The Effect of Laser Power on the Interface Microstructure of a Laser Remelting Nano-SiC Modified Fe-Based Ni/WC Composite Coating

Abstract

1. Introduction

2. Experimental Work

2.1. Coating Preparation

2.2. Analysis and Characterisation

3. Results and Analysis

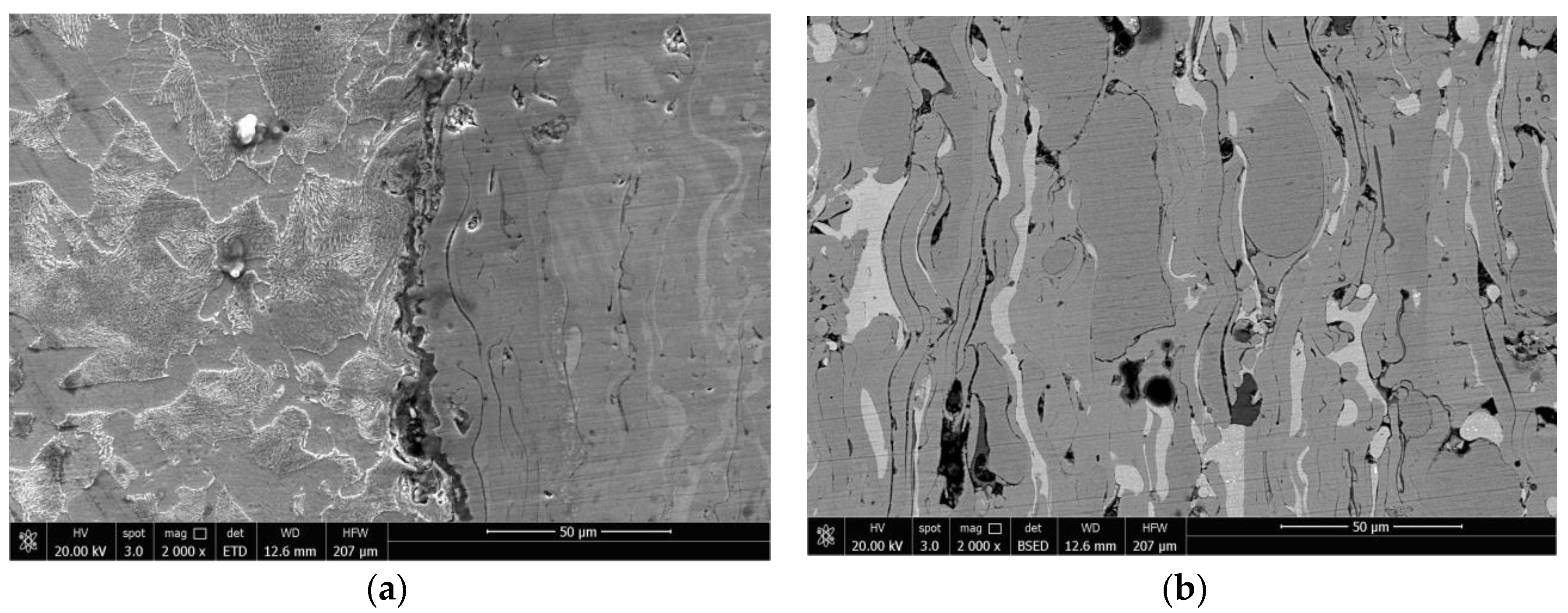

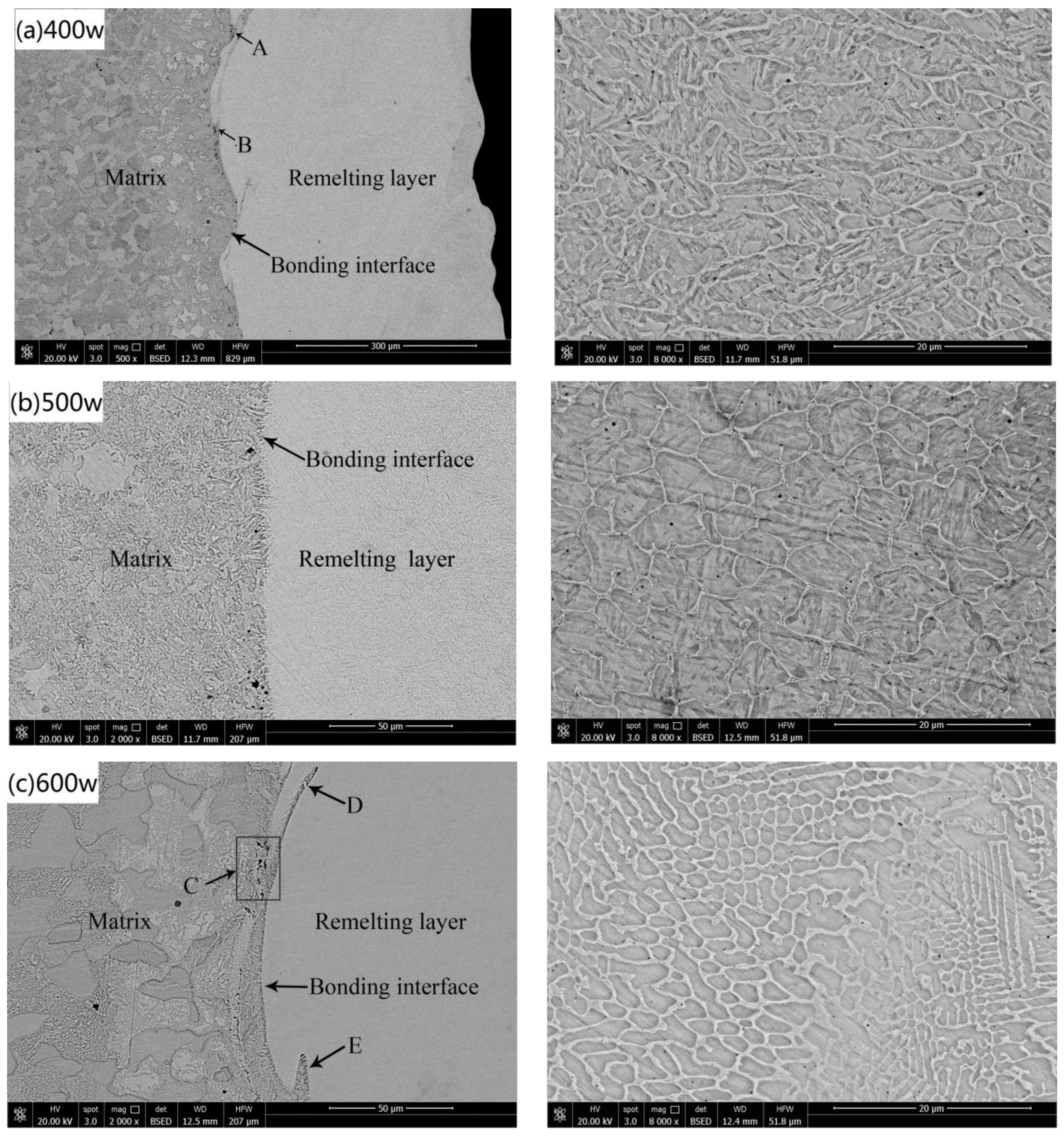

3.1. Analysis of Interface Morphology

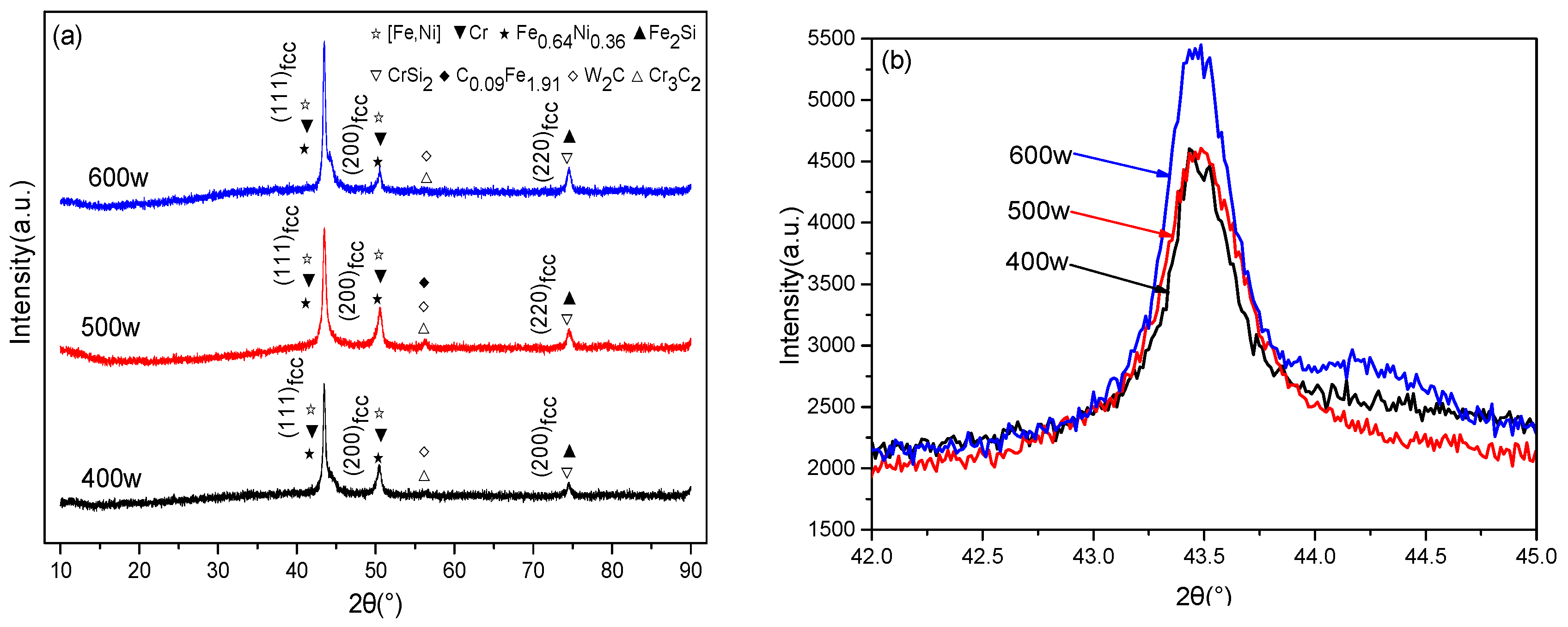

3.2. Phase and Grain Analysis

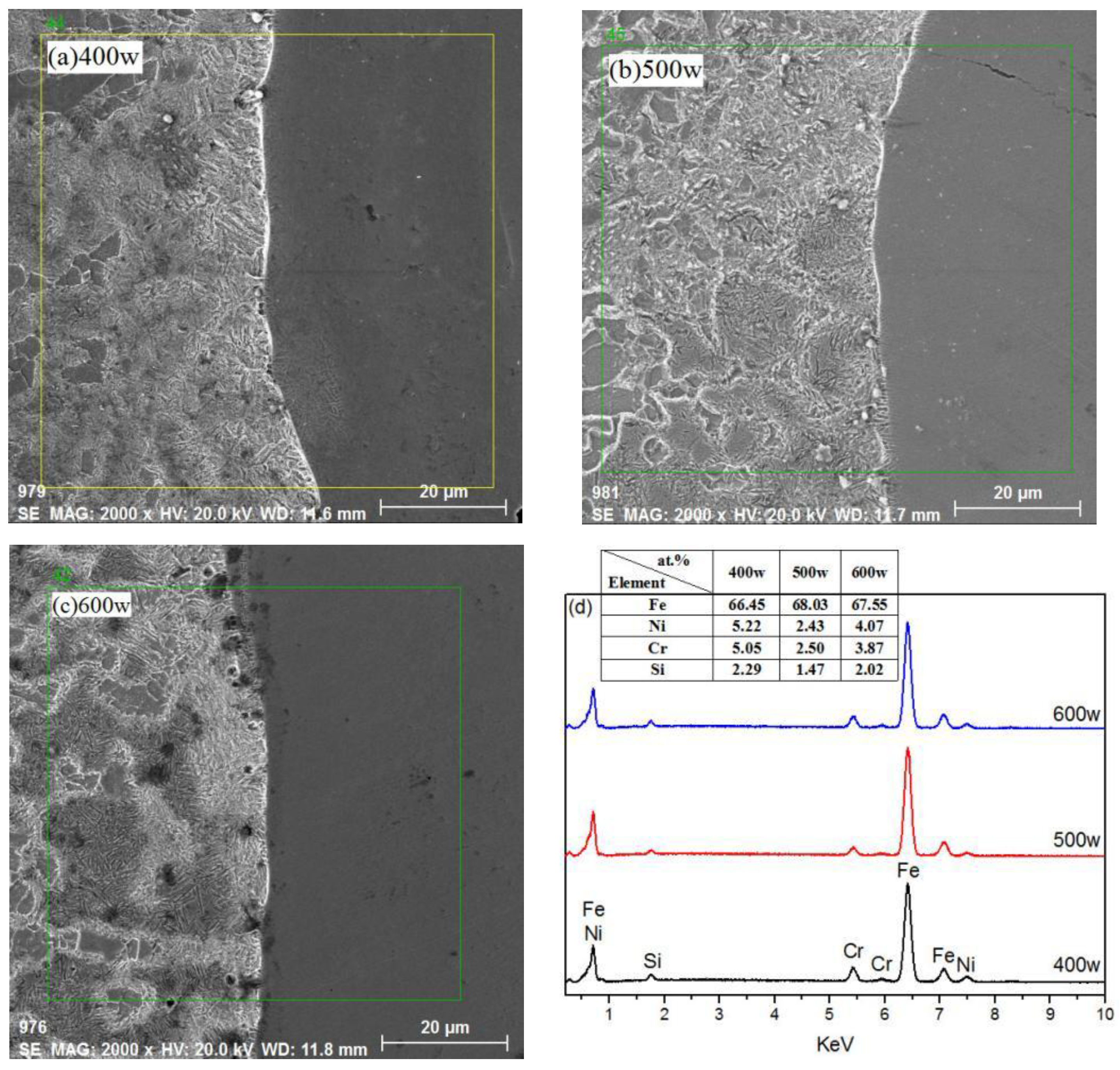

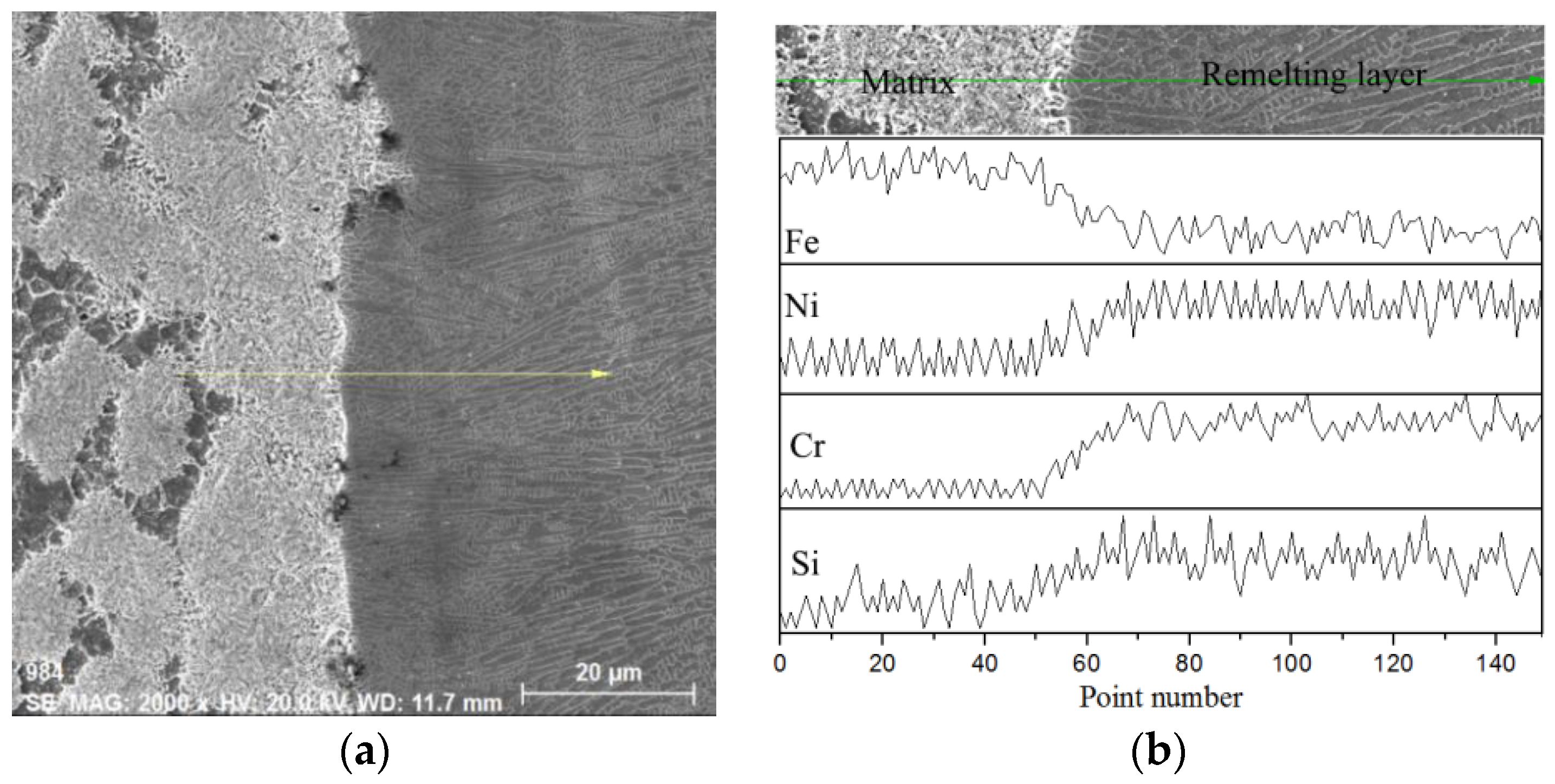

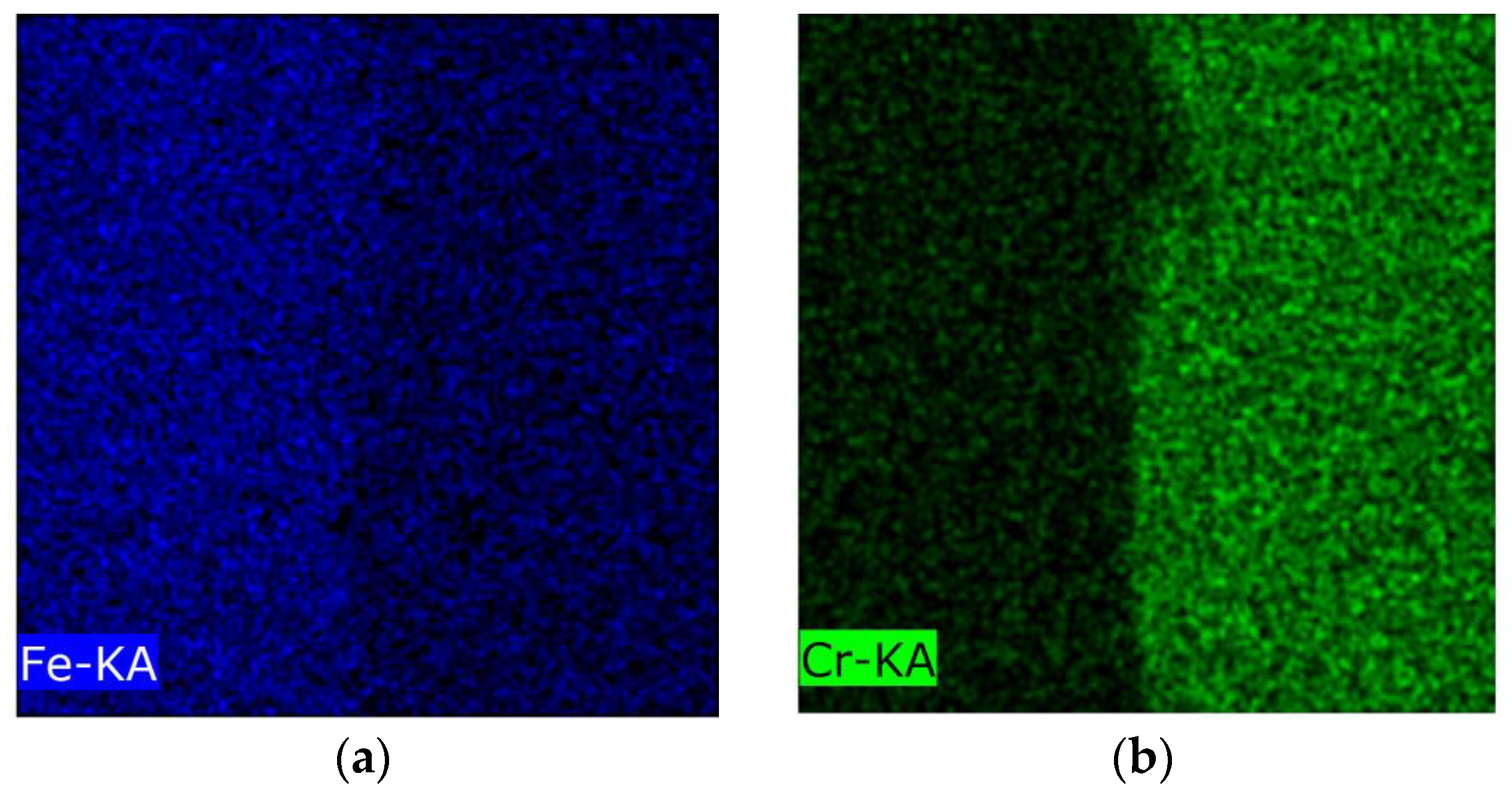

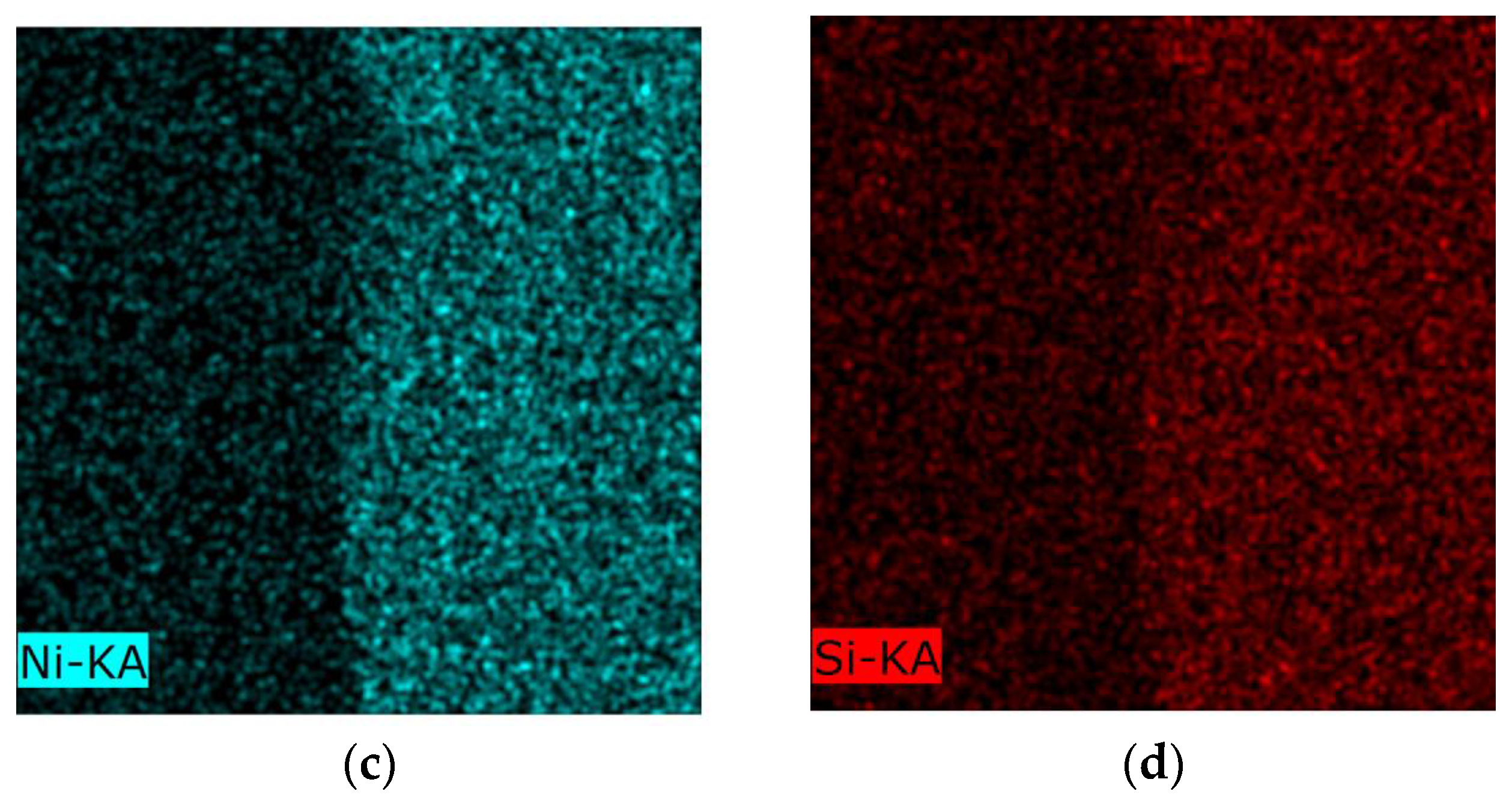

3.3. Analysis of the Coating Interface Elements

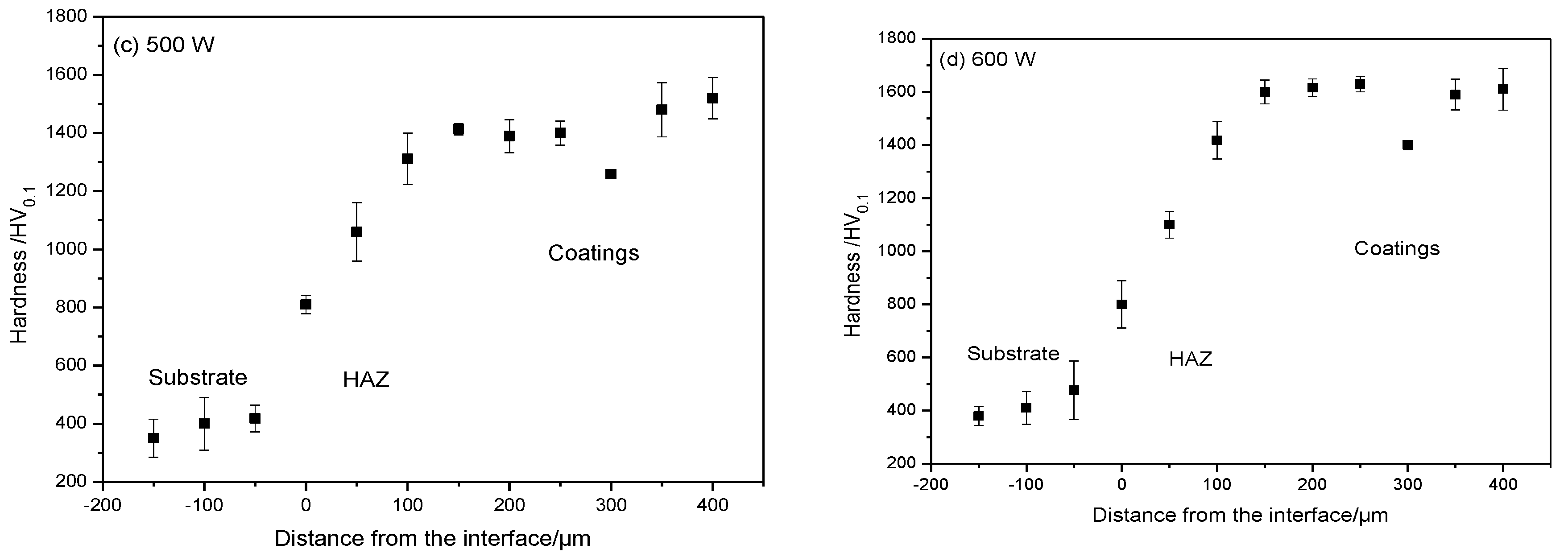

3.4. Micro-Hardness Analysis

4. Conclusions

- The interface of the plasma spraying coating contained several large holes and obvious interlayer cracks. A layered structure and mechanical bonding were the main features.

- After laser remelting, the nano-SiC modified remelting coating was smooth and dense without fine cracks. The interfacial metallurgical bonding, caused by the interdiffusion of metal elements Fe, Ni, Cr, and Si, reached the best effect at 500 W. The nano-SiC modified remelting layer was mainly composed of [Fe,Ni], Cr, Fe0.04Ni0.36 phases.

- The nano-sized SiC particles served as the core of the heterogeneous nucleation to refine the grains on the one hand, and promote the formation of a hard intermediate phase in the coating on the other hand. Therefore, the addition of nano-SiC particles improved the microhardness of the coating greatly. With increasing laser power, the hardness increased in general terms and the maximum hardness increased by 51%.

- With the increase of power, the average grain size and half-peak height (FWHM) became smaller and wider, respectively. The greater the laser power, the lesser the corresponding number of holes. When the laser power was 600 W, a complete “fishbone type” of network structure could be found.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, F.; He, J.; Chen, K.; Qin, Y.; Li, C.; Yin, F. Microstructure evolution and mechanical properties of TiCN-Cr nano/micro composite coatings prepared by reactive plasma spraying. Appl. Surf. Sci. 2018, 428, 905–914. [Google Scholar] [CrossRef]

- Nishinoiri, S.; Enoki, M.; Tomita, K. In situ monitoring of microfracture during plasma spray coating by laser AE technique. Sci. Technol. Adv. Mater. 2003, 4, 623–631. [Google Scholar] [CrossRef]

- Gao, Y.; Jie, M.; Liu, Y. Mechanical properties of Al2O3 ceramic coatings prepared by plasma spraying on magnesium alloy. Surf. Coat. Technol. 2017, 315, 214–219. [Google Scholar] [CrossRef]

- Yumiba, N. Trend of thermal spray industry and applications. Therm. Spray Technol. 2010, 3, 452–457. [Google Scholar]

- Yasuo, N.; Nagai, M. Thermal spray coating on conductor rolls in electroplating line. Baosteel Tech. Res. 2010, 4, 41. [Google Scholar]

- González, R.; Cadenas, M.; Fernández, R.; Cortizo, J.L.; Rodríguez, E. Wear behaviour of flame sprayed NiCrBSi coating remelted by flame or by laser. Wear 2007, 262, 301–307. [Google Scholar] [CrossRef]

- Lei, J.; Shi, C.; Zhou, S.; Gu, Z.; Zhang, L. Enhanced corrosion and wear resistance properties of carbon fiber reinforced Ni-based composite coating by laser cladding. Surf. Coat. Technol. 2018, 334, 274–285. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, G.; Feng, Z.; Zhang, B.; Liang, Y.; Liu, F. Oxidation behavior of laser remelted plasma sprayed NiCrAlY and NiCrAlY-Al2O3 coatings. Surf. Coat. Technol. 2001, 138, 56–60. [Google Scholar] [CrossRef]

- Shi, C.; Lei, J.; Zhou, S.; Dai, X.; Zhang, L. Microstructure and mechanical properties of carbon fibers strengthened Ni-based coatings by laser cladding: The effect of carbon fiber contents. J. Alloys Compd. 2018, 744, 146–155. [Google Scholar] [CrossRef]

- Ma, Q.; Li, Y.; Wang, J.; Liu, K. Homogenization of carbides in Ni60/WC composite coatings made by fiber laser remelting. Mater. Manuf. Processes 2015, 30, 1417–1424. [Google Scholar]

- Yu, P.; Zhang, L.; Zhang, W.; Das, J.; Kim, K.B.; Eckert, J. Interfacial reaction during the fabrication of Ni60Nb40 metallic glass particles-reinforced Al based MMCs. Mater. Sci. Eng. A 2007, 444, 206–213. [Google Scholar] [CrossRef]

- Liu, W.; Sheng, T.; Kong, D. Effects of laser remelting on surface-interface morphologies, bonding modes and corrosion performances of arc-sprayed Al coating. Anti-Corros. Methods Mater. 2017, 64, 43–51. [Google Scholar]

- Movchan, B.A.; Marinski, G.S. Gradient protective coatings of different application produced by EB-PVD. Surf. Coat. Technol. 1998, 100–101, 309–315. [Google Scholar] [CrossRef]

- Gao, X.; Tian, Z.; Liu, Z.; Shen, L. Interface characteristics of Al2O3–13%TiO2 ceramic coatings prepared by laser cladding. Trans. Nonferrous Met. Soc. China 2012, 22, 2498–2503. [Google Scholar] [CrossRef]

- Jia, Z.; Li, J.; Liu, L.; Liu, Y.; Wang, Y.; Li, H. Influence and application of laser parameters on unit of H13 steel by laser remelting process. Int. J. Adv. Manuf. Technol. 2015, 79, 551–568. [Google Scholar] [CrossRef]

- Ciubotariu, C.-R.; Frunzăverde, D.; Mărginean, G.; Șerban, V.-A.; Bîrdeanu, A.-V. Optimization of the laser remelting process for HVOF-sprayed Stellite 6 wear resistant coatings. Opt. Laser Technol. 2016, 77, 98–103. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Guo, L.; Tian, W. Laser remelting of plasma sprayed nanostructured Al2O3-TiO2 coatings at different laser power. Surf. Coat. Technol. 2010, 204, 3559–3566. [Google Scholar] [CrossRef]

- Klug, H.P.; Alexander, L.E. X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials; Wiley: Hoboken, NJ, USA, 1974. [Google Scholar]

- Ungár, T.; Langford, J.I.; Cernik, R.J.; Vörös, G.; Pflaumer, R.; Oszlányi, G.; Kovács, I. Microbeam X-ray diffraction studies of structural properties of polycrystalline metals by means of synchrotron radiation. Mater. Sci. Eng. A 1998, 247, 81–87. [Google Scholar] [CrossRef]

- Zhang, W. Welding Metallurgy; Machinery Industry Press: Beijing, China, 1997; pp. 116–127. (In Chinese) [Google Scholar]

- Gell, M.; Jordan, E.H.; Sohn, Y.H.; Goberman, D.; Shaw, L.; Xiao, T. Development and implementation of plasma sprayed nanostructured ceramic coatings. Surf. Coat. Technol. 2001, 146–147, 48–54. [Google Scholar] [CrossRef]

- Lima, R.S.; Kucuk, A.; Berndt, C.C. Integrity of nanostructured partially stabilized zirconia after plasma spray processing. Mater. Sci. Eng. A 2001, 313, 75–82. [Google Scholar] [CrossRef]

- Anderson, P.M.; Li, C. Hall-petch relations for multilayered materials. Nanostruct. Mater. 1995, 5, 349–362. [Google Scholar] [CrossRef]

| Element | Content | Measured Value |

|---|---|---|

| Ni | 8–12 | 8.9 |

| Cr | 15–20 | 16.4 |

| B | 1.5–3 | 2.1 |

| Si | 1.5–3 | 1.9 |

| C | <0.5 | – |

| Fe | Trace | – |

| Element | Content | Measured Value |

|---|---|---|

| Ni | Trace | – |

| Cr | 15–20 | 17.2 |

| B | 3.0–4.5 | 3.1 |

| Si | 3.5–5 | 4.1 |

| C | 0.5–1.1 | 0.93 |

| Fe | ≤10 | 9.3 |

| WC | 35 | 35 |

| Laser Power (P/W) | Scanning Speed (V) (mm/min) | Spot Diameter (D) (mm) |

|---|---|---|

| 400 | 200 | 1.5 |

| 500 | 200 | 1.5 |

| 600 | 200 | 1.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; He, W.; Du, H.; Luo, P. The Effect of Laser Power on the Interface Microstructure of a Laser Remelting Nano-SiC Modified Fe-Based Ni/WC Composite Coating. Coatings 2018, 8, 297. https://doi.org/10.3390/coatings8090297

Zhao Y, He W, Du H, Luo P. The Effect of Laser Power on the Interface Microstructure of a Laser Remelting Nano-SiC Modified Fe-Based Ni/WC Composite Coating. Coatings. 2018; 8(9):297. https://doi.org/10.3390/coatings8090297

Chicago/Turabian StyleZhao, Yuncai, Wen He, Huihui Du, and Peng Luo. 2018. "The Effect of Laser Power on the Interface Microstructure of a Laser Remelting Nano-SiC Modified Fe-Based Ni/WC Composite Coating" Coatings 8, no. 9: 297. https://doi.org/10.3390/coatings8090297

APA StyleZhao, Y., He, W., Du, H., & Luo, P. (2018). The Effect of Laser Power on the Interface Microstructure of a Laser Remelting Nano-SiC Modified Fe-Based Ni/WC Composite Coating. Coatings, 8(9), 297. https://doi.org/10.3390/coatings8090297