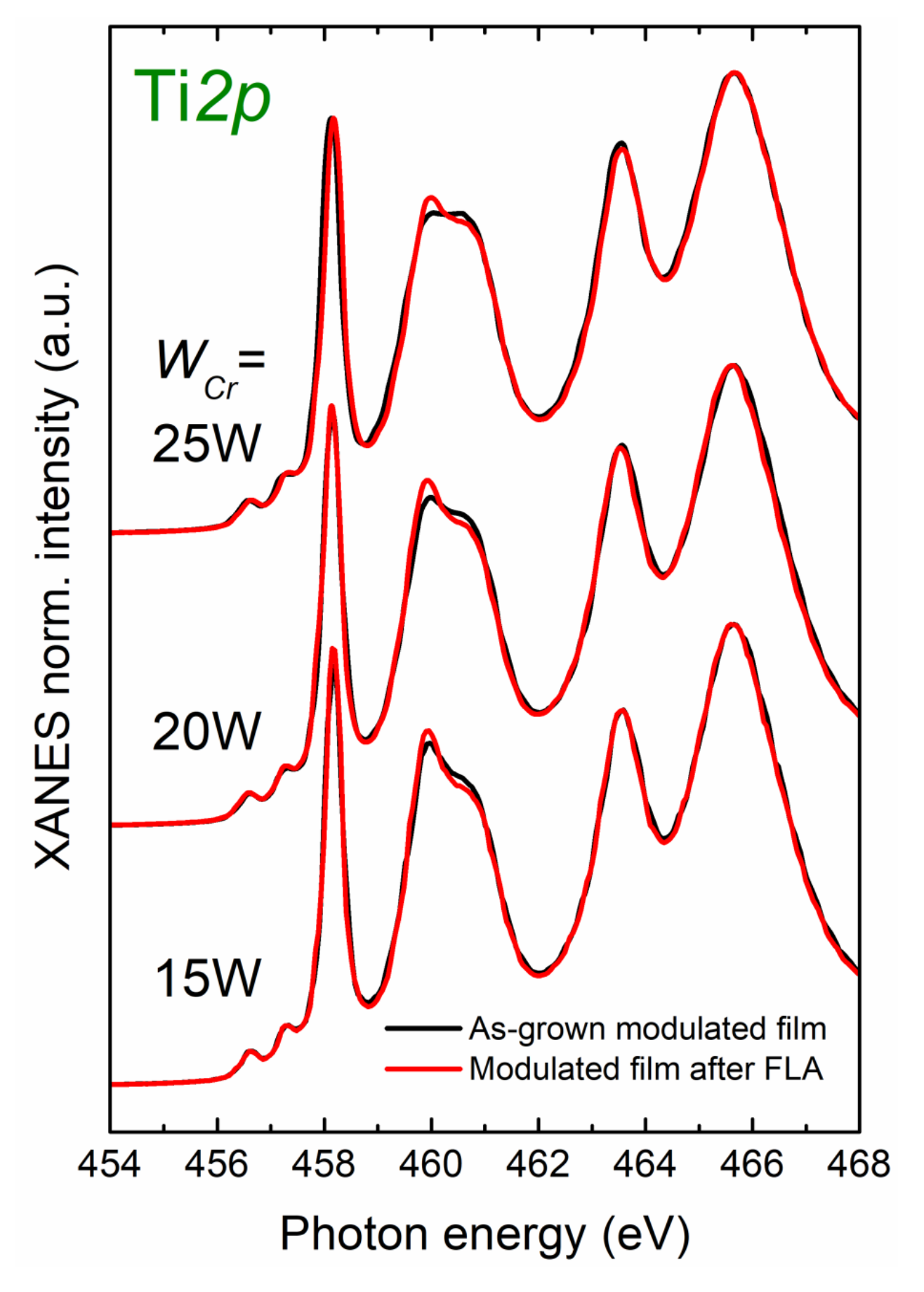

3.3. Effect of Flash-Lamp-Annealing (FLA)

3.4. Final Remarks

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Diebold, U. The surface science of titanium dioxide. Surf. Sci. Rep. 2003, 48, 53–229. [Google Scholar] [CrossRef]

- Henderson, M.A. A surface science perspective on TiO2 photocatalysis. Surf. Sci. Rep. 2011, 66, 185–297. [Google Scholar] [CrossRef]

- Matsumoto, Y.; Murakami, M.; Shono, T.; Hasegawa, T.; Fukumura, T.; Kawasaki, M.; Ahmet, P.; Chikyow, T.; Koshihara, S.; Koinuma, H. Room-temperature ferromagnetism in transparent transition metal-doped titanium dioxide. Science 2001, 291, 854–856. [Google Scholar] [CrossRef] [PubMed]

- Serpone, N. Is the band gap of pristine TiO2 narrowed by anion- and cation-doping of titanium dioxide in second-generation photocatalysts? J. Phys. Chem. B 2006, 110, 24287–24293. [Google Scholar] [CrossRef] [PubMed]

- Vitiello, G.; Pezzella, A.; Calcagno, V.; Silvestri, B.; Raiola, L.; D’Errico, G.; Costantini, A.; Branda, F.; Luciani, G. 5,6-Dihydroxyindole-2-carboxylic acid–TiO2 charge transfer complexes in the radical polymerization of melanogenic precursor(s). J. Phys. Chem. C 2016, 120, 6262–6268. [Google Scholar] [CrossRef]

- Chiodi, M.; Cheney, C.P.; Vilmercati, P.; Cavaliere, E.; Mannella, N.; Weitering, H.H.; Gavioli, L. Enhanced dopant solubility and visible-light absorption in Cr–N codoped TiO2 nanoclusters. J. Phys. Chem. C 2012, 116, 311–318. [Google Scholar] [CrossRef]

- Asahi, R.; Morikawa, T.; Ohwaki, T.; Aoki, K.; Taga, Y. Visible-light photocatalysis in nitrogen-doped titanium oxides. Science 2001, 293, 269–271. [Google Scholar] [CrossRef]

- Batzill, M.; Morales, E.H.; Diebold, U. Influence of nitrogen doping on the defect formation and surface properties of TiO2 rutile and anatase. Phys. Rev. Lett. 2006, 96, 026103. [Google Scholar] [CrossRef]

- Clarizia, L.; Vitiello, G.; Pallotti, D.K.; Silvestri, B.; Nadagouda, M.; Lettieri, S.; Luciani, G.; Andreozzi, R.; Maddalena, P.; Marotta, R. Effect of surface properties of copper-modified commercial titanium dioxide photocatalysts on hydrogen production through photoreforming of alcohols. Int. J. Hydrogen Energy 2017, 42, 28349–28362. [Google Scholar] [CrossRef]

- Zhu, J.; Deng, Z.; Chen, F.; Zhang, J.; Chen, H.; Anpo, M.; Huang, J.; Zhang, L. Hydrothermal doping method for preparation of Cr3+–TiO2 photocatalysts with concentration gradient distribution of Cr3+. Appl. Catal. B: Environ. 2006, 62, 329–335. [Google Scholar] [CrossRef]

- Fan, X.; Chen, X.; Zhu, S.; Li, Z.; Yu, T.; Ye, J.; Zou, Z. The structural, physical and photocatalytic properties of the mesoporous Cr-doped TiO2. J. Mol. Catal. A Chem. 2008, 284, 155–160. [Google Scholar] [CrossRef]

- Kaspar, T.C.; Heald, S.M.; Wang, C.M.; Bryan, J.D.; Droubay, T.; Shutthanandan, V.; Thevuthasan, S.; McCready, D.E.; Kellock, A.J.; Gamelin, D.R.; et al. Negligible magnetism in excellent structural quality CrxTi1−xO2 anatase: contrast with high-TC ferromagnetism in structurally defective CrxTi1−xO2. Phys. Rev. Lett. 2005, 95, 217203. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Qiu, X.; Iancu, V.; Chen, X.Q.; Pan, H.; Wang, W.; Dimitrijevic, M.N.; Rajh, T.; Meyer, H.M.; Paranthaman, M.P.; et al. Band gap narrowing of titanium oxide semiconductors by noncompensated anion-cation codoping for enhanced visible-light photoactivity. Phys. Rev. Lett. 2009, 103, 226401. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Cheng, Z.; Tan, S.; Shao, X.; Wang, B.; Hou, J.G. Characterization of Cr–N codoped anatase TiO2(001) thin films epitaxially grown on SrTiO3(001) substrate. Surf. Sci. 2013, 616, 93. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhang, L.; Dong, S.; Ma, X.; Ju, H.; Zhu, J.; Cui, X.; Zhao, J.; Wang, B. Electronic properties of Cr–N codoped rutile TiO2(110) thin films. Surf. Sci. 2017, 666, 84–89. [Google Scholar] [CrossRef]

- Kollbek, K.; Szkudlarek, A.; Marzec, M.M.; Lyson-Sypien, B.; Cecot, M.; Bernasik, A.; Radecka, M.; Zakrzewska, K. Optical and electrical properties of Ti(Cr)O2:N thin films deposited by magnetron co-sputtering. Appl. Surf. Sci. 2016, 380, 73–82. [Google Scholar] [CrossRef]

- Gago, R.; Prucnal, S.; Pérez-Casero, R.; Caretti, I.; Jiménez, I.; Lungwitz, F.; Cornelius, S. Structural impact of chromium incorporation in as-grown and flash-lamp-annealed sputter deposited titanium oxide films. J. Alloy Compd. 2017, 729, 438–445. [Google Scholar] [CrossRef]

- Xu, M.; Gao, Y.; Martinez-Moreno, E.; Kunst, M.; Muhler, M.; Wang, Y.; Idriss, H.; Wöll, C. Photocatalytic activity of bulk TiO2 anatase and rutile single crystals using infrared absorption spectroscopy. Phys. Rev. Lett. 2011, 106, 138302. [Google Scholar] [CrossRef]

- Houska, J.; Mraz, S.; Schneider, J.M. Experimental and molecular dynamics study of the growth of crystalline TiO2. J. Appl. Phys. 2012, 112, 073527. [Google Scholar] [CrossRef]

- Gago, R.; Redondo-Cubero, A.; Vinnichenko, M.; Lehmann, J.; Munnik, F.; Palomares, F.J. Spectroscopic evidence of NOx formation and band-gap narrowing in N-doped TiO2 films grown by pulsed magnetron sputtering. Mater. Chem. Phys. 2012, 136, 729–736. [Google Scholar] [CrossRef]

- Skorupa, W.; Gebel, T.; Yankov, R.A.; Paul, S.; Lerch, W.; Downey, D.F.; Arevalo, E.A. Advanced thermal processing of ultrashallow implanted junctions using flash lamp annealing. J. Electrochem. Soc. 2005, 152, G436–G440. [Google Scholar] [CrossRef]

- Mayer, M. SIMNRA User’s Guide 6.05; Max-Planck-Institut für Plasmaphysik: Garching, Germany, 2009. [Google Scholar]

- Barradas, N.P.; Jeynes, C.; Webb, R.P. Simulated annealing analysis of Rutherford backscattering data. Appl. Phys. Lett. 1997, 71, 291–293. [Google Scholar] [CrossRef]

- Stöhr, J. NEXAFS Spectroscopy; Springer: New York, NY, USA, 1992. [Google Scholar]

- Crocombette, J.P.; Jollet, F. Ti 2p X-ray absorption in titanium dioxides (TiO2): The influence of the cation site environment. J. Phys. Condens. Matter 1994, 6, 10811. [Google Scholar] [CrossRef]

- Gago, R.; Vinnichenko, M.; Redondo-Cubero, A.; Czigány, Z.; Vázquez, L. Surface morphology of heterogeneous nanocrystalline rutile/amorphous anatase TiO2 films grown by reactive pulsed magnetron sputtering. Plasma Process. Polym. 2010, 7, 813–823. [Google Scholar] [CrossRef]

- Lindgren, T.; Mwabora, J.M.; Avendano, E.; Jonsson, J.; Hoel, A.; Granqvist, C.G.; Lindquist, S. Photoelectrochemical and optical properties of nitrogen doped titanium dioxide films prepared by reactive DC magnetron sputtering. J. Phys. Chem. B 2003, 107, 5709–5716. [Google Scholar] [CrossRef]

- Madhavi, V.; Kondaiah, P.; Mohan Rao, G. Influence of silver nanoparticles on titanium oxide and nitrogen doped titanium oxide thin films for sun light photocatalysis. Appl. Surf. Sci. 2018, 436, 708–719. [Google Scholar]

- Mwabora, J.M.; Lindgren, T.; Avendaño, E.; Jaramillo, T.F.; Lu, J.; Lindquist, S.E.; Granqvist, C.G. Structure, composition, and morphology of photoelectrochemically active TiO2−xNx thin films deposited by reactive DC magnetron sputtering. J. Phys. Chem. B 2004, 108, 20193–20198. [Google Scholar] [CrossRef]

- Klug, H.P.; Alexander, L.E. X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials; Wiley: Hoboken, NJ, USA, 1974. [Google Scholar]

- Ruus, R.; Kikas, A.; Saar, A.; Ausmees, A.; Nommiste, E.; Aarik, J.; Aidla, A.; Uustare, T.; Martinson, I. Ti 2p and O 1s X-ray absorption of TiO2 polymorphs. Solid State Commun. 1997, 104, 199–203. [Google Scholar] [CrossRef]

- Kucheyev, S.O.; Sadigh, B.; Baumann, T.F.; Wang, Y.M.; Felter, T.E.; Van Buuren, T.; Gash, A.E.; Satcher, J.H., Jr.; Hamza, A.V. Electronic structure of chromia aerogels from soft X-ray absorption spectroscopy. J. Appl. Phys. 2007, 101, 124315. [Google Scholar] [CrossRef]

- Schedel-Niedrig, T.; Neisius, T.; Simmons, C.T.; Köhler, K. X-ray absorption spectroscopy of small chromium oxide particles (Cr2O3, CrO2) supported on titanium dioxide. Langmuir 1996, 12, 6377–6381. [Google Scholar]

- Dedkov, Y.S.; Vinogradov, A.S.; Fonin, M.; König, C.; Vyalikh, D.V.; Preobrajenski, A.B.; Krasnikov, S.A.; Kleimenov, E.Y.; Nesterov, M.A.; Rüdiger, U.; et al. Correlations in the electronic structure of half-metallic ferromagnetic CrO2 films: An X-ray absorption and resonant photoemission spectroscopy study. Phys. Rev. B 2005, 72, 060401(R). [Google Scholar] [CrossRef]

- Gago, R.; Vinnichenko, M.; Hübner, R.; Redondo-Cubero, A. Bonding structure and morphology of chromium oxide films grown by pulsed-DC reactive magnetron sputter deposition. J. Alloy Compd. 2016, 672, 529–535. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gago, R.; Prucnal, S.; Hübner, R.; Munnik, F.; Esteban-Mendoza, D.; Jiménez, I.; Palomares, J. Phase Selectivity in Cr and N Co-Doped TiO2 Films by Modulated Sputter Growth and Post-Deposition Flash-Lamp-Annealing. Coatings 2019, 9, 448. https://doi.org/10.3390/coatings9070448

Gago R, Prucnal S, Hübner R, Munnik F, Esteban-Mendoza D, Jiménez I, Palomares J. Phase Selectivity in Cr and N Co-Doped TiO2 Films by Modulated Sputter Growth and Post-Deposition Flash-Lamp-Annealing. Coatings. 2019; 9(7):448. https://doi.org/10.3390/coatings9070448

Chicago/Turabian StyleGago, Raúl, Slawomir Prucnal, René Hübner, Frans Munnik, David Esteban-Mendoza, Ignacio Jiménez, and Javier Palomares. 2019. "Phase Selectivity in Cr and N Co-Doped TiO2 Films by Modulated Sputter Growth and Post-Deposition Flash-Lamp-Annealing" Coatings 9, no. 7: 448. https://doi.org/10.3390/coatings9070448

APA StyleGago, R., Prucnal, S., Hübner, R., Munnik, F., Esteban-Mendoza, D., Jiménez, I., & Palomares, J. (2019). Phase Selectivity in Cr and N Co-Doped TiO2 Films by Modulated Sputter Growth and Post-Deposition Flash-Lamp-Annealing. Coatings, 9(7), 448. https://doi.org/10.3390/coatings9070448