Study of Surface Wear of Punches and Molds for Optimization of Nuclear Fuel Production

Abstract

1. Introduction

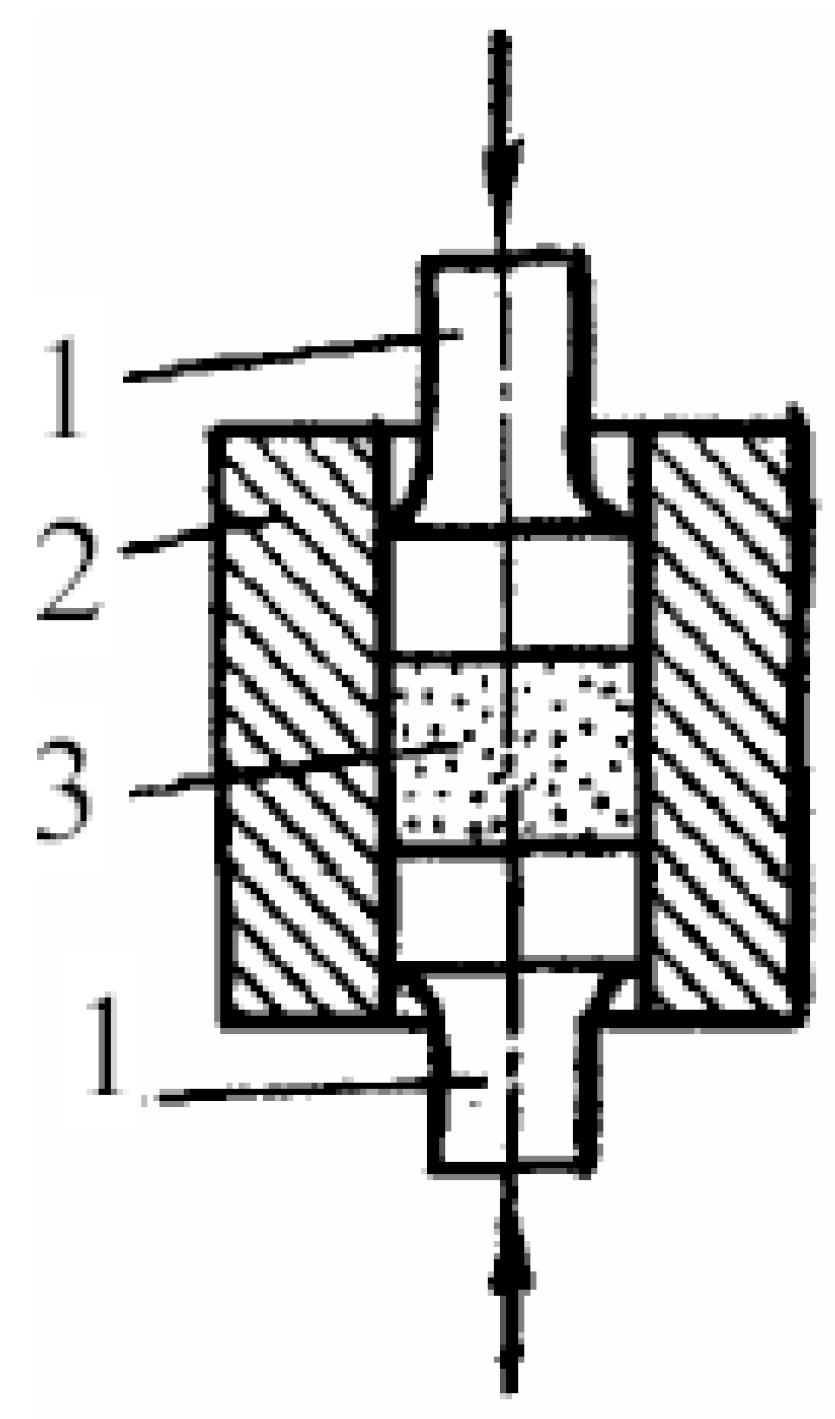

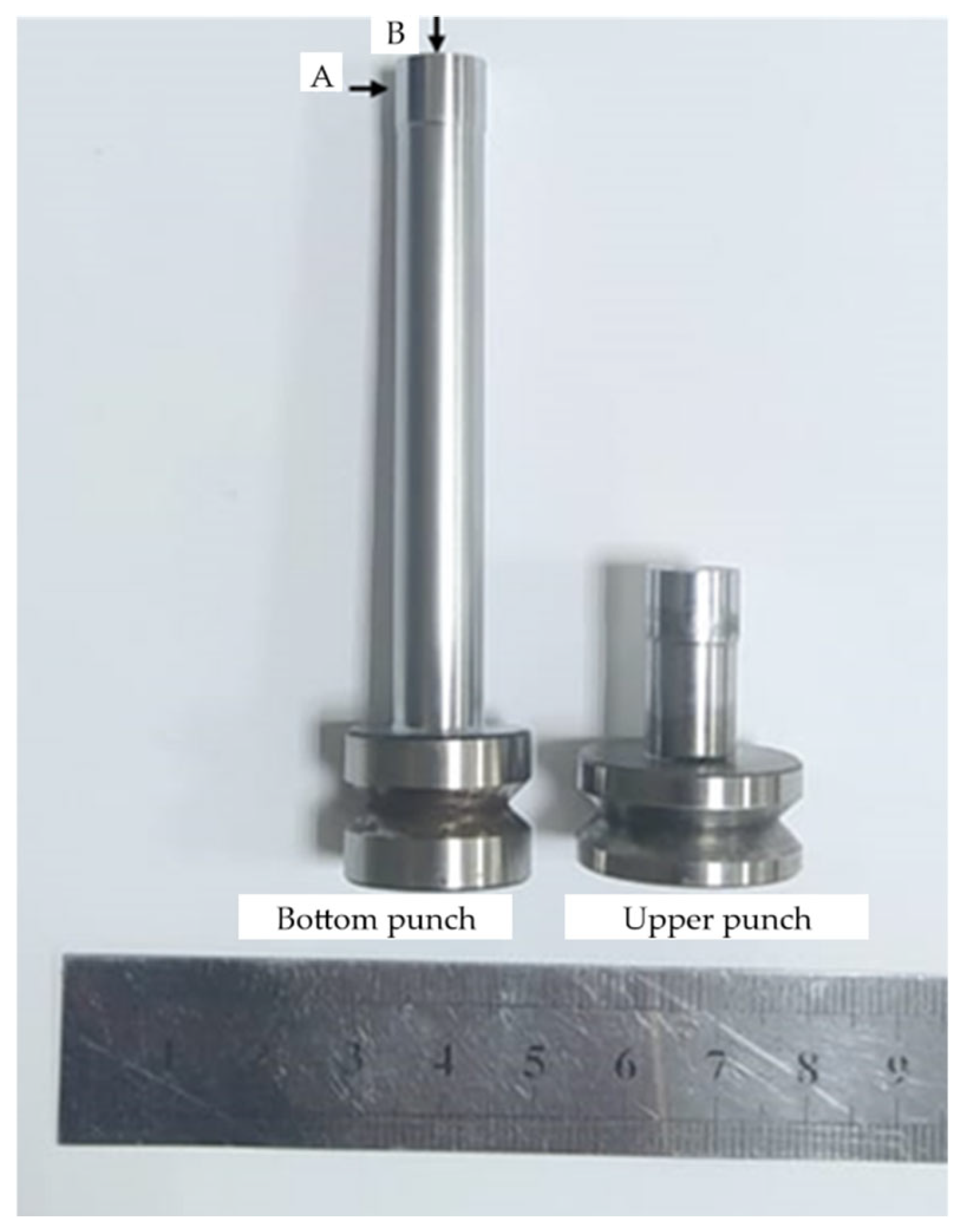

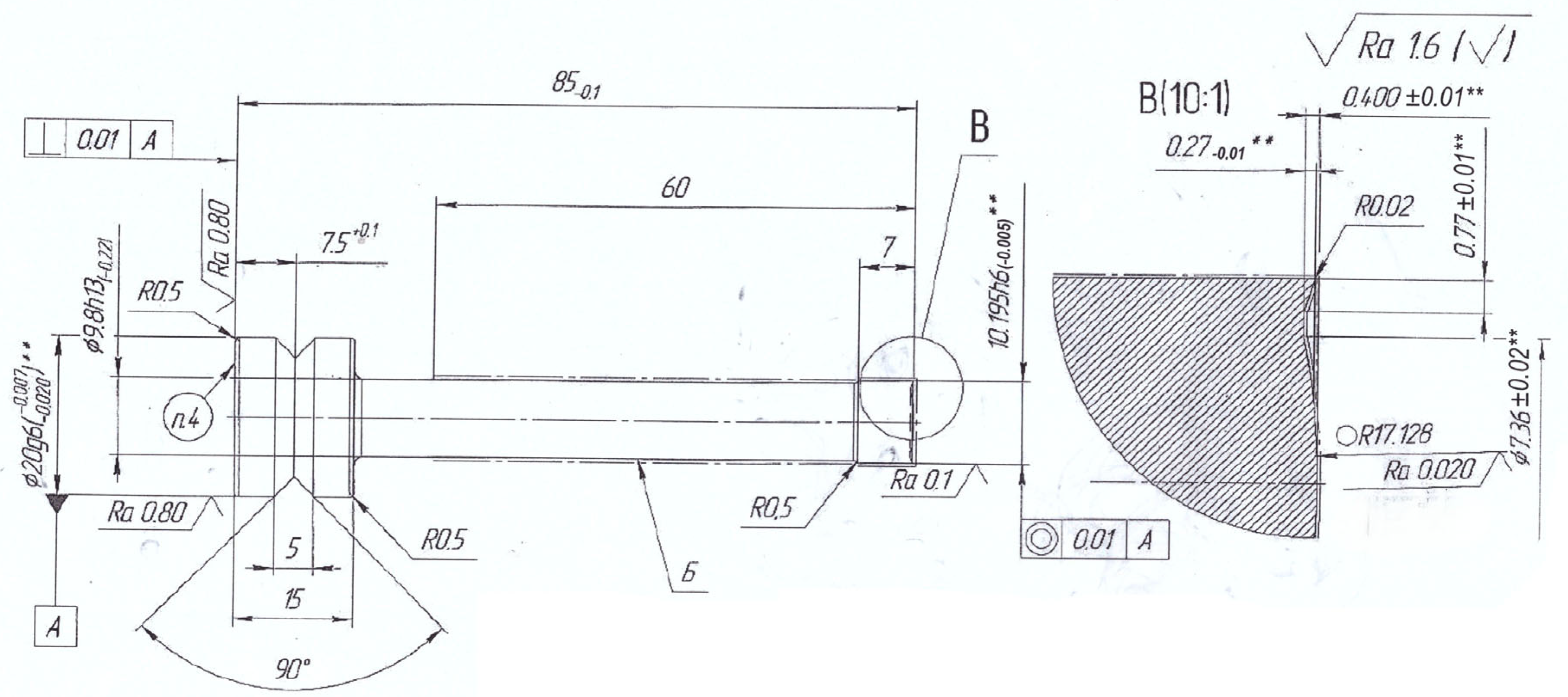

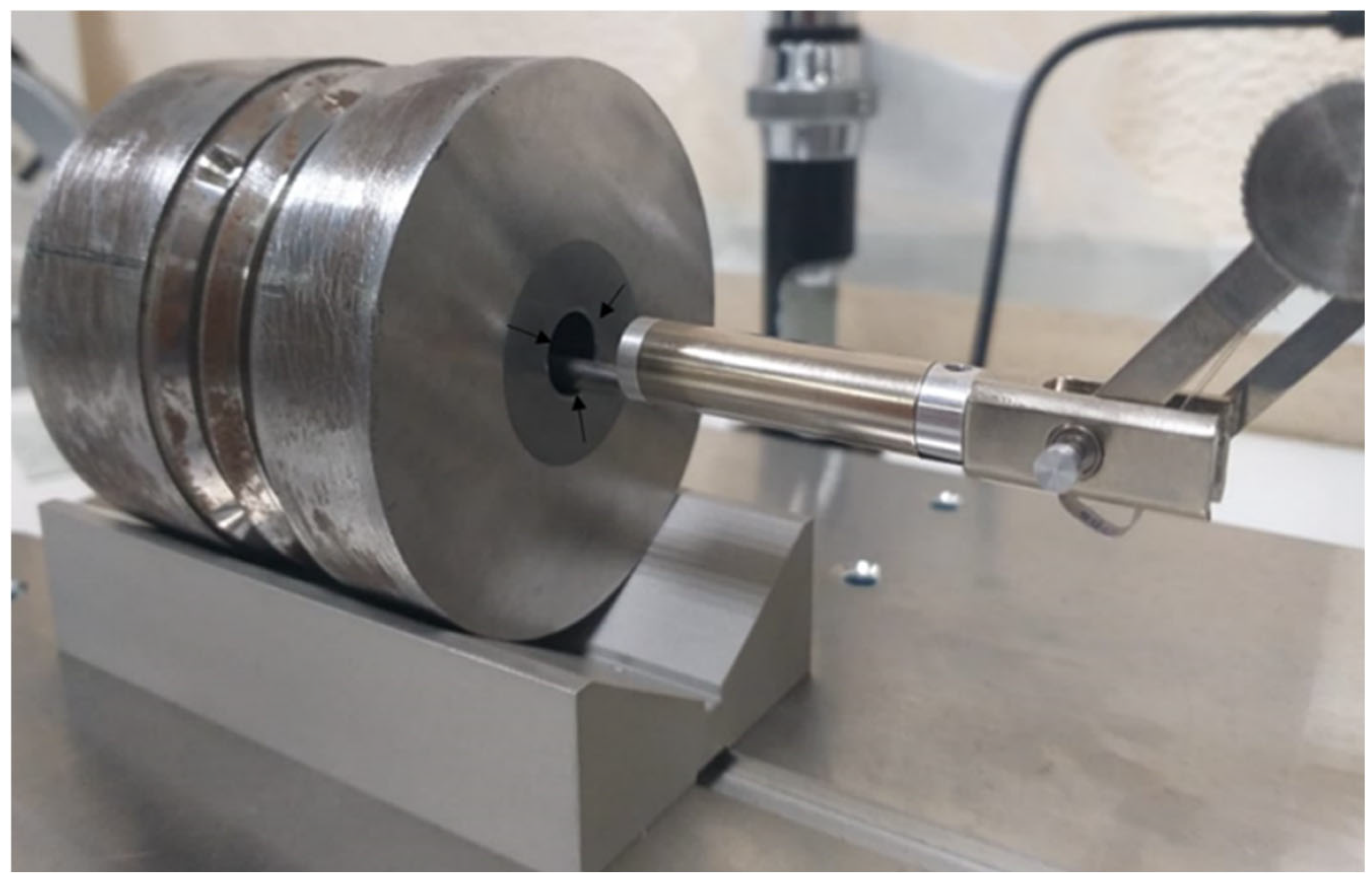

2. Materials and Methods

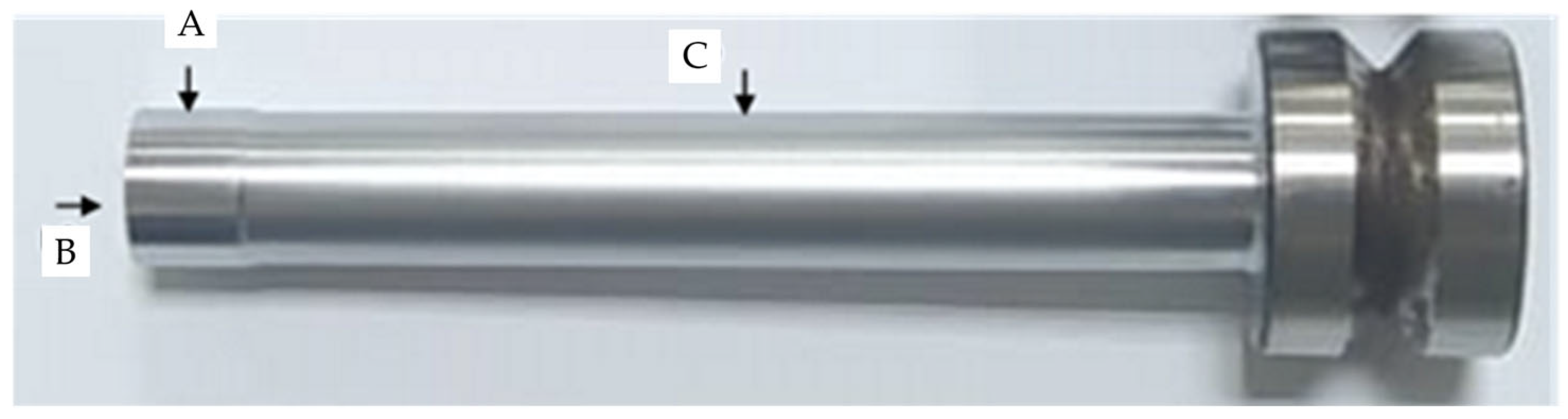

2.1. Materials

2.2. Research Methods

3. Research Results

3.1. Surface Roughness Analysis

3.2. Microhardness

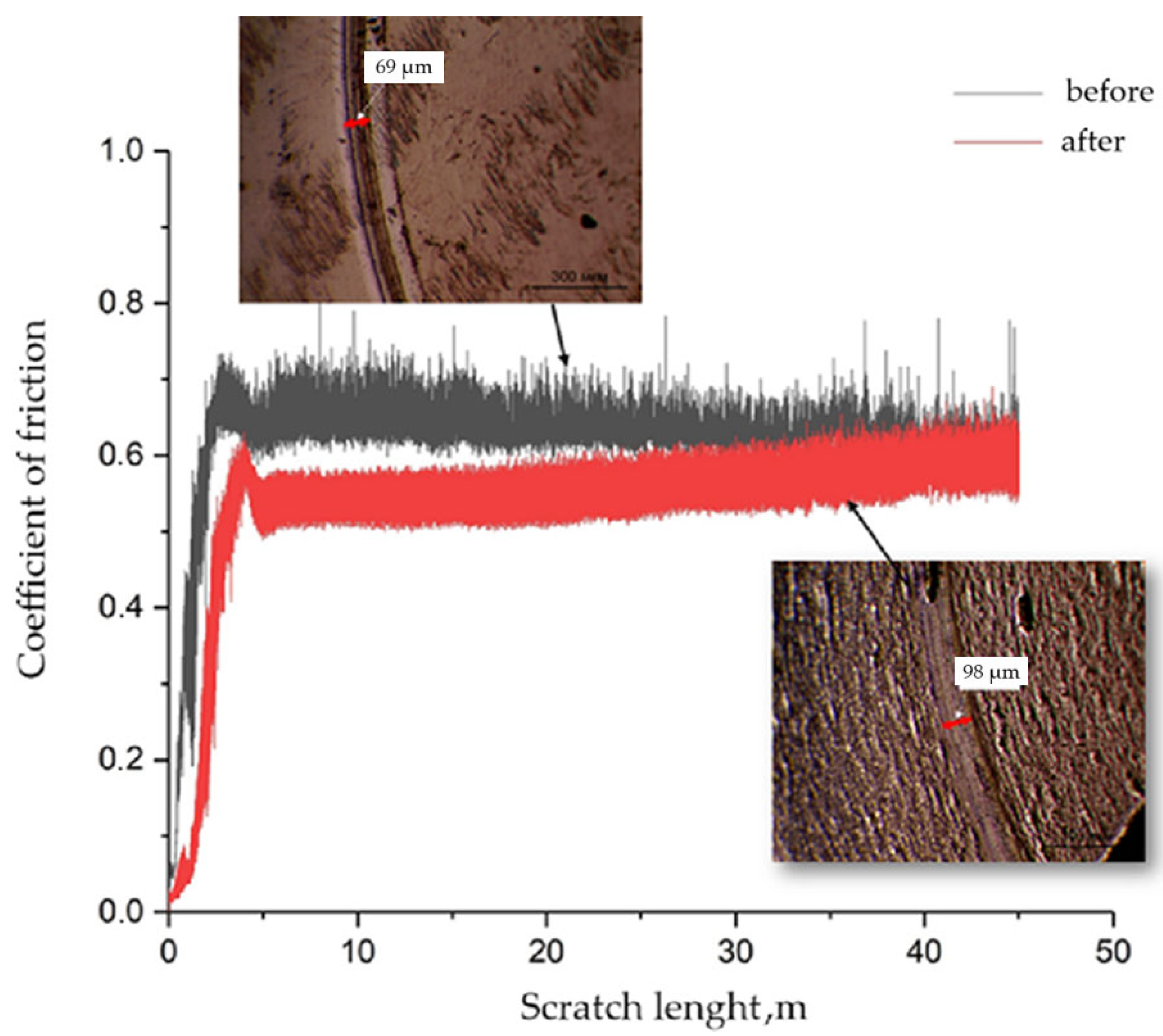

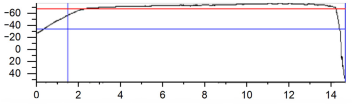

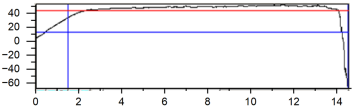

3.3. Analysis of Tribological Tests

3.4. Xrf (X-Ray Fluorescence) Results

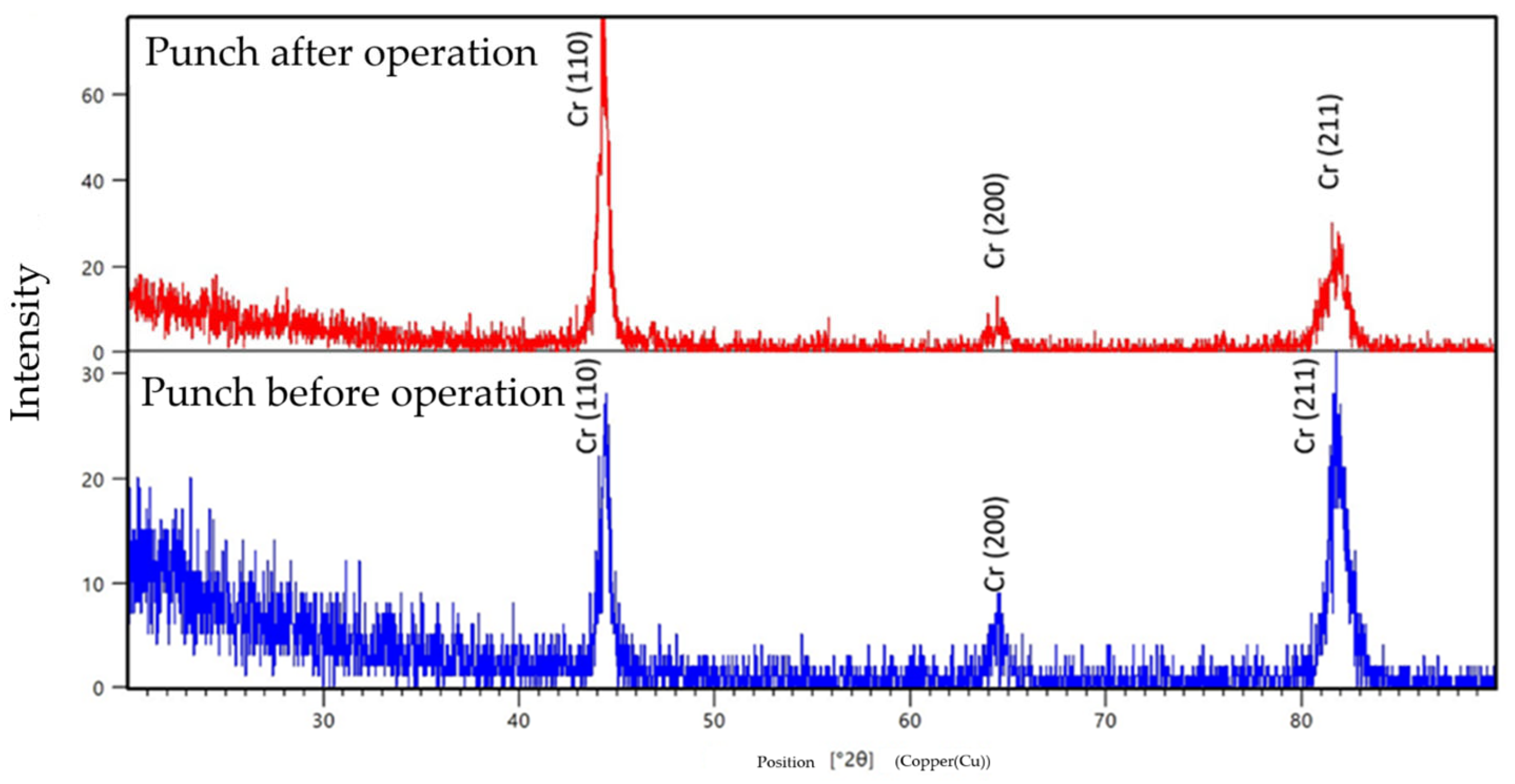

3.5. X-Ray Phase Analysis (XRD—X-Ray Diffraction)

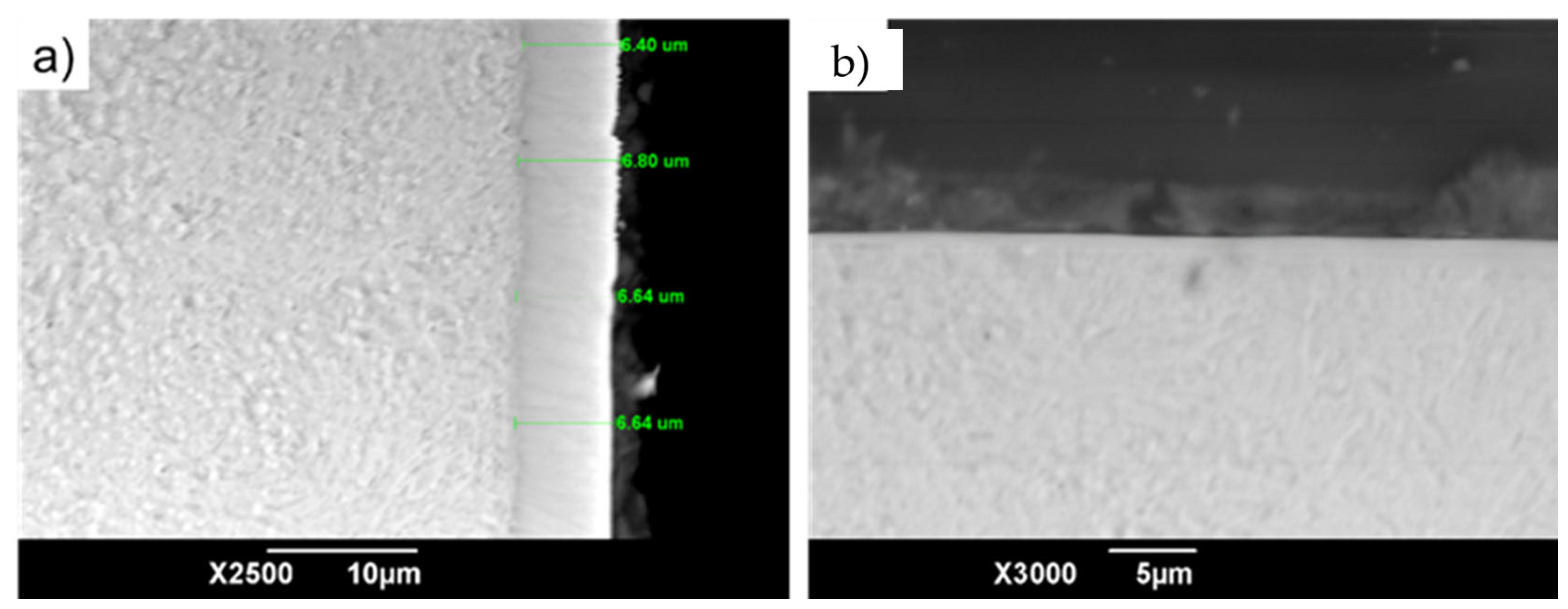

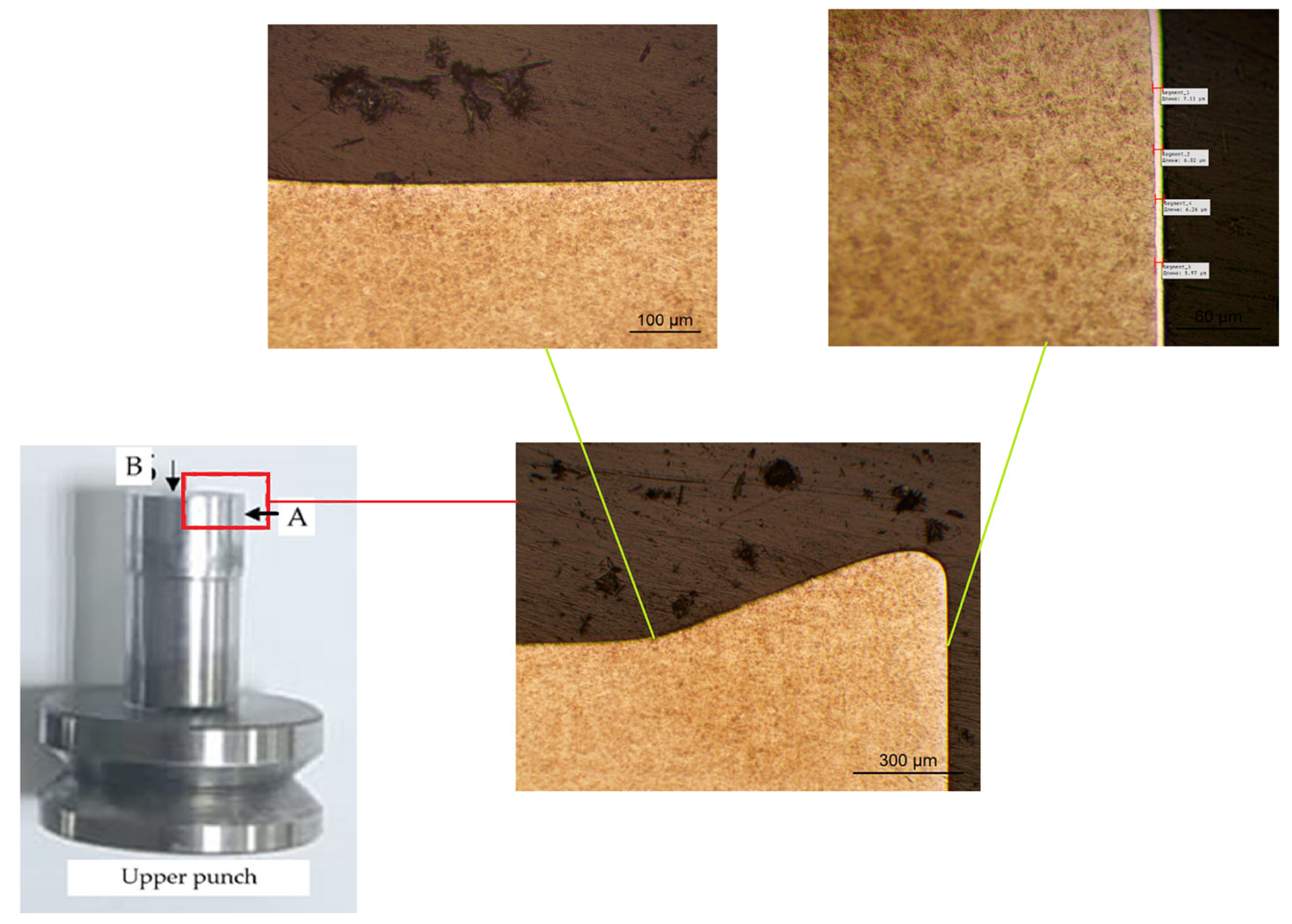

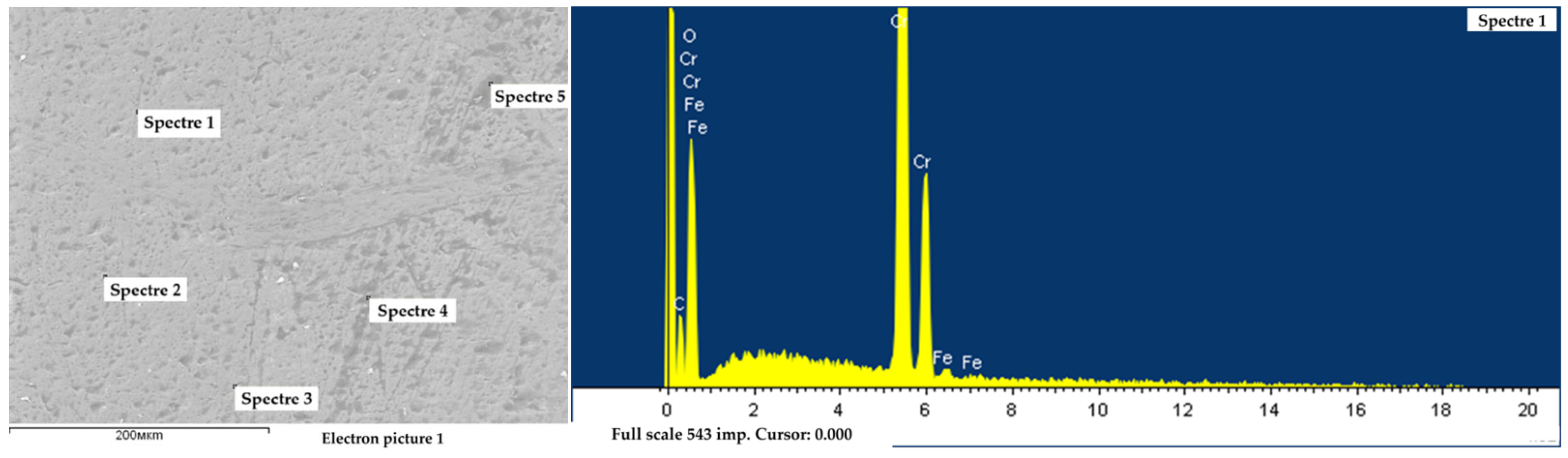

3.6. Results of M Croscopic Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Santra, N. Advances in Process Materials for Production of UO2. 2021. Available online: https://www.academia.edu/56709344/Advances_in_Process_Materials_for_Production_of_Uo (accessed on 19 August 2025).

- Jeon, S.-C.; Lee, J.-W.; Lee, J.-H.; Kang, S.-J.; Lee, K.-Y.; Cho, Y.-Z.; Ahn, D.-H.; Song, K.-C. Fabrication of UO2 Porous Pellets on a Scale of 30 kg-U/Batch at the PRIDE Facility. Adv. Mater. Sci. Eng. 2015, 2015, 376173. [Google Scholar] [CrossRef]

- Tyrpekl, V.; Cologna, M.; Vigier, J.-F.; Cambriani, A.; De Weerd, W.; Somers, J. Preparation of bulk-nanostructured UO2 pellets using high-pressure spark plasma sintering for LWR fuel safety assessment. J. Am. Ceram. Soc. 2017, 100, 1269–1274. [Google Scholar] [CrossRef]

- Li, B.; Yang, Z.; Wang, Z.; Huang, Q.; Zhang, D.; Xu, Q.; Xie, L.; Zhong, Y.; Wang, Y.; Duan, L.; et al. Thermal conductivity of UO2 pellets enhanced by a semi-continuous structure of Ti3SiC2. Ceram. Int. 2023, 49, 26049–26056. [Google Scholar] [CrossRef]

- Gorton, J.P.; McDuffee, J.L.; Snarr, P.L.; Petrie, C.M.; Nelson, A.T. Heat transfer optimization of uo2-mo fuel using genetic algorithms. Nucl. Eng. Des. 2024, 418, 112861. [Google Scholar] [CrossRef]

- Fu, J.; Li, J.; Wang, Z.; Cong, T.; Guo, H.; Xiao, Y.; Gu, H. Numerical study of the effect of helical fuel rod geometry on single-phase flow and heat transfer characteristics. Ann. Nucl. Energy 2024, 205, 110574. [Google Scholar] [CrossRef]

- Sedgi, I.; Moyal, A.; Assulin, M.; Rubinstein, A.; Brandis, M.; Gershinsky, G.; Edry, I.; Halevy, I.; Fruchter, N.; Zakon, Y.; et al. Nuclear forensic signatures of UO2 fuel pellets for differentiation and provenance determination illustrated using synthetic database. J. Nucl. Mater. 2023, 587, 154730. [Google Scholar] [CrossRef]

- Dooley, P.; Contryman, D.; Hervey, A.; Ivers, R.; Reddish, I.; Song, Y. Design of an optimized nuclear fuel pellet. Nucl. Sci. Technol. Open Res. 2024, 2, 1. [Google Scholar] [CrossRef]

- Rakhadilov, B.K.; Kurbanbekov, S.R.; Kilishkhanov, M.K.; Kenesbekov, A.B.; Amanzholov, S. Changing the structure and phasestates and the microhardness of the R6M5 steel surface layer after electrolytic-plasma nitriding. Eurasian J. Phys. Funct. Mater. 2018, 2, 259–266. [Google Scholar] [CrossRef]

- Balboa, H.; Van Brutzel, L.; Chartier, A.; Le Bouar, Y. Assessment of empirical potential for MOX nuclear fuels and thermomechanical properties. J. Nucl. Mater. 2017, 495, 67–77. [Google Scholar] [CrossRef]

- Cheng, J.; Zhao, J.-H.; Zhang, J.-Y.; Guo, Y.; He, K.; Shang-guan, J.-J.; Wen, F.-L. Microstructure and Mechanical Properties of Galvanized-45 Steel/AZ91D Bimetallic Material by Liquid-Solid Compound Casting. Materials 2019, 12, 1651. [Google Scholar] [CrossRef]

- Bai, X.; Jiang, J.; Li, C.H.; Dong, L.; Duan, Z.; Zhang, H. Lubrication Performance of Different Concentrations of Al2O3 Nanofluids on Minimum Quantity Lubrication Milling. Res. Sq. 2021. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Kengesbekov, A.; Zhurerova, L.; Kozhanova, R.; Sagdoldina, Z. Impact of electronic radiation on the morphology of the fine structure of the surface layer of R6M5 steel. Machines 2021, 9, 24. [Google Scholar] [CrossRef]

- El-Atwani, O.; Kim, H.; Gigax, J.G.; Harvey, C.; Aytuna, B.; Efe, M.; Maloy, S.A. Stable, Ductile and Strong Ultrafine HT-9 Steels via Large Strain Machining. Nanomaterials 2021, 11, 2538. [Google Scholar] [CrossRef]

- Chen, Y. Irradiation Effects Of Ht-9 Martensitic Steel. Nucl. Eng. Technol. 2013, 45, 311–322. [Google Scholar] [CrossRef]

- Sprouster, D.J.; Adam, B.; Koziol, A.; Rolly, L.; Huotilainen, C.; Tucker, J.D. Long-term thermal aging effects in ferritic-martensitic steel HT9. Mater. Charact. 2024, 217, 114418. [Google Scholar] [CrossRef]

- Byun, T.S.; Collins, D.A.; Lach, T.G.; Choi, J.P.; Maloy, S.A. Thermomechanical Processing for Improved Mechanical Properties of HT9 Steels. Materials 2024, 17, 3803. [Google Scholar] [CrossRef] [PubMed]

- Kengesbekov, A.; Rakhadilov, B.; Satbaeva, Z.; Kambarov, Y. Effect of Helium Plasma Irradiation on Microstructures and Mechanical Properties of Tungsten. Adv. Mater. Sci. Eng. 2024, 2024, 1968615. [Google Scholar] [CrossRef]

- Kengesbekov, A. Influence of Plasma Arc Current and Gas Flow on the Structural and Tribological Properties of TiN Coatings Obtained by Plasma Spraying. Coatings 2024, 14, 1404. [Google Scholar] [CrossRef]

- Xie, Z.; Yin, C.; Zhang, J.; Jiao, Y.; Ding, G.; Yang, Q.; Ding, S.; Chen, P. On the creep mechanisms and macroscopic creep rate modeling of high-uranium-density composite fuels. J. Nucl. Mater. 2023, 586, 154679. [Google Scholar] [CrossRef]

- GOST-2789-73; Surface Roughness. Parameters and Characteristics. In Consulting: Ukraine, Russia, 2006.

- ASTM G99/G133-22; Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear. ASTM: West Conshohocken, PA, USA, 2022.

- GOST 9450-76; Measurement of Microhardness by Indentation of Diamond Tips. In Consulting: Ukraine, Russia, 1977.

- ISO 6507-1:2023; Metallic Materials—Vickers Hardness Test. Part 1: Test method. ISO: Geneva, Switzerland, 2023.

- Kolyvanov, E.L.; Afonikova, N.S.; Kobelev, N.P. X-ray Diffraction Tests of Near-Surface Layer of Copper Treated by Ball Rolling. Inorg. Mater. Appl. Res. 2018, 9, 699–702. [Google Scholar] [CrossRef]

- Harrington, G.F.; Santiso, J. Back-to-Basics tutorial: X-ray diffraction of thin films. J. Electroceram. 2021, 47, 141–163. [Google Scholar] [CrossRef]

- Rizal, C. Microstructure, Surface Plasmon, Magneto-optic Surface Plasmon, and Sensitivity Properties of Magneto-plasmonic Co/Au Multilayers. IEEE Trans. Magn. 2018, 54, 5300309. [Google Scholar] [CrossRef]

- Bai, X.; Jiang, J.; Li, C.; Dong, L.; Ali, H.M.; Sharma, S. Tribological Performance of Different Concentrations of Al2O3 Nanofluids on Minimum Quantity Lubrication Milling. Chin. J. Mech. Eng. 2023, 36, 11. [Google Scholar] [CrossRef]

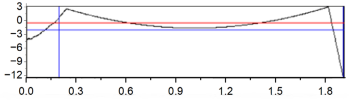

| Sample | Profile Along the Punch Length | Parameters, Microns |

|---|---|---|

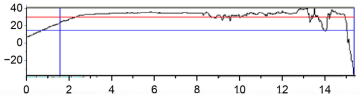

| Matrix before operation |  | Ra = 0.0559 Rz = 0.125 Rq = 0.0779 Rv = 0.119 |

| Ra = 0.0623 Rz = 0.143 Rq = 0.0881 Rv = 0.125 | |

| Ra = 0.0573 Rz = 0.131 Rq = 0.0837 Rv = 0.125 | |

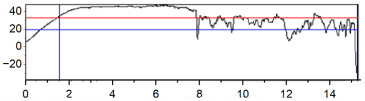

| Matrix after operation |  | Ra = 0.150 Rz = 0.474 Rq = 0.212 Rv = 0.354 |

| Ra = 0.206 Rz = 0.549 Rq = 0.261 Rv = 0.455 | |

| Ra = 0.161 Rz = 0.493 Rq = 0.234 Rv = 0.395 |

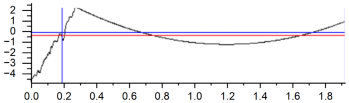

| Sample | Punch Length Profile | Parameters, Microns |

|---|---|---|

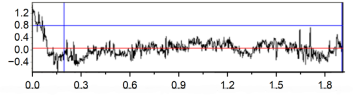

| Punch before operation (side A) |  | Ra = 0.140 Rz = 1.11 Rt = 1.62 Rq = 0.192 Rv = 0.659 |

| Punch after operation, (side A) |  | Ra = 0.212 Rz = 1.21 Rt = 1.75 Rq = 0.285 Rv = 0.772 |

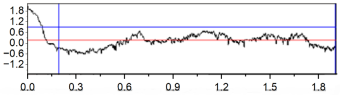

| Punch before operation (side B) |  | Ra = 0.158 Rz = 0.914 Rt = 9.96 Rq = 0.243 Rv = 0.586 |

| Punch after operation (side B) |  | Ra = 0.368 Rz = 2.23 Rt = 4.42 Rq = 0.529 Rv = 0.937 |

| Punch | Punch Before Operation (Side B) | Punch After Operation (Side B) | Punch Before Operation (Side A) | Punch After Operation (Side A) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Element | % | % | % | +/−[×] | % | +/−[×] | % | +/−[×] | |

| Fe | 60.1404 | 81.1313 | 81.1313 | 0.6170 | 26.7715 | 0.6170 | 39.4792 | 0.7736 | |

| Cr | 38.4234 | 17.7758 | 17.7758 | 0.6626 | 71.7405 | 0.6626 | 58.7249 | 0.6478 | |

| Co | 1.1787 | 0.7074 | 0.7074 | 0.1623 | 1.1837 | 0.1623 | 1.2483 | 0.1922 | |

| As | 0.1516 | 0.2501 | 0.2501 | 0.0548 | 0.0729 | 0.0548 | 0.1686 | 0.0890 | |

| Cu | 0.0702 | 0.0981 | 0.0981 | 0.0190 | 0.0395 | 0.0190 | 0.0416 | 0.0236 | |

| Mo | 0.0156 | 0.0173 | 0.0173 | 0.0090 | 0.0148 | 0.0090 | 0.00473 | 0.00135 | |

| Au | - | - | - | 0.0450 | 0.1017 | 0.0450 | - | - | |

| V | - | - | - | 0.0443 | 0.0470 | 0.0443 | 0.2246 | 0.0641 | |

| Ni | - | - | - | - | - | - | - | - | |

| Zn | - | 0.0041 | 0.0041 | - | - | - | - | - | |

| Spectrum | In Stat. | O | Cr | Fe | Total |

|---|---|---|---|---|---|

| Spectrum 1 | Yes | 4.54 | 94.71 | 0.75 | 100.00 |

| Spectrum 2 | Yes | 5.28 | 94.21 | 0.51 | 100.00 |

| Spectrum 3 | Yes | 2.79 | 96.17 | 1.05 | 100.00 |

| Spectrum 4 | Yes | 2.91 | 95.74 | 1.36 | 100.00 |

| Spectrum 5 | Yes | 3.30 | 95.77 | 0.93 | 100.00 |

| Average | 3.76 | 95.32 | 0.92 | 100.00 | |

| Standard deviation | 1.10 | 0.82 | 0.32 | ||

| Max. | 5.28 | 96.17 | 1.36 | ||

| Min. | 2.79 | 94.21 | 0.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rakhadilov, B.; Magazov, N.; Kengesbekov, A.; Kylyshkanov, M.; Kussainov, A. Study of Surface Wear of Punches and Molds for Optimization of Nuclear Fuel Production. Coatings 2025, 15, 1088. https://doi.org/10.3390/coatings15091088

Rakhadilov B, Magazov N, Kengesbekov A, Kylyshkanov M, Kussainov A. Study of Surface Wear of Punches and Molds for Optimization of Nuclear Fuel Production. Coatings. 2025; 15(9):1088. https://doi.org/10.3390/coatings15091088

Chicago/Turabian StyleRakhadilov, Bauyrzhan, Nurtoleu Magazov, Aidar Kengesbekov, Manarbek Kylyshkanov, and Arystanbek Kussainov. 2025. "Study of Surface Wear of Punches and Molds for Optimization of Nuclear Fuel Production" Coatings 15, no. 9: 1088. https://doi.org/10.3390/coatings15091088

APA StyleRakhadilov, B., Magazov, N., Kengesbekov, A., Kylyshkanov, M., & Kussainov, A. (2025). Study of Surface Wear of Punches and Molds for Optimization of Nuclear Fuel Production. Coatings, 15(9), 1088. https://doi.org/10.3390/coatings15091088