Effects of sp2/sp3 Ratio and Hydrogen Content on In Vitro Bending and Frictional Performance of DLC-Coated Orthodontic Stainless Steels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. DLC Coating Procedure

2.3. Phase Identification by X-ray Diffraction and Scanning Electron Microscopy of the Coating

2.4. Compositional Characterization of the Coating by High-Resolution Elastic Recoil Analysis and Microscale X-ray Photoelectron Spectroscopy

2.5. Mechanical Properties of the Coating from Nanoindentation and Three-Point Bending Testing

2.6. Evaluation of the Elastic Modulus of the DLC-Coated Wires by the Three-Point Bending Testing

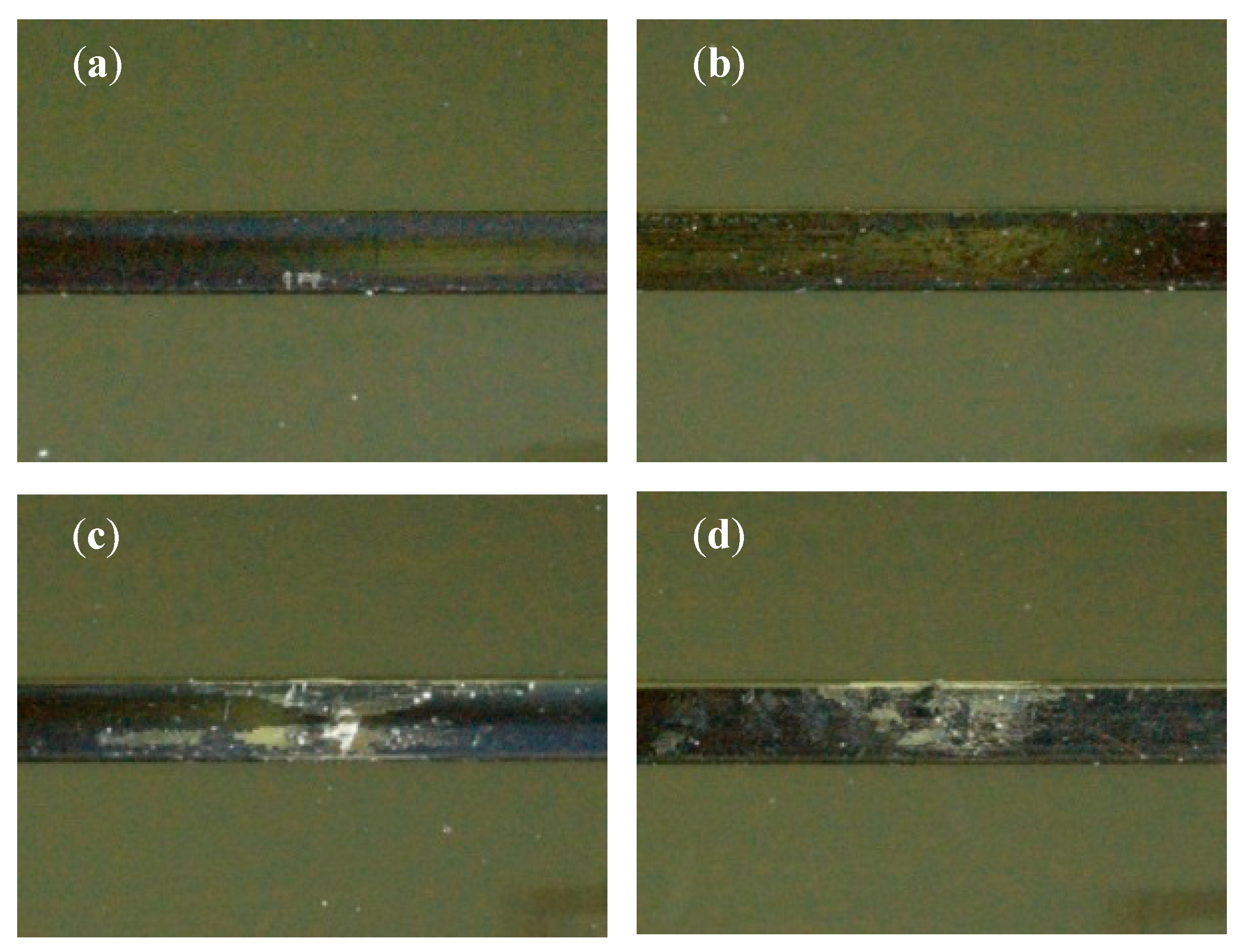

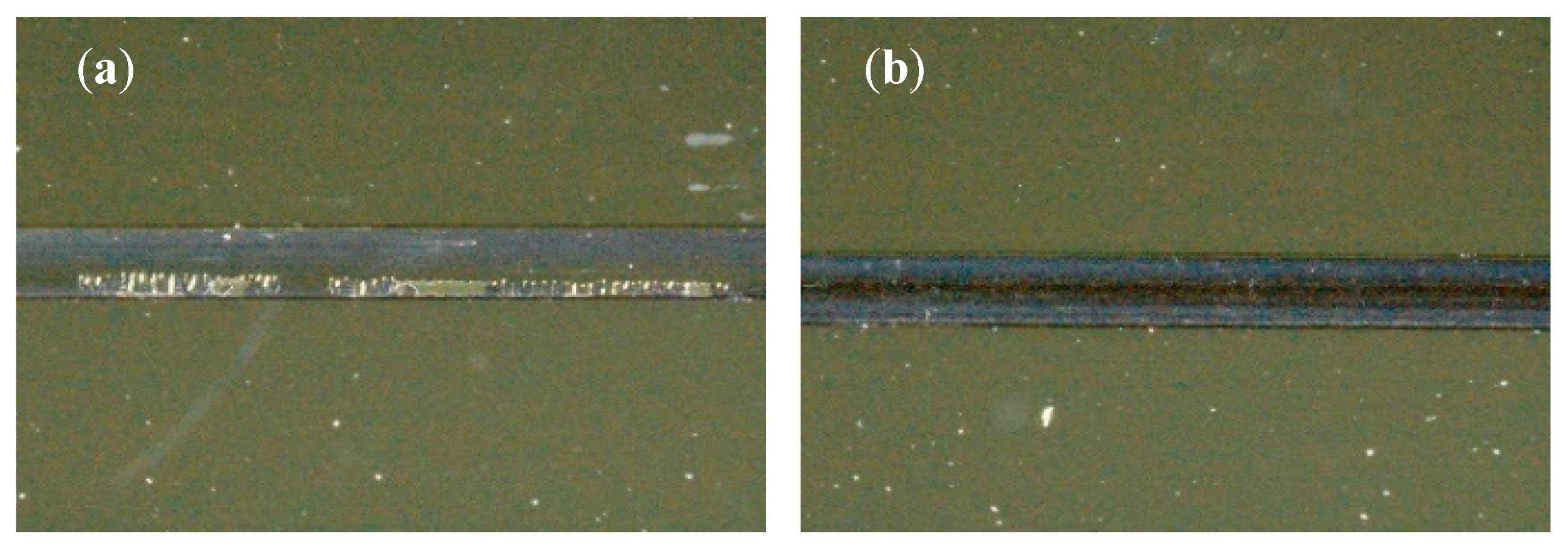

2.7. Frictional Properties Measured by the Progressive Load Scratch Test and Drawing Friction Test

2.8. Statistical Analyses

3. Results

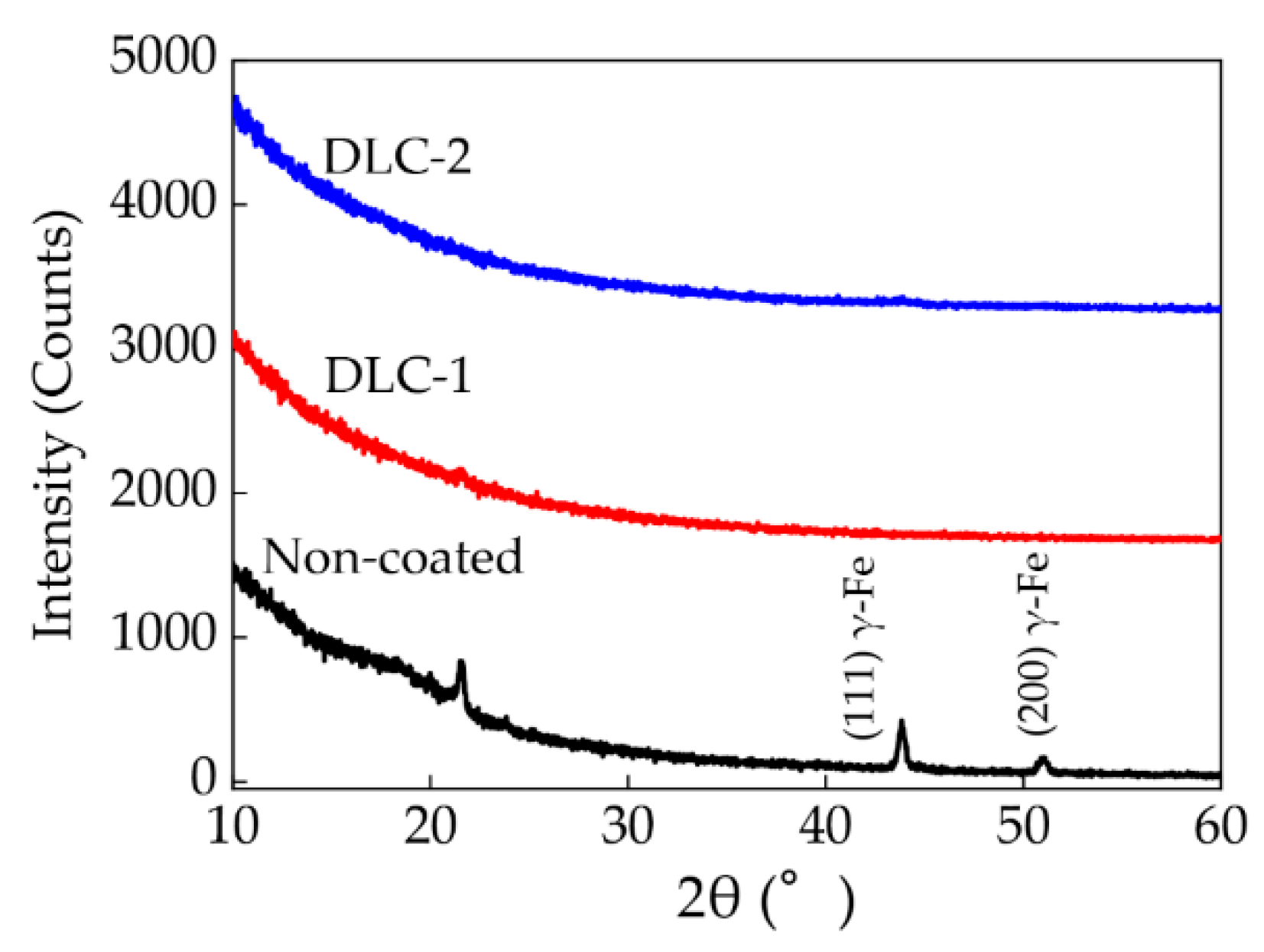

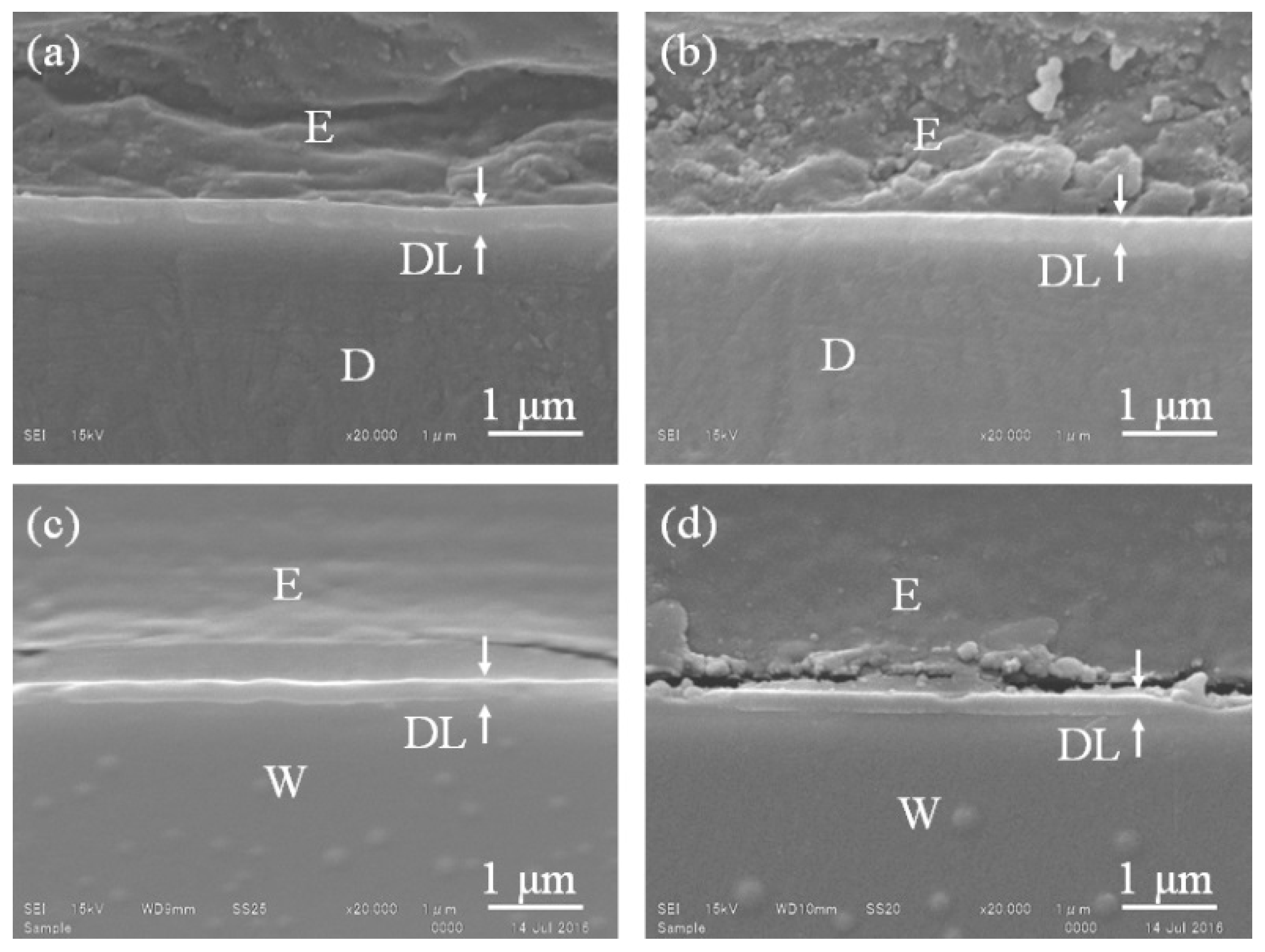

3.1. Crystal Structures and Morphological Features of the Coating Layers

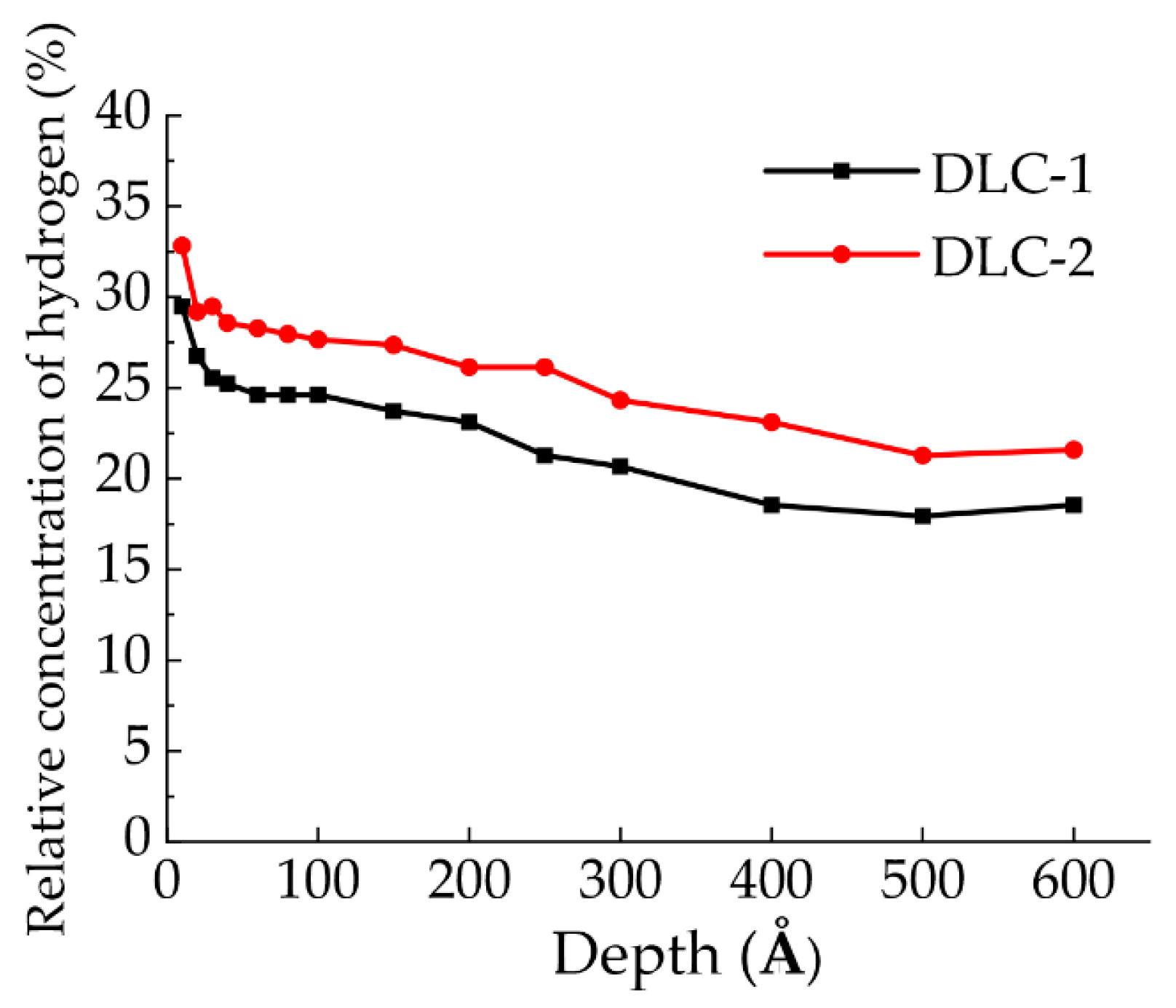

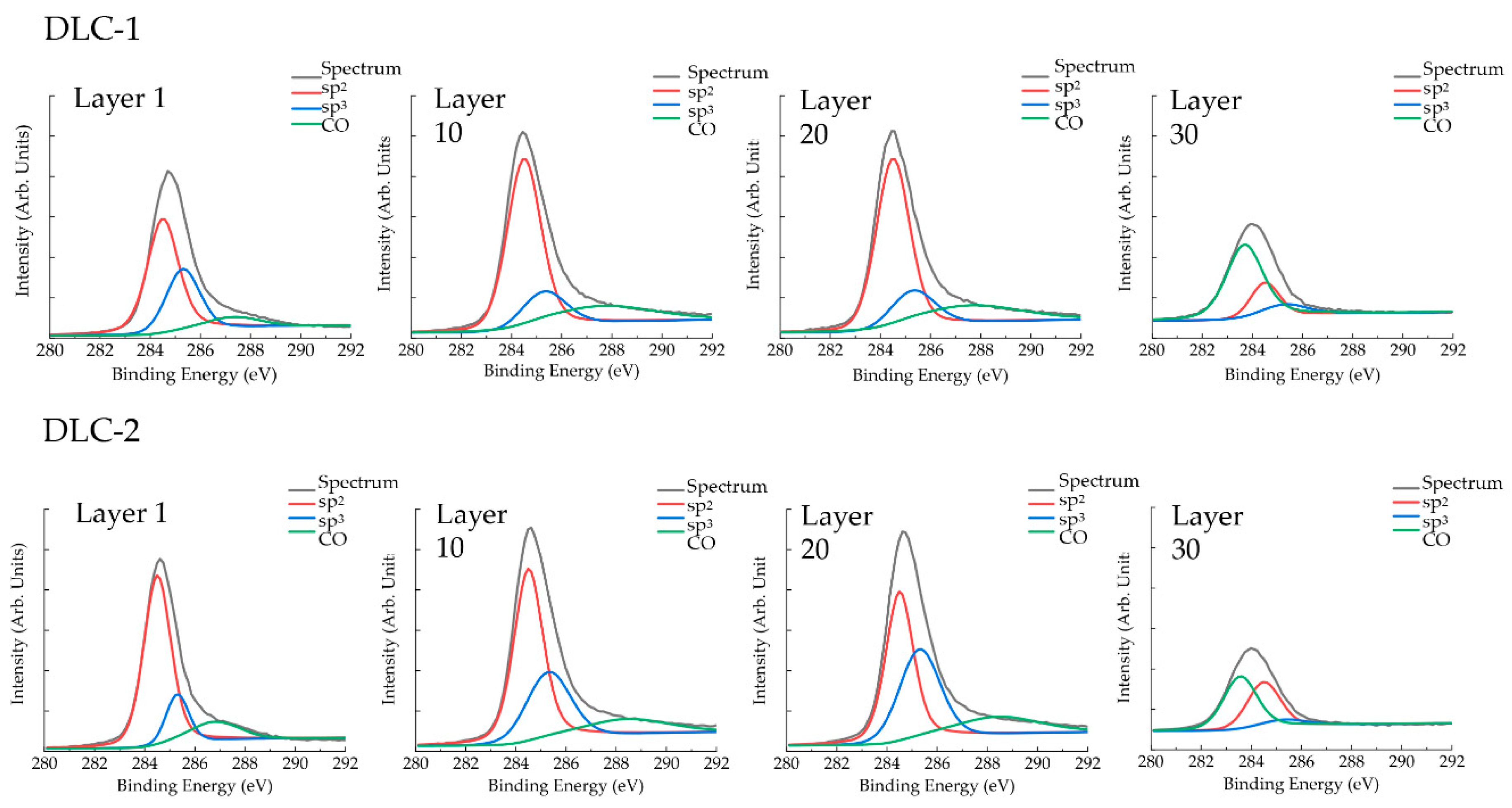

3.2. Compositional Characterization of the Coating

3.3. Mechanical Properties of the Coating

3.4. Frictional Properties Measured by the Progressive Load Scratch Test and Drawing Friction Test

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Iijima, M.; Zinelis, S.; Papageorgiou, S.N.; Brantley, W.; Eliades, T. Orthodontic brackets. In Orthodontic Application of Biomaterials; Eliades, T., Brantley, W., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 75–96. [Google Scholar]

- Iijima, M.; Endo, K.; Yuasa, T.; Ohno, H.; Hayashi, K.; Kakizaki, M.; Mizoguchi, I. Galvanic corrosion behavior of orthodontic archwire alloys coupled to bracket alloys. Angle Orthod. 2006, 76, 705–711. [Google Scholar] [PubMed]

- Bakhtari, A.; Bradley, T.G.; Lobb, W.K.; Berzins, D.W. Galvanic corrosion between various combinations of orthodontic brackets and archwires. Am. J. Orthod. Dentofac. Orthop. 2011, 140, 25–31. [Google Scholar] [CrossRef] [PubMed]

- Genelhu, M.C.; Marigo, M.; Alves-Oliveira, L.F.; Malaquias, L.C.; Gomez, R.S. Characterization of nickel-induced allergic contact stomatitis associated with fixed orthodontic appliances. Am. J. Orthod. Dentofac. Orthop. 2005, 28, 378–381. [Google Scholar] [CrossRef] [PubMed]

- Amini, F.; Jafari, A.; Amini, P.; Sepasi, S. Metal ion release from fixed orthodontic appliances—An in vivo study. Eur. J. Orthod. 2012, 34, 126–130. [Google Scholar] [CrossRef] [PubMed]

- Sifakakis, I.; Eliades, T. Adverse reactions to orthodontic materials. Aust. Dent. J. 2017, 62, 20–28. [Google Scholar] [CrossRef] [PubMed]

- Kusy, R.P.; Tobin, E.J.; Whitley, J.Q.; Sioshansi, P. Frictional coefficients of ion-implanted alumina against ion-implanted beta-titanium in the low load, low velocity, single pass regime. Dent. Mater. 1992, 8, 167–172. [Google Scholar] [CrossRef]

- Burrow, S.J. Friction and resistance to sliding in orthodontics: A critical review. Am. J. Orthod. Dentofac. Orthop. 2009, 135, 442–447. [Google Scholar] [CrossRef] [PubMed]

- Muguruma, T.; Iijima, M.; Brantley, W.A.; Mizoguchi, I. Effects of a diamond-like carbon coating on the frictional properties of orthodontic wires. Angle Orthod. 2011, 81, 141–148. [Google Scholar] [CrossRef] [PubMed]

- Muguruma, T.; Iijima, M.; Brantley, W.A.; Nakagaki, S.; Endo, K.; Mizoguchi, I. Frictional and mechanical properties of diamond-like carbon-coated orthodontic brackets. Eur. J. Orthod. 2013, 35, 216–222. [Google Scholar] [CrossRef] [PubMed]

- Akaike, S.; Hayakawa, T.; Kobayashi, D.; Aono, Y.; Hirata, A.; Hiratsuka, M.; Nakamura, Y. Reduction in static friction by deposition of a homogeneous diamond-like carbon (DLC) coating on orthodontic brackets. Dent. Mater. J. 2015, 34, 888–895. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Guo, S.; Wang, D.; Zhou, T.; Wang, L.; Ma, J. Effects of nanostructured, diamondlike, carbon coating and nitrocarburizing on the frictional properties and biocompatibility of orthodontic stainless steel wires. Angle Orthod. 2016, 86, 782–788. [Google Scholar] [CrossRef] [PubMed]

- Iijima, M.; Yuasa, T.; Endo, K.; Muguruma, T.; Ohno, H.; Mizoguchi, I. Corrosion behavior of ion implanted nickel-titanium orthodontic wire in fluoride mouth rinse solutions. Dent. Mater. J. 2010, 29, 53–58. [Google Scholar] [CrossRef] [PubMed]

- D’Antò, V.; Rongo, R.; Ametrano, G.; Spagnuolo, G.; Manzo, P.; Martina, R.; Paduano, S.; Valletta, R. Evaluation of surface roughness of orthodontic wires by means of atomic force microscopy. Angle Orthod. 2012, 82, 922–928. [Google Scholar] [CrossRef] [PubMed]

- Kawaguchi, K.; Iijima, M.; Endo, K.; Mizoguchi, I. Electrophoretic deposition as a new bioactive glass coating process for orthodontic stainless steel. Coatings 2017, 7, 199. [Google Scholar] [CrossRef]

- Fontaine, J.; Donnet, C.; Erdemir, A. Fundamentals of the tribology of DLC coating. In Tribology of Diamond-Like-Carbon Films; Donnet, C., Erdemir, A., Eds.; Springer: New York, NY, USA, 2008; pp. 139–154. [Google Scholar]

- Roy, R.K.; Lee, K.R. Biomedical applications of diamond-like carbon coatings: A review. J. Biomed. Mater. Res. B Appl. Biomater. 2007, 83, 72–84. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, S.; Ohgoe, Y.; Ozeki, K.; Hirakuri, K.; Aoki, H. Dissolution effect and cytotoxicity of diamond-like-carbon coating on orthodontic archwires. J. Mater. Sci. Mater. Med. 2007, 18, 2263–2268. [Google Scholar] [CrossRef] [PubMed]

- Bentahar, Z.; Barouins, M.; Clin, M.; Bouhammar, N.; Boussirik, K. Tribological performance of DLC-coated stainless steel, TMA and Cu-NiTi. Int. Orthod. 2008, 6, 335–342. [Google Scholar] [CrossRef]

- Huang, S.Y.; Huang, J.J.; Kang, T.; Diao, D.F.; Duan, Y.Z. Coating NiTi archwires with diamond-like carbon films: Reducing fluoride-induced corrosion and improving frictional properties. J. Mater. Sci. Mater. Med. 2013, 24, 2287–2292. [Google Scholar] [CrossRef] [PubMed]

- Okubo, H.; Tsuboi, R.; Sasaki, S. Frictional properties of DLC films in low-pressure hydrogen conditions. Wear 2015, 340, 2–8. [Google Scholar] [CrossRef]

- Zhang, T.F.; Xie, D.; Huang, N.; Leng, Y. The effect of hydrogen on the tribological behavior of diamond like carbon (DLC) coating sliding against Al2O3 in water environment. Surf. Coat. Technol. 2017, 320, 619–623. [Google Scholar] [CrossRef]

- ISO 14577-1:2002 Metallic Materials–Instrumented Indentation Test for Hardness and Materials Parameters–Part 1: Test Method; International Organization for Standardization: Geneva, Switzerland, 2002.

- Antunes, R.A.; de Lima, N.B.; Rizzutto Mde, A.; Higa, O.Z.; Saiki, M.; Costa, I. Surface interactions of a W-DLC-coated biomedical AISI 316L stainless steel in physiological solution. J. Mater. Sci. Mater. Med. 2013, 24, 863–876. [Google Scholar] [CrossRef] [PubMed]

- Tai, F.C.; Lee, S.C.; Wei, C.H.; Tyan, S.L. Correlation between ID/IG ratio from visible raman spectra and sp2/sp3 ratio from XPS spectra of annealed hydrogenated DLC film. Mater. Trans. 2006, 47, 1847–1852. [Google Scholar] [CrossRef]

- Ahmed, M.H.; Byrne, J.A.; McLaughlin, J.A.D.; Elhissi, A.; Ahmed, W. Comparison between FTIR and XPS characterization of amino acid glycine adsorption onto diamond-like carbon (DLC) and silicone doped DLC. Appl. Surf. Sci. 2013, 273, 507–514. [Google Scholar] [CrossRef]

- Torrisi, L.; Cutroneo, M. Elastic recoil detection analysis (ERDA) in hydrogenated samples for TNSA laser irradiation. Surf. Interface Anal. 2016, 48, 10–16. [Google Scholar] [CrossRef]

- Ronkainen, H.; Varjus, S.; Koskinen, J.; Holmberg, K. Differentiating the tribological performance of hydrogenated and hydrogen-free DLC coatings. Wear 2001, 249, 260–266. [Google Scholar] [CrossRef]

- Papakonstantinou, P.; Zhao, J.F.; Lemoine, P.; McAdams, E.T.; McLaughlin, J.A. The effects of Si incorporation on the electrochemical and nanomechanical properties of DLC thin films. Diam. Relat. Mater. 2002, 11, 1074–1080. [Google Scholar] [CrossRef]

- Iijima, M.; Muguruma, T.; Brantley, W.A.; Mizoguchi, I. Comparison of nanoindentation, 3-point bending, and tension tests for orthodontic wires. Am. J. Orthod. Dentofac. Orthop. 2011, 140, 65–71. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Maltha, J.C.; Kuijpers-Jagtman, A.M. Optimum force magnitude for orthodontic tooth movement: A systematic literature review. Angle Orthod. 2003, 73, 86–92. [Google Scholar] [PubMed]

- Muguruma, T.; Iijima, M.; Nagano-Takebe, F.; Endo, K.; Mizoguchi, I. Frictional properties and characterization of a diamond-like carbon coating formed on orthodontic stainless steel. J. Biomater. Tissue Eng. 2017, 7, 119–126. [Google Scholar] [CrossRef]

- Cazalini, E.M.; Miyakawa, W.; Teodoro, G.R.; Sobrinho, A.S.S.; Matieli, J.E.; Massi, M.; Koga-Ito, C.Y. Antimicrobial and anti-biofilm properties of polypropylene meshes coated with metal-containing DLC thin films. J. Mater. Sci. Mater. Med. 2017, 28, 97. [Google Scholar] [CrossRef] [PubMed]

- Muguruma, T.; Iijima, M.; Yuasa, T.; Kawaguchi, K.; Mizoguchi, I. Characterization of the coatings covering esthetic orthodontic archwires and their influence on the bending and frictional properties. Angle Orthod. 2017, 87, 610–617. [Google Scholar] [CrossRef] [PubMed]

| DLC Coating Procedure | Target Voltage | Gas Atmosphere | Deposition Time |

|---|---|---|---|

| DLC-1 | 10 kV | Acetylene + Toluene | 3 min |

| DLC-2 | 7 kV | Toluene | 4 min |

| Layers | DLC-1 | DLC-2 | ||||

|---|---|---|---|---|---|---|

| sp2 | sp3 | sp3/(sp2 + sp3) | sp2 | sp3 | sp3/(sp2 + sp3) | |

| 1 | 51,573 | 26,885 | 0.343 | 64,025 | 14,128 | 0.181 |

| 5 | 82,776 | 25,388 | 0.235 | 80,737 | 31,883 | 0.283 |

| 10 | 78,206 | 19,654 | 0.201 | 73,440 | 38,368 | 0.343 |

| 15 | 74,470 | 20,126 | 0.213 | 63,305 | 45,916 | 0.420 |

| 20 | 76,467 | 20,132 | 0.208 | 60,451 | 47,915 | 0.442 |

| 25 | 73,992 | 20,656 | 0.218 | 71,608 | 23,626 | 0.248 |

| 30 | 12,557 | 6553 | 0.343 | 19,183 | 3356 | 0.149 |

| 35 | 3864 | 2553 | 0.398 | 911 | 2221 | 0.709 |

| 40 | disappeared | disappeared | – | disappeared | disappeared | – |

| Mechanical Properties | Analysis Depth | DLC-1 | DLC-2 | p Value 1 |

|---|---|---|---|---|

| Hardness | 20 nm | 8.13 (1.24) | 7.49 (1.55) | 0.317 |

| 70 nm | 9.18 (0.64) | 9.69 (1.18) | 0.241 | |

| Elastic modulus | 20 nm | 117.16 (19.59) | 106.35 (36.60) | 0.421 |

| 70 nm | 123.68 (6.42) | 135.40 (12.04) | 0.014 |

| Bending | Non-Coated | DLC-1 | DLC-2 | p-Value |

|---|---|---|---|---|

| 1 mm | 170.45 a (1.87) | 185.89 b (5.85) | 181.84 b (3.50) | 0.000 |

| 1.5 mm | 170.26 a (2.18) | 188.42 b (4.51) | 180.80 c (2.54) | 0.000 |

| Scratch Distances | Non-Coated | DLC-1 | DLC-2 | p-Value |

|---|---|---|---|---|

| 5.0 mm | 2.31 a (0.02) | 2.01 b (0.03) | 1.97 b (0.01) | 0.000 |

| 0.5 mm | 1.20 a (0.04) | 1.03 b (0.07) | 0.95 c (0.02) | 0.000 |

| Distance for detachment (mm) | – | 1.05 (0.37) | 1.27 (0.20) | 0.269 † |

| Friction Test | Condition | Non-Coated | DLC-1 | DLC-2 | p-Value |

|---|---|---|---|---|---|

| Static friction | Wet | 2.39 a (0.30) | 2.37 a (0.16) | 2.09 b (0.22) | 0.013 |

| Dry | 2.49 (0.33) | 2.47 (0.18) | 2.25 (0.24) | 0.088 | |

| Kinetic friction | Wet | 2.37 a (0.27) | 2.32 a (0.17) | 1.99 b (0.17) | 0.001 |

| Dry | 2.55 a (0.21) | 2.55 a (0.30) | 2.21 b (0.18) | 0.004 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muguruma, T.; Iijima, M.; Kawaguchi, M.; Mizoguchi, I. Effects of sp2/sp3 Ratio and Hydrogen Content on In Vitro Bending and Frictional Performance of DLC-Coated Orthodontic Stainless Steels. Coatings 2018, 8, 199. https://doi.org/10.3390/coatings8060199

Muguruma T, Iijima M, Kawaguchi M, Mizoguchi I. Effects of sp2/sp3 Ratio and Hydrogen Content on In Vitro Bending and Frictional Performance of DLC-Coated Orthodontic Stainless Steels. Coatings. 2018; 8(6):199. https://doi.org/10.3390/coatings8060199

Chicago/Turabian StyleMuguruma, Takeshi, Masahiro Iijima, Masahiro Kawaguchi, and Itaru Mizoguchi. 2018. "Effects of sp2/sp3 Ratio and Hydrogen Content on In Vitro Bending and Frictional Performance of DLC-Coated Orthodontic Stainless Steels" Coatings 8, no. 6: 199. https://doi.org/10.3390/coatings8060199

APA StyleMuguruma, T., Iijima, M., Kawaguchi, M., & Mizoguchi, I. (2018). Effects of sp2/sp3 Ratio and Hydrogen Content on In Vitro Bending and Frictional Performance of DLC-Coated Orthodontic Stainless Steels. Coatings, 8(6), 199. https://doi.org/10.3390/coatings8060199