Cracking, Microstructure and Tribological Properties of Laser Formed and Remelted K417G Ni-Based Superalloy

Abstract

:1. Introduction

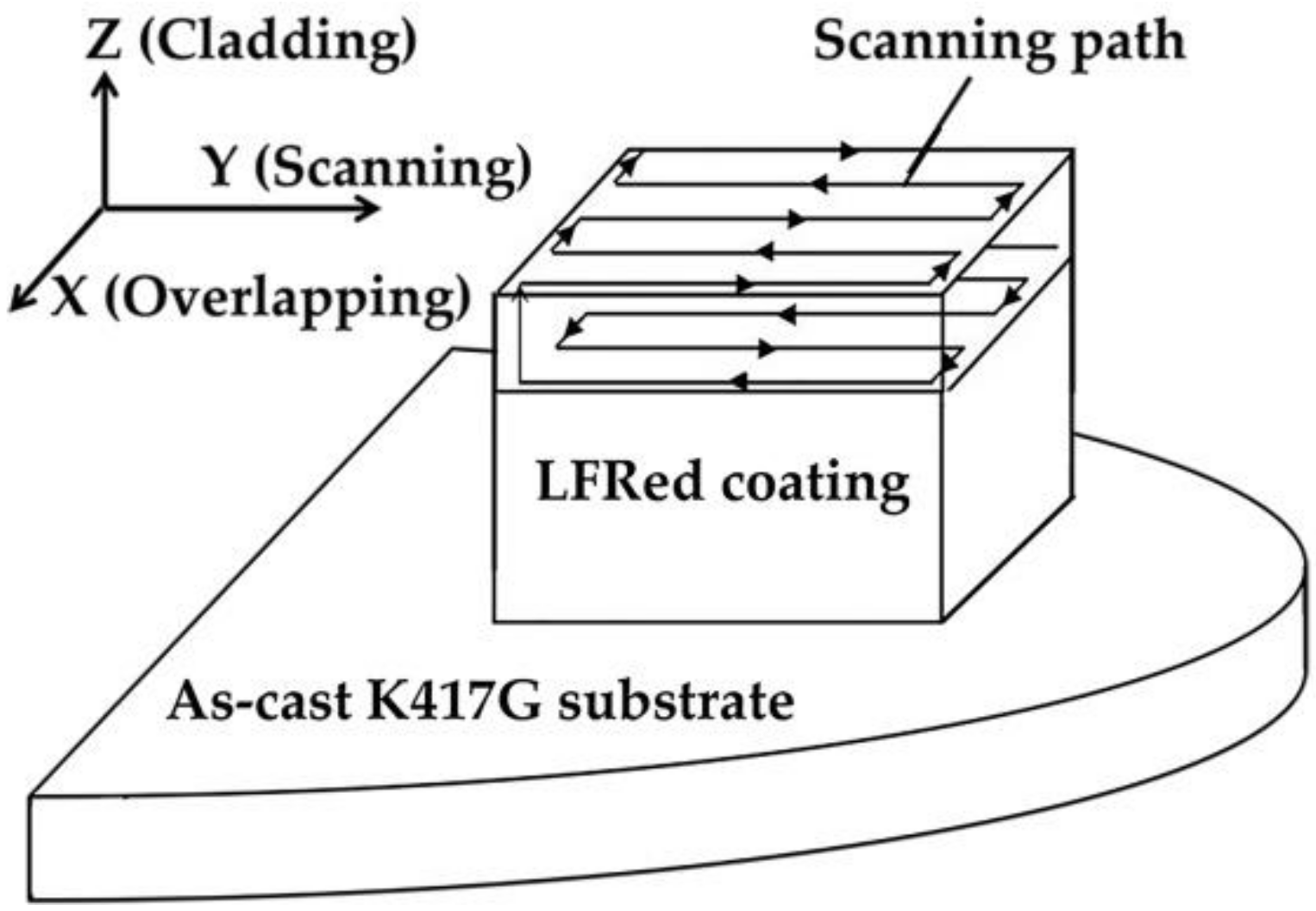

2. Materials and Methods

3. Results and Discussion

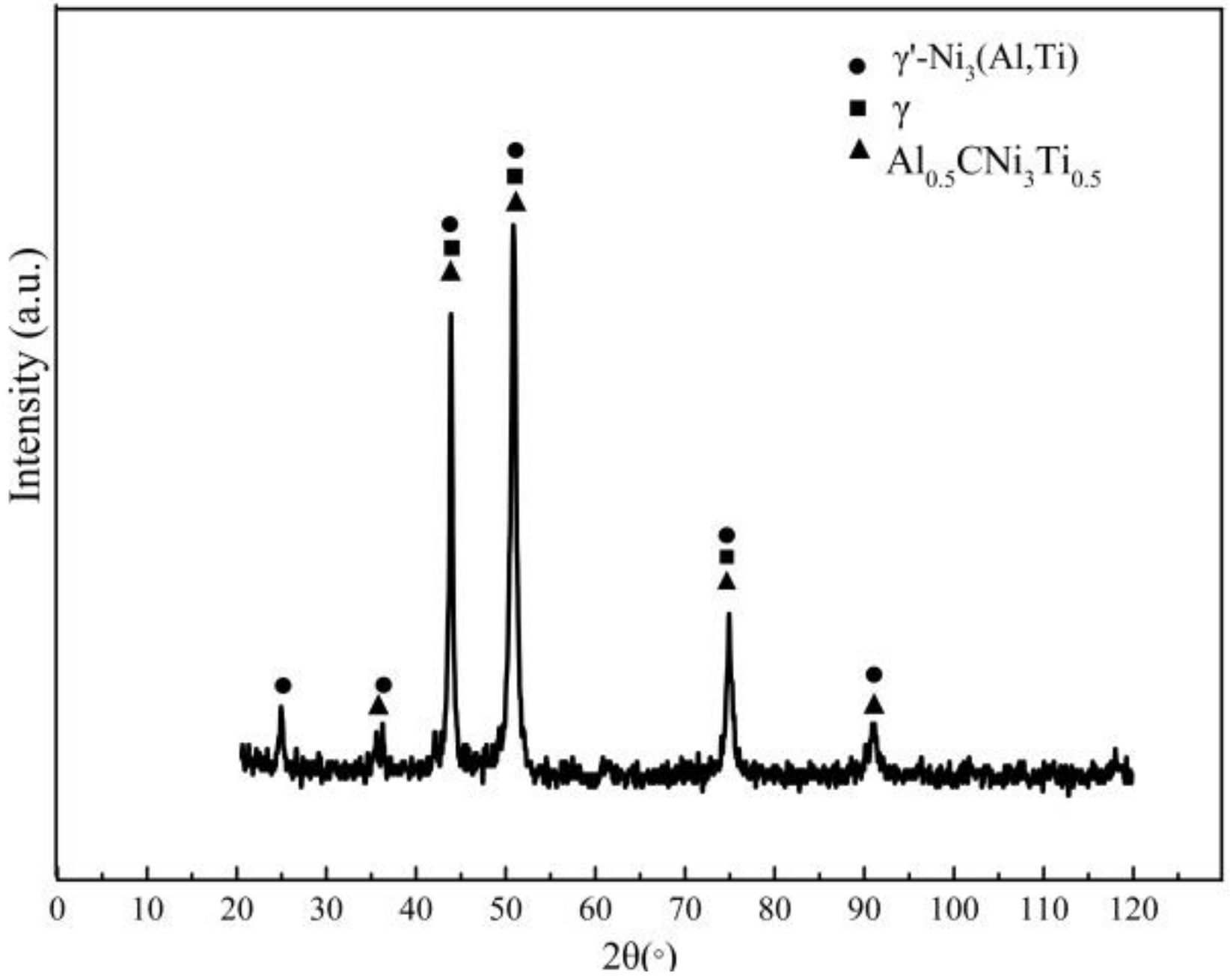

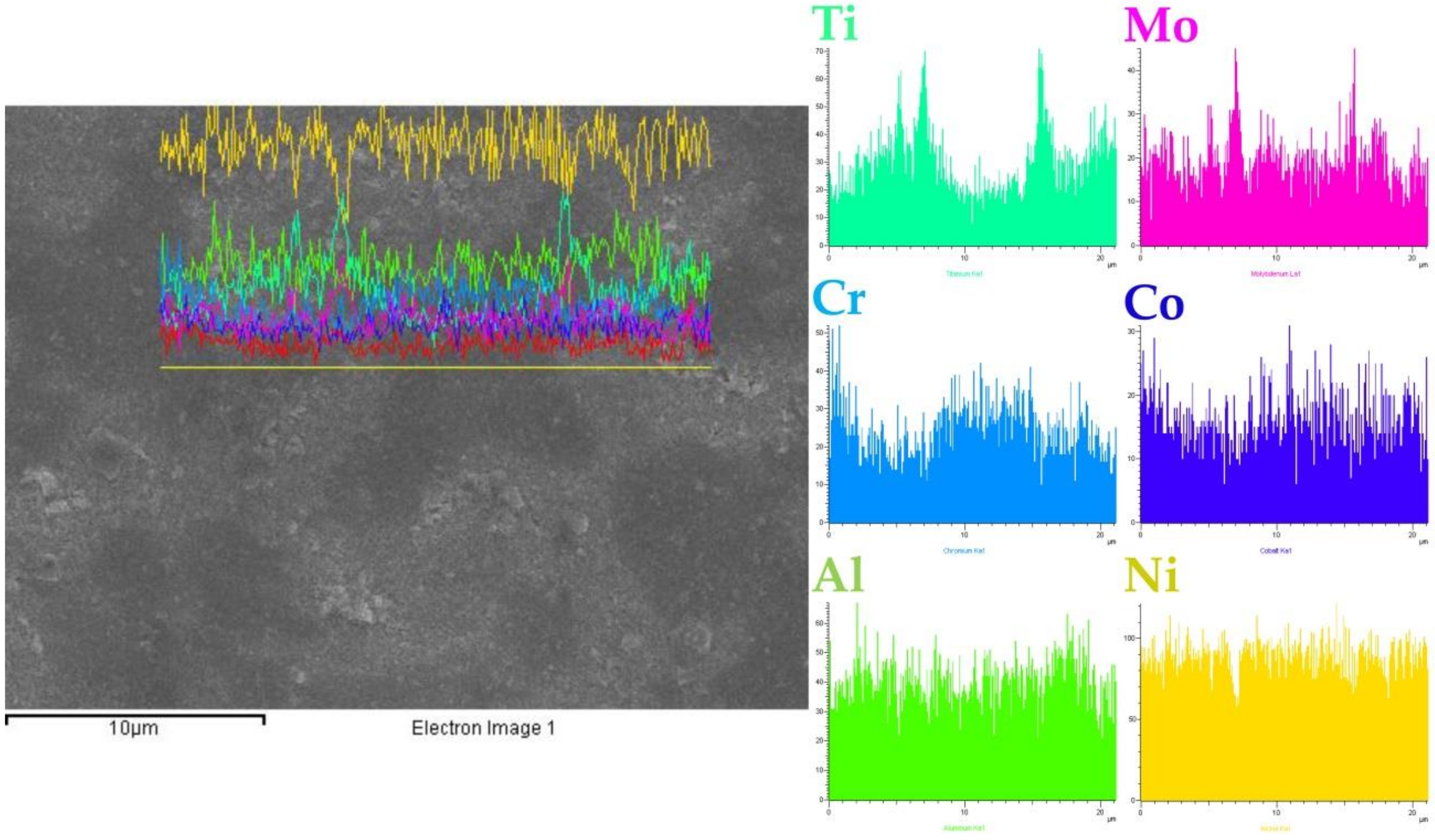

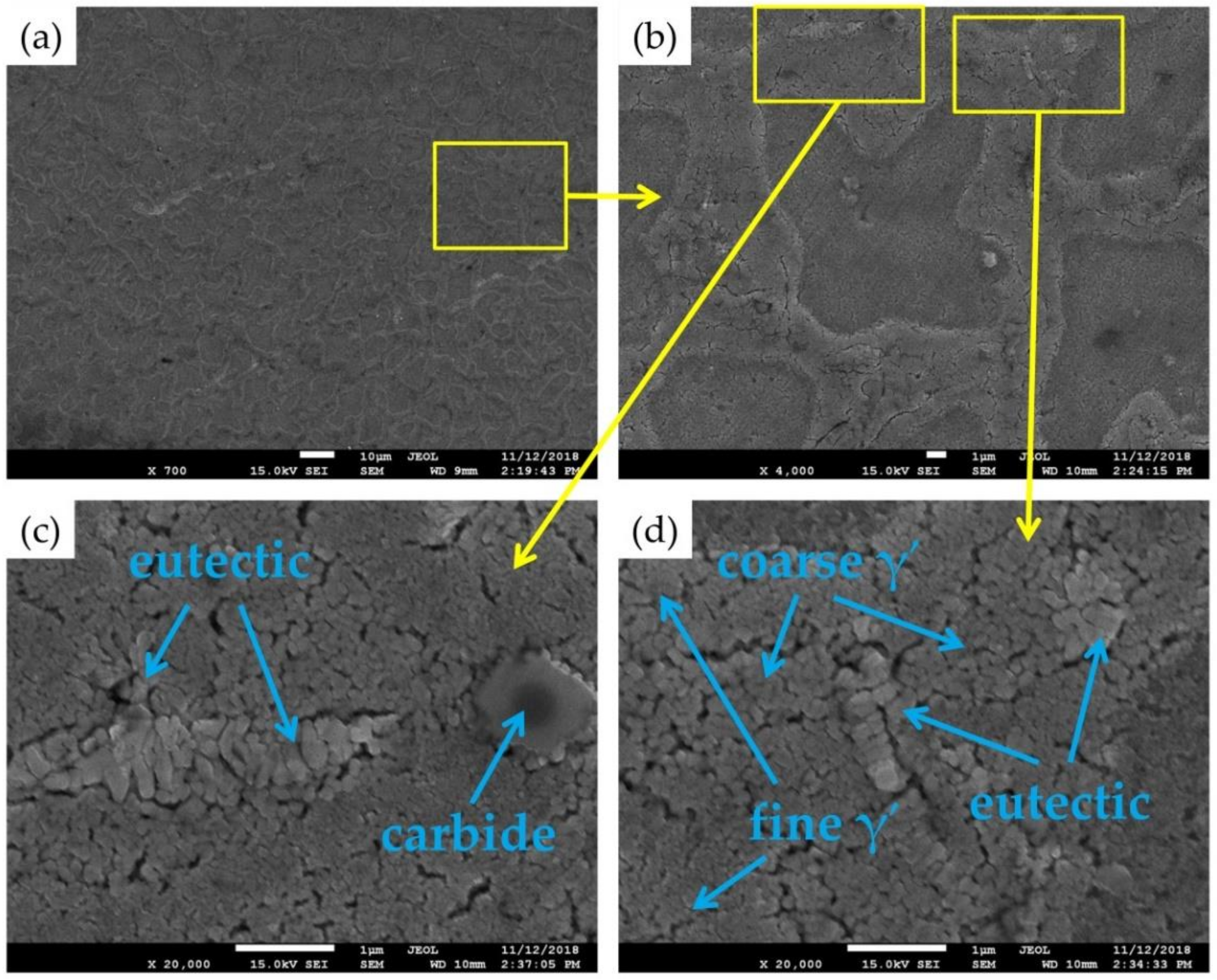

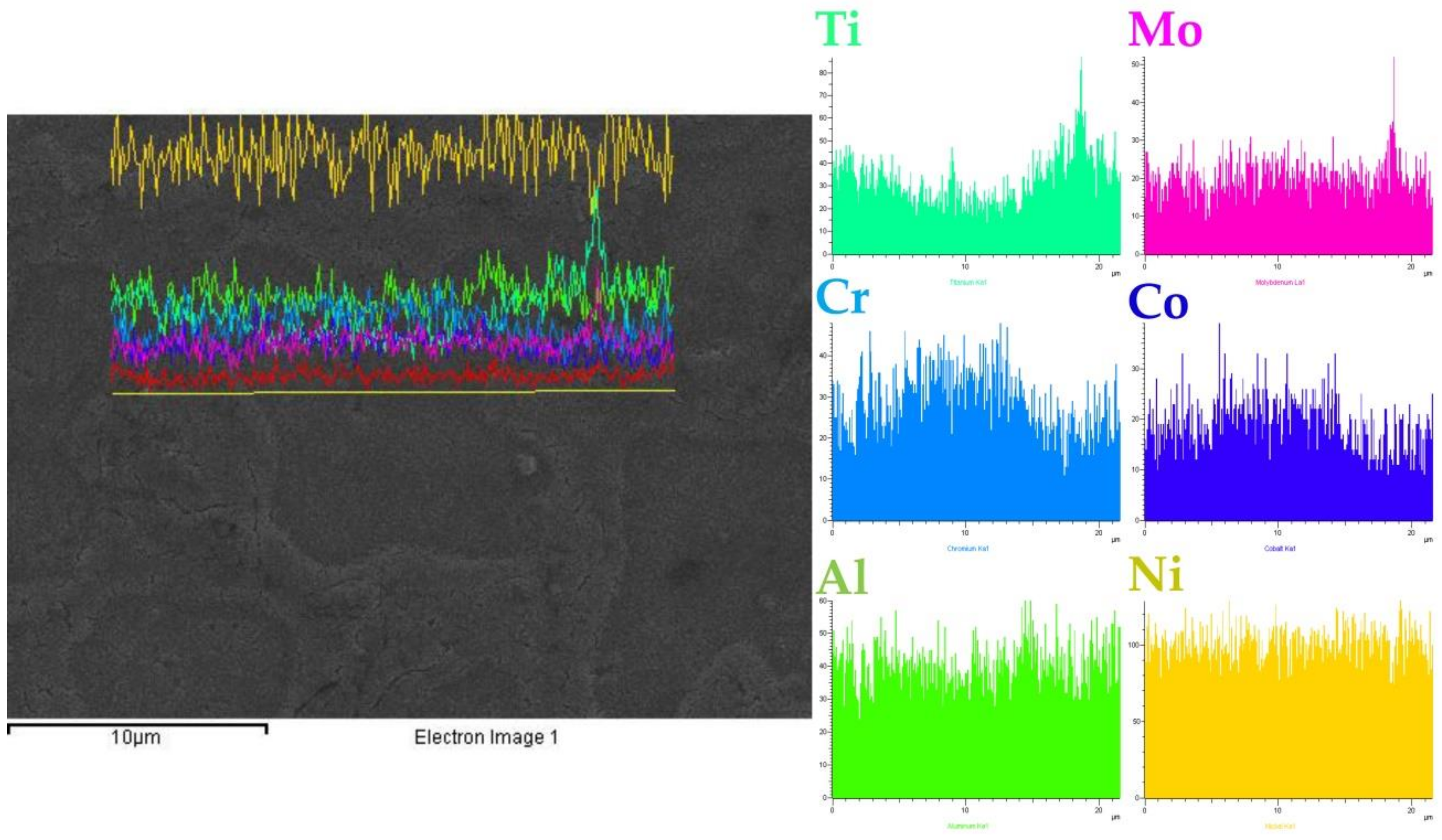

3.1. Microstructure and Main Phases of LFRed K417G Superalloy

3.2. Cracking Behavior and Mechanisms of LFRed K417G Superalloy

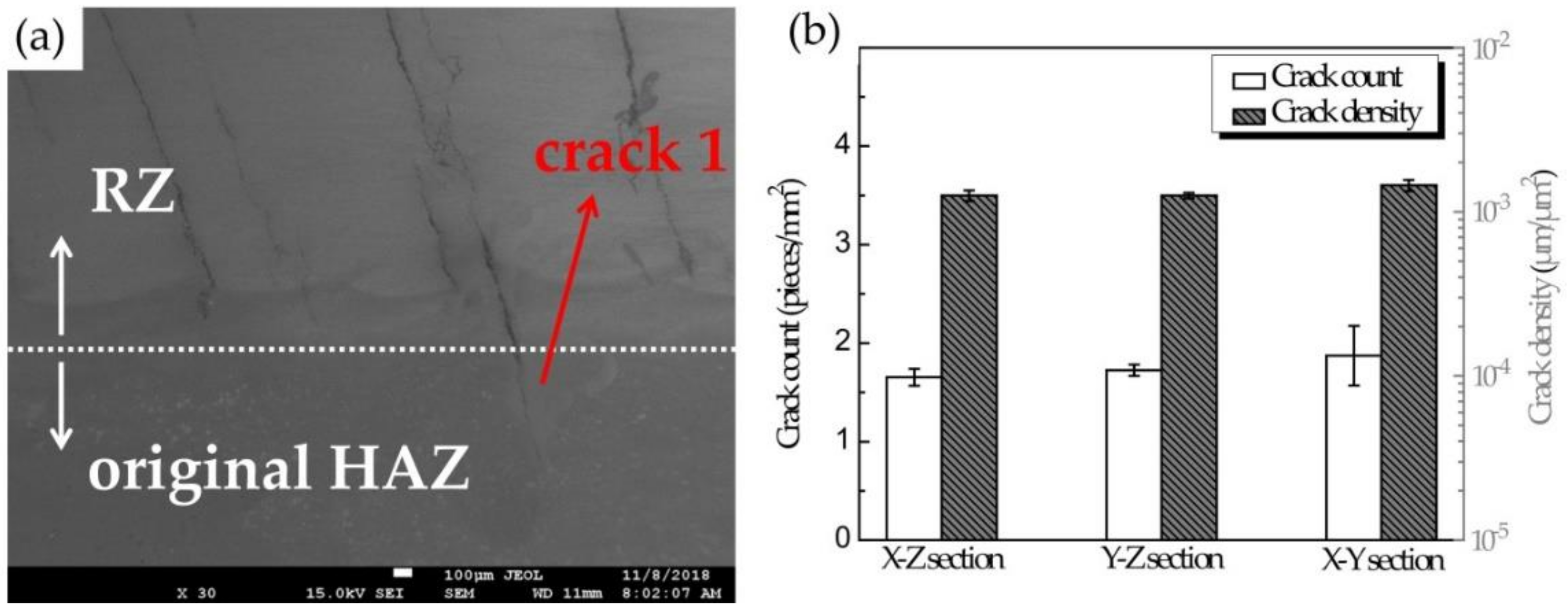

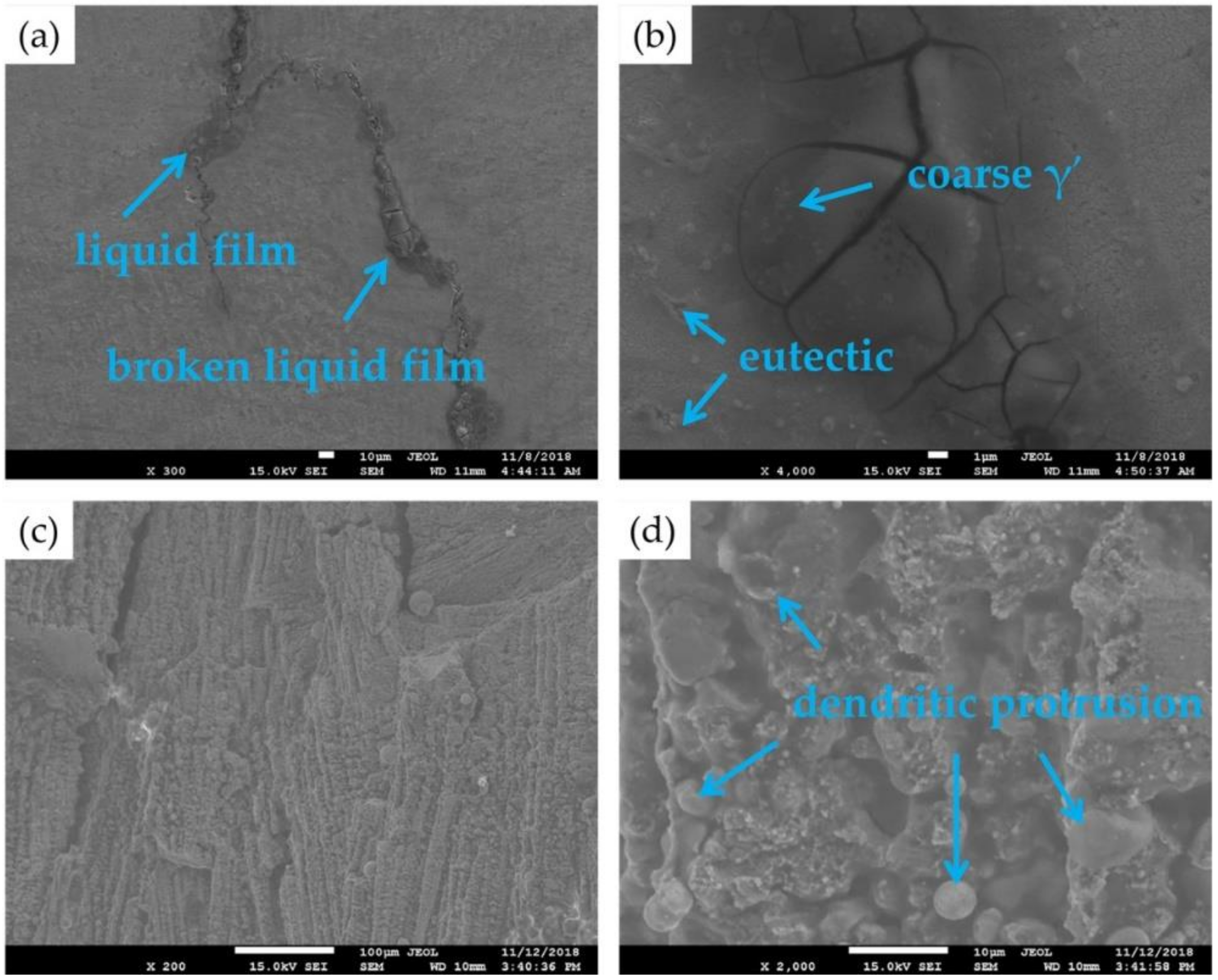

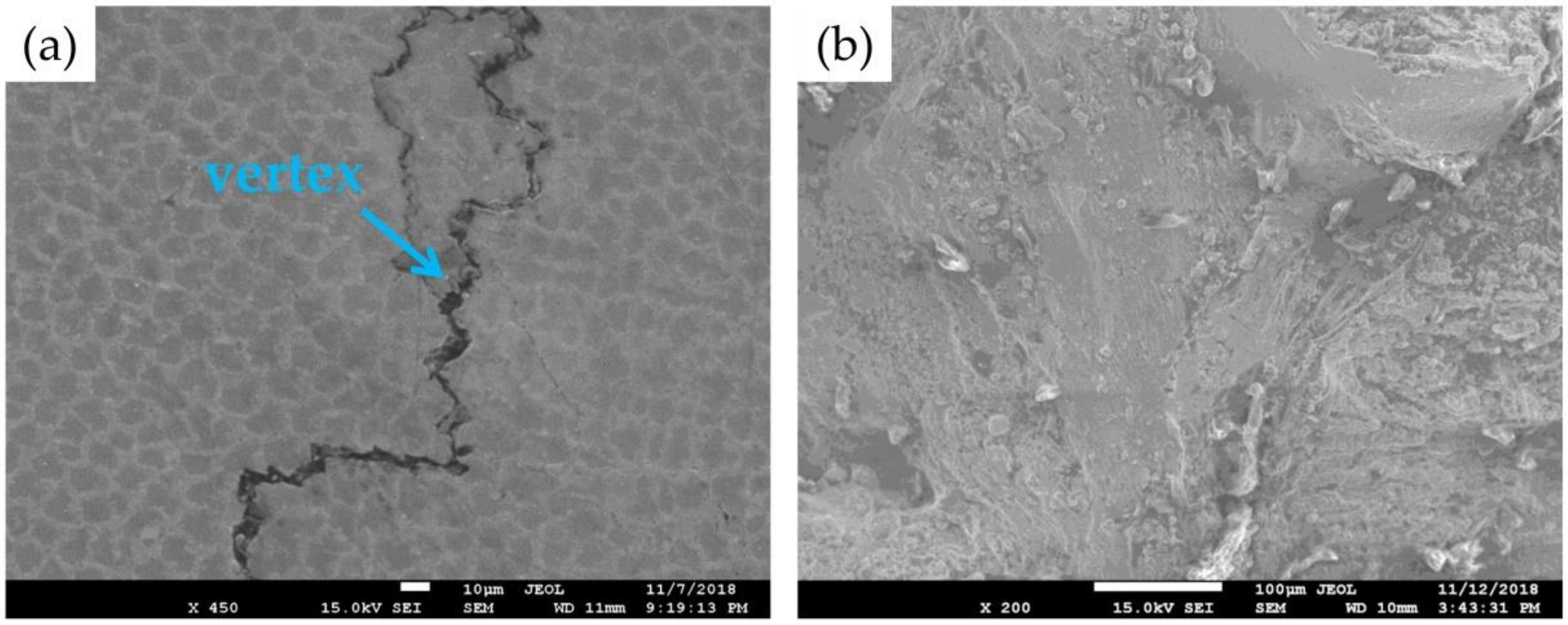

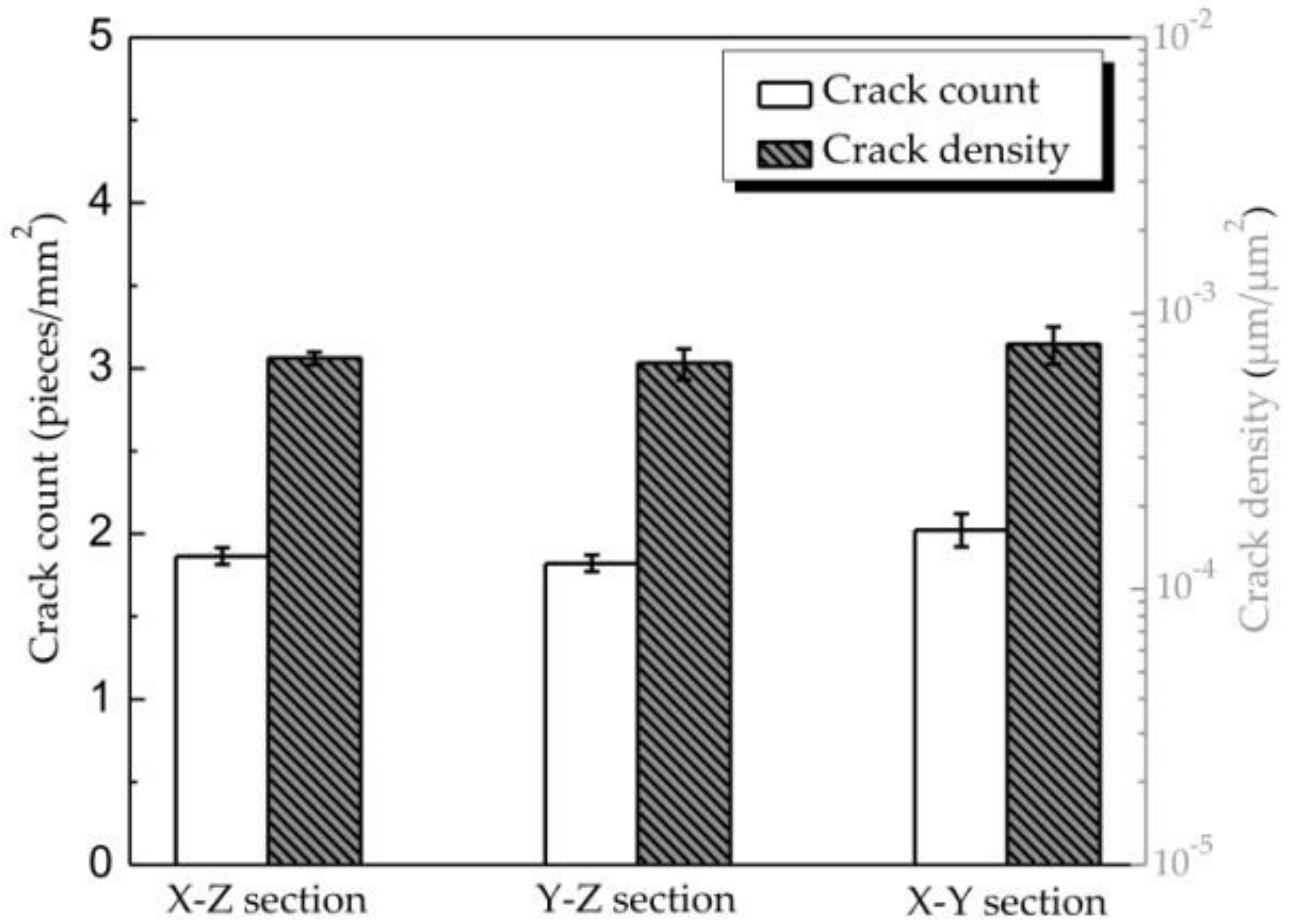

3.2.1. Crack Observation and Analysis

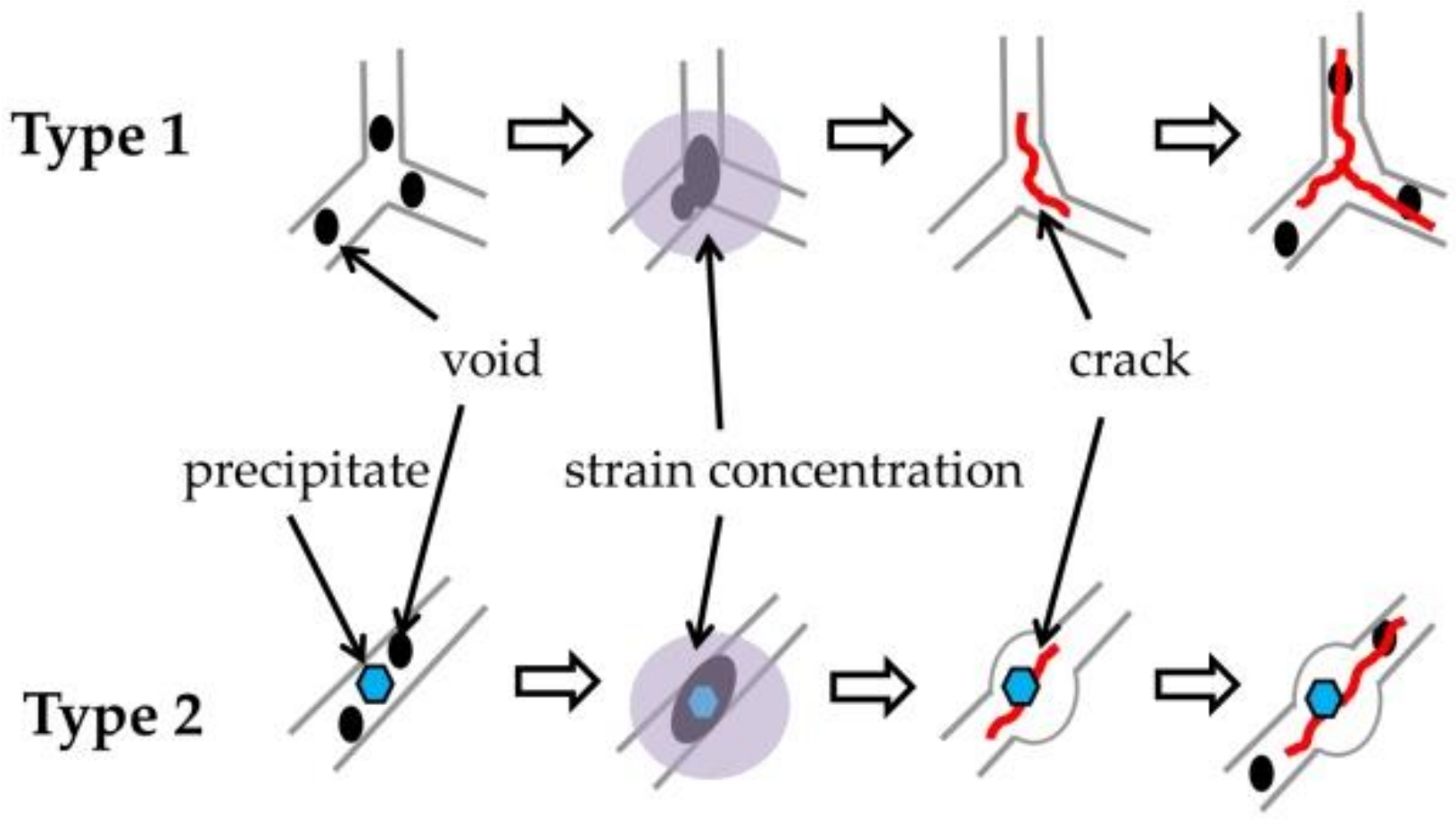

3.2.2. Cracking Mechanisms

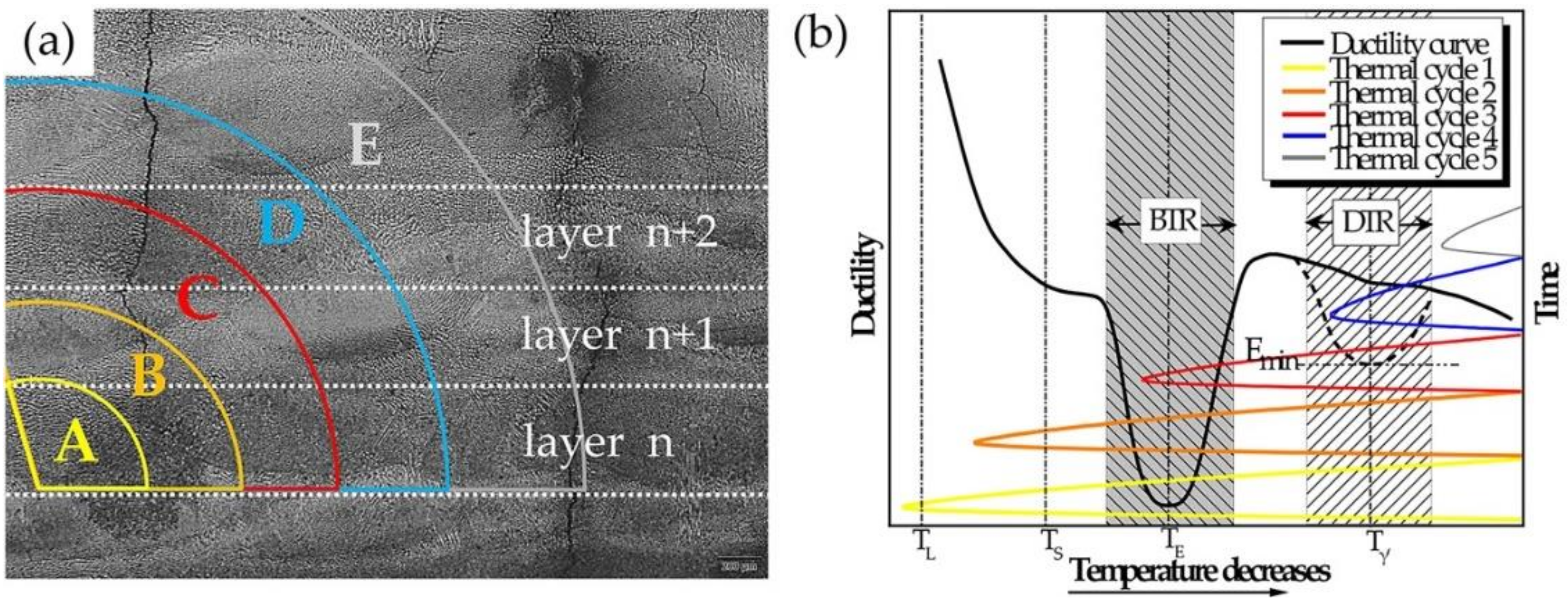

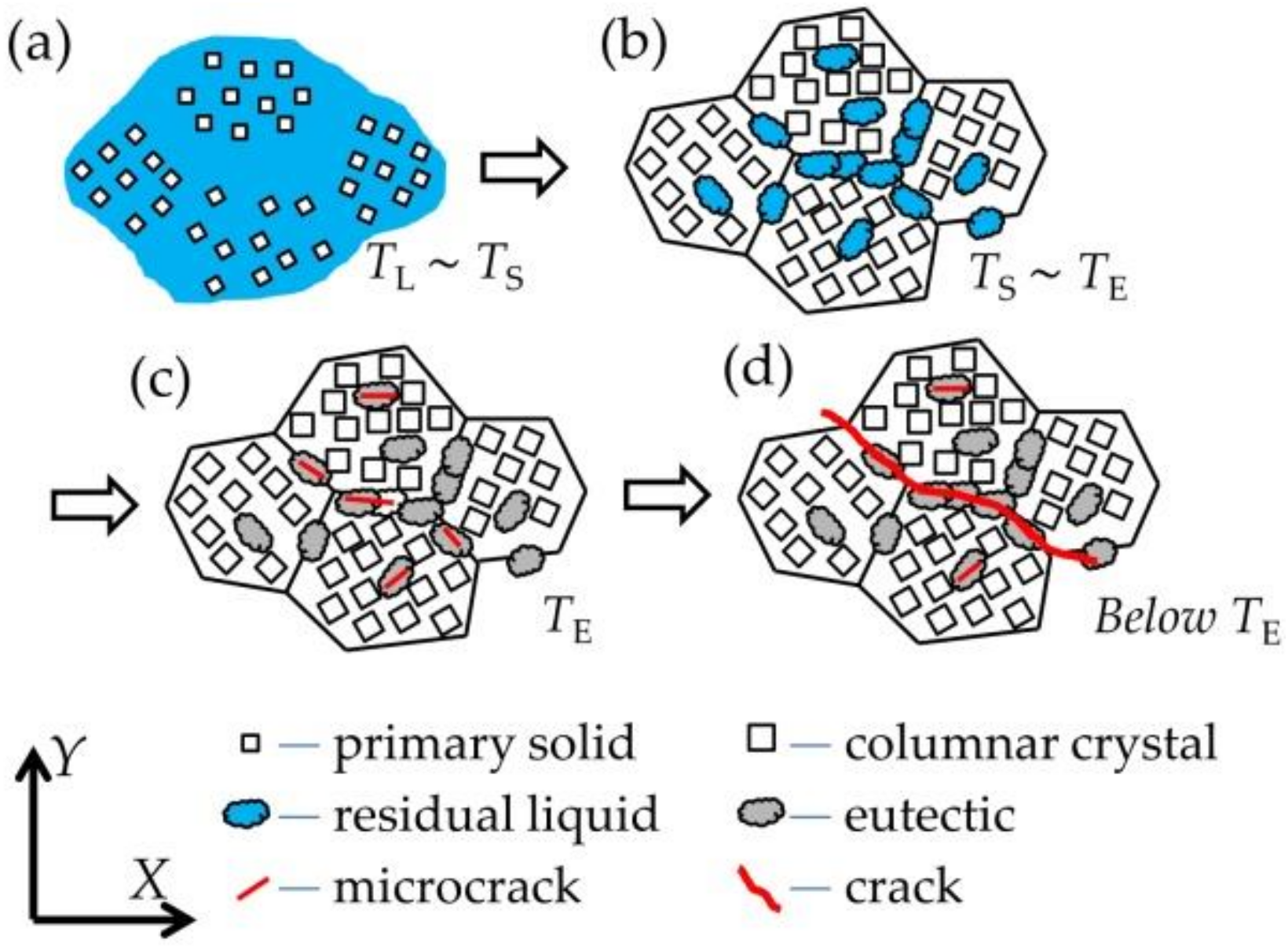

Solidification Cracking

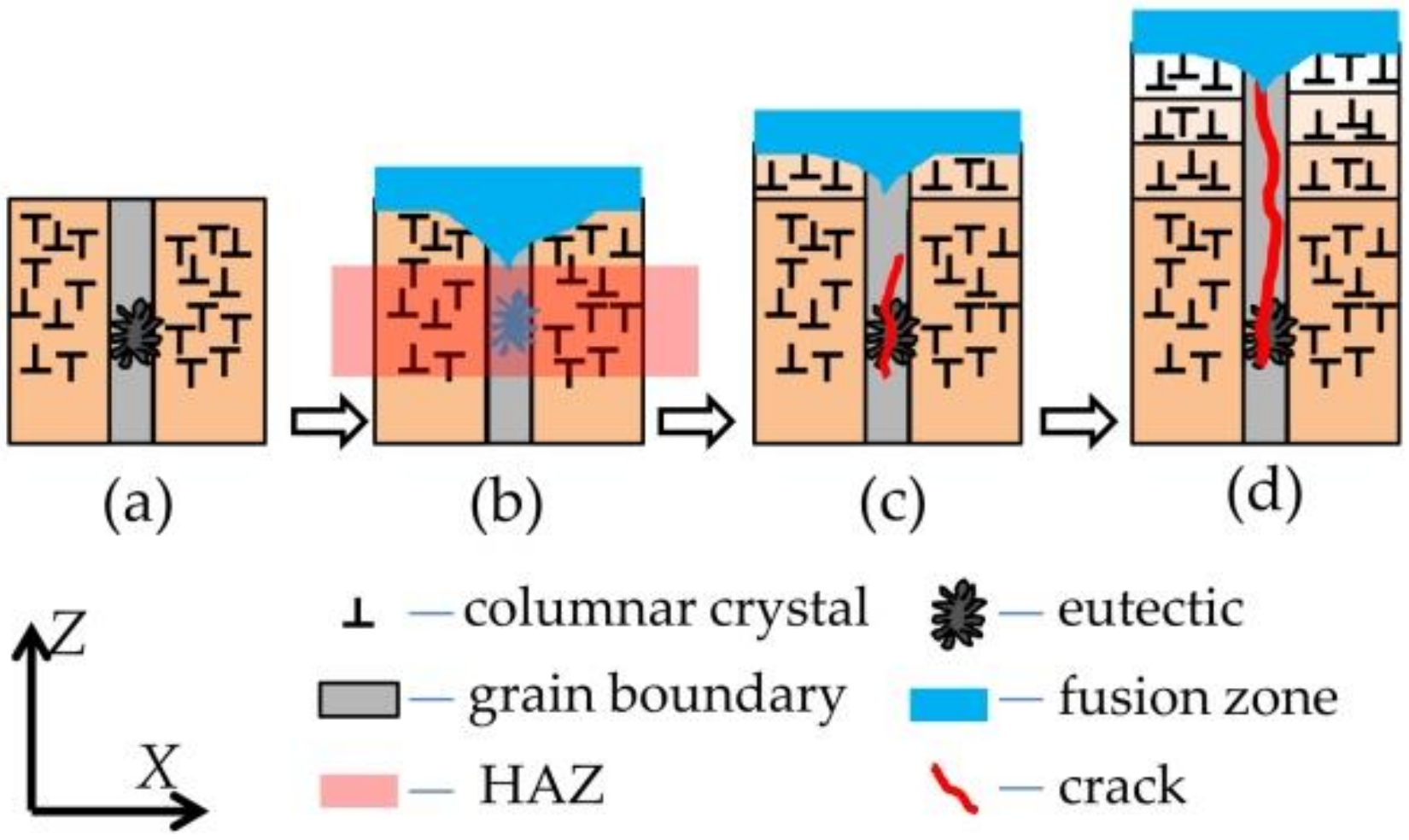

Liquation Cracking

Ductility Dip Cracking

3.3. Effect of Laser Remelting Process on Microstructure and Cracking Behavior

3.3.1. Microstructure after Remelting

3.3.2. Cracking Behavior after Remelting

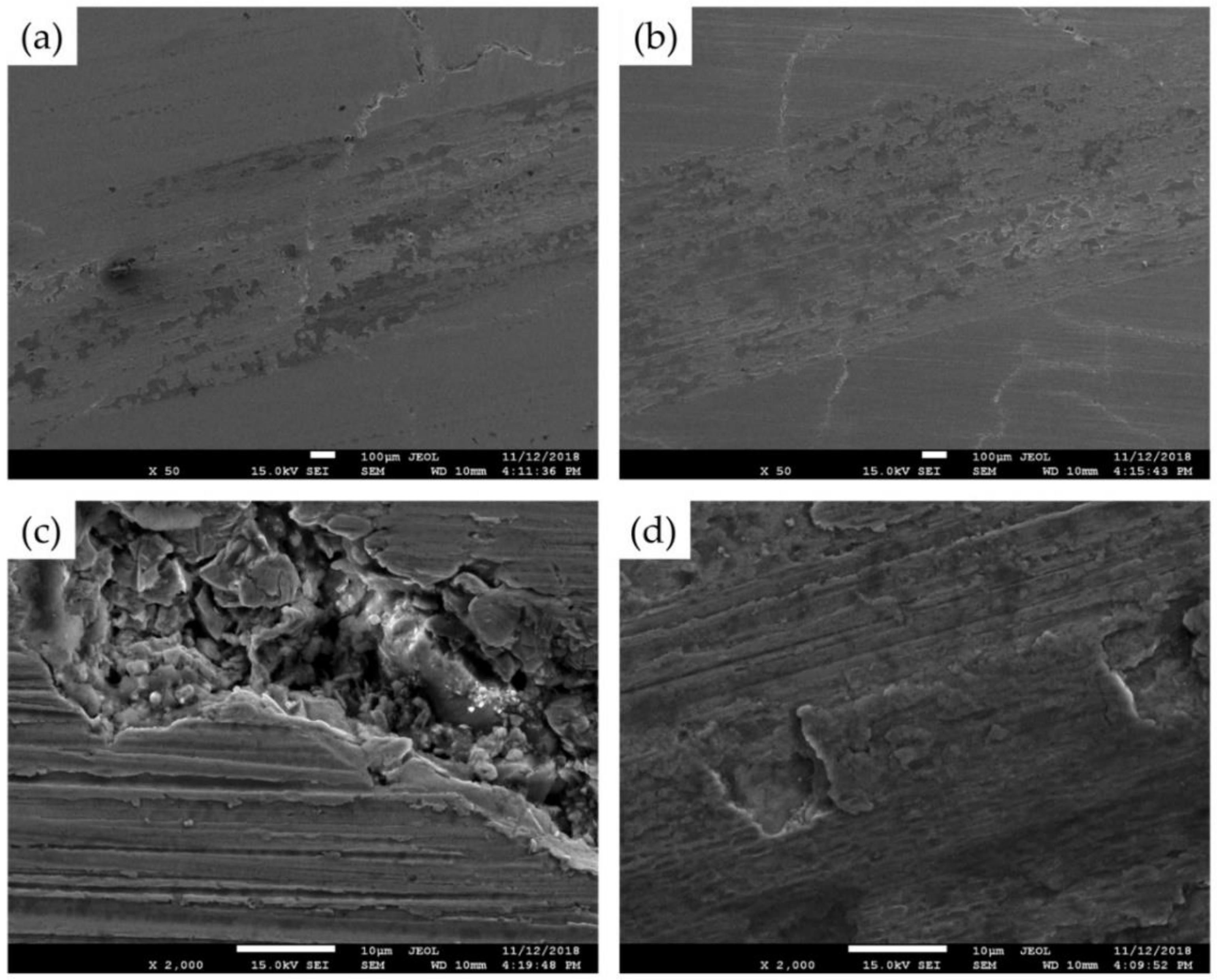

3.4. Effect of Laser Remelting Process on Microhardness and Tribological Properties

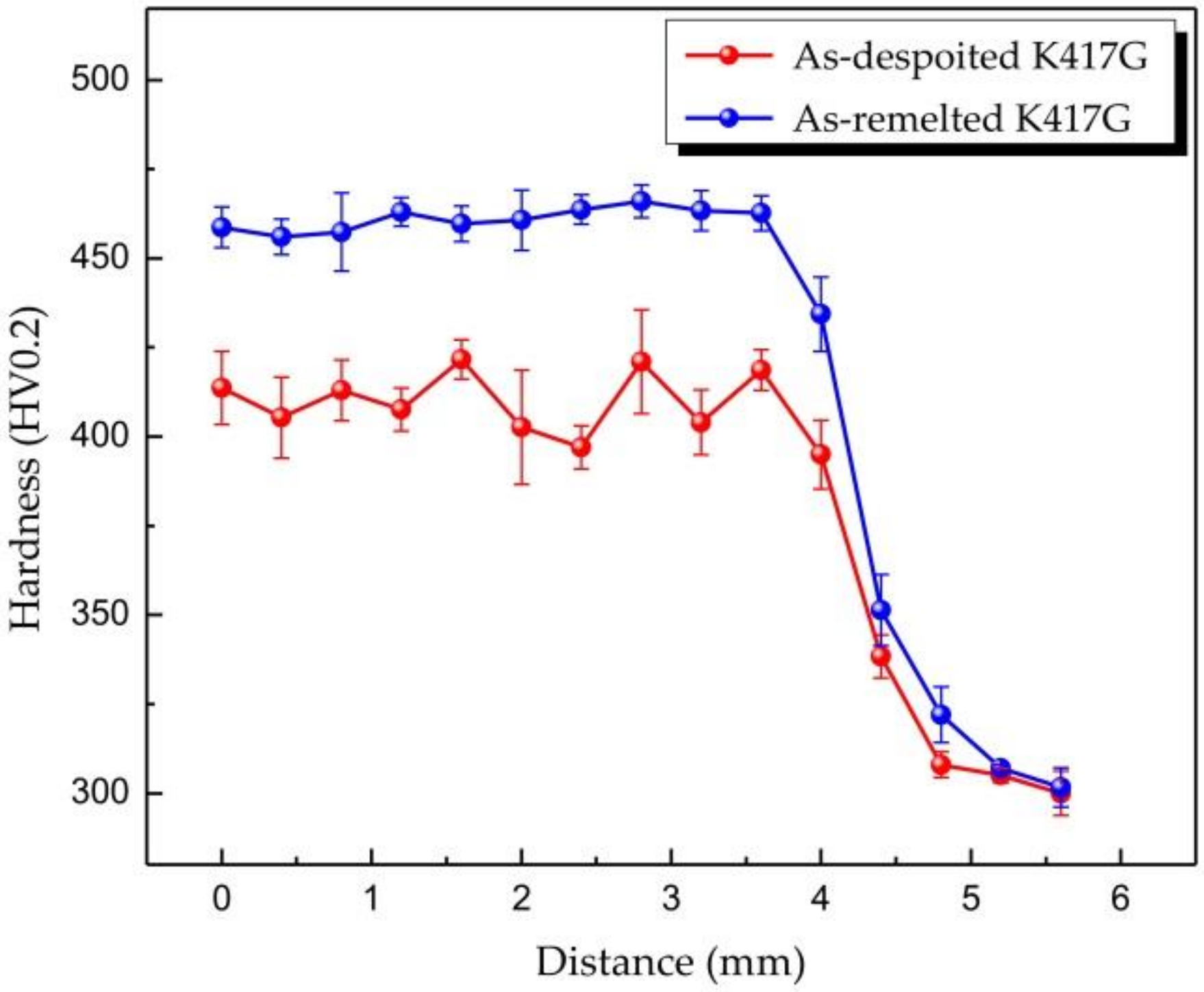

3.4.1. Microhardness

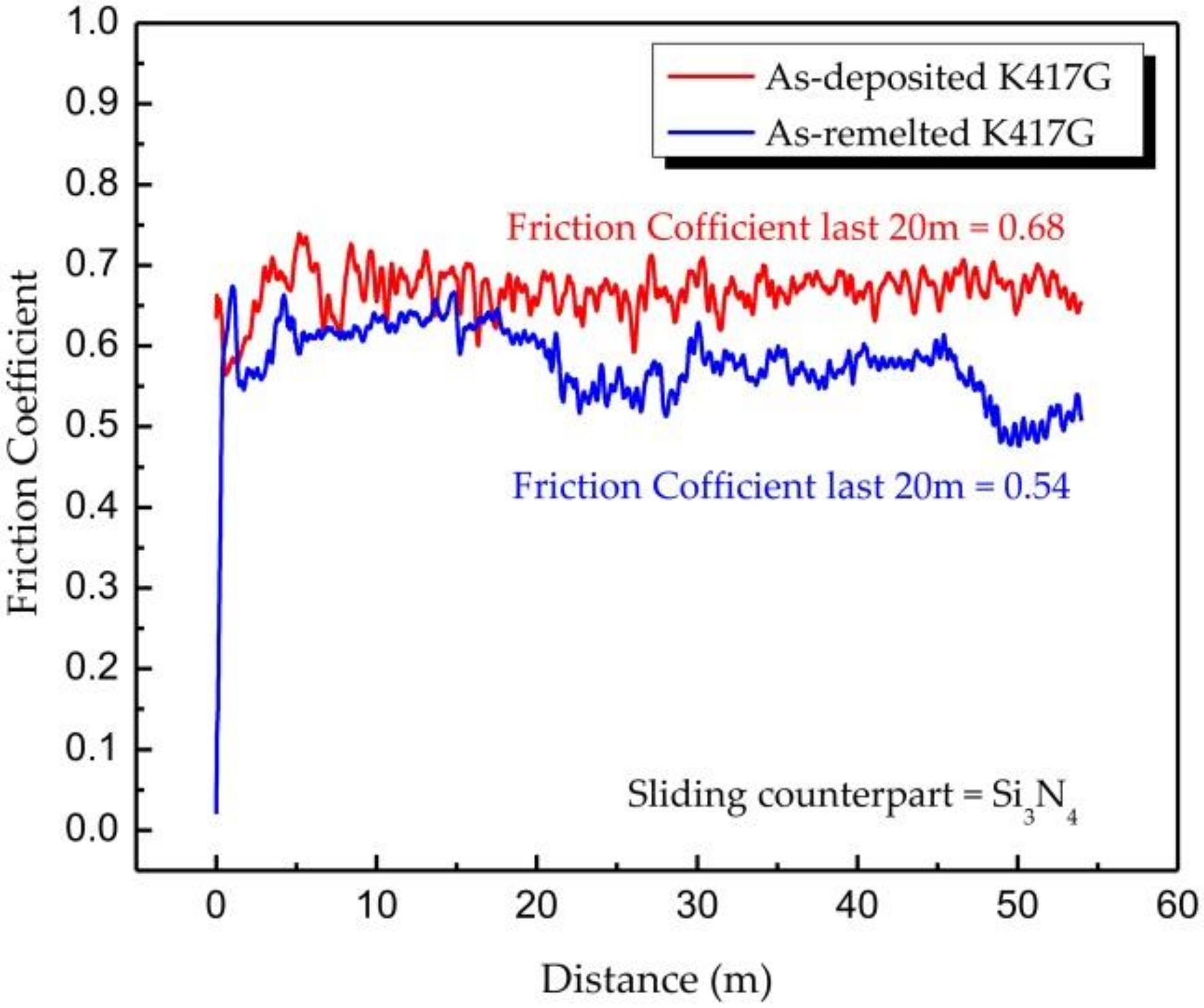

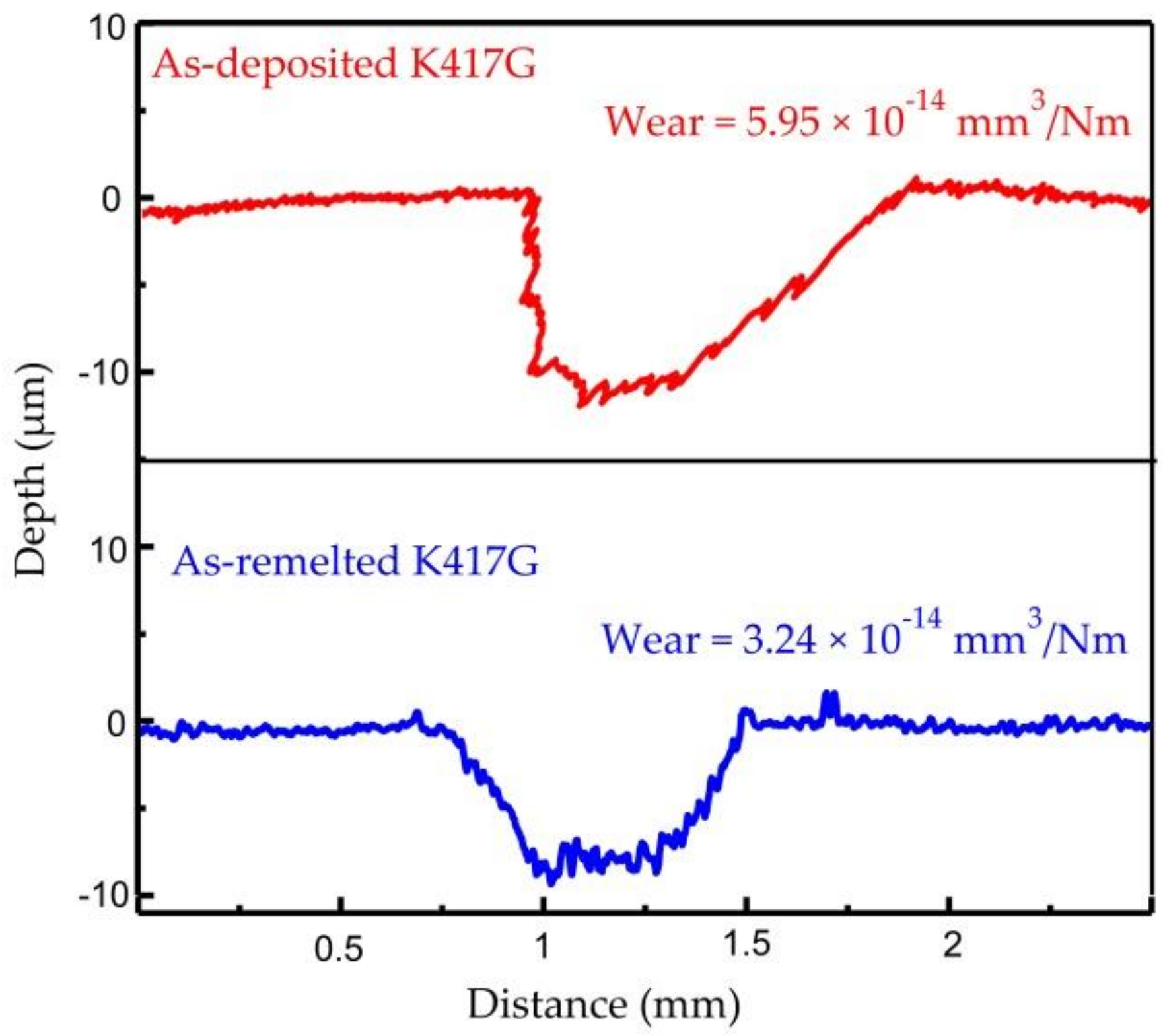

3.4.2. Tribological Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| LFR | Laser Forming Repairing |

| LFRed | Laser Forming Repaired |

| HAZ | Heat Affected Zone |

| RZ | Repaired Zone |

References

- Koh, K.H.; Griffin, J.H.; Filippi, S.; Akay, A. Characterization of turbine blade friction dampers. J. Eng. Gas Turbines Power 2004, 127, 856–862. [Google Scholar] [CrossRef]

- Yang, C.X.; Xu, Y.L.; Nie, H.; Xiao, X.S.; Jia, G.Q.; Shen, Z. Effects of heat treatments on the microstructure and mechanical properties of Rene 80. Mater. Des. 2013, 43, 66–73. [Google Scholar] [CrossRef]

- Yang, Y.H.; Xie, Y.J.; Wang, M.S.; Ye, W. Microstructure and tensile properties of nickel-based superalloy K417G bonded using transient liquid-phase infiltration. Mater. Des. 2013, 51, 141–147. [Google Scholar] [CrossRef]

- Du, B.N.; Yang, J.X.; Cui, C.Y.; Sun, X.F. Effects of grain refinement on the microstructure and tensile behavior of K417G superalloy. Mater. Sci. Eng. A 2015, 623, 59–67. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure and properties. J. Propul. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Gaumann, M.; Henry, S.; Cleton, F.; Wegniere, J.D.; Kurz, W. Epitaxial laser metal forming: Analysis of microstructure formation. Mater. Sci. Eng. A 1999, 271, 232–241. [Google Scholar] [CrossRef]

- Lin, X.; Yue, T.M.; Yang, H.O.; Huang, W.D. Microstructure and phase evolution in laser rapid forming of a functionally graded Ti–Rene88DT Alloy. Acta Mater. 2006, 54, 1901–1915. [Google Scholar] [CrossRef]

- Liu, F.C.; Lin, X.; Huang, C.P.; Song, M.H.; Yang, G.L.; Chen, J.; Huang, W.D. The effect of laser scanning path on microstructures and mechanical properties of laser solid formed Nickel-base superalloy Inconel 718. J. Alloys Compd. 2011, 205, 4505–4509. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. Contribution of constitutional liquation of gamma prime precipitate to weld HAZ cracking of cast Inconel 738 superalloy. Scr. Mater. 2004, 50, 641–646. [Google Scholar] [CrossRef]

- Ojo, O.A.; Chaturvedi, M.C. On the role of liquated γ′ precipitates in weld heat affected zone microfissuring of a Nickel-based superalloy. Mater. Sci. Eng. A 2005, 403, 77–86. [Google Scholar] [CrossRef]

- Li, Q.G.; Lin, X.; Wang, X.H.; Yang, H.O.; Song, M.H.; Huang, W.D. Research on the grain boundary liquation mechanism in heat affected zones of laser forming repaired K465 Nickel-based superalloy. Metals 2016, 6, 64. [Google Scholar] [CrossRef]

- Tancret, F. Thermo-Calc and Dictra simulation of constitutional liquation of gamma prime (γ′) during welding of Ni base superalloys. Comput. Mater. Sci. 2007, 41, 13–19. [Google Scholar] [CrossRef]

- Li, X.L.; Liu, J.W.; Zhong, M.L. Research on laser cladding superalloy K403. Appl. Laser 2002, 22, 283–286. [Google Scholar]

- Zhou, Z.H.; Zhu, B.D. The study on the laser cladding process and cracking of cast Ni-based superalloy K3. J. Mater. Eng. 1996, 1, 32–35. [Google Scholar]

- Yang, J.J.; Li, F.Z.; Wang, Z.M.; Zeng, X.Y. Cracking behavior and control of Rene 104 superalloy produced by direct laser fabrication. J. Mater. Process. Technol. 2015, 225, 229–239. [Google Scholar] [CrossRef]

- Zhou, S.F.; Xu, Y.B.; Liao, B.Q.; Sun, Y.J.; Dai, X.Q.; Yang, J.X.; Li, Z.Y. Effect of laser remelting on microstructure and properties of WC reinforced Fe-based amorphous composite coatings by laser cladding. Opt. Laser Technol. 2018, 103, 8–16. [Google Scholar] [CrossRef]

- Gao, W.Y.; Zhao, S.S.; Wang, Y.B.; Liu, F.L.; Zhou, C.Y.; Lin, X.C. Effect of re-melting on the cladding coating of Fe-based composite powder. Mater. Des. 2014, 64, 490–496. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Lin, X.; Wang, L.L.; Wei, L.; Liu, F.G.; Huang, W.D. Microstructural analysis of Zr55Cu30Al10Ni5 bulk metallic glasses by laser surface remelting and laser solid forming. Intermetallics 2015, 66, 22–30. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Xi, Y.C.; Zhao, Y.H.; Liu, S.; Bai, S.L.; Liu, Z.D. Effects of laser re-melting and annealing on microstructure, mechanical property and corrosion resistance of Fe-based amorphous/crystalline composite coating. Mater. Charact. 2017, 127, 239–247. [Google Scholar] [CrossRef]

- Li, R.F.; Jin, Y.J.; Li, Z.G.; Zhu, Y.Y.; Wu, M.F. Effect of the remelting scanning speed on theamorphous forming ability of Ni-based alloy using laser cladding plus a laser remelting process. Surf. Coat. Technol. 2014, 259, 725–731. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Yang, J. Scanning strategies for texture and anisotropy tailoring during selective laser melting of TiC/316L stainless steel nanocomposites. J. Alloy. Compd. 2017, 728, 424–435. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Cheng, J.; Ertas, Y. Thermal behavior of the molten pool, microstructural evolution, and tribological performance during selective laser melting of TiC/316L stainless steel nanocomposites: Experimental and simulation methods. J. Mater. Process. Technol. 2018, 257, 288–301. [Google Scholar] [CrossRef]

- Tabernero, I.; Lamikiz, A.; Martinez, S.; Ukar, E.; Figueras, J. Evaluation of the mechanical properties of Inconel 718 components built by laser cladding. Int. J. Mach. Tool. Manuf. 2011, 51, 465–470. [Google Scholar] [CrossRef]

- Choi, J.P.; Shin, G.H.; Yang, S.G.; Yang, D.Y.; Lee, J.S.; Brochu, M.; Yu, J.H. Densification and microstructural investigation of Inconel 718 parts fabricated by a selective laser melting. Powder Technol. 2017, 310, 60–66. [Google Scholar] [CrossRef]

- Li, Q.G.; Lin, X.; Liu, F.C.; Huang, W.D. Microstructural characteristics and mechanical properties of laser solid formed K465 superalloy. Mater. Sci. Eng. A 2017, 700, 649–655. [Google Scholar] [CrossRef]

- Montazeri, M.; Ghaini, F.M. The liquation cracking behavior of IN738LC superalloy during low power Nd:YAG pulsed laser welding. Mater. Charact. 2012, 67, 65–73. [Google Scholar] [CrossRef]

- Gong, L.; Chen, B.; Du, Z.H.; Zhang, M.S.; Liu, R.C.; Liu, K. Investigation of solidification and segregation characteristics of cast Ni-Base superalloy K417G. J. Mater. Sci. Technol. 2018, 34, 541–550. [Google Scholar] [CrossRef]

- Gong, L.; Chen, B.; Yang, Y.Q.; Du, Z.H.; Liu, K. Effect of N content on microsegregation, microstructure and mechanical property of cast Ni-base superalloy K417G. Mater. Sci. Eng. A 2017, 701, 111–119. [Google Scholar] [CrossRef]

- Basak, A.; Das, S. Microstructure of nickel-base superalloy MAR-M247 additively manufactured through scanning laser epitaxy (SLE). J. Alloy. Compd. 2017, 705, 806–816. [Google Scholar] [CrossRef]

- Carter, L.N.; Martin, C.; Withers, P.J.; Attallah, M.M. The influence of the laser scan strategy on grain structure and cracking behavior in SLM powder-bed fabricated nickel superalloy. J. Alloy. Compd. 2014, 615, 338–347. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Partha, S. Crack and wear behavior of SiC particulate reinforced aluminium based metal matrix composite fabricated by direct metal laser sintering process. Mater. Des. 2011, 32, 139–145. [Google Scholar] [CrossRef]

- Zhao, X.M.; Chen, J.; Lin, X.; Huang, W.D. Study on microstructure and mechanical properties of laser rapid forming Inconel 718. Mater. Sci. Eng. A 2008, 478, 119–124. [Google Scholar] [CrossRef]

- Ola, O.T.; Ojo, O.A.; Chaturvedi, M.C. Role of filler alloy composition on laser arc hybrid weldability of nickel-base IN738 superalloy. Mater. Sci. Technol. 2014, 30, 1461–1469. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Hao, L. Effect of hot isostatic pressing (HIP) on Al composite parts made from laser consolidated Al/Fe2O3 powder mixtures. J. Mater. Process. Technol. 2012, 212, 2474–2483. [Google Scholar] [CrossRef]

- Wei, K.W.; Gao, M.; Wang, Z.M.; Zeng, X.Y. Effect of energy input on formability, microstructure and mechanical properties of selective laser melted AZ91D magnesium alloy. Mater. Sci. Eng. A 2014, 611, 212–222. [Google Scholar] [CrossRef]

- Alimardani, M.; Fallah, V.; Iravani-Tabrizipour, M.; Khajepour, A. Surface finish in laser solid freeform fabrication of an AISI 303L stainless steel thin wall. J. Mater. Process. Technol. 2012, 212, 113–119. [Google Scholar] [CrossRef]

- Hussein, A.; Hao, L.; Yan, C.; Everson, R. Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Mater. Des. 2013, 52, 638–647. [Google Scholar] [CrossRef]

- Zhou, Z.P.; Huang, L.; Shang, Y.J.; Li, Y.P.; Jiang, L.; Lei, Q. Causes analysis on cracks in nickel-based single crystal superalloy fabricated by laser powder deposition additive manufacturing. Mater. Des. 2018, 160, 1238–1249. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. Microstructural study of weld fusion zone of TIG welded IN 738LC nickel-based superalloy. Scr. Mater. 2004, 51, 683–688. [Google Scholar] [CrossRef]

- Ramirez, A.J.; Lippold, J.C. High temperature behavior of Ni-base weld metal Part II—Insight into the mechanism for ductility dip cracking. Mater. Sci. Eng. A 2004, 380, 245–258. [Google Scholar] [CrossRef]

| Laser Power (W) | Scanning Speed (mm/s) | Powder Feeding Amount (g/min) | Powder Flow (L/min) | Overlap Rate (%) | Z-Axis Lift (mm) | Interlayer Cooling Time (min) |

|---|---|---|---|---|---|---|

| 600 | 5.4 | 5 | 3.5 | 40 | 0.4 | 10 |

| Element | C | Al | Ti | Cr | Fe | Ni | Mo | Co |

|---|---|---|---|---|---|---|---|---|

| Point 1 | 1.79 | 4.65 | 1.91 | 9.33 | 7.87 | 62.34 | 2.81 | 9.45 |

| Point 2 | 2.61 | 5.85 | 7.36 | 5.73 | 2.46 | 64.13 | 4.62 | 3.52 |

| Point 3 | 8.72 | 5.56 | 6.24 | 9.23 | 5.62 | 51.23 | 3.20 | 5.72 |

| Point 4 | 3.87 | 3.52 | 6.03 | 7.52 | 3.16 | 61.25 | 3.23 | 5.26 |

| Powders | 0.14 | 6.37 | 4.79 | 9.84 | 2.80 | 61.2 | 3.18 | 11.4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Yu, H.; Wang, Y.; Zhang, X.; Li, J.; Chen, S.; Liu, C. Cracking, Microstructure and Tribological Properties of Laser Formed and Remelted K417G Ni-Based Superalloy. Coatings 2019, 9, 71. https://doi.org/10.3390/coatings9020071

Liu S, Yu H, Wang Y, Zhang X, Li J, Chen S, Liu C. Cracking, Microstructure and Tribological Properties of Laser Formed and Remelted K417G Ni-Based Superalloy. Coatings. 2019; 9(2):71. https://doi.org/10.3390/coatings9020071

Chicago/Turabian StyleLiu, Shuai, Haixin Yu, Yang Wang, Xue Zhang, Jinguo Li, Suiyuan Chen, and Changsheng Liu. 2019. "Cracking, Microstructure and Tribological Properties of Laser Formed and Remelted K417G Ni-Based Superalloy" Coatings 9, no. 2: 71. https://doi.org/10.3390/coatings9020071

APA StyleLiu, S., Yu, H., Wang, Y., Zhang, X., Li, J., Chen, S., & Liu, C. (2019). Cracking, Microstructure and Tribological Properties of Laser Formed and Remelted K417G Ni-Based Superalloy. Coatings, 9(2), 71. https://doi.org/10.3390/coatings9020071