Experimental Study on Static Ice Adhesion Characteristics of Wind Turbine Blade Surfaces After Sand Erosion

Abstract

1. Introduction

2. Test Devices and Methods

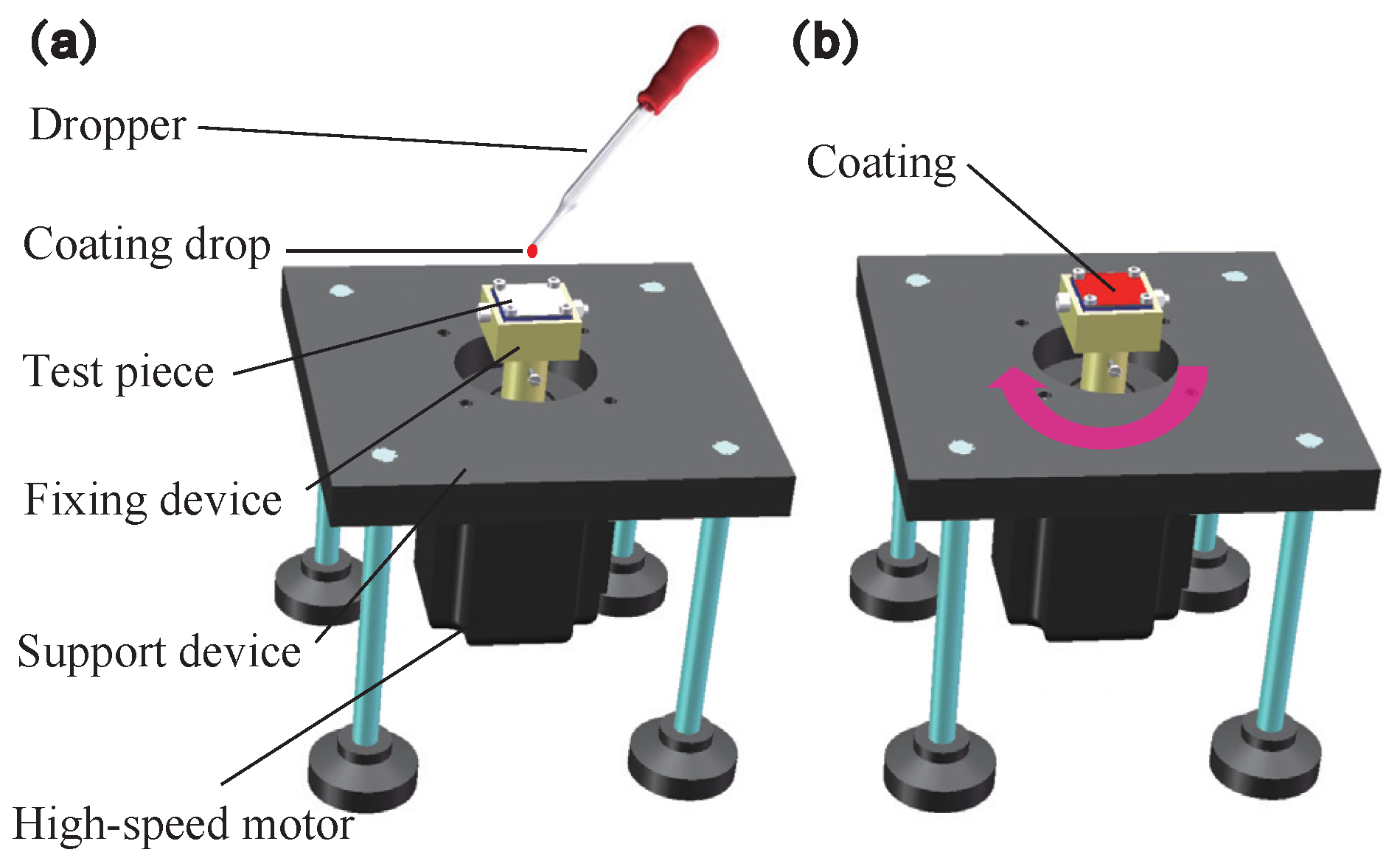

2.1. Coating Preparation

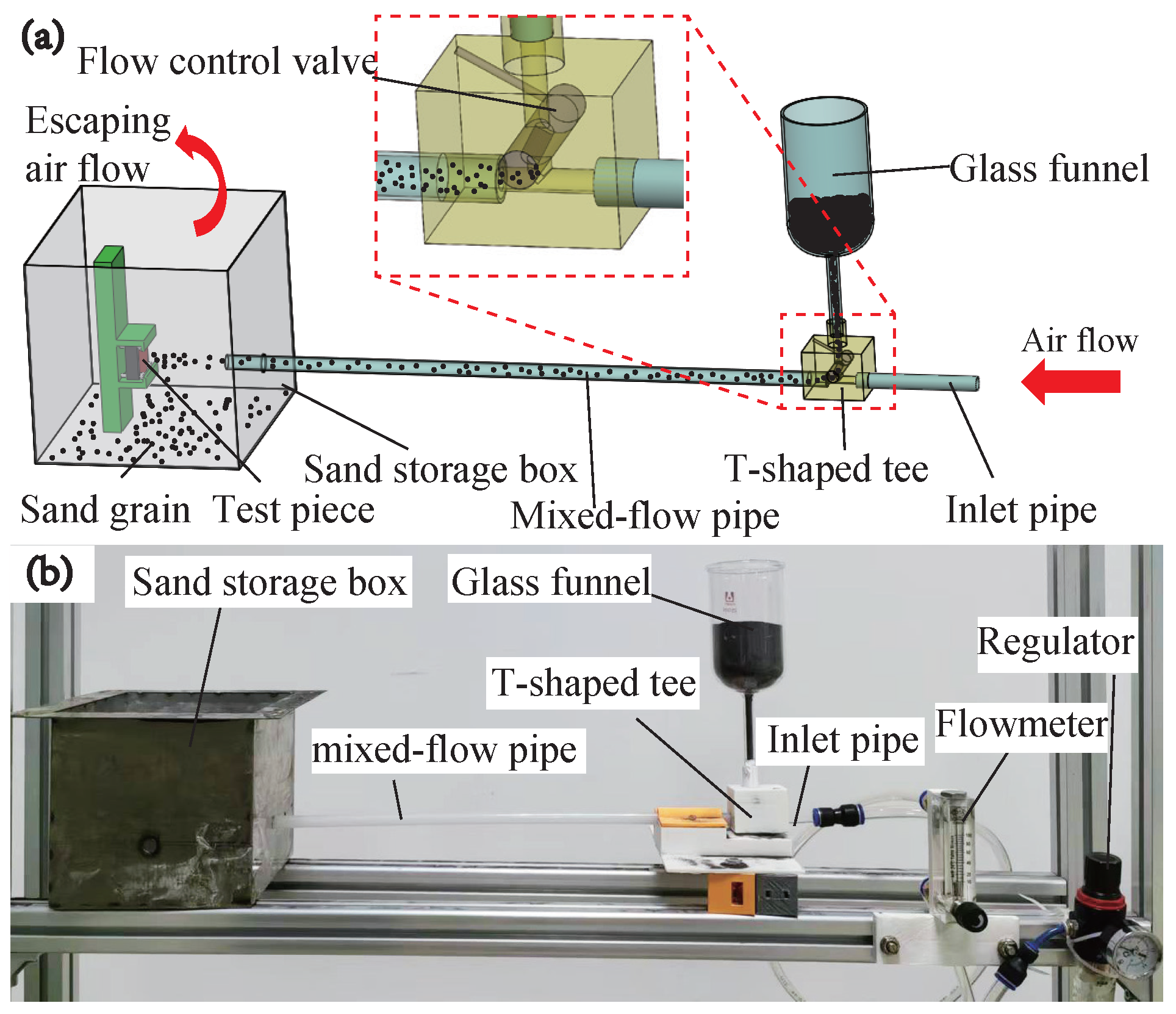

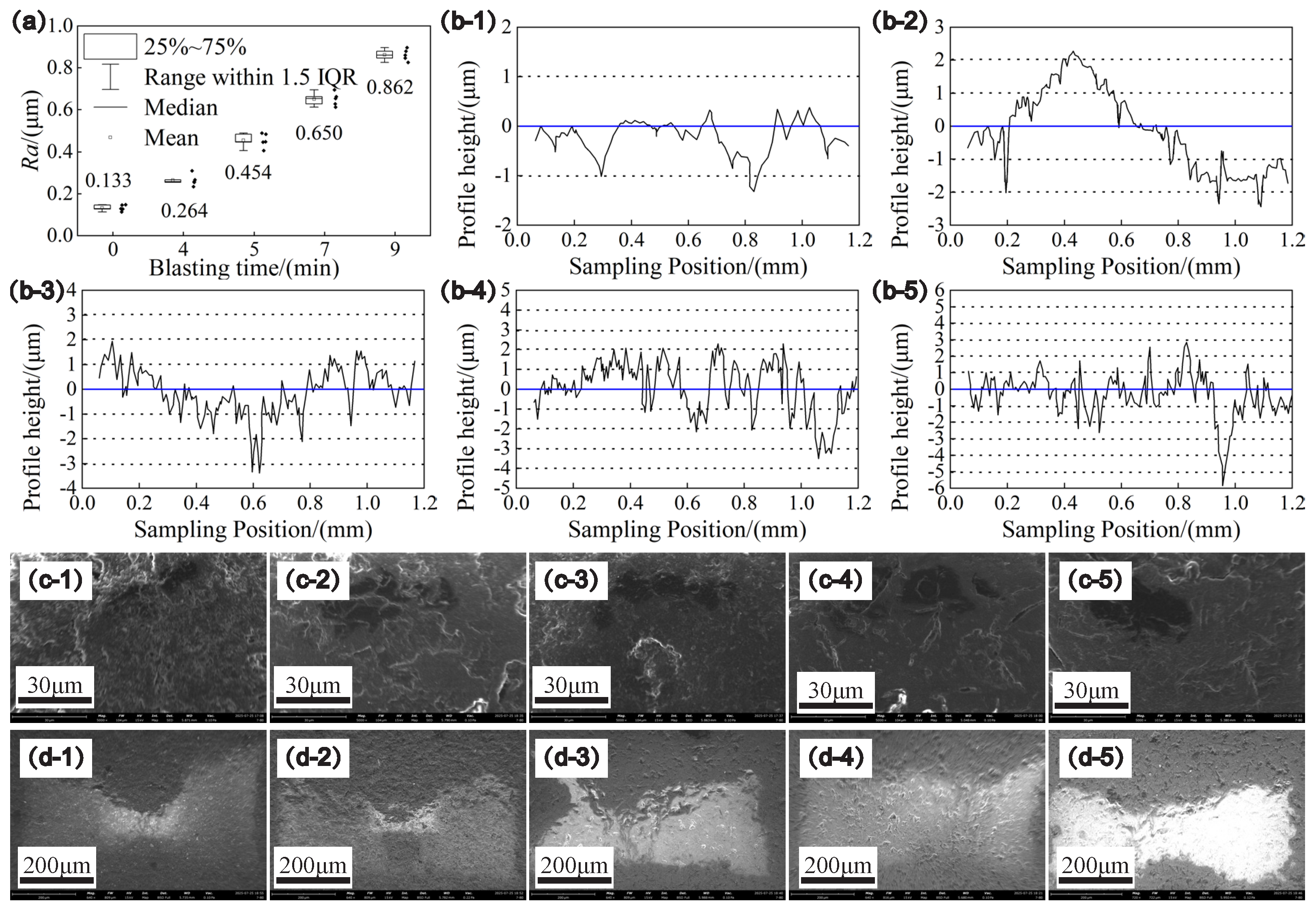

2.2. Sand Erosion Wear Simulation Device

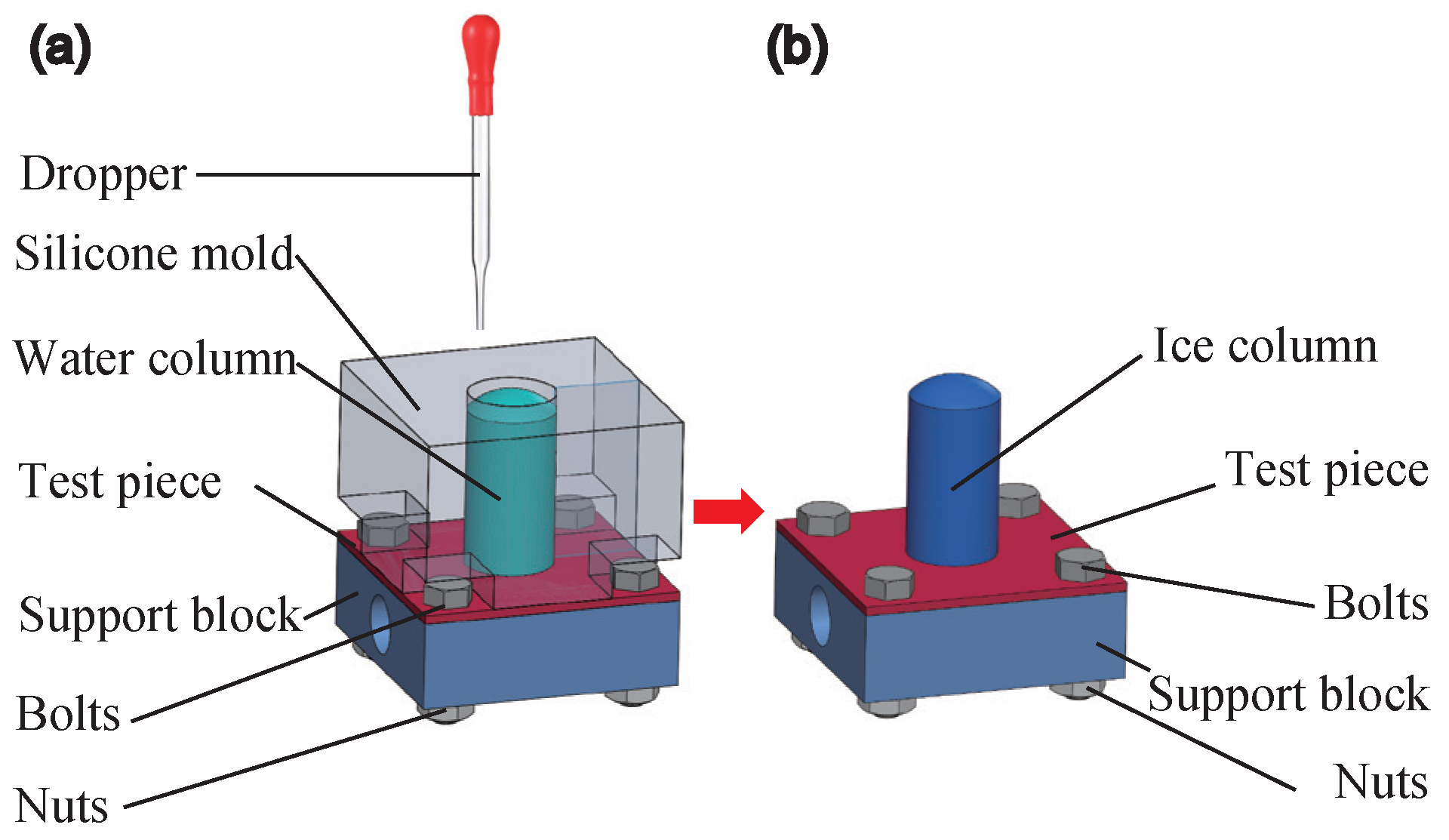

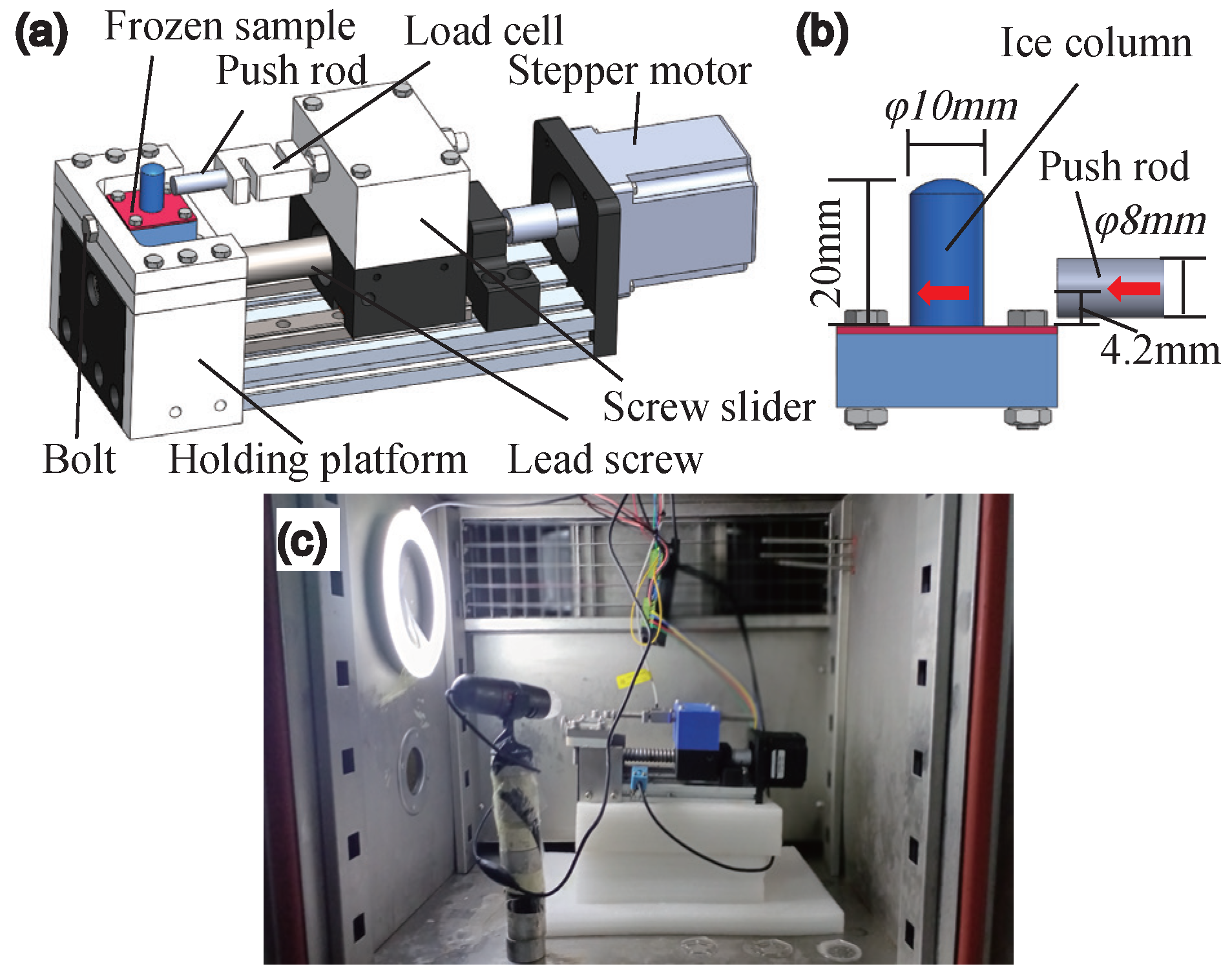

2.3. Method for Testing Tangential Adhesive Force of Ice Coating

3. Results and Analysis

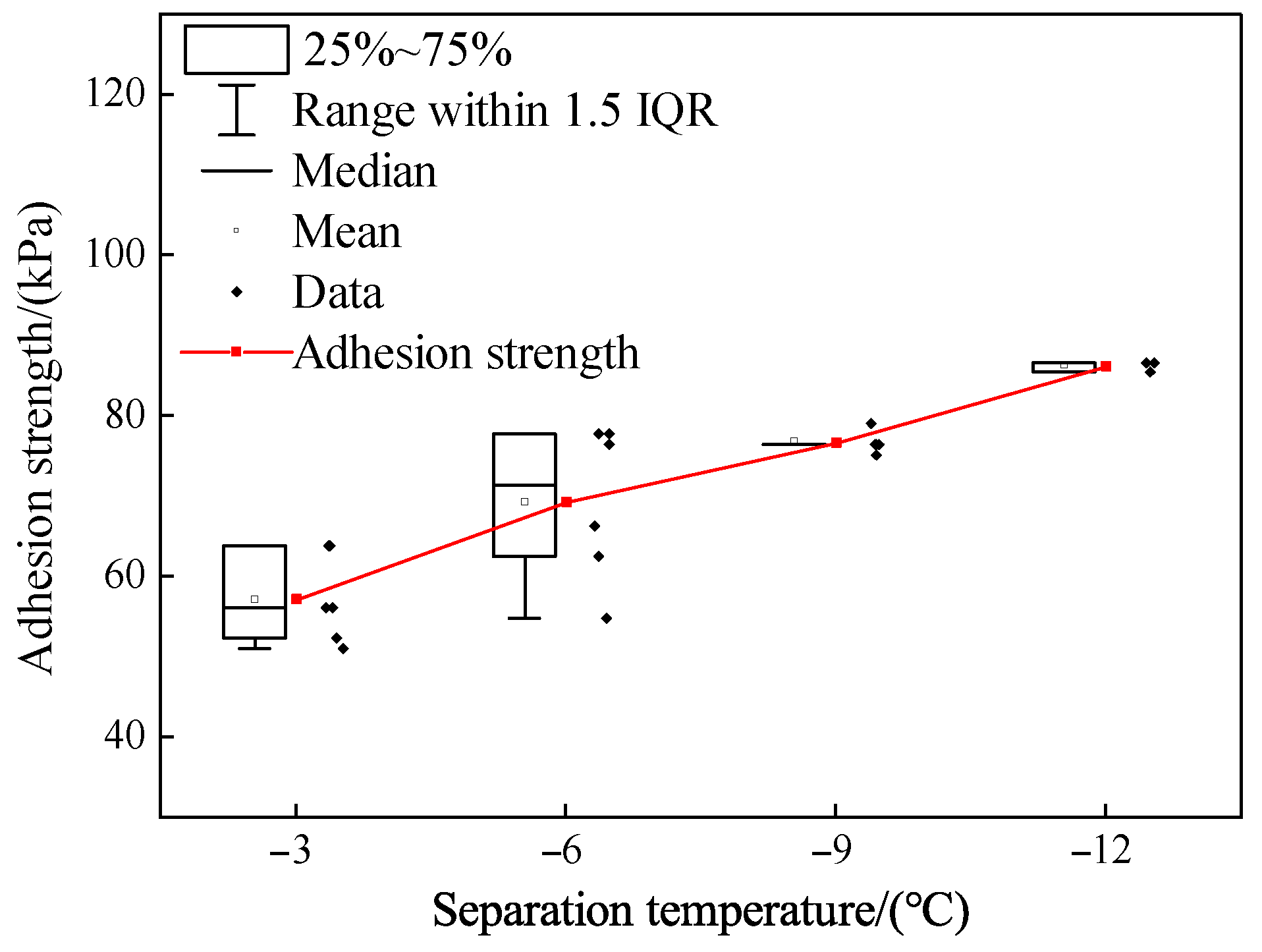

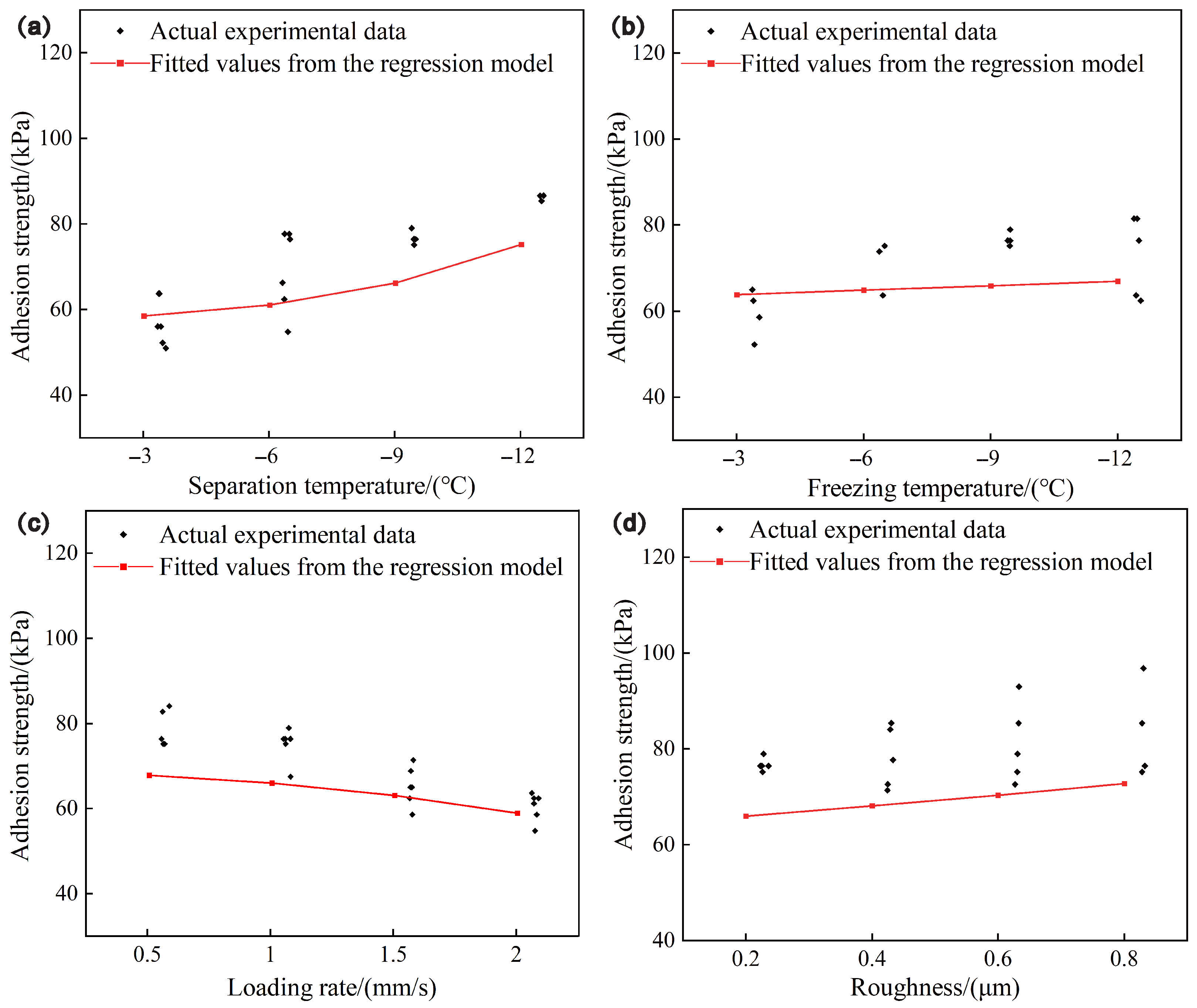

3.1. Influence of Separation Temperature on Ice Adhesion Strength

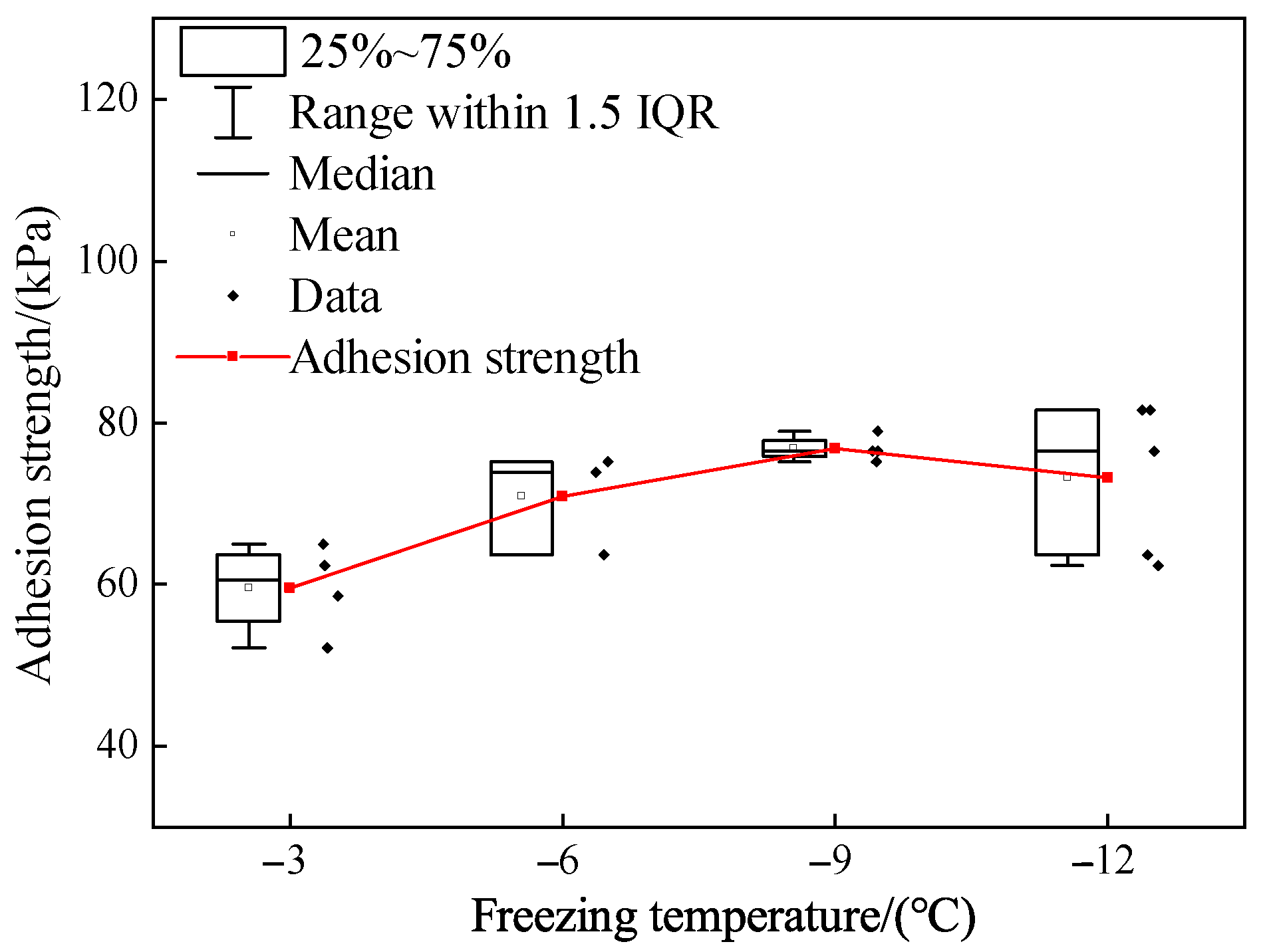

3.2. Influence of Freezing Temperature on Ice Adhesion Strength

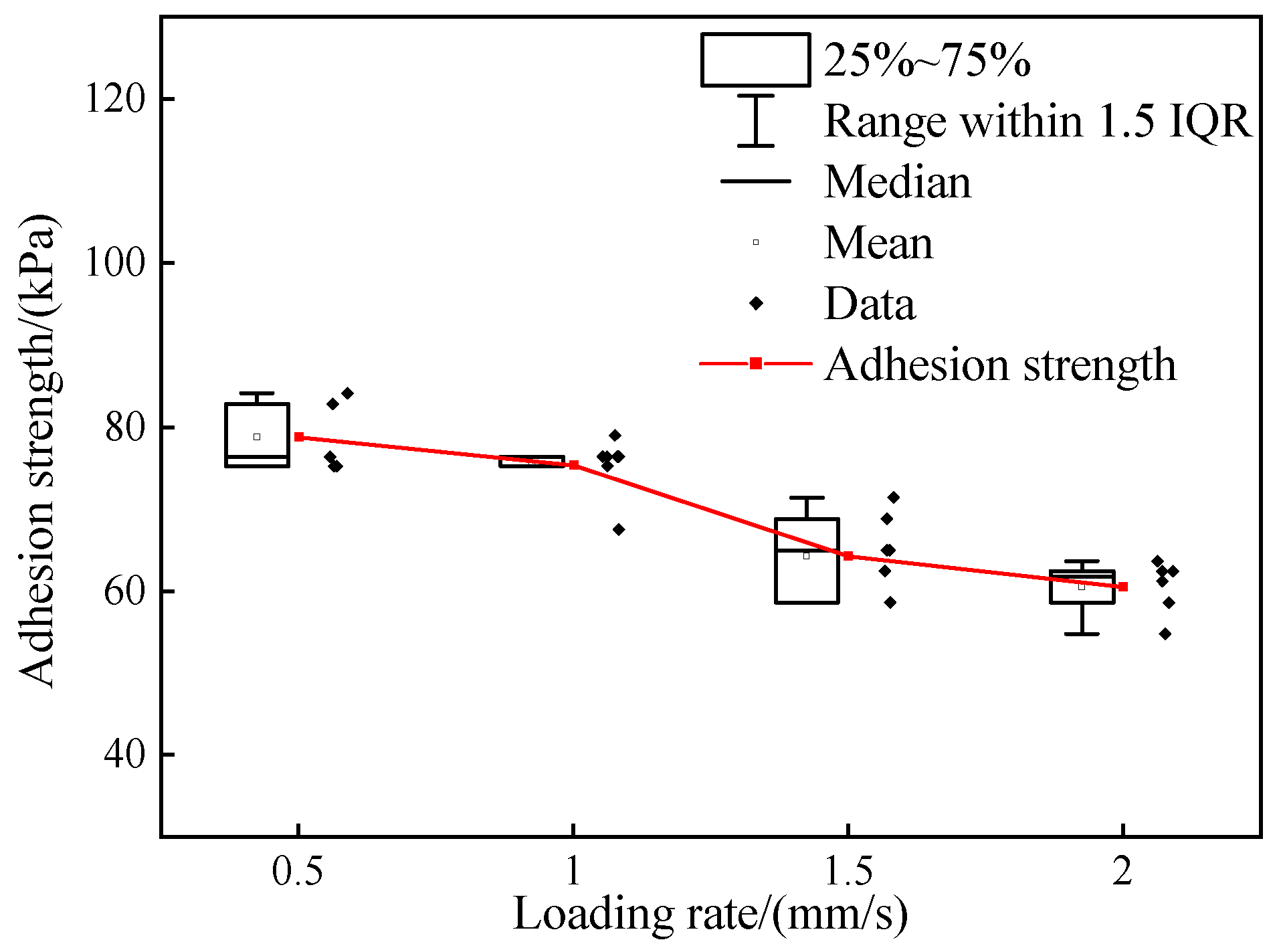

3.3. Influence of Loading Rate on Ice Adhesion Strength

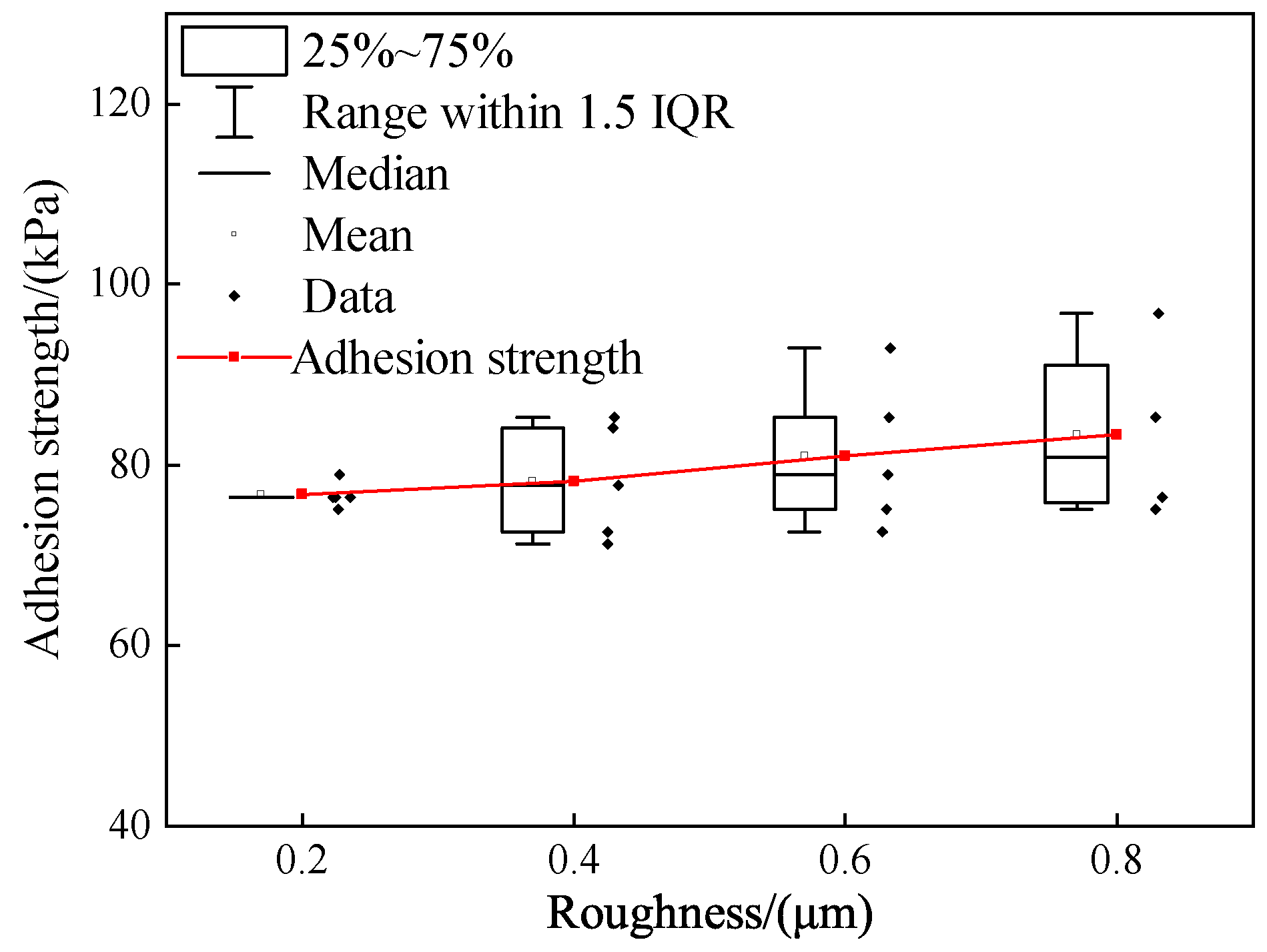

3.4. Influence of Roughness on Ice Adhesion Strength

3.5. Coupling Effects on Ice Adhesion Strength

4. Conclusions

- (1)

- As the separation temperature decreases, the ice adhesion strength increases linearly. When the freezing temperature exceeds the separation temperature, the adhesion strength increases linearly with the decreasing in the separation temperature; when the freezing temperature is lower than the separation temperature, the adhesion strength decreases linearly as the separation temperature drops. An increase in the loading rate leads to a decrease in the ice adhesion strength, while an increase in the surface roughness after sand erosion results in increased ice adhesion strength.

- (2)

- The orthogonal experiments have shown that the order of influence of various factors on the ice adhesion force is as follows separation temperature > loading rate > freezing temperature > surface roughness. Here, the first two factors exerting the most significant impacts.

- (3)

- A regression equation for ice adhesion strength was established based on the orthogonal test results, which can effectively predict the ice adhesion strength under untested parameter combinations. The good agreement between the measured values from single-factor experiments and the fitted values from the regression model verifies its reliability, providing a theoretical tool for the development and optimization of de-icing systems in engineering practice.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chehouri, A.; Younes, R.; Ilinca, A.; Perron, J. Review of performance optimization techniques applied to wind turbines. Appl. Energy 2015, 142, 361–388. [Google Scholar] [CrossRef]

- Jung, C.; Schindler, D. Changing wind speed distributions under future global climate. Energy Convers. Manag. 2019, 198, 111841. [Google Scholar] [CrossRef]

- Cherp, A.; Vinichenko, V.; Tosun, J.; Gordon, J.A.; Jewell, J. National growth dynamics of wind and solar power compared to the growth required for global climate targets. Nat. Energy 2021, 6, 742–754. [Google Scholar] [CrossRef]

- Douvi, E.; Douvi, D. Aerodynamic Characteristics of Wind Turbines Operating under Hazard Environmental Conditions: A Review. Energies 2023, 16, 7681. [Google Scholar] [CrossRef]

- Lee, K.-C.; Chau, S.-W. Extreme Wind Loading Prediction of a 2MW Horizontal-Axis Wind Turbine. In Proceedings of the Second Conference of Global Chinese Scholars on Hydrodynamics, Wuxi, China, 20–23 November 2016; Published on Available via ResearchGate (Berlin, Germany). Available online: https://www.researchgate.net/publication/369185059_Extreme_Wind_Loading_Prediction_of_a_2MW_Horizontal-Axis_Wind_Turbine (accessed on 9 July 2025).

- Yang, N.; Jiang, W.; Jin, C.; Zhang, S.; Hou, W. Numerical simulation of the effect of atmospheric condition on the lightning strike for wind turbine. Front. Earth Sci. 2023, 10, 1123747. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Zhang, X.; Hu, Q.; Jiang, X. A Review of Wind Turbine Icing and Anti/De-Icing Technologies. Energies 2024, 17, 2805. [Google Scholar] [CrossRef]

- Castorrini, A.; Corsini, A.; Rispoli, F.; Venturini, P.; Takizawa, K.; Tezduyar, T.E. Computational analysis of performance deterioration of a wind turbine blade strip subjected to environmental erosion. Comput. Mech. 2019, 64, 1133–1153. [Google Scholar] [CrossRef]

- Keegan, M.H.; Nash, D.H.; Stack, M.M. On erosion issues associated with the leading edge of wind turbine blades. J. Phys. D Appl. Phys. 2013, 46, 383001. [Google Scholar] [CrossRef]

- Abu El-Maaty, A.E.; Abdallah, H.K.; Kotb, M.A.; Ben-Mansour, R.; Alatawi, E.S. Numerical investigation of sand erosion rate in a horizontal axis wind turbine. Heliyon 2024, 10, e27676. [Google Scholar] [CrossRef]

- Gao, L.; Hu, H. Wind turbine icing characteristics and icing-induced power losses to utility-scale wind turbines. Proc. Natl. Acad. Sci. USA 2021, 118, e2111461118. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Zhao, H.; Zhang, Y.; Wang, Y.; Chang, J. Quantitative Modeling of Effects of Extreme Low Temperature on Wind Turbine Blade Performance Based on Nonlinear Random-Coefficient Regression Model. IEEE Access 2023, 11, 8804–88058. [Google Scholar] [CrossRef]

- Godfrey, M.; Siederer, O.; Zekonyte, J.; Barbaros, I.; Wood, R. The effect of temperature on the erosion of polyurethane coatings for wind turbine leading edge protection. Wear 2021, 476, 203720. [Google Scholar] [CrossRef]

- Shu, L.; Li, H.; Hu, Q.; Jiang, X.; Qiu, G.; McClure, G.; Yang, H. Study of ice accretion feature and power characteristics of wind turbines at natural icing environment. Cold Reg. Sci. Technol. 2018, 147, 45–54. [Google Scholar] [CrossRef]

- Li, M.; Zhang, W.; Liu, J.; Chen, J.; Wang, Y. Risk Assessment and Value of Action Analysis for Icing Conditions of Wind Turbines Close to Highways. Energies 2019, 12, 2653. [Google Scholar] [CrossRef]

- Yang, X.; Bai, X.; Cao, H. Influence analysis of rime icing on aerodynamic performance and output power of offshore floating wind turbine. Ocean Eng. 2022, 258, 111725. [Google Scholar] [CrossRef]

- Lamraoui, F.; Fortin, G.; Benoit, R.; Perron, J.; Masson, C. Atmospheric icing impact on wind turbine production. Cold Reg. Sci. Technol. 2014, 100, 36–49. [Google Scholar] [CrossRef]

- Han, Y.; Lei, Z.; Dong, Y.; Wang, Q.; Li, H.; Feng, F. The Icing Characteristics of a 1.5 MW Wind Turbine Blade and Its Influence on the Blade Mechanical Properties. Coatings 2024, 14, 242. [Google Scholar] [CrossRef]

- Lehtomäki, V.; Rissanen, S.; Wadham-Gagnon, M.; Sandel, K.; Moser, W.; Jacob, D. Fatigue loads of iced turbines: Two case studies. J. Wind Eng. Ind. Aerodyn. 2016, 158, 37–50. [Google Scholar] [CrossRef]

- Makkonen, L. Ice Adhesion —Theory, Measurements and Countermeasures. J. Adhes. Sci. Technol. 2012, 26, 413–445. [Google Scholar] [CrossRef]

- Janjua, Z.A. The influence of freezing and ambient temperature on the adhesion strength of ice. Cold Reg. Sci. Technol. 2017, 140, 14–19. [Google Scholar] [CrossRef]

- Quayson-Sackey, E.; Nyantekyi-Kwakye, B.; Ayetor, G.K. Technological advancements for anti-icing and de-icing offshore wind turbine blades. Cold Reg. Sci. Technol. 2025, 231, 104400. [Google Scholar] [CrossRef]

- Madi, E.; Pope, K.; Huang, W.; Iqbal, T. A review of integrating ice detection and mitigation for wind turbine blades. Renew. Sustain. Energy Rev. 2019, 103, 269–281. [Google Scholar] [CrossRef]

- Mu, Z.; Li, Y.; Guo, W.; Shen, H.; Tagawa, K. An Experimental Study on Adhesion Strength of Offshore Atmospheric Icing on a Wind Turbine Blade Airfoil. Coatings 2023, 13, 164. [Google Scholar] [CrossRef]

- Piscitelli, F.; Fanciullo, M.; Sarcinella, A.; Costantini, M.; Frigione, M. Icephobic Properties of Superhydrophobic Coatings Developed for Aeronautical Applications. Coatings 2025, 15, 621. [Google Scholar] [CrossRef]

- Zhang, W.; Li, J.; Wang, H.; Zhao, Y. Icing and Adhesive Characteristics of Iced Airfoils Under Rime Ice Conditions. Coatings 2025, 15, 606. [Google Scholar] [CrossRef]

- Shen, H.; Li, Y.; Guo, W.; Zhang, F.; Feng, F.; Mu, Z. An experimental study of ice adhesion on wind turbine blades: Effects of materials, airfoils and attack angles. Appl. Therm. Eng. 2025, 273, 126546. [Google Scholar] [CrossRef]

- Wang, J.; Gao, J.; Zhang, Y.; Cui, H. Analysis of the Sand Erosion Effect and Wear Mechanism of Wind Turbine Blade Coating. Energies 2024, 17, 413. [Google Scholar] [CrossRef]

- Zou, M.; Beckford, S.; Wei, R.; Ellis, C.; Hatton, G.; Miller, M.A. Effects of surface roughness and energy on ice adhesion strength. Appl. Surf. Sci. 2011, 257, 3786–3792. [Google Scholar] [CrossRef]

- Hassan, M.F.; Lee, H.P.; Lim, S.P. The variation of ice adhesion strength with substrate surface roughness. Meas. Sci. Technol. 2010, 21, 075701. [Google Scholar] [CrossRef]

- Schulz, M.; Sinapius, M. Evaluation of Different Ice Adhesion Tests for Mechanical Deicing Systems. In Proceedings of the SAE 2015 International Conference on Icing of Aircraft, Engines, and Structures, Prague, Czech Republic, 22–25 June 2015. SAE Technical Paper Proceedings; ISSN 0148-7191 (Print), 2688-3627 (Electronic). [Google Scholar] [CrossRef]

- Sivakumar, G.; Sundararajan, S. The effect of surface roughness, stiffness, and size on ice adhesion. Cold Reg. Sci. Technol. 2024, 225, 104271. [Google Scholar] [CrossRef]

- Aoyama, T.; Ishikawa, M.; Hira, T.; Ukigai, K. Effect of Surface Roughness on Adhesive Shear Strength between Pure Ice and a Solid Surface. Trans. Jpn. Soc. Refrig. Air Cond. Eng. 2006, 23, 273–281. [Google Scholar] [CrossRef]

- Kraj, A.G.; Bibeau, E.L. Measurement method and results of ice adhesion force on the curved surface of a wind turbine blade. Renew. Energy 2010, 35, 741–746. [Google Scholar] [CrossRef]

- Jiang, X.; Lin, Y.; Xuan, X.; Zhuo, Y.; Wu, J.; He, J.; Du, X.; Zhang, Z.; Li, T. Stiffening surface lowers ice adhesion strength by stress concentration sites. Colloids Surfaces A Physicochem. Eng. Asp. 2023, 666, 131334. [Google Scholar] [CrossRef]

- Kelly, J.; Vogel, C.; Willden, R. Impact and mitigation of blade surface roughness effects on wind turbine performance. Wind Energy 2022, 25, 660–677. [Google Scholar] [CrossRef]

- Bharathidasan, T.; Kumar, S.V.; Bobji, M.S.; Chakradhar, R.P.S.; Basu, B.J. Effect of wettability and surface roughness on ice-adhesion strength of hydrophilic, hydrophobic and superhydrophobic surfaces. Appl. Surf. Sci. 2014, 314, 241–250. [Google Scholar] [CrossRef]

- Memon, H.; Liu, J.; De Focatiis, D.S.A.; Choi, K.-s.; Hou, X. Intrinsic dependence of ice adhesion strength on surface roughness. Surf. Coatings Technol. 2020, 385, 125382. [Google Scholar] [CrossRef]

| Factor | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|

| Separation temperature | −3 | −6 | −9 | −12 |

| Freezing temperature | −3 | −6 | −9 | −12 |

| Loading rate | 0.5 | 1 | 1.5 | 2 |

| Roughness | 0.264 | 0.454 | 0.650 | 0.862 |

| No. | Separation Temperature A/°C | Freezing Temperature B/°C | Loading Rate C/(mm/s) | Roughness D/μm | Adhesion Strength (Y)/(kPa) |

|---|---|---|---|---|---|

| 1 | −3 | −3 | 0.5 | 0.264 | 61.2 |

| 2 | −3 | −6 | 1 | 0.454 | 54.8 |

| 3 | −3 | −9 | 1.5 | 0.650 | 57.3 |

| 4 | −3 | −12 | 2 | 0.862 | 53.5 |

| 5 | −6 | −3 | 1 | 0.650 | 61.2 |

| 6 | −6 | −6 | 0.5 | 0.862 | 63.7 |

| 7 | −6 | −9 | 2 | 0.264 | 54.8 |

| 8 | −6 | −12 | 1.5 | 0.454 | 62.4 |

| 9 | −9 | −3 | 1.5 | 0.862 | 63.7 |

| 10 | −9 | −6 | 2 | 0.650 | 58.6 |

| 11 | −9 | −9 | 0.5 | 0.454 | 72.6 |

| 12 | −9 | −12 | 1 | 0.264 | 66.2 |

| 13 | −12 | −3 | 2 | 0.454 | 70.1 |

| 14 | −12 | −6 | 1.5 | 0.264 | 66.2 |

| 15 | −12 | −9 | 1 | 0.862 | 82.8 |

| 16 | −12 | −12 | 0.5 | 0.650 | 87.3 |

| 56.700 | 64.050 | 71.200 | 62.100 | ||

| 60.525 | 60.825 | 66.250 | 64.975 | ||

| 65.275 | 66.875 | 62.400 | 66.100 | ||

| 76.600 | 67.350 | 59.250 | 65.925 | ||

| R | 19.900 | 6.525 | 11.950 | 4.000 |

| Factor | Sum of Squares | Degree of Freedom | Mean Square | F | Significance (p) |

|---|---|---|---|---|---|

| Corrected Model | 1361.655 | 12 | 113.471 | 19.002 | 0.017 |

| Intercept | 67,132.810 | 1 | 67,132.810 | 11,241.888 | <0.001 |

| Separation Temperature | 893.395 | 3 | 297.798 | 49.869 | 0.005 |

| Freezing Temperature | 108.675 | 3 | 36.225 | 6.066 | 0.086 |

| Loading rate | 318.490 | 3 | 106.163 | 17.778 | 0.021 |

| Roughness | 41.095 | 3 | 13.698 | 2.294 | 0.257 |

| Error | 17.915 | 3 | 5.972 | ||

| Total | 68,512.380 | 16 | |||

| Corrected Total | 1379.570 | 15 | |||

| (adjusted ) | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, L.; Chen, H.; Wang, S.; Zhang, L.; Kou, X. Experimental Study on Static Ice Adhesion Characteristics of Wind Turbine Blade Surfaces After Sand Erosion. Coatings 2025, 15, 955. https://doi.org/10.3390/coatings15080955

Shi L, Chen H, Wang S, Zhang L, Kou X. Experimental Study on Static Ice Adhesion Characteristics of Wind Turbine Blade Surfaces After Sand Erosion. Coatings. 2025; 15(8):955. https://doi.org/10.3390/coatings15080955

Chicago/Turabian StyleShi, Lei, Hongliang Chen, Shaolong Wang, Liang Zhang, and Xinwei Kou. 2025. "Experimental Study on Static Ice Adhesion Characteristics of Wind Turbine Blade Surfaces After Sand Erosion" Coatings 15, no. 8: 955. https://doi.org/10.3390/coatings15080955

APA StyleShi, L., Chen, H., Wang, S., Zhang, L., & Kou, X. (2025). Experimental Study on Static Ice Adhesion Characteristics of Wind Turbine Blade Surfaces After Sand Erosion. Coatings, 15(8), 955. https://doi.org/10.3390/coatings15080955