Anti- and De-Icing Behaviors of Superhydrophobic Fabrics

Abstract

:1. Introduction

2. Experimental Setup

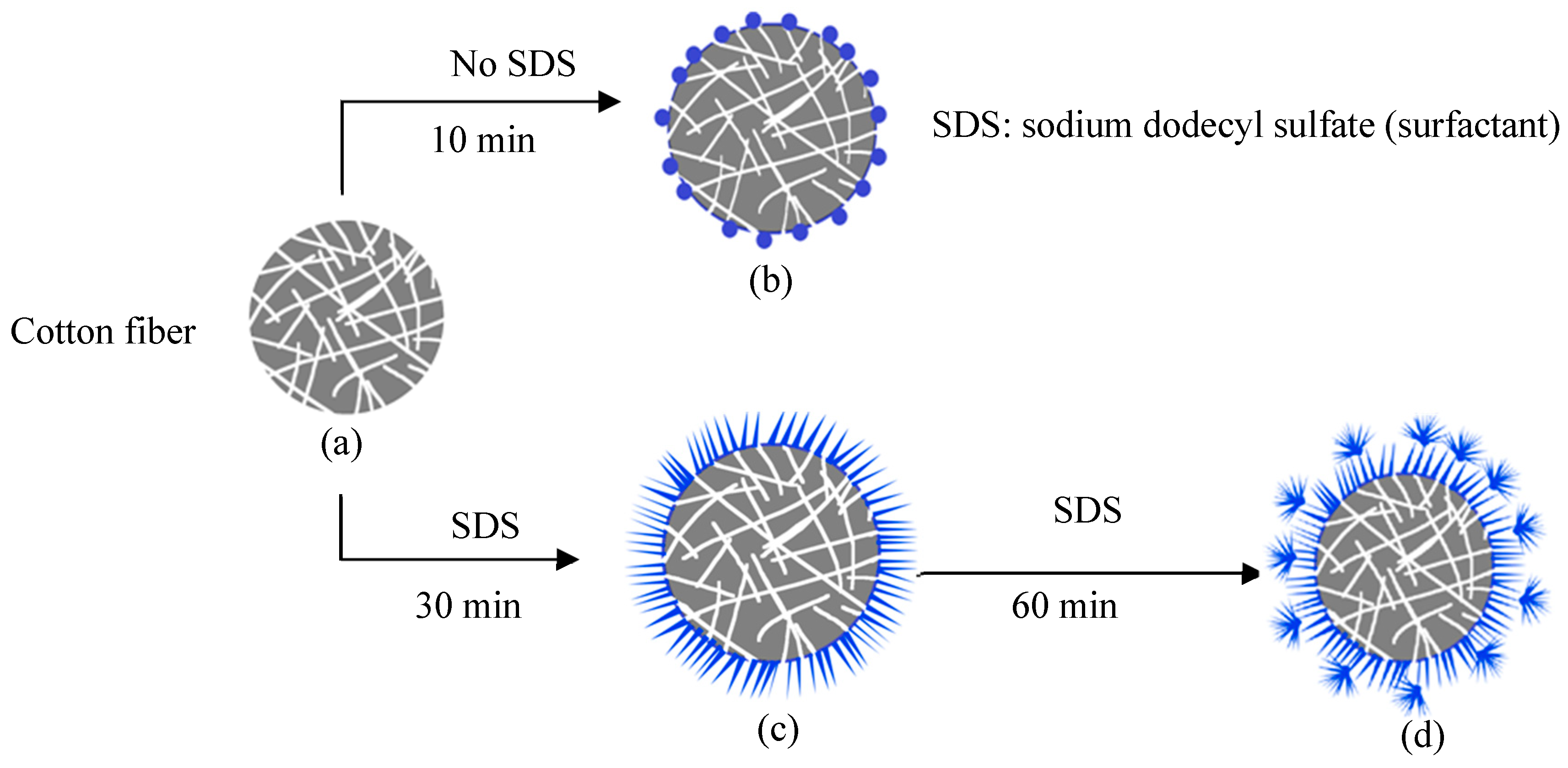

2.1. Preparation of Cotton Fibers Decorated with ZnO Structures

2.2. Hydrophobic Coating of Cotton Fabric Samples with Teflon

2.3. Evaluation of Surface Wettability

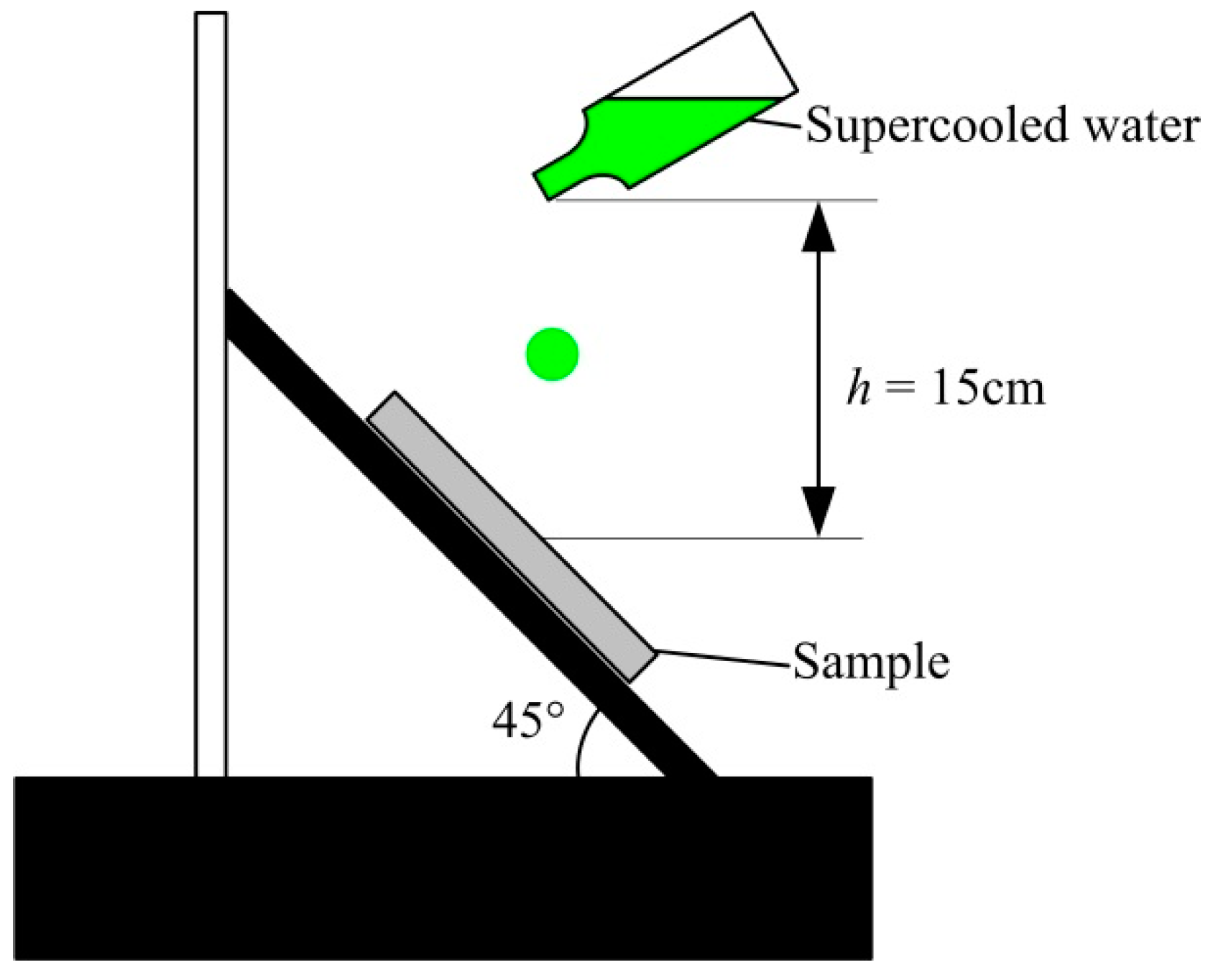

2.4. Evaluation of Anti-Icing and De-Icing Properties

3. Results and Discussion

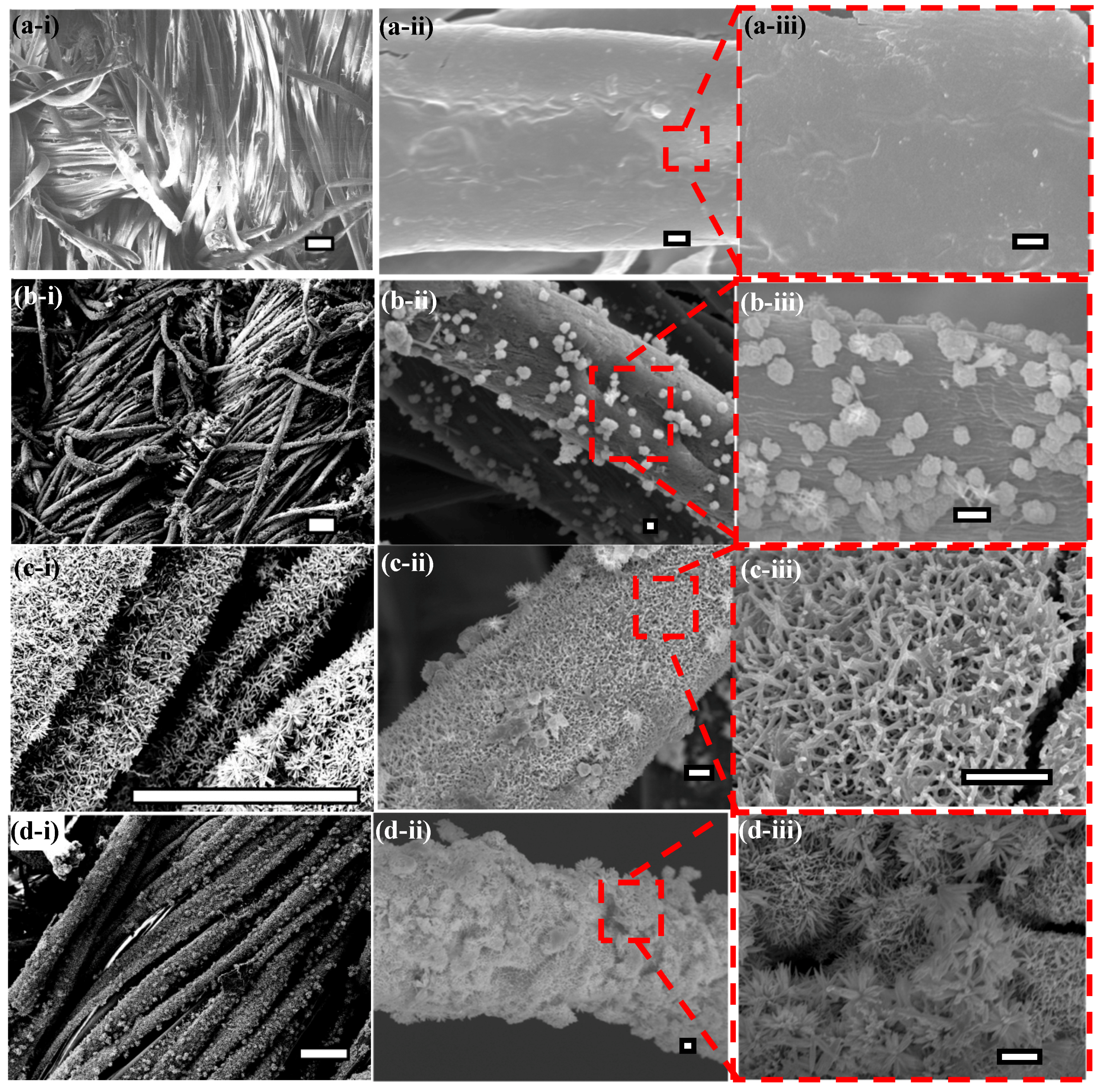

3.1. ZnO Surface Structures Grown on Cotton Fibers

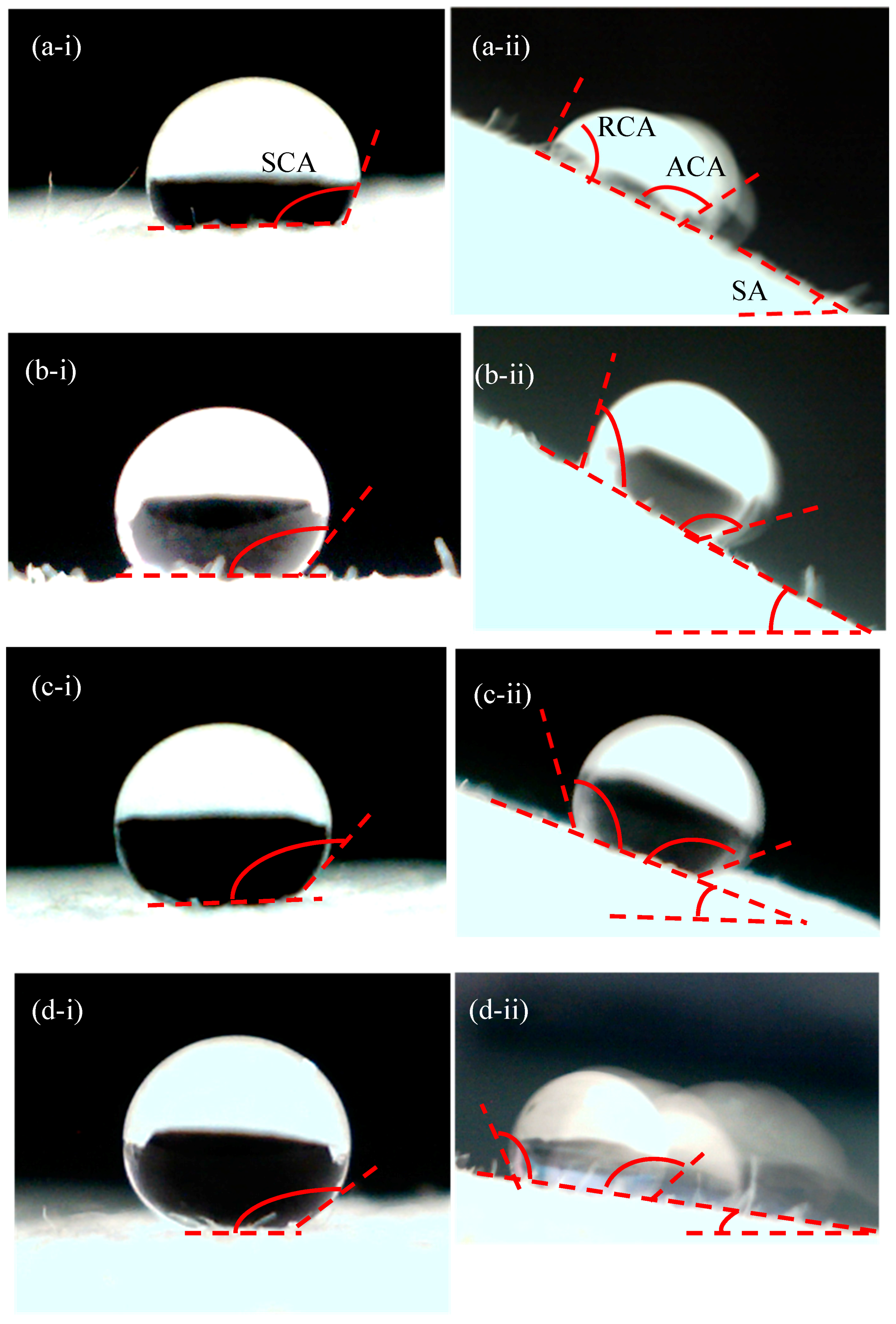

3.2. Surface Wettability of Treated Cotton Fabrics

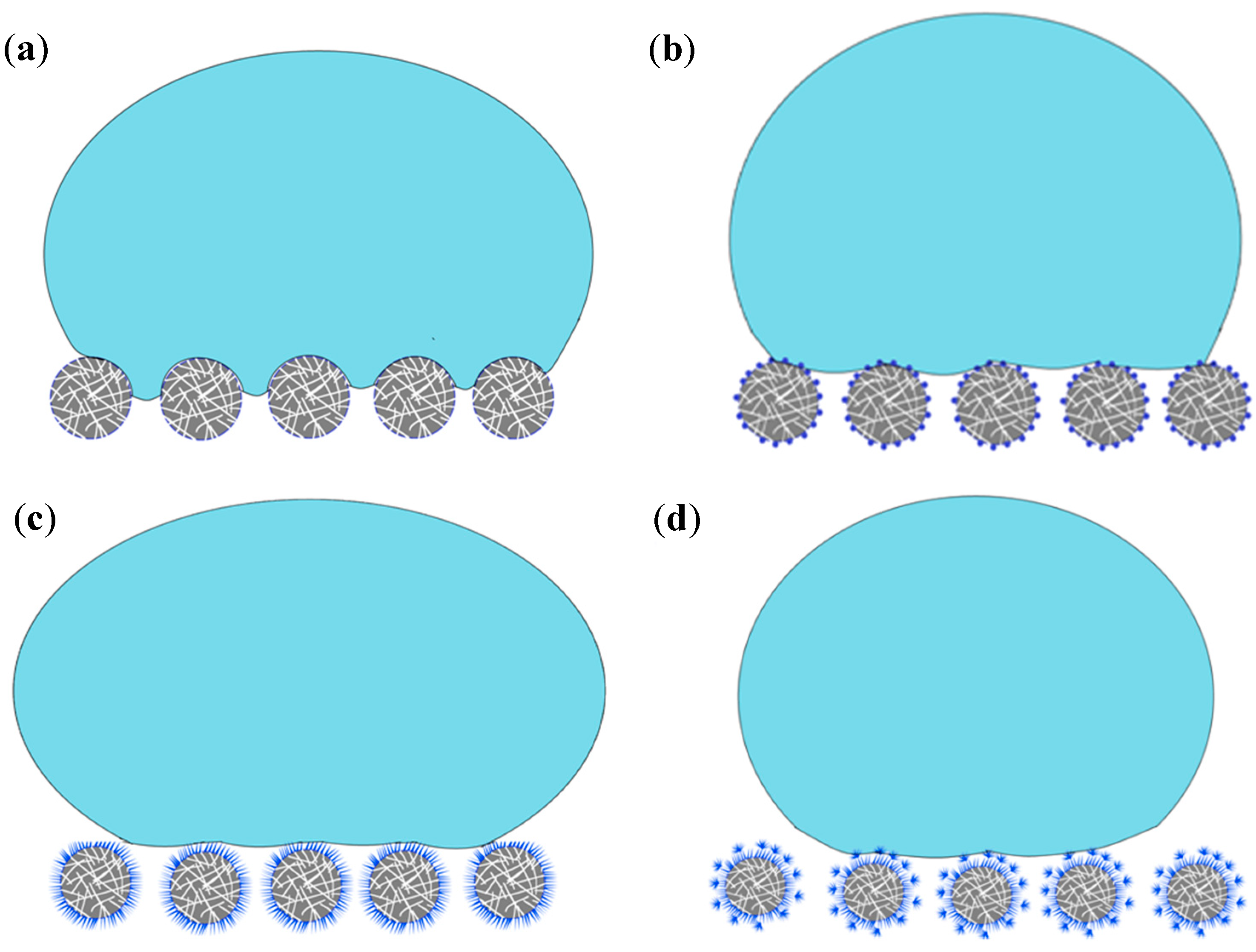

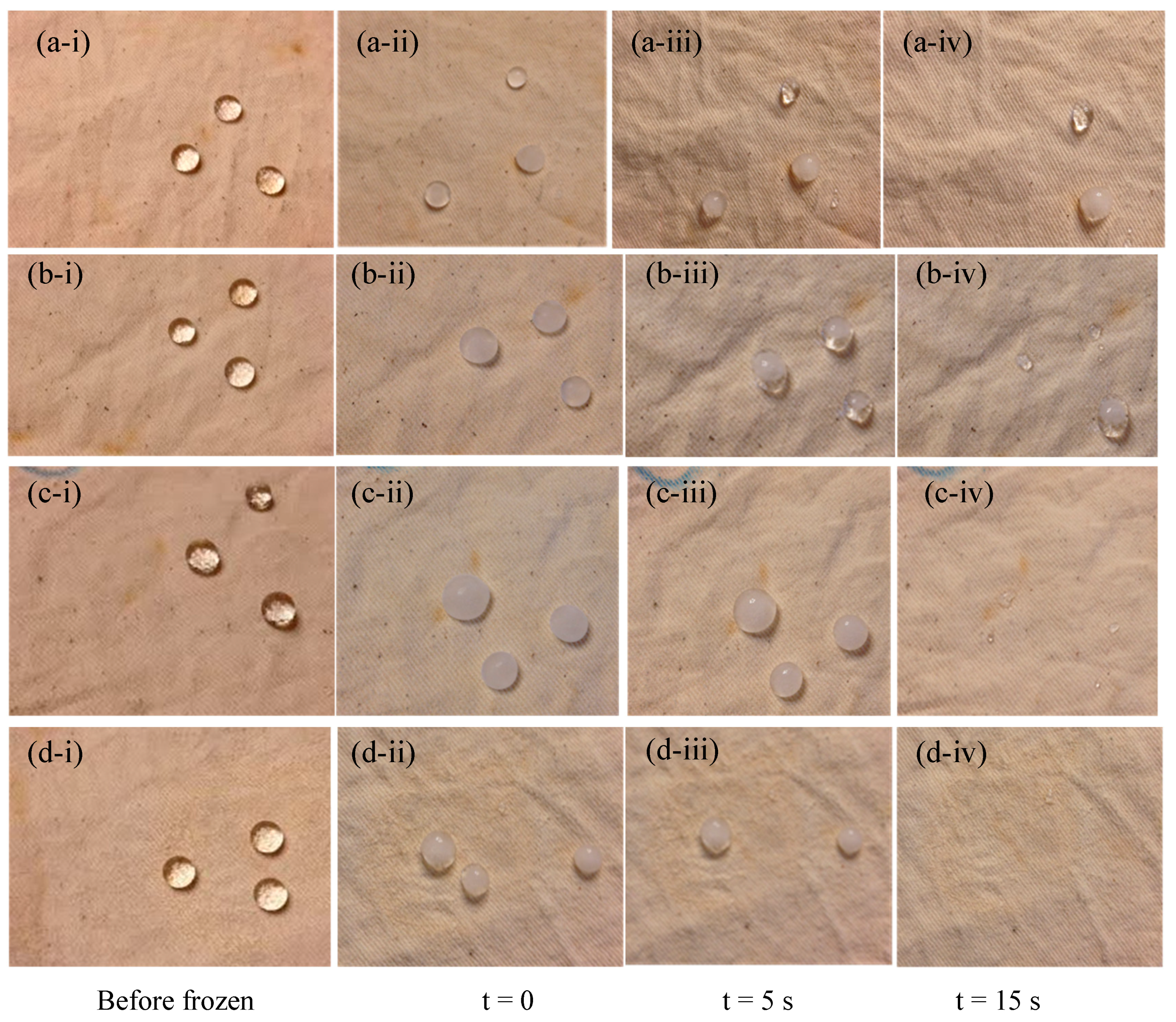

3.3. Anti-Icing and De-Icing Testing under Static Condition

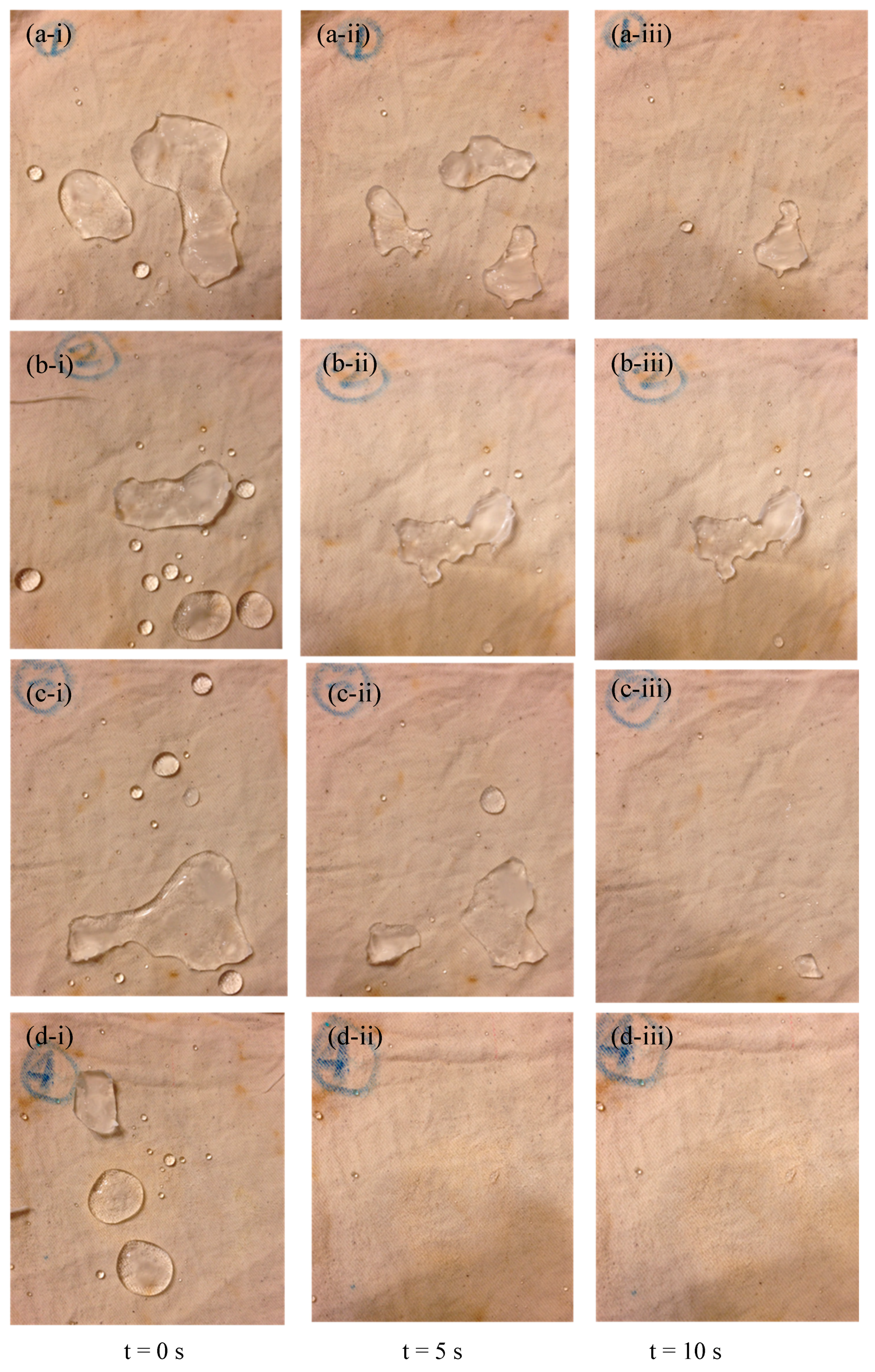

3.4. Anti-Icing and De-Icing Testing under Dynamic Condition

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nakajima, A.; Hashimoto, K.; Watanabe, T. Recent Studies on Super-Hydrophobic Films. Monatsh. Chem. 2001, 132, 31–41. [Google Scholar] [CrossRef]

- Lafuma, A.; Quere, D. Superhydrophobic States. Nat. Mater. 2003, 2, 457–460. [Google Scholar] [CrossRef] [PubMed]

- Roach, P.; Shirtcliffe, N.J.; Newton, M.I. Progress in Superhydrophobic Surface Development. Soft Matter 2008, 4, 224–240. [Google Scholar] [CrossRef]

- Bocquet, L.; Lauga, E. A Smooth Future? Nat. Mater. 2011, 10, 334–337. [Google Scholar] [CrossRef] [PubMed]

- Blossey, R. Self-Cleaning Surfaces-Virtual Realities. Nat. Mater. 2003, 2, 301–306. [Google Scholar] [CrossRef] [PubMed]

- Fürstner, R.; Barthlott, W.; Neinhuis, C.; Walzel, P. Wetting and Self-Cleaning Properties of Artificial Superhydrophobic Surfaces. Langmuir 2005, 21, 956–961. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Xin, J.H.; Choi, C.-H. Cotton Fabrics with Single-Faced Superhydrophobicity. Langmuir 2012, 28, 17426–17434. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Choi, C.-H.; Kim, C.-J. Superhydrophobic Drag Reduction in Laminar Flows: A Critical Review. Exp. Fluids 2016, 57, 176. [Google Scholar] [CrossRef]

- Aljallis, E.; Sarshar, M.A.; Datla, R.; Sikka, V.; Jones, A.; Choi, C.-H. Experimental Study of Skin Friction Drag Reduction on Superhydrophobic Flat Plates in High Reynolds Number Boundary Layer Flow. Phys. Fluids 2013, 25, 025103. [Google Scholar] [CrossRef]

- Song, D.; Song, B.; Hu, H.; Du, X.; Du, P.; Choi, C.-H.; Rothstein, J.P. Effect of a Surface Tension Gradient on the Slip Flow along a Superhydrophobic Air-Water Interface. Phys. Rev. Fluids 2018, 3, 033303. [Google Scholar] [CrossRef]

- Gao, L.; Jones, A.K.; Sikka, V.K.; Wu, J.; Gao, D. Anti-Icing Superhydrophobic Coatings. Langmuir 2009, 25, 12444–12448. [Google Scholar]

- Kripa, K.V.; Tao, D.; Smith, J.D.; Ming, H.; Nitin, B. Frost Formation and Ice Adhesion on Superhydrophobic Surfaces. Appl. Phys. Lett. 2010, 97, 234102. [Google Scholar] [CrossRef]

- Mishchenko, L.; Hatton, B.; Bahadur, V.; Taylor, J.A.; Krupenkin, T.; Aizenberg, J. Design of Ice-Free Nanostructured Surfaces Based on Repulsion of Impacting Water Droplets. ACS Nano 2010, 4, 7699–7707. [Google Scholar] [CrossRef] [PubMed]

- Sarshar, M.A.; Swarctz, C.; Hunter, S.; Simpson, J.; Choi, C.H. Effects of Contact Angle Hysteresis on Ice Adhesion and Growth on Superhydrophobic Surfaces under Dynamic Flow Conditions. Colloid Polym. Sci. 2013, 291, 427–435. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, M.; Zhai, J.; Wang, J.; Jiang, L. Bioinspired Construction of Mg-Li Alloys Surfaces with Stable Superhydrophobicity and Improved Corrosion Resistance. Appl. Phys. Lett. 2008, 92, 183103. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, L.; Chen, H.; Xu, S.; Evans, D.G.; Duan, X. Corrosion Resistance of Superhydrophobic Layered Double Hydroxide Films on Aluminum. Angew. Chem. Int. Ed. 2008, 47, 2466–2469. [Google Scholar] [CrossRef] [PubMed]

- Jeong, C.; Lee, J.; Sheppard, K.; Choi, C.-H. Air-Impregnated Nanoporous Anodic Aluminum Oxide Layers for Enhancing the Corrosion Resistance of Aluminum. Langmuir 2015, 31, 11040–11050. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Shin, S.; Jiang, Y.; Jeong, C.; Stone, H.A.; Choi, C.-H. Oil-Impregnated Nanoporous Oxide Layer for Corrosion Protection with Self-Healing. Adv. Funct. Mater. 2017, 27, 1606040. [Google Scholar] [CrossRef]

- Ressine, A.; Marko-Varga, G.; Laurell, T.; El-Gewely, M.R. Porous Silicon Protein Microarray Technology and Ultra-/Superhydrophobic States for Improved Bioanalytical Readout. Biotechnol. Annu. Rev. 2007, 13, 149–200. [Google Scholar] [PubMed]

- Choi, C.-H.; Kim, C.-J. Droplet Evaporation of Pure Water and Protein Solution on Nanostructured Superhydrophobic Surfaces of Varying Heights. Langmuir 2009, 25, 7561–7567. [Google Scholar] [CrossRef] [PubMed]

- Hizal, F.; Rungraeng, N.; Lee, J.; Jun, S.; Busscher, H.J.; van der Mei, H.C.; Choi, C.-H. Nanoengineered Superhydrophobic Surfaces of Aluminum with Extremely Low Bacterial Adhesivity. ACS Appl. Mater. Int. 2017, 9, 12118–12129. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Choi, C.-H. Effects of Surface Topography and Colloid Particles on the Evaporation Kinetics of Sessile Droplets on Superhydrophobic Surfaces. J. Heat Transf. 2012, 134, 051022–051027. [Google Scholar] [CrossRef]

- Miljkovic, N.; Enright, R.; Wang, E.N. Effect of Droplet Morphology on Growth Dynamics and Heat Transfer during Condensation on Superhydrophobic Nanostructured Surfaces. ACS Nano 2012, 6, 1776–1785. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Choi, C.-H. Condensation-Induced Wetting State and Contact Angle Hysteresis on Superhydrophobic Lotus Leaves. Colloid Polym. Sci. 2013, 291, 437–445. [Google Scholar] [CrossRef]

- Betz, A.R.; Jenkins, J.; Kim, C.J.; Attinger, D. Boiling Heat Transfer on Superhydrophilic, Superhydrophobic, and Superbiphilic Surfaces. Int. J. Heat Mass. Tranf. 2013, 57, 733–741. [Google Scholar] [CrossRef]

- Xu, W.; Leeladhar, R.; Tsai, Y.-T.; Yang, E.-H.; Choi, C.-H. Evaporative Self-Assembly of Nanowires on Superhydrophobic Surfaces of Nanotip Latching Structures. Appl. Phys. Lett. 2011, 98, 073101. [Google Scholar] [CrossRef]

- Lee, S.; Kim, W.; Yong, K. Overcoming the Water Vulnerability of Electronic Devices: A Highly Water-Resistant ZnO Nanodevice with Multifunctionality. Adv. Mater. 2011, 23, 4398–4402. [Google Scholar] [CrossRef] [PubMed]

- De Angelis, F.; Gentile, F.; Mecarini, F.; Das, G.; Moretti, M.; Candeloro, P.; Coluccio, M.L.; Cojoc, G.; Accardo, A.; Liberale, C. Breaking the Diffusion Limit with Super-Hydrophobic Delivery of Molecules to Plasmonic Nanofocusing SERS Structures. Nat. Photon. 2011, 5, 682–687. [Google Scholar] [CrossRef]

- Jung, S.; Tiwari, M.K.; Poulikakos, D. Frost Halos from Supercooled Water Droplets. Proc. Natl. Acad. Sci. USA 2012, 109, 16073–16078. [Google Scholar] [CrossRef] [PubMed]

- Cassie, A.B.D.; Baxter, S. Wettability of Porous Surfaces. Trans. Faraday Soc. 1944, 40, 0546–0550. [Google Scholar] [CrossRef]

- Vasileiou, T.; Gerber, J.; Prautzsch, J.; Schutzius, T.M.; Poulikakos, D. Superhydrophobicity Enhancement through Substrate Flexibility. Proc. Natl. Acad. Sci. USA 2016, 113, 13307–13312. [Google Scholar] [CrossRef] [PubMed]

- Gilet, T.; Bourouiba, L. Fluid Fragmentation Shapes Rain-Induced Foliar Disease Transmission. J. R. Soc. Interface 2015, 12, 20141092. [Google Scholar] [CrossRef] [PubMed]

- Ina, R.; James, W.; Reza, R.; Thomas, B.; Sachin, K.; Ramesh, J. Nanoindentation Measurements of Teflon-AF Nanosheets. J. Appl. Polym. Sci. 2015, 132, 41360. [Google Scholar]

- Ramimoghadam, D.; Hussein, M.; Taufiq-Yap, H. The Effect of Sodium Dodecyl Sulfate (SDS) and Cetyltrimethylammonium Bromide (CTAB) on the Properties of ZnO Synthesized by Hydrothermal Method. Int. J. Mol. Sci. 2012, 13, 13275–13293. [Google Scholar] [CrossRef] [PubMed]

- Kołodziejczak-Radzimska, A.; Jesionowski, T. Zinc Oxide—From Synthesis to Application: A Review. Materials 2014, 7, 2833–2881. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.Y.A.; Umar, A.A.; Taslim, R.; Salleh, M.M. Effect of Surfactant on the Physical Properties of Zno Nanorods and the Performance of Zno Photoelectrochemical Cell. J. Exp. Nanosci. 2015, 10, 599–609. [Google Scholar] [CrossRef]

- Usui, H. The Effect of Surfactants on the Morphology and Optical Properties of Precipitated Wurtzite ZnO. Mater. Lett. 2009, 63, 1489–1492. [Google Scholar] [CrossRef]

- Jin, C.; Li, J.; Han, S.; Wang, J.; Sun, Q. A Durable, Superhydrophobic, Superoleophobic and Corrosion-Resistant Coating with Rose-Like ZnO Nanoflowers on a Bamboo Surface. Appl. Surf. Sci. 2014, 320, 322–327. [Google Scholar] [CrossRef]

- Wang, C.-F.; Tzeng, F.-S.; Chen, H.-G.; Chang, C.-J. Ultraviolet-Durable Superhydrophobic Zinc Oxide-Coated Mesh Films for Surface and Underwater–Oil Capture and Transportation. Langmuir 2012, 28, 10015–10019. [Google Scholar] [CrossRef] [PubMed]

- Shaban, M.; Mohamed, F.; Abdallah, S. Production and Characterization of Superhydrophobic and Antibacterial Coated Fabrics utilizing ZnO Nanocatalyst. Sci. Rep. 2018, 8, 3925. [Google Scholar] [CrossRef] [PubMed]

- Wenzel, R.N. Resistance of Solid Surfaces to Wetting by Water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Bhushan, B.; Nosonovsky, M. The Rose Petal Effect and the Modes of Superhydrophobicity. Philos. Trans. R. Soc. A 2010, 368, 4713–4728. [Google Scholar] [CrossRef] [PubMed]

| Samples | SCA (°) | ACA (°) | RCA (°) | CAH (°) | SA (°) |

|---|---|---|---|---|---|

| (a) | 137 | 142 | 98 | 44 | 36 |

| (b) | 143 | 148 | 113 | 35 | 27 |

| (c) | 151 | 156 | 138 | 18 | 22 |

| (d) | 153 | 162 | 149 | 13 | 9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Song, D.; Choi, C.-H. Anti- and De-Icing Behaviors of Superhydrophobic Fabrics. Coatings 2018, 8, 198. https://doi.org/10.3390/coatings8060198

Liu Y, Song D, Choi C-H. Anti- and De-Icing Behaviors of Superhydrophobic Fabrics. Coatings. 2018; 8(6):198. https://doi.org/10.3390/coatings8060198

Chicago/Turabian StyleLiu, Yuyang, Dong Song, and Chang-Hwan Choi. 2018. "Anti- and De-Icing Behaviors of Superhydrophobic Fabrics" Coatings 8, no. 6: 198. https://doi.org/10.3390/coatings8060198

APA StyleLiu, Y., Song, D., & Choi, C.-H. (2018). Anti- and De-Icing Behaviors of Superhydrophobic Fabrics. Coatings, 8(6), 198. https://doi.org/10.3390/coatings8060198