Influence of Thermochromic Pigment Powder on Properties of Waterborne Primer Film for Chinese Fir

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Materials

2.2. Preparation of Thermochromic Pigment Powder

2.3. Preparation of Thermochromic Color-Changing Waterborne Coatings

2.4. Performance Test

3. Results and Discussion

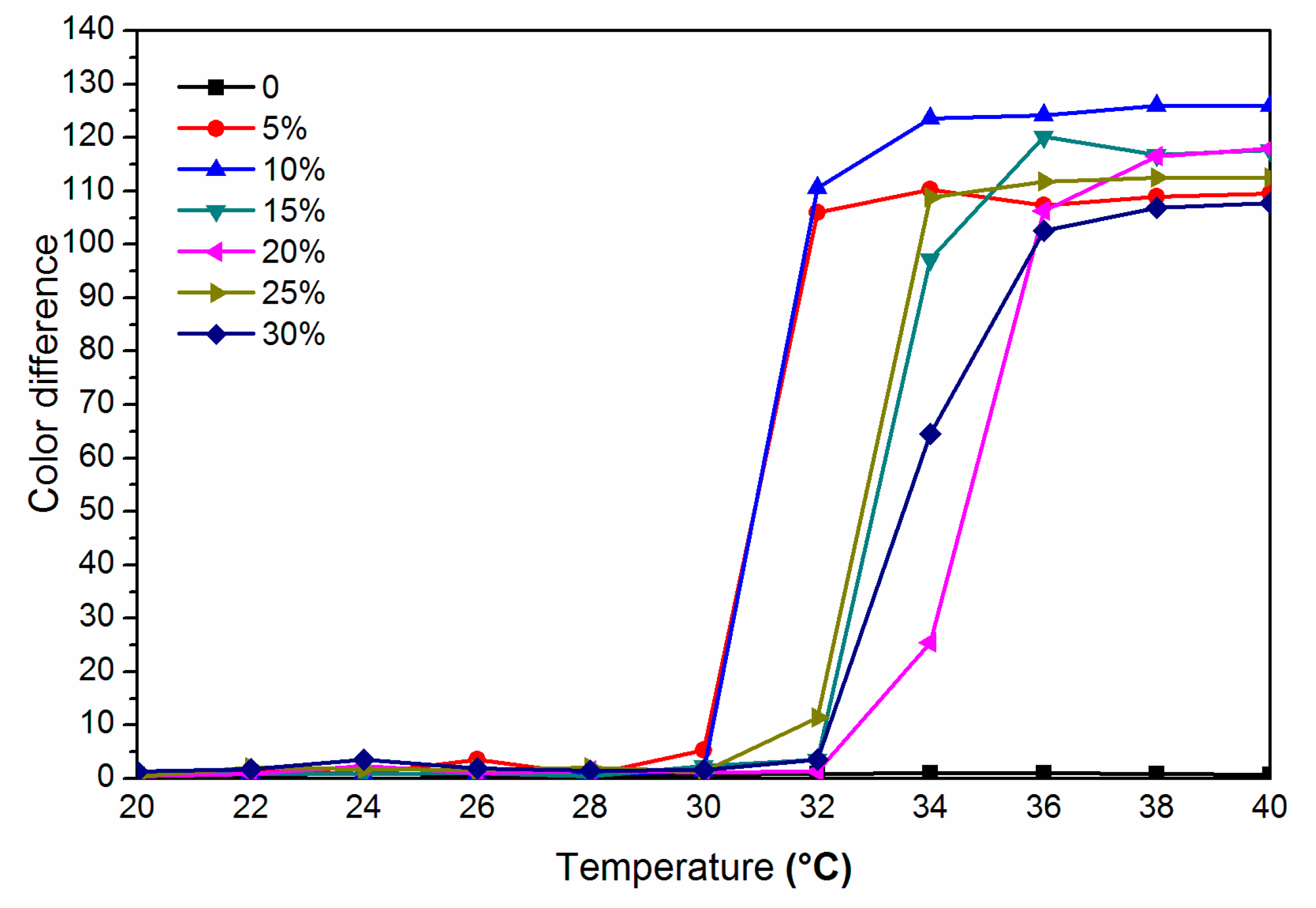

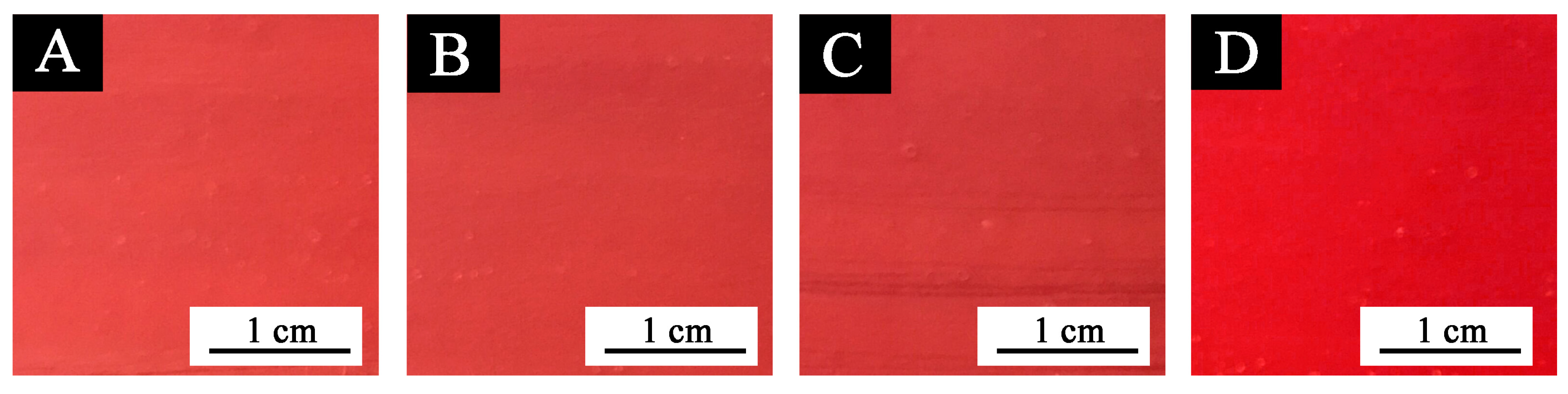

3.1. Influence of Thermochromic Pigment Powder on Optical Properties

3.2. Influence of Thermochromic Pigment Powder on Mechanical Properties

3.3. Influence of Thermochromic Pigment Powder on Liquid Resistance Properties

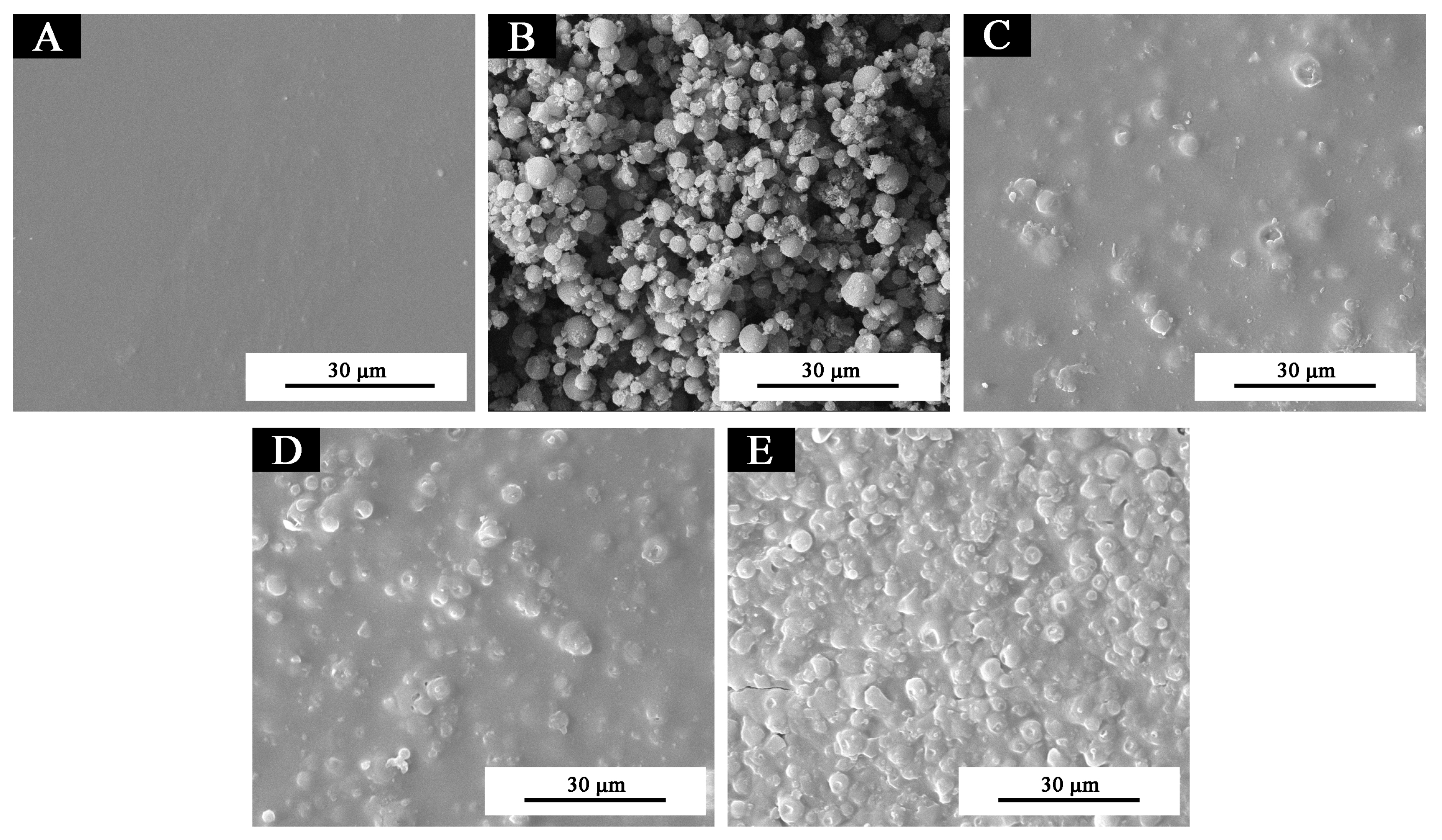

3.4. The SEM Analysis of Thermochromic Color-Changing Waterborne Primer Film

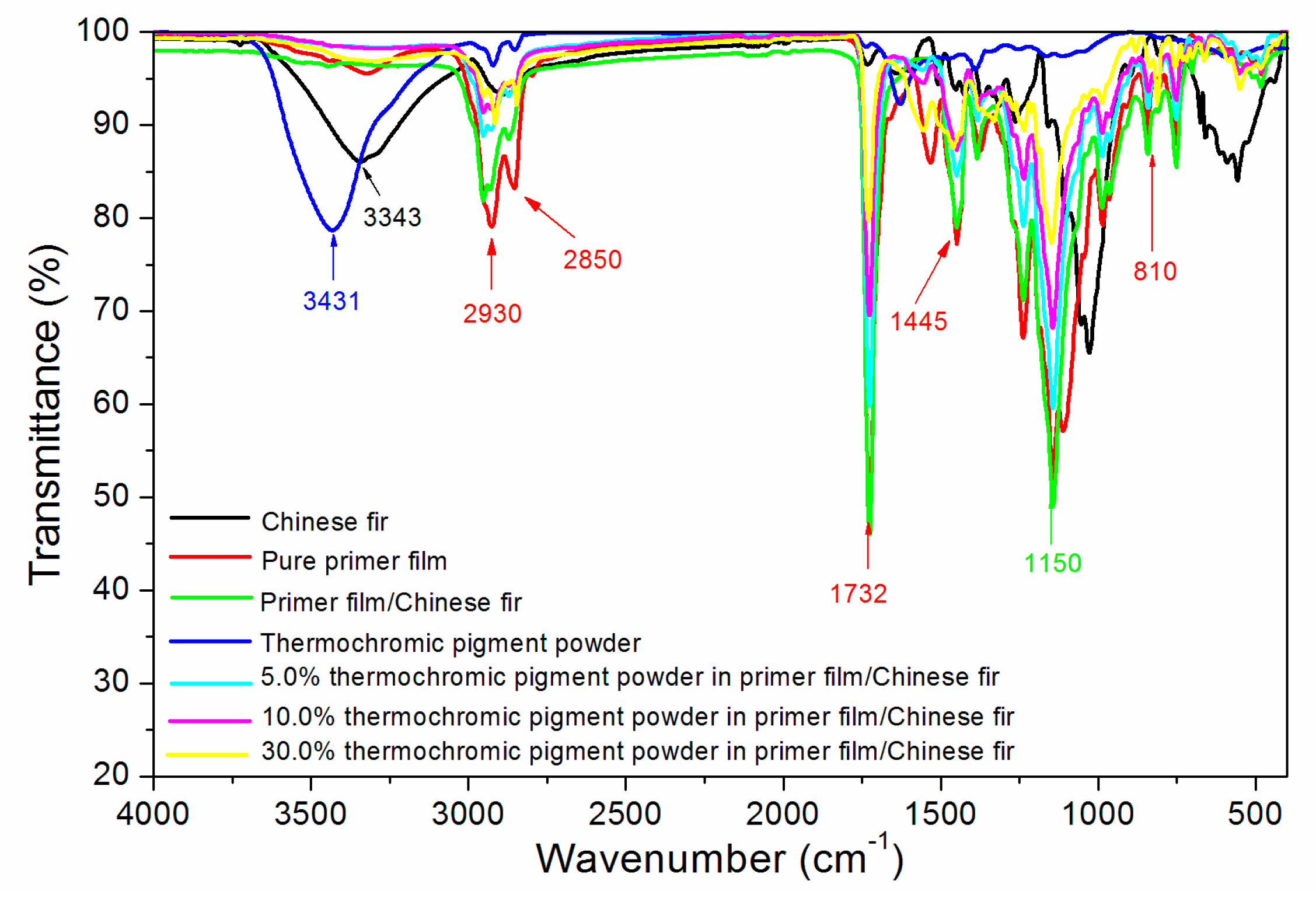

3.5. The Fourier Transform Infrared Spectroscopy (FTIR) Analysis of Thermochromic Color-Changing Waterborne Primer Film

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liang, R.Q.; Sun, Y.Y.; Aburas, M.; Wilson, R.; Wu, Y.P. An exploration of the combined effects of NIR and VIS spectrally selective thermochromic materials on building performance. Energ. Build. 2019, 201, 149–162. [Google Scholar] [CrossRef]

- Du, J.H.; Sheng, L.; Chen, Q.N.; Xu, Y.; Li, W.; Wang, X.J.; Li, M.J.; Zhang, S.X.A. Simple and general platform for highly adjustable thermochromic fluorescent materials and multi-feasible applications. Mater. Horiz. 2019, 6, 1654–1662. [Google Scholar] [CrossRef]

- Jin, Y.; Lin, Y.L.; Kiani, A.; Joshipura, I.D.; Ge, M.Q.; Dickey, M.D. Materials tactile logic via innervated soft thermochromic elastomers. Nat. Commun. 2019, 10, 4187. [Google Scholar] [CrossRef]

- Zauhar, G.; Radojcic, D.S.; Kaliman, Z.; Schnurrer-Luke-Vrbanic, T.; Jurkovic, S. Determination of physiotherapy ultrasound beam quality parameters from images derived using thermochromic material. Ultrasonics 2019, 99, 105943. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.Z.; Shi, L.M.; Zhang, Q.; Wang, W.J. Microencapsulation of 1-hexadecanol as a phase change material with reversible thermochromic properties. Res. Adv. 2017, 7, 42129–42137. [Google Scholar] [CrossRef]

- Wang, H.; Luo, J.; Yang, Y.Y.; Zhao, L.; Song, G.L.; Tang, G.Y. Fabrication and characterization of microcapsulated phase change materials with an additional function of thermochromic performance. Sol. Energy 2016, 139, 591–598. [Google Scholar] [CrossRef]

- Ren, C.X.; Liu, F.F.; Umair, M.M.; Jin, X.; Zhang, S.F.; Tang, B.T. Excellent temperature-control based on reversible thermochromic materials for light-driven phase change materials system. Molecules 2019, 24, 1623. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Cao, X.; Shao, Z.W.; Sun, G.Y.; Long, S.W.; Chang, T.C.; Luo, H.J.; Jin, P. Highly enhanced thermochromic performance of VO2 film using “movable” antireflective. ACS Appl. Mater. Interfaces 2019, 11, 4712–4718. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Yue, L.N.; Wang, X.W.; Deng, M.G.; Sun, Y.J.; Gao, M. Imitation-mussel-based high-performance conductive coating on hydrophobic fabric for thermochromic application. J. Appl. Polym. Sci. 2019, 136, 47751. [Google Scholar] [CrossRef]

- Liu, F.F.; Zhang, S.F.; Jin, X.; Wang, W.T.; Tang, B.T. Thermal-responsive photonic crystal with function of color switch based on thermochromic system. ACS Appl. Mater. Interfaces 2019, 11, 39125–39131. [Google Scholar] [CrossRef]

- Huang, A.; Li, G.; Fu, F.; Fei, B. Use of visible and near infrared spectroscopy to predict klason lignin content of bamboo, Chinese fir, Paulownia, and Poplar. J. Wood Chem. Technol. 2008, 28, 194–206. [Google Scholar] [CrossRef]

- Li, R.S.; Zheng, W.H.; Yang, Q.P.; Zhang, W.D.; Chi, Y.G.; Wang, P.; Xu, M.; Guan, X.; Chen, L.C.; Wang, Q.K.; et al. The response of soil respiration to thinning was not affected by understory removal in a Chinese fir (Cunninghamia lanceolata) plantation. Geoderma 2019, 353, 47–54. [Google Scholar] [CrossRef]

- Noreen, A.; Zia, K.M.; Zuber, M.; Tabasum, S.; Saif, M.J. Recent trends in environmentally friendly water-borne polyurethane coatings: A review. Korean J. Chem. Eng. 2016, 33, 388–400. [Google Scholar] [CrossRef]

- Xu, J.C.; Jiang, Y.; Zhang, T.; Dai, Y.T.; Zhang, D.Y.; Qiu, F.X.; Yu, Z.P.; Yang, P.F. Synthesis of UV-curing waterborne polyurethane-acrylate coating and its photopolymerization kinetics using FT-IR and photo-DSC methods. Prog. Org. Coat. 2018, 122, 10–18. [Google Scholar] [CrossRef]

- Yan, X.X.; Wang, L.; Qian, X.Y. Effect of urea-formaldehyde-coated epoxy microcapsule modification on gloss, toughness and chromatic distortion of acrylic copolymers waterborne coating. Coatings 2019, 9, 239. [Google Scholar] [CrossRef]

- Veigel, S.; Grull, G.; Pinkl, S.; Obersriebnig, M.; Muller, U.; Gindl-Altmutter, W. Improving the mechanical resistance of waterborne wood coatings by adding cellulose nanofibres. React. Funct. Polym. 2014, 85, 214–220. [Google Scholar] [CrossRef]

- GB/T 1732-1993 Determination of Impact Resistance of Film; Standardization Administration of the People’s Republic of China: Beijing, China, 1993; pp. 418–420. (In Chinese)

- GB/T 1720-1989 Determination of Adhesion of Film; Standardization Administration of the People’s Republic of China: Beijing, China, 1979; pp. 378–379. (In Chinese)

- Standardization Administration of the People’s Republic of China. GB/T 1733-1993 Determination of Resistence to Water of Films; Standardization Administration of the People’s Republic of China: Beijing, China, 1993; pp. 421–423. (In Chinese)

- Valdesueiro, D.; Hettinga, H.; Drijfhout, J.P.; Lips, P.; Meesters, G.M.H.; Kreutzer, M.T.; van Ommen, J.R. Tuning roughness and gloss of powder coating paint by encapsulating the coating particles with thin Al2O3 films. Powder Technol. 2017, 318, 401–410. [Google Scholar] [CrossRef]

- Mirabedini, S.M.; Kiamanesh, A. The effect of micro and nano-sized particles on mechanical and adhesion properties of a clear polyester powder coating. Prog. Org. Coat. 2013, 76, 1625–1632. [Google Scholar] [CrossRef]

- Smikalla, M.; Mescher, A.; Walzel, P.; Urbanetz, N.A. Impact of excipients on coating efficiency in dry powder coating. Int. J. Pharmaceut. 2010, 405, 122–131. [Google Scholar] [CrossRef]

- Wang, C.Q.; Xue, L.; Dong, Y.H.; Hou, L.Y.; Wei, Y.H.; Chen, J.Q.; Jiao, R.Z. The development of Chinese fir plantations undergo significant changes in soil microbial metabolic function and enzyme activities. J. Forest Res. Jpn. 2019, 24, 261–265. [Google Scholar]

- Yan, X.X.; Wang, L.; Qian, X.Y. Effect of high-temperature calcined wheat straw powder after lignin removal on properties of waterborne wood coatings. Coatings 2019, 9, 444. [Google Scholar] [CrossRef]

| Compound | Molecular Formula | MW (g/mol) | CAS No. | Producer | Concentration (%) | Function |

|---|---|---|---|---|---|---|

| methyl red | C15H15N3O2 | 269.30 | 493-52-7 | Huancai Discoloration Technology Co., Ltd., Shenzhen, China | 99.9 | leuco agent |

| bisphenol A | C15H16O2 | 228.29 | 80-05-7 | Huancai Discoloration Technology Co., Ltd., Shenzhen, China | 99.9 | chromogenic reagent |

| melamine | C3H6N6 | 126.12 | 108-78-1 | Huancai Discoloration Technology Co., Ltd., Shenzhen, China | 99.9 | wall material |

| sodium dodecylbenzene sulfonate | C18H29NaO3S | 348.48 | 25155-30-0 | Xilong Chemical Co., Ltd., Guangzhou, China | 99.9 | emulsifier |

| formaldehyde solution | CH2O | 30.03 | 50-00-0 | Xilong Chemical Co., Ltd., Guangzhou, China | 37.0 | wall material |

| anhydrous ethanol | C2H6O | 46.07 | 64-17-5 | Xilong Chemical Co., Ltd., Guangzhou, China | 99.9 | for rinsing microcapsules |

| lauryl alcohol | C12H26O | 186.34 | 112-53-8 | Xilong Chemical Co., Ltd., Guangzhou, China | 99.9 | co-solvent |

| citric acid monohydrate | C6H10O8 | 210.14 | 5949-29-1 | Xilong Chemical Co., Ltd., Guangzhou, China | 99.9 | pH regulator |

| triethanolamine | C6H15NO3 | 149.19 | 102-71-6 | Xilong Chemical Co., Ltd., Guangzhou, China | 99.9 | pH regulator |

| NaCl solution | – | – | – | Qingdao Hainuo Bioengineering Co., Ltd., Qingdao, China | 15.0 | liquid resistance test solution |

| medical ethanol | – | – | – | Qingdao Hainuo Bioengineering Co., Ltd., Qingdao, China | 70.0 | liquid resistance test solution |

| detergent | – | – | – | Shanghai Hutchison Whitecat Co., Ltd., Shanghai, China | – | liquid resistance test solution |

| red ink | – | – | – | Fine Stationery Co., Ltd., Shanghai, China | – | liquid resistance test solution |

| waterborne wood primer | – | – | – | Hengchang paint Co., Ltd., Huiyang, China | – | primer film |

| Thermochromic Pigment Powder Concentration (%) | Thermochromic Color-Changing Powder (g) | Waterborne Primer (g) | Thermoreversible Color-Changing Waterborne Coatings (g) |

|---|---|---|---|

| 0 | 0 | 100.0 | 100.0 |

| 5.0 | 5.0 | 95.0 | 100.0 |

| 10.0 | 10.0 | 90.0 | 100.0 |

| 15.0 | 15.0 | 75.0 | 100.0 |

| 20.0 | 20.0 | 80.0 | 100.0 |

| 25.0 | 25.0 | 75.0 | 100.0 |

| 30.0 | 30.0 | 70.0 | 100.0 |

| Thermochromic Pigment Powder Concentration (%) | Chromatic Values | 18 °C | 20 °C | 22 °C | 24 °C | 26 °C | 28 °C | 30 °C | 32 °C | 34 °C | 36 °C | 38 °C | 40 °C |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | L | 85.5 | 85.2 | 84.8 | 85.0 | 85.1 | 85.3 | 84.7 | 84.7 | 84.6 | 84.7 | 84.7 | 84.7 |

| a | 6.1 | 5.4 | 6.3 | 6.5 | 6.6 | 5.9 | 6.1 | 5.9 | 5.0 | 5.6 | 5.9 | 6.3 | |

| b | 29.5 | 29.5 | 29.9 | 30.1 | 29.7 | 30.3 | 29.5 | 29.8 | 29.9 | 29.7 | 29.8 | 29.5 | |

| c | 30.1 | 30.0 | 30.6 | 30.8 | 30.4 | 30.9 | 30.1 | 30.3 | 30.3 | 30.2 | 30.3 | 30.2 | |

| H | 78.1 | 79.5 | 78.0 | 77.8 | 77.4 | 78.8 | 78.2 | 78.8 | 80.4 | 79.3 | 78.8 | 77.9 | |

| 5 | L | 52.2 | 52.9 | 51.6 | 52.0 | 53.9 | 52.3 | 54.5 | 95.4 | 97.7 | 97.0 | 97.4 | 97.5 |

| a | 60.8 | 60.2 | 61.3 | 61.6 | 57.9 | 60.4 | 56.1 | −21.9 | −23.3 | −22.2 | −22.7 | −23.1 | |

| b | 42.7 | 42.4 | 41.2 | 42.3 | 44.1 | 42.0 | 43.9 | 92.9 | 97.7 | 93.8 | 96.1 | 96.5 | |

| c | 74.3 | 73.6 | 73.8 | 74.8 | 72.8 | 73.6 | 71.3 | 95.5 | 100.5 | 96.4 | 98.7 | 99.3 | |

| H | 35.0 | 35.1 | 33.9 | 34.4 | 37.2 | 34.8 | 38.0 | 103.2 | 103.4 | 103.3 | 103.3 | 103.4 | |

| 10 | L | 49.4 | 49.9 | 49.8 | 49.7 | 49.6 | 50.0 | 50.3 | 94.8 | 99.4 | 99.5 | 100.0 | 100.0 |

| a | 60.3 | 59.5 | 60.3 | 59.7 | 59.4 | 59.8 | 59.7 | −14.2 | −22.4 | −22.9 | −23.9 | −24.4 | |

| b | 36.2 | 36.3 | 37.1 | 36.8 | 36.6 | 36.5 | 37.3 | 104.0 | 113.1 | 113.6 | 115.0 | 114.6 | |

| c | 70.3 | 69.7 | 70.8 | 70.2 | 69.8 | 70.1 | 70.4 | 105.0 | 115.3 | 115.9 | 117.5 | 117.2 | |

| H | 31.0 | 31.4 | 31.6 | 31.6 | 31.7 | 31.4 | 32.0 | 97.7 | 101.1 | 101.4 | 101.7 | 102.0 | |

| 15 | L | 50.1 | 50.2 | 49.9 | 49.8 | 49.6 | 49.8 | 49.0 | 49.9 | 91.7 | 98.7 | 96.9 | 97.1 |

| a | 57.2 | 56.8 | 57.9 | 57.7 | 58.0 | 57.3 | 55.7 | 53.7 | −1.9 | −16.6 | −17.9 | −18.2 | |

| b | 34.2 | 33.6 | 33.6 | 33.5 | 34.0 | 34.5 | 32.8 | 34.2 | 99.3 | 115.6 | 110.5 | 111.4 | |

| c | 66.6 | 66.0 | 67.0 | 66.8 | 67.2 | 66.9 | 64.7 | 63.7 | 99.3 | 116.8 | 111.9 | 112.9 | |

| H | 30.8 | 30.6 | 30.1 | 30.1 | 30.4 | 31.0 | 30.5 | 32.4 | 91.1 | 98.2 | 99.2 | 99.3 | |

| 20 | L | 50.6 | 51.2 | 50.0 | 50.8 | 49.9 | 50.0 | 50.1 | 50.3 | 64.7 | 95.3 | 98.1 | 98.7 |

| a | 56.3 | 55.8 | 55.8 | 54.1 | 56.1 | 55.0 | 55.2 | 55.1 | 41.5 | −7.8 | −13.9 | −15.2 | |

| b | 32.8 | 34.2 | 33.2 | 33.4 | 32.1 | 32.5 | 32.6 | 32.2 | 47.9 | 104.8 | 112.7 | 113.4 | |

| c | 65.1 | 65.5 | 64.9 | 63.6 | 64.6 | 63.9 | 64.1 | 63.9 | 63.4 | 105.0 | 113.6 | 114.5 | |

| H | 30.2 | 31.5 | 30.7 | 31.7 | 29.8 | 30.5 | 30.5 | 30.3 | 49.1 | 94.2 | 97.0 | 97.6 | |

| 25 | L | 50.8 | 50.5 | 49.2 | 50.5 | 49.4 | 49.2 | 49.6 | 56.4 | 95.7 | 96.9 | 96.5 | 96.8 |

| a | 53.6 | 53.4 | 52.9 | 51.9 | 53.7 | 52.9 | 53.0 | 46.4 | −10.3 | −11.9 | −13.2 | −12.7 | |

| b | 31.8 | 32.0 | 30.6 | 32.1 | 31.0 | 30.6 | 31.5 | 38.7 | 107.6 | 109.8 | 109.9 | 110.1 | |

| c | 62.3 | 62.3 | 61.2 | 61.1 | 62.0 | 61.2 | 61.7 | 60.4 | 108.1 | 110.4 | 110.7 | 110.9 | |

| H | 30.6 | 30.9 | 30.0 | 31.7 | 30.0 | 30.0 | 30.7 | 39.8 | 95.4 | 96.2 | 96.8 | 96.6 | |

| 30 | L | 50.4 | 50.7 | 49.4 | 50.2 | 49.2 | 49.6 | 49.5 | 49.1 | 79.4 | 93.0 | 94.8 | 95.1 |

| a | 52.8 | 51.5 | 52.7 | 49.2 | 51.6 | 52.0 | 51.8 | 50.1 | 14.7 | −7.8 | −9.8 | −10.1 | |

| b | 31.7 | 31.6 | 30.2 | 31.7 | 30.9 | 30.7 | 30.6 | 29.9 | 74.9 | 102.6 | 105.9 | 106.8 | |

| c | 61.6 | 60.5 | 60.8 | 58.6 | 60.1 | 60.4 | 60.2 | 58.4 | 76.4 | 102.9 | 106.3 | 107.3 | |

| H | 30.9 | 31.5 | 29.8 | 32.7 | 30.9 | 30.6 | 30.6 | 30.8 | 78.8 | 94.3 | 95.3 | 95.4 |

| Thermochromic Pigment Powder Concentration (%) | 20° (%) | 60° (%) | 85° (%) |

|---|---|---|---|

| 0 | 12.2 ± 0.4 | 45.5 ± 0.9 | 52.5 ± 0.4 |

| 5.0 | 2.4 ± 0.1 | 12.4 ± 0.3 | 26.9 ± 0.4 |

| 10.0 | 1.1 ± 0 | 6.8 ± 0.1 | 13.5 ± 0.1 |

| 15.0 | 0.7 ± 0 | 3.7 ± 0.1 | 9.2 ± 0.1 |

| 20.0 | 0.4 ± 0 | 2.4 ± 0.1 | 9.4 ± 0.1 |

| 25.0 | 0.3 ± 0 | 1.5 ± 0 | 8.0 ± 0.2 |

| 30.0 | 0.3 ± 0 | 1.4 ± 0 | 7.8 ± 0.1 |

| Thermochromic Pigment Powder Concentration (%) | Damaged Area (%) | Adhesion Grade |

|---|---|---|

| 0 | 0 ± 0 | 0 ± 0 |

| 5.0 | 0 ± 0 | 0 ± 0 |

| 10.0 | 0 ± 0 | 0 ± 0 |

| 15.0 | 0 ± 0 | 0 ± 0 |

| 20.0 | 0 ± 0 | 0 ± 0 |

| 25.0 | 5 ± 0 | 1 ± 0 |

| 30.0 | 5 ± 0 | 1 ± 0 |

| Thermochromic Pigment Powder Concentration (%) | Resistance to the Impact (kg·cm) |

|---|---|

| 0 | 5.0 |

| 5.0 | 5.0 |

| 10.0 | 6.0 |

| 15.0 | 7.0 |

| 20.0 | 7.0 |

| 25.0 | 7.0 |

| 30.0 | 9.0 |

| Thermochromic Pigment Powder Concentration (%) | Chromatic Values | Original | NaCl | Detergent | Ethanol | Red Ink |

|---|---|---|---|---|---|---|

| 0 | L | 85.5 | 85.7 | 86.2 | 86.1 | 73.4 |

| a | 6.1 | 6.3 | 6.8 | 6.2 | 40.2 | |

| b | 29.5 | 30.3 | 30.2 | 30.5 | 19.6 | |

| c | 30.1 | 31.1 | 31.0 | 31.2 | 44.8 | |

| H | 78.1 | 77.0 | 77.5 | 78.6 | 26.0 | |

| 5 | L | 52.2 | 52.5 | 52.8 | 53.1 | 55.9 |

| a | 60.8 | 59.8 | 61.1 | 60.7 | 57.4 | |

| b | 42.7 | 43.1 | 42.9 | 43.1 | 41.4 | |

| c | 74.3 | 73.8 | 75.5 | 74.0 | 70.8 | |

| H | 35.0 | 36.4 | 34.6 | 35.6 | 35.8 | |

| 10 | L | 49.4 | 50.1 | 50.9 | 49.6 | 47.7 |

| a | 60.3 | 61.0 | 59.6 | 59.7 | 64.7 | |

| b | 36.2 | 36.1 | 36.8 | 36.0 | 34.9 | |

| c | 70.3 | 70.9 | 69.5 | 67.2 | 73.5 | |

| H | 31.0 | 30.6 | 31.9 | 30.4 | 28.3 | |

| 15 | L | 50.1 | 49.7 | 49.9 | 49.5 | 48.8 |

| a | 57.2 | 58.1 | 58.1 | 57.6 | 61.7 | |

| b | 34.2 | 33.9 | 33.7 | 34.3 | 32.6 | |

| c | 66.6 | 67.2 | 67.2 | 66.1 | 69.8 | |

| H | 30.8 | 29.7 | 30.1 | 29.3 | 27.8 | |

| 20 | L | 50.6 | 50.2 | 50.8 | 49.8 | 48.4 |

| a | 56.3 | 55.7 | 55.8 | 57.0 | 58.3 | |

| b | 32.8 | 31.9 | 32.3 | 32.6 | 30.3 | |

| c | 65.1 | 64.8 | 64.5 | 64.9 | 65.7 | |

| H | 30.2 | 29.6 | 30.0 | 29.2 | 27.4 | |

| 25 | L | 50.8 | 50.8 | 50.9 | 50.3 | 48.7 |

| a | 53.6 | 54.2 | 54.2 | 54.1 | 57.2 | |

| b | 31.8 | 31.5 | 31.7 | 30.9 | 29.2 | |

| c | 62.3 | 63.3 | 63.7 | 62.8 | 64.2 | |

| H | 30.6 | 29.9 | 29.8 | 29.2 | 27.0 | |

| 30 | L | 50.4 | 50.5 | 50.4 | 49.7 | 48.7 |

| a | 52.8 | 53.6 | 53.9 | 53.7 | 57.0 | |

| b | 31.7 | 31.1 | 31.8 | 30.9 | 29.1 | |

| c | 61.6 | 62.2 | 63.0 | 62.2 | 64.0 | |

| H | 30.9 | 30.0 | 29.2 | 28.8 | 27.0 |

| Thermochromic Pigment Powder Concentration (%) | NaCl | Detergent | Ethanol | Red Ink |

|---|---|---|---|---|

| 0 | 0.8 | 1.2 | 1.2 | 37.5 |

| 5.0 | 1.1 | 0.7 | 1.0 | 5.2 |

| 10.0 | 1.0 | 1.8 | 0.7 | 4.9 |

| 15.0 | 1.0 | 1.0 | 0.7 | 4.9 |

| 20.0 | 1.2 | 0.7 | 1.1 | 3.9 |

| 25.0 | 0.7 | 0.6 | 1.1 | 4.9 |

| 30.0 | 1.0 | 1.1 | 1.4 | 5.2 |

| Thermochromic Pigment Powder Concentration (%) | NaCl | Detergent | Ethanol | Red Ink |

|---|---|---|---|---|

| 0 | 1 | 1 | 1 | 3 |

| 5.0 | 1 | 1 | 1 | 3 |

| 10.0 | 1 | 1 | 1 | 3 |

| 15.0 | 1 | 1 | 1 | 3 |

| 20.0 | 1 | 1 | 1 | 3 |

| 25.0 | 1 | 1 | 1 | 3 |

| 30.0 | 1 | 1 | 1 | 3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Wang, L.; Qian, X. Influence of Thermochromic Pigment Powder on Properties of Waterborne Primer Film for Chinese Fir. Coatings 2019, 9, 742. https://doi.org/10.3390/coatings9110742

Yan X, Wang L, Qian X. Influence of Thermochromic Pigment Powder on Properties of Waterborne Primer Film for Chinese Fir. Coatings. 2019; 9(11):742. https://doi.org/10.3390/coatings9110742

Chicago/Turabian StyleYan, Xiaoxing, Lin Wang, and Xingyu Qian. 2019. "Influence of Thermochromic Pigment Powder on Properties of Waterborne Primer Film for Chinese Fir" Coatings 9, no. 11: 742. https://doi.org/10.3390/coatings9110742

APA StyleYan, X., Wang, L., & Qian, X. (2019). Influence of Thermochromic Pigment Powder on Properties of Waterborne Primer Film for Chinese Fir. Coatings, 9(11), 742. https://doi.org/10.3390/coatings9110742