Towards Functional Silicon Nitride Coatings for Joint Replacements

Abstract

1. Introduction

2. Materials and Methods

2.1. Coating Preparation

2.2. Compositional Analysis

2.3. Cross-Section Characterization

2.4. Surface Roughness

2.5. Adhesion

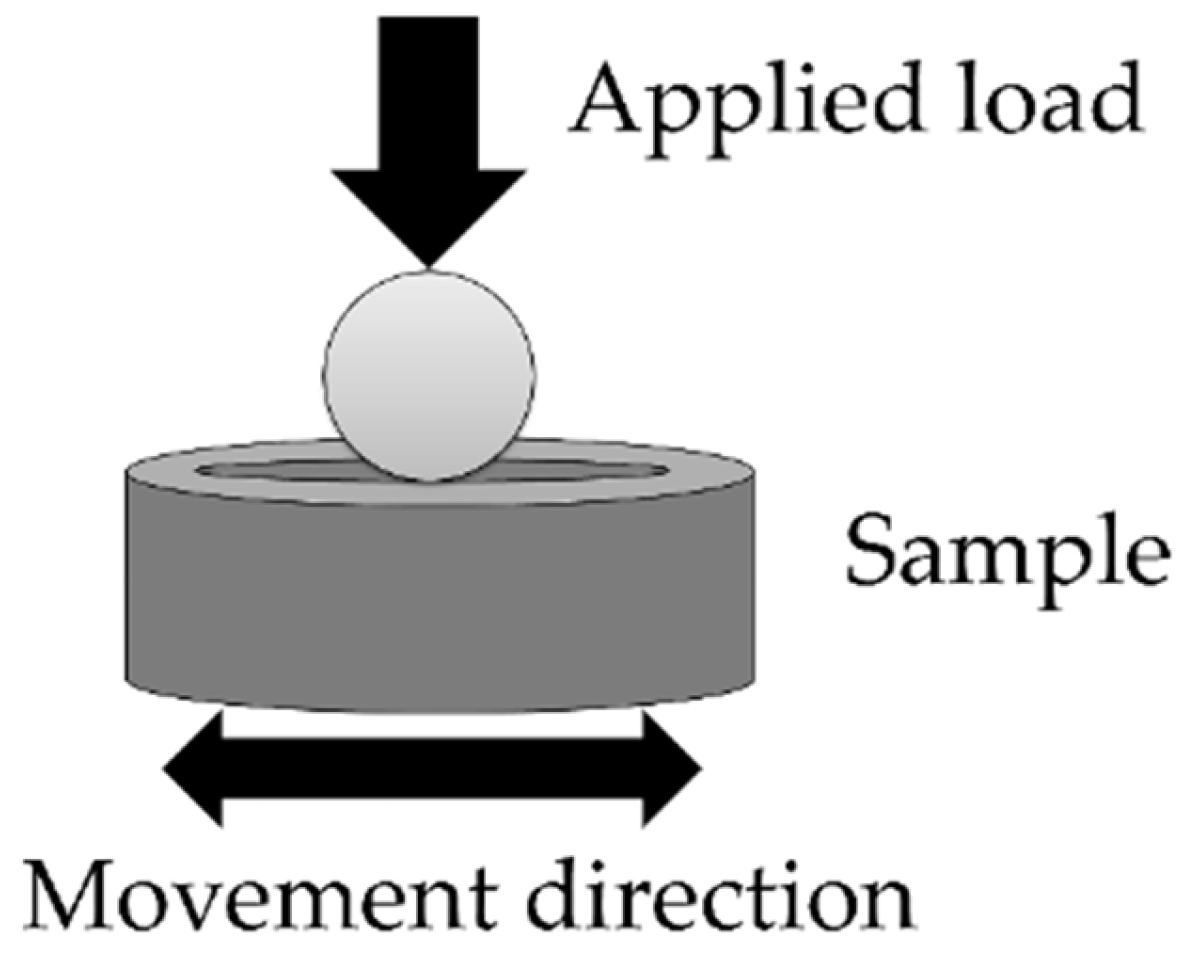

2.6. Wear Resistance

2.7. Statistical Analysis

3. Results

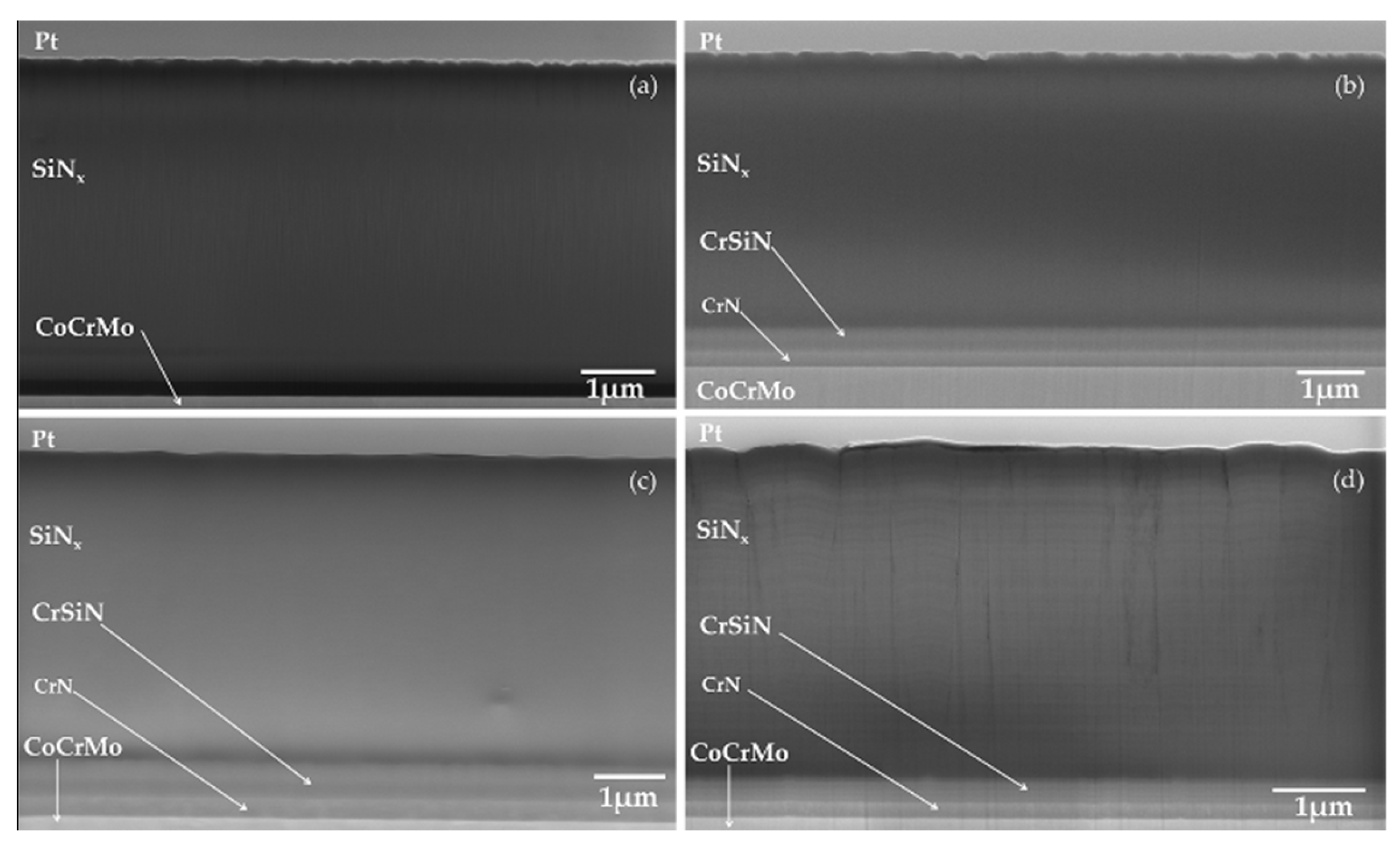

3.1. Microstructure, Coating Thickness, and Composition

3.2. Surface Roughness

3.3. Adhesion

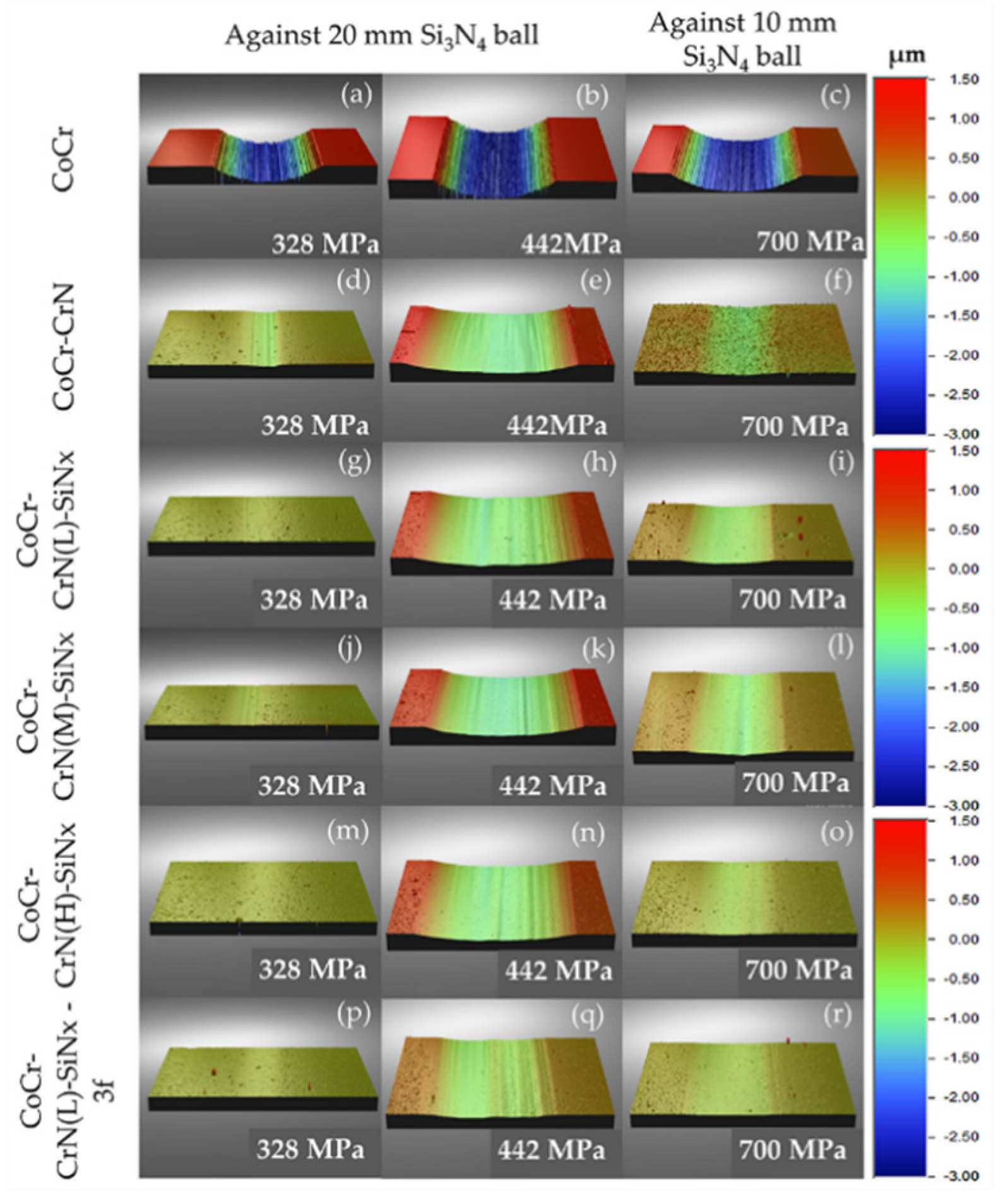

3.4. Wear Resistance

4. Discussion

5. Conclusions

- 3-fold deposition gave rise to less dense coatings as compared to 1-fold rotation, as demonstrated by the FIB cross-sections;

- The deposition method resulted in wear-resistant coatings, with no wearing down or flaking off when run against Si3N4, likely due to their high N content as well as their relatively high density;

- Despite the relatively higher roughness and lower density, the CoCr-CrN(L)-SiNx-3f coating, deposited at a lower bias voltage and by 3-fold rotation, presented the lowest specific wear rate against Si3N4 balls, also compared to a CoCrMo control.

Author Contributions

Funding

Acknowledgements

Conflicts of Interest

Appendix A

References

- Kärrholm, J.; Lindahl, H.; Malchau, H.; Mohaddes, M.; Rogmark, C.; Rolfson, O. Swedish Hip Arthroplasty Register Annual Report 2015; Swedish Hip Arthroplasty Register: Gothenburg, Sweden, 2015. [Google Scholar]

- Sundberg, M.; Lidgren, L.; W-Dahl, A.; Robertsson, O. Swedish Knee Arthroplasty Register Annual Report 2015; Swedish Hip Arthroplasty Register: Lund, Sweden, 2015. [Google Scholar]

- Verheyen, C.C.; Verhaar, J.A. Failure rates of stemmed metal-on-metal hip replacements. Lancet 2012, 380, 105. [Google Scholar] [CrossRef]

- Learmonth, I.D.; Young, C.; Rorabeck, C. The operation of the century: Total hip replacement. Lancet 2007, 370, 1508–1519. [Google Scholar] [CrossRef]

- Pettersson, M. Silicon Nitride for Total Hip Replacements. Ph.D. Thesis, Uppsala University, Uppsala, Sweden, May 2015. [Google Scholar]

- Berry, D.J.; Abdel, M.P.; Callaghan, J.J. What are the current clinical issues in wear and tribocorrosion? Clin. Orthop. Relat. Res. 2014, 472, 3659–3664. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, S.M.; Medel, F.J.; MacDonald, D.W.; Parvizi, J.; Kraay, M.J.; Rimnac, C.M. Reasons for revision of first-generation highly cross-linked polyethylenes. J. Arthroplast. 2010, 25, 67–74. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, S.M.; Gawel, H.A.; Patel, J.D. History and systematic review of wear and osteolysis outcomes for first-generation highly crosslinked polyethylene. Clin. Orthop. Relat. Res. 2011, 469, 2262–2277. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Salvati, E.; Betts, F.; DiCarlo, E.; Doty, S.; Bullough, P. Size of metallic and polyethylene debris particles in failed cemented total hip replacements. J. Bone Jt. Surg. Br. Vol. 1992, 74, 380–384. [Google Scholar] [CrossRef]

- Drummond, J.; Tran, P.; Fary, C. Metal-on-metal hip arthroplasty: A review of adverse reactions and patient management. J. Funct. Biomater. 2015, 6, 486–499. [Google Scholar] [CrossRef]

- Bitounis, D.; Pourchez, J.; Forest, V.; Boudard, D.; Cottier, M.; Klein, J.P. Detection and analysis of nanoparticles in patients: A critical review of the status quo of clinical nanotoxicology. Biomaterials 2016, 76, 302–312. [Google Scholar] [CrossRef]

- Ayu, H.M.; Izman, S.; Daud, R.; Krishnamurithy, G.; Shah, A.; Tomadi, S.H.; Salwani, M.S. Surface modification on CoCrMo alloy to improve the adhesion strength of hydroxyapatite coating. Procedia Eng. 2017, 184, 399–408. [Google Scholar] [CrossRef]

- Datta, S.; Das, M.; Krishna, V.; Bodhak, S.; Murugesan, V.K. Mechanical, wear, corrosion and biological properties of arc deposited titanium nitride coatings. Surf. Coat. Technol. 2018, 344, 214–222. [Google Scholar] [CrossRef]

- Marchiori, G.; Lopomo, N.; Boi, M.; Berni, M.; Bianchi, M.; Gambardella, A.; Visani, A.; Russo, A.; Marcacci, M. Optimizing thickness of ceramic coatings on plastic components for orthopedic applications: A finite element analysis. Mater. Sci. Eng. C 2016, 58, 381–388. [Google Scholar] [CrossRef] [PubMed]

- Grupp, T.M.; Giurea, A.; Miehlke, R.K.; Hintner, M.; Gaisser, M.; Schilling, C.; Schwiesau, J.; Kaddick, C. Biotribology of a new bearing material combination in a rotating hinge knee articulation. Acta Biomater. 2013, 9, 7054–7063. [Google Scholar] [CrossRef] [PubMed]

- Ajwani, S.H.; Charalambous, C.P. Availability of total knee arthroplasty implants for metal hypersensitivity patients. Knee Surg. Relat. Res. 2016, 28, 312–318. [Google Scholar] [CrossRef] [PubMed]

- Pettersson, M.; Tkachenko, S.; Schmidt, S.; Berlind, T.; Jacobson, S.; Hultman, L.; Engqvist, H.; Persson, C. Mechanical and tribological behavior of silicon nitride and silicon carbon nitride coatings for total joint replacements. J. Mech. Behav. Biomed. Mater. 2013, 25, 41–47. [Google Scholar] [CrossRef] [PubMed]

- Mazzocchi, M.; Bellosi, A. On the possibility of silicon nitride as a ceramic for structural orthopaedic implants. Part I: Processing, microstructure, mechanical properties, cytotoxicity. J. Mater. Sci. Mater. Med. 2008, 19, 2881–2887. [Google Scholar] [CrossRef] [PubMed]

- Bal, B.S.; Khandkar, A.; Lakshminarayanan, R.; Clarke, I.; Hoffman, A.A.; Rahaman, M.N. Fabrication and testing of silicon nitride bearings in total hip arthroplasty: Winner of the 2007 “HAP” PAUL award. J. Arthroplast. 2009, 24, 110–116. [Google Scholar] [CrossRef] [PubMed]

- Rahaman, M.; Xiao, W. Silicon nitride bioceramics in healthcare. Int. J. Appl. Ceram. Technol. 2018, 15, 861–872. [Google Scholar] [CrossRef]

- Pettersson, M.; Bryant, M.; Schmidt, S.; Engqvist, H.; Hall, R.M.; Neville, A.; Persson, C. Dissolution behaviour of silicon nitride coatings for joint replacements. Mater. Sci. Eng. C 2016, 62, 497–505. [Google Scholar] [CrossRef]

- Pettersson, M.; Skjöldebrand, C.; Filho, L.; Engqvist, H.; Persson, C. Morphology and dissolution rate of wear debris from silicon nitride coatings. ACS Biomater. Sci. Eng. 2016, 2, 998–1004. [Google Scholar] [CrossRef]

- Lal, S.; Hall, R.M.; Tipper, J.L. A novel method for isolation and recovery of ceramic nanoparticles and metal wear debris from serum lubricants at ultra-low wear rates. Acta Biomater. 2016, 42, 420–428. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Ehiasarian, A.P.; Purandare, Y.P.; Biswas, B.; Pérez, F.J.; Lasanta, M.I.; De Miguel, M.T.; Illana, A.; Juez-Lorenzo, M.; Muelas, R.; et al. Performance of HIPIMS deposited CrN/NbN nanostructured coatings exposed to 650 °C in pure steam environment. Mater. Chem. Phys. 2016, 179, 110–119. [Google Scholar] [CrossRef]

- Paulitsch, J.; Schenkel, M.; Zufraß, T.; Mayrhofer, P.H.; Münz, W.D. Structure and properties of high power impulse magnetron sputtering and DC magnetron sputtering CrN and TiN films deposited in an industrial scale unit. Thin Solid Films 2010, 518, 5558–5564. [Google Scholar] [CrossRef]

- Ma, Q.; Li, L.; Xu, Y.; Gu, J.; Wang, L.; Xu, Y. Effect of bias voltage on TiAlSiN nanocomposite coatings deposited by HiPIMS. Appl. Surf. Sci. 2017, 392, 826–833. [Google Scholar] [CrossRef]

- Bohlmark, J.; Lattemann, M.; Gudmundsson, J.T.; Ehiasarian, A.P.; Aranda Gonzalvo, Y.; Brenning, N.; Helmersson, U. The ion energy distributions and ion flux composition from a high power impulse magnetron sputtering discharge. Thin Solid Films 2006, 515, 1522–1526. [Google Scholar] [CrossRef]

- Williams, S.; Isaac, G.; Hatto, P.; Stone, M.H.; Ingham, E.; Fisher, J. Comparative wear under different conditions of surface-engineered metal-on-metal bearings for total hip arthroplasty. J. Arthroplast. 2004, 19, 112–117. [Google Scholar] [CrossRef]

- ASTM F799-11 Standard Specification for Cobalt-28Chromium-6Molybdenum Alloy Forgings for Surgical Implants (UNS R31537, R31538, R31539); ASTM International: West Conshohocken, PA, USA, 2011.

- ISO 26443-2008 Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics) Rockwell Indentation Test for Evaluation of Adhesion of Ceramic Coatings; ISO: Geneva, Switzerland, 2008.

- ASTM F2094/F2094M-18a Standard Specification for Silicon Nitride Bearing Balls; ASTM International: West Conshohocken, PA, USA, 2018.

- Olofsson, J.; Pettersson, M.; Teuscher, N.; Heilmann, A.; Larsson, K.; Grandfield, K.; Persson, C.; Jacobson, S.; Engqvist, H. Fabrication and evaluation of SixNy coatings for total joint replacements. J. Mater. Sci. Mater. Med. 2012, 23, 1879–1889. [Google Scholar] [CrossRef] [PubMed]

- ASTM F1537-11 Standard Specification for Wrought Cobalt-28Chromium-6Molybdenum Alloys for Surgical Implants (UNS R31537, UNS R31538, and UNS R31539); ASTM International: West Conshohocken, PA, USA, 2011.

- Fialho, J.C.; Fernandes, P.R.; Eça, L.; Folgado, J. Computational hip joint simulator for wear and heat generation. J. Biomech. 2007, 40, 2358–2366. [Google Scholar] [CrossRef]

- Sanders, A.P.; Brannon, R.M. Assessment of the applicability of the Hertzian contact theory to edge-loaded prosthetic hip bearings. J. Biomech. 2011, 44, 2802–2808. [Google Scholar] [CrossRef]

- ASTM F732-17 Standard Test Method for Wear Testing of Polymeric Materials Used in Total Joint Prostheses; ASTM International: West Conshohocken, PA, USA, 2017.

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- ASTM F2033-12 Standard Specification for Total Hip Joint Prosthesis and Hip Endoprosthesis Bearing Surfaces Made of Metallic, Ceramic, and Polymeric Materials; ASTM International: West Conshohocken, PA, USA, 2012.

- Nedfors, N.; Mockute, A.; Palisaitis, J.; Persson, P.O.Å.; Näslund, L.Å.; Rosen, J. Influence of pulse frequency and bias on microstructure and mechanical properties of TiB2 coatings deposited by high power impulse magnetron sputtering. Surf. Coat. Technol. 2016, 304, 203–210. [Google Scholar] [CrossRef]

- Panjan, M.; Čekada, M.; Panjan, P.; Zupanič, F.; Kölker, W. Dependence of microstructure and hardness of TiAlN/VN hard coatings on the type of substrate rotation. Vacuum 2012, 86, 699–702. [Google Scholar] [CrossRef]

- Ehiasarian, A.P.; Münz, W.D.; Hultman, L.; Helmersson, U.; Petrov, I.; Seitz, F. High power pulsed magnetron sputtered CrNx films. Galvanotechnik 2003, 163, 267–272. [Google Scholar] [CrossRef]

- Schmidt, S.; Hänninen, T.; Goyenola, C.; Wissting, J.; Jensen, J.; Hultman, L.; Goebbels, N.; Tobler, M.; Högberg, H. SiNx coatings deposited by reactive high power impulse magnetron sputtering: Process parameters influencing the nitrogen content. ACS Appl. Mater. Interfaces 2016, 8, 20385–20395. [Google Scholar] [CrossRef] [PubMed]

- Ortega-Saenz, J.A.; Hernandez-Rodriguez, M.A.L.; Ventura-Sobrevilla, V.; Michalczewski, R.; Smolik, J.; Szczerek, M. Tribological and corrosion testing of surface engineered surgical grade CoCrMo alloy. Wear 2011, 271, 2125–2131. [Google Scholar] [CrossRef]

- Sahasrabudhe, H.; Bose, S.; Bandyopadhyay, A. Laser processed calcium phosphate reinforced CoCrMo for load-bearing applications: Processing and wear induced damage evaluation. Acta Biomater. 2018, 66, 118–128. [Google Scholar] [CrossRef]

- Dante, R.C.; Kajdas, C.K. A review and a fundamental theory of silicon nitride tribochemistry. Wear 2012, 288, 27–38. [Google Scholar] [CrossRef]

- López, A.; Filho, L.C.; Cogrel, M.; Engqvist, H.; Schmidt, S.; Högberg, H.; Persson, C. Morphology and adhesion of silicon nitride coatings upon soaking in fetal bovine serum. In Proceedings of the 15th International Symposium on Computer Methods in Biomechanics and Biomedical Engineering and the 3rd Conference on Imaging and Visualization, Lisbon, Portugal, 26–29 March 2018. [Google Scholar]

- Saikko, V.; Calonius, O.; Kernen, J. Effect of counterface roughness on the wear of conventional and crosslinked ultrahigh molecular weight polyethylene studied with a multi-directional motion pin-on-disk device. J. Biomed. Mater. Res. 2001, 57, 506–512. [Google Scholar] [CrossRef]

- Williams, S.; Tipper, J.L.; Ingham, E.; Stone, M.H.; Fisher, J. In vitro analysis of the wear, wear debris and biological activity of surface-engineered coatings for use in metal-on-metal total hip replacements. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2003, 217, 155–163. [Google Scholar] [CrossRef]

- Leslie, I.J.; Williams, S.; Brown, C.; Anderson, J.; Isaac, G.; Hatto, P.; Ingham, E.; Fisher, J. Surface engineering: A low wearing solution for metal-on-metal hip surface replacements. J. Biomed. Mater. Res. Part B Appl. Biomater. 2009, 90, 558–565. [Google Scholar] [CrossRef]

- Bal, B.S.; Rahaman, M.N. Orthopedic applications of silicon nitride ceramics. Acta Biomater. 2012, 8, 2889–2898. [Google Scholar] [CrossRef]

- Olofsson, J.; Grehk, T.M.; Berlind, T.; Persson, C.; Jacobson, S.; Engqvist, H. Evaluation of silicon nitride as a wear resistant and resorbable alternative for total hip joint replacement. Biomatter 2012, 2, 94–102. [Google Scholar] [CrossRef] [PubMed]

- Das, M.; Bhimani, K.; Balla, V.K. In vitro tribological and biocompatibility evaluation of sintered silicon nitride. Mater. Lett. 2018, 212, 130–133. [Google Scholar] [CrossRef]

- Mak, M.; Jin, Z.; Fisher, J.; Stewart, T.D. Influence of acetabular cup rim design on the contact stress during edge loading in ceramic-on-ceramic hip prostheses. J. Arthroplast. 2011, 26, 131–136. [Google Scholar] [CrossRef] [PubMed]

| Material | Interlayer | SiNx Thickness (nm) | Interlayer Thickness (nm) | Top Layer Composition | |||

|---|---|---|---|---|---|---|---|

| Si (at.%) | N (at.%) | O (at.%) | N/Si Ratio | ||||

| CoCr | – | – | – | – | – | – | – |

| CoCr-SiNx | – | 4360 | – | 46 | 50 | 2.1 | 1.10 |

| CoCr-CrN(L)-SiNx | CrN | 4260 | 810 | 44 | 52 | 2.2 | 1.11 |

| CoCr-CrN(M)-SiNx | CrN | 4400 | 750 | 44 | 53 | 2.1 | 1.19 |

| CoCr-CrN(H)-SiNx | CrN | 4400 | 650 | 43 | 53 | 2.2 | 1.25 |

| CoCr-CrN(L)-SiNx-3f | CrN | 4200 | 500 | 45 | 51 | – | 1.11 |

| Material | Ra (nm) | HRC Adhesion, (ISO Class) |

|---|---|---|

| CoCr | 6.6 ± 0.4 | N/A |

| CoCr-SiNx | 16.3 ± 1.8 | 3 |

| CoCr-CrN(L)-SiNx | 25.2 ± 0.1 | 1 |

| CoCr-CrN(M)-SiNx | 26.1 ± 1.2 | 2 |

| CoCr-CrN(H)-SiNx | 32.8 ± 2.7 | 2 |

| CoCr-CrN(L)-SiNx-3f | 23.9 ± 0.7 | 0–1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Filho, L.; Schmidt, S.; Leifer, K.; Engqvist, H.; Högberg, H.; Persson, C. Towards Functional Silicon Nitride Coatings for Joint Replacements. Coatings 2019, 9, 73. https://doi.org/10.3390/coatings9020073

Filho L, Schmidt S, Leifer K, Engqvist H, Högberg H, Persson C. Towards Functional Silicon Nitride Coatings for Joint Replacements. Coatings. 2019; 9(2):73. https://doi.org/10.3390/coatings9020073

Chicago/Turabian StyleFilho, Luimar, Susann Schmidt, Klaus Leifer, Håkan Engqvist, Hans Högberg, and Cecilia Persson. 2019. "Towards Functional Silicon Nitride Coatings for Joint Replacements" Coatings 9, no. 2: 73. https://doi.org/10.3390/coatings9020073

APA StyleFilho, L., Schmidt, S., Leifer, K., Engqvist, H., Högberg, H., & Persson, C. (2019). Towards Functional Silicon Nitride Coatings for Joint Replacements. Coatings, 9(2), 73. https://doi.org/10.3390/coatings9020073