Nickel Film Deposition with Varying RF Power for the Reduction of Contact Resistance in NiSi

Abstract

1. Introduction

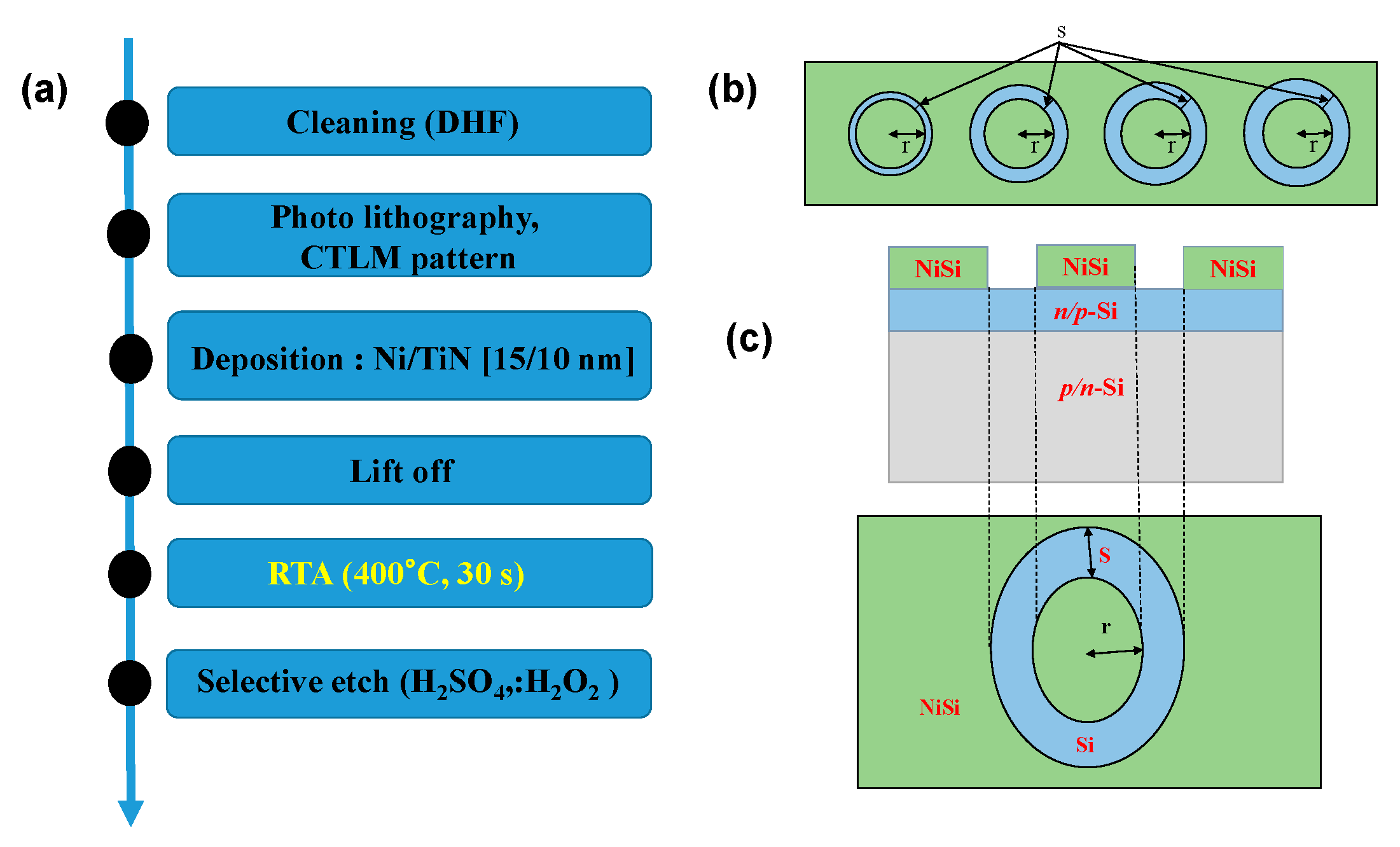

2. Materials and Methods

2.1. Ni Films Deposition

2.2. Nickel Silicide Fabrication and Contact Resistance Measurement

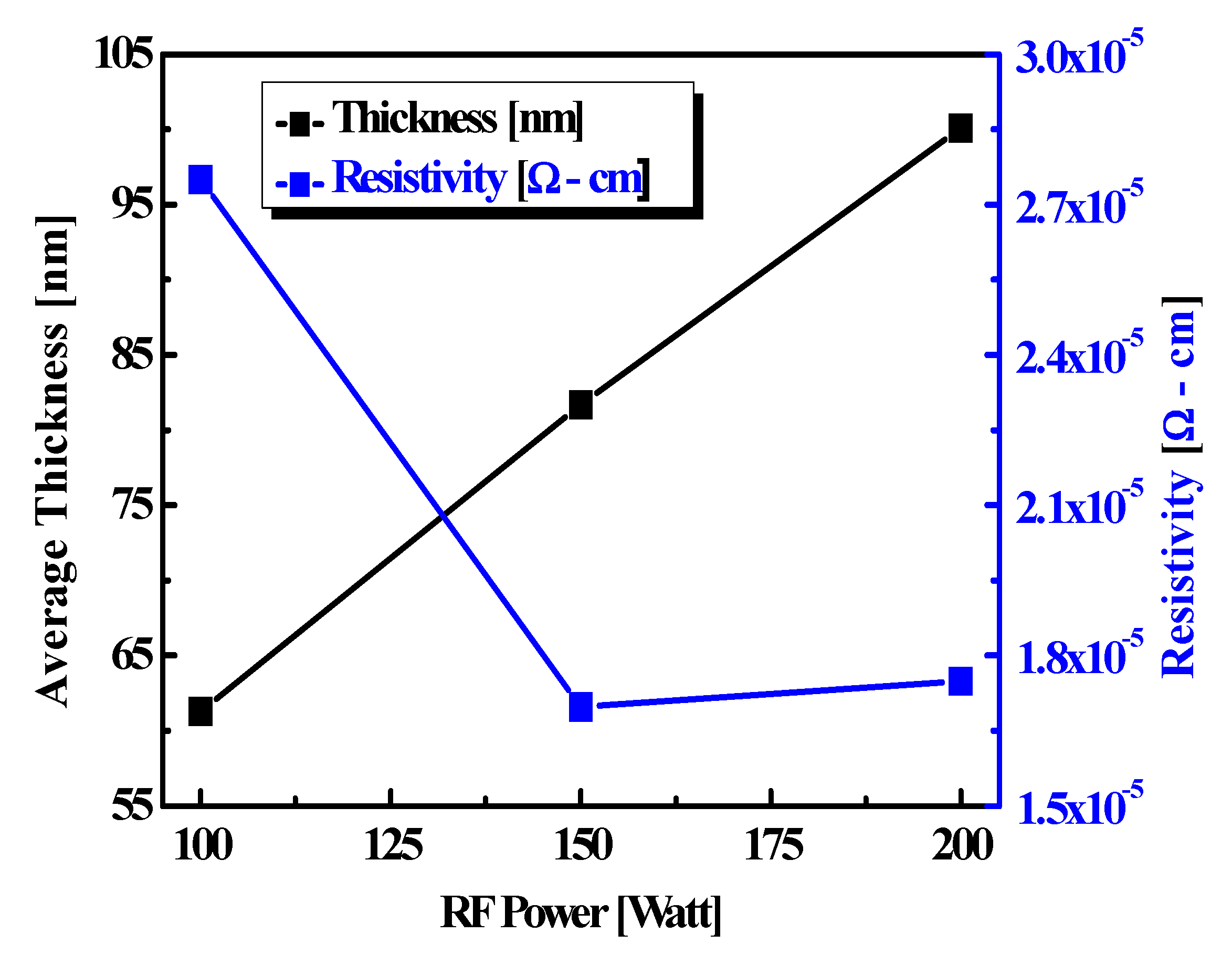

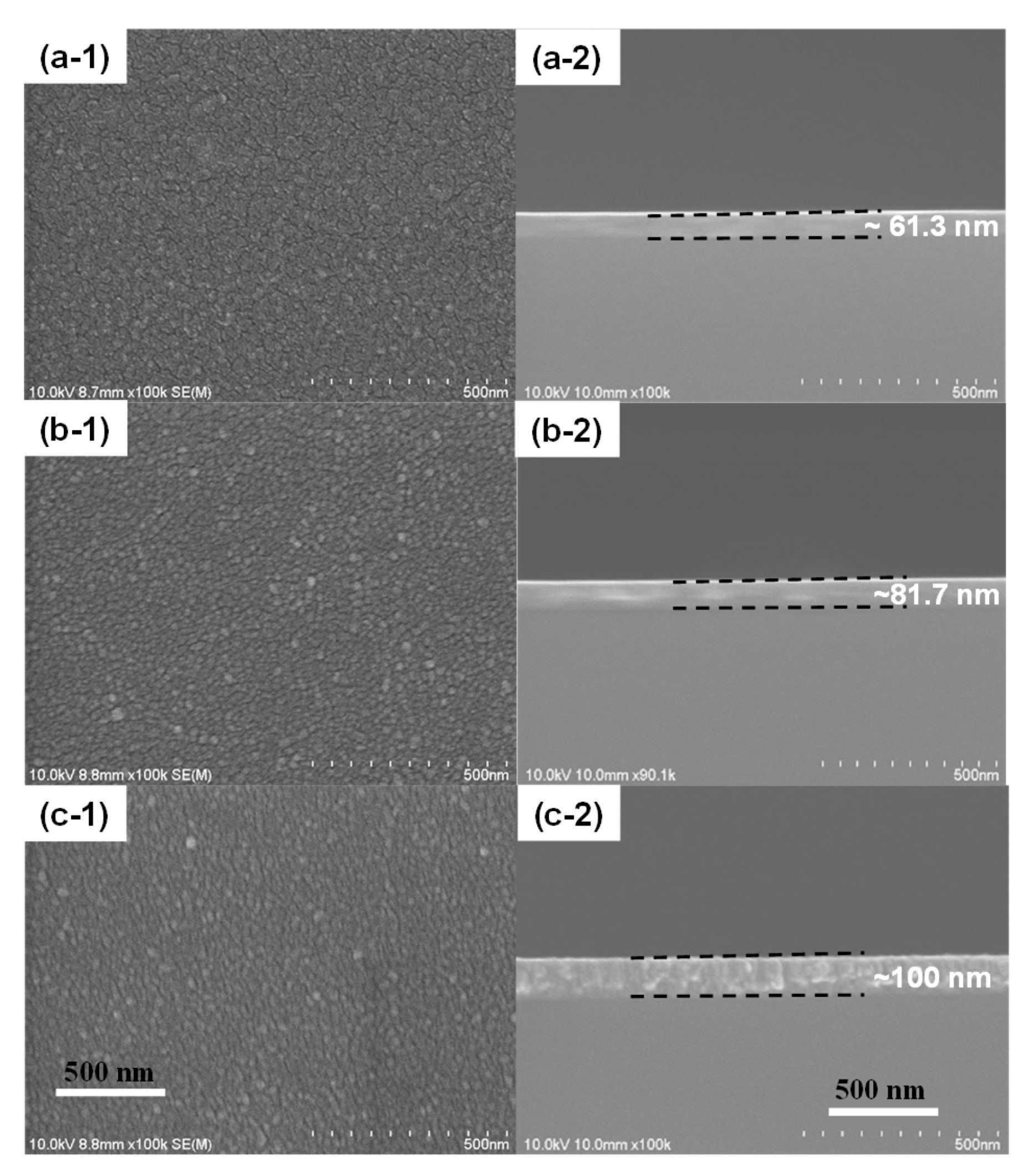

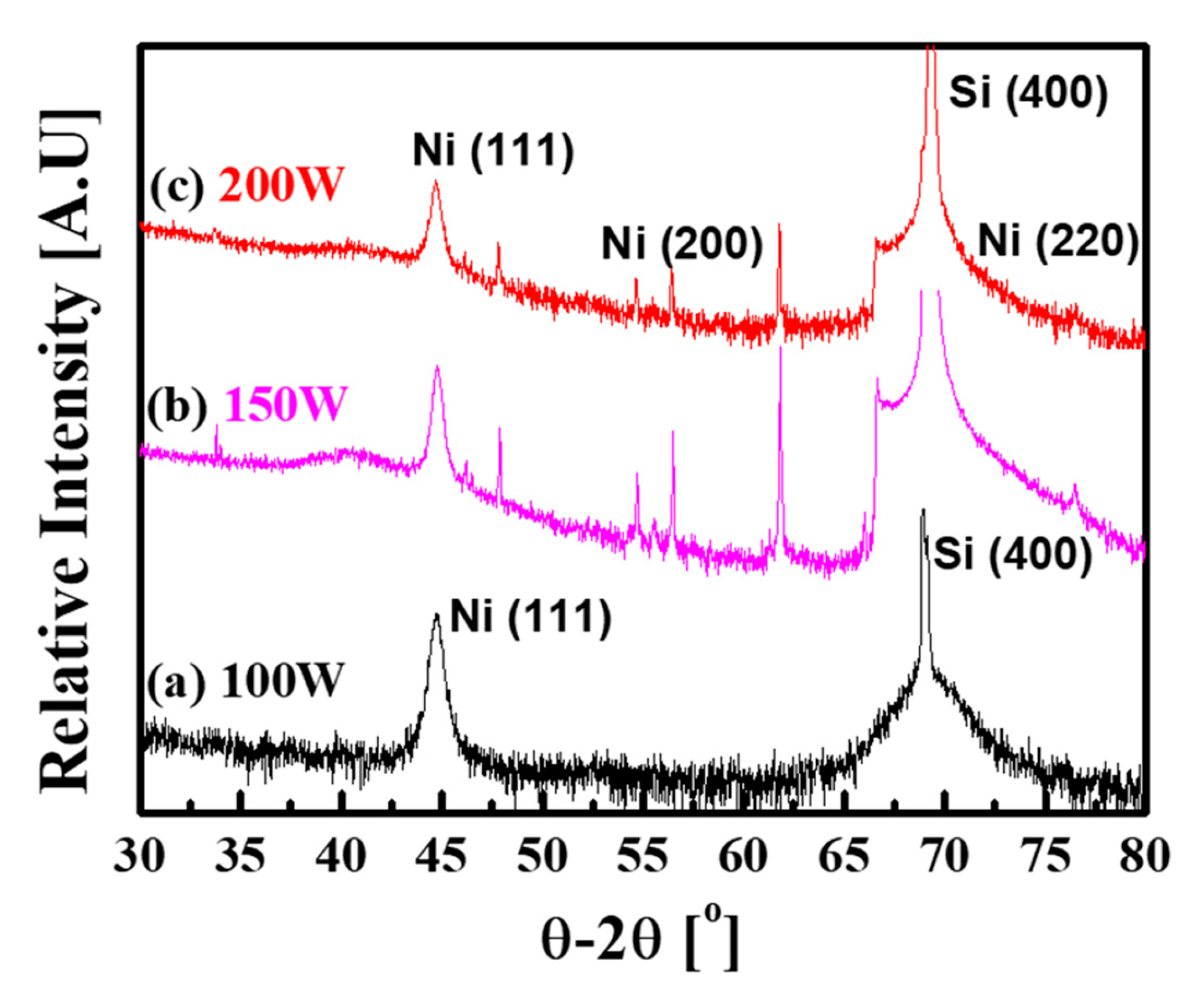

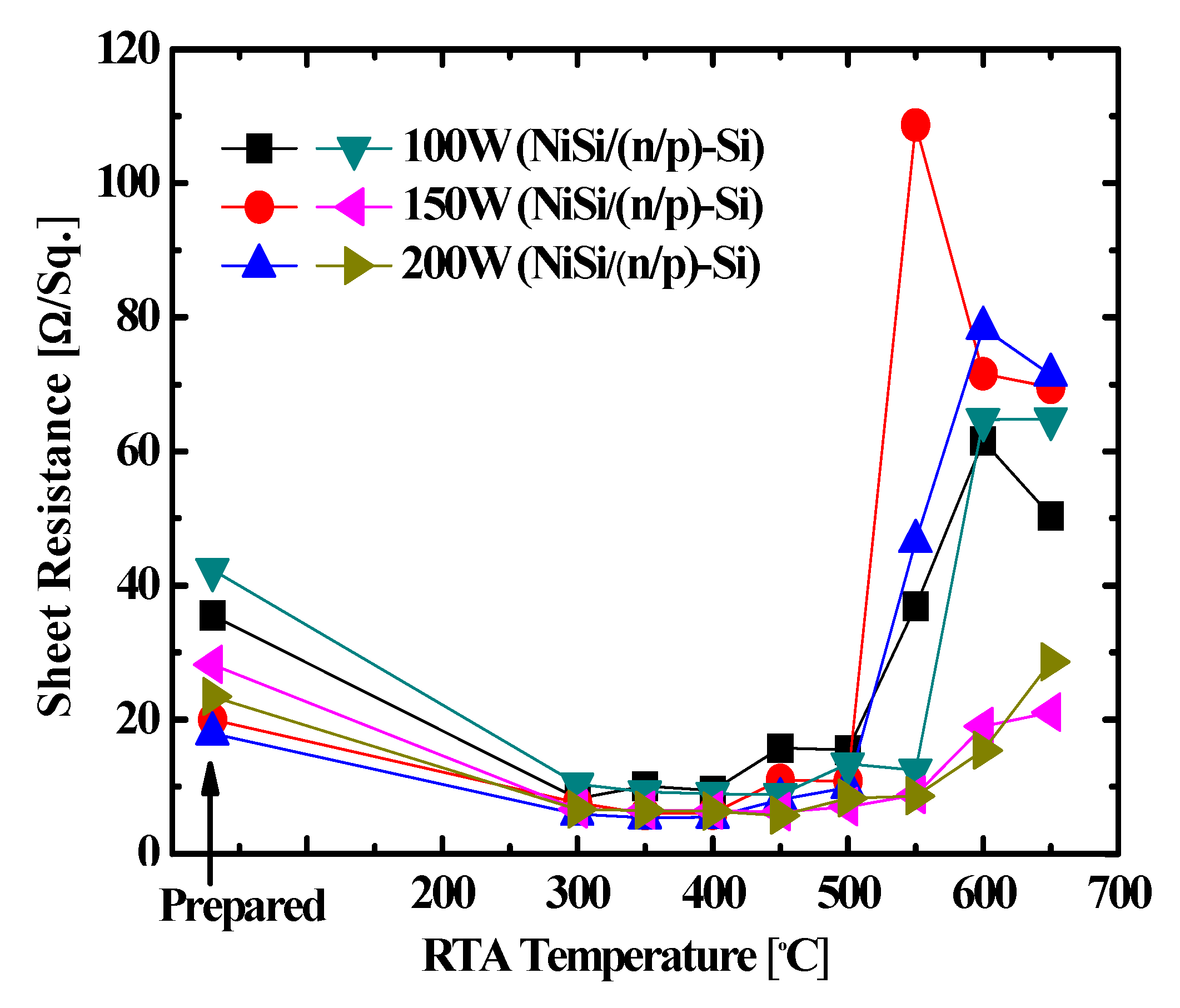

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rabab, R.B.; Amir, N.H.; Arwa, T.K.; Abdurrahman, G.; Muhammad, M.H. Impact of nickel silicide rear metallization on the series resistance of crystalline silicon solar cells. Energy Technol. 2018, 6, 1627–1632. [Google Scholar]

- Geenen, F.A.; Van Stiphout, K.; Nanakoudis, A.; Bals, S.; Vantomme, A.; Jordan-Sweet, J.; Lavoie, C.; Detavernier, C. Controlling the formation and stability of ultra-thin nickel silicides—An alloying strategy for preventing agglomeration. J. Appl. Phys. 2018, 123, 075303. [Google Scholar] [CrossRef]

- Wolansky, D.; Grabolla, T.; Lenke, T.; Schulze, S.; Zaumseil, P. Impact of nickel silicide on SiGe BiCMOS devices. Semicond. Sci. Technol. 2018, 33, 124003. [Google Scholar] [CrossRef]

- Ramly, M.M.; Omar, F.S.; Rohaizad, A.; Aspanut, Z.; Rahman, S.A.; Goh, B.T. Solid-phase diffusion controlled growth of nickel silicide nanowires for supercapacitor electrode. Appl. Surf. Sci. 2018, 456, 515–525. [Google Scholar] [CrossRef]

- Vijselaar, W.; Tiggelaar, R.M.; Gardeniers, H.J.; Huskens, J. Efficient and stable silicon microwire photocathodes with a nickel silicide interlayer for operation in strongly alkaline solutions. ACS Energy Lett. 2018, 3, 1086–1092. [Google Scholar] [CrossRef] [PubMed]

- Marshall, A.; Florent, K.; Tapriya, A.; Lee, B.G.; Kurinec, S.K.; Young, D.L. Nickel silicide metallization for passivated tunneling contacts for silicon solar cells. In Proceedings of the IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016; pp. 2479–2482. [Google Scholar]

- El Kousseifi, M.; Hoummada, K.; Bertoglio, M.; Mangelinck, D. Selection of the first Ni silicide phase by controlling the Pt incorporation in the intermixed layer. Acta Mater. 2016, 106, 193–198. [Google Scholar] [CrossRef]

- Jung, S.M.; Kim, J.H.; Park, C.J.; Shin, M.W. Nickel mono-silicide formation using a photo-thermal process assisted by ultra-violet laser. Mater. Sci. Semicond. Process. 2018, 75, 263–268. [Google Scholar] [CrossRef]

- Richard, M.-I.; Mangelinck, D.; Guichet, C.; Thomas, O.; Texier, M.; Fouet, J.; Boudet, N.; Portavoce, A. Silicide formation during reaction between Ni ultra-thin films and Si (001) substrates. Mater. Lett. 2013, 116, 139–142. [Google Scholar]

- Tous, L.; Lerat, J.-F.; Emeraud, T.; Negru, R.; Huet, K.; Uruena, A.; Aleman, M.; Russell, R.; John, J.; Poortmans, J.; et al. Nickel silicide formation using excimer laser annealing. Energy Procedia 2012, 27, 503–509. [Google Scholar] [CrossRef][Green Version]

- Lee, K.M.; Kim, C.Y.; Choi, C.K.; Yun, S.W.; Ha, J.B.; Lee, J.H.; Lee, J.Y. Interface properties of nickel-silicide films deposited by using plasma-assisted atomic layer deposition. J. Korean Phys. Soc. 2009, 55, 1153–1157. [Google Scholar] [CrossRef]

- Alizadeh, M.; Hamzan, N.B.; Ooi, P.C.; Bin Omar, M.F.; Dee, C.F.; Goh, B.T. Solid-state limited nucleation of NiSi/SiC core-shell nanowires by hot-wire chemical vapor deposition. Materials 2019, 12, 674. [Google Scholar] [CrossRef]

- Terashima, K.; Miura, Y.; Ikarashi, N.; Oshida, M.; Manabe, K.; Yoshihara, T.; Tanaka, M.; Wakabayashi, H. Formation of Nickel Self-Aligned Silicide by Using Cyclic Deposition Method. In Proceedings of the 2004 International Conference on Solid State Devices and Materials, Tokyo, Japan, 14–17 September 2004; pp. 182–183. [Google Scholar]

- Azimirad, R.; Kargarian, M.; Akhavan, O.; Moshfegh, A.Z. Improved thermal stability of NiSi nanolayer in Ni-Si Co-sputtered structure. Int. J. Nanosci. Nanotechnol. 2011, 7, 14–20. [Google Scholar]

- Guo, Q.; Guo, Z.; Shi, J.; Sang, L.; Gao, B.; Chen, Q.; Liu, Z.; Wang, X. Fabrication of nickel and nickel carbide thin films by pulsed chemical vapor deposition. MRS Commun. 2018, 8, 88–94. [Google Scholar] [CrossRef]

- Han, W.S.; Kim, S.; Hwang, J.; Park, J.-M.; Koh, W.; Lee, W.-J. Plasma-enhanced atomic layer deposition of nickel thin film using is (1,4-diisopropyl-1,4-diazabutadiene) nickel. J. Vac. Sci. Technol. A Vacuum Surf. Film 2017, 36, 01A119. [Google Scholar]

- Widodo, S. Characterization of Thin Film Nickel (Ni) Deposition by Sputtering Method. Int. J. Innov. Sci. Technol. 2015, 2, 380–385. [Google Scholar]

- Nishiyama, T.; Tanaka, T.; Shikada, K.; Ohtake, M.; Kirino, F.; Futamoto, M. Growth of Ni Thin Films on Al2O3 Single-Crystal Substrates. Jpn. J. Appl. Phys. 2009, 48, 13003. [Google Scholar] [CrossRef]

- Valladares, L.D.L.S.; Ionescu, A.; Holmes, S.; Barnes, C.H.W.; Dominguez, A.B.; Quispe, O.A.; Gonzalez, J.C.; Milana, S.; Barbone, M.; Ferrari, A.C.; et al. Characterization of Ni thin films following thermal oxidation in air. J. Vac. Sci. Technol. B 2014, 32, 51808. [Google Scholar] [CrossRef]

- Kassem, W.; Roumie, M.; Tabbal, M. Pulsed Laser Deposition of Tungsten Thin Films on Graphite. Adv. Mater. 2011, 324, 77–80. [Google Scholar] [CrossRef]

- Li, J.-D.; Zhang, P.; Wu, Y.-H.; Liu, Y.-S.; Xuan, M. Uniformity study of nickel thin-film microstructure deposited by electroplating. Microsyst. Technol. 2009, 15, 505–510. [Google Scholar] [CrossRef]

- Peri, B.; Borah, B.; Dash, R.K. Effect of RF power and gas flow ratio on the growth and morphology of the PECVD SiC thin film s for MEMS applications. Mater. Sci. 2015, 38, 1105–1112. [Google Scholar] [CrossRef]

- Posadowski, W.; Wiatrowski, A.; Kapka, G. Effect of pulsed magnetron sputtering process for the deposition of thin layers of nickel and nickel oxide. Mater. Sci. 2018, 36, 69–74. [Google Scholar] [CrossRef]

- Vergara, J.; Madurga, V. Structure and magnetic properties of Ni films obtained by pulsed laser ablation deposition. J. Mater. 2002, 17, 2099–2104. [Google Scholar] [CrossRef]

- D’Agostino, A.T. Determination of thin metal film thickness by X-ray diffractometry using the Scherrer equation, atomic absorption analysis and transmission/reflection visible spectroscopy. Anal. Chim. Acta 1992, 262, 269–275. [Google Scholar] [CrossRef]

- Zhao, F.F.; Zheng, J.Z.; Shen, Z.X.; Osipowicz, T.; Gao, W.Z.; Chan, L.H. Thermal stability study of NiSi and NiSi2 thin films. Microelectron. Eng. 2004, 71, 104–111. [Google Scholar] [CrossRef]

- Schroder, D.K. Semiconductor Material and Device Characterization, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006; p. 144. ISBN 9780471739067. [Google Scholar]

- Kuchuk, A.V.; Borowicz, P.; Wzorek, M.; Borysiewicz, M.; Ratajczak, R.; Golaszewska, K.; Kaminska, E.; Kladko, V.; Piotrowska, A. Ni-based ohmic contacts to n-type 4H-SiC: The formation mechanism and thermal stability. Adv. Condens. Matter Phys. 2016, 2016, 26. [Google Scholar] [CrossRef]

- Gordillo, G.; Mesa, F.; Calderón, C. Electrical and morphological properties of low resistivity Mo thin Films prepared by magnetron sputtering. Braz. J. Phys. 2006, 36, 982–985. [Google Scholar] [CrossRef]

- Zhang, S.-L.; Smith, U. Self-aligned silicides for Ohmic contacts in complementary metal–oxide–semiconductor technology: TiSi2, CoSi2, and NiSi. J. Vac. Sci. Technol. A Vacuum Surf. Film 2004, 22, 1361–1370. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, B.; Li, C.; Shao, Z.; Su, D.; Williams, C.T.; Liang, C. Structural and electrochemical properties of nanostructured nickel silicides by reduction and silicification of high-surface-area nickel oxide. Mater. Res. Bull. 2012, 47, 867–877. [Google Scholar] [CrossRef]

- Lauwers, A.; Kitt, J.A.; Van Dal, M.J.H.; Chamirian, O.; Pawlak, M.A.; De Potter, M.; Lindsay, R.; Raymakers, T.; Pages, X.; Mebarki, B. Ni based suicides for 45 nm CMOS and beyond. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2004, 114–115, 29–41. [Google Scholar] [CrossRef]

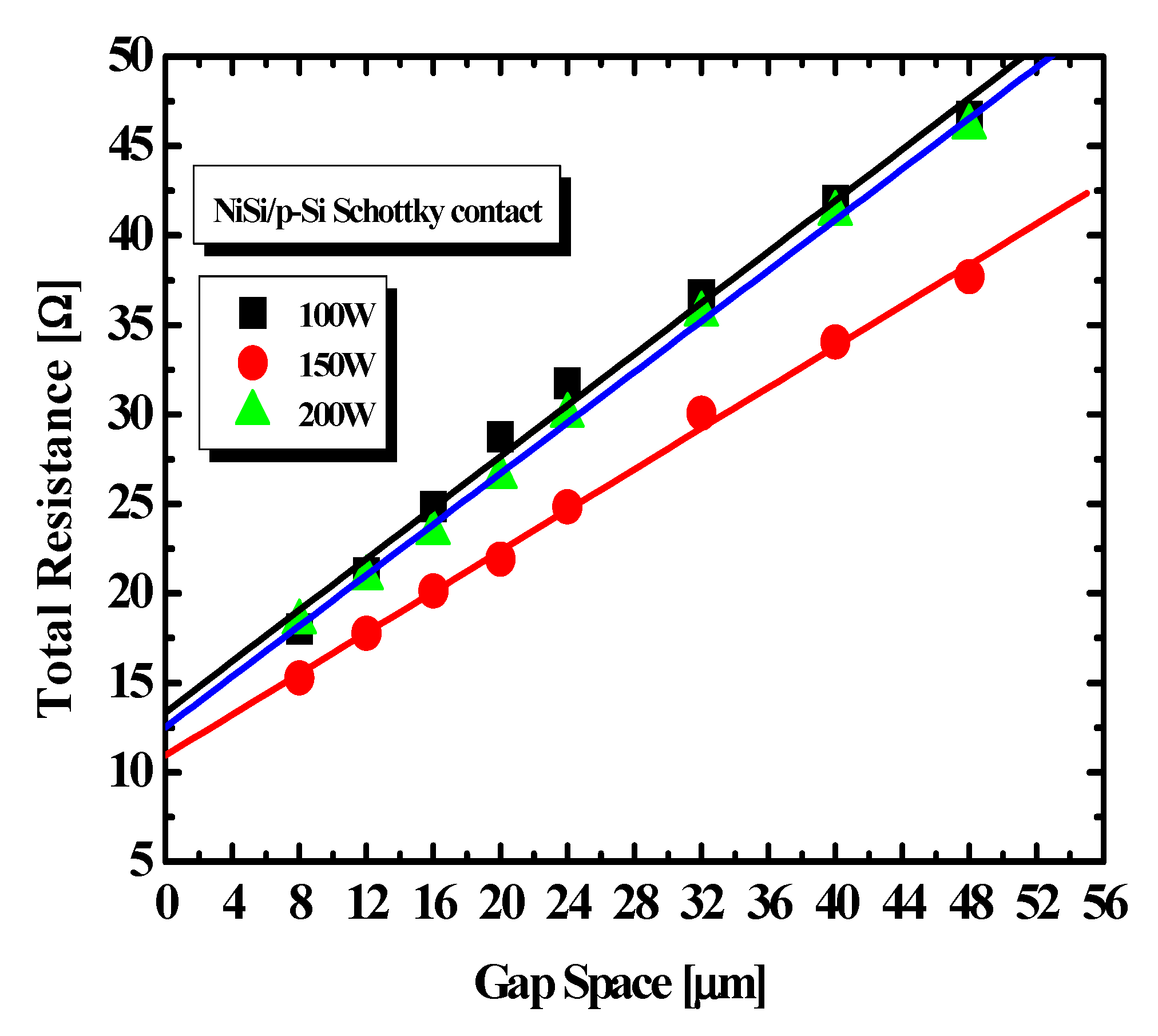

| Sample | NiSi/n-Si | NiSi/p-Si | |||

|---|---|---|---|---|---|

| RF Power | ρC [Ω-cm2] | LT [μm] | ρC [Ω-cm2] | LT [μm] | |

| Ni/TiN [15/10 nm] | 100 W | 8.08 × 10−5 | 8.128 | 7.82 × 10−5 | 4.663 |

| 150 W | 5.84 × 10−5 | 7.493 | 6.58 × 10−5 | 4.787 | |

| 200 W | 1.18 × 10−4 | 10.29 | 6.94 × 10−5 | 4.411 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eadi, S.B.; Song, H.-S.; Song, H.-D.; Oh, J.; Lee, H.-D. Nickel Film Deposition with Varying RF Power for the Reduction of Contact Resistance in NiSi. Coatings 2019, 9, 349. https://doi.org/10.3390/coatings9060349

Eadi SB, Song H-S, Song H-D, Oh J, Lee H-D. Nickel Film Deposition with Varying RF Power for the Reduction of Contact Resistance in NiSi. Coatings. 2019; 9(6):349. https://doi.org/10.3390/coatings9060349

Chicago/Turabian StyleEadi, Sunil Babu, Hyeong-Sub Song, Hyun-Dong Song, Jungwoo Oh, and Hi-Deok Lee. 2019. "Nickel Film Deposition with Varying RF Power for the Reduction of Contact Resistance in NiSi" Coatings 9, no. 6: 349. https://doi.org/10.3390/coatings9060349

APA StyleEadi, S. B., Song, H.-S., Song, H.-D., Oh, J., & Lee, H.-D. (2019). Nickel Film Deposition with Varying RF Power for the Reduction of Contact Resistance in NiSi. Coatings, 9(6), 349. https://doi.org/10.3390/coatings9060349