Improvement in Tribological Properties of Cr12MoV Cold Work Die Steel by HVOF Sprayed WC-CoCr Cermet Coatings

Abstract

1. Introduction

2. Experimental Procedure

3. Results and Discussion

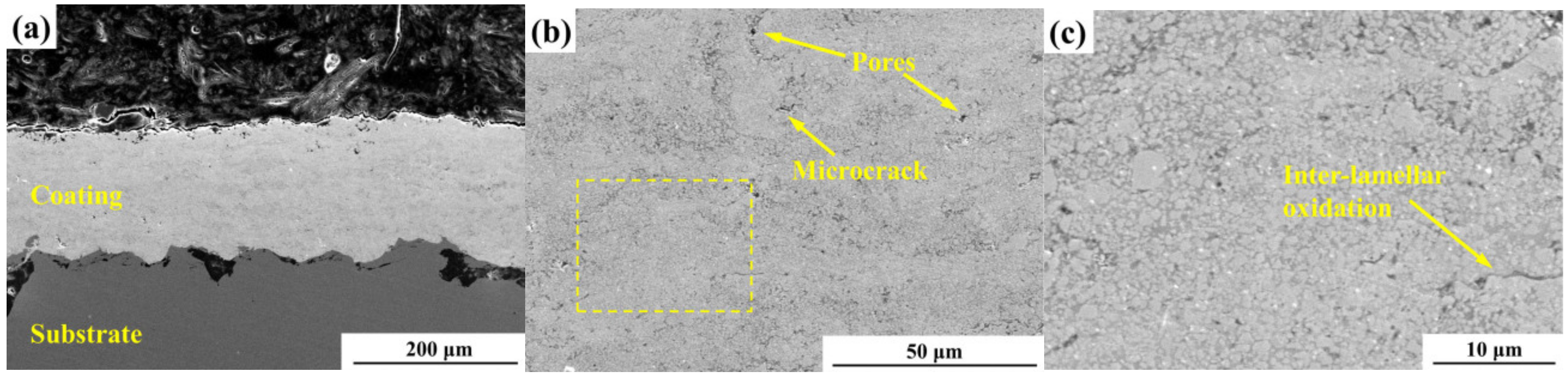

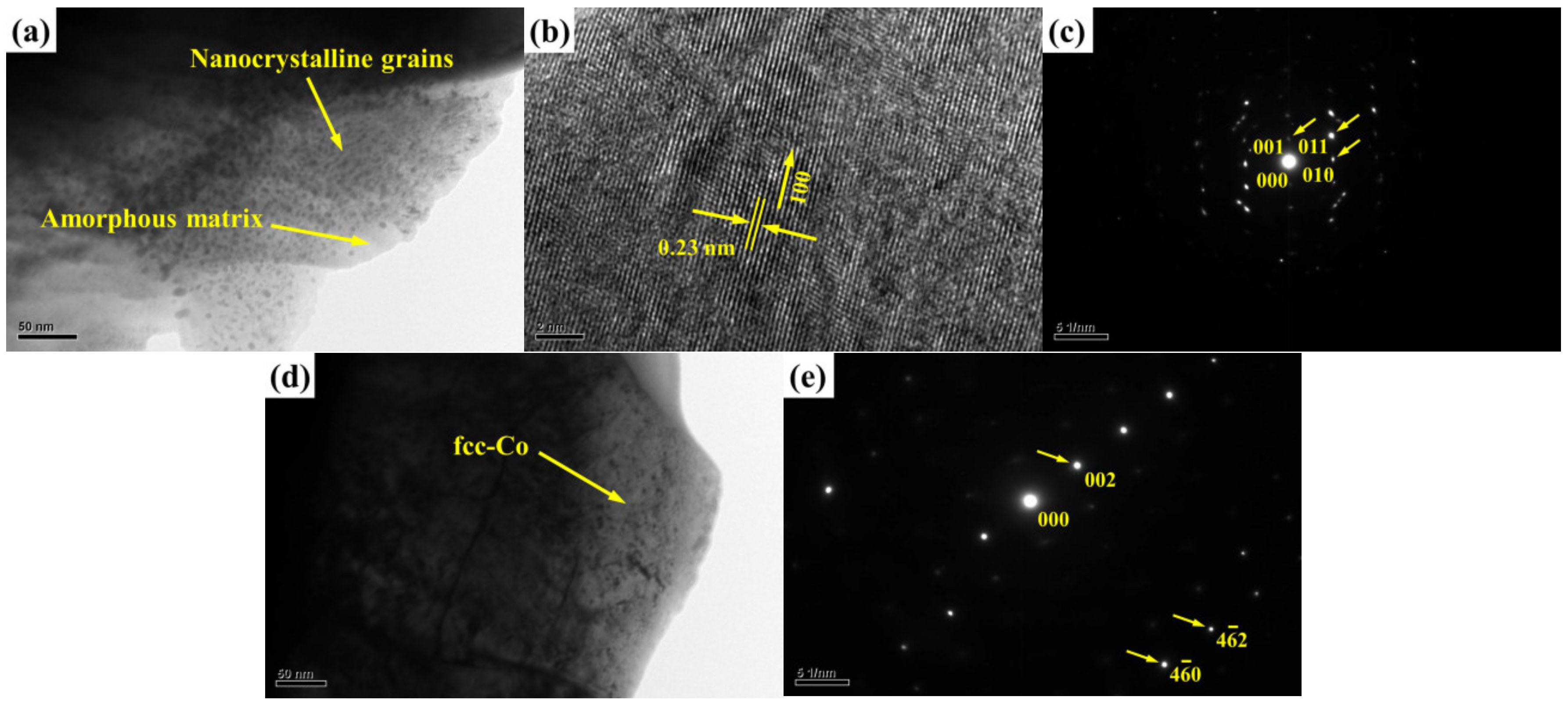

3.1. Microstructural Analysis of WC-CoCr Coatings

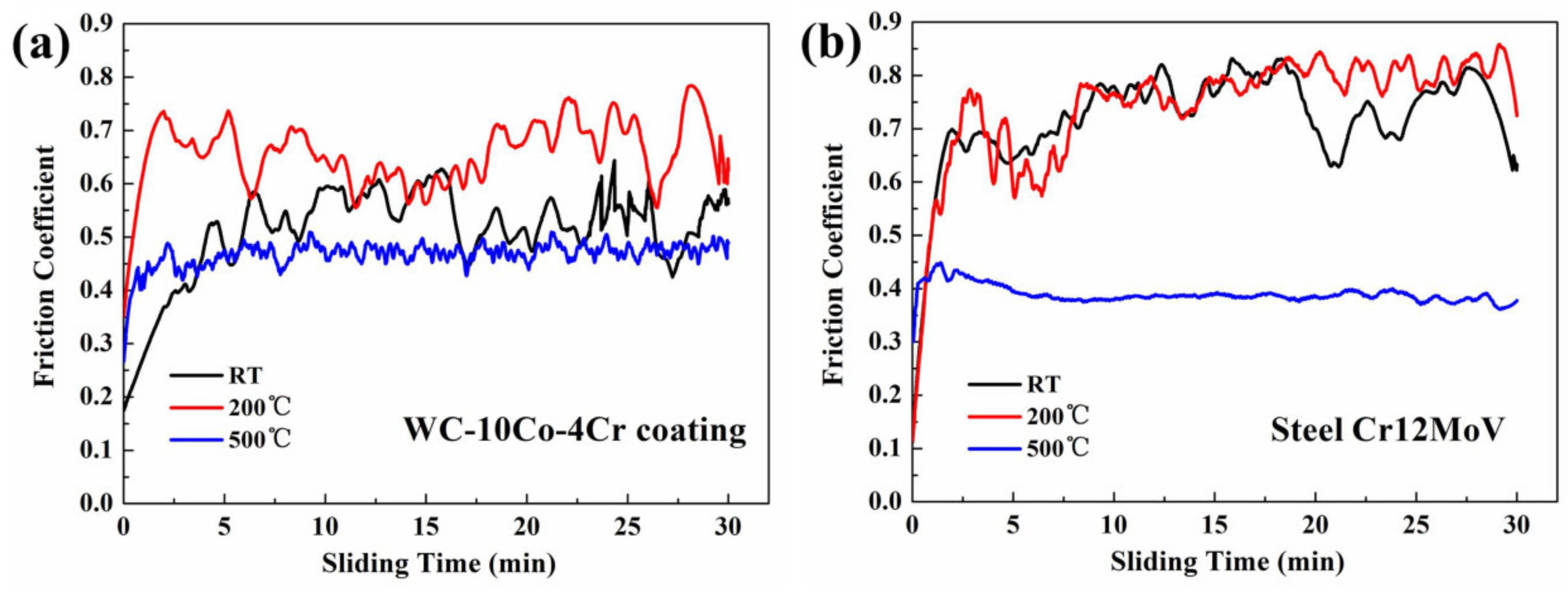

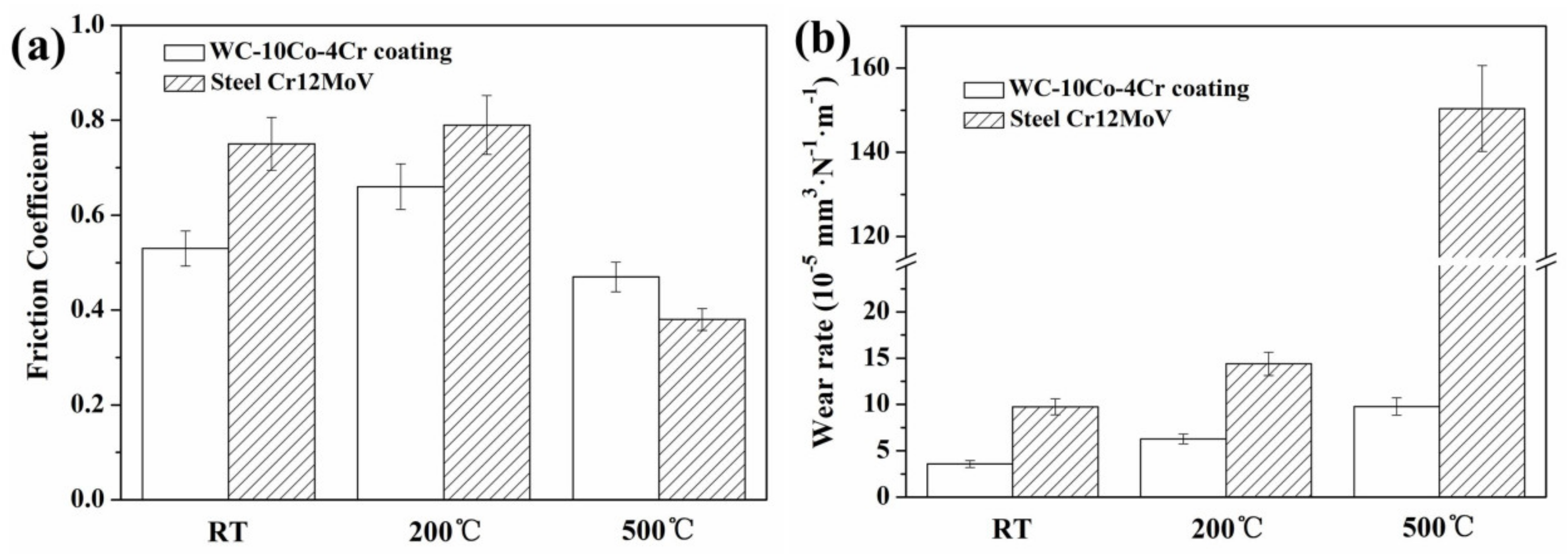

3.2. Friction and Wear Properties

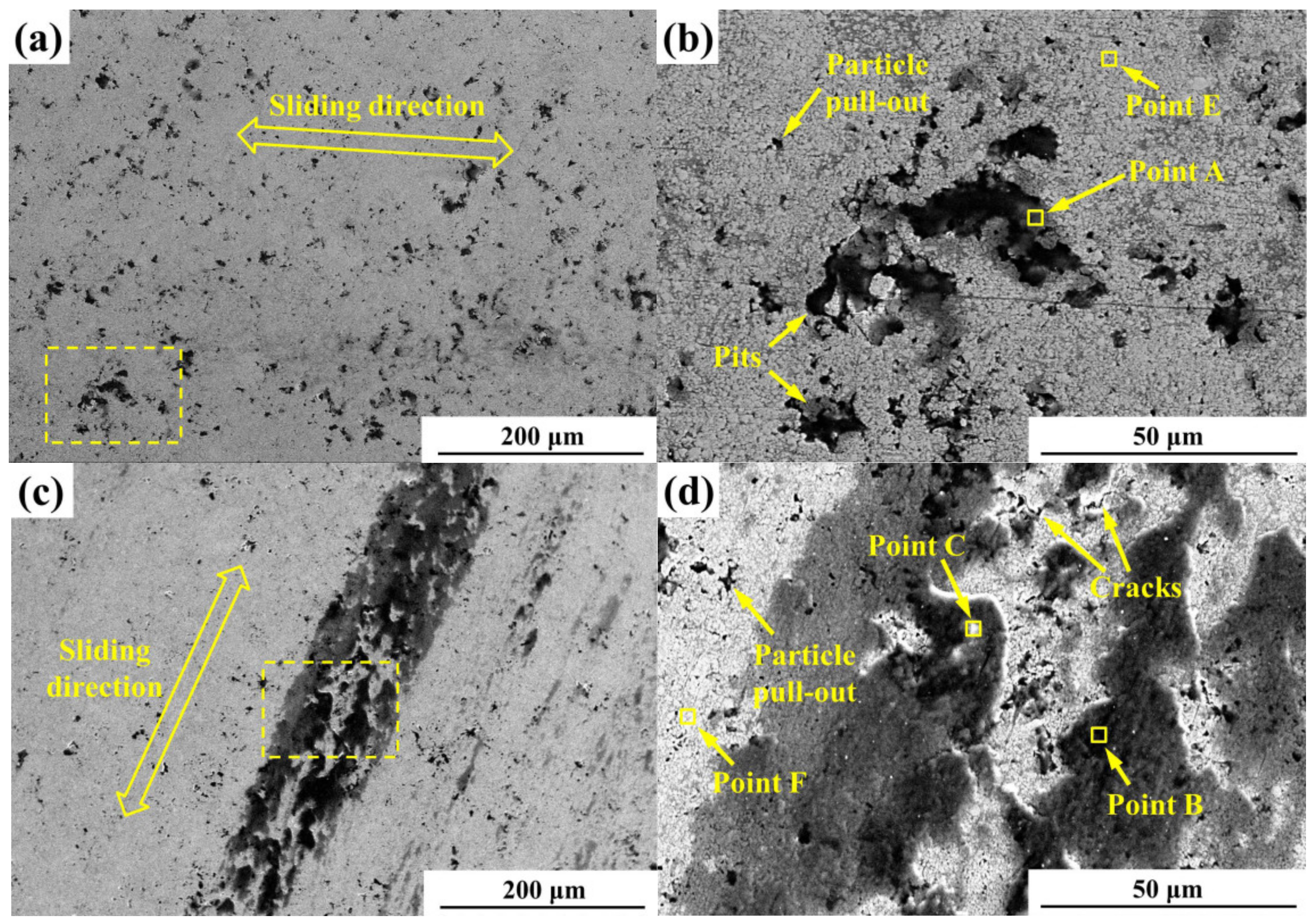

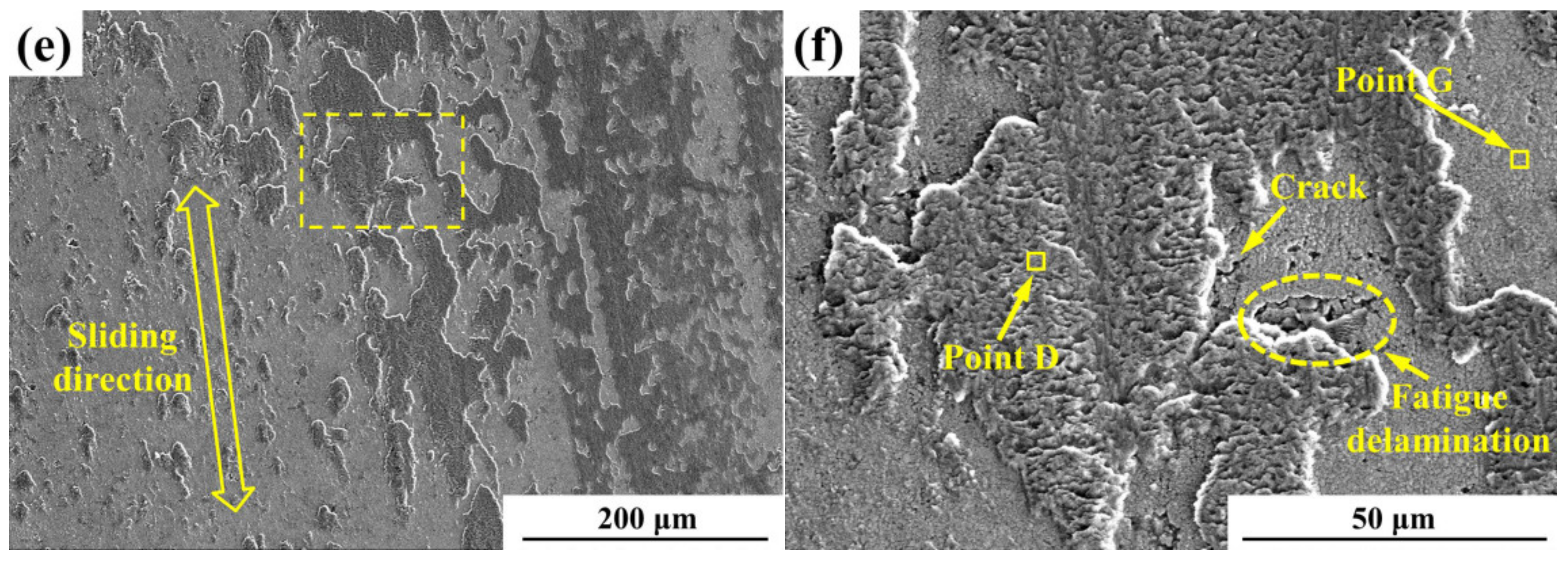

3.3. Worn Surfaces Analysis

4. Conclusions

- (1)

- The HVOF-sprayed WC-CoCr coating had a dense microstructure and compact interfacial bonding. A nanocrystalline/amorphous structure and an fcc-Co phase could be obtained in this coating, which could increase the mechanical strength, reduce the oxidize rate and maintain the resistance to sliding wear of the coating in comparison with die steel.

- (2)

- Dry sliding friction and wear tests indicated that the Ra value of the worn surface and the wear rate both increased with increasing test temperature for the coatings and die steels, while the friction coefficient firstly increased as the test temperature increased from RT to 200 °C and then decreased from 200 to 500 °C. For each test temperature, the Ra value of worn surface and the wear rates of the coatings were consistently lower than those of the die steels, especially at 500 °C.

- (3)

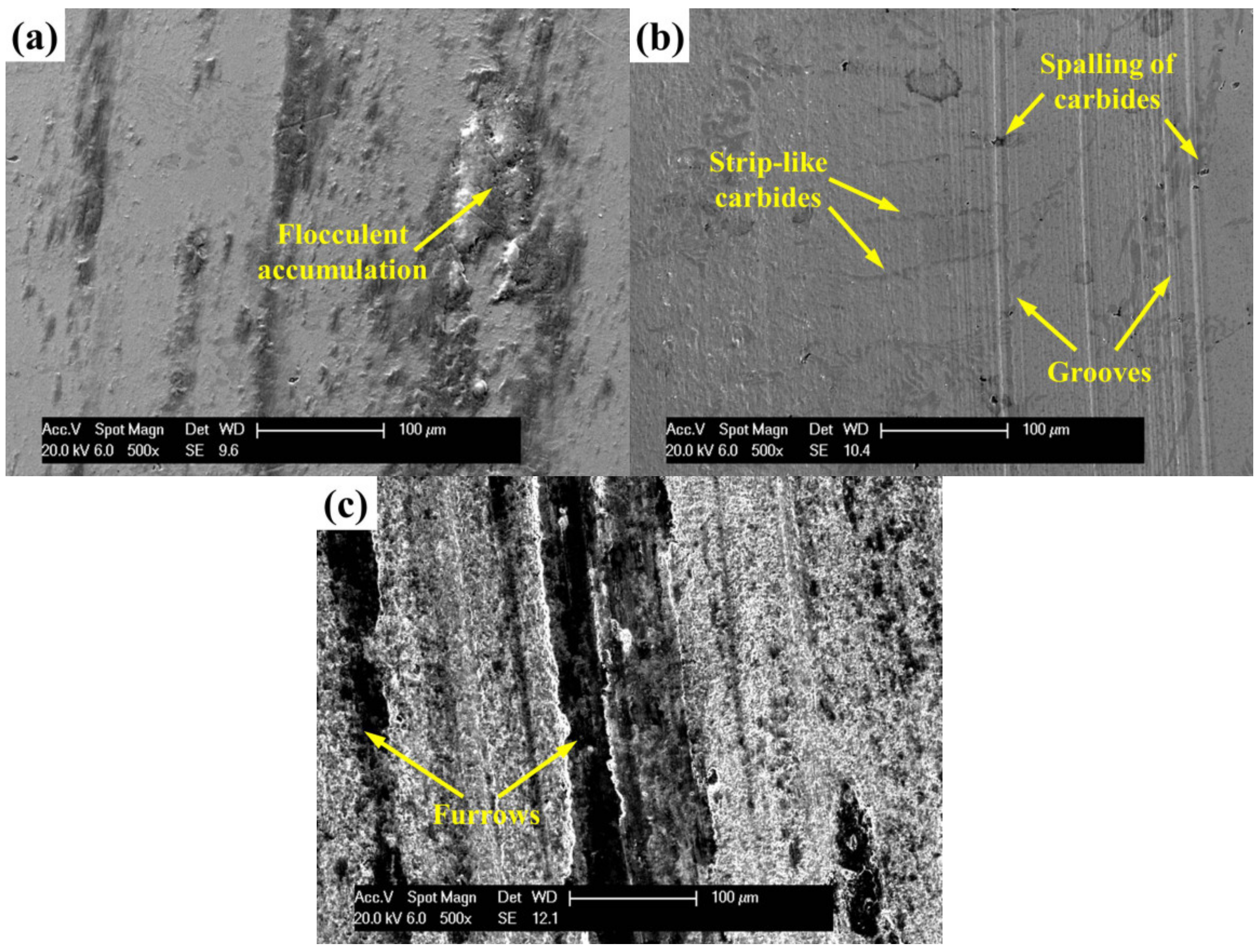

- After the sliding wear at RT and 200 °C for the coating, the presence of oxides was not identified by XRD analysis. The intensities of WO3 and CoWO4 peaks increased as the test temperature reached 500 °C. As for the die steels, a new phase of Fe2O3 was identified in the XRD pattern at 500 °C as compared to those at RT and 200 °C.

- (4)

- The tribological properties of coated steel were improved, which could be attributed to its high hardness, low surface roughness, and friction coefficient resulting from the formation of nanocrystalline/amorphous structure and the fcc-Co phase in the coating.

- (5)

- The sliding wear mechanisms of the coatings were extrusion deformation at RT, carbide pull-out and adhesive wear at 200 °C, and tribo-oxidation wear and fatigue wear at 500 °C. The mechanisms involved in the sliding wear process of the die steels with the increase of the temperature were plastic deformation, the flocculent accumulation of debris, the formation of strip-like carbides, furrows, and abrasive wear.

Author Contributions

Funding

Conflicts of Interest

References

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Grabon, W.; Pawlus, P.; Wos, S.; Koszela, W.; Wieczorowski, M. Effects of cylinder liner surface topography on friction and wear of liner-ring system at low temperature. Tribol. Int. 2018, 121, 148–160. [Google Scholar] [CrossRef]

- Szala, M.; Hejwowski, T. Cavitation erosion resistance and wear mechanism model of flame-sprayed Al2O3–40%TiO2/NiMoAl cermet coatings. Coatings 2018, 8, 254. [Google Scholar] [CrossRef]

- Bayer, I.S. On the durability and wear resistance of transparent superhydrophobic coatings. Coatings 2017, 7, 12. [Google Scholar] [CrossRef]

- Silva, F.; Martinho, R.; Andrade, M.; Baptista, A.; Alexandre, R. Improving the wear resistance of moulds for the injection of glass fibre-reinforced plastics using PVD coatings: A comparative study. Coatings 2017, 7, 28. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372, 21–41. [Google Scholar] [CrossRef]

- Tian, L.H.; Feng, Z.K.; Xiong, W. Microstructure, microhardness, and wear resistance of AlCoCrFeNiTi/Ni60 coating by plasma spraying. Coatings 2018, 8, 112. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.L.; Darut, G.; Poirier, T.; Stella, J.; Wang, K.; Liao, H.L.; Planche, M.P. A novel structured suspension plasma sprayed YSZ-PTFE composite coating with tribological performance improvement. Surf. Coat. Technol. 2019, 358, 108–113. [Google Scholar] [CrossRef]

- Singh, J.; Kumar, S.; Mohapatra, S.K. Tribological performance of Yttrium (III) and Zirconium (IV) ceramics reinforced WC-10Co4Cr cermet powder HVOF thermally sprayed on X2CrNiMo-17-12-2 steel. Ceram. Int. 2019, 45, 23126–23142. [Google Scholar] [CrossRef]

- Singh, J.; Kumar, S.; Mohapatra, S.K. Tribological analysis of WC-10Co-4Cr and Ni-20Cr2O3 coating on stainless steel 304. Wear 2017, 376, 1105–1111. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Hong, S.; Lin, J.R.; Zheng, Y. Influence of ultrasonic excitation sealing on the corrosion resistance of HVOF-sprayed nanostructured WC-CoCr coatings under different corrosive environments. Coatings 2019, 9, 724. [Google Scholar] [CrossRef]

- Yuan, J.H.; Ma, C.W.; Yang, S.L.; Yu, Z.S.; Li, H. Improving the wear resistance of HVOF sprayed WC-Co coatings by adding submicron-sized WC particles at the splats’ interfaces. Surf. Coat. Technol. 2016, 285, 17–23. [Google Scholar] [CrossRef]

- Geng, Z.; Hou, S.H.; Shi, G.L.; Duan, D.L.; Li, S. Tribological behaviour at various temperatures of WC-Co coatings prepared using different thermal spraying techniques. Tribol. Int. 2016, 104, 36–44. [Google Scholar] [CrossRef]

- Da Silva, F.S.; Cinca, N.; Dosta, S.; Cano, I.G.; Couto, M.; Guilemany, J.M.; Benedetti, A.V. Corrosion behavior of WC-Co coatings deposited by cold gas spray onto AA 7075-T6. Corros. Sci. 2018, 136, 231–243. [Google Scholar] [CrossRef]

- Yang, Q.Q.; Senda, T.; Ohmori, A. Effect of carbide grain size on microstructure and sliding wear behavior of HVOF-sprayed WC–12% Co coatings. Wear 2003, 254, 23–34. [Google Scholar] [CrossRef]

- Wesmann, J.A.R.; Espallargas, N. Effect of atmosphere, temperature and carbide size on the sliding friction of self-mated HVOF WC-CoCr contacts. Tribol. Int. 2016, 101, 301–313. [Google Scholar] [CrossRef]

- Mateen, A.; Saha, G.C.; Khan, T.I.; Khalid, F.A. Tribological behaviour of HVOF sprayed near-nanostructured and microstructured WC-17wt.%Co coatings. Surf. Coat. Technol. 2011, 206, 1077–1084. [Google Scholar] [CrossRef]

- Bolelli, G.; Berger, L.M.; Bonetti, M.; Lusvarghi, L. Comparative study of the dry sliding wear behaviour of HVOF-sprayed WC-(W,Cr)2C-Ni and WC-CoCr hardmetal coatings. Wear 2014, 309, 96–111. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.P.; Wang, B.; Zheng, Y.G.; Gao, W.W.; Li, G.Y. High-velocity oxygen-fuel spray parameter optimization of nanostructured WC-10Co-4Cr coatings and sliding wear behavior of the optimized coating. Mater. Des. 2014, 55, 286–291. [Google Scholar] [CrossRef]

- Qiao, Y.F.; Fischer, T.E.; Dent, A. The effects of fuel chemistry and feedstock powder structure on the mechanical and tribological properties of HVOF thermal-sprayed WC-Co coatings with very fine structures. Surf. Coat. Technol. 2003, 172, 24–41. [Google Scholar] [CrossRef]

- Basak, A.K.; Celis, J.P.; Vardavoulias, M.; Matteazzi, P. Effect of nanostructuring and Al alloying on friction and wear behaviour of thermal sprayed WC-Co coatings. Surf. Coat. Technol. 2012, 206, 3508–3516. [Google Scholar] [CrossRef]

- Rovatti, L.; Lecis, N.; Dellasega, D.; Russo, V.; Gariboldi, E. Influence of aging in the temperature range 250–350 °C on the tribological performance of a WC-CoCr coating produced by HVOF. Int. J. Refract. Met. Hard Mater. 2018, 75, 218–224. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.P.; Wang, B.; Zhang, J.F.; Zheng, Y.; Qiao, L. The effect of temperature on the dry sliding wear behavior of HVOF sprayed nanostructured WC-CoCr coatings. Ceram. Int. 2017, 43, 458–462. [Google Scholar] [CrossRef]

- Wu, Y.P.; Wang, B.; Hong, S.; Zhang, J.F.; Qin, Y.J.; Li, G.Y. Dry sliding wear properties of HVOF sprayed WC-10Co-4Cr coating. Trans. Indian Inst. Metals 2015, 68, 581–586. [Google Scholar] [CrossRef]

- ASTM G99-05 Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus; ASTM International: West Conshohocken, PA, USA, 2010.

- Hong, S.; Wu, Y.P.; Gao, W.W.; Wang, B.; Guo, W.M.; Lin, J.R. Microstructural characterisation and microhardness distribution of HVOF sprayed WC-10Co-4Cr coating. Surf. Eng. 2014, 30, 53–58. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.P.; Gao, W.W.; Zhang, J.F.; Zheng, Y.G.; Zheng, Y. Slurry erosion-corrosion resistance and microbial corrosion electrochemical characteristics of HVOF sprayed WC-10Co-4Cr coating for offshore hydraulic machinery. Int. J. Refract. Met. Hard Mater. 2018, 74, 7–13. [Google Scholar] [CrossRef]

- Schwetzke, R.; Kreye, H. Microstructure and properties of tungsten carbide coatings sprayed with various High-velocity oxygen fuel spray systems. J. Therm. Spray Technol. 1999, 8, 433–439. [Google Scholar] [CrossRef]

- Niu, Y.R.; Zheng, X.B.; Ji, H.; Qi, L.J.; Ding, C.X.; Chen, J.L.; Luo, G.N. Microstructure and thermal property of tungsten coatings prepared by vacuum plasma spraying technology. Fusion Eng. Des. 2010, 85, 1521–1526. [Google Scholar] [CrossRef]

- Stewart, D.A.; Shipway, P.H.; McCartney, D.G. Microstructural evolution in thermally sprayed WC-Co coatings: Comparison between nanocomposite and conventional starting powders. Acta Mater. 2000, 48, 1593–1604. [Google Scholar] [CrossRef]

- Li, C.J.; Ohmori, A.; Harada, Y. Formation of an amorphous phase in thermally sprayed WC-Co. J. Therm. Spray Technol. 1996, 5, 69–73. [Google Scholar] [CrossRef]

- Jiang, N.; Shen, Y.G.; Mai, Y.W.; Chan, T.; Tung, S.C. Nanocomposite Ti-Si-N films deposited by reactive unbalanced magnetron sputtering at room temperature. Mater. Sci. Eng. B 2004, 106, 163–171. [Google Scholar] [CrossRef]

- Lee, K.H.; Chang, D.; Kwon, S.C. Properties of electrodeposited nanocrystalline Ni-B alloy films. Electrochim. Acta 2005, 50, 4538–4543. [Google Scholar] [CrossRef]

- Sobolev, V.V.; Guilemany, J.M.; Miguel, J.R.; Calero, J.A. Investigation of the development of coating structure during high velocity oxy-fuel (HVOF) spraying of WC-Ni powder particles. Surf. Coat. Technol. 1996, 82, 114–120. [Google Scholar] [CrossRef]

- Sharma, P.; Majumdar, J.D. Surface characterization and mechanical properties evaluation of Boride-dispersed Nickel-based coatings deposited on copper through thermal spray routes. J. Therm. Spray Technol. 2012, 21, 800–809. [Google Scholar] [CrossRef]

- Human, A.M.; Roebuck, B.; Exner, H.E. Electrochemical polarisation and corrosion behaviour of cobalt and Co (W, C) alloys in 1 N sulphuric acid. Mater. Sci. Eng. A 1998, 241, 202–210. [Google Scholar] [CrossRef]

- Blau, P.J. Friction and Wear Transitions of Materials; Noyes Publishing: Park Ridge, NJ, USA, 1989. [Google Scholar]

- Zhu, Y.C.; Yukimura, K.; Ding, C.X.; Zhang, P.Y. Tribological properties of nanostructured and conventional WC-Co coatings deposited by plasma spraying. Thin Solid Films 2001, 388, 277–282. [Google Scholar] [CrossRef]

- Wu, L.; Chen, J.X.; Liu, M.Y.; Bao, Y.W.; Zhou, Y.C. Reciprocating friction and wear behavior of Ti3AlC2 and Ti3AlC2/Al2O3 composites against AISI52100 bearing steel. Wear 2009, 266, 158–166. [Google Scholar] [CrossRef]

- Lekatou, A.; Sioulas, D.; Karantzalis, A.E.; Grimanelis, D. A comparative study on the microstructure and surface property evaluation of coatings produced from nanostructured and conventional WC-Co powders HVOF-sprayed on Al7075. Surf. Coat. Technol. 2015, 276, 539–556. [Google Scholar] [CrossRef]

- Shipway, P.H.; McCartney, D.G.; Sudaprasert, T. Sliding wear behaviour of conventional and nanostructured HVOF sprayed WC-Co coatings. Wear 2005, 259, 820–827. [Google Scholar] [CrossRef]

- Wang, Q.; Li, L.X.; Yang, G.B.; Zhao, X.Q.; Ding, Z.X. Influence of heat treatment on the microstructure and performance of high-velocity oxy-fuel sprayed WC–12Co coatings. Surf. Coat. Technol. 2012, 206, 4000–4010. [Google Scholar] [CrossRef]

- Geng, Z.; Li, S.; Duan, D.L.; Liu, Y. Wear behavior of WC-Co HVOF coatings at different temperatures in air and argon. Wear 2015, 330, 348–353. [Google Scholar] [CrossRef]

- Guo, J.; Ai, L.Q.; Wang, T.T.; Feng, Y.L.; Wan, D.C.; Yang, Q.X. Microstructure evolution and micro-mechanical behavior of secondary carbides at grain boundary in a Fe-Cr-W-Mo-V-C alloy. Mater. Sci. Eng. A 2018, 715, 359–369. [Google Scholar] [CrossRef]

- Wayne, S.F.; Baldoni, J.G.; Buljan, S.T. Abrasion and erosion of WC-Co with controlled microstructures. Tribol. Trans. 1990, 33, 611–617. [Google Scholar] [CrossRef]

- Huth, S.; Krasokha, N.; Theisen, W. Development of wear and corrosion resistant cold-work tool steels produced by diffusion alloying. Wear 2009, 267, 449–457. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Li, C.Y.; Xu, Y.H.; Tang, Q.H.; Zheng, Y.; Liu, H.W.; Fernandez-Rodriguez, E. Study on propellers distribution and flow field in the oxidation ditch based on two-phase CFD model. Water 2019, 11, 2506. [Google Scholar] [CrossRef]

| Characteristic Parameters | WC-10Co–4Cr Coatings | Cr12MoV Steel | ||||

|---|---|---|---|---|---|---|

| RT | 200 °C | 500 °C | RT | 200 °C | 500 °C | |

| Average friction coefficient during the steady period | 0.53 | 0.66 | 0.47 | 0.75 | 0.79 | 0.38 |

| Average surface roughness (Ra) values of worn surfaces, μm | 0.13 | 0.16 | 0.21 | 0.28 | 0.45 | 2.27 |

| Average wear rate, 10−5 mm3·N−1·m−1 | 3.58 | 6.29 | 9.79 | 9.76 | 14.39 | 150.4 |

| Element, wt.% | Positions | |||||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | Non-Rubbed | |

| C K | 1.74 | – | 1.69 | – | 10.79 | 10.10 | 3.49 | 21.55 |

| O K | 37.95 | 48.60 | 32.38 | 25.58 | 2.32 | 5.17 | 16.15 | 0.85 |

| Al K | – | – | 21.35 | – | – | – | – | – |

| Cr K | 2.46 | 2.99 | 2.24 | 2.85 | 1.59 | 0.93 | 2.28 | 5.30 |

| Co K | 8.23 | 7.37 | 6.33 | 8.72 | 11.05 | 9.67 | 11.34 | 13.96 |

| W K | 49.62 | 41.05 | 36.01 | 62.86 | 74.25 | 74.13 | 66.74 | 58.34 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, S.; Wu, Y.; Wang, B.; Lin, J. Improvement in Tribological Properties of Cr12MoV Cold Work Die Steel by HVOF Sprayed WC-CoCr Cermet Coatings. Coatings 2019, 9, 825. https://doi.org/10.3390/coatings9120825

Hong S, Wu Y, Wang B, Lin J. Improvement in Tribological Properties of Cr12MoV Cold Work Die Steel by HVOF Sprayed WC-CoCr Cermet Coatings. Coatings. 2019; 9(12):825. https://doi.org/10.3390/coatings9120825

Chicago/Turabian StyleHong, Sheng, Yuping Wu, Bo Wang, and Jinran Lin. 2019. "Improvement in Tribological Properties of Cr12MoV Cold Work Die Steel by HVOF Sprayed WC-CoCr Cermet Coatings" Coatings 9, no. 12: 825. https://doi.org/10.3390/coatings9120825

APA StyleHong, S., Wu, Y., Wang, B., & Lin, J. (2019). Improvement in Tribological Properties of Cr12MoV Cold Work Die Steel by HVOF Sprayed WC-CoCr Cermet Coatings. Coatings, 9(12), 825. https://doi.org/10.3390/coatings9120825