Abstract

Alkyd resins are among the most common coatings used for exterior wood joinery. In Romania, solvent-borne alkyd coatings are widely used to finish wood. The study aims to compare the performance after 7 years of outdoor exposure of two types of alkyd coatings, a semi-transparent brown stain with micronized pigments (Alk1) and an opaque white enamel (Alk2), applied directly on wood or wood pre-treated with three types of resins: acryl-polyurethane (R1), epoxy (R2), and alkyd-polyurethane (R3). Fir (Abies alba) wood served as the substrate. Cracking, coating adhesion, and biological degradation were periodically assessed through visual inspection and microscopy. Additionally, a cross-cut test was performed, and the loss of coating on the directly exposed upper faces was measured using ImageJ. The results indicated that resin pretreatments somewhat reduced cracking but negatively affected coating adhesion after long-term exposure. All samples pretreated with resins and coated with Alk1 lost more than 50% (up to 78%) of the original finishing film by the end of the test. In comparison, coated control samples lost less than 50%. The Alk2 coating exhibited a film loss between 2% and 12%, compared to an average loss of 9% for the coated control. Overall, samples pretreated with alkyd-polyurethane resin (R3) and coated with alkyd enamel (Alk2) demonstrated the best performance in terms of cracking, adhesion, and discoloration.

1. Introduction

The service life prediction of exterior wood commodities is directly connected with their use class and influenced by several factors, including wood substrate, special pre-treatments to improve unfavorable wood properties (e.g., natural durability, dimensional instability, and ultraviolet (UV) degradation), characteristics of the finishing materials, application details, and exposure severity [1,2,3,4,5,6,7]. Coatings for exterior purposes generally offer some protection against moisture and related dimensional changes, photochemical degradation, and biological degradation [8]. When selecting a type of finish, consideration is given to appearance, protection, and cleanability, as well as how the wood’s surface properties affect application and performance [2]. Two types of coating are known for exterior wood protection [1]. One type forms a clearly visible film or coating on the surface of the wood, while the other penetrates the wood, leaving (almost) no distinct layer. Exterior use coatings include all types of paints, varnishes, and lacquers. The formulations of penetrating finishes can include preservatives, water repellents, and micronized pigments, and are often semi-transparent stains.

Wood is one of the most versatile but anisotropic substrates, which will have a significant impact on the adhesion of the coating and on the expected service life of coated wood in outdoor applications. Fir (Abies alba) wood, alongside pine (Pinus sylvestris, Pinus nigra) and spruce (Picea sp.), is a common species used for outdoor applications [7,9,10,11,12] due to its physical, mechanical, and technological properties [2]. Also, in Romania, these species are preferred due to their widespread occurrence in the country, exploitability, and availability on the market [13]. Special attention is given to the durability of these species in outdoor conditions and also to the preservation treatments and finishes.

Numerous studies and field tests have examined the influence of different wood species and modifications on the performance of coating systems on various types of wood substrates [14,15,16,17]. Some standardized methods according to EN 927-3:2019 and EN 330:2014 [14,18,19] evaluate coating performance and assess the biodegradation of wood and degradation of coating films, as well as the relationship between these phenomena [20,21,22,23]. Wood joinery is one of the most common applications for exterior coatings. Therefore, many studies have focused on this type of end use to determine the effectiveness of preservatives or coatings [24,25,26,27].

Regarding coatings for exterior joinery, alkyd resins are among the most common. Although these resins have been available since the 1950s, they only gained widespread use after the 1970s. Applying solvent-borne alkyd coatings has been a standard method for finishing wood joinery [28,29,30]. Recently, new formulations, including waterborne alkyd resins, have revitalized and expanded their potential for various exterior wood coating applications [12,31].

Depending on their chemical components, outdoor alkyd coatings are available in various formulations and viscosities, providing several benefits for outdoor use, such as water repellence, elasticity, UV resistance, durability, and gloss [3,5,7,26,32]. However, solvent-based formulations raise concerns about VOC emissions, although newer formulations feature fewer toxic solvents and higher solid content [2,28,32]. The coating industry actively develops more sustainable finishing systems [31,33,34].

Many studies have shown interest in substrate preparation by treating before coating, but they mainly considered water repellent preservatives, biocides, treatments with UV absorbers, and their influence on wood durability and coating performance [4,5,6,35,36,37,38]. Evans et al. [39] and Cogulet et al. [7] reviewed the different strategies to enhance the durability of clear coatings by pre-treatments with chromic acid or UV stabilizers to increase the durability of the coating and UV resistance. The impact of pretreatments on the performance of the paint system on window frames was a topic of discussion in the Alblas et al. study [29]. Additionally, post-treatments with waterborne acrylate resin with wax additives, applied on top of alkyds, were investigated, but the results were minimal in terms of increasing the durability of exterior finishes [40]. The main aspects considered in the literature for the assessment of coating performance when exposed to weathering were the influence of the wood substrate, the coating penetration into the wood and film thickness, gloss, color changes, adhesion and film failure, moisture transport, and fungal development. [3,8,41]. Therefore, the present research aims to make a contribution to this area of research. Moreover, only a few field studies have been conducted in Romania regarding the performance of exterior joinery coatings [12,22]. Additionally, no studies have examined the influence of short-time dipping pre-treatments on the dimensional stability of fir wood or its impact on coating adhesion and film failure.

The study aims to compare the performance after 7 years of outdoor exposure of two types of alkyd coatings, applied directly on wood or on wood pre-treated with three types of resins that are intended to improve the substrate’s dimensional stability. The relevant degradation phenomena of the wood-coated surfaces, such as loss of adhesion, cracking, and biological degradation by fungi, are presented, as well as how they are influenced by pre-treatments. Additionally, the influence of the actual exposure situation of the tested samples’ surfaces on coating adherence was considered.

2. Materials and Methods

2.1. Materials

Fir (Abies alba Mill.) wood samples were used as horizontal elements with a tenon in L-joint assemblies. The elements were machined from square cross-sections (38 × 38 × 203 mm), with perfectly radial and tangential faces and without defects. The samples were conditioned at 20 °C and 55% RH until reaching an equilibrium moisture content of 9%. Before treatment, they were sanded with consecutive H80, H100, and H120 grinding papers to obtain a smooth surface. The wood sanding operation was also considered in coatings studies, which were compared with planed or rough surfaces [2,10,25] or followed the technical specification of the producers.

Pre-treatment aimed at dimensional stabilization of the wood surfaces with three synthetic resins: acryl-polyurethane- coded R1, epoxy-coded R2, and alkyd-polyurethane- coded R3. Two alkyd solvent-borne coatings, commonly used for exterior joinery, manufactured by “Policolor S.A”, Bucharest, Romania, were selected as finishing materials. The first was a slightly brown pigmented (semi-transparent), UV-resistant alkyd lacquer of “lasure” type (coded Alk1), and the second was a white, glossy alkyd enamel (coded Alk2). Numerous researchers have extensively used similar products, including acrylic and alkyd products, which are very popular on the market [5,8,24,26,29,31,40], etc.

2.2. Treatment Method

Three series of coated samples were prepared:

- •

- Series 1—containing control samples, directly coated with the two alkyd products (coded C-Alk1 and C-Alk2).

- •

- Series 2—containing samples pre-treated by short time immersion (15 min at 20 °C) with the three types of resins (R1, R2, R3) and then coated with the brown impregnation lasure (Alk1).

- •

- Series 3—involved resin pre-treated samples, subsequently coated with the white, glossy alkyd enamel (Alk2).

Each of the three resins (coded R1, R2, R3) was diluted to the same viscosity (flowing time 12 s, Φ4 mm, 20 °C) in order to facilitate penetration into the wood and ensure similar penetration among the samples involved in different treatments. All coatings were applied in two layers by brushing on the exterior surfaces except the tenon [19]. The coating (Alk1) was applied at delivery viscosity (13 s, Φ4 mm, 20 °C), whereas the coating (Alk2) was diluted to a viscosity of 45 s, Φ4 mm, 20 °C. All samples were weighed before and after treatments in order to calculate the product uptake in g/m2.

After coating, the transversal ending edges were sealed with epoxydic resin to prevent water ingress. After treatments, the samples were conditioned for a minimum of 14 days in laboratory conditions. Samples were prepared in four replicates for each variant: three were exposed in the test and one was kept as a control in the laboratory, protected against light and other physical and chemical factors.

The specifications of products and codes of treatments are listed in Table 1.

Table 1.

Characteristics of chemical products and specifications for utilization.

2.3. Exposure

A modified L-joint field test, adapted from the procedure proposed by Van Acker and Stevens, for studying the natural durability of wood for out-of-ground contact [21,42], was employed. The original test EN 330 is a field test, designed for the evaluation of the efficiency of wood preservatives to be used under a coating in use class 3 (UC3) (outdoors, above ground, unprotected against weathering factors), but it allows for a complex evaluation of wood and coatings degradation [19]. Details on the modified procedure employed in the research reported in this paper were previously published [22,23].

The L-joints resulted from tenon pieces mounted in a longer mortise member made of two non-durable reference wood species, sapwood of Pinus sylvestris and Fagus sylvatica, glued together with water-resistant PVAc glue (D4). The mortise members were not treated or finished in any way, allowing rapid infestation by microorganisms and spreading them to the actual testing pieces (the tenon members) through direct contact in the joining area. More details on the practical procedure of preparing the testing samples and mortise have been previously published by the authors [22,23].

Figure 1 shows images of the experimental testing rack and the exposed samples. The samples were oriented with their tangential faces on the upper side and had a 10° backward slope to promote water ingress into the tenon–mortise joint, as a means of accelerating biodegradation [19].

Figure 1.

(a) General view of the testing stand in Brașov, Romania, with a 10° backward inclination facing south; (b) detail of L-joint samples coated with two alkyd products (tenon pieces mounted in a mortise member).

2.4. Assessment of Wood and Coating Degradation

The total exposure period was 7 years. Samples were periodically visually evaluated after 9, 16, 27, and 48 months. The initial macroscopic assessments included rating biological degradation, crack formation in the wood, and film adhesion; afterwards, the samples were returned to the stand. At the end of the tests, after 84 months (7 years) of exposure, the microscopic appearance of the coated surfaces was also examined, and the adhesion performance of the alkyd films was evaluated both by the cross-cut standard method (EN ISO 2409:2020) [43] and through image analysis of the entire exposed upper face.

2.4.1. Macroscopic Evaluation

Although the L-joint test is primarily a field test for wood preservatives used beneath a coating, it provides multiple evaluation opportunities: biological degradation phenomena, coating performance due to weathering, the effectiveness of different products, or a combination of treatments. This paper focuses exclusively on degradation phenomena observed on the coated surfaces. Important aspects such as wood cracking caused by dimensional changes, biodegradation indicated by surface discoloration from mold or sap stain fungi, and decay were considered. Discoloration was rated according to PrCEN/TS 12037:2003 (E) [18], with scores from 0 to 3, where 0 indicates no discoloration and 3 indicates very extensive and dark growth covering the entire surface [42]. Decay was rated from 0 to 4, with 0 meaning no visible decay and 4 indicating very severe, extensive decay. The original methods used by the authors for visual assessment and rating of cracks in wood and coating adherence were applied [22,23]. Cracks in wood were rated from 0 to 4: 0—no cracks; 1—isolated, small cracks less than 1 cm long; 2—one large crack along the entire length of the sample or several cracks 1–3 cm long; 3—two big cracks along the entire length of the sample or numerous cracks 3–5 cm long; 4—large and/or numerous small cracks. Coating adherence was evaluated through careful visual inspection of the overall appearance of the coating film and testing the ease of removal by gentle fingernail scratching. Ratings ranged from 0 to 3: 0—very good, no visible degradation, coating not removable; 1—good, slight changes in appearance or micro-fissures that cannot be removed by scraping with a fingernail; 2—medium, some areas where the film can be removed with a fingernail or has flaked; 3—failure, visible degradation, easy to remove the film with a fingernail.

At the end of the test, a destructive cross-cut test was employed [43]. The tested areas were then inspected for flaking and coating loss and rated from 0 (no flaking, 0% loss—the edges of the cross cuts are completely smooth; none of the squares of the lattice is detached) to 5 (extensive flaking, more than 65% film loss—the coating has flaked along the edges of the cuts in large ribbons and/or some squares have detached partly or wholly). In parallel with exposed samples, the unexposed samples were identically tested in order to assess the initial adherence.

2.4.2. Microscopic Investigation

Microscopic images were captured using a Nikon SMZ18 stereomicroscope (Nikon Corporation, Tokyo, Japan) at magnifications of 22.5 and 90×. The microscope camera Ds-Fi3 with 5.9 Mp resolution and the NIS Elements Imaging Software (D 5.30.02) 64 bit allowed us to obtain images of high quality on bio-deterioration areas on the wood surface, as well as film loss or damage.

2.4.3. ImageJ Analysis of the Coating Film

The loss of coating was evaluated by ImageJ processing (version 1.54 Win Java8, available online: https://imagej.net/ij/download.html (accessed on 19 May 2025)) on the upper face of the samples, which was also the most deteriorated area. Analysis involved a quantitative evaluation by comparing the image considered that was initially fully covered by coating and the same image after the test. Pictures were analyzed in a binary system. The remaining coating is selected and highlighted in red. Analyzing the particles from the program menu, the percentage of the loss area of the film was calculated.

2.4.4. Statistical Analysis

The data obtained were statistically processed by employing the Minitab software (version 22). Multifactorial ANOVA analysis of variance (95% CI) was performed for the cross-cut test and the response optimization between pre-treatments and coatings was applied.

3. Results and Discussion

The long-term experimental data demonstrated that the field tests used in this study are a complex tool for the evaluation of different wood substrates and types of treatments and finishes. As other research has demonstrated [20,24], the accelerated method of L-joint test used in this manuscript as a field test for assessing two alkyd coatings was an appropriate test for associated degradations, specific for wood exposed outdoors, and out of ground contact.

3.1. Aspects of Degradation of Coated Wood Surfaces

Complex degradation of both coatings and wood substrate occurred after 7 years of outdoor exposure as a result of a combination of non-biotic and biotic factors. Common features of degradation include cracking of the coating and wood, loss of coating adhesion, blistering, flaking, and evidence of biological attack, especially by mold fungi.

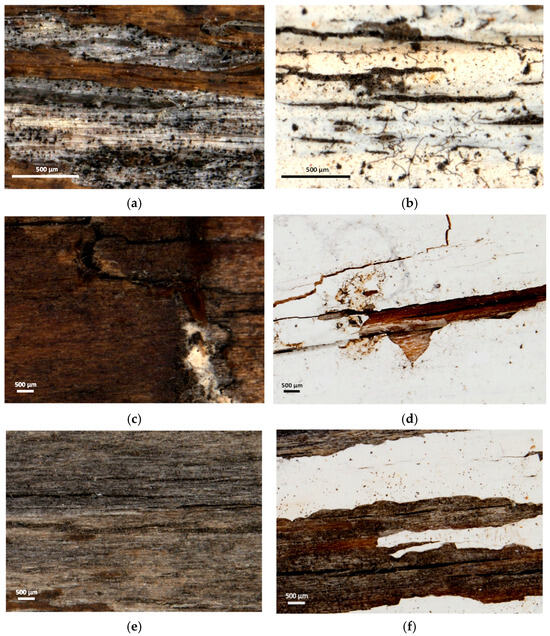

Figure 2 illustrates the degradation effects on the coated wood surfaces, as revealed by a microscopic evaluation of the upper faces of the test samples. For example, cracks in the wood and coatings, as well as areas with partial or total loss of the coating films (Alk1) and flaking areas of the films (Alk2), were present. Coating the wood with the two types of alkyds did not prevent, but only delayed, the growth of mold fungi, which was visible as black dots and filaments. This attack often results in localized degradation and/or microfissuring of the coating film, leading to further flaking (Figure 2a,b). Some decay-affected areas were detected for all categories of coated samples, more frequently close to the tenon area, which was not treated or coated (Figure 2c), but also along the tenon (Figure 2d). The weathered appearance of wood after seven years outdoors was also highlighted in the areas with coating film loss. This is evidenced by the rough surface, defibration, as well as deep wood cracks, combined with fungal growth spots. (Figure 2e,f).

Figure 2.

Microscopic aspects of wood and coatings degradation after 7 years outdoor exposure for fir (Abies alba) wood surfaces coated with (a,c,e) the brown alkyd stain (Alk1) and (b,d,f) the white alkyd enamel (Alk2).

Despite these common degradation patterns, there were some obvious differences in the occurrence and extent of degradation phenomena, depending on the type of pre-treatment and coating material. The results are further presented and discussed from the perspective of a comparative quantitative assessment of wood and coating films degradation in relation to the wood substrate pre-treatments with three different resins and the influence of exposure on the adherence of coatings after 7 years of outdoor exposure.

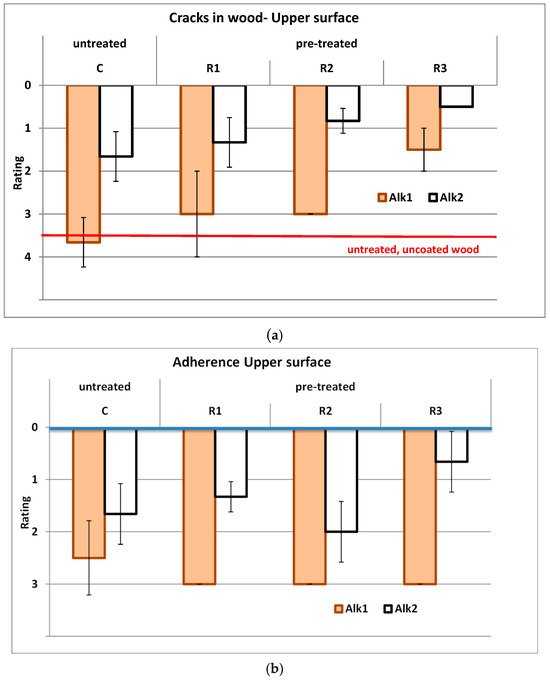

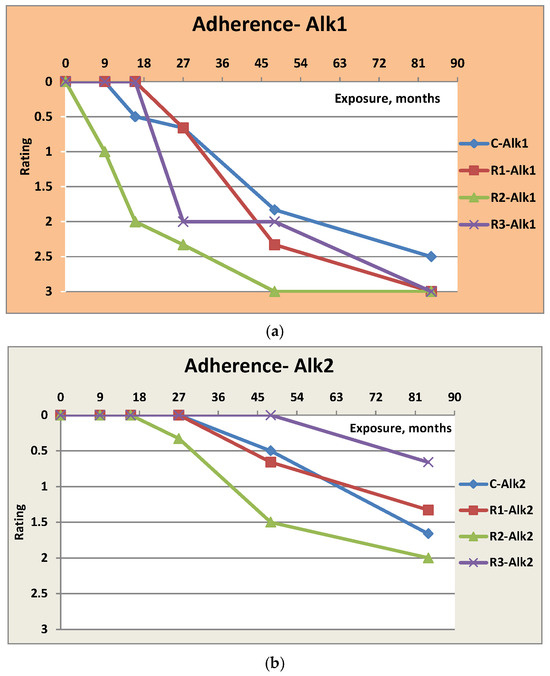

3.2. Influence of Resin Pre-Treatments on Wood Cracking and Adherence of Coating Films: Visual, Non-Destructive Assessment After 7 Years of Exposure

The surface pre-treatment of wood substrate with the three types of resins was intended to reduce swelling and shrinking of wood and potentially improve the coated wood performance by minimizing cracking and preventing adherence loss. The graphs in Figure 3 illustrate the influence of the substrate pre-treatment on the incidence and severity of cracking on the upper face and the adherence of the coating films after 7 years of exposure.

Figure 3.

Influence of resin pre-treatments on the cracking of wood substrate (a) and adherence of the coating films (b) after 7 years of exposure. Note: Original rating scales for cracks (0–4) and adherence (0–3) were employed, blue line—initial adherence (grade 0).

All three pre-treatments (R1, R2, R3) might have had a positive effect on wood substrate dimensional stabilization, resulting in reduced substrate cracking (Figure 3a) compared to the not-pre-treated controls (C), regardless of the type of coating material (Alk1, Alk2). This effect, however, depended on the resin type, compatibility, and adherence between layers, which are important factors for ensuring stable, adherent, and durable finishes. Otherwise, these requests may have the opposite effect of accelerating cracking and flaking or promoting fungal growth. An encouraging result was obtained for samples treated with the alkyd-polyurethane resin (R3), where the incidence of cracks was limited to 1.5 for samples coated with (Alk1) and 0.5 for samples coated with (Alk2). This represented a reduction of 59% and 70%, respectively, compared to the untreated coated controls (C). Compared with untreated wood (C), cracking diminished by 18% for those pre-treated with (R1) and (R2), and by 60% for those pre-treated with (R3) resins and coated with (Alk1) and 50%, 20%, and 70% for (R2), (R1), and (R3) resins coated with (Alk2). In all cases (control and pre-treated substrates) the white enamel (Alk2) offered better protection against cracking than the brown stain (Alk1).

All the coated samples (controls and pre-treated) initially had a very good adherence (grade 0), but this was significantly diminished by outdoor exposure. The non-destructive assessment of the adherence after 7 years of exposure demonstrated that the semi-transparent alkyd coating (Alk1) lost significant adherence to the wood substrate and presented visible degradation. Adherence was rated with a minimum score of 3 for all the wood samples pre-treated with resins (R1, R2, R3), which was inferior to that for the untreated coated control samples (C), rated 2.5. In contrast, for the white enamel (Alk2), the experimental results indicated a better retained adherence, rated with 0.66–2, compared to 1.7 for the coated control (Figure 3b). These results indicate a positive effect of pre-treatment with R3 followed by coating with the white enamel Alk2 on the long-term adherence of the coating film. To conclude, resin-pre-treatment had generally no or a negative influence on the adherence of the coating films after long-time exposure to the climatic factors, except pre-treatment with alkyd-polyurethane resin (R3) followed by coating with alkyd enamel (Alk2). When comparing the performance of the two alkyd coating materials in terms of adherence after long-term outdoor exposure, the white enamel (Alk2) presented a better behavior compared to the brown alkyd stain (Alk1).

The type of resin used led to stress development, causing cracking in the film, for instance, the incompatibility of the properties between the epoxy resin (R2) and the alkyd coatings. In contrast, the alkyd-polyurethane resin (R3) was more compatible with both alkyd coatings, creating a more stable and adherent film. This behavior has been reported by other studies as well [26,44].

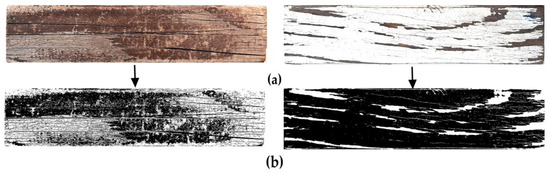

3.3. ImageJ Analysis of Coating Film Loss After 7 Years of Exposure

The visual assessments could have limited reproducibility and could be subjective. Therefore, in addition to visual assessment of adherence and its relative rating on the 0–3 scale, a complementary evaluation of the adherence was achieved. The film loss on the upper faces was calculated employing ImageJ software. Two examples of pictures representing one sample coated with (Alk1) and one sample coated with (Alk2), converted by software in a binary system, are given in Figure 4a,b. The percentage loss of the coating film was calculated as the ratio of the white areas to the total surface of the samples (Figure 4b).

Figure 4.

Examples of ImageJ analysis of coating film loss for two samples covered with alkyd stain (Alk1) and white enamel (Alk2)—(a) original image and (b) the same image in a binary system.

All the samples pre-treated with resins and further covered with (Alk1) lost more than 50%, reaching up to 78% from the original film after 7 years of exposure, on the upper, directly exposed faces. The control coated samples with (Alk1) presented a film loss below 50%. In this situation, the wood substrate preparation by resin pre-treatment seemed to negatively affect the adherence of the brown alkyd stain due to limited compatibility, though this was not evident from the initial non-destructive visual assessment of adherence. Moreover, swelling and shrinking, aging of materials, and degradation phenomena occurring during long-term exposure must have accentuated the effects of this limited compatibility, leading to coating degradation and finally to the loss of the film. The coating (Alk2) registered a film loss between 2% and 12%, compared with coated controls with an average loss of 9%. The best results, indicating a minimum coating film loss, were registered for wood pretreated with (R3) and (R1), with a loss of film of 2 and 7%, respectively. These digital instruments are easy to use, very intuitive, and useful to complete the information obtained by visual assessments, with more consistent and reliable data. They have also been successfully employed in other research projects studying the cracks in wood or fungi spots [5,15].

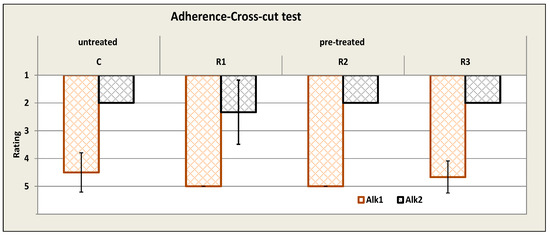

3.4. Cross-Cut Test

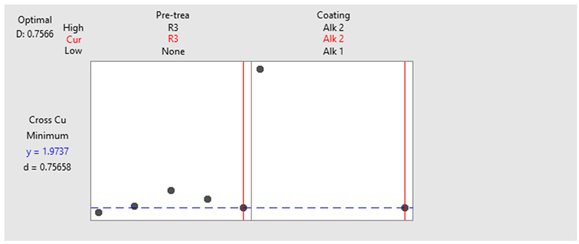

It is acknowledged that a coating has a protective role as long as it remains continuous and adherent to the substrate [45]. The film loss was caused by the loss of adhesion, assessed by visual observation previously presented (Figure 3) and cross-cut test (Figure 5).

Figure 5.

Results of the cross-cut method for assessing coating film adhesion.

Both methods for adhesion evaluation showed poor adherence for the samples coated with Alk1 and medium adherence for those coated with Alk2.

Results after the cross-cut test indicated that initial adherence was rated as 1.0 (no more than 5% of cross-cut area affected) for both (Alk1) and (Alk2) coatings, except for wood pretreated with epoxy resin R2, where the adherence of the film was less satisfactory, rated as 2.0 (less than 15% of cross-area affected). Therefore, the wood treated with this resin showed inferior behavior in terms of adherence, cracks, and biological degradation.

At the end of the test, all samples coated with (Alk1) were rated with the lowest adherence value of 4.5–5.0, while (Alk2) was rated with 2.0–2.33 (no greater than 15% of the cross-cut area was affected), with a decrease in adhesion compared to unexposed. The loss of film could also be correlated with the initial resin uptake, which was probably insufficient for (Alk1), resulting in a thin coating layer (see Table 1). That is why it tended to degrade rather quickly as UV resistance diminishes [26], leading to more than 50% of the flaking on the directly exposed faces. Equally, a thicker, less adherent film on the wood substrate could initially lead to small areas of spot-wise damage that develop into flaking spots accelerated by fungal colonization. It seems very likely that the adhesion of the coating to the wood depends on a certain degree of penetration, which is related to viscosity and solids. However, deep penetration is not always necessary for good adhesion [28]. This result was obtained in the present study, where the (Alk2) enamel had a good adherence compared with the (Alk1) semi-transparent lacquer, even if the latter had a low viscosity and almost the same solid content.

3.5. Statistics

The One-way ANOVA analysis of variance and the response optimization were provided by Minitab software 2.2. and presented in Table 2.

Table 2.

One-way ANOVA response, analysis of variance for the cross-cut test (95%CI).

The One-way ANOVA analysis showed that the cross-cut rate was significantly influenced by the coating layer (p-value ≤ 0.05).

The response optimization of the cross-cut as a minimal target was applied to find the best combination of factors that satisfy the objective. The result presented in Table 3 shows that the best cross-cut rate is achieved when the samples are pre-treated with resin R3 and coated with Alk 2. The composite desirability coefficient is satisfactory (0.76).

Table 3.

Response optimization of the cross-cut test.

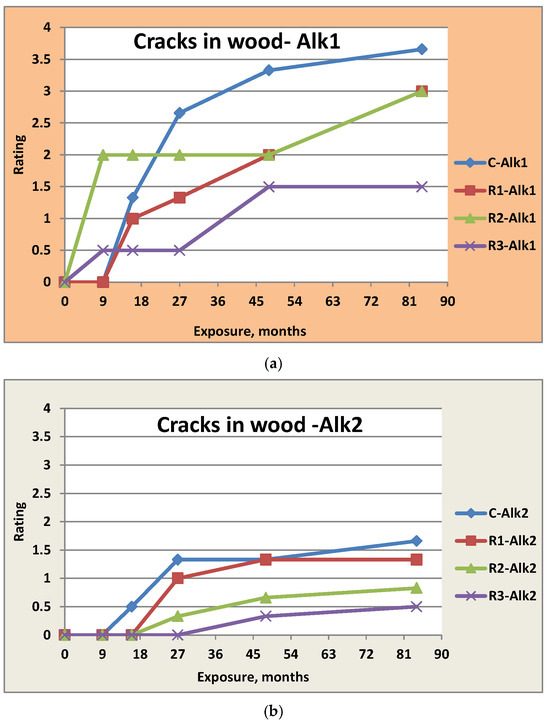

3.6. In-Time Evolution of Wood Cracking and Adherence During Outdoor Exposure

Wood substrate cracking and adherence causing a loss of coatings evolved in time during the 7 years of exposure, as illustrated in Figure 6, based on data from periodical evaluations after 9, 16, 27, 48, and 84 months (7 years) of exposure. Generally, the cracking at the macroscale diminished when the wood substrate was pre-treated before coating, but the cracking evolution pattern was dependent on the type of resin and influenced by the type of coating (Figure 6a,b). The best result was registered for wood pre-treated with alkyd-polyurethane resin R3, coated with (Alk2), where cracking was noted only after 27 months of exposure, later than in the rest of the samples.

Figure 6.

In-time evolution of the cracking phenomenon for the two coatings: (Alk1)—(a) and (Alk2) —(b).

When comparing the two alkyd finishes, cracking started more rapidly for samples coated with Alk1, even after 9 months of exposure (Figure 6a), than for those coated with Alk2 (after 16 or 27 months of exposure), depending on wood pre-treatment. In the latter case, the cracks evolved more slowly for all types of treatments. After seven years outdoors, the extent of cracks reached a maximum value of less than 2, which is below the maximum of 4. (Figure 6b).

The wood cracking phenomenon is delayed on samples coated with alkyd enamel (Alk2) compared to those coated with semi-transparent alkyd lacquer (Alk1). Similarly to the results obtained by Feist [35] for alkyd paints, cracks in the film appeared after 27 months (more than two years) of exposure. In other research, a failure of the film was observed for alkyd coatings after four years of exposure [24,46]. Another alkyd finish tested had ratings of 3 or less (3 out of a maximum of 10—no degradation) of cracking after seven years of weathering [46].

The adherence of (Alk1) reached the lowest rating of 3, meaning a visible degradation at the end of the test (Figure 7a). The adherence of the (Alk2) coating film for all tested samples ranged from good to medium (below 2), as shown in Figure 7b.

Figure 7.

The evolution of coating adherence over time for the two alkyds tested (Alk1 (a) and Alk2 (b)) after periodic assessments (9, 16, 27, 48, and 84 months).

The results show that loss of adhesion correlates with the presence of cracks in the wood at each evaluation period.

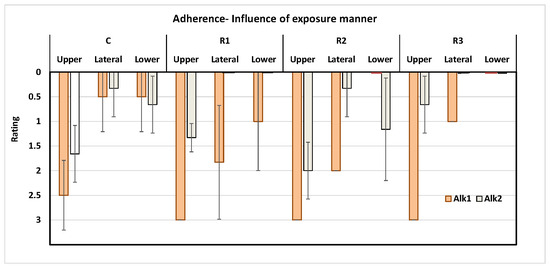

3.7. Influence of Exposure Situation on the Adherence of the Coating Films After 7 Years of Exposure

All the data presented so far referred exclusively to the upper faces of the test samples, which were the most degraded due to their direct exposure to the climatic factors. However, different degrees of degradation of the coating films were observed depending on the actual exposure situation. Accordingly, the directly exposed upper faces and the non-directly exposed parts of the samples (lateral and lower faces) differed in terms of adherence of the coating films after 7 years of outdoor exposure. Most obviously, upper faces showed a complete failure of adherence with grades between (2.5–3), confirmed by flaking and film loss. A fairly good film adherence was preserved, varying in intervals (0–2) for the non-directly exposed faces of the samples (Figure 8).

Figure 8.

Comparative results of adherence evaluated after 7 years according to exposure manner (upper, directly exposed faces and non-direct exposed lateral and lower faces).

The semi-transparent coating (Alk1) was substantially degraded due to erosion on the upper face, compared to (Alk2). The adhesion was quite good on the non-directly exposed surfaces (lateral and lower) and pre-treatments appeared to have a positive effect compared with untreated and coated samples.

The results align with other studies on the topic, which state that pre-treatment significantly influences the performance of the coating system, depending on the treatment and substrate [29,36].

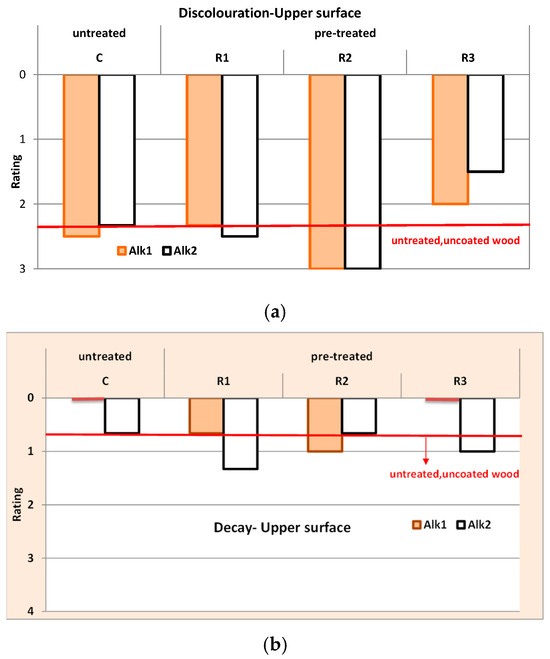

3.8. Influence of Resin Pre-Treatments on Biological Degradation of Coated Surfaces

In support of the above statements, the visual assessment of biodegradation confirmed that extensive discoloration, exceeding grade 2, was registered for most of the samples, demonstrating that the coating films applied could not provide long-term protection against mold and stain fungi. Maximum conventional grade (3) of discoloration was recorded for the samples pre-treated with R2. The treatment with resin (R3)-alkyd polyurethane resulted in less discoloration than untreated and uncoated wood, with a rating below 2, compared to the other treatments (Figure 9a).

Figure 9.

Illustration of biodegradation phenomena after 7 years of outdoor exposure on the upper faces of coated samples. (a) Discoloration; (b) Decay.

Decay assessment of the surface indicated a small rate of attack (below 1—very slight attack, Figure 9b) and the signs of decay were visible mainly towards the tenon, as also shown in Figure 2c,d. This area was more exposed to water access and fungal infestation. The biological degradation evaluated by visual assessment and microscopy could also be connected with adherence. Discoloration occurred after short exposure times. After 9 months of exposure, samples treated with (Alk1) showed discoloration, while samples treated with (Alk2) showed discoloration later, after 16 or 27 months. Discoloration was particularly noticeable in flaked areas. It evolved on the surface or under the coating film, where the spot-wise damage occurred. These findings agree with other results reporting that semi-transparent stains failed more rapidly because of cracking, flaking, erosion, blue stain, and mold [32]. Moreover, opaque paint can maintain its coating for about 10 years outdoors, but semi-transparent coating offers lower weathering protection [37]. Generally, a similar result indicated that white enamel (Alk2) had an overall improved durability in exterior compared with semi-transparent pigmented coating (Alk1). The content of pigment from opaque enamel likely increased the durability of the finish in exterior, blocking the UV light compared with semi-transparent, which makes the wood grain visible. It confirms the knowledge of many years from previous studies [26,45].

Wood substrate preparation by sanding seemed to be effective as a prior step to coating application, resulting in an even and homogenous finish spread [47], although other studies stated that rough sawn surfaces enhanced the penetration of semi-transparent coating and lasted 10 years compared with smooth surfaces, where the lifespan was 2–4 years [2]. The expected service life of semi-transparent coatings on fir with a smooth surface is short, at 2–3 years, compared with opaque coatings, which have a moderate expected service life of 6–10 years [2].

4. Conclusions

The 7-year exposure period in the present study is quite long to make a conclusion about the performance of the two alkyd coatings examined. This research indicates that the performance of coating systems depends not only on the coating formulation but also on substrate preparation and exposure conditions. Careful selection of coatings and substrates is crucial for predicting and enhancing the service life of outdoor finishing technologies.

All pre-treatments with the three resins, acryl-polyurethane (R1), epoxydic (R2), and alkyd-polyurethane (R3), might have a positive effect on fir wood substrate dimensional stabilization, leading to less cracking compared with the untreated wood. Furthermore, resin pre-treatment generally had no influence or had a negative influence on the adhesion of the coating films after 7 years of outdoor exposure. The best performance in terms of cracking, adherence, and discoloration was observed for samples pre-treated with alkyd-polyurethane resin (R3) and further coated with alkyd enamel (Alk2).

Regarding adherence, the white enamel (Alk2) performed better than the brown alkyd stain (Alk1), where the loss of coating due to erosion was more than 50% and up to 78% from the original film for all series of samples.

Using pre-treatments that can dimensionally stabilize the wood alone is not enough to improve the performance of the coating. Photo stabilizers for UV protection and biocides to restrict fungal colonization of the wood interface must be used as well. Furthermore, the wood’s surface exposure to weathering must be considered as an important factor in the occurrence and severity of coating degradation.

Author Contributions

Conceptualization, E.C.B. and M.C.T.; methodology, E.C.B. and M.C.T.; software, E.C.B. and E.-A.S.M.; validation, E.C.B., M.C.T., and E.-A.S.M.; formal analysis, E.-A.S.M.; investigation, E.C.B.; writing—original draft preparation, E.C.B.; writing—review and editing, E.C.B., M.C.T., and E.-A.S.M.; visualization, E.-A.S.M.; supervision, M.C.T. and E.-A.S.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

We acknowledge Transilvania University of Brasov, Romania (ICDT Research Institute) for providing the infrastructure used in this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Feist, W.C. Painting and Finishing Wood for Use Outdoors. New Ideas Materials Procedures. In Proceedings of the Seventh Annual Educational Conference, Baltimore, MD, USA, 5–8 February 1984; pp. 1–27. [Google Scholar]

- Williams, R.S. Finishing of wood. In Wood Handbook, Chapter 16; Forest Products Laboratory, United States Department of Agriculture Forest Service: Madison, WI, USA, 2010; pp. 16-2–16-37. [Google Scholar]

- Ekstedt, J. Studies On The Barrier Properties Of Exterior Wood Coatings. Doctoral Thesis, KTH-Royal Institute of Technology, Stockholm, Sweden, 2002. [Google Scholar]

- Özgenç, Ö.; Hiziroglu, S.; Ylidiz, U.C. Weathering properties of wood species treated with different coating applications. BioResources 2012, 7, 4875–4888. [Google Scholar] [CrossRef]

- Nejad, M.; Cooper, P.A. Exterior wood coatings. Part-1: Performance of semitransparent stains on preservative-treated wood. J. Coat. Technol. Res. 2011, 8, 449–458. [Google Scholar] [CrossRef]

- Nejad, M.; Cooper, P.A. Exterior wood coatings. In Wood in Civil Engineering; IntechOpen Limited: London, UK, 2017; pp. 111–129. [Google Scholar] [CrossRef]

- Cogulet, A.; Blanchet, P.; Landry, V. The multifactorial aspect of wood weathering: A review based on a holistic approach of wood degradation protected by clear coating. BioResources 2018, 13, 2116–2138. [Google Scholar] [CrossRef]

- Oberhofnerová, E.; Šimunková, K.; Dvorák, O.; Šterbová, I.; Hiziroglu, S.; Šedivka, P.; Pánek, M. Comparison of Exterior Coatings Applied to Oak Wood as a Function of Natural and Artificial Weathering Exposure. Coatings 2019, 9, 864. [Google Scholar] [CrossRef]

- Jirous-Rajkovic, V.; Vrsaljko, D.; Mihulja, G. Coating adhesion and wettability of aged and preweathered FIR wood and pine wood surfaces. Wood Res. 2007, 52, 39–48. [Google Scholar]

- Yaremchuk, L.; Hogaboam, L.; Slabejova, G.; Sedliacik, J. Comparative analysis of the quality properties of oil-based and alkyd coating materials for wood. Acta Fac. Xylologiae Zvolen 2023, 65, 63–71. [Google Scholar] [CrossRef]

- Özgenç, Ö.; Bilici, E.; Durmaz, S.; Söğütlü, C.; Emik, S. Enhancing Weathering Durability of Pre-Protected and Unprotected Wood by Using Bark Extracts as Natural UV Absorbers in Waterborne Acrylic Coating. J. Coat. Technol. Res. 2022, 19, 303–321. [Google Scholar] [CrossRef]

- Mihăilă, A.; Ipate, A.M.; Zaltariov, M.F.; Rusu, D.; Balan-Porcarasu, M.; Stoica, I.; Lisa, G. Evaluation of natural ageing of alkyd paints used for wood protection. Polym. Degrad. Stab. 2024, 229, 110947. [Google Scholar] [CrossRef]

- National Institute of Statistics-INS (31 October 2024). Available online: https://insse.ro/cms/ro/content/seria-silvicultura-volumul-de-lemn-exploatat-%C3%AEn-anul-2023 (accessed on 16 July 2025).

- EN 927-3:2019; Paints and Varnishes. Coating Materials and Coating System for Exterior Wood, Part 3: Natural Weathering Test. European Committee for Standardization: Brussels, Belgium, 2019.

- Hundhausen, U.; Reimann, C.; Gobakken, L.R. Evaluation of mould growth on coated wood using digital image analysis (ImageJ). COST Action FP1006 Bringing new functions to wood through surface modification. In Proceedings of the 3rd Workshop–Process and Service life modelling, Ghent, Belgium, 17–19 April 2013. [Google Scholar]

- Podgorski, L.; Reynaud, C.; Montibus, M. Fungal Growth on Coated Wood Exposed Outdoors: Influence of Coating Pigmentation, Cardinal Direction, and Inclination ofWood Surfaces. Coatings 2019, 9, 27. [Google Scholar] [CrossRef]

- Dvorak, O.; Kvietková, M.S.; Šimunková, K.; Machanec, O.; Pánek, M.; Pastierovič, F.; Lin, C.-F.; Jones, D. The Influence of the Initial Treatment of OakWood on Increasing the Durability of Exterior Transparent Coating Systems. Polymers 2023, 15, 3251. [Google Scholar] [CrossRef]

- ENV–12037:2003; Wood Preservatives-Field Test Method for Determining the Relative Protective Effectiveness of A Wood Preservative Exposed out of Ground Contact-Horizontal Lap-Joint Method. European Committee for Standardization: Brussels, Belgium, 2003.

- EN 330:2014; Wood Preservatives-Determination of the Relative Protective Effectiveness of A Wood Preservative for Use Under A Coating and Exposed out-of-Ground Contact-Field Test: L-Joint Method. European Committee for Standardization: Brussels, Belgium, 2014.

- Råberg, U.; Terziev, N. Testing and evaluation of natural durability of wood in above ground conditions in Europe-An overview. J. Wood Sci. 2005, 51, 429–440. [Google Scholar] [CrossRef]

- Van Acker, J.; Stevens, M. Biological durability of wood in relation to end-use--Part 2: The use of an accelerated outdoor L-joint performance test. Eur. J. Wood Wood Prod. 2003, 61, 125–132. [Google Scholar] [CrossRef]

- Timar, M.C.; Beldean, E.; Zeleniuc, O.; Varodi, A. An Insight Into Beech Wood (Fagus sylvatica L.) Degradation in Outdoors, Above Ground, Long-time Exposure. Part 1: Degradation and Influence of Surface Treatments Revealed by Non-Destructive Evaluation after 7 Years. Pro Ligno 2012, 8, 37–52. [Google Scholar]

- Beldean, E.C.; Timar, M.C.; Varodi, A. Assesing protecting efficiency of some surface treatments on fir wood after 7 years outdoor exposure. Pro Ligno 2015, 11, 275–282. [Google Scholar]

- Miller, E.R.; Boxall, J. The effectiveness of end-grain sealers in improving paint performance in softwood joinery. L-joints results after 4 years natural weathering. Holz als Roh- und Werkstoff 1987, 45, 69–74. [Google Scholar] [CrossRef]

- Van den Bulcke, J.; Joris Van Acker, J.; Stevens, M. Laboratory testing and computer simulation of blue stain growth on and in wood coatings. Int. Biodeterior. Biodegrad. 2007, 59, 137–147. [Google Scholar] [CrossRef]

- De Windt, I.; Van den Bulcke, J.; Inge Wuijtens, I.; Coppens, H.; Van Acker, J. Outdoor weathering performance parameters of exterior wood coating systems on tropical hardwood substrates. Eur. J. Wood Prod. 2014, 72, 261–272. [Google Scholar] [CrossRef]

- Davis, C.; Leavengood, S.; Morrell, J.J. Performance of Exterior Wood Coatings in Temperate Climates. Coatings 2021, 11, 325. [Google Scholar] [CrossRef]

- Rijckaert, V.; Stevens, M.; Van Acker, J. Effect of some formulation parameters on the penetration and adhesion of water-borne primers into wood. Holz als Roh- und Werkstoff 2001, 59, 344–350. [Google Scholar] [CrossRef]

- Alblas, B.P.; Kettenis, J.J. Assessing the performance of joinery coatings. Surf. Coat. Int. Part B. Coat. Trans. 2002, 85, 169–242. [Google Scholar] [CrossRef]

- Laleicke, F.; Hubbe, M. Outdoor Wood Finishing: A Review on Making Wood Resistant to Moisture, Ultraviolet Light, and Degradation. BioResources 2025, 20, 7903–7982. [Google Scholar] [CrossRef]

- Ifijen, I.H.; Maliki, M.; ·Odiachi, I.J.; Aghedo, O.N.; ·Ohiocheoya, E.B. Review on Solvents Based Alkyd Resins and Water Borne Alkyd Resins:Impacts of Modification on Their Coating Properties. Chem. Afr. 2022, 5, 211–225. [Google Scholar] [CrossRef]

- De Meijer, M. Interactions Between Wood and Coatings with Low Organic Solvent Content. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 1999. [Google Scholar]

- Landry, V.; Boivin, G.; Schorr, D.; Mottoul, M.; Mary, A.; Abid, L.; Carrère, M.; Laratte, B. Recent Developments and Trends in Sustainable and Functional Wood Coatings. Curr. For. Rep. 2023, 9, 319–331. [Google Scholar] [CrossRef]

- Etxeberria, I.; Ingemar Svensson, I.; Diaz, A.I.; Barruetabena, L. Novel Bio-Based Formulations for Alkyd Wood Coatings: Effect on Biodegradation and Technical Performance. Coatings 2025, 15, 400. [Google Scholar] [CrossRef]

- Feist, W.C. Weathering performance of painted wood pretreated with water-repellent preservatives. For. Prod. J. 1990, 40, 21–26. [Google Scholar]

- Pavlic, M.; Kricej, B.; M Tomazic, M.; Petric, M. Influence of biocide pre-treatment of wood on performance of exterior coatings. Surf. Coat. Int. Part B. Coat. Trans. 2005, 88, 41–48. [Google Scholar] [CrossRef]

- Kim, Y.S. Current Researches on the Protection of Exterior Wood from Weathering. J. Korean Wood Sci. Technol. 2018, 46, 449–470. [Google Scholar] [CrossRef]

- Baysal, E.; Toker, H.; Tűrkoğlu, T.; Gűndűz, A.; Altay, C.; Küçüktüvek, M.; Peker, H. Weathering characteristics of impregnated and coated Calabrian pine wood. Maderas Cienc. Tecnol. 2021, 23, 1–10. [Google Scholar] [CrossRef]

- Evans, P.D.; Haase, J.G.; Shakri, A.; Seman, B.M.; Kiguchi, M. The Search for Durable Exterior Clear Coatings for Wood. Coatings 2015, 5, 830–864. [Google Scholar] [CrossRef]

- Pánek, M.; Dvorák, O.; Oberhofnerová, E.; Šimunková, K.; Zeidler, A. Efectiveness of Two Different Hydrophobic Topcoats for Increasing of Durability of Exterior Coating Systems on Oak Wood. Coatings 2019, 9, 280. [Google Scholar] [CrossRef]

- Kropat, M.; Hubbe, M.A.; Laleike, F. Natural, Accelerated and Simulated Weathering of wood: A Review. BioResources 2020, 15, 9998–10062. [Google Scholar] [CrossRef]

- Van Acker, J.; Stevens, M.A. New Concept for the Evaluation of Wood for out of Ground Contact Using Accelerated L-Joint Testing; Document No. IRG/WP 97-20123; International Research Group on Wood Preservation: Whistler, BC, Canada, 1997; Available online: http://hdl.handle.net/1854/LU-275427 (accessed on 4 June 2025).

- ISO 2409:2020; Paints and Varnishes—Cross-Cut Test. European Committee for Standardization: Brussels, Belgium, 2020.

- Yamasaki, R.S. Mechanism of Weathering of Paints. Technical Note (National Research Council of Canada. Division of Building Research); National Research Council of Canada: Ottawa, ON, Canada, 1965. [Google Scholar] [CrossRef]

- Kropf, F.W.; Sell, J.; Feist, W.C. Comparative weathering tests of North American and European exterior wood finishes. For. Prod. J. 1994, 44, 33. [Google Scholar]

- Williams, R.S.; Peter Sotos, P.; Feist, W.C. Evaluation of several finishes on severely weathered wood. J. Coat. Technol. 1999, 71, 97–102. [Google Scholar] [CrossRef]

- Richter, K.; Feist, W.C.; Knaebe, M.T. The effect of surface roughness on the performance of finishes. Part 1. Roughness characterisation and stain performance. For. Prod. J. 1995, 45, 91. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).