Manufacturing Errors of Concrete Cover as a Reason of Reinforcement Corrosion in a Precast Element—Case Study

Abstract

1. Introduction

- The geometry of the element;

- Reinforcement distribution;

- Concrete cover parameters.

2. Materials and Methods

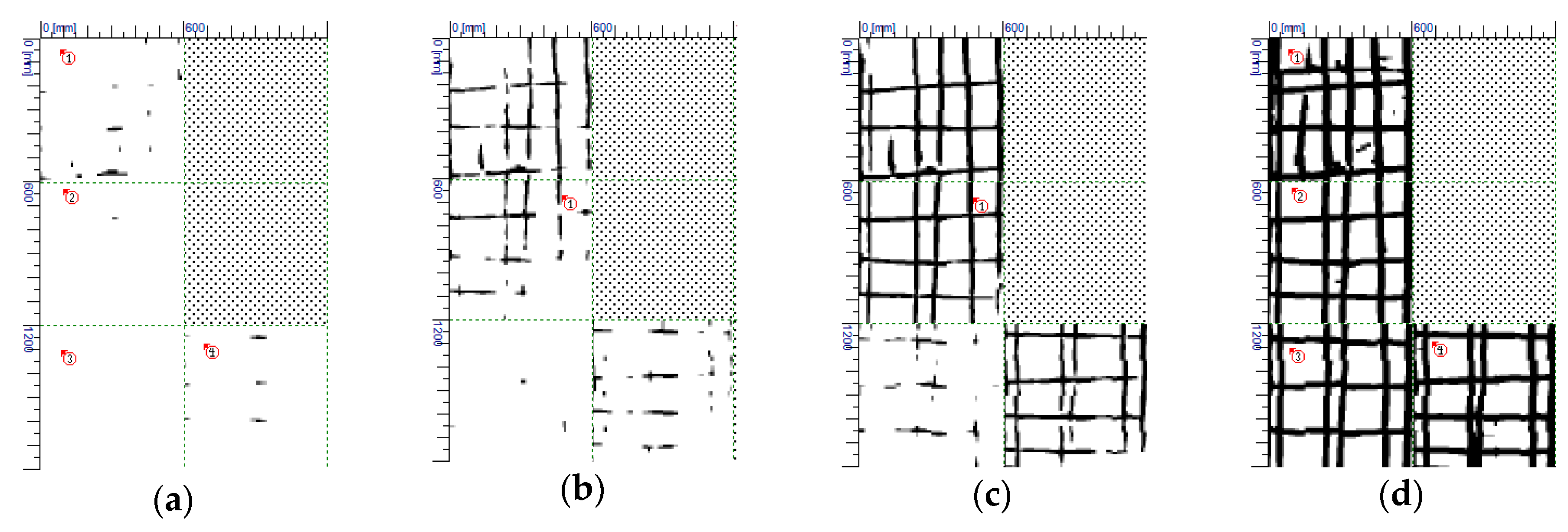

2.1. Measurements of the Reinforcement Distribution and the Concrete Cover Thickness

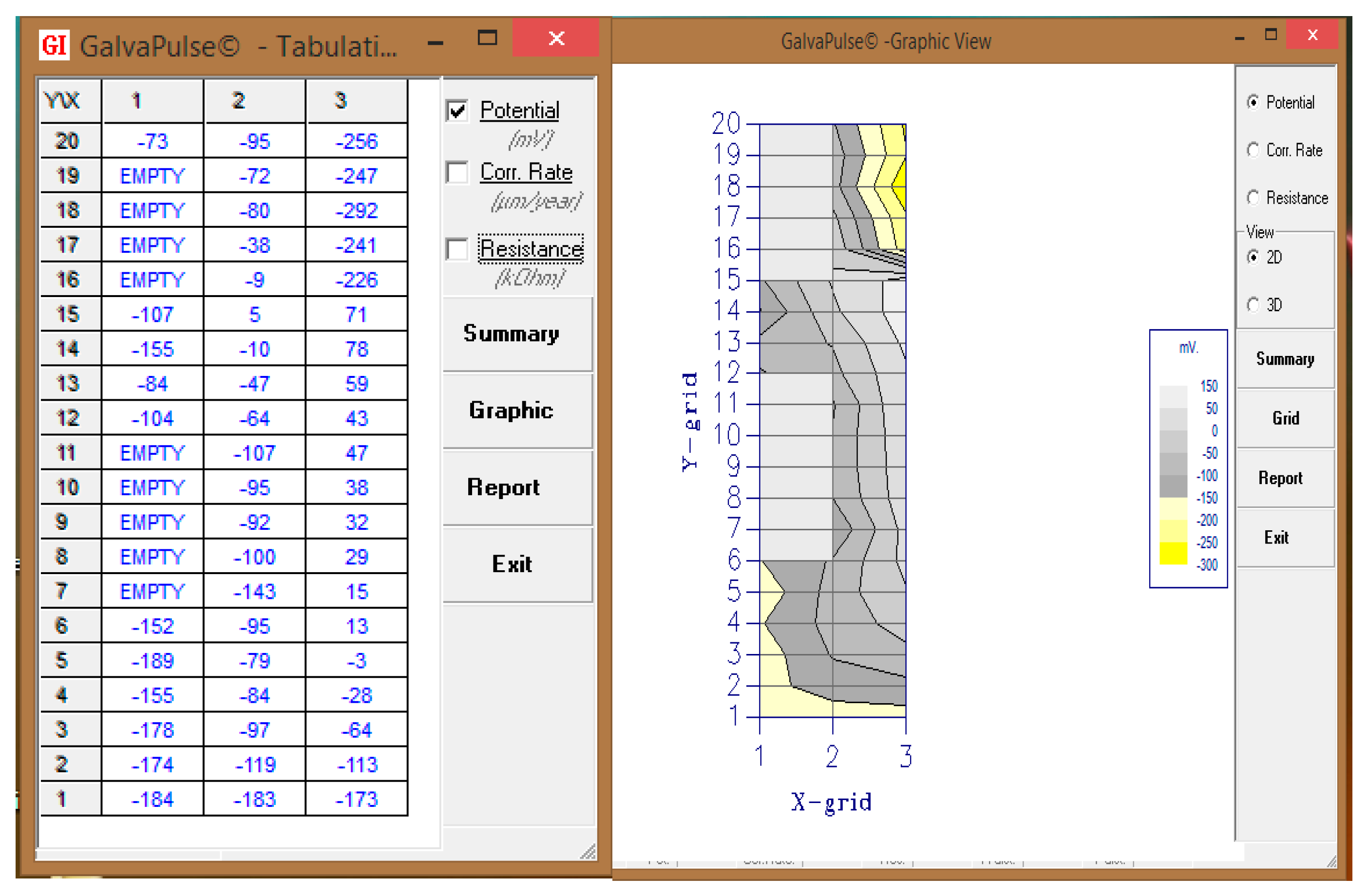

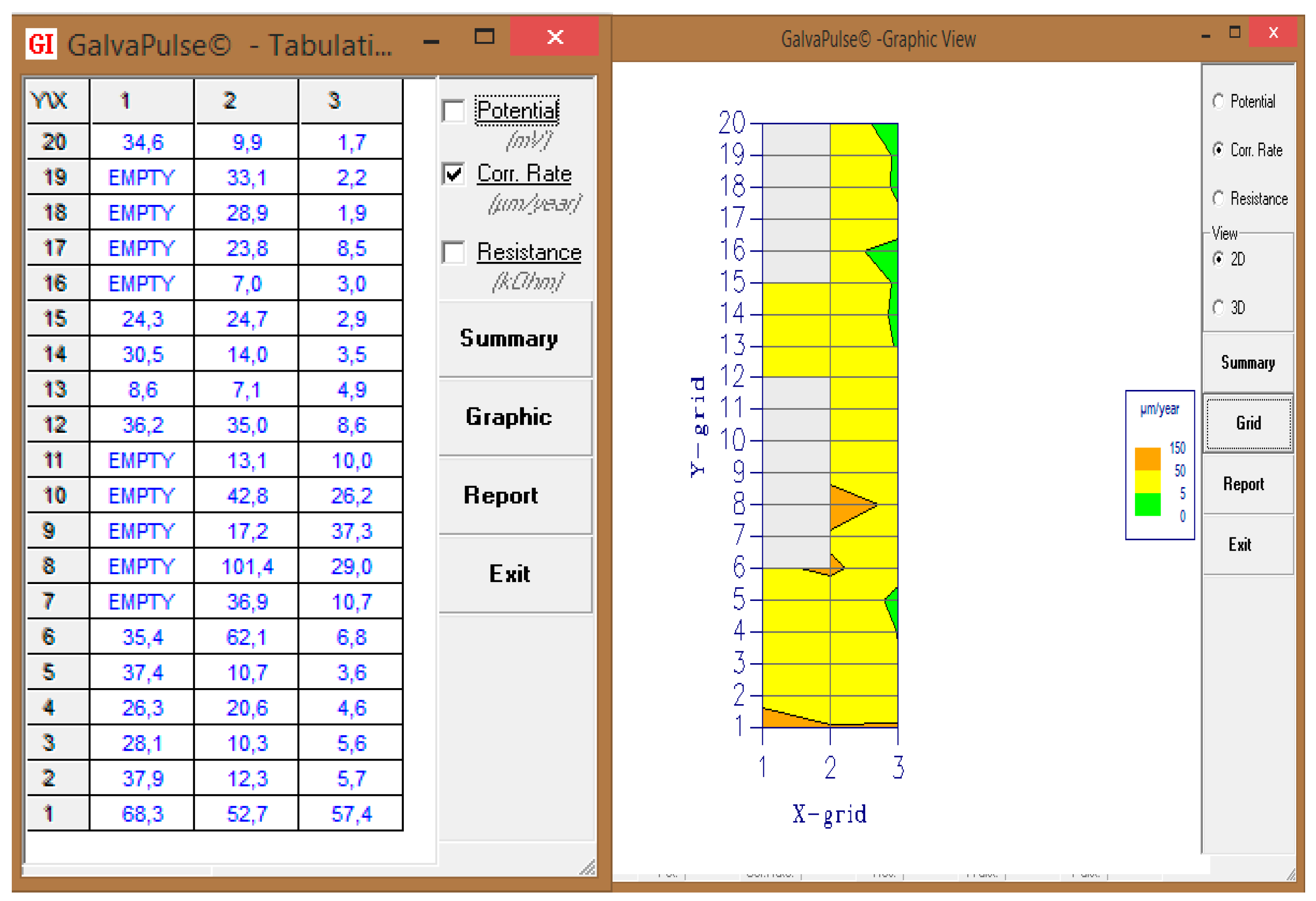

2.2. The Reinforcement Corrosion Test

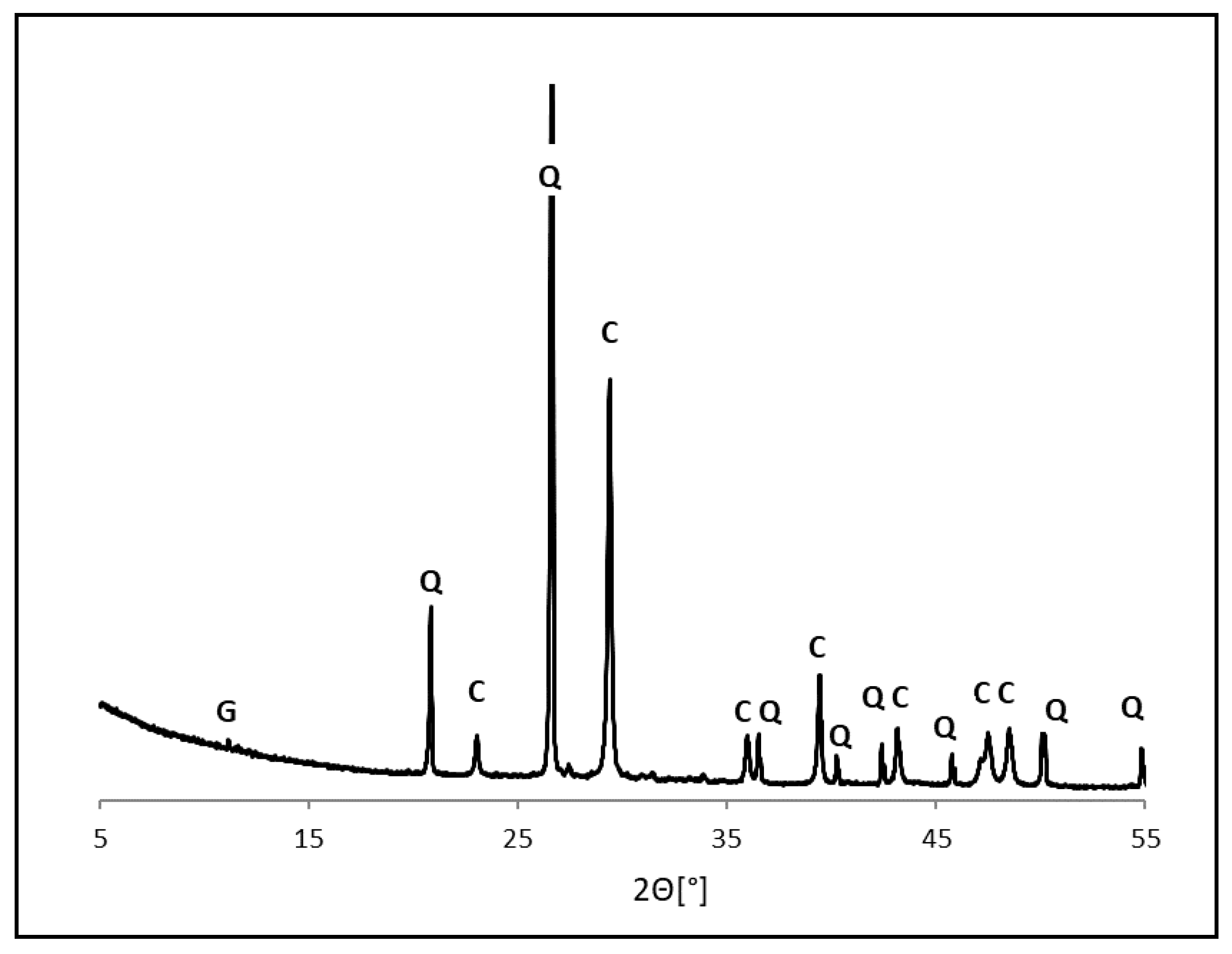

2.3. Test of the Concrete Phase Composition

3. Results and Analysis

3.1. Analysis of the Reinforcement Distribution and the Concrete Cover Thickness

3.2. The Reinforcement Corrosion Test Analysis

3.3. The Analysis of the Concrete Phase Composition

4. Summary and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Beyer, C.; Ortlepp, S.; Naumann, T.; Ortlepp, R. Reinforced concrete roof frames as a typical construction form of the post-war period. Bautechnik 2018, 95, 16–26. [Google Scholar] [CrossRef]

- Borodinecs, A.; Zemitis, J.; Dobelis, M.; Kalinka, M.; Geikins, A. Development of Prefabricated Modular Retrofitting Solution for Post-World War II Buildings. In Proceedings of the Environmental Engineering 10th International Conference, Vilnius Gediminas Technical University, Vilnius, Lithuania, 27–28 April 2017. [Google Scholar]

- Gu, W.; Zhao, Y.; Zhang, D. The Application of PC Technology in Public Buildings: A Case Study of Security Center. In Proceedings of the Twelfth National Athletics, International Conference on Advances in Energy and Environmental Science (ICAEES), Guangzhou, China, 30–31 July 2013. [Google Scholar]

- Segura, I.; Cavalaro, S.; de la Fuente, A.; Aguado, A.; Alegre, V. Service-Life Assessment of Existing Precast Concrete Structure Exposed to Severe Marine Conditions. J. Perform. Constr. Facil. 2016, 30, 1–14. [Google Scholar] [CrossRef]

- Melchers, R.E.; Li, C.Q. Reinforcement Corrosion in Concrete Exposed to the North Sea for More Than 60 Years. Corrosion 2009, 65, 554–566. [Google Scholar] [CrossRef]

- Saffiuddin, M. Concrete damage in Field Conditions and Protective Sealer and Coating Systems. Coatings 2017, 7, 90. [Google Scholar] [CrossRef]

- Tworzewski, P.; Szczecina, M.; Uzarska, I. Numerical Modeling of Reinforced Concrete Beams, Including the Real Position of Reinforcing Bars. Struct. Environ. 2018, 10, 28–38. [Google Scholar]

- Tworzewski, P.; Goszczyńska, B. Relation between Reliability and Reinforcement Manufacturing Errors in Reinforced Concrete Beams. Struct. Environ. 2017, 9, 16–24. [Google Scholar]

- Tworzewski, P.; Goszczyńska, B. An Application of an Optical Measuring System to Reinforced Concrete Beams Analysis. In Proceedings of the 2016 Prognostics and System Health Management Conference (PHM-Chengdu), Chengdu, China, 19–21 October 2016. [Google Scholar]

- Parasonis, J. Quality control with the assurance of normative precision of geometrical parameters in erection of one-storey framed buildings. In Proceedings of the 8th International Conference on Durability of Building Materials and Components (8dbmc), Vancouver, BC, Canada, 30 May–3 June 1999. [Google Scholar]

- Li, J.; Ji, Y.; Huang, G.; Zhang, L. Microstructure Evolution of Magnesium Phosphate Protective Layer on Concrete Structures in a Sulfate Environment. Coatings 2018, 8, 140. [Google Scholar] [CrossRef]

- Li, G.; Cui, H.; Zhou, J.; Hu, W. Improvements of Nano-TiO2 on the Long-Term Chloride Resistance of Concrete with Polymer Coatings. Coatings 2019, 9, 323. [Google Scholar] [CrossRef]

- Climent, M.A.; Carmona, J.; Garces, P. Graphite-Cement Paste: A New Coating of Reinforced Concrete Structural Elements for the Application of Electrochemical Anti-Corrosion Treatments. Coatings 2016, 6, 32. [Google Scholar] [CrossRef]

- Concrete, Reinforced Concrete and Prestressed Structures. Static Calculations and Design; PN-84/B-03264; Polish Standardization, Measurement and Quality Committee: Warsaw, Poland, 1986; [Konstrukcje betonowe, żelbetowe i sprężone. Obliczenia statyczne i projektowanie in Polish].

- LST, E. PN-EN 206–1 Concrete—Part 1: Specification, Performance, Production and Conformity; British Standards Institution: London, UK, 2002. [Google Scholar]

- Steel for Determined Purposes—Steel for Concrete Reinforcement—Grades; PN-89/H-84023/06; Polish Standardization, Measurement and Quality Committee: Warsaw, Poland, 1989; [Stal określonego zastosowania. Stal do zbrojenia betonu. Gatunki. in Polish].

- Eurocode 2—Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings; PN-EN 1992-1-1; European Committee for Standardization: Brussels, Belgium, 2004.

- Urbanowicz, D.; Warzocha, M. Wykorzystanie urządzeń ferromagnetycznych w diagnostyce konstrukcji budowlanych. Prz. Bud. 2015, 5, 32–35. [Google Scholar]

- De Alcantara, N.P.; Costa, D.C.; Guedes, D.S.; Artori, R.V.; Bastos, P.S. A Non-Destructive Testing Based on Electromagnetic Measurements and Neural Networks for the Inspection of Concrete Structures. Adv. Mater. Res. 2011, 301, 597–602. [Google Scholar] [CrossRef]

- Salman, A.A. Non-Destructive Test of Concrete Structures Using: FERROSCAN. Eng. Technol. J. 2011, 29, 2933–2941. [Google Scholar]

- Ahmad, S. Reinforcement corrosion in concrete structures, its monitoring and service life prediction—A review. Cem. Concr. Compos. 2003, 25, 459–473. [Google Scholar] [CrossRef]

- Poursaee, A.; Hanson, C.M. Galvanostatic pulse technique with the current confinement guard ring: The laboratory and finite element analysis. Corros. Sci. 2008, 50, 2739–2746. [Google Scholar] [CrossRef]

- Song, H.W.; Saraswathy, V. Corrosion monitoring of reinforced concrete structures—A review. Int. J. Electrochem. Sci. 2007, 2, 1–28. [Google Scholar]

- Standard Test Method for Half-Cell Potentials of Uncoated Reinforcing Steel in Concrete. In American Society of Testing and Materials; ASTM C876–09; ASTM: West Conshohocken, PA, USA, 2009.

- Klinghoffer, O. In situ monitoring of reinforcement corrosion by means of electrochemical methods. Nord. Concr. Res. 1995, 1, 1–13. [Google Scholar]

- Elsner, B.; Klinghoffer, O.; Frolund, T.; Rislund, E.; Schiegg, Y.; Böhni, H. Assessment of Reinforcement Corrosion by Means of Galvanostatic Pulse Technique. In Proceedings of the International Conference Repair of Concrete Structures Norway, Svolvaer, Norway, 28–30 May 1997. [Google Scholar]

- Frølund, T.; Klinghoffer, O.; Poulsen, E. Rebar Corrosion Rate Measurements for Service Life Estimates; ACI Fall Convention: Toronto, ON, Canada, 2000. [Google Scholar]

- Vedalakshmi, R.; Balamurugan, L.; Saraswathy, V.; Kim, S.-H.; Ann, K.Y. Reliability of Galvanostatic Pulse Technique in Assessing the Corrosion Rate of Rebar in Concrete Structures: Laboratory vs Field Studies. KSCE J. Civ. Eng. 2010, 14, 867–877. [Google Scholar] [CrossRef]

- Standard Test Method for Bulk Electrical Resistivity or Bulk Conductivity of Concrete; ASTM C1876–19; ASTM: West Conshohocken, PA, USA, 2012.

- Nikoo, M.; Sadowski, Ł.; Nikoo, M. Prediction of the Corrosion Current Density in Reinforced Concrete Using a Self-Organizing Feature Map. Coatings 2017, 7, 160. [Google Scholar] [CrossRef]

- Raczkiewicz, W.; Wójcicki, A. Evaluation of effectiveness of concrete coat as a steel bars protection in the structure—Galvanostatic pulse method. In Proceedings of the 26th International Conference Metallurgy and Materials, Brno, Czech Republic, 24–26 May 2017; pp. 1425–1431. [Google Scholar]

- Raczkiewicz, W. Influence of the Air-Entraining Agent in the Concrete Coating on the Reinforcement Corrosion Process in Case of Simultaneous Action of Chlorides and Frost. Adv. Mater. Sci. 2018, 18, 13–19. [Google Scholar] [CrossRef]

- Galva Pulse. Available online: http://www.germann.org/TestSystems/GalvaPulse/GalvaPulse.pdf (accessed on 28 September 2019).

- Anticorrosive Protection in Construction. Concrete and Reinforced Concrete Structures. Classification and Definition of Environments; PN-80/B-01800; Polish Standardization, Measurement and Quality Committee: Warsaw, Poland, 1981; [Antykorozyjne zabezpieczenia w budownictwie. Konstrukcje betonowe i żelbetowe. Klasyfikacja i określenie środowisk in Polish].

- Rasheeduzzafar. Influence of Cement Composition on Concrete Durability. ACI Mater. J. 1992, 89, 574–586. [Google Scholar]

- Cement Aggregates Concrete. Available online: https://www.gorazdze.pl/pl/system/files_force/assets/document/c2__korozja_chemiczna_betonu.pdf?download=1 (accessed on 28 September 2019).

| Nr | fci,CUBE [MPa] | fcm,CUBE [MPa] | Standard Deviations [MPa] | Coefficient of Variation ϑ [%] |

|---|---|---|---|---|

| 1 | 41.8 | 39.6 | 5.1 | 12.90% |

| 2 | 33.8 | |||

| 3 | 47.1 | |||

| 4 | 35.8 | |||

| 5 | 34.6 | |||

| 6 | 44.3 |

| Steel Type | Re [16] (fyk [17]), [MPa] | C [%] | Si [%] | Mn [%] | P [%] | S [%] | Cu [%] | Cr [%] | Ni [%] | Mo [%] |

|---|---|---|---|---|---|---|---|---|---|---|

| St3SX | 240 | Max 0.22 | Max 0.07 | Max 1.10 | Max 0.05 | Max 0.50 | Max 0.30 | Max 0.30 | Max 0.30 | Max 0.10 |

| 18G2 | 355 | 0.15 ÷ 0.22 | 0.20 ÷ 0.55 | 1.00 ÷ 1.50 | Max 0.05 | Max 0.05 | Max 0.35 | Max 0.30 | Max 0.30 | Max 0.10 |

| Criteria for Assessing the Degree of Reinforcement Corrosion Risk by Use the Galvanostatic Pulse Method | ||||

|---|---|---|---|---|

| Reinforcement Corrosion Activity | Corrosion Pace; [mm·year−1] | |||

| On the basis of corrosion current density | icor [μA·cm−2] | <0.5 | not forecasted corrosion activity | <0.006 |

| 0.5 ÷ 2.0 | irrelevant activity corrosion | 0.006 ÷ 0.023 | ||

| 2.0 ÷ 5.0 | low corrosion activity | 0.023 ÷ 0.058 | ||

| 5.0 ÷ 15.0 | moderate corrosion activity | 0.058 ÷ 0.174 | ||

| >15.0 | high corrosion activity | >0.174 | ||

| On the basis of reinforcement stationary potential | Est [mV] | <−350 | 95% of corrosion probability | |

| −350 ÷ −200 | 50% of corrosion probability | |||

| >−200 | 5% of corrosion probability | |||

| On the basis of concrete cover resistivity | Θ [kΩ⋅cm] | ≤10 | high corrosion probability | |

| 10 ÷ 20 | medium corrosion probability | |||

| ≥20 | small corrosion probability | |||

| Measuring Point | Concrete Cover [mm] | Average Cover [mm] | Coefficients of Variation [%] | Minimum Standard Concrete Cover by [14] [mm] | Required Concrete Cover by [14] [mm] | Differences in Concrete Cover [mm] |

|---|---|---|---|---|---|---|

| C1 | 5 | 7.3 | 24.24% | 20 | 25 | −20 |

| C2 | 6 | −19 | ||||

| C3 | 6 | −19 | ||||

| C4 | 7 | −18 | ||||

| C5 | 6 | −19 | ||||

| C6 | 5 | −20 | ||||

| C7 | 9 | −16 | ||||

| C8 | 10 | −15 | ||||

| C9 | 8 | −17 | ||||

| C10 | 8 | −17 | ||||

| C11 | 10 | −15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bacharz, K.; Raczkiewicz, W.; Bacharz, M.; Grzmil, W. Manufacturing Errors of Concrete Cover as a Reason of Reinforcement Corrosion in a Precast Element—Case Study. Coatings 2019, 9, 702. https://doi.org/10.3390/coatings9110702

Bacharz K, Raczkiewicz W, Bacharz M, Grzmil W. Manufacturing Errors of Concrete Cover as a Reason of Reinforcement Corrosion in a Precast Element—Case Study. Coatings. 2019; 9(11):702. https://doi.org/10.3390/coatings9110702

Chicago/Turabian StyleBacharz, Kamil, Wioletta Raczkiewicz, Magdalena Bacharz, and Wioletta Grzmil. 2019. "Manufacturing Errors of Concrete Cover as a Reason of Reinforcement Corrosion in a Precast Element—Case Study" Coatings 9, no. 11: 702. https://doi.org/10.3390/coatings9110702

APA StyleBacharz, K., Raczkiewicz, W., Bacharz, M., & Grzmil, W. (2019). Manufacturing Errors of Concrete Cover as a Reason of Reinforcement Corrosion in a Precast Element—Case Study. Coatings, 9(11), 702. https://doi.org/10.3390/coatings9110702