Study on the Influence of Heat Input on Microstructure and Properties of Q420C Steel Welded Joints

Abstract

1. Introduction

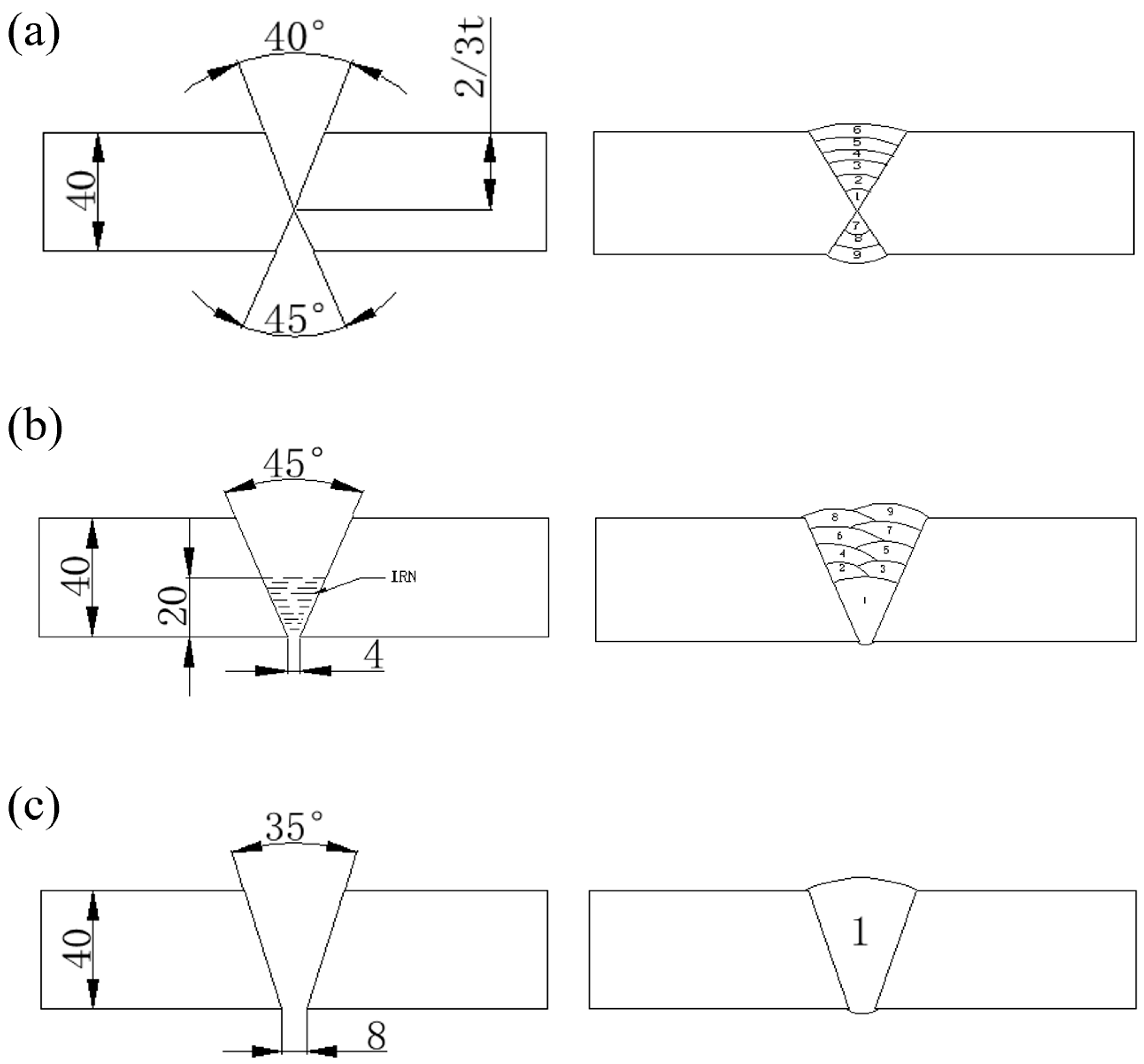

2. Materials and Methods

3. Results

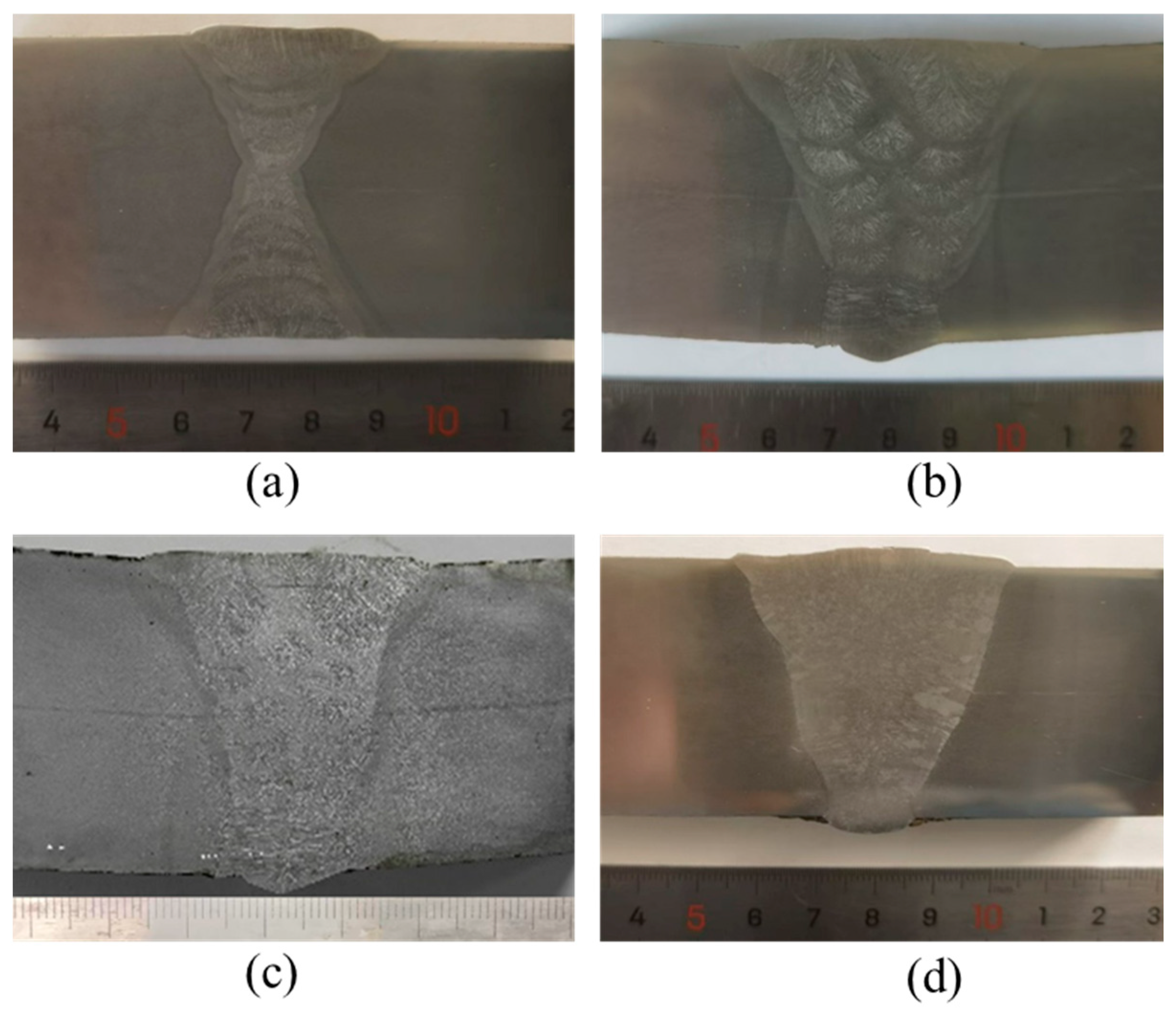

3.1. Macroscopic Morphologies

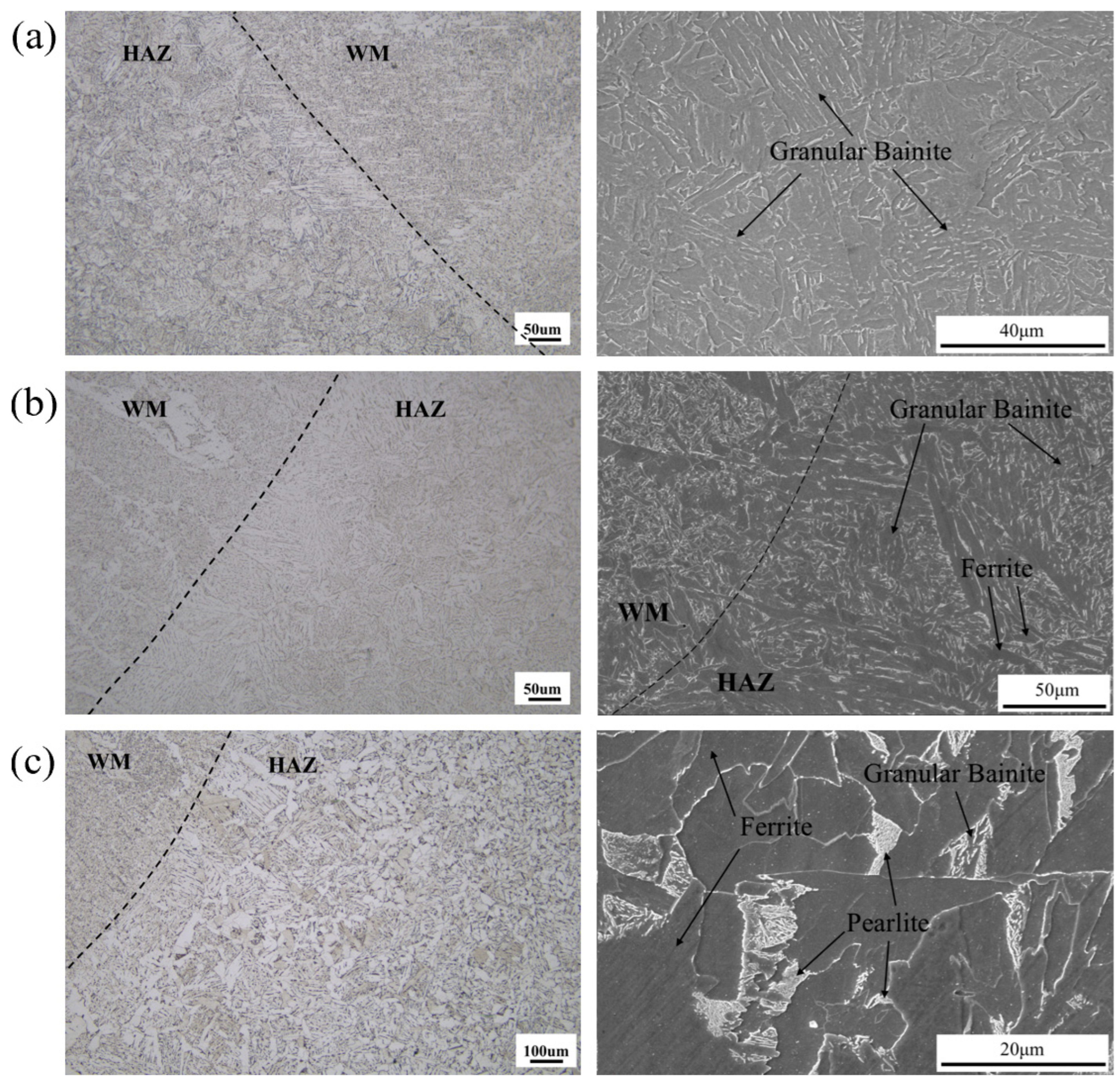

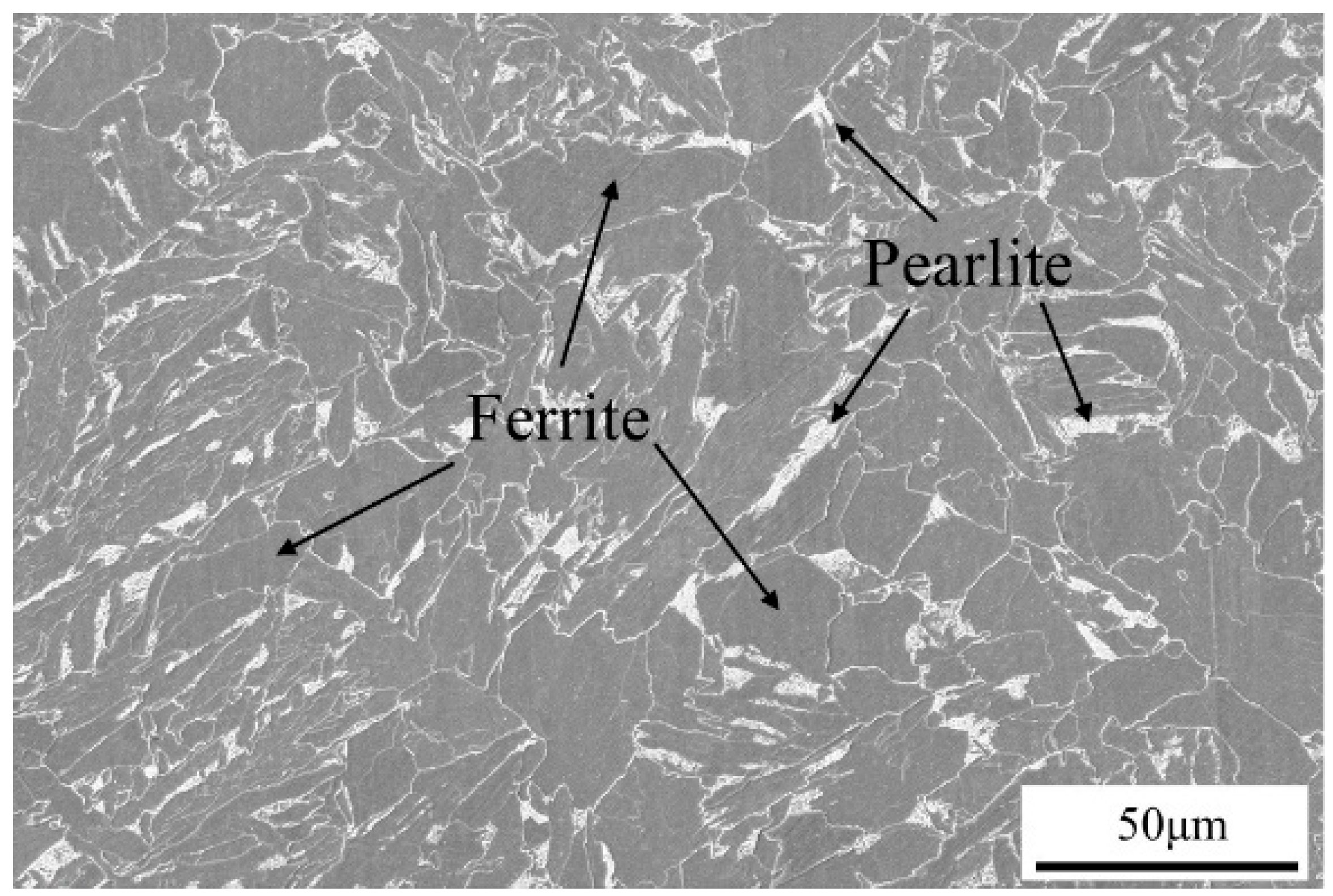

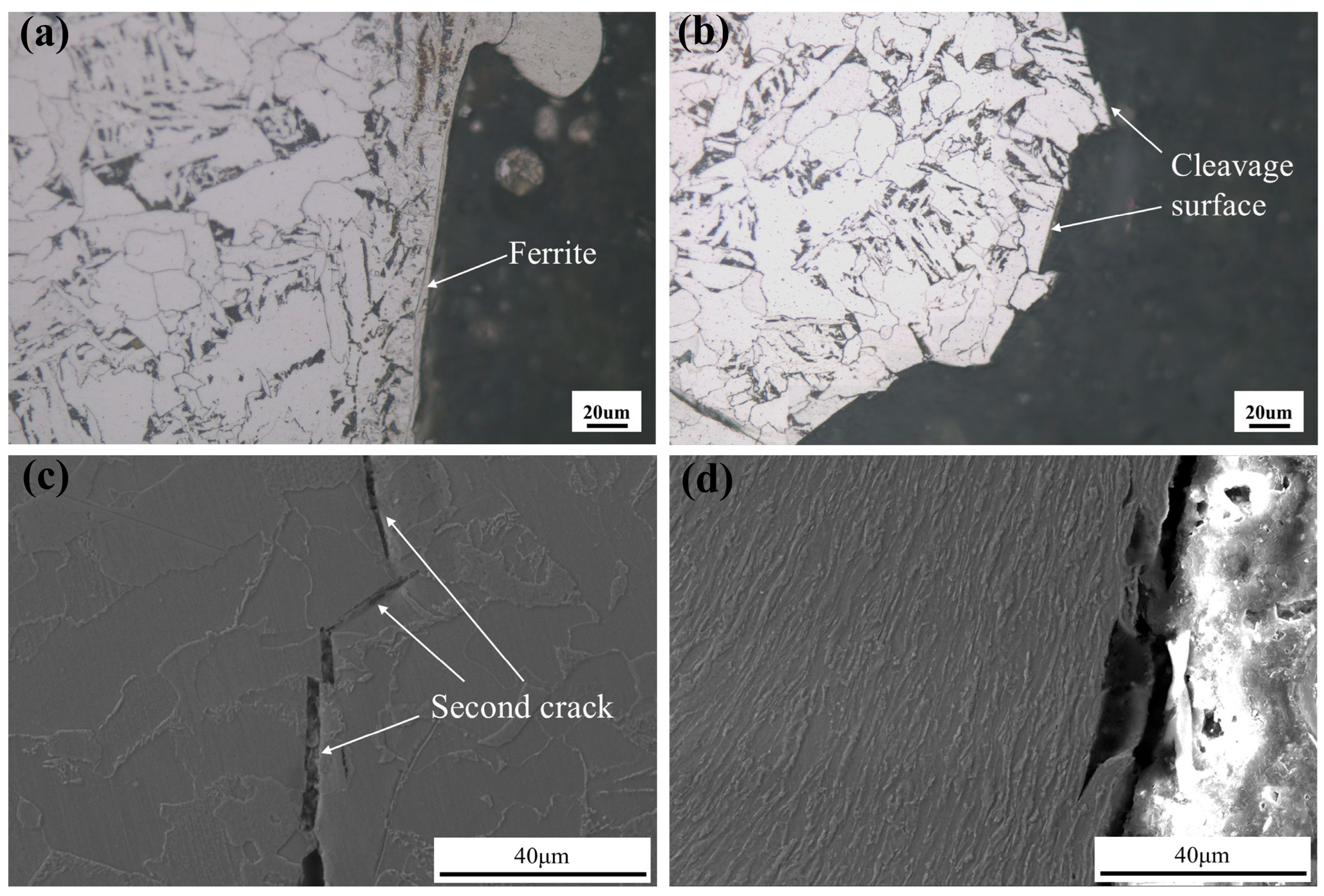

3.2. Microstructures

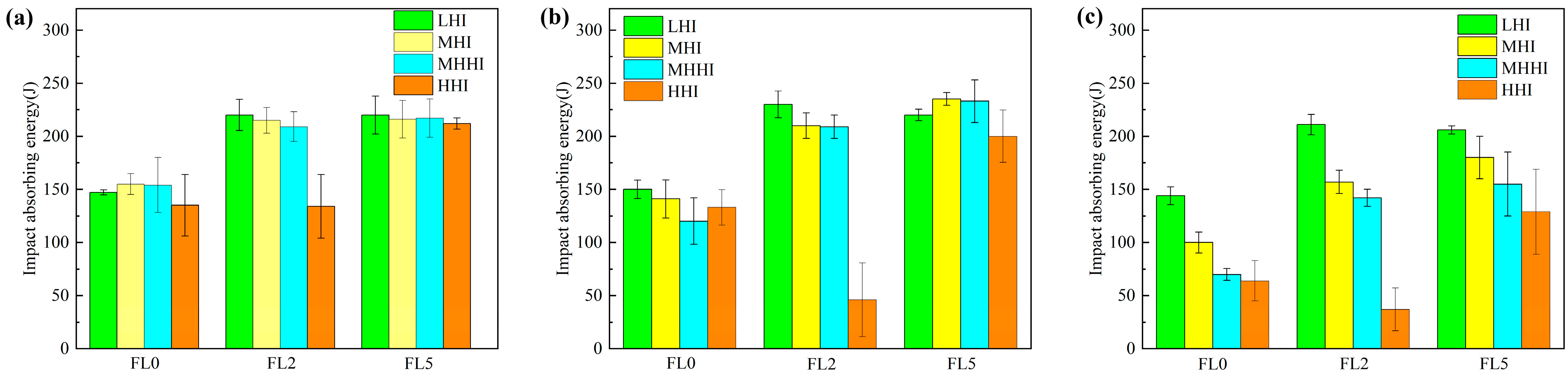

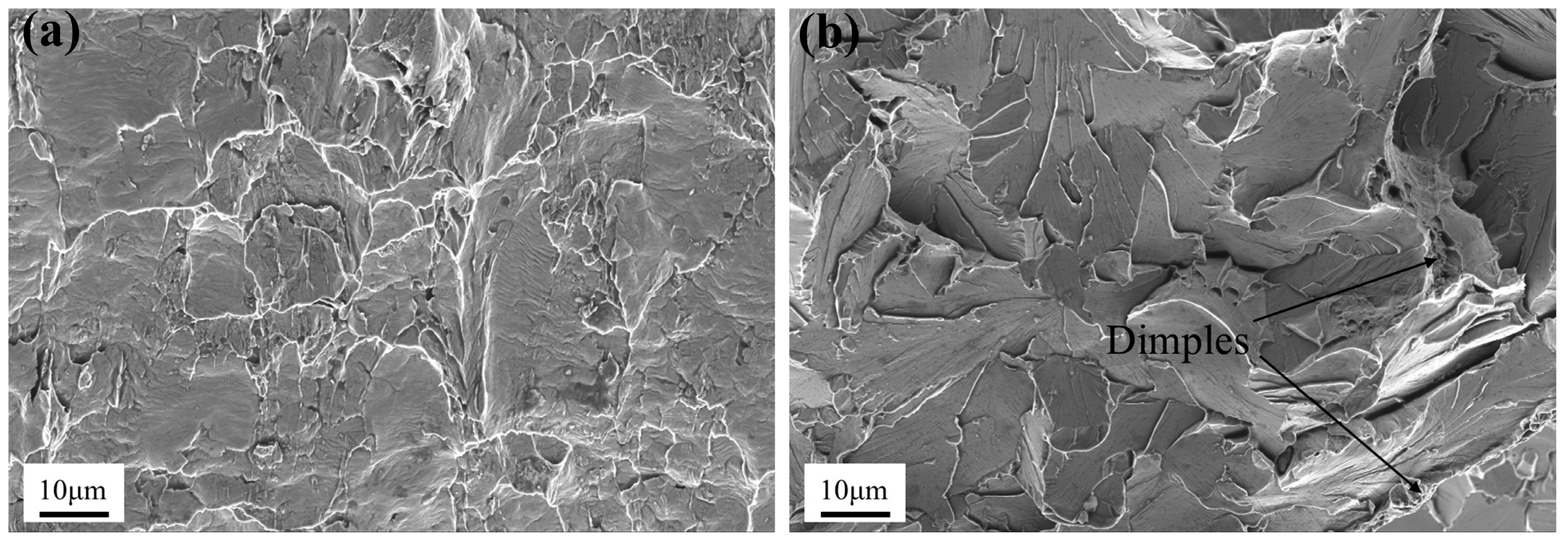

3.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Men, P.F.; Ho, H.C.; Zhou, X.H.; Chung, K.F. Experimental investigations into stocky composite columns of concrete-filled circular S690 steel tubes under compression. Eng. Struct. 2024, 309, 118016. [Google Scholar] [CrossRef]

- Wang, J.; Di, J.; Zhang, Q.; Qin, F.J.; Men, P.F. Local buckling analysis of axially compressed welded box-section stub columns using Q420–Q960 steel. J. Constr. Steel Res. 2023, 210, 108100. [Google Scholar] [CrossRef]

- Gong, W.W.; Yang, B.K.; Chen, H.; Chen, Y.; Shen, X.L.; Hao, W.K.; Wang, X.F.; Huang, L.Y. Effects of Ce-La rare earth microalloying on the microstructure and corrosion characteristics of Q420 high-strength steel. Int. J. Electrochem. Sci. 2023, 18, 100242. [Google Scholar] [CrossRef]

- Wang, J.; Di, J.; Zhang, Q.; Qin, F.J. Overall buckling behaviour of Q420–Q960 steel welded H-section axial compression members. Eng. Struct. 2021, 249, 113340. [Google Scholar] [CrossRef]

- Li, Z.R.; Zhang, D.C.; Wu, H.Y.; Huang, F.H.; Hong, W.; Zang, X.S. Fatigue properties of welded Q420 high strength steel at room and low temperatures. Constr. Build. Mater. 2018, 189, 955–966. [Google Scholar] [CrossRef]

- Yang, L.G.; Xing, Y.M. Experimental Study on High-Cycle Fatigue Properties of Q420C Steel at Room Temperature. Mater. Res.-Ibero-Am. J. Mater. 2022, 25, e20210589. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, H.; Wang, Z.Y.; Chen, X.H.; Huo, X.X.; Wu, H.Y.; Du, L.X. Effect of Heat Input on Microstructural Evolution and Impact Toughness of the Simulated CGHAZ for a Novel Q690 MPa V-N Medium and Heavy Plate. Mater. 2025, 18, 1148. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.B.; Hu, C.Y.; Li, S.B.; Wan, X.L.; Zhong, M.; Hu, F.; Zhou, S.B.; Li, G.Q.; Wu, K.M. Grain Refinement Mechanism in the CGHAZ of Ultra-High-Strength Structural Steel: A Critical Analysis of the Impacts of Prior Austenite Grain and Cooling Rates. JOM 2024, 76, 7120–7134. [Google Scholar] [CrossRef]

- Sheng, J.; Ma, J.J.; Wei, F.F.; Meng, Y.H.; Ma, Z.W.; Liang, Y.J.; Duan, H.G. Study on the Mechanical Properties and Constitutive Model of Q420 Steel Under Different Strain Rates. Nano 2025, 20, 2550023. [Google Scholar] [CrossRef]

- Xu, Z.B.; Lv, X.W.; Wang, X.Y.; Feng, J.A.; Liu, X.L.; Peng, J.F.; Wu, H. Electrochemically assisted laser surface microtexture preparation and tribological properties research. J. Manuf. Processes 2024, 122, 54–64. [Google Scholar] [CrossRef]

- Du, H.; Wen, J.Y.; Song, G.H.; Wu, H.; Feng, J.A.; Wang, Y.J.; Huang, Y.; Yin, Y.S. Effect of inserting a-C layers on anticorrosion behavior of Ni-NiCr-NiCrAlSi composite coating on copper through magnetron sputtering for marine applications. Thin Solid Films 2024, 808, 140558. [Google Scholar] [CrossRef]

- An, L.Q.; Jiang, W.Q.; Liu, Y.P.; Shi, Q.; Liu, S.X. Experimental study of mechanical behaviour of angles in transmission towers under freezing temperature. Adv. Steel Constr. 2017, 14, 461–478. [Google Scholar] [CrossRef]

- Su, Z. The Application of Q420C Steel in Welding Quality Control of Box-Shaped Beam-Columns for Architectural Steel Structures. Weld. Technol. 2024, 53, 119–122. [Google Scholar]

- GB/T 1591—2018; High-Strength Low Alloy Structural Steels. Standards Press of China: Beijing, China, 2018. Available online: https://openstd.samr.gov.cn/bzgk/gb/std_list?r1=public&r2=GB/T%201591 (accessed on 1 August 2025).

- Park, S.J.; Heogh, W.; Yang, J.H.; Kang, S.; Jeong, W.; Lee, H.; Jang, T.S.; Jung, H.D.; Jahazi, M.; Han, S.C.; et al. Meta-structure of amorphous-inspired 65.1Co28.2Cr5.3Mo lattices augmented by artificial intelligence. Adv. Compos. Hybrid Mater. 2024, 7, 224. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Lee, H.; Yeon, S.M.; Aranas, C., Jr.; Choi, K.; Yoon, J.; Yang, S.W.; Lee, H. Selective compositional range exclusion via directed energy deposition to produce a defect-free Inconel 718/SS 316L functionally graded material. Addit. Manuf. 2021, 47, 102288. [Google Scholar] [CrossRef]

| Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Charpy Impact Energy (J) | |

|---|---|---|---|---|

| ≤100 mm | >16 mm∼40 mm | >16 mm∼40 mm | >16 mm∼40 mm | |

| 520∼680 | ≥400 | ≥19 | 0 °C | ≥34 |

| C | Mn | Si | Al | Ti | Mg | Nb | Mo | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.06 | 1.47 | 0.25 | 0.032 | 0.018 | 0.002 | 0.035 | 0.056 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, H.; Wang, G.; Wang, P.; Ma, J.; Luo, X.; He, H. Study on the Influence of Heat Input on Microstructure and Properties of Q420C Steel Welded Joints. Coatings 2025, 15, 957. https://doi.org/10.3390/coatings15080957

Long H, Wang G, Wang P, Ma J, Luo X, He H. Study on the Influence of Heat Input on Microstructure and Properties of Q420C Steel Welded Joints. Coatings. 2025; 15(8):957. https://doi.org/10.3390/coatings15080957

Chicago/Turabian StyleLong, Hanxin, Guoping Wang, Pingxin Wang, Jinjun Ma, Xiong Luo, and Huan He. 2025. "Study on the Influence of Heat Input on Microstructure and Properties of Q420C Steel Welded Joints" Coatings 15, no. 8: 957. https://doi.org/10.3390/coatings15080957

APA StyleLong, H., Wang, G., Wang, P., Ma, J., Luo, X., & He, H. (2025). Study on the Influence of Heat Input on Microstructure and Properties of Q420C Steel Welded Joints. Coatings, 15(8), 957. https://doi.org/10.3390/coatings15080957