1. Introduction

Currently, due to infrastructure updates, urban relocation, road and bridge construction, and natural disasters, etc., there is a continuous cycle of new building constructions and demolitions taking place. However, the construction of new buildings inevitably leads to substantial consumption of natural resources while the demolition process generates significant amounts of waste. According to statistics, billions of tons of natural aggregate are consumed in the global concrete industry annually and an immense volume of construction waste is simultaneously produced. In 2005 alone, China witnessed at least 210 million tons of total construction waste (including both from construction activities and demolition) along with a minimum estimate of 100 million tons of waste concrete (comprising both production process leftovers and demolished structures). It is projected that these figures are still on the rise [

1]. Consequently, research focusing on recycling construction waste for reuse in new buildings has emerged as a crucial area for investigation. The proposition of recycled aggregate concrete (RAC) not only addressed concerns regarding excessive depletion of natural resources but also offered a solution to the challenge posed by limited disposal options for construction waste. Moreover, it aligns with China’s strategic objective towards sustainable development and environmental conservation [

2].

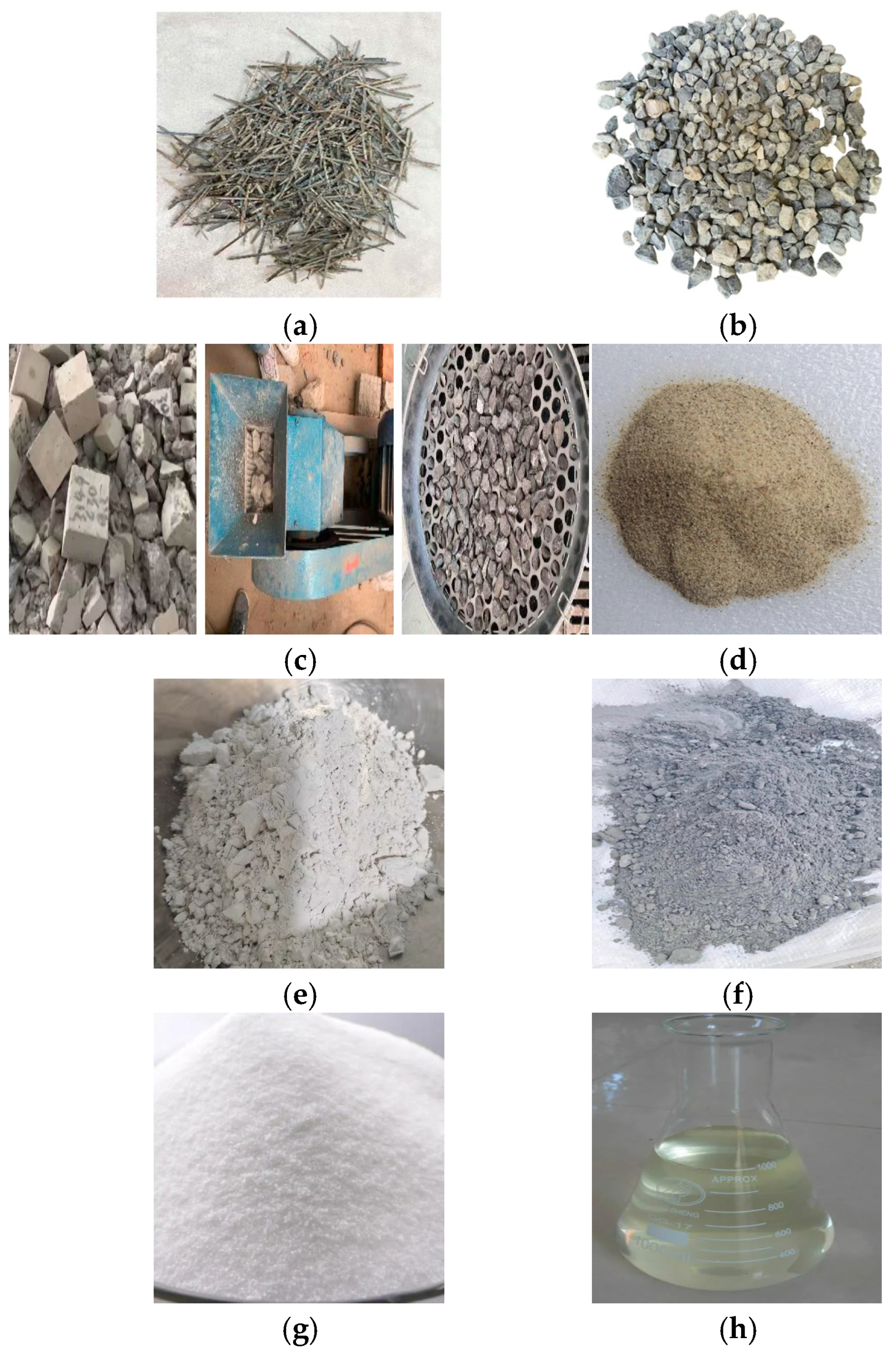

The term RAC refers to the production of concrete through the mixing of crushed, screened, washed, and graded debris from demolished buildings and roads with a specific proportion and gradation of recycled aggregate obtained by crushing, screening, washing, and grading waste concrete. However, due to the presence of internal pores and cracks in most recycled aggregates which are primarily composed of pebbles and cement mortar blocks wrapped in sand, their high water absorption rate significantly impacts the mechanical properties of RAC. Li et al. [

3] demonstrated that as the replacement ratio increases when using recycled aggregate instead of ordinary gravel, there is a corresponding decrease in concrete compressive strength. This reduction becomes more pronounced when the replacement ratio for recycled coarse aggregate exceeds 70%. Bravo et al. [

4] revealed that incorporating recycled aggregate into concrete leads to a reduction in both tensile strength and modulus of elasticity.

To address these challenges, the incorporation of metal fibers into cementitious gel networks has emerged as a promising approach, drawing inspiration from the concept of metallogels—composite materials where metals are integrated into gel matrices to enhance mechanical and functional properties [

5]. Ahmadi et al. [

6] conducted a study that demonstrated that the addition of steel fibers resulted in increased tensile strength, flexural strength, and flexural toughness of RAC. The maximum strength of RAC was achieved when the steel fiber content reached 1%. Bayraktar et al. [

7] revealed that incorporating steel fibers significantly improved both split tensile strength and flexural strength of RAC, and the enhancement effect was more pronounced as the aspect ratio of steel fibers increased.

However, steel fibers are susceptible to corrosion, particularly in the saline soil area of the Yellow River Basin in China where high sulfate levels lead to sulfate ion penetration and the formation of ettringite and gypsum, resulting in cracks. Corrosion-induced rust cracking is not uncommon and has caused significant concrete aggregate loss, leading to premature structural failure and a notable decline in concrete’s mechanical and durability performance [

8]. Incorporating ordinary steel fibers into reinforced concrete components can shorten their service life due to fiber corrosion, thereby affecting long-term durability. Poorsaheli et al. [

9] demonstrated that steel fibers may compromise concrete’s anti-corrosion performance and even weaken the positive impact of polyolefin fibers on corrosion resistance. Stainless steel fibers, as a novel industrial material with inherent non-rusting properties along with high tensile strength and modulus of elasticity, offer potential benefits when added to concrete. Their distributed presence can effectively inhibit internal microcrack expansion while their chromium (Cr) and nickel (Ni) elements enhance acid and alkali resistance, thus improving overall corrosion resistance [

10]. The innovative addition of stainless steel fibers not only enhances the properties of recycled concrete but also avoids the decrease in the properties of recycled concrete due to the incorporation of ordinary steel fibers.

Wang et al. [

11] utilized fractal dimension to characterize the self-similarity and structural complexity of the fracture network, elucidating the morphological disparities of fractures in dry–wet cycles. Zhang et al. [

12] demonstrated that the compressive strength, local density, dynamic modulus of elasticity, etc., of RAC were more responsive than ordinary concrete in sulfate-rich environments, particularly during frequent or periodic humidity fluctuations. Simultaneously, they postulated that the interface transition zone (ITZ) between the new aggregate and the cement paste as well as the old mortar played a pivotal role in determining the durability of RAC. Sobhan et al. [

13] investigated the deleterious effects of wet–dry cycles and repeated mechanical loading on a rolled concrete pavement composed of recycled concrete aggregate (RCA) and cement, uncovering that the absorption rate of the ITZ was primarily responsible for diminishing compressive and residual bending strength of RCA concrete under dry–wet exposure. Liu et al. [

14] analyzed the load–deflection curve (F-δ curve) and characteristic parameters of steel fiber concrete subjected to dry–wet cycles and sulfate corrosion, revealing distinct morphological variations characterized by multi-crack structures and pore formations after successive dry–wet cycles and sulfate corrosion events within localized regions. Shahidzadeh-Bonn et al. [

15] discovered through their research that sulfate can induce severe damage to porous materials following dry–wet cycles due to partial dissolution of anhydrous sodium sulfate crystals with concurrent formation of numerous hydrated crystals (Na

2SO

4 ·10H

2O) when relative humidity increases. However, most previous studies have focused on the influence of a single or two factors on the performance of concrete. In reality, the environment is often the result of multiple factors acting simultaneously. There are relatively few studies on the combined effect of the content of stainless steel fibers, the concentration of sulfate solution, and the number of dry–wet cycles.

In addition to recycled aggregate concrete, the durability of cement-based composites under aggressive environments has been widely studied in other material systems. For example, Verre [

16] investigated the debonding behavior of fiber-reinforced cementitious matrix–concrete joints conditioned in alkaline and hot water environments, highlighting the significant influence of environmental exposure on bond capacity and failure mechanisms. Such findings demonstrate that the deterioration of cementitious composites in aggressive conditions is a broader concern across different structural applications, which further underpins the necessity of exploring the sulfate resistance of recycled aggregate concrete reinforced with stainless steel fibers.

The present study builds upon the existing research foundation to investigate the mechanical properties and corrosion resistance of SSFRAC under various sulfate dry–wet cycles. By incorporating stainless steel fibers into the cementitious gel network, SSFRAC is conceptualized as a hybrid material that combines the principles of metallogels and functional composites. Regenerated concrete samples with 1%, 1.5%, and 2% volume fractions of stainless steel fibers were subjected to 30, 60, and 90 cycles of dry–wet exposure in Na2SO4 solutions with concentrations ranging from 0% to 5%. Using response surface methodology (RSM), this study explores the significant effects of three key factors—dry–wet cycle number, stainless steel fiber volume fraction, and Na2SO4 concentration—on the compressive strength corrosion resistance coefficient Sc and flexural strength corrosion resistance coefficient Sf. The findings highlight the potential of cement-based gels as raw materials for synthesizing durable and high-performance composites, where the integration of metal fibers enhances both mechanical properties and environmental resistance. These results provide valuable theoretical support for the further development and practical application of SSFRAC in advanced construction materials, particularly in aggressive environments.

6. Analysis and Discussion of RSM Model Results

6.1. Influences of Various Factors and Their Interaction on

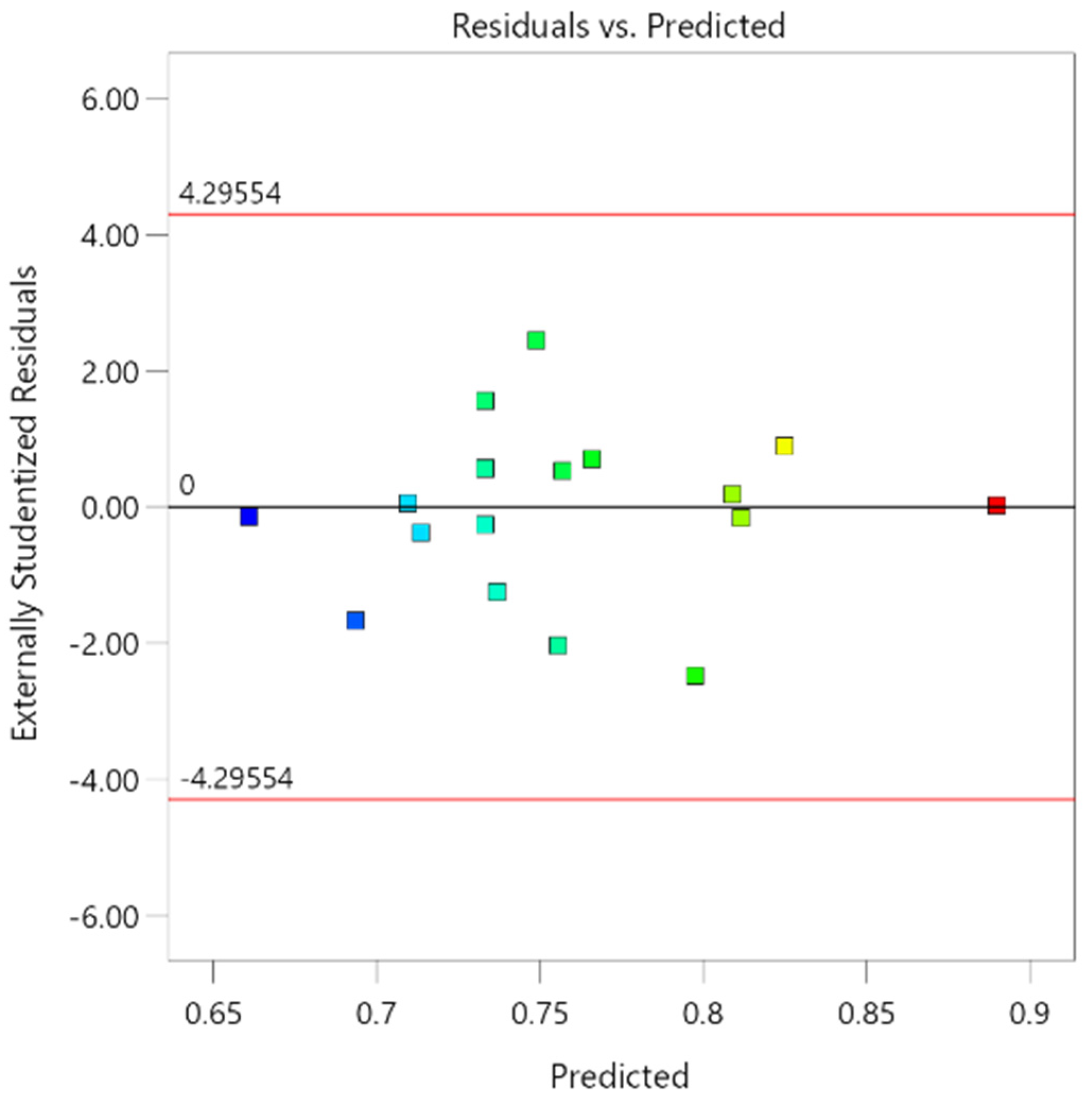

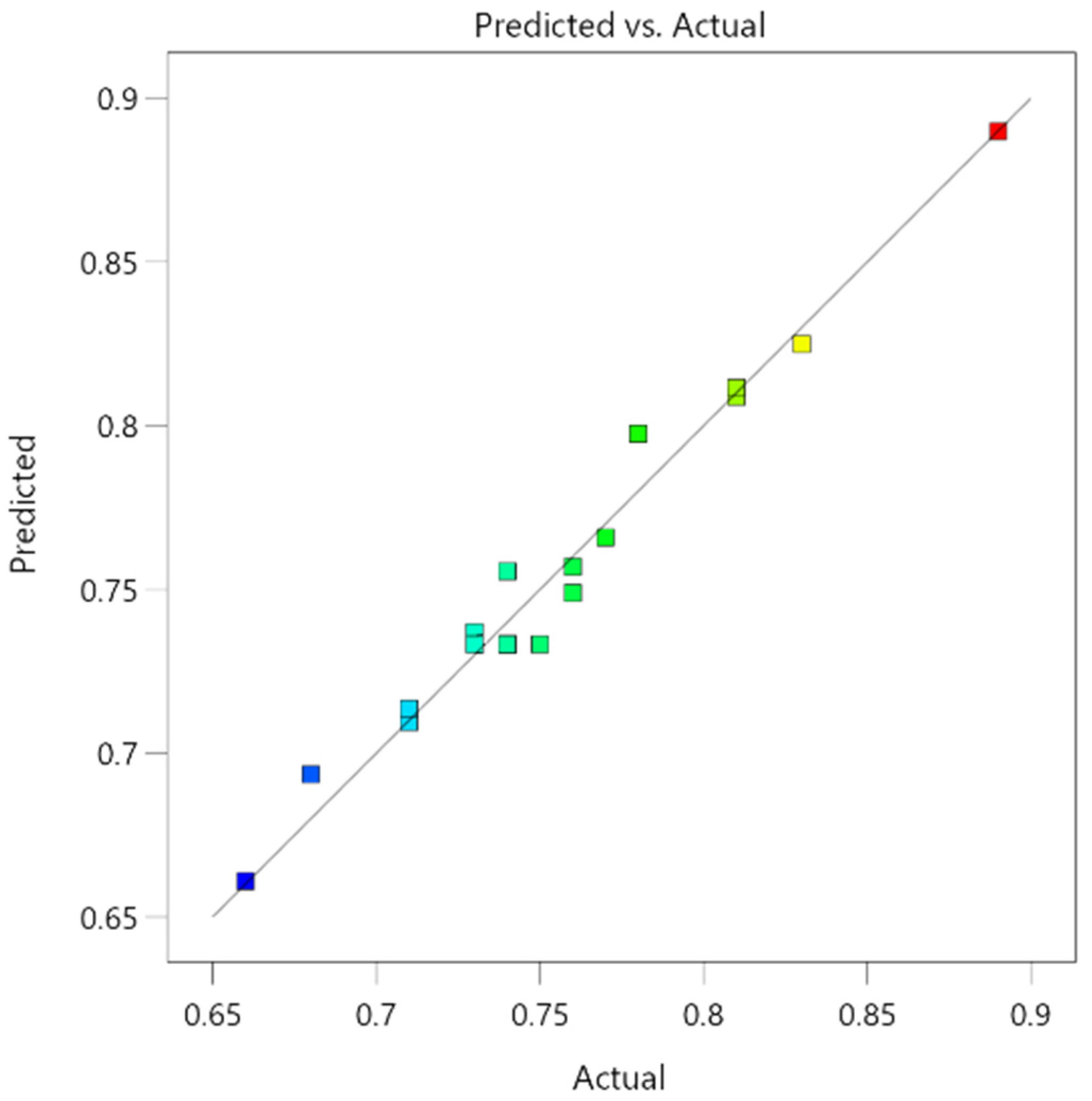

Figure 11a presents contour plots, depicting

versus the number of dry–wet cycles and stainless steel fiber content, along with a three-dimensional response surface plot 11b ased on Equation (4). The density of the contour lines in 11a reveals that the vertical coordinate representing stainless steel fiber content is less densely populated than the horizontal coordinate denoting dry–wet cycle count, indicating that the influence of stainless steel fiber content on

is comparatively less significant than that of dry–wet cycle count.

In 11b, the three-dimensional response surface can be described as follows: When the fixed number of dry–wet cycles is considered, an increase in stainless steel fiber content leads to a sustained upward trend in SSFRAC’s . This observation suggests that within the 1%–2% range, higher fiber content results in enhanced compressive strength due to the bridge-like action of fibers, which inhibits the formation and expansion of macroscopic cracks. Conversely, when maintaining constant fiber content, an increase in dry–wet cycles causes a continuous decline in SSFRAC’s , indicating that an increased number of dry–wet cycles weakens SSFRAC’s resistance to pressure.

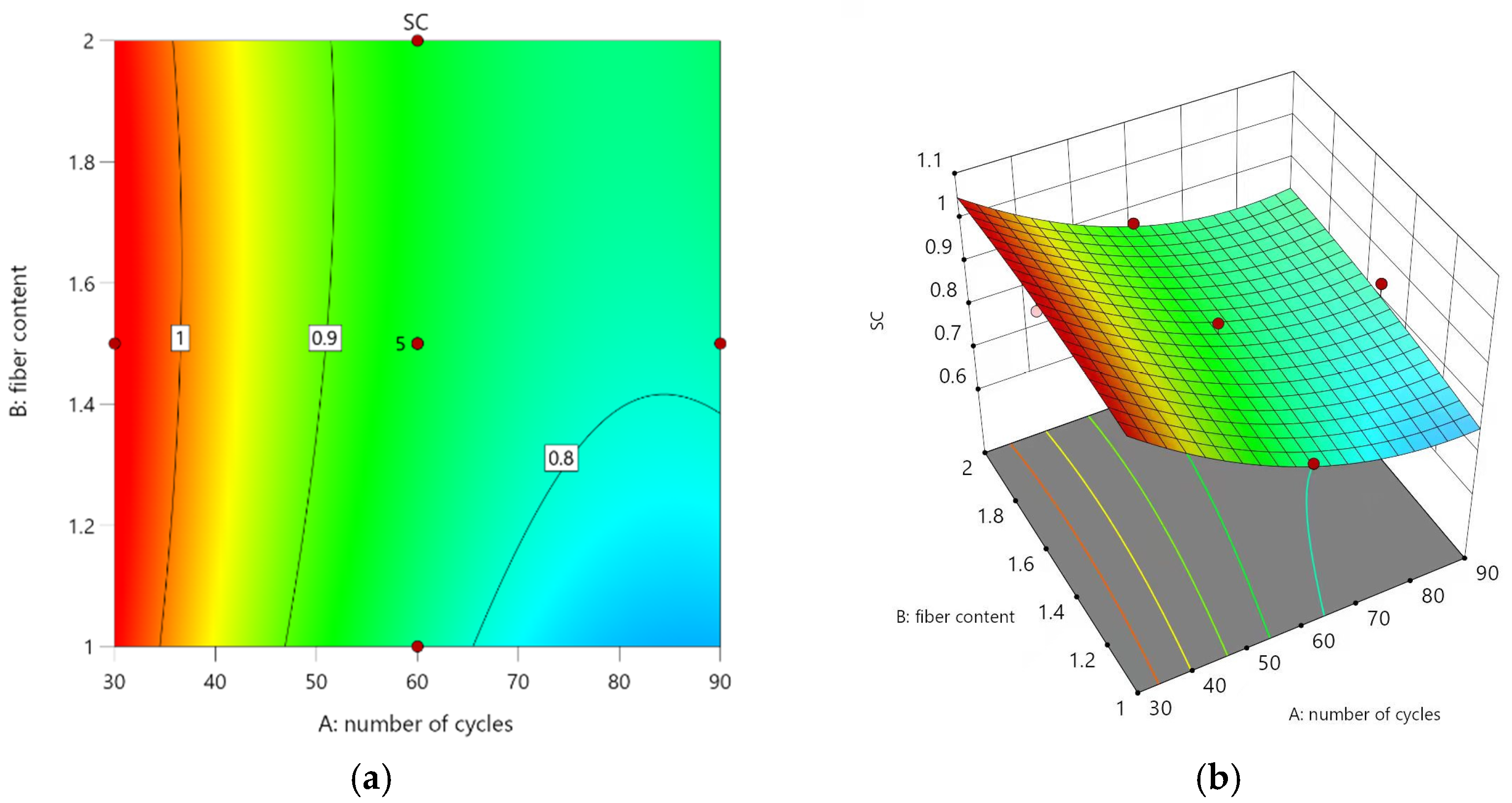

Figure 12a presents contour maps, depicting

concerning the number of dry–wet cycles and Na

2SO

4 concentration, along with a three-dimensional response surface plot

Figure 12b based on Equation (4). The density of the contour lines in

Figure 12a reveals that the Na

2SO

4 concentration contour lines are less dense than those representing dry–wet cycles, indicating that the influence of Na

2SO

4 concentration on

is comparatively less significant than that of dry–wet cycles.

In 12b, the three-dimensional response surface can be described as follows: The increase in the concentration of Na2SO4 solution is related to the increase in the number of cycles, leading to a declining trend in . This indicates that as the cycle progresses, the concrete’s salt solution attains saturation, triggering crystallization and precipitation. Subsequently, this mechanism exacerbates erosion on the concrete surface and results in a significant reduction in SSFRAC’s compressive strength.

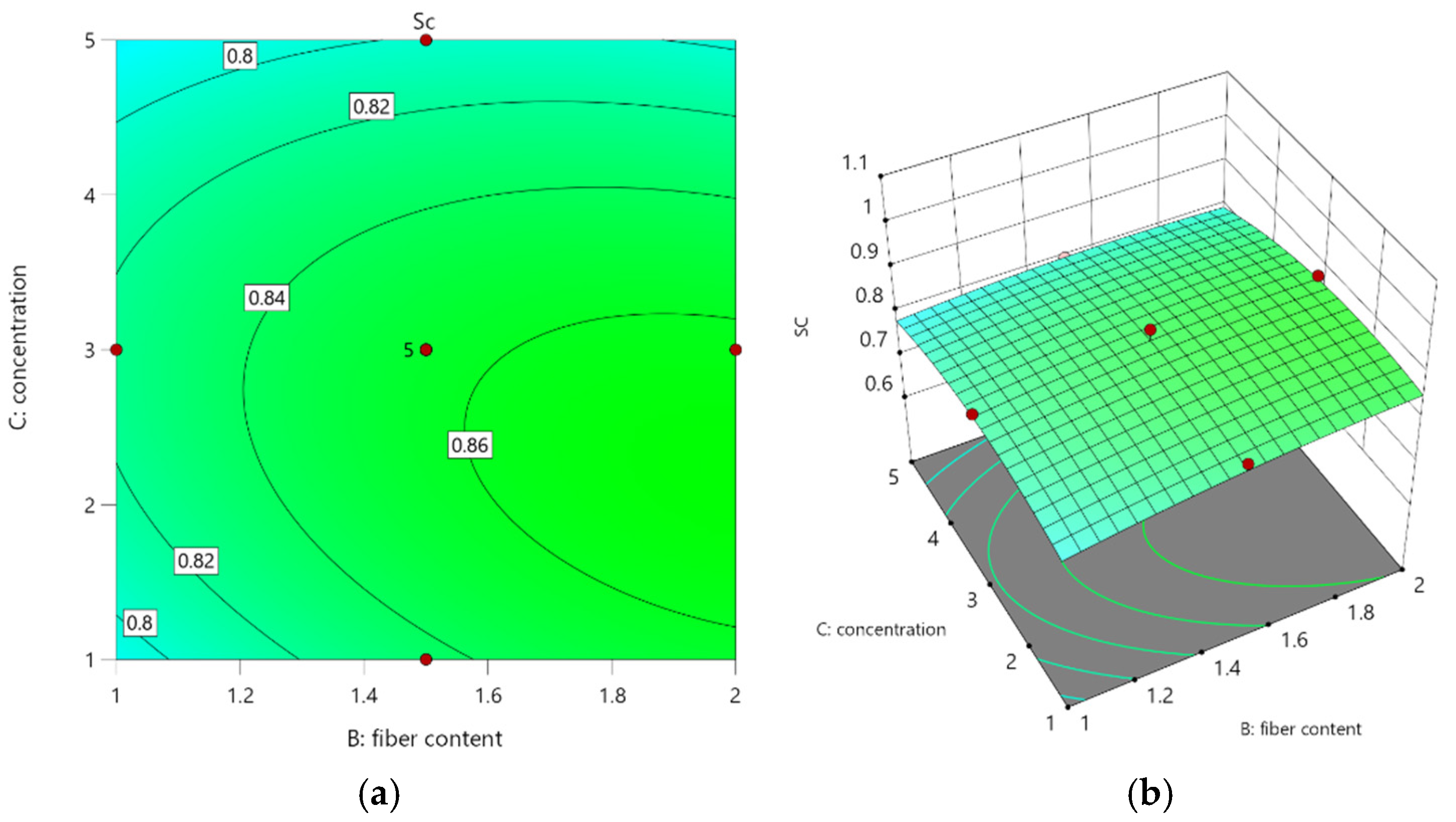

Figure 13 displays contour plots and 3D response surfaces of

concerning stainless steel fiber content and Na

2SO

4 concentration based on Equation (4). The figure illustrates that the contour lines representing fiber content on the horizontal axis in

Figure 13a are less dense than those depicting Na

2SO

4 concentration on the vertical axis, suggesting that the impact of fiber content on

is comparatively less significant than that of Na

2SO

4 concentration. In

Figure 13b, the 3D response surface can be described as follows:

When the Na2SO4 concentration remains constant, the trend of SSFRAC’s consistently rises with increasing stainless steel fiber content, suggesting that within the 1%–2% range, higher fiber content leads to improved pressure resistance. Conversely, when the fiber content is held constant, the trend of SSFRAC’s declines with increasing Na2SO4 concentration, indicating that higher Na2SO4 concentrations result in reduced pressure resistance for SSFRAC.

6.2. Influences of Various Factors and Their Interaction on

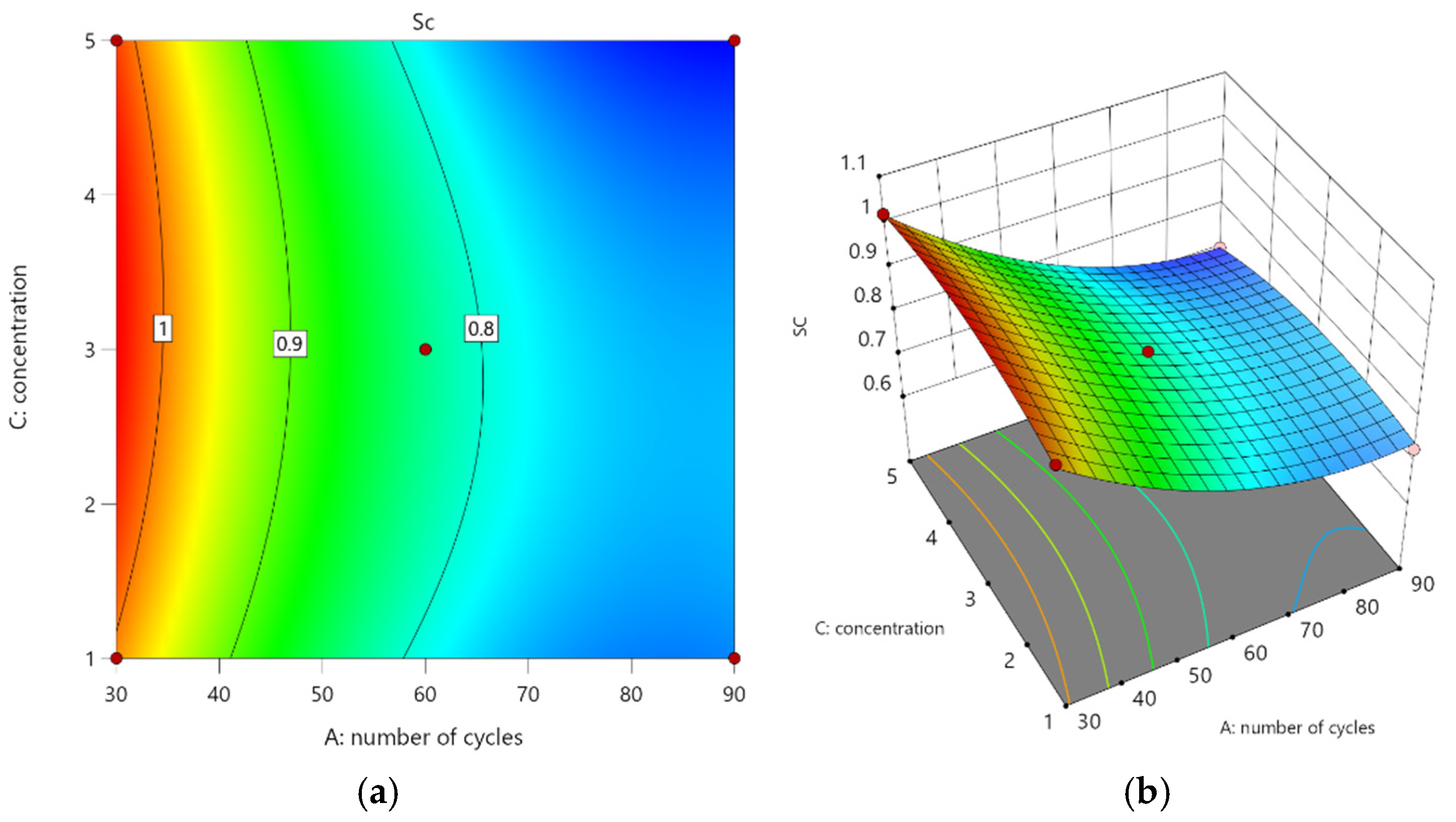

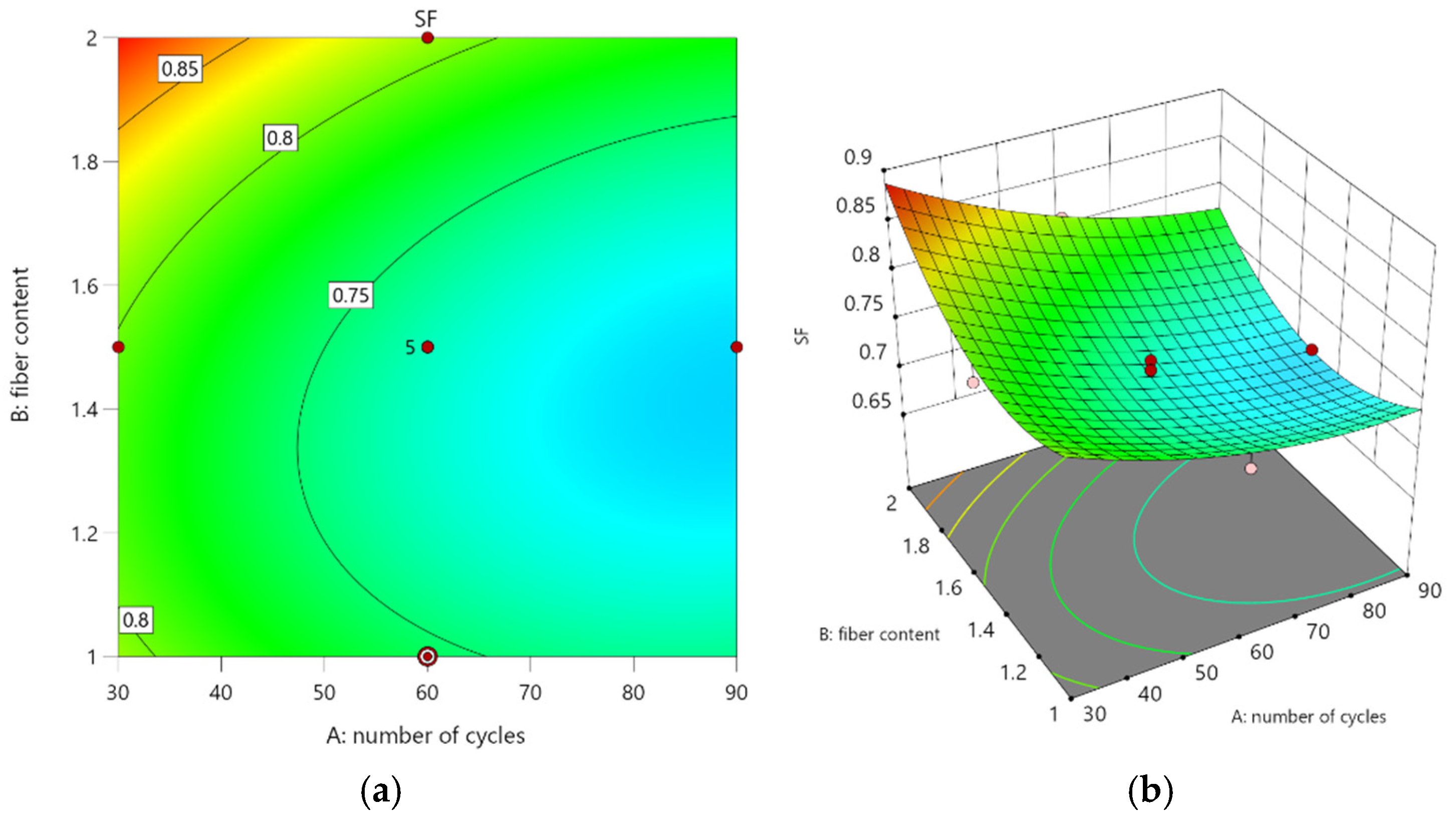

Figure 14a presents contour plot, illustrating

concerning the number of dry–wet cycles and stainless steel fiber content, along with a three-dimensional response surface plot

Figure 14b based on Equation (5). The density of the contour lines in

Figure 14a reveals that the vertical coordinate representing fiber content is more densely packed than the horizontal coordinate depicting dry–wet cycle count, indicating that the influence of fiber content on

is more significant than that of dry–wet cycle count. In

Figure 14b, a concave three-dimensional response surface is depicted, which can be described as follows:

When the number of dry–wet cycles is held constant, the trend of consistently rises with increasing stainless steel fiber content, suggesting that higher fiber content within the 1%–2% range leads to improved bending resistance. Conversely, when the fiber content is kept constant, the trend of declines with increasing dry–wet cycle count, indicating that a greater number of dry–wet cycles results in reduced bending resistance.

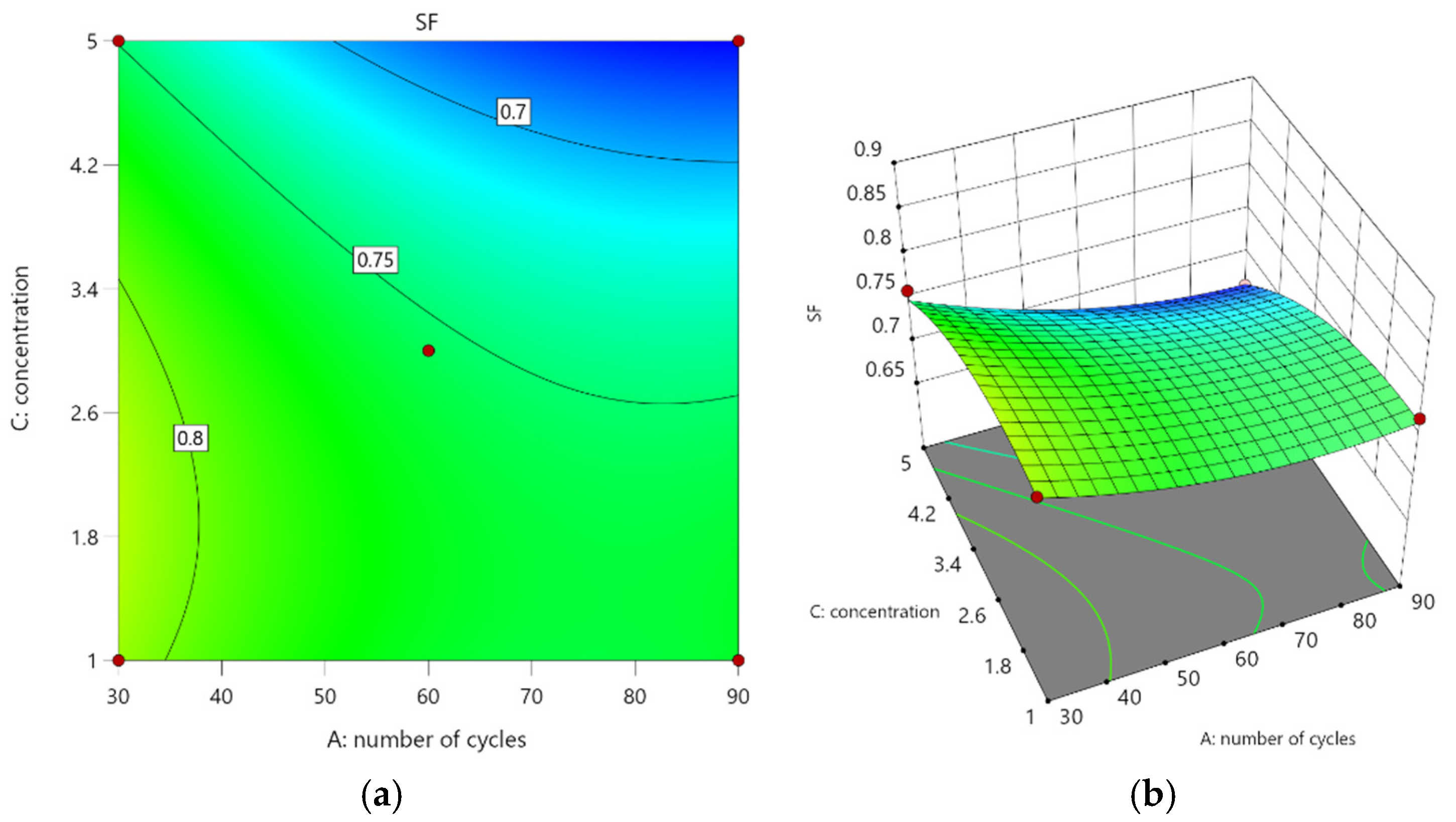

Figure 15a presents contour plot illustrating

concerning the number of dry–wet cycles and Na

2SO

4 concentration, along with a three-dimensional response surface plot

Figure 15b based on Equation (5). The density of the contour lines in

Figure 15a reveals that the Na

2SO

4 concentration contour lines are more densely packed than the dry–wet cycle contour lines, indicating that the influence of Na

2SO

4 concentration on

is more significant than the number of dry–wet cycles. In

Figure 15b, a concave three-dimensional response surface is depicted, which can be described as follows:

When the Na2SO4 concentration remains constant, the three-dimensional response surface of exhibits a decreasing trend with an increase in dry–wet cycling times, indicating that higher dry–wet cycling times lead to reduced bending resistance for SSFRAC. Conversely, when the number of dry–wet cycling times is held constant, the three-dimensional response surface of demonstrates an initial upward trend followed by a downward trend with increasing Na2SO4 solution concentration. This suggests that during the secondary hydration stage, Na2SO4 accelerates the generation of hydration products, filling pores and compacting the internal structure of SSFRAC while enhancing its strength. However, as the concentration of Na2SO4 increases, concrete’s internal salt solution easily reaches saturation and crystallizes; subsequently eroding surface crystals further degrade concrete. Therefore, an increase in Na2SO4 concentration results in decreased flexural strength for SSFRAC.

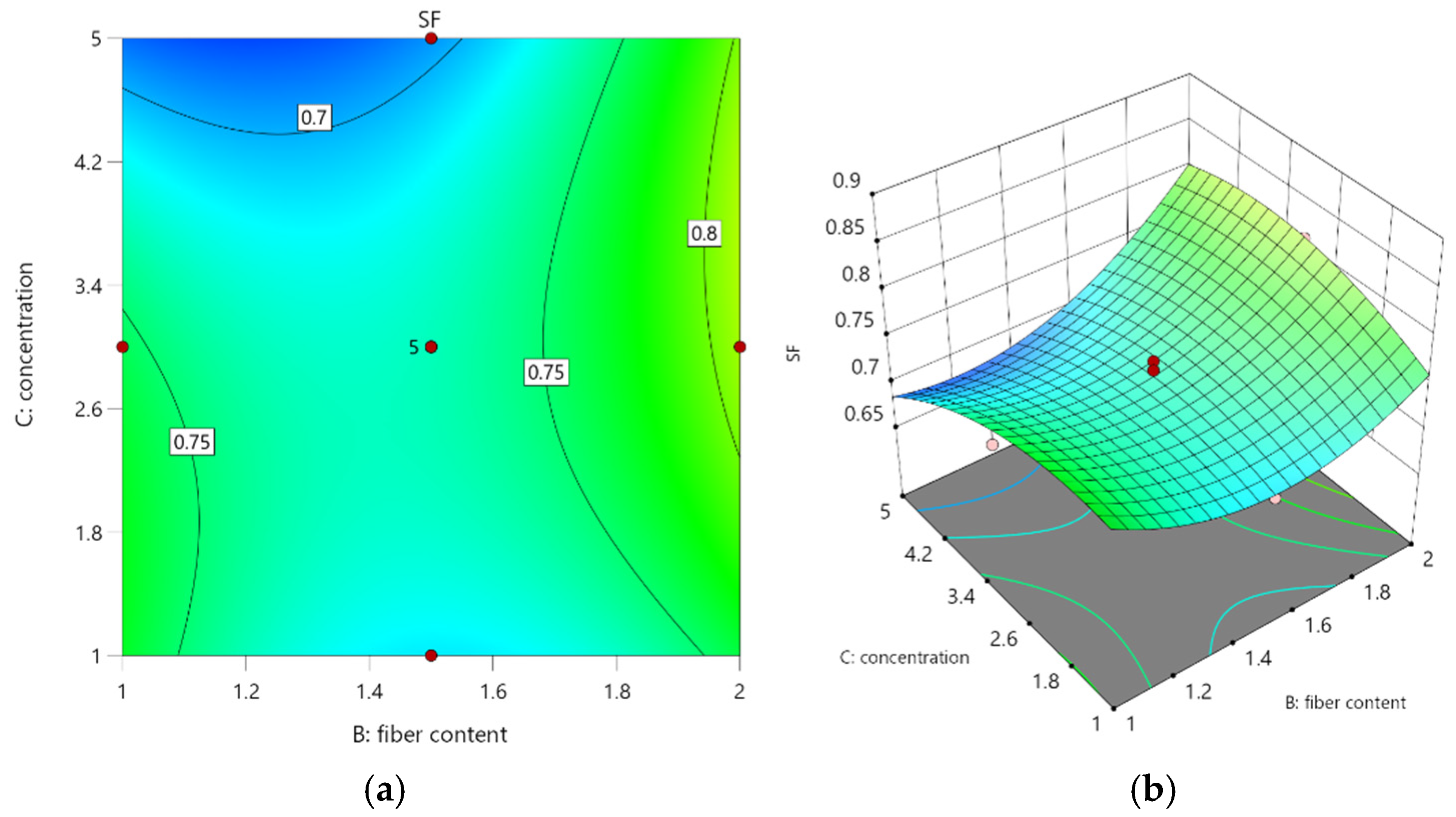

Figure 16 depicts a contour plot and a 3D response surface plot of

as a function of stainless steel fiber content and Na

2SO

4 concentration, derived from Equation (5). The density of contour lines in

Figure 16a’s horizontal axis, representing the fiber content, closely mirrors that in the vertical axis, which signifies the Na

2SO

4 concentration. This observation suggests that both factors exert a comparable influence on

when assessing its performance. In

Figure 16b, the 3D response surface is presented as follows:

When a small amount of Na2SO4 solution is added and the concentration of Na2SO4 solution is 1%, the curve exhibits a gradual increase with rising stainless steel fiber content. However, as the concentration of Na2SO4 solution increases, the curve demonstrates an upward trend that is more pronounced than at lower concentrations, indicating that an appropriate Na2SO4 concentration can synergistically enhance the effect of stainless steel fiber content.

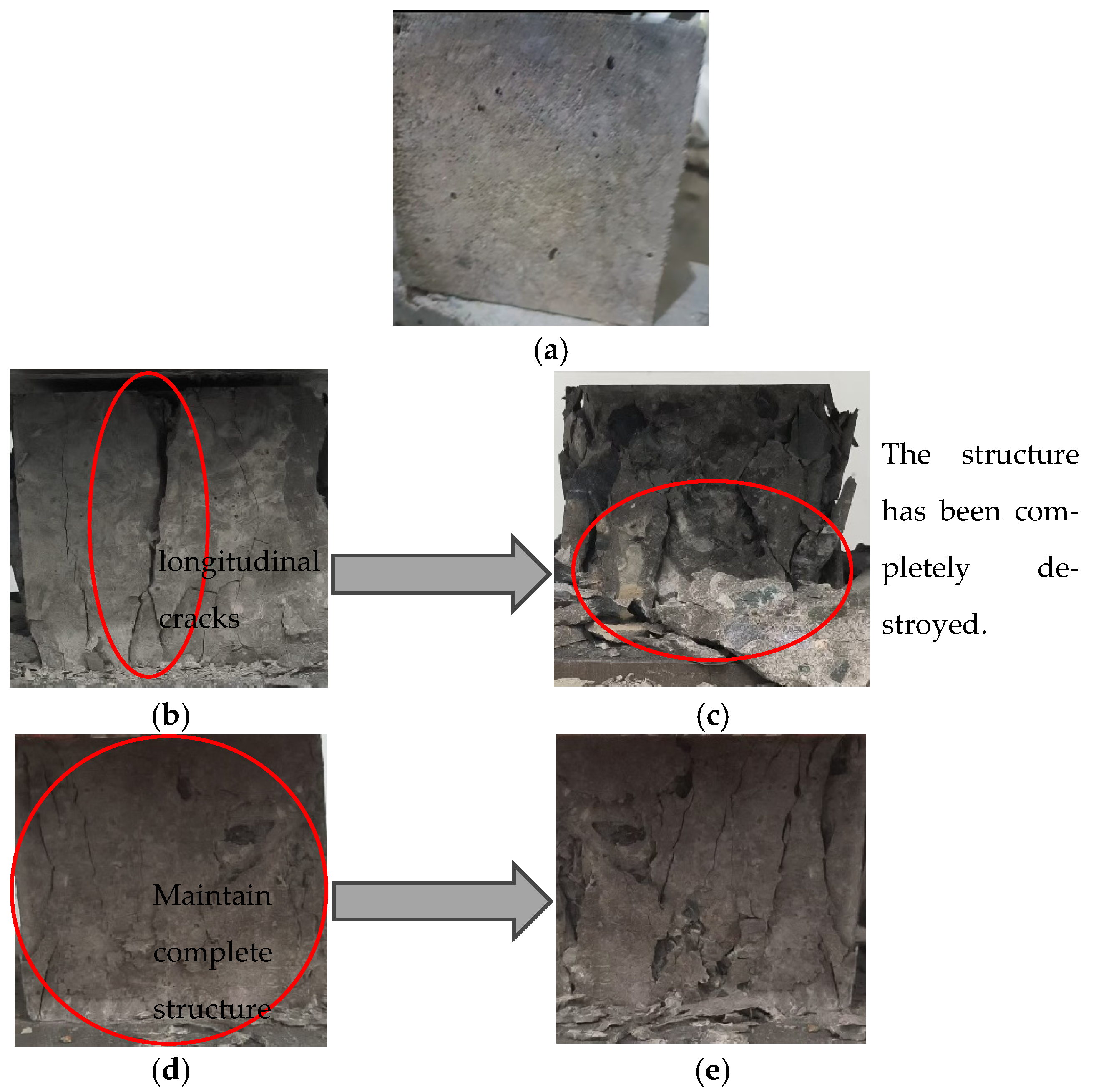

6.3. Corrosion of SSFRAC by Na2SO4

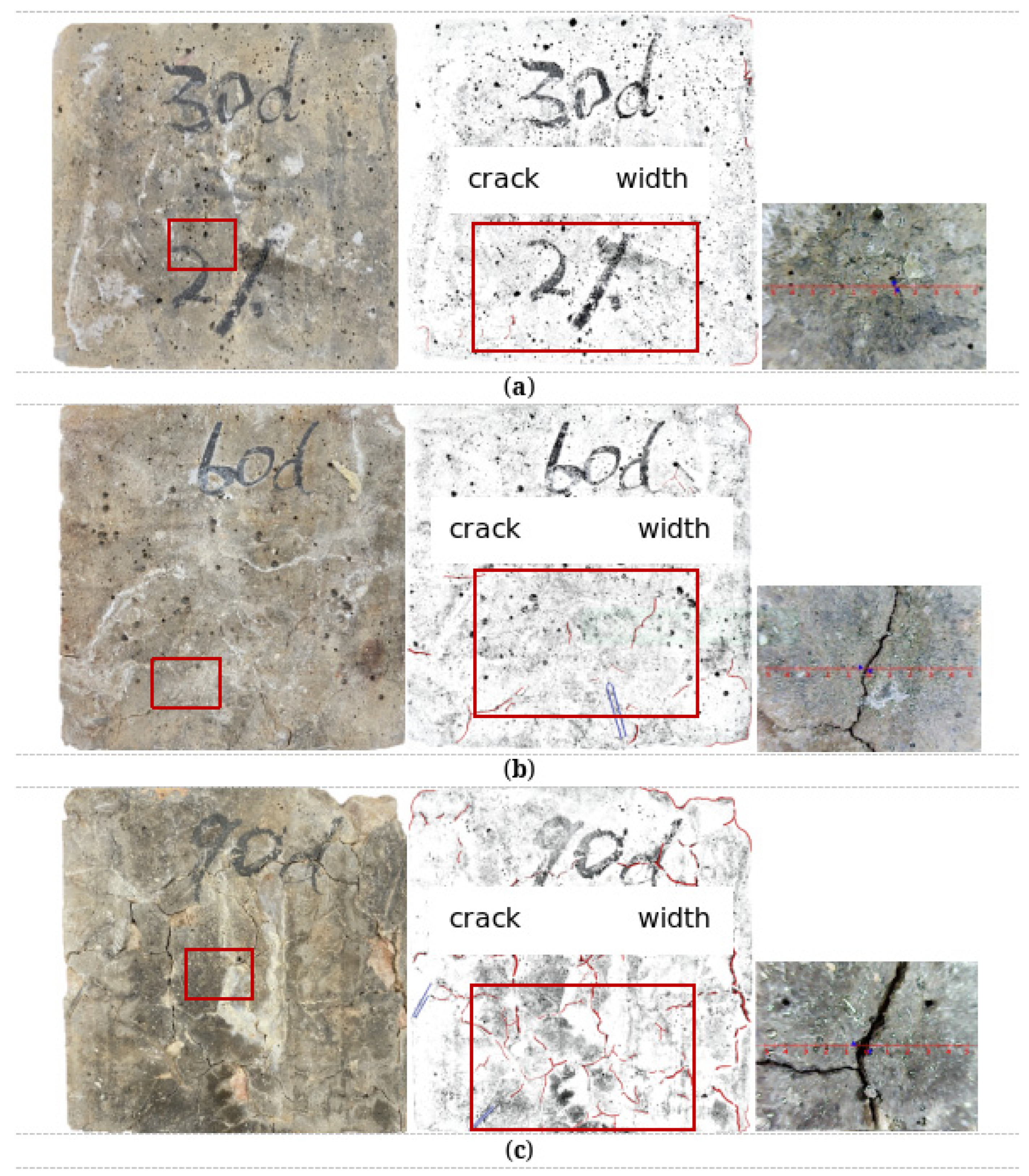

Figure 17 illustrates the observed alterations in the test specimens under a 5% Na

2SO

4 concentration, 2% stainless steel fiber content, and dry–wet cycling for 30, 60, and 90 cycles. The cracks were detected using PS and depicted. It is evident that with an increase in the number of dry–wet cycles from

Figure 17a–c, there is a corresponding escalation in both the quantity and width of cracks on the specimen surface. Utilizing the KS-105 wireless crack width gauge alongside advanced electronic imaging technology, the original state of the specimen surface was displayed on a tablet screen, enabling automatic measurement of crack widths using a high-precision ruler. The measured crack widths on the specimen surface after 90 dry–wet cycles were found to be 0.49 mm; after 60 cycles they were recorded at 0.23 mm, while after just 30 cycles they measured only at 0.03 mm. There is a varying degree of precipitation on the surface, indicating a violent chemical reaction within the concrete. The hydration product Ca(OH)

2 reacts with Na

2SO

4 solution to form gypsum, leading to the gradual formation of cracks in both the interior and surface of the concrete. As dry–wet cycling times increase, crack width and connectivity continue to expand, accompanied by precipitation of gypsum crystals that reduce bonding material between aggregates. Visible cracks can be observed on aggregate surfaces as well. At this stage, the bending resistance of the test piece decreases. Furthermore, higher stainless steel fiber content results in more internal pores and faster deterioration, explaining why higher stainless steel fiber content leads to faster decline compared to lower content.

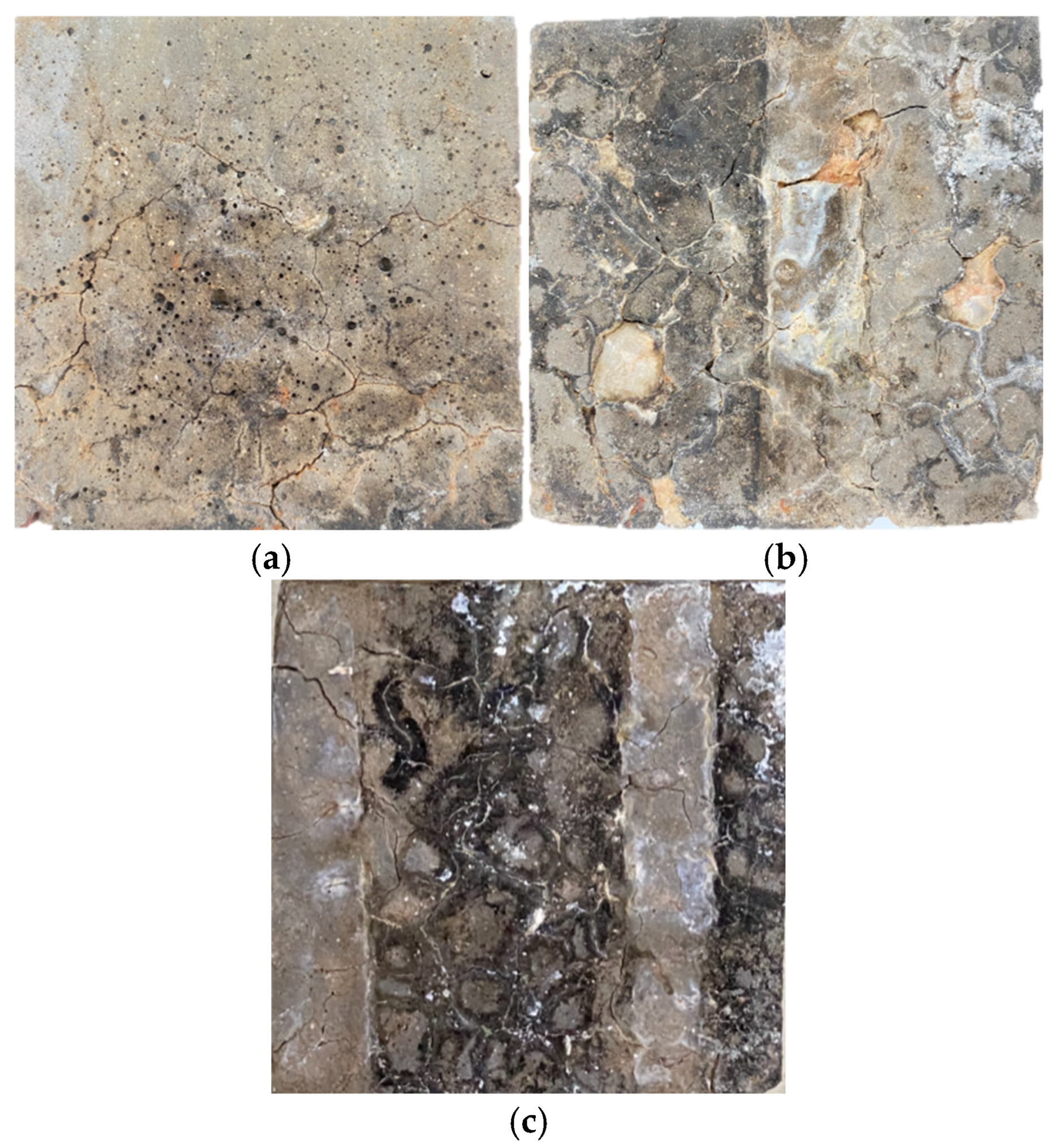

Figure 18 illustrates apparent changes in test pieces after 90 dry–wet cycles with 2% stainless steel fiber content and Na

2SO

4 concentrations at 1%, 3%, and 5%. From

Figure 17c, it is evident that at a Na

2SO

4 concentration of 5%, there is increased precipitation and more pronounced deterioration on the test piece surface.

6.4. Theoretical Analysis of Na2SO4 for SSFRAC

Sulfate attack primarily involves two stages: the initial stage occurs when sulfate ions infiltrate SSFRAC and react with the hydration products of cement, Ca(OH)

2, to form gypsum, which fills the pores within SSFRAC. The subsequent stage occurs as some sulfate ions penetrate further, leading to the formation of ettringite (AFt), which induces internal stress expansion upon contact with the pore wall. Once this internal stress expansion reaches the tensile strength of concrete aggregate, microcracks are generated, thereby facilitating salt precipitation [

26,

27,

28,

29].

In the experiment, a dark red substance was observed on the surface of the sample immersed in the solution and on the concrete specimen in the dry–wet cycling tank, indicating the presence of Fe

2O

3. While stainless steel fibers did not exhibit visible corrosion, microscopic corrosion products had already formed internally, with iron elements detected within these products. Equation (6) depicts the chemical reaction of sulfate ions penetrating the specimen during testing, while Equation (7) illustrates how this reaction involving Cr

2O

3 unique to stainless steel fibers differs from that of common steel fibers.

It should be noted that the feasibility of the reaction expressed in Equation (7) is also governed by thermodynamic principles. According to reported thermodynamic data of the relevant oxides and sulfates (ΔG and ΔH values), the reaction between Cr2O3 in stainless steel fibers and sulfate ions is thermodynamically permissible under aqueous conditions. This indicates that the reaction can proceed spontaneously, although the rate may be limited by kinetic factors such as ion diffusion and local concentration gradients during dry–wet cycling. Therefore, Equation (7) is not only a hypothetical mechanism but is also supported by thermodynamic considerations, which distinguishes the corrosion resistance mechanism of stainless steel fibers from that of ordinary steel fibers.