Fabrication of a Conjugated Fluoropolymer Film Using One-Step iCVD Process and its Mechanical Durability

Abstract

:1. Introduction

2. Experiment

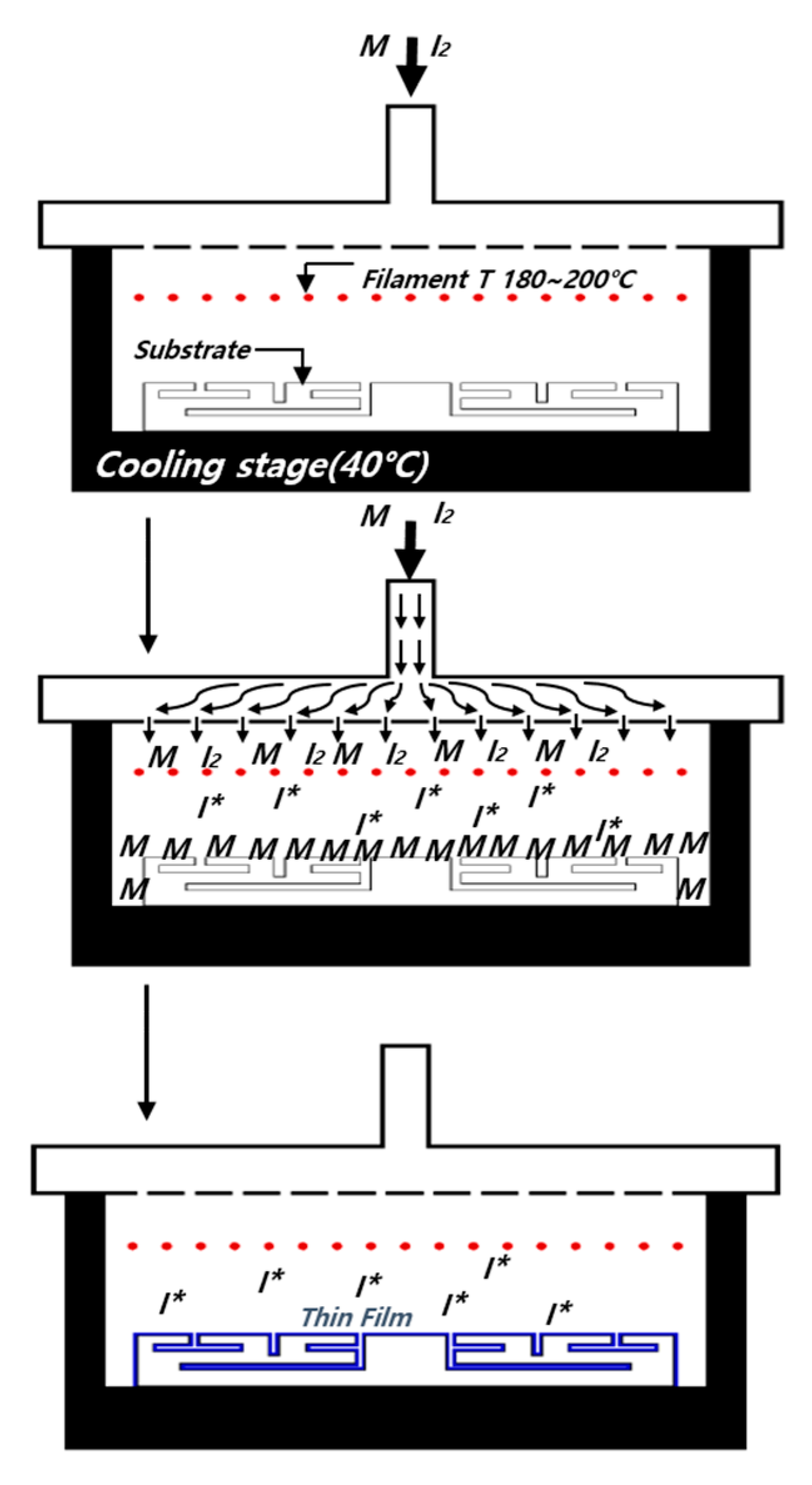

2.1. iCVD Process Basics

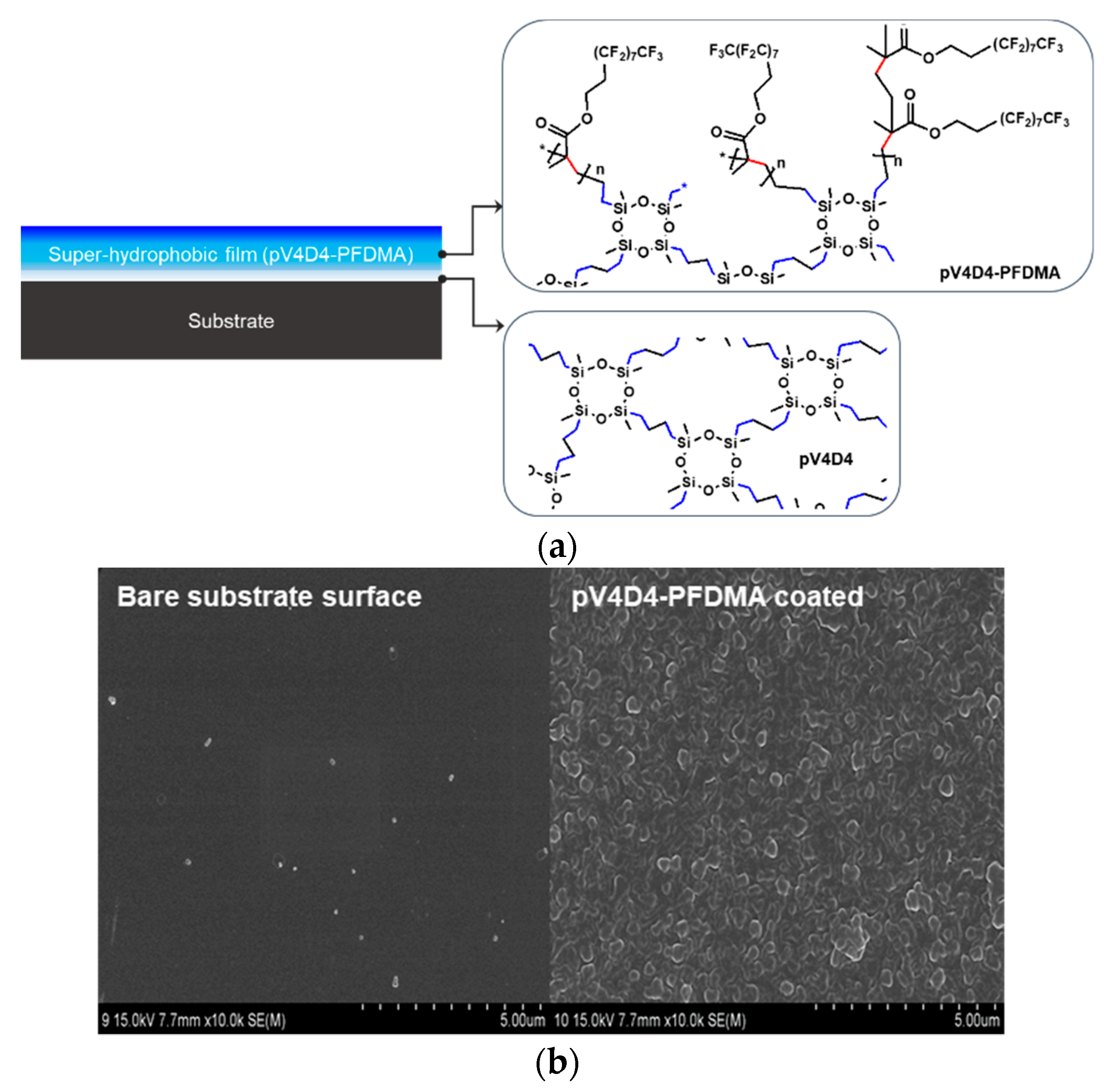

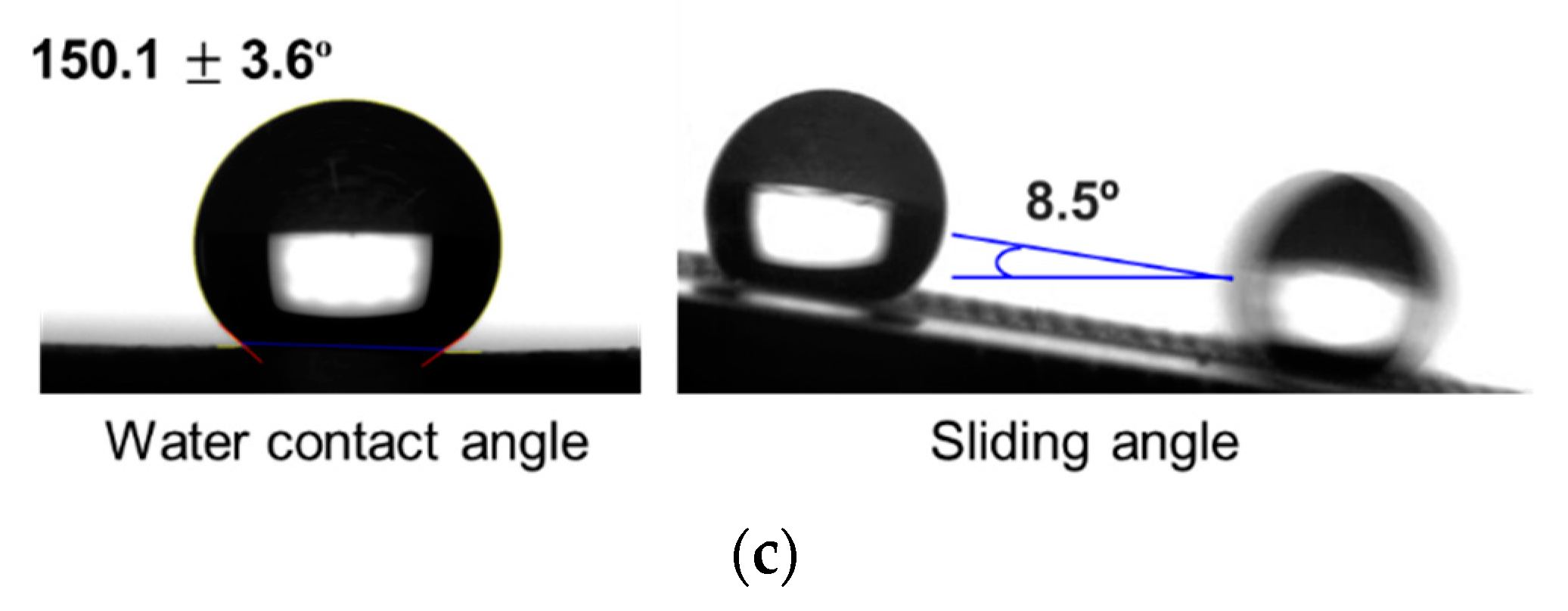

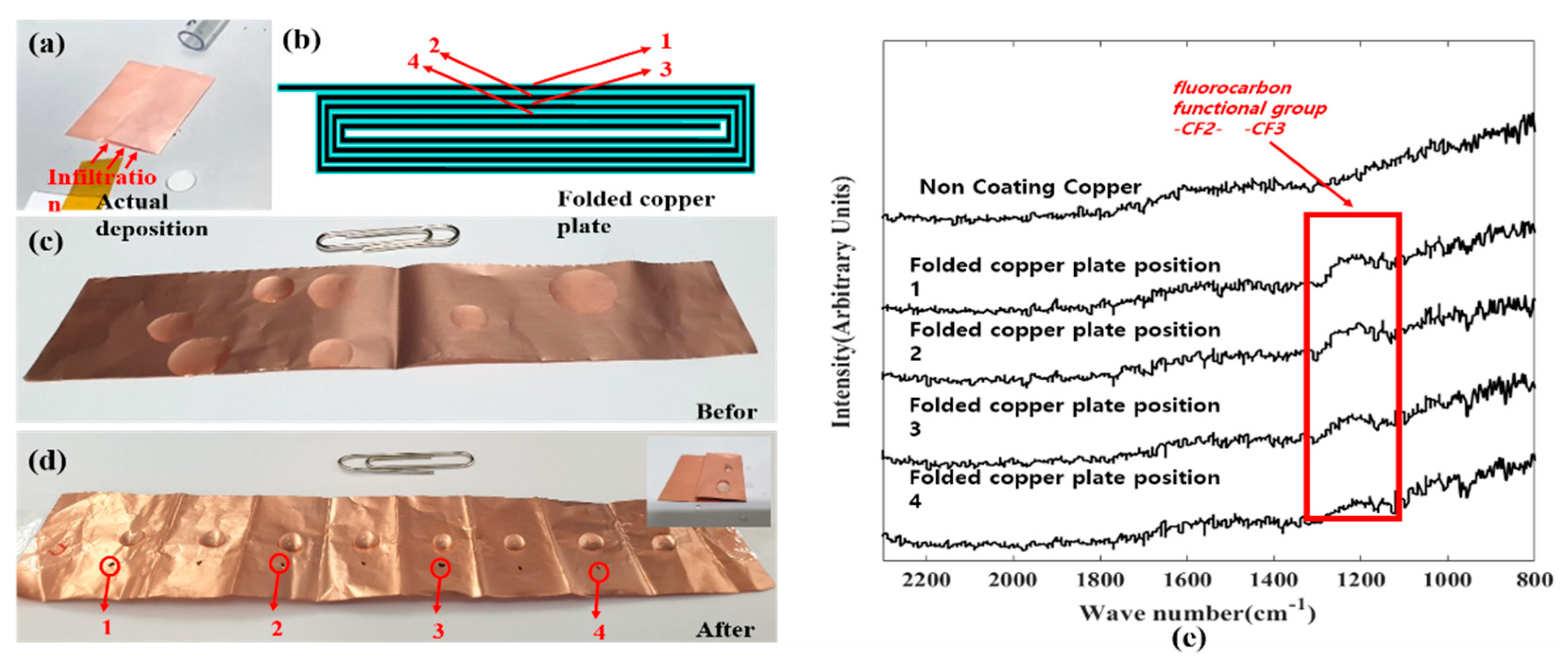

2.2. Fabrication of Superhydrophobic Film and its Characteristics

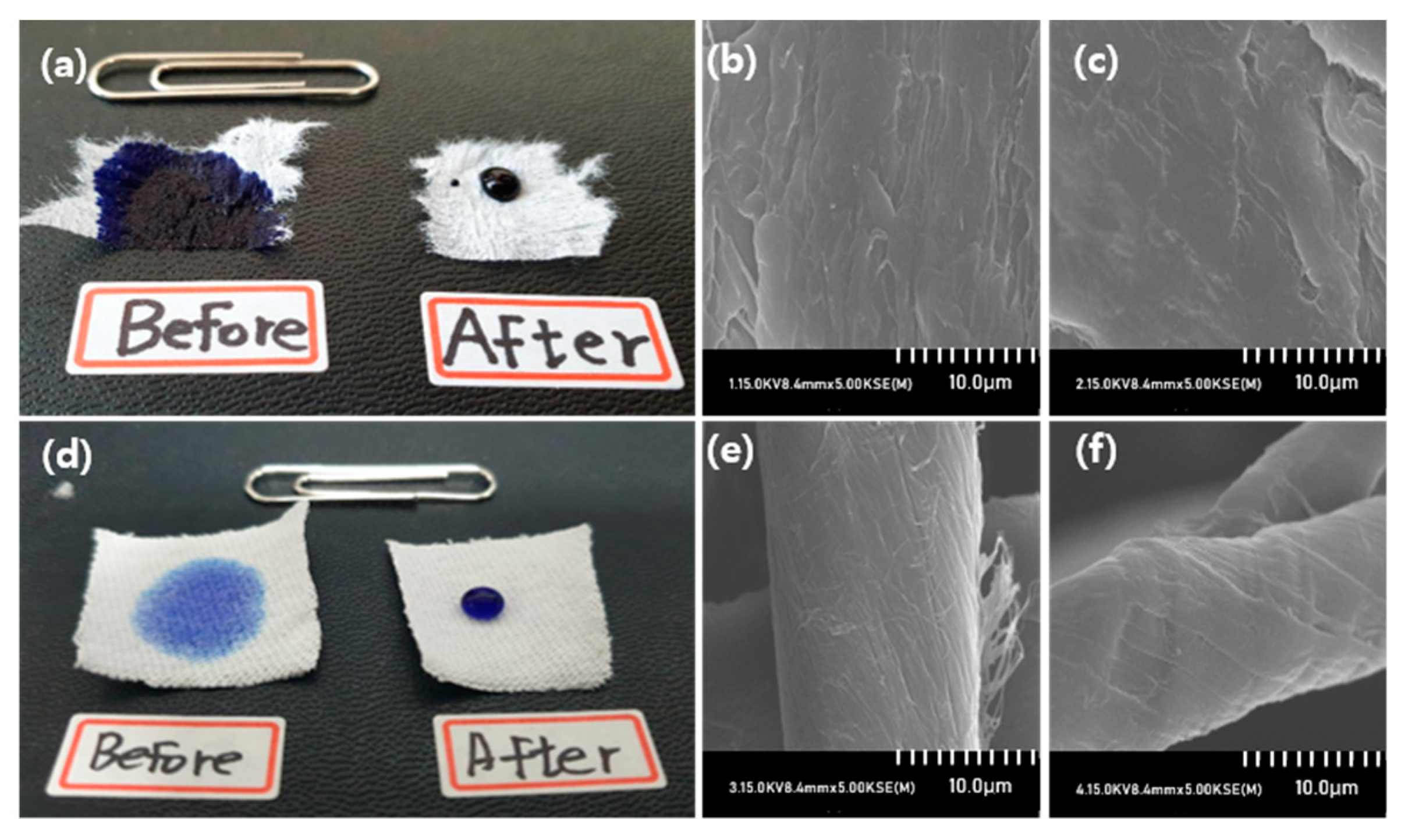

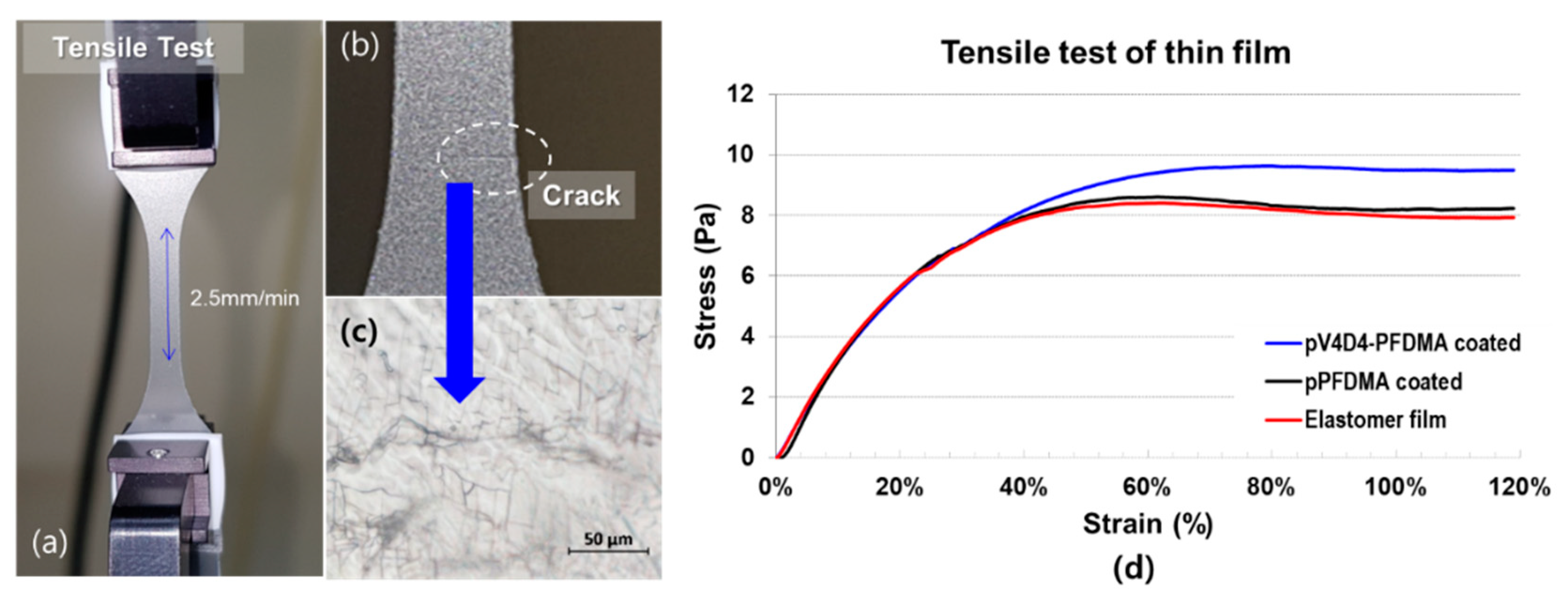

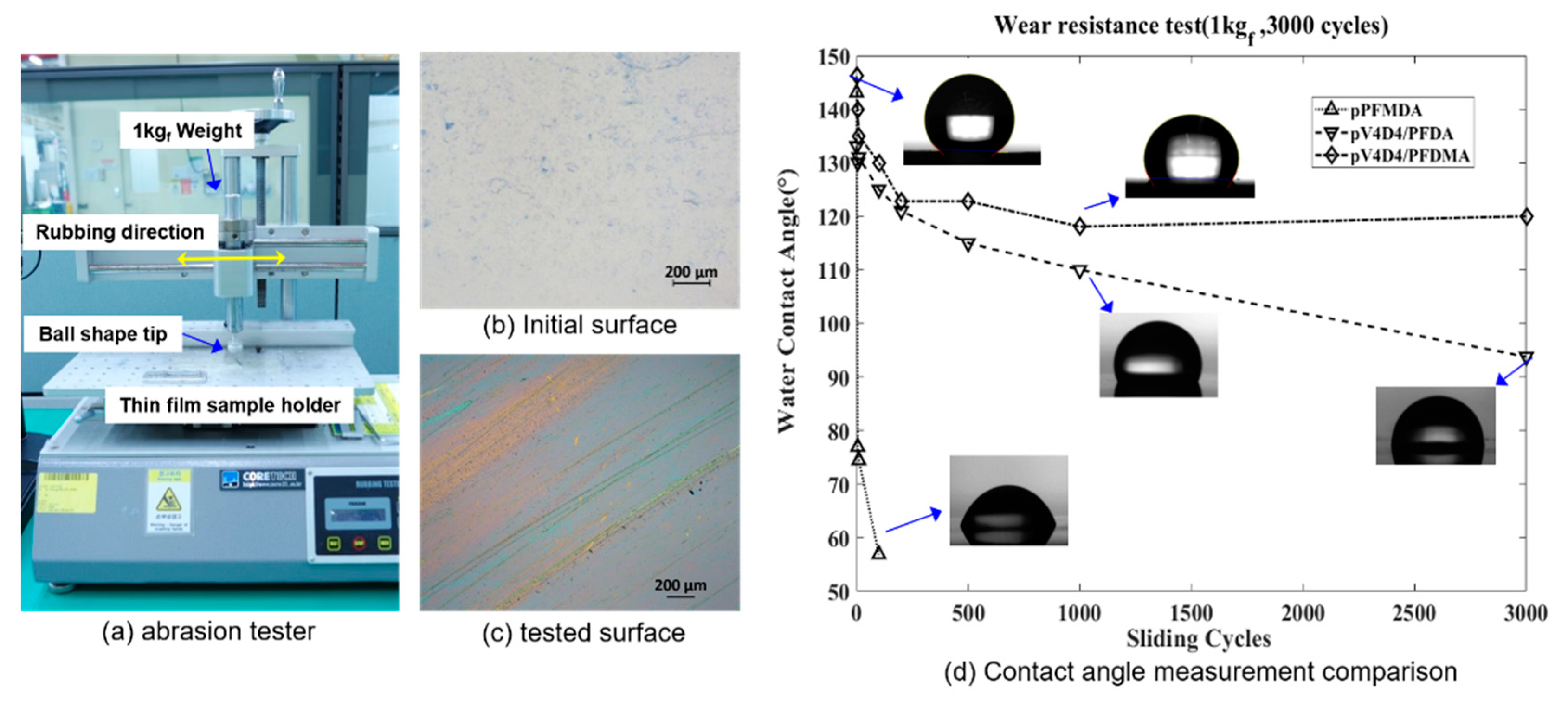

2.3. Examination of Durability

3. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wu, D.; Guo, Z. Robust and muti-repaired superhydrophobic surfaces via one-step method on copper and aluminum alloys. Mater. Lett. 2018, 213, 290–293. [Google Scholar] [CrossRef]

- Latthe, S.S.; Sudhagar, P.; Devadoss, A.; Kumar, A.M.; Liu, S.; Terashima, C.; Nakata, K.; Fujishima, A. A mechanically bendable superhydrophobic steel surface with self-cleaning and corrosion-resistant properties. J. Mater. Chem. A 2015, 3, 14263–14271. [Google Scholar] [CrossRef]

- He, J.; Wu, M.; Zhang, R.; Liu, J.; Deng, Y.; Guo, Z. A one-step hot-embossing process for fabricating a channel with superhydrophobic inner walls. J. Manuf. Process. 2018, 36, 351–359. [Google Scholar] [CrossRef]

- Liu, S.; Liu, X.; Latthe, S.S.; Gao, L.; An, S.; Yoon, S.S.; Liu, B.; Xing, R. Self-cleaning transparent superhydrophobic coatings through simple sol-gel processing of fluoroalkylsilane. Appl. Surf. Sci. 2015, 351, 897–903. [Google Scholar] [CrossRef]

- Latthe, S.S.; Sutar, R.S.; Kodag, V.S.; Bhosale, A.K.; Kumar, A.M.; Sadasivuni, K.K.; Xing, X.; Liu, S. Self–cleaning superhydrophobic coatings: Potential industrial applications. Prog. Org. Coat. 2019, 128, 52–58. [Google Scholar] [CrossRef]

- Li, Y.; Men, X.; Zhu, X.; Ge, B.; Chu, F.; Zhang, Z. One-step spraying to fabricate nonfluorinated superhydrophobic coatings with high transparency. J. Mater. Sci. 2016, 51, 2411–2419. [Google Scholar] [CrossRef]

- Fang, Z.; Li, H.; Xia, M.; Liu, Y.; Zhang, Y.; Li, Y.; Jiang, X.; He, P. A facile method to fabricate super-hydrophobic surface with water evaporation-induced phase inversion of stearic acid. Mater. Lett. 2018, 223, 124–127. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, Z.; Mai, W.; Min, C.; Zhou, B.; Shan, M.; Li, Y.; Yang, C.; Wang, Z.; Qian, X. Improved hydrophilicity, permeability, antifouling and mechanical performance of PVDF composite ultrafiltration membranes tailored by oxidized low-dimensional carbon nanomaterials. J. Mater. Chem. A 2013, 1, 3101–3111. [Google Scholar] [CrossRef]

- Zhang, L.; Zuo, W.; Li, T. Controlled synthesis of bifunctional PbWO4 dendrites via a facile solution method at room temperature: Photoluminescence and superhydrophobic property. Mater. Sci. Semicond. Process. 2015, 39, 188–191. [Google Scholar] [CrossRef]

- Perkas, N.; Amirian, G.; Girshevitz, O.; Gedanken, A. Hydrophobic coating of GaAs surfaces with nanostructured ZnO. Mater. Lett. 2016, 175, 101–105. [Google Scholar] [CrossRef]

- Rivero, P.J.; Iribarren, A.; Larumbe, S.; Palacio, J.F.; Rodríguez, R. A comparative study of multifunctional coatings based on electrospun fibers with incorporated ZnO nanoparticles. Coatings 2019, 9, 367. [Google Scholar] [CrossRef]

- Ellinas, K.; Tserepi, A.; Gogolides, E. Superhydrophobic fabrics with mechanical durability prepared by a two-step plasma processing method. Coatings 2018, 8, 351. [Google Scholar] [CrossRef]

- Zhou, M.; Feng, C.; Wu, C.; Ma, W.; Cai, L. Superhydrophobic multi-scale ZnO nanostructures fabricated by chemical vapor deposition method. J. Nanosci. Nanotechnol. 2009, 9, 4211–4214. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Wang, H.; Niu, H.; Gestos, A.; Wang, X.; Lin, T. Fluoroalkyl silane modified silicone rubber/nanoparticle composite: A super durable, robust superhydrophobic fabric coating. Adv. Mater. 2012, 24, 2409–2412. [Google Scholar] [CrossRef]

- Yan, X.; Li, J.; Yi, L. Fabrication of pH-responsive hydrophilic/hydrophobic Janus cotton fabric via plasma-induced graft polymerization. Mater. Lett. 2017, 208, 46–49. [Google Scholar] [CrossRef]

- Heydari Gharahcheshmeh, M.; Gleason, K.K. Device fabrication based on oxidative chemical vapor deposition (oCVD) synthesis of conducting polymers and related conjugated organic materials. Adv. Mater. Interfaces 2019, 6, 1801564. [Google Scholar] [CrossRef]

- Baxamusa, S.H.; Gleason, K.K. Thin polymer films with high step coverage in microtrenches by initiated CVD. Chem. Vap. Depos. 2008, 14, 313–318. [Google Scholar] [CrossRef]

- Martin, T.P.; Lau, K.K.; Chan, K.; Mao, Y.; Gupta, M.; O’Shaughnessy, W.S.; Gleason, K.K. Initiated chemical vapor deposition (iCVD) of polymeric nanocoatings. Surf. Coat. Technol. 2007, 201, 9400–9405. [Google Scholar] [CrossRef]

- Mao, Y.; Gleason, K.K. Positive-tone nanopatterning of chemical vapor deposited polyacrylic thin films. Langmuir 2006, 22, 1795–1799. [Google Scholar] [CrossRef]

- Gupta, M.; Gleason, K.K. Initiated chemical vapor deposition of poly(1H, 1H, 2H, 2H-perfluorodecyl acrylate) thin films. Langmuir 2006, 22, 10047–10052. [Google Scholar] [CrossRef]

- Ma, M.; Gupta, M.; Li, Z.; Zhai, L.; Gleason, K.K.; Cohen, R.E.; Rubner, M.F.; Rutledge, G.C. Decorated electrospun fibers exhibiting superhydrophobicity. Adv. Mater. 2007, 19, 255–259. [Google Scholar] [CrossRef]

- Ma, M.; Mao, Y.; Gupta, M.; Gleason, K.K.; Rutledge, G.C. Superhydrophobic fabrics produced by electrospinning and chemical vapor deposition. Macromolecules 2005, 38, 9742–9748. [Google Scholar] [CrossRef]

- Kim, J.H.; Park, S.K.; Lee, J.W.; Yoo, B.; Lee, J.K.; Kim, Y.H. Hydrophobic perfluoropolymer thin-film encapsulation for enhanced stability of inverted polymer solar cells. J. Korean Phys. Soc. 2014, 65, 1448–1452. [Google Scholar] [CrossRef]

- Tsibouklis, J.; Graham, P.; Eaton, P.J.; Smith, J.R.; Nevell, T.G.; Smart, J.D.; Ewen, R.J. Poly(perfluoroalkyl methacrylate) film structures: surface organization phenomena, surface energy determinations, and force of adhesion measurements. Macromolecules 2000, 33, 8460–8465. [Google Scholar] [CrossRef]

- Gleason, K.K. CVD Polymer: Fabrication of Organic Surfaces and Devices; WILET-VCH: Weinheim, Germany, 2015. [Google Scholar]

- Moni, P.; Al-Obeidi, A.; Gleason, K.K. Vapor deposition routes to conformal polymer thin films. Beilstein J. Nanotechnol. 2017, 8, 723–735. [Google Scholar] [CrossRef] [PubMed]

- Chan, K.; Gleason, K.K. A mechanistic study of initiated chemical vapor deposition of polymers: analyses of deposition rate and molecular weight. Macromolecules 2006, 39, 3890–3894. [Google Scholar] [CrossRef]

- ASTM D882-18: Standard Test Method for Tensile Properties of Thin Plastic Sheeting; ASTM International: West Conshohocken, PA, USA, 2018.

| Structure | Name (Abbreviation) | Function | Chemical Formula |

|---|---|---|---|

| tert-butyl peroxide (TBPO) | Initiator | C8H18O2 |

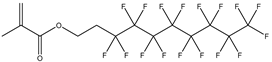

| 1H,1H,2H,2H-Perfluorodecyl acrylate (PFDA) | Super-hydrophobic | C13H7F17O2 |

| 1H,1H,2H,2H-Perfluorodecyl methacrylate (PFDMA) | Super-hydrophobic | C14H9F17O2 |

| 1,3,5,7-tetravinyl-1,3,5,7-tetramethylcyclotetrasiloxane (V4D4) | Cross-linker | C12H24O4Si4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.S.; Kim, H.; Lee, J.H.; Kwak, J.B. Fabrication of a Conjugated Fluoropolymer Film Using One-Step iCVD Process and its Mechanical Durability. Coatings 2019, 9, 430. https://doi.org/10.3390/coatings9070430

Lee HS, Kim H, Lee JH, Kwak JB. Fabrication of a Conjugated Fluoropolymer Film Using One-Step iCVD Process and its Mechanical Durability. Coatings. 2019; 9(7):430. https://doi.org/10.3390/coatings9070430

Chicago/Turabian StyleLee, Hyo Seong, Hayeong Kim, Jeong Heon Lee, and Jae B. Kwak. 2019. "Fabrication of a Conjugated Fluoropolymer Film Using One-Step iCVD Process and its Mechanical Durability" Coatings 9, no. 7: 430. https://doi.org/10.3390/coatings9070430

APA StyleLee, H. S., Kim, H., Lee, J. H., & Kwak, J. B. (2019). Fabrication of a Conjugated Fluoropolymer Film Using One-Step iCVD Process and its Mechanical Durability. Coatings, 9(7), 430. https://doi.org/10.3390/coatings9070430