RF Magnetron Sputtering Deposition of TiO2 Thin Films in a Small Continuous Oxygen Flow Rate

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrate Preparation

2.2. Deposition Parameters

2.3. Characterization Techniques

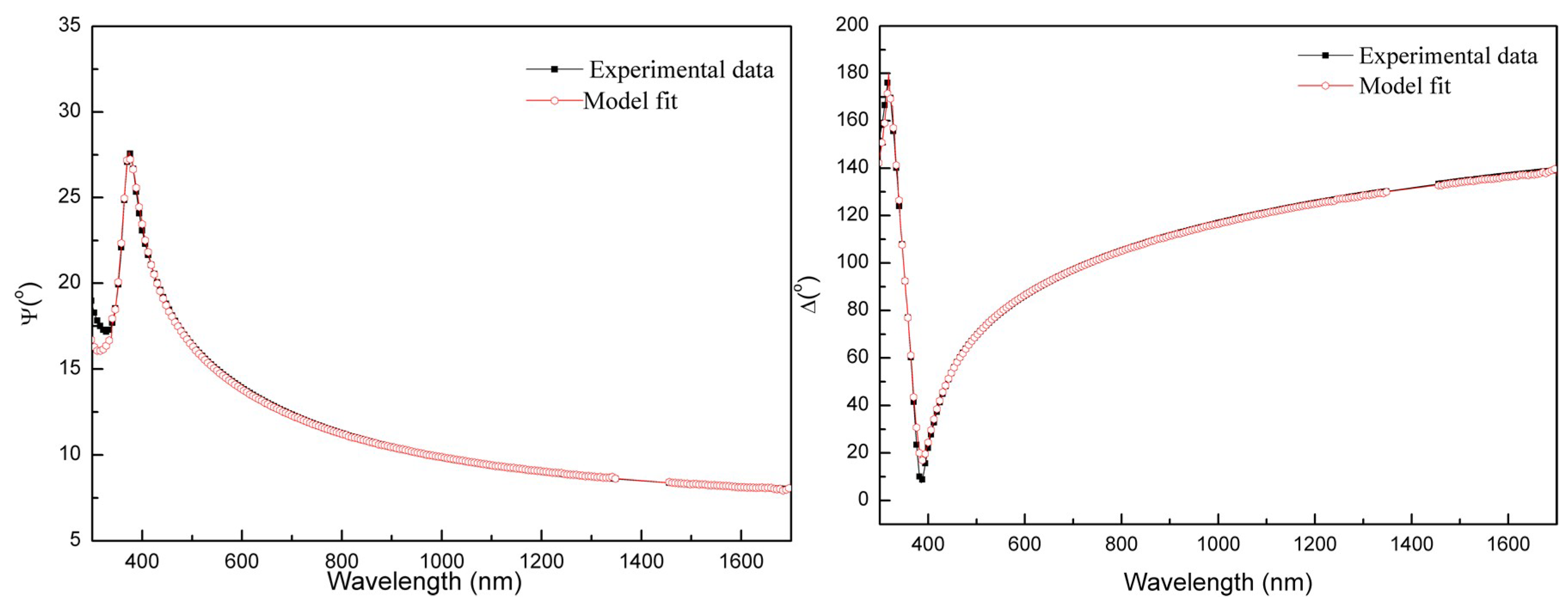

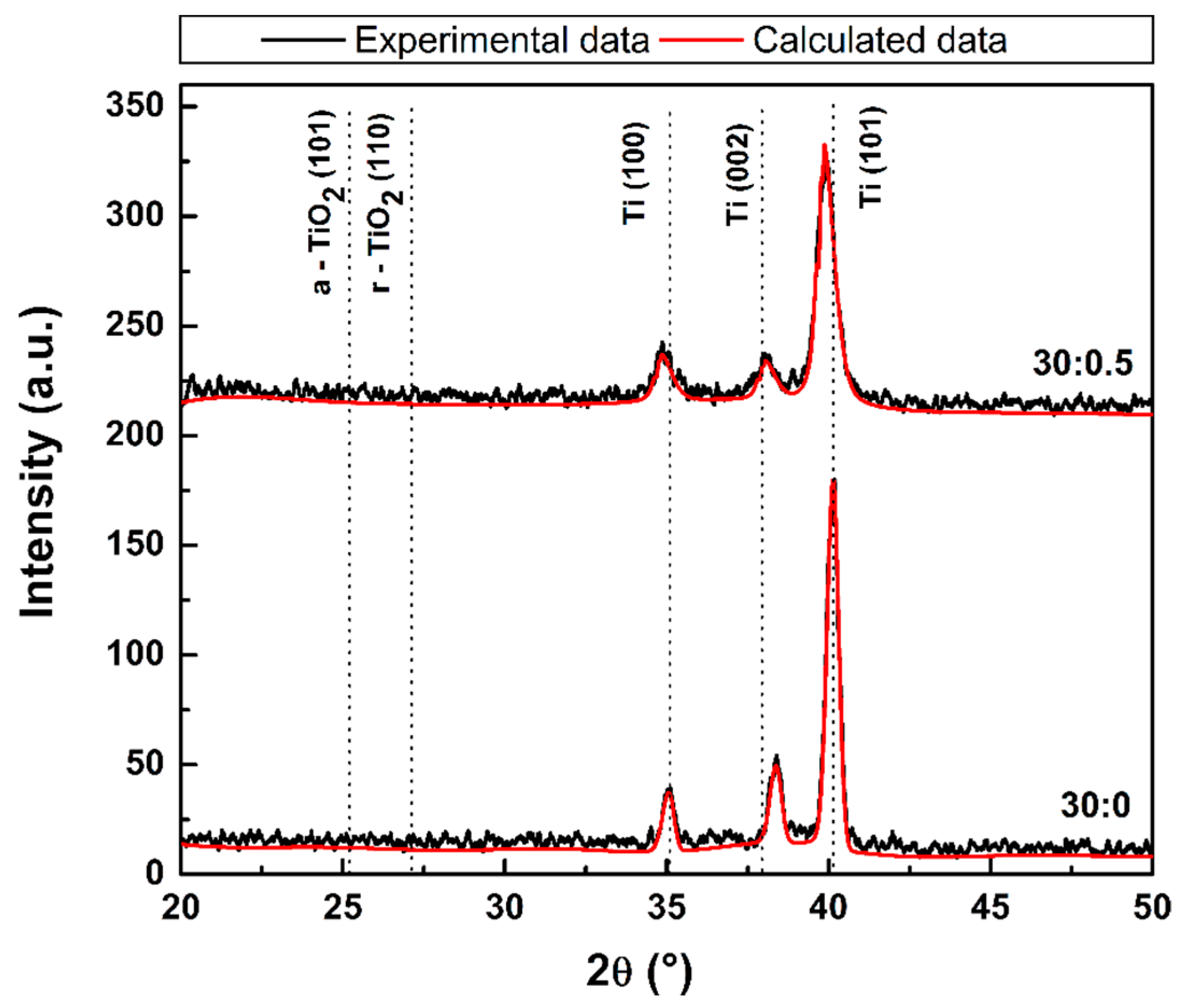

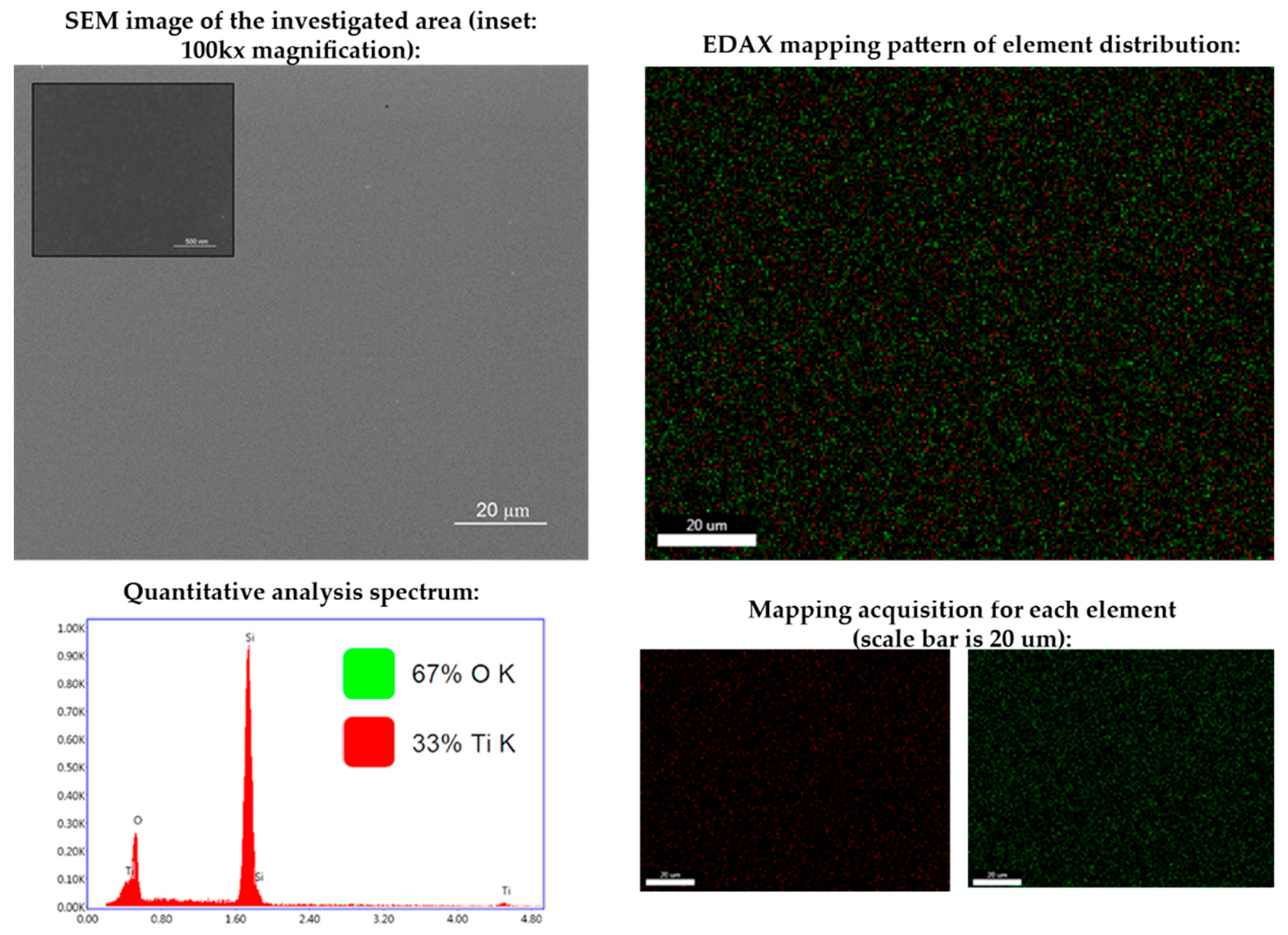

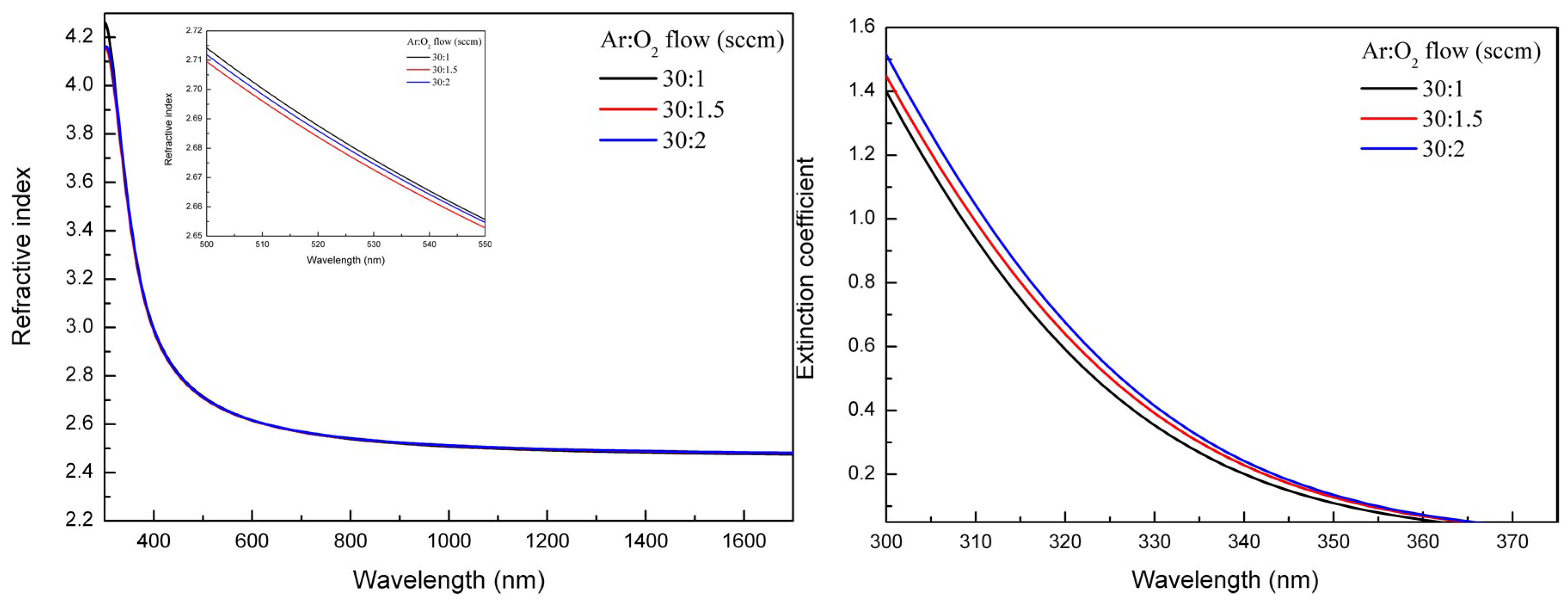

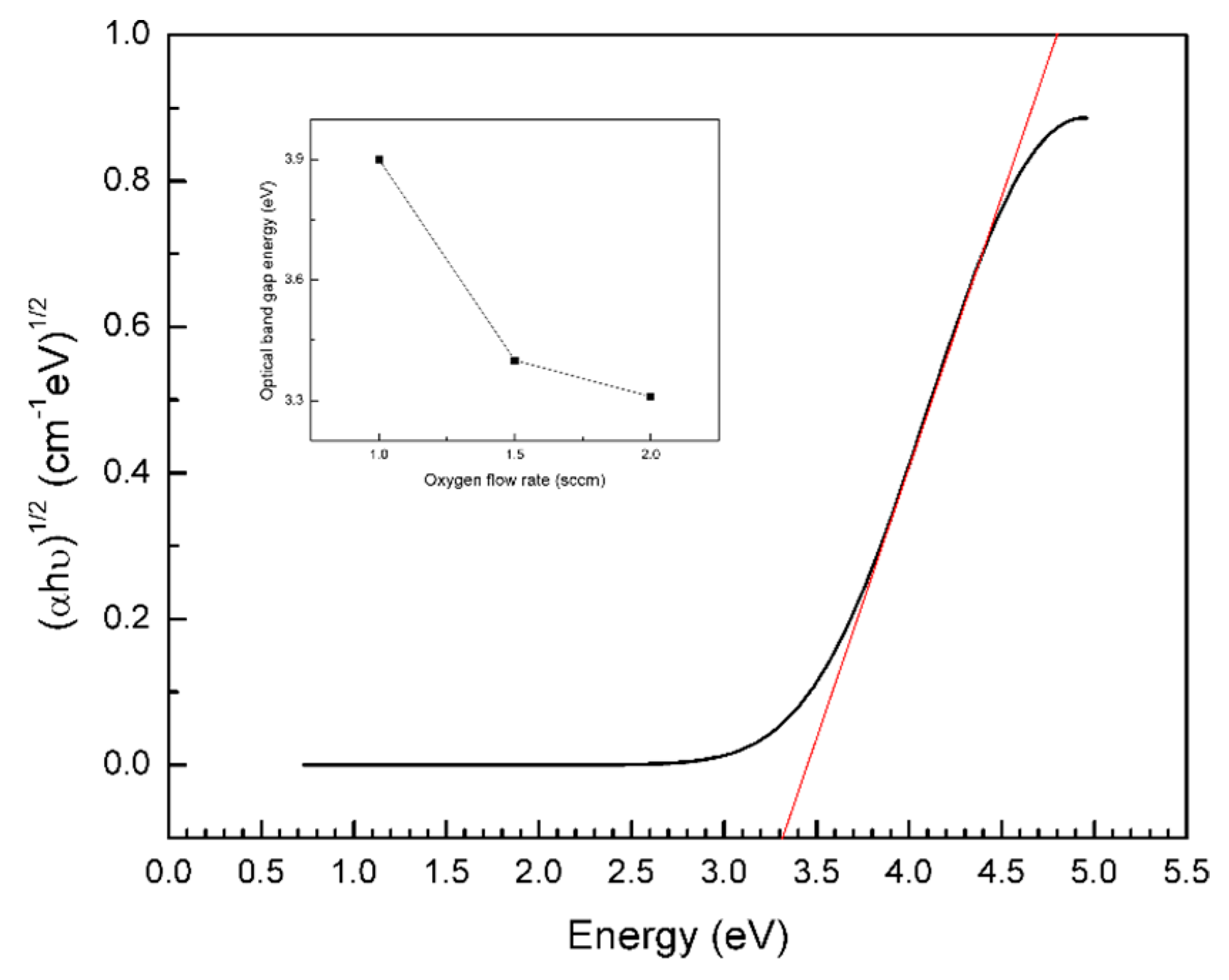

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Richards, B. Single-material TiO2 double-layer antireflection coatings. Sol. Energy Mater. Sol. Cells 2003, 79, 369–390. [Google Scholar] [CrossRef]

- Majeed, A.; He, J.; Jiao, L.; Zhong, X.; Sheng, Z. Surface properties and biocompatibility of nanostructured TiO2 film deposited by RF magnetron sputtering. Nanoscale Res. Lett. 2015, 10, 91. [Google Scholar] [CrossRef]

- Bait, L.; Azzouz, L.; Saoula, N.; Madaoui, N. Influence of substrate bias voltage on the properties of TiO2 deposited by radio-frequency magnetron sputtering on 304L for biomaterials applications. Appl. Surf. Sci. 2017, 395, 72–77. [Google Scholar] [CrossRef]

- Krishna, D.S.R.; Sun, Y. Thermally oxidised rutile-TiO2 coating on stainless steel for tribological properties and corrosion resistance enhancement. Appl. Surf. Sci. 2005, 252, 1107–1116. [Google Scholar] [CrossRef]

- Shen, G.; Chen, Y.; Lin, L.; Lin, C.; Scantlebury, D. Study on a hydrophobic nano-TiO2 coating and its properties for corrosion protection of metals. Electrochim. Acta 2005, 50, 5083–5089. [Google Scholar] [CrossRef]

- Bamoulid, L.; Maurette, M.T.; De Caro, D.; Guenbour, A.; Bachir, A.B.; Aries, L.; El Hajjaji, S.; Benoît-Marquié, F.; Ansart, F. An efficient protection of stainless steel against corrosion: Combination of a conversion layer and titanium dioxide deposit. Surf. Coat. Technol. 2008, 202, 5020–5026. [Google Scholar] [CrossRef][Green Version]

- Shan, C.; Hou, X.; Choy, K.L. Corrosion resistance of TiO2 films grown on stainless steel by atomic layer deposition. Surf. Coat. Technol. 2008, 202, 2399–2402. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, F.; Xue, C.; Li, L.; Yin, Y. Structure stability and corrosion resistance of nano-TiO2 coatings on aluminum in seawater by a vacuum dip-coating method. Surf. Coat. Technol. 2010, 205, 2335–2339. [Google Scholar] [CrossRef]

- Xie, D.; Wang, H.; Ganesan, R.; Leng, Y.; Sun, H.; Huang, N. Fatigue durability and corrosion resistance of TiO2 films on CoCrMo alloy under cyclic deformation. Surf. Coat. Technol. 2015, 275, 252–259. [Google Scholar] [CrossRef]

- Wang, N.; Fu, W.; Zhang, J.; Li, X.; Fang, Q. Corrosion performance of waterborne epoxy coatings containing polyethylenimine treated mesoporous-TiO2 nanoparticles on mild steel. Prog. Org. Coat. 2015, 89, 114–122. [Google Scholar] [CrossRef]

- Karunagaran, B.; Uthirakumar, P.; Chung, S.; Velumani, S.; Suh, E.K. TiO2 thin film gas sensor for monitoring ammonia. Mater. Charact. 2007, 58, 680–684. [Google Scholar] [CrossRef]

- Dhivya, P.; Prasad, A.K.; Sridharan, M. Nanostructured TiO2 films: Enhanced NH3 detection at room temperature. Ceram. Int. 2014, 40, 409–415. [Google Scholar] [CrossRef]

- Patil, M.K.; Shaikh, S.; Ganesh, I. Recent advances on TiO2 thin film based photocatalytic applications (A review). Curr. Nanosci. 2015, 11, 271–285. [Google Scholar] [CrossRef]

- Nair, P.B.; Justinvictor, V.B.; Daniel, G.P.; Joy, K.; Raju, K.J.; Kumar, D.D.; Thomas, P.V. Optical parameters induced by phase transformation in RF magnetron sputtered TiO2 nanostructured thin films. Prog. Nat. Sci. Mater. Int. 2014, 24, 218–225. [Google Scholar] [CrossRef]

- Schönberger, W.; Bartzsch, H.; Schippel, S.; Bachmann, T. Deposition of rutile TiO2 films by pulsed and high power pulsed magnetron sputtering. Surf. Coat. Technol. 2016, 293, 16–20. [Google Scholar] [CrossRef]

- Wypych, A.; Bobowska, I.; Tracz, M.; Opasińska, A.; Kadlubowski, S.; Krzywania-Kaliszewska, A.; Grobelny, J.; Wojciechowski, P. Dielectric properties and characterisation of titanium dioxide obtained by different chemistry methods. J. Nanomater. 2014, 2014, 1–9. [Google Scholar] [CrossRef]

- Sekhar, M.C.; Kondaiah, P.; Chandra, S.J.; Rao, G.M.; Uthanna, S. Effect of substrate bias voltage on the structure, electric and dielectric properties of TiO2 thin films by DC magnetron sputtering. Appl. Surf. Sci. 2011, 258, 1789–1796. [Google Scholar] [CrossRef]

- Selhofer, H.; Muller, R. Comparison of pure and mixed coating materials for AR coatings for use by reactive evaporation on glass and plastic lenses. Thin Solid Film. 1999, 351, 180–183. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, X. Effect of substrates on the photocatalytic activity of nanometer TiO2 thin films. Mater. Res. Bull. 2000, 35, 1293–1301. [Google Scholar] [CrossRef]

- Song, P.; Irie, Y.; Shigesato, Y. Crystallinity and photocatalytic activity of TiO2 films deposited by reactive sputtering with radio frequency substrate bias. Thin Solid Film. 2006, 496, 121–125. [Google Scholar] [CrossRef]

- Jagadale, T.C.; Takale, S.P.; Sonawane, R.S.; Joshi, H.M.; Patil, S.I.; Kale, B.B.; Ogale, S.B. N-Doped TiO2 nanoparticle based visible light photocatalyst by modified peroxide sol−gel method. J. Phys. Chem. C 2008, 112, 14595–14602. [Google Scholar] [CrossRef]

- Višniakov, J.; Janulevičius, A.; Maneikis, A.; Matulaitienė, I.; Selskis, A.; Stanionytė, S.; Suchodolskis, A. Antireflection TiO2 coatings on textured surface grown by HiPIMS. Thin Solid Film. 2017, 628, 190–195. [Google Scholar] [CrossRef]

- Šícha, J.; Novák, O.; Kudláček, P.; Vlček, J. Ion flux characteristics in pulsed dual magnetron discharges used for deposition of photoactive TiO2 films. Plasma Process. Polym. 2011, 8, 191–199. [Google Scholar] [CrossRef]

- Šícha, J.; Heřman, D.; Musil, J.; Stryhal, Z.; Pavlík, J. High-rate low-temperature DC pulsed magnetron sputtering of photocatalytic TiO2 films: The effect of repetition frequency. Nanoscale Res. Lett. 2007, 2, 123–129. [Google Scholar] [CrossRef][Green Version]

- Musil, J.; Šícha, J.; Heřman, D.; Čerstvý, R. Role of energy in low-temperature high-rate formation of hydrophilic TiO2 thin films using pulsed magnetron sputtering. J. Vac. Sci. Technol. A 2007, 25, 666. [Google Scholar] [CrossRef]

- Nezar, S.; Sali, S.; Faiz, M.; Mekki, M.; Laoufi, N.A.; Saoula, N.; Tabet, N. Properties of TiO2 thin films deposited by rf reactive magnetron sputtering on biased substrates. Appl. Surf. Sci. 2017, 395, 172–179. [Google Scholar] [CrossRef]

- Herzinger, C.M.; Johs, B.; McGahan, W.A.; Woollam, J.A.; Paulson, W. Ellipsometric determination of optical constants for silicon and thermally grown silicon dioxide via a multi-sample, multi-wavelength, multi-angle investigation. J. Appl. Phys. 1998, 83, 3323–3336. [Google Scholar] [CrossRef]

- Fujiwara, H. Spectroscopic Ellipsometry Principles and Applications; John Wiley & Sons Ltd.: West Sussex, UK, 2007; ISBN 978-0-470-01608-4. [Google Scholar]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Musil, J. Flexible hard nanocomposite coatings. RSC Adv. 2015, 5, 60482–60495. [Google Scholar] [CrossRef]

- Kelly, P.J.; Arnell, R.D. Development of a novel structure zone model relating to the closed-field unbalanced magnetron sputtering system. J. Vac. Sci. Technol. A 1998, 16, 2858–2869. [Google Scholar] [CrossRef]

- Miao, L.; Jin, P.; Kaneko, K.; Terai, A.; Nabatova-Gabain, N.; Tanemura, S. Preparation and characterization of polycrystalline anatase and rutile TiO2 thin films by rf magnetron sputtering. Appl. Surf. Sci. 2003, 212, 255–263. [Google Scholar] [CrossRef]

- Thornton, J.A. Influence of apparatus geometry and deposition conditions on the structure and topography of thick sputtered coatings. J. Vac. Sci. Technol. 1974, 11, 666–670. [Google Scholar] [CrossRef]

- Tanemura, S.; Miao, L.; Jin, P.; Kaneko, K.; Terai, A.; Nabatova-Gabain, N. Optical properties of polycrystalline and epitaxial anatase and rutile TiO2 thin films by rf magnetron sputtering. Appl. Surf. Sci. 2003, 212, 654–660. [Google Scholar] [CrossRef]

- Sekhar, M.C.; Kondaiah, P.; Krishna, B.R.; Uthanna, S. Effect of oxygen partial pressure on the electrical and optical properties of DC magnetron sputtered amorphous TiO2 films. J. Spectrosc. 2013, 2013, 1–7. [Google Scholar] [CrossRef]

- Liao, M.; Niu, H.; Chen, G. Effect of sputtering pressure and post-annealing on hydrophilicity of TiO2 thin films deposited by reactive magnetron sputtering. Thin Solid Film. 2010, 518, 7258–7262. [Google Scholar] [CrossRef]

- Wiatrowski, A.; Mazur, M.; Obstarczyk, A.; Wojcieszak, D.; Kaczmarek, D.; Morgiel, J.; Gibson, D. Comparison of the physicochemical properties of TiO2 thin films obtained by magnetron sputtering with continuous and pulsed gas flow. Coatings 2018, 8, 412. [Google Scholar] [CrossRef]

- Zheng, J.; Bao, S.; Guo, Y.; Jin, P. TiO2 films prepared by DC reactive magnetron sputtering at room temperature: Phase control and photocatalytic properties. Surf. Coat. Technol. 2014, 240, 293–300. [Google Scholar] [CrossRef]

- Nair, P.B.; Justinvictor, V.; Daniel, G.P.; Joy, K.; Ramakrishnan, V.; Thomas, P. Effect of RF power and sputtering pressure on the structural and optical properties of TiO2 thin films prepared by RF magnetron sputtering. Appl. Surf. Sci. 2011, 257, 10869–10875. [Google Scholar] [CrossRef]

- Wang, S.F.; Hsu, Y.F.; Lee, Y.S. Microstructural evolution and optical properties of doped TiO2 films prepared by RF magnetron sputtering. Ceram. Int. 2006, 32, 121–125. [Google Scholar] [CrossRef]

- Pradhan, S.S.; Sahoo, S.; Pradhan, S. Influence of annealing temperature on the structural, mechanical and wetting property of TiO2 films deposited by RF magnetron sputtering. Thin Solid Film. 2010, 518, 6904–6908. [Google Scholar] [CrossRef]

- Shen, Y.; Yu, H.; Yao, J.; Shao, S.; Fan, Z.; He, H.; Shao, J. Investigation on properties of TiO2 thin films deposited at different oxygen pressures. Opt. Laser Technol. 2008, 40, 550–554. [Google Scholar] [CrossRef]

- Chapman, B.N. Sputtering. In Glow Discharge Processes—Sputtering and Plasma Etching; Wiley: New York, NY, USA, 1980; pp. 177–296. [Google Scholar]

| Parameter | Value |

|---|---|

| Target | Ti (99.5% pure) |

| Target-to-substrate distance (mm) | 90 |

| Base pressure (Pa) | 1.33 × 10−5 |

| Process pressure (Pa) | 0.26 |

| RF power (W) | 500 |

| RF power target density 1 (W/cm2) | 2.83 |

| Argon flow rate (sccm 2) | 30 (99.999% pure) |

| Oxygen flow rate (sccm) | 0–2 (0.5 step) (99.999% pure) |

| Ar:O2 Flow (sccm) | Amp | En (eV) | Br (eV) | Einf1 | MSE |

|---|---|---|---|---|---|

| 30:1 | 20.852 ± 0.0704 | 4.5444 ± 0.0062 | 0.91657 ± 0.00601 | 3.1789 ± 0.0236 | 6.552 |

| 30:1.5 | 19.369 ± 0.075 | 4.5151 ± 0.00603 | 0.92139 ± 0.00632 | 3.3776 ± 0.0325 | 7.901 |

| 30:2 | 19.411 ± 0.0736 | 4.4924 ± 0.00634 | 0.90886 ± 0.00628 | 3.3995 ± 0.0271 | 7.79 |

| Ar:O2 Flow (sccm) | Lattice Constant (nm) | Lattice Strain (%) | Mean Crystallite Size (nm) | ||

|---|---|---|---|---|---|

| a | b | c | |||

| 30:0 | 0.29 | 0.29 | 0.46 | 0.15 | 11.4 |

| 30:0.5 | 0.30 | 0.30 | 0.47 | 0.44 | 4.9 |

| 30:1 | 0.46 | 0.46 | 0.29 | 0.67 | 4.3 |

| 30:1.5 | 0.46 | 0.46 | 0.29 | 0.55 | 3.1 |

| 30:2 | 0.46 | 0.46 | 0.29 | 0.61 | 3.7 |

| Present Work | Nezar et al. [26] | |

|---|---|---|

| RF power (W) | 500 | 250 |

| Process pressure (Pa) | 0.26 | 2.66 |

| O2 (%) | 0–6.25 | 25 |

| Target-to-substrate distance (mm) | 90 | 30 |

| Crystallization phase | rutile | anatase |

| Main crystal orientation | (110), (211) and (220) | (101) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simionescu, O.-G.; Romanițan, C.; Tutunaru, O.; Ion, V.; Buiu, O.; Avram, A. RF Magnetron Sputtering Deposition of TiO2 Thin Films in a Small Continuous Oxygen Flow Rate. Coatings 2019, 9, 442. https://doi.org/10.3390/coatings9070442

Simionescu O-G, Romanițan C, Tutunaru O, Ion V, Buiu O, Avram A. RF Magnetron Sputtering Deposition of TiO2 Thin Films in a Small Continuous Oxygen Flow Rate. Coatings. 2019; 9(7):442. https://doi.org/10.3390/coatings9070442

Chicago/Turabian StyleSimionescu, Octavian-Gabriel, Cosmin Romanițan, Oana Tutunaru, Valentin Ion, Octavian Buiu, and Andrei Avram. 2019. "RF Magnetron Sputtering Deposition of TiO2 Thin Films in a Small Continuous Oxygen Flow Rate" Coatings 9, no. 7: 442. https://doi.org/10.3390/coatings9070442

APA StyleSimionescu, O.-G., Romanițan, C., Tutunaru, O., Ion, V., Buiu, O., & Avram, A. (2019). RF Magnetron Sputtering Deposition of TiO2 Thin Films in a Small Continuous Oxygen Flow Rate. Coatings, 9(7), 442. https://doi.org/10.3390/coatings9070442