Effect of Basalt Fibers on the Performance of CO2-Cured Recycled Aggregate Concrete Composite Slab–Column Assemblies with Bolted Connections Under NaCl Erosion

Abstract

1. Introduction

2. Experimental

2.1. Raw Materials

2.2. Specimen Preparation

2.3. Freeze–Thaw Cycles and Dry–Wet Alternations Test Procedure

2.4. Measurement Methods

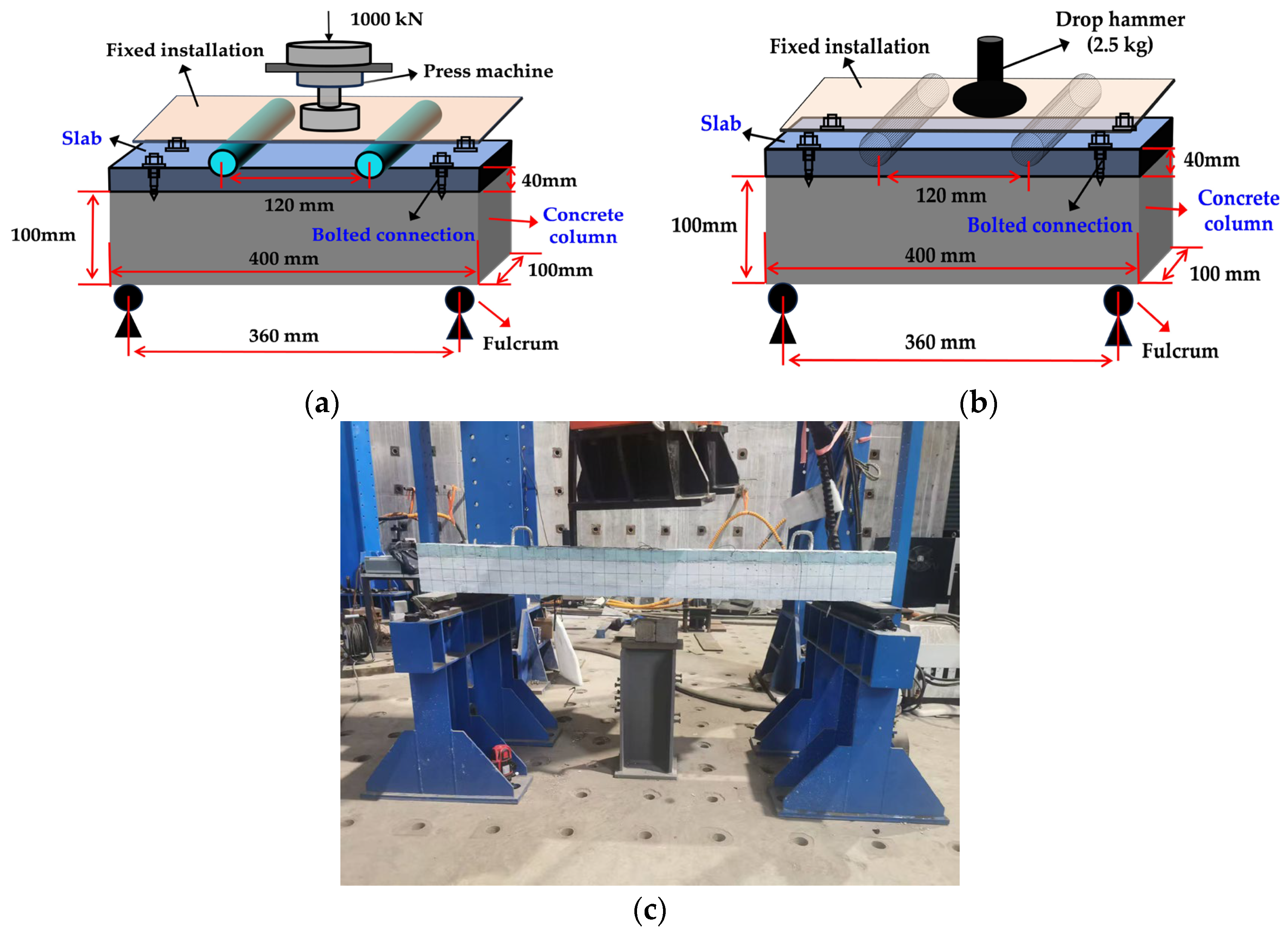

2.4.1. Dynamic Modulus of Elasticity Test

2.4.2. Axial Compressive Strength

2.4.3. Flexural and Impact Toughness

2.4.4. Scanning Electron Microscopy Energy-Dispersive Spectroscopy

3. Results and Discussion

3.1. NaCl Freeze–Thaw Cycles

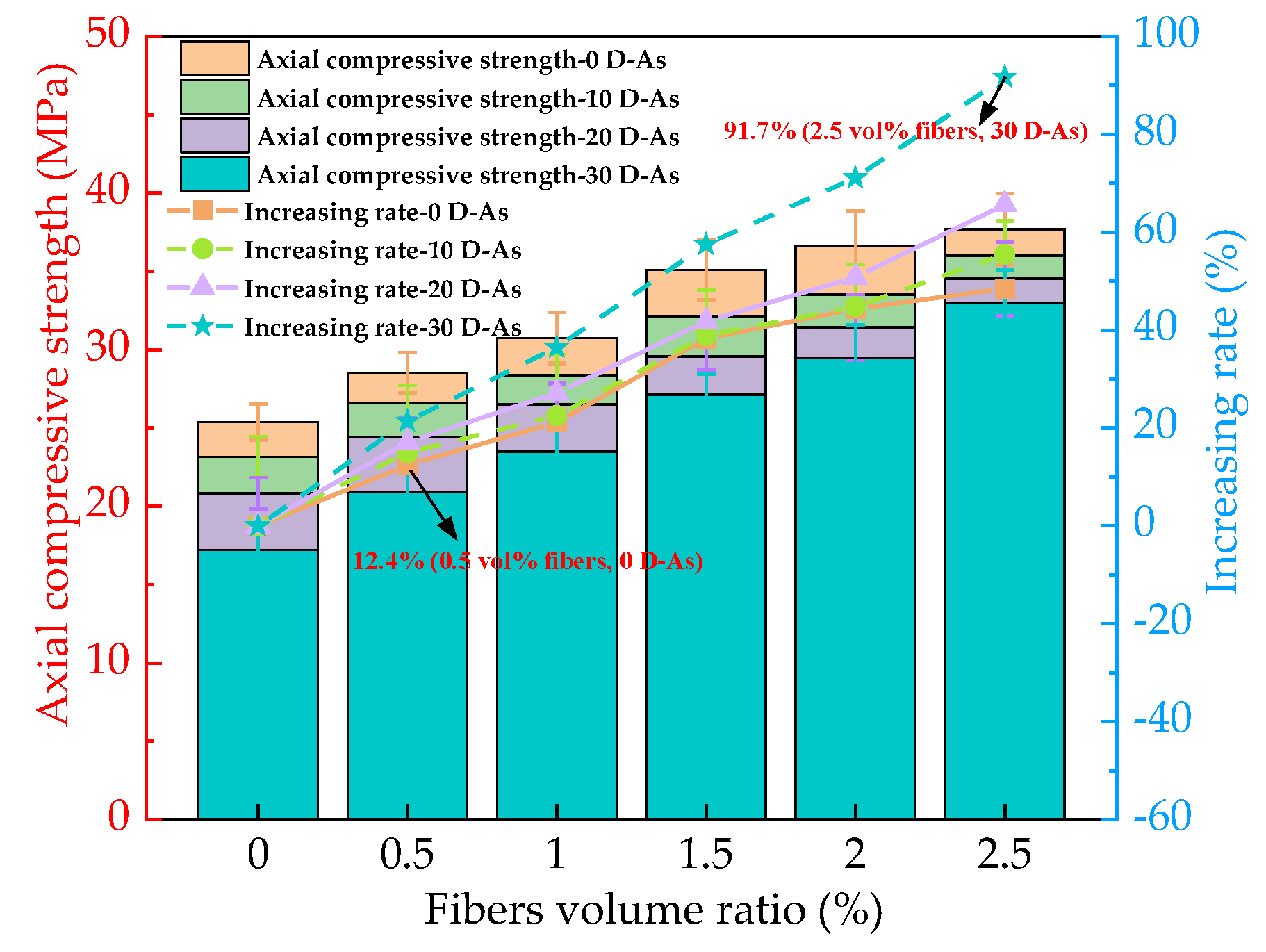

3.1.1. Axial Compressive Strength

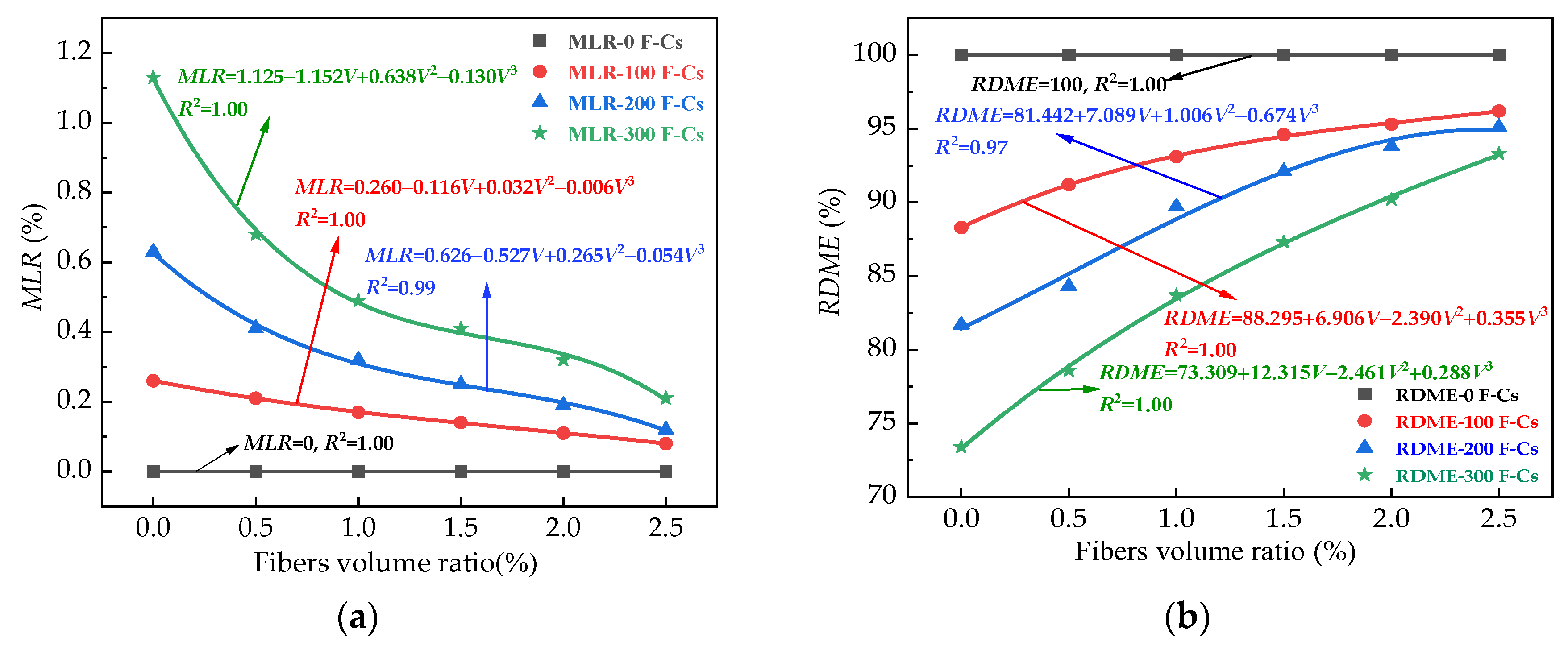

3.1.2. Mass Loss Rate and Relative Dynamic Modulus of Elasticity

3.1.3. Flexural Toughness Behavior Analysis

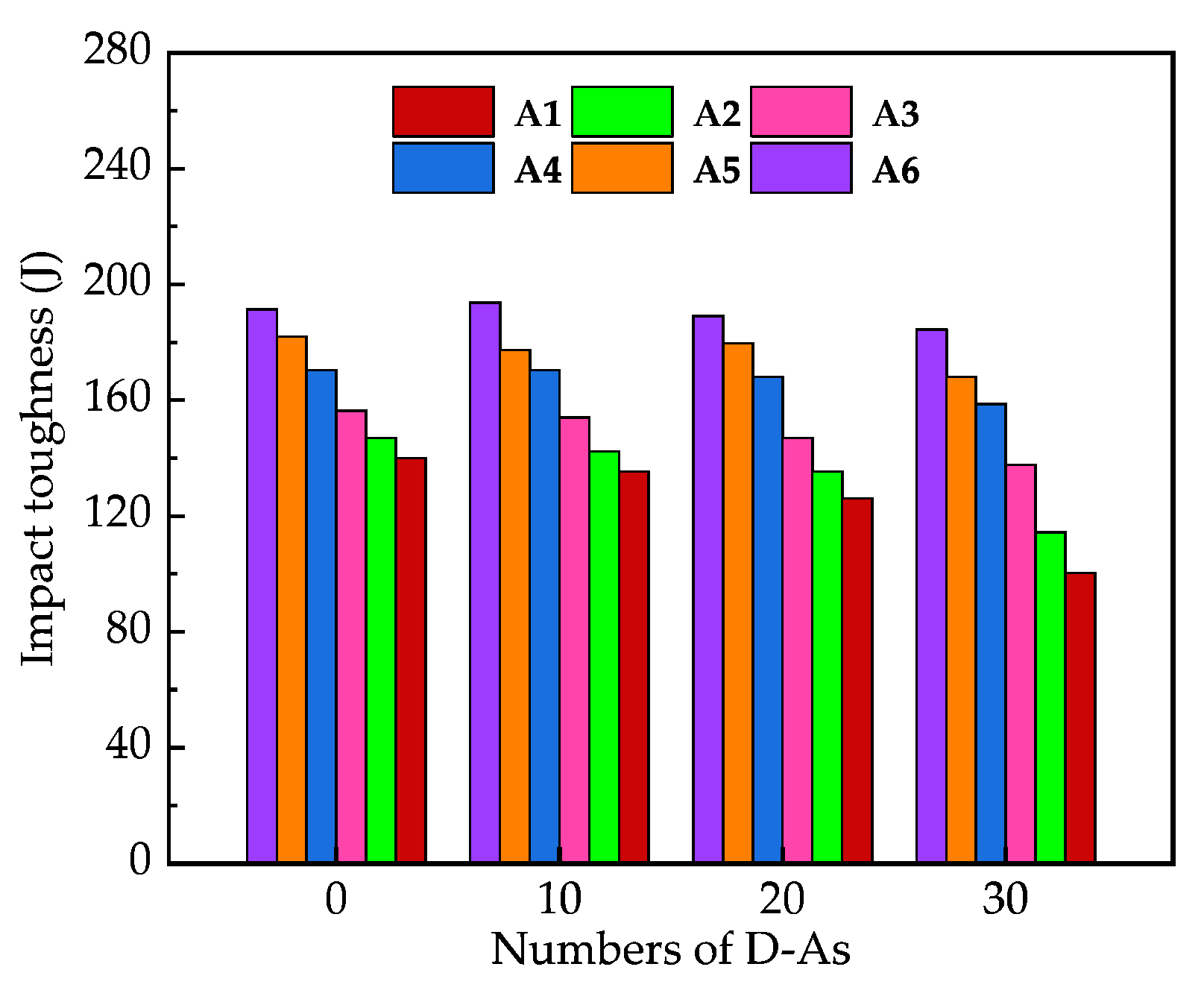

3.1.4. Impact Toughness Analysis

3.1.5. Microscopic Analysis

3.2. NaCl Dry–Wet Alternations

3.2.1. Axial Compressive Strength

3.2.2. Mass Loss Rate and Relative Dynamic Modulus of Elasticity

3.2.3. Flexural Toughness Behavior Analysis

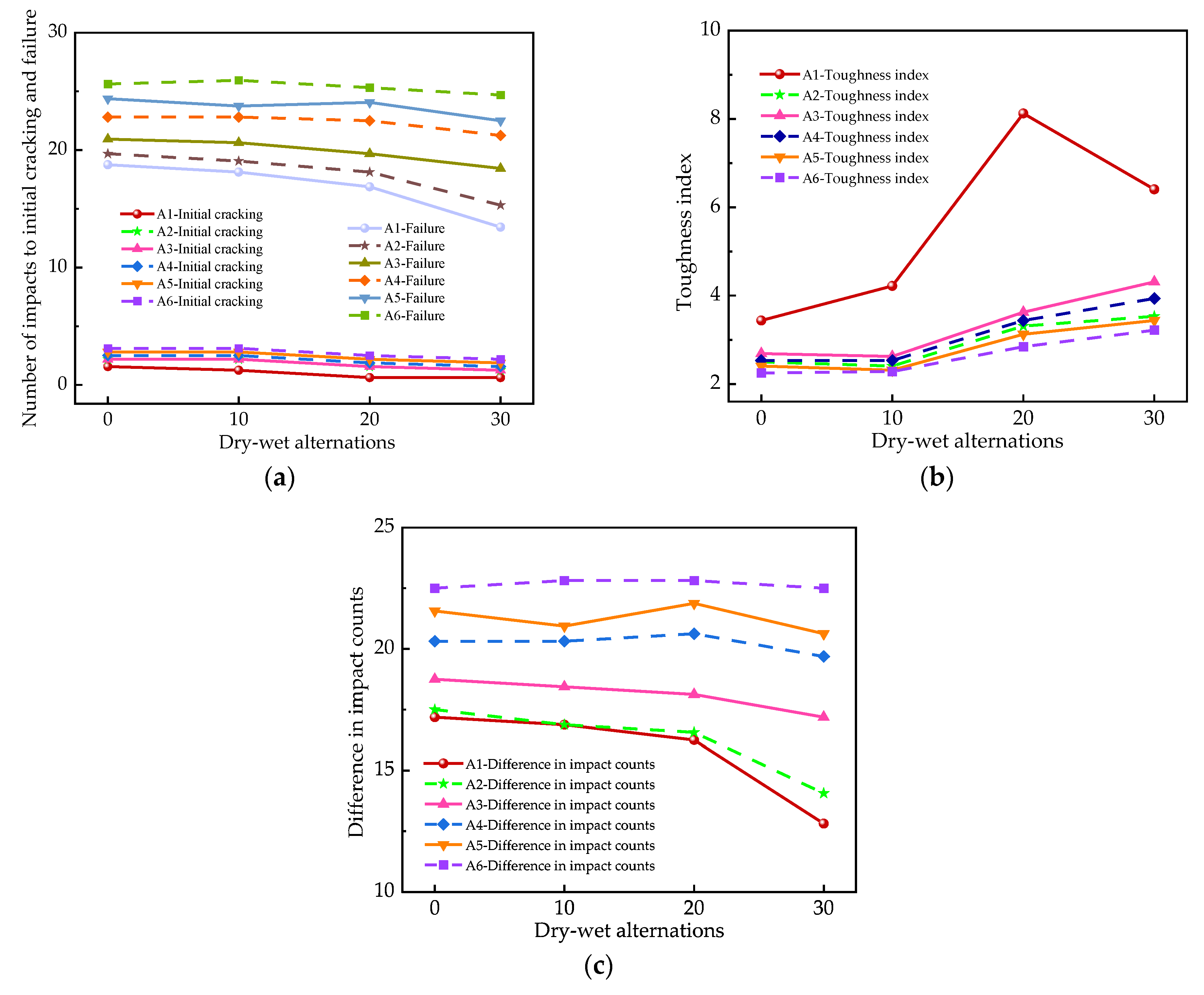

3.2.4. Impact Toughness Analysis

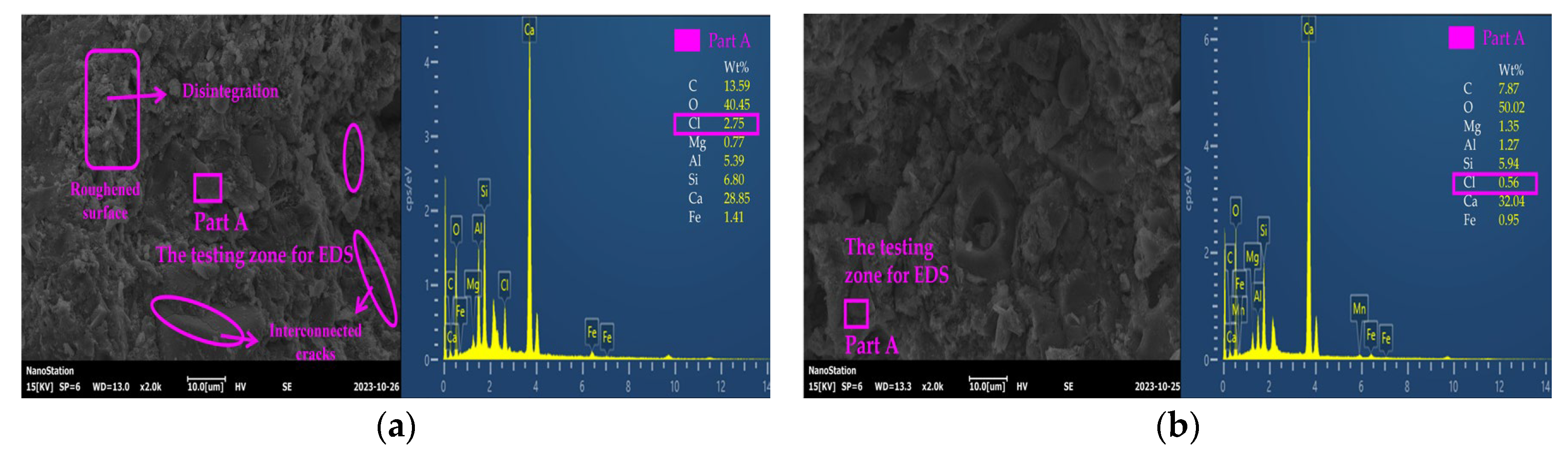

3.2.5. Microscopic Analysis

3.3. Comparative Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nguyen, M.H.; Huynh, T.P. Turning incinerator waste fly ash into interlocking concrete bricks for sustainable development. Constr. Build. Mater. 2022, 321, 126385. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B. Experimental research on the performance of lightweight concrete containing foam and expanded clay aggregate. Compos. Part B Eng. 2019, 171, 46–60. [Google Scholar] [CrossRef]

- Song, P.; Peng, X.; Zheng, R.; Xia, J. Material properties and mechanical performances of manufactured factory-produced glass fiber-reinforced autoclaved aerated concrete panel. Buildings 2024, 14, 2895. [Google Scholar] [CrossRef]

- Barbosa, K.; Silva, W.T.; Silva, R.; Vital, W.; Bezerra, L.M. Experimental investigation of axially loaded precast sandwich panels. Buildings 2023, 13, 1993. [Google Scholar] [CrossRef]

- Zheng, L.; Wu, H.; Zhang, H.; Duan, H.; Wang, J.; Jiang, W.; Song, Q. Characterizing the generation and flows of construction and demolition waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef]

- Akan, A.E.; Ünal, F.; Koçyiğit, F. Investigation of energy saving potential in buildings using novel developed lightweight concrete. Int. J. Thermophys. 2021, 42, 4. [Google Scholar] [CrossRef]

- Zhou, C.; Shi, S.Q.; Chen, Z.; Cai, L.; Smith, L. Comparative environmental life cycle assessment of fiber reinforced cement panel between kenaf and glass fibers. J. Clean. Prod. 2018, 200, 196–204. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, X.; Kong, L. Evaluation of carbon and economic benefits of producing recycled aggregates from construction and demolition waste. J. Clean. Prod. 2023, 425, 138946. [Google Scholar] [CrossRef]

- Duan, H.; Miller, T.R.; Liu, G.; Tam, V.W. Construction debris becomes growing concern of growing cities. Waste Manag. 2019, 83, 1–5. [Google Scholar] [CrossRef]

- Ding, Z.; Wang, N.; Zou, P.X.W. Barriers and countermeasures of construction and demolition waste recycling enterprises under circular economy. J. Clean. Prod. 2023, 420, 138235. [Google Scholar] [CrossRef]

- Bai, G.; Zhu, C.; Liu, C.; Liu, B. An evaluation of the recycled aggregate characteristics and the recycled aggregate concrete mechanical properties. Constr. Build. Mater. 2020, 240, 117978. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; King, D.; Ceylan, H.; Kim, S. Comparative life cycle assessment of natural and recycled aggregate concrete: A review. Sci. Total Environ. 2024, 950, 175310. [Google Scholar] [CrossRef] [PubMed]

- Hu, K.; Gillani, S.T.A.; Tao, X.; Tariq, J.; Chen, D. Eco-friendly construction: Integrating demolition waste into concrete masonry blocks for sustainable development. Constr. Build. Mater. 2025, 460, 139797. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Cao, D.; Dang, H.; Ding, B. Comparison of recycled aggregate treatment methods on the performance for recycled concrete. Constr. Build. Mater. 2020, 234, 117366. [Google Scholar] [CrossRef]

- Neupane, R.P.; Imjai, T.; Makul, N.; Garcia, R.; Kim, B.; Chaudhary, S. Use of recycled aggregate concrete in structural members: A review focused on Southeast Asia. J. Asian Archit. Build. Eng. 2023, 24, 1197–1220. [Google Scholar] [CrossRef]

- Thomas, B.S.; Yang, J.; Bahurudeen, A.; Chinnu, S.N.; Abdalla, J.A.; Hawileh, R.A.; Hamada, H.M. Geopolymer concrete incorporating recycled aggregates: A comprehensive review. Clean. Mater. 2022, 3, 100056. [Google Scholar] [CrossRef]

- Abdulhaleem, K.N.; Van Mohammed, R.; Hamada, H.M.; Humada, A.M.; Majdi, A. Effect of Recycled Aggregate Concrete and Steel Fibers on the Strength of Self-Compacting Concrete. In E3S Web of Conferences; EDP Sciences: Paris, France, 2023; Volume 427, p. 02012. [Google Scholar]

- Lin, D.; Wu, J.; Yan, P.; Chen, Y. Effect of residual mortar on compressive properties of modeled recycled coarse aggregate concrete. Constr. Build. Mater. 2023, 402, 132511. [Google Scholar] [CrossRef]

- Jadon, S.; Kumar, S. Stone dust and recycled concrete aggregates in concrete construction: An efficient way of sustainable development. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Mistri, A.; Bhattacharyya, S.K.; Dhami, N.; Mukherjee, A.; Barai, S.V. A review on different treatment methods for enhancing the properties of recycled aggregates for sustainable construction materials. Constr. Build. Mater. 2020, 233, 117894. [Google Scholar] [CrossRef]

- Liang, C.; Wang, S.; Cai, Z.; Yin, Y.; Gao, Y.; Guo, M.Z.; Ma, Z. Effects of CO2 curing methods on frost resistance and mechanical properties of recycled aggregate concrete. Case Stud. Constr. Mater. 2024, 20, e02973. [Google Scholar] [CrossRef]

- Frankovič, A.; Ducman, V.; Dolenec, S.; Panizza, M.; Tamburini, S.; Natali, M.; Bernardi, A. Up-scaling and performance assessment of façade panels produced from construction and demolition waste using alkali activation technology. Constr. Build. Mater. 2020, 262, 120475. [Google Scholar] [CrossRef]

- Hossain, F.Z.; Pal, A.; Ahmed, K.S.; Bediwy, A.; Alam, M.S. Shear behavior of polypropylene fiber-reinforced concrete beams containing recycled aggregate and crumb rubber. J. Clean. Prod. 2023, 412, 137370. [Google Scholar] [CrossRef]

- Zheng, Y.; Lv, X.; Hu, S.; Zhuo, J.; Wan, C.; Liu, J. Mechanical properties and durability of steel fiber reinforced concrete: A review. J. Build. Eng. 2024, 82, 108025. [Google Scholar] [CrossRef]

- Malchiodi, B.; Pelaccia, R.; Pozzi, P.; Siligardi, C. Three sustainable polypropylene surface treatments for the compatibility optimization of PP fibers and cement matrix in fiber-reinforced concrete. Ceram. Int. 2023, 49, 24611–24619. [Google Scholar] [CrossRef]

- Zhang, S.; Gao, D.; Zhu, H.; Chen, L.; He, Z.; Yang, L. Flexural behavior of seawater-mixed steel fiber reinforced concrete exposed to simulated marine environments. Constr. Build. Mater. 2023, 373, 130858. [Google Scholar] [CrossRef]

- Chen, C.; Ding, Y.; Wang, X.; Bao, L. Recent advances to engineer tough basalt fiber reinforced composites: A review. Polym. Compos. 2024, 45, 12559–12574. [Google Scholar] [CrossRef]

- Zhu, M.; Zhu, M.; Zhai, R.; Zhu, W.; He, J. Research Progress on the Surface Modification of Basalt Fibers and Composites: A Review. Materials 2025, 18, 1164. [Google Scholar] [CrossRef]

- Al-Kharabsheh, B.N.; Arbili, M.M.; Majdi, A.; Alogla, S.M.; Hakamy, A.; Ahmad, J.; Deifalla, A.F. Basalt fiber reinforced concrete: A compressive review on durability aspects. Materials 2023, 16, 429. [Google Scholar] [CrossRef]

- You, J.J.; Song, Q.Y.; Tan, D.; Yang, C.; Liu, Y.F. Mechanical properties and microstructure of basalt fiber-biobased-basic magnesium sulfate cement. Cement Concr. Compos. 2023, 137, 104934. [Google Scholar] [CrossRef]

- ASTM C1611/C1611M-21; Standard Test Method for Slump Flow of Self-Consolidating Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C192/C192M-21; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2021.

- GB/T 50204-2015; Code for Acceptance of Constructional Quality of Concrete Structures. Ministry of Housing and Urban-Rural Development, People’s Republic of China: Beijing, China, 2015.

- Meng, T.; Wei, H.; Yang, X.; Zhang, B.; Zhang, Y.; Zhang, C. Effect of mixed recycled aggregate on the mechanical strength and microstructure of concrete under different water cement ratios. Materials 2021, 14, 2631. [Google Scholar] [CrossRef] [PubMed]

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Ministry of Housing and Urban-Rural Development, People’s Republic of China: Beijing, China, 2009.

- He, Y.; Zhao, Y.G.; Lin, S.; Zhang, Z. Prefabricated bolted PEC beam-to-CFST column joints: Development and its seismic behavior. Eng. Struct. 2024, 314, 118442. [Google Scholar] [CrossRef]

- Huang, A.; Qu, H.; Li, W.; Song, F.; Wang, Z. Mechanical properties of high-strength bolted connections with different bolt hole types under corrosion conditions. Structures 2025, 71, 108135. [Google Scholar] [CrossRef]

- GB/T 23900-2009; Non-Destructive Testing—Practice for Measuring Ultrasonic Velocity in Materials. Standardization Admin-istration of China, People’s Republic of China: Beijing, China, 2009.

- Wang, A.; Sun, W.; Lu, M.; Peng, X.; Wang, H.; Ji, Y. Research on the Corrosion Resistance of Reactive Powder Concrete with Straw Fibers under Chloride Environment. Coatings 2024, 14, 961. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Urban-Rural Development, People’s Republic of China: Beijing, China, 2019.

- Wang, H.; Wang, A.; Wang, J.; Zhang, J.; Du, T.; Shen, J. Optimizing quaternary chemical additives and steel fiber dispersion in CSA cement based HPC for rapid repair engineering. Constr. Build. Mater. 2025, 489, 142265. [Google Scholar] [CrossRef]

- Wu, D.; Liang, Y.; Liu, H.; Peng, S. Behavior of Demountable and Replaceable Fabricated RC Beam with Bolted Connection Under Mid-Span Compression. Buildings 2025, 15, 2589. [Google Scholar] [CrossRef]

- ACI 544.2R-89. Measurement of Properties of Fiber Reinforced Concrete; American Concrete Institute: Farmington Hills, MI, USA, 1999; pp. 1–12. [Google Scholar]

- Murali, G.; Wong, L.S.; Abid, S.R. A comprehensive review of drop weight impact testing: Evaluating the pros and cons in fiber-reinforced concrete performance assessment. J. Build. Eng. 2024, 94, 109934. [Google Scholar] [CrossRef]

- Wang, D.; Xu, Z.; Cao, Z.; Xu, N.; Li, C.; Tian, X.; Wang, H. Research on the Performance of Steel Strand-Reinforced Reactive Powder Concrete with Mixed Steel Fibers and Basalt Fibers under the Salt Dry–Wet Erosion. Coatings 2024, 14, 833. [Google Scholar] [CrossRef]

- Cai, Z.; Ren, J.; Shen, G.; Gu, X.; Cheng, W.; Wang, H. The influence of assembly unit of fibers on the mechanical and long-term properties of reactive powder concrete. Coatings 2023, 13, 412. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, K.; Yin, Z.; Zhou, J. Deterioration performance of recycled aggregate pervious concrete under freezing–thawing cycle and chloride environment. Buildings 2023, 13, 645. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, Z.; Wei, F.; Wen, X.; Li, X.; Dai, L.; Liu, L. Study on concrete deterioration in different NaCl-Na2SO4 solutions and the mechanism of Cl− diffusion. Materials 2021, 14, 5054. [Google Scholar] [CrossRef]

- Xu, W.; Li, Z. Service life prediction of basalt fiber reinforced concrete under salt freeze–thaw cycles. Stavební obzor—Civil Eng. J. 2022, 31, 222–234. [Google Scholar] [CrossRef]

- Sun, H.; Sun, W.; Shi, F.; Miao, L.; Wang, H. The influence of salt erosion on the mechanical performances of ultra-high-performance concrete with secondary aluminum dross. Coatings 2024, 14, 189. [Google Scholar] [CrossRef]

- Wang, H.; Jin, K.; Zhang, A.; Zhang, L.; Han, Y.; Liu, J.; Feng, L. External erosion of sodium chloride on the degradation of self-sensing and mechanical properties of aligned stainless steel fiber reinforced reactive powder concrete. Constr. Build. Mater. 2021, 287, 123028. [Google Scholar] [CrossRef]

- Yang, J.; Guo, Y.; Tan, J.; Shen, A.; Wu, H.; Li, Y.; Wang, L. Strength deterioration and crack dilation behavior of BFRC under dynamic fatigue loading. Case Stud. Constr. Mater. 2022, 16, e01051. [Google Scholar] [CrossRef]

- Xiao, R.; An, B.; Wu, F.; Wang, W.; Sui, Y.; Wang, Y. Freeze–Thaw Damage Characterization of Cement-Stabilized Crushed Stone Base with Skeleton Dense Gradation. Materials 2024, 17, 1228. [Google Scholar] [CrossRef]

- Yuan, C.; Qu, S.; Bai, W.; Guan, J.; Xie, Y. Study on the mechanical properties and mesoscopic damage mechanism of recycled aggregate concrete under different dynamic strain rates after freeze-thaw cycles. Case Stud. Constr. Mater. 2025, 22, e04182. [Google Scholar] [CrossRef]

- Jiang, X.; Mu, S.; Liu, J. Influence of chlorides and salt concentration on salt crystallization damage of cement-based materials. J. Build. Eng. 2022, 61, 105260. [Google Scholar] [CrossRef]

- Li, Y.; Shen, A.; Wu, H. Fractal dimension of basalt fiber reinforced concrete (BFRC) and its correlations to pore structure, strength, and shrinkage. Materials 2020, 13, 3238. [Google Scholar] [CrossRef]

- Zhao, Y.-R.; Wang, L.; Lei, Z.-K.; Han, X.-F.; Xing, Y.-M. Experimental study on dynamic mechanical properties of the basalt fiber reinforced concrete after the freeze-thaw based on the digital image correlation method. Constr. Build. Mater. 2017, 147, 194–202. [Google Scholar] [CrossRef]

- Da, B.; Yu, H.; Ma, H.; Wu, Z. Reinforcement corrosion research based on the linear polarization resistance method for coral aggregate seawater concrete in a marine environment. Anti-Corros. Methods Mater. 2018, 65, 458–470. [Google Scholar] [CrossRef]

- Jiang, W.Q.; Shen, X.H.; Jin, X.; Mao, L.X.; Yang, J.; Liu, Q.F. A numerical study on chloride diffusion in freeze-thaw affected concrete. Constr. Build. Mater. 2018, 179, 553–565. [Google Scholar] [CrossRef]

- Tang, X.; Xu, Q.; Qian, K.; Ruan, S.; Lian, S.; Zhan, S. Effects of cyclic seawater exposure on the mechanical performance and chloride penetration of calcium sulfoaluminate concrete. Constr. Build. Mater. 2021, 303, 124139. [Google Scholar] [CrossRef]

- Huang, G.; Wang, H.; Shi, F. Coupling effect of salt freeze-thaw cycles and carbonation on the mechanical performance of quick hardening sulphoaluminate cement-based reactive powder concrete with basalt fibers. Coatings 2021, 11, 1142. [Google Scholar]

- Chen, J.; Yang, M. Advances of environment damage mechanics in marine engineering concrete. Mech. Eng. 2023, 45, 499–512. [Google Scholar]

- Chen, C.; Wang, L.; Liu, R.; Zhu, P.; Liu, H.; Wang, X.; Chen, Y. Chloride penetration of concrete exposed to dry-wet cycle with various dry-wet ratios and temperature. Constr. Build. Mater. 2023, 400, 132883. [Google Scholar] [CrossRef]

- Diao, R.; Cao, Y.; Michel, M.M.; Wang, A.; Sun, L.; Yang, F. Mechanical performance study of PVA fiber-reinforced seawater and sea sand cement-based composite materials. Sci. Rep. 2024, 14, 18161. [Google Scholar] [CrossRef]

- Liu, Y. Study on the damage characteristics of concrete structures by chloride erosion. J. Xi′an Univ. Archit. Technol. (Nat. Sci. Ed.). 2020, 52, 390–395. (In Chinese) [Google Scholar]

- Dong, W.; Wang, J. Degradation mechanism and strength prediction of aeolian sand concrete under sulphate dry-wet cycles. Constr. Build. Mater. 2024, 450, 138617. [Google Scholar] [CrossRef]

- Chen, C.; Wang, L.; Liu, R.; Yu, J.; Liu, H.; Wu, J. Chloride penetration of recycled fine aggregate concrete under drying–wetting cycles. Materials 2023, 16, 1306. [Google Scholar] [CrossRef]

- Yang, W.; Huang, Y.; Tang, Z.; Xiong, X.; Li, C.; Zhong, X.; Liu, L.; Zhou, H.; Zhang, X. Impermeability performance and corrosion resistance mechanism of basalt fiber recycled concrete under the coastal tidal environment. Constr. Build. Mater. 2024, 411, 134510. [Google Scholar] [CrossRef]

- Yan, C.; An, N.; Wang, Y.; Sun, W. Effect of Dry–Wet Cycles and Freeze–Thaw Cycles on the Antierosion Ability of Fiber–Reinforced Loess. Adv. Mater. Sci. Eng. 2021, 2021, 8834598. [Google Scholar] [CrossRef]

- Ye, Y.; Xie, T.; Guo, T.; Ding, W. Durability of basalt fiber-reinforced aeolian sand concrete in extreme environments: Resistance to wind-sand erosion and salt freeze–thaw cycles. Constr. Build. Mater. 2024, 457, 139264. [Google Scholar] [CrossRef]

| Chemical Composition/% | Median Particle Size D50/μm | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | MnO | R2O | SO3 | Loss on Ignition | |

| 62.51 | 21.18 | 5.19 | 3.84 | 1.81 | 0.15 | 0.47 | 2.90 | 1.95 | 18.6 |

| Type | Strength Grade/MPa | Density/(g·cm−3) | Initial Setting Time/min | Final Setting Time/min |

|---|---|---|---|---|

| OPC | 42.5 | 3.01 | 112.3 | 216 |

| Group | Water | Cement | Sand | Recycled Aggregate | Basalt Fibers | Water Reducing Agent | Basalt Fibers Content/% |

|---|---|---|---|---|---|---|---|

| A1 | 175 | 583.31 | 648.50 | 972.95 | 0 | 0.75 | 0% |

| A2 | 175 | 583.31 | 648.50 | 972.95 | 13.18 | 1.00 | 0.5% |

| A3 | 175 | 583.31 | 648.50 | 972.95 | 26.35 | 1.25 | 1.0% |

| A4 | 175 | 583.31 | 648.50 | 972.95 | 39.53 | 1.50 | 1.5% |

| A5 | 175 | 583.31 | 648.50 | 972.95 | 52.70 | 1.75 | 2.0% |

| A6 | 175 | 583.31 | 648.50 | 972.95 | 65.88 | 2.00 | 2.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Wu, Y.; Xu, Z.; Xu, N.; Li, C.; Tian, X.; Shi, F.; Wang, H. Effect of Basalt Fibers on the Performance of CO2-Cured Recycled Aggregate Concrete Composite Slab–Column Assemblies with Bolted Connections Under NaCl Erosion. Coatings 2025, 15, 1053. https://doi.org/10.3390/coatings15091053

Wang D, Wu Y, Xu Z, Xu N, Li C, Tian X, Shi F, Wang H. Effect of Basalt Fibers on the Performance of CO2-Cured Recycled Aggregate Concrete Composite Slab–Column Assemblies with Bolted Connections Under NaCl Erosion. Coatings. 2025; 15(9):1053. https://doi.org/10.3390/coatings15091053

Chicago/Turabian StyleWang, Di, Yuanfeng Wu, Zhiqiang Xu, Na Xu, Chuanqi Li, Xu Tian, Feiting Shi, and Hui Wang. 2025. "Effect of Basalt Fibers on the Performance of CO2-Cured Recycled Aggregate Concrete Composite Slab–Column Assemblies with Bolted Connections Under NaCl Erosion" Coatings 15, no. 9: 1053. https://doi.org/10.3390/coatings15091053

APA StyleWang, D., Wu, Y., Xu, Z., Xu, N., Li, C., Tian, X., Shi, F., & Wang, H. (2025). Effect of Basalt Fibers on the Performance of CO2-Cured Recycled Aggregate Concrete Composite Slab–Column Assemblies with Bolted Connections Under NaCl Erosion. Coatings, 15(9), 1053. https://doi.org/10.3390/coatings15091053