Hot Corrosion Behavior of BaLa2Ti3O10 Thermal Barrier Ceramics in V2O5 and Na2SO4 + V2O5 Molten Salts

Abstract

1. Introduction

2. Experimental Procedures

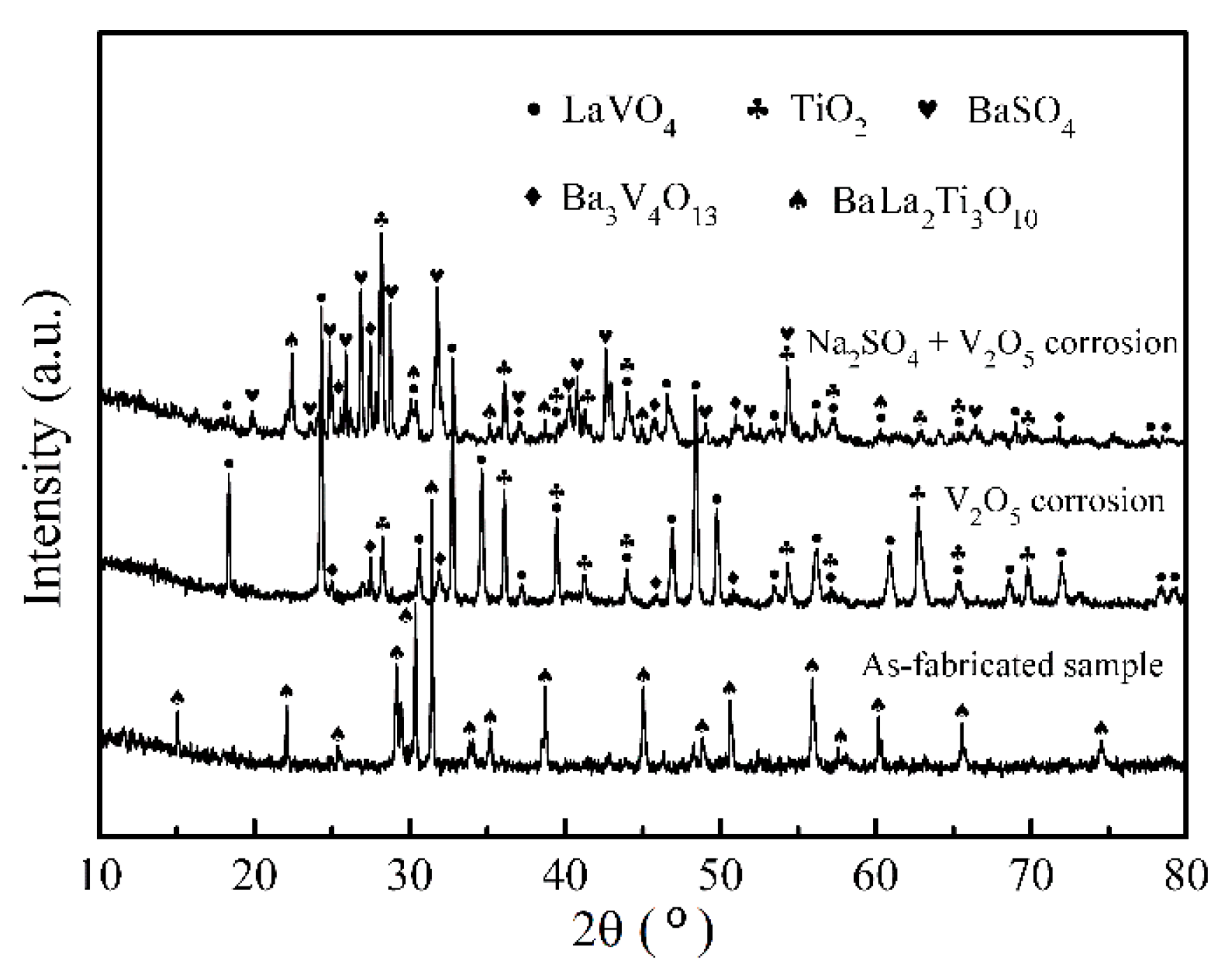

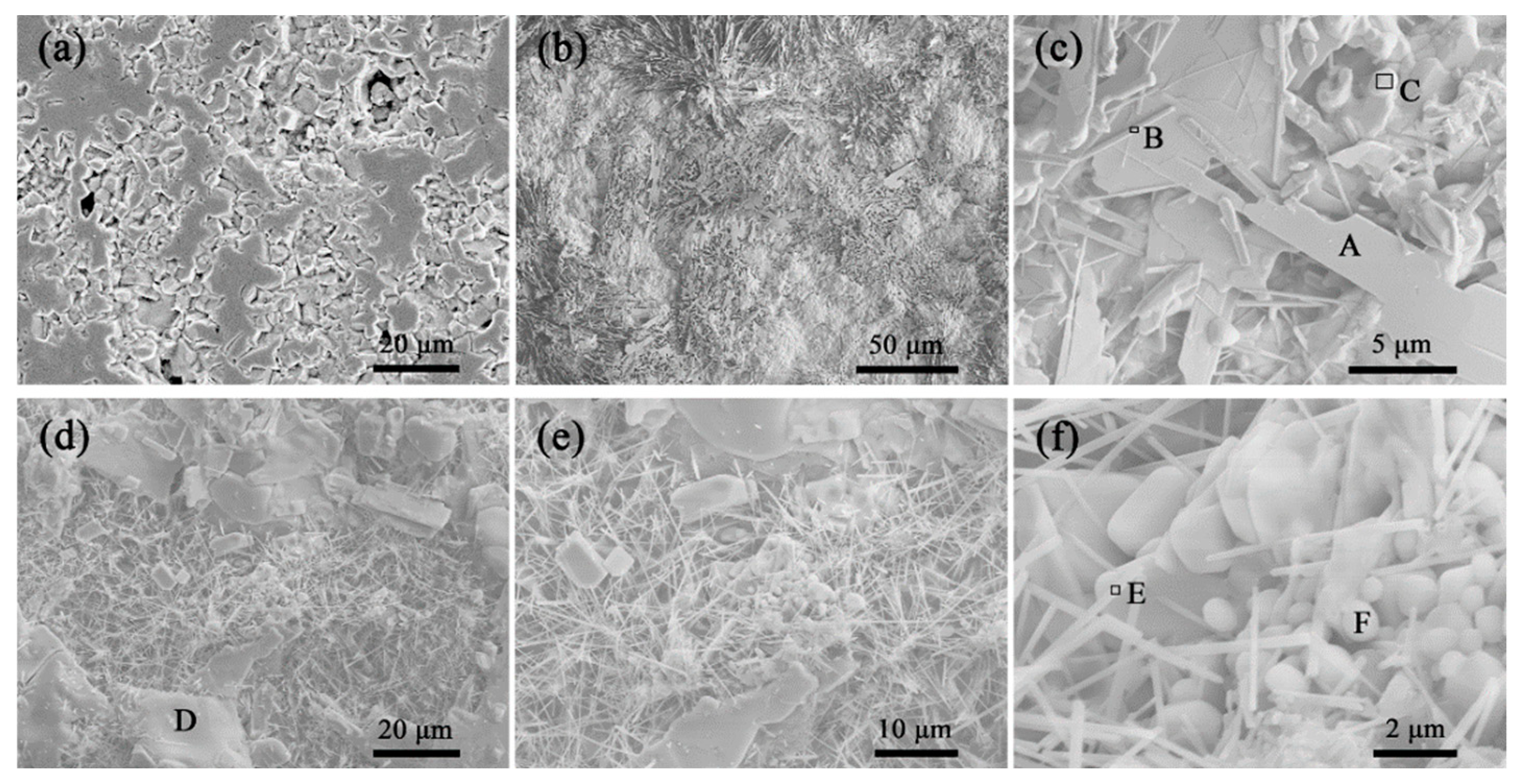

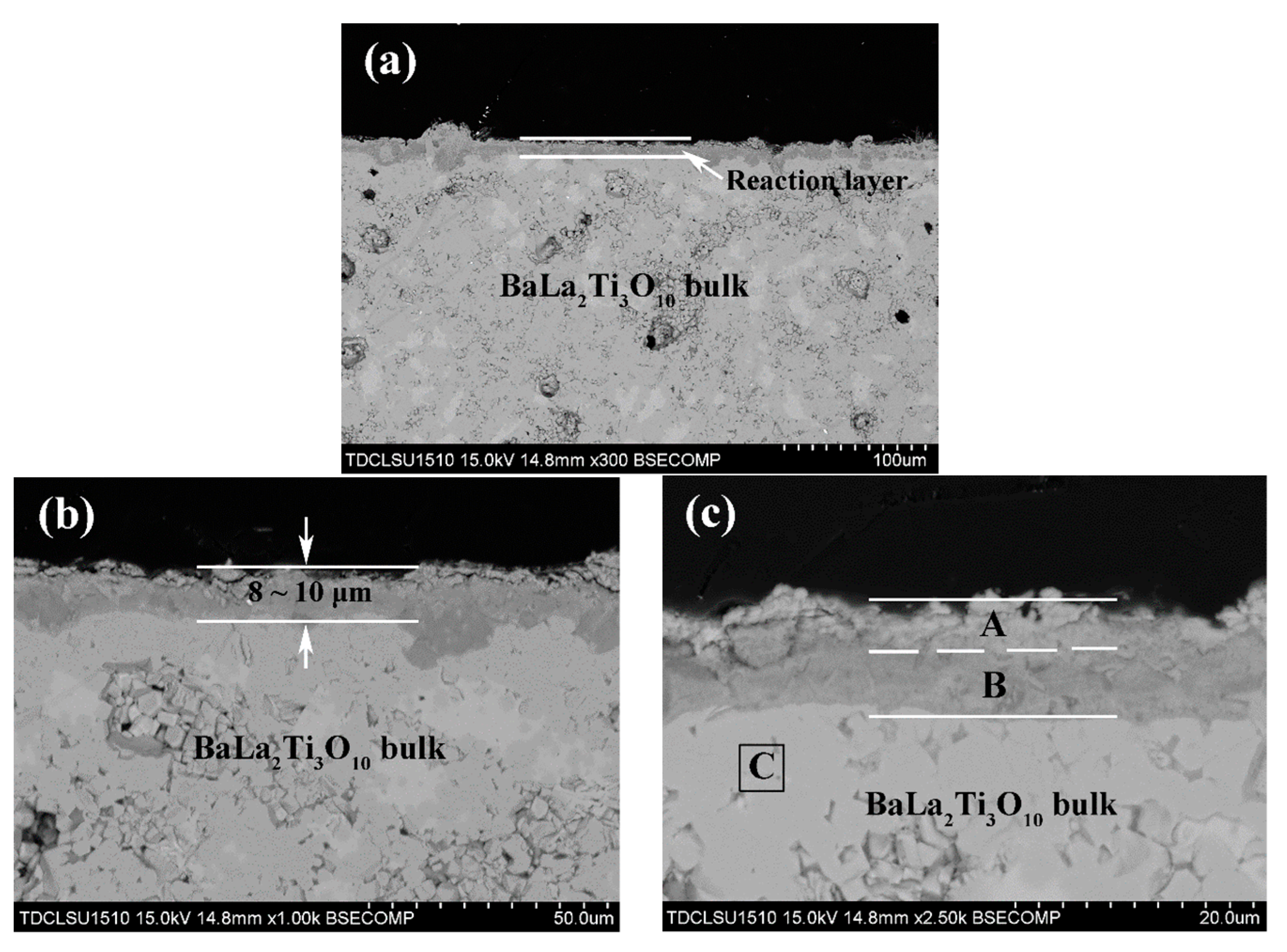

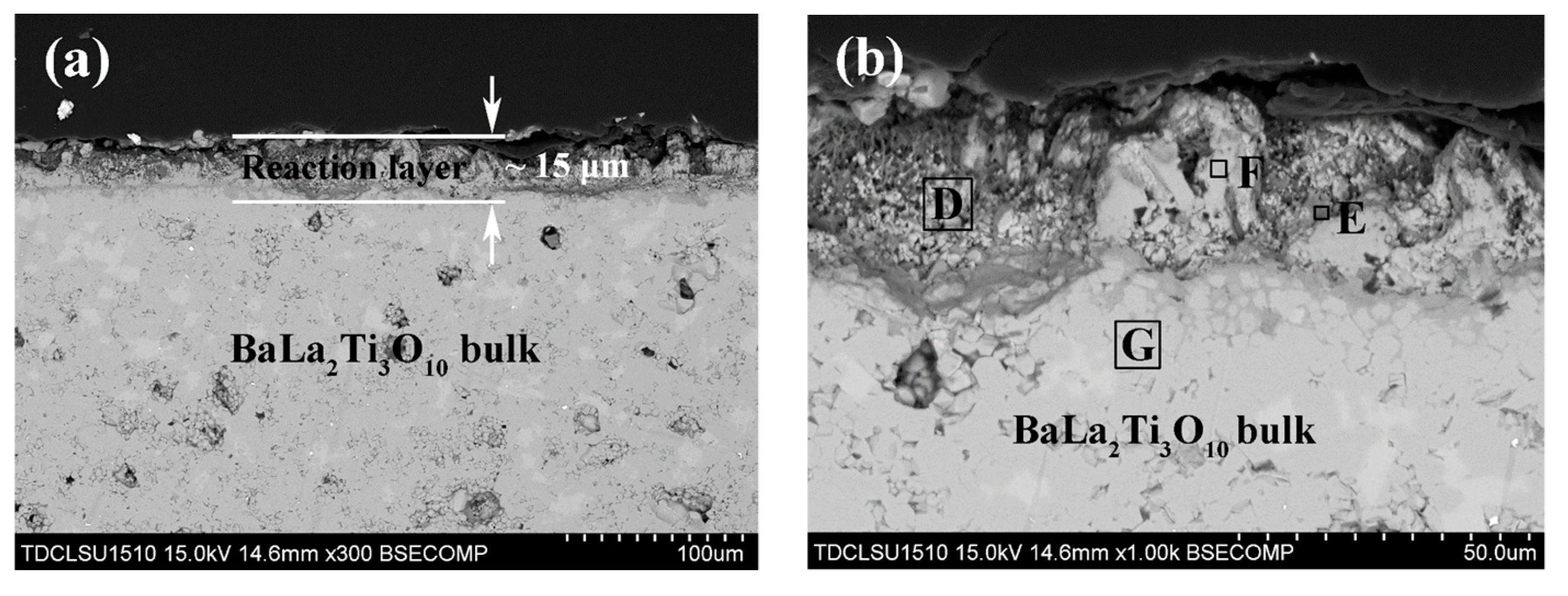

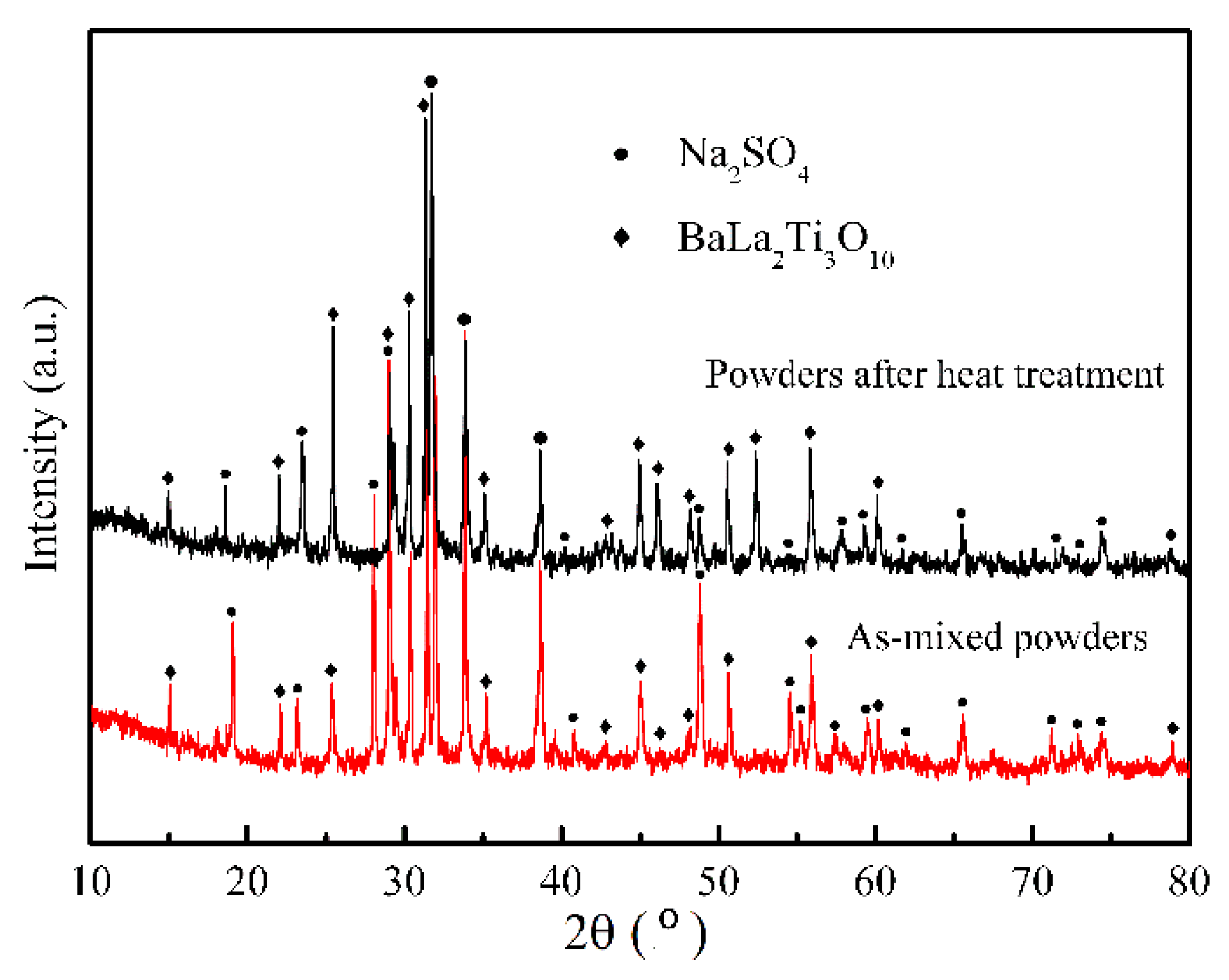

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vaßen, R.; Jarligo, M.O.; Steinke, T.; Mack, D.E.; Stöver, D. Overview on advanced thermal barrier coatings. Surf. Coat. Technol. 2010, 205, 938–942. [Google Scholar] [CrossRef]

- Guo, H.; Gong, S.; Zhou, C.; Xu, H. Investigation on hot-fatigue behaviors of gradient thermal barrier coatings by EB-PVD. Surf. Coat. Technol. 2001, 148, 110–116. [Google Scholar] [CrossRef]

- Padture, N.P. Advanced structural ceramics in aerospace propulsion. Nat. Mater. 2016, 15, 804–809. [Google Scholar] [CrossRef]

- Qiao, M.; Zhou, C. Hot corrosion behavior of Co modified NiAl coating on nickel base superalloys. Corros. Sci. 2012, 63, 239–245. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Meng, G.H.; Yang, G.J.; Li, C.X.; Li, C.J. Dependence of scale thickness on the breaking behavior of the initial oxide on plasma spray bond coat surface during vacuum pre-treatment. Appl. Surf. Sci. 2017, 397, 125–132. [Google Scholar] [CrossRef]

- Han, B.; Ma, Y.; Peng, H.; Zheng, L.; Guo, H. Effect of Mo, Ta, and Re on high-temperature oxidation behavior of minor Hf doped β-NiAl alloy. Corros. Sci. 2016, 102, 222–232. [Google Scholar] [CrossRef]

- Guo, H.B.; Vaßen, R.; Stöver, D. Atmospheric plasma sprayed thick thermal barrier coatings with high segmentation crack density. Surf. Coat. Technol. 2004, 186, 353–363. [Google Scholar] [CrossRef]

- Curry, N.; VanEvery, K.; Snyder, T.; Markocsan, N. Thermal conductivity analysis and lifetime testing of suspension plasma-sprayed thermal barrier coatings. Coatings 2014, 4, 630–650. [Google Scholar] [CrossRef]

- Wang, Q.; Guo, L.; Yan, Z.; Ye, F. Phase composition, thermal conductivity, and toughness of TiO2-doped, Er2O3-stabilized ZrO2 for thermal barrier coating applications. Coatings 2018, 8, 253. [Google Scholar] [CrossRef]

- Xu, Z.H.; Zhou, X.; Wang, K.; Dai, J.W.; He, L.M. Thermal barrier coatings of new rare-earth composite oxide by EB-PVD. J. Alloy. Compd. 2014, 587, 126–132. [Google Scholar] [CrossRef]

- Dong, H.; Han, Y.; Zhou, Y.; Li, X.; Yao, J.T.; Li, Y. The temperature distribution in plasma-sprayed thermal-barrier coatings during crack propagation and coalescence. Coatings 2018, 8, 311. [Google Scholar] [CrossRef]

- Li, C.; Guo, H.; Gao, L.; Wei, L.; Gong, S.; Xu, H. Microstructures of yttria-stabilized zirconia coatings by plasma spray-physical vapor deposition. J. Therm. Spray Technol. 2015, 24, 534–541. [Google Scholar] [CrossRef]

- Gao, L.; Wei, L.; Guo, H.; Gong, S.; Xu, H. Deposition mechanisms of yttria-stabilized zirconia coatings during plasma spray physical vapor deposition. Ceram. Int. 2016, 42, 5530–5536. [Google Scholar] [CrossRef]

- Huang, H.; Liu, C.; Ni, L.; Zhou, C. Evaluation of microstructural evolution of thermal barrier coatings exposed to Na2SO4 using impedance spectroscopy. Corros. Sci. 2011, 53, 1369–1374. [Google Scholar] [CrossRef]

- Liu, Z.G.; Ouyang, J.H.; Zhou, Y.; Zhu, R.X. Hot corrosion of V2O5-coated NdMgAl11O19 ceramic in air at 950 °C. J. Eur. Ceram. Soc. 2013, 33, 1975–1979. [Google Scholar] [CrossRef]

- Li, S.; Liu, Z.G.; Ouyang, J.H. Growth of YbVO4 crystals evolved from hot corrosion reactions of Yb2Zr2O7 against V2O5 and Na2SO4 + V2O5. Appl. Surf. Sci. 2013, 276, 653–659. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, Z.; He, L.; Xu, J.; Zou, B.; Cao, X. Hot corrosion behavior of LaTi2Al9O19 ceramic exposed to vanadium oxide at temperatures of 700–950 °C in air. Corros. Sci. 2016, 104, 310–318. [Google Scholar] [CrossRef]

- Habibi, M.H.; Wang, L.; Liang, J.; Guo, S.M. An investigation on hot corrosion behavior of YSZ-Ta2O5 in Na2SO4 + V2O5 salt at 1100 °C. Corros. Sci. 2013, 75, 409–414. [Google Scholar] [CrossRef]

- Zhong, X.H.; Wang, Y.M.; Xu, Z.H.; Zhang, Y.F.; Zhang, J.F.; Cao, X.Q. Hot-corrosion behaviors of overlay-clad yttria-stabilized zirconia coatings in contact with vanadate-sulfate salts. J. Eur. Ceram. Soc. 2010, 30, 1401–1408. [Google Scholar] [CrossRef]

- Jamali, H.; Mozafarinia, R.; Shoja-Razavi, R.; Ahmadi-Pidani, R. Comparison of hot corrosion behaviors of plasma-sprayed nanostructured and conventional YSZ thermal barrier coatings exposure to molten vanadium pentoxide and sodium sulfate. J. Eur. Ceram. Soc. 2014, 34, 485–492. [Google Scholar] [CrossRef]

- Loghman-Estarki, M.R.; Razavi, R.S.; Edris, H.; Bakhshi, S.R.; Nejati, M.; Jamali, H. Comparison of hot corrosion behavior of nanostructured ScYSZ and YSZ thermal barrier coatings. Ceram. Int. 2016, 42, 7432–7439. [Google Scholar] [CrossRef]

- Loghman-Estarki, M.R.; Razavi, R.S.; Jamali, H. Effect of molten V2O5 salt on the corrosion behavior of micro- and nano-structured thermal sprayed SYSZ and YSZ coatings. Ceram. Int. 2016, 42, 12825–12837. [Google Scholar] [CrossRef]

- Nejati, M.; Rahimipour, M.R.; Mobasherpour, I. Evaluation of hot corrosion behavior of CSZ, CSZ/micro Al2O3 and CSZ/nano Al2O3 plasma sprayed thermal barrier coatings. Ceram. Int. 2014, 40, 4579–4590. [Google Scholar] [CrossRef]

- Liu, H.F.; Xiong, X.; Li, X.B.; Wang, Y.L. Hot corrosion behavior of Sc2O3-Y2O3-ZrO2 thermal barrier coatings in presence of Na2SO4 + V2O5 molten salt. Corros. Sci. 2014, 85, 87–93. [Google Scholar] [CrossRef]

- Liu, Z.G.; Ouyang, J.H.; Zhou, Y.; Xia, X.L. Hot corrosion behavior of V2O5-coated Gd2Zr2O7 ceramic in air at 700–850 °C. J. Eur. Ceram. Soc. 2009, 29, 2423–2427. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, C.; He, Q.; Yu, J.; Yan, Z.; Ye, F.; Dan, C.; Ji, V. Microstructure evolution and hot corrosion mechanisms of Ba2REAlO5 (RE = Yb, Er, Dy) exposed to V2O5 + Na2SO4 molten salt. J. Eur. Ceram. Soc. 2018, 38, 3555–3563. [Google Scholar] [CrossRef]

- Zhang, C.; Li, M.; Zhang, Y.; Guo, L.; Dong, J.; Ye, F.; Li, L.; Ji, V. Hot corrosion behavior of (Gd0.9Sc0.1)2Zr2O7 in V2O5 molten salt at 700–1000 °C. Ceram. Int. 2017, 43, 9041–9046. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, C.; Li, M.; Sun, W.; Zhang, Z.; Ye, F. Hot corrosion evaluation of Gd2O3-Yb2O3 co-doped Y2O3 stabilized ZrO2 thermal barrier oxides exposed to Na2SO4 + V2O5 molten salt. Ceram. Int. 2017, 43, 2780–2785. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, C.; He, Q.; Li, Z.; Yu, J.; Liu, X.; Ye, F. Corrosion products evolution and hot corrosion mechanisms of REPO4 (RE = Gd, Nd, La) in the presence of V2O5 + Na2SO4 molten salt. J. Eur. Ceram. Soc. 2019, 39, 1496–1506. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, H.; Ma, G.; Gong, S. Thermo-physical and thermal cycling properties of plasma-sprayed BaLa2Ti3O10 coating as potential thermal barrier materials. Surf. Coat. Technol. 2009, 204, 691–696. [Google Scholar] [CrossRef]

- Chen, X.; Cao, X.; Zou, B.; Gong, J.; Sun, C. Corrosion of lanthanum magnesium hexaaluminate as plasma-sprayed coating and as bulk material when exposed to molten V2O5-containing salt. Corros. Sci. 2015, 91, 185–194. [Google Scholar] [CrossRef]

- Habibi, M.H.; Yang, S.; Guo, S.M. Phase stability and hot corrosion behavior of ZrO2-Ta2O5 compound in Na2SO4-V2O5 mixtures at elevated temperatures. Ceram. Int. 2014, 40, 4077–4083. [Google Scholar] [CrossRef]

- Gitanjaly, H.; Singh, S.; Prakash, S. Role of CeO2 coating in enhancing high temperature corrosion resistance of Ni-base superalloys as an inhibitor. Mater. High Temp. 2010, 27, 109–116. [Google Scholar] [CrossRef]

- Rocca, E.; Aranda, L.; Moliere, M.; Steinmetz, P. Nickel oxide as a new inhibitor of vanadium-induced hot corrosion of superalloys-comparison to MgO-based inhibitor. J. Mater. Chem. 2002, 12, 3766–3772. [Google Scholar] [CrossRef]

- Ramachandran, C.S.; Balasubramanian, V.; Ananthapadmanabhan, P.V. On the cyclic hot corrosion behavior of atmospheric plasma sprayed lanthanum zirconate based coatings in contact with a mixture of sodium sulphate and vanadate salts: A comparison with the traditional YSZ duplex and NiCrAlY coated samples. Vacuum 2013, 97, 81–95. [Google Scholar] [CrossRef]

| Corrosion Products | Ba | La | Ti | V | S | O |

|---|---|---|---|---|---|---|

| A | 15.87 | – | – | 21.56 | – | 62.57 |

| B | – | – | 31.58 | – | – | 68.42 |

| C | – | 16.38 | – | 17.63 | – | 65.99 |

| D | 16.45 | – | – | – | 18.53 | 65.02 |

| E | – | – | 33.16 | – | – | 66.84 |

| F | – | 17.57 | – | 18.46 | – | 63.97 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Cai, J.; Zhu, J. Hot Corrosion Behavior of BaLa2Ti3O10 Thermal Barrier Ceramics in V2O5 and Na2SO4 + V2O5 Molten Salts. Coatings 2019, 9, 351. https://doi.org/10.3390/coatings9060351

Liu H, Cai J, Zhu J. Hot Corrosion Behavior of BaLa2Ti3O10 Thermal Barrier Ceramics in V2O5 and Na2SO4 + V2O5 Molten Salts. Coatings. 2019; 9(6):351. https://doi.org/10.3390/coatings9060351

Chicago/Turabian StyleLiu, Hui, Jin Cai, and Jihong Zhu. 2019. "Hot Corrosion Behavior of BaLa2Ti3O10 Thermal Barrier Ceramics in V2O5 and Na2SO4 + V2O5 Molten Salts" Coatings 9, no. 6: 351. https://doi.org/10.3390/coatings9060351

APA StyleLiu, H., Cai, J., & Zhu, J. (2019). Hot Corrosion Behavior of BaLa2Ti3O10 Thermal Barrier Ceramics in V2O5 and Na2SO4 + V2O5 Molten Salts. Coatings, 9(6), 351. https://doi.org/10.3390/coatings9060351