Performance Evaluation of Waterborne Epoxy Resin-Reinforced SBS, Waterborne Acrylate or SBR Emulsion for Road

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

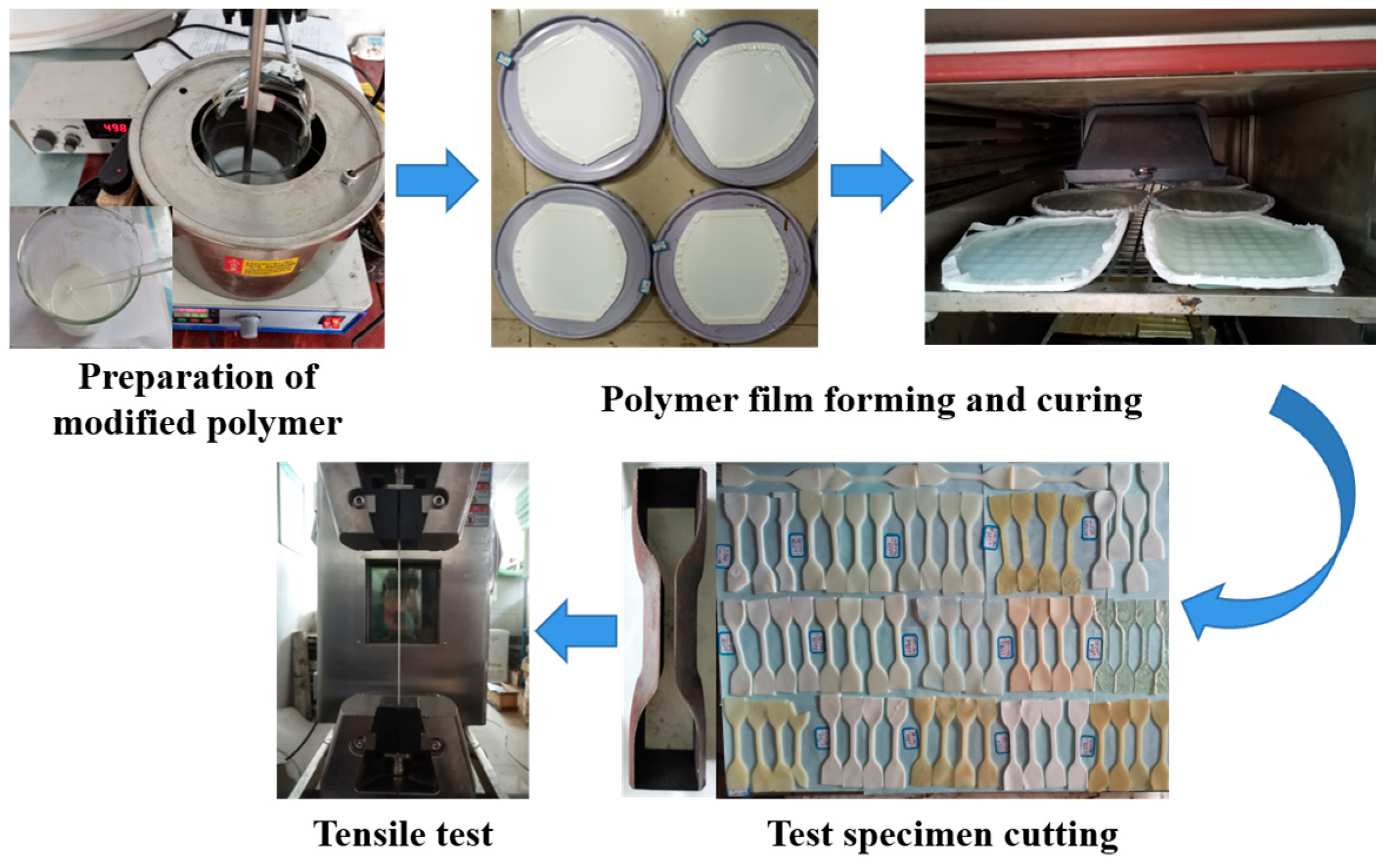

2.2. Preparation of WER-Modified SBS, WA or SBR Emulsions

- Preparation of WER emulsion: First, the epoxy resin was emulsified by the phase inversion method [24]. A certain weight of emulsified epoxy resin, WER curing agent and defoaming leveling agent were weighed, which were stirred at the rate of 200–300 r/min for 30 s to mix evenly, and then stirred at the rate of 400–500 r/min for 3 min. Finally, WER emulsion was obtained after defoaming treatment.

- Modification of SBS, WA or SBR emulsions: A certain weight of WER emulsion was weighed and added to SBS, WA or SBR emulsions. First, they were sheared and stirred at low speed (100–300 r/min) for 3 min by using a high-speed mixing shear apparatus, and then sheared and stirred at high speed (500–800 r/min) for 2 min. During the mixing process, the shearing speed can be adjusted appropriately. After defoaming, the WER-modified SBS, WA or SBR emulsions were obtained.

2.3. Performance Test Method

2.3.1. Tensile Test

2.3.2. Adhesion Test of Waterborne Polymer and Aggregate

2.3.3. Low-Temperature Impact Test

2.3.4. Pull-Off Strength Test

2.3.5. Attenuated Total Reflection FTIR Test

2.3.6. TG Test

3. Results and Discussion

3.1. Composition Optimization and Performance Evaluation of WER-Modified SBS, WA or SBR

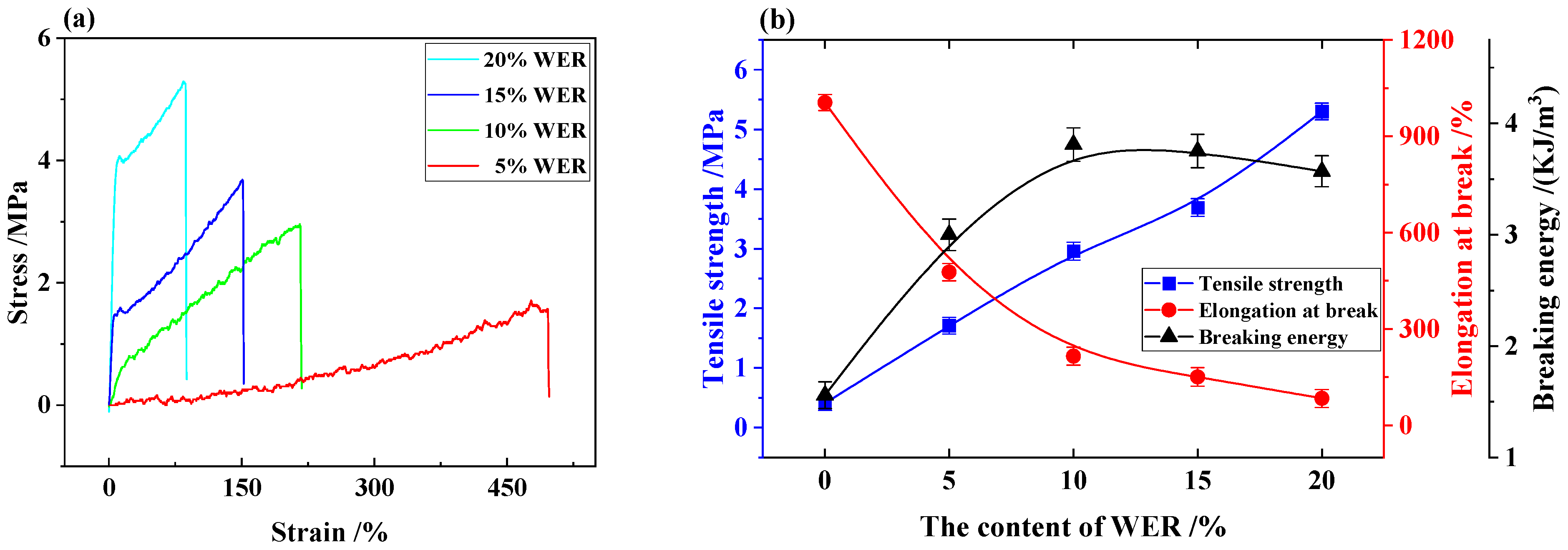

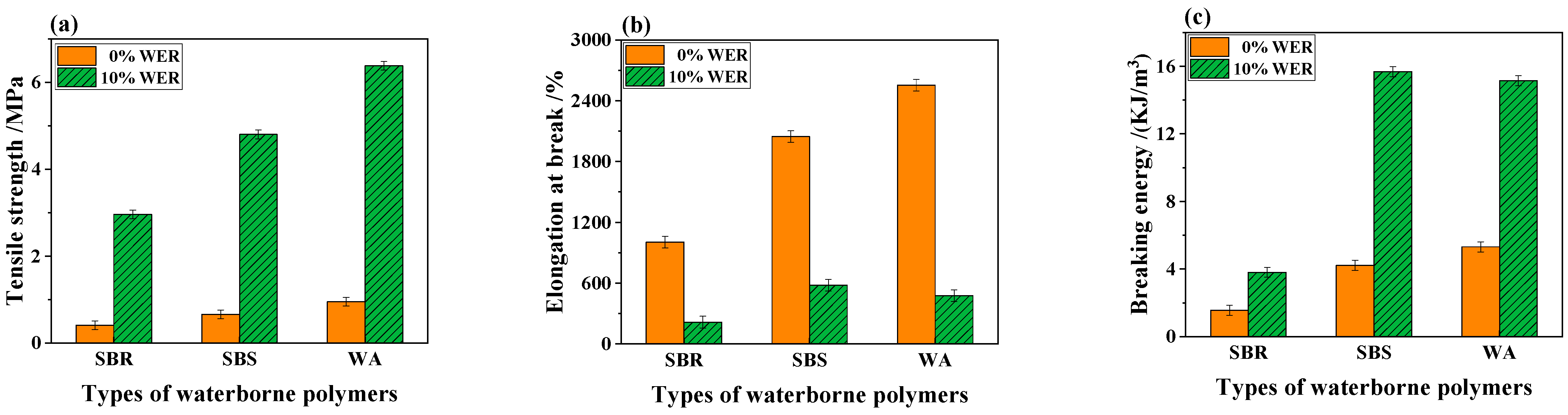

3.1.1. Tensile Properties

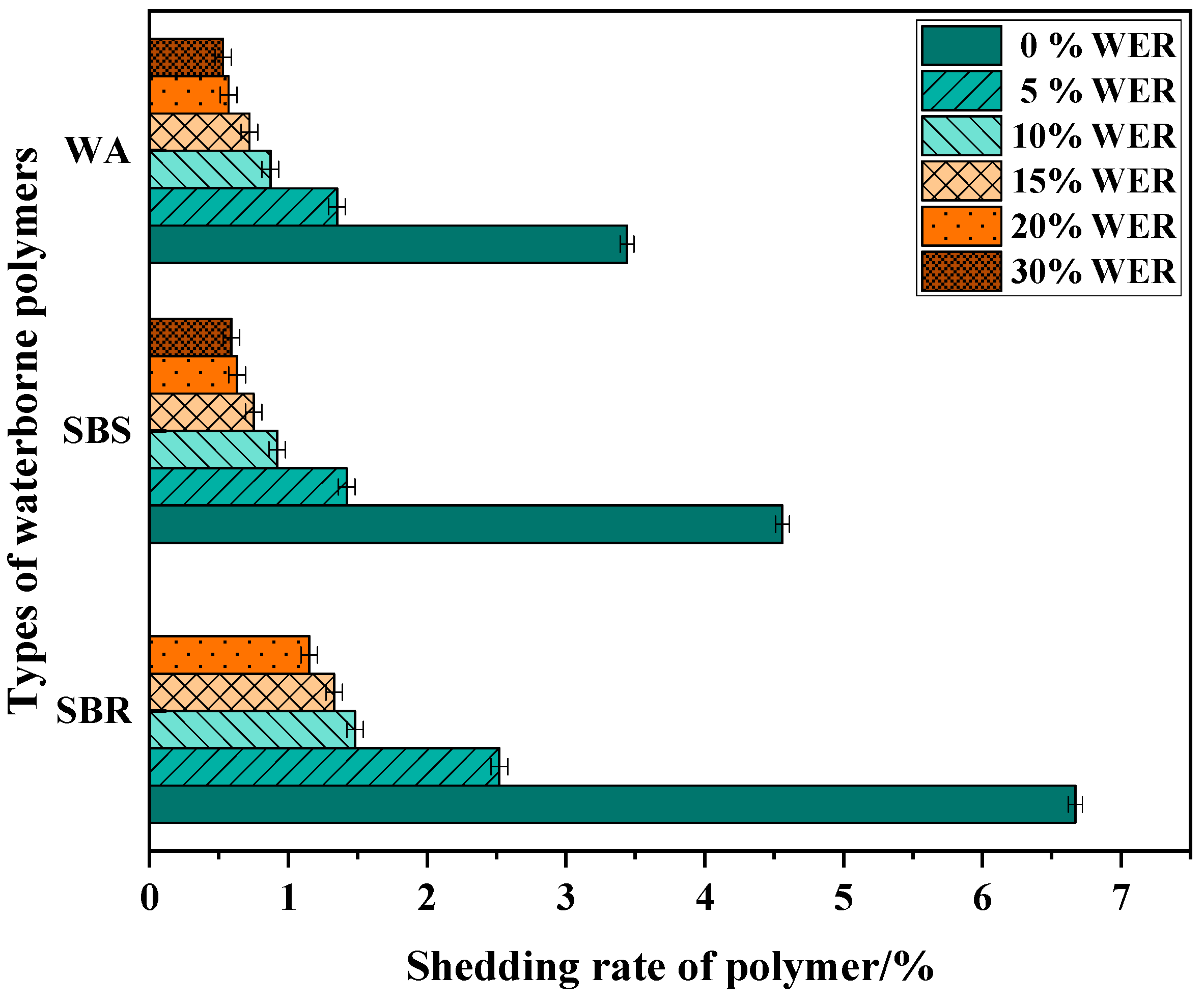

3.1.2. Adhesion Performance

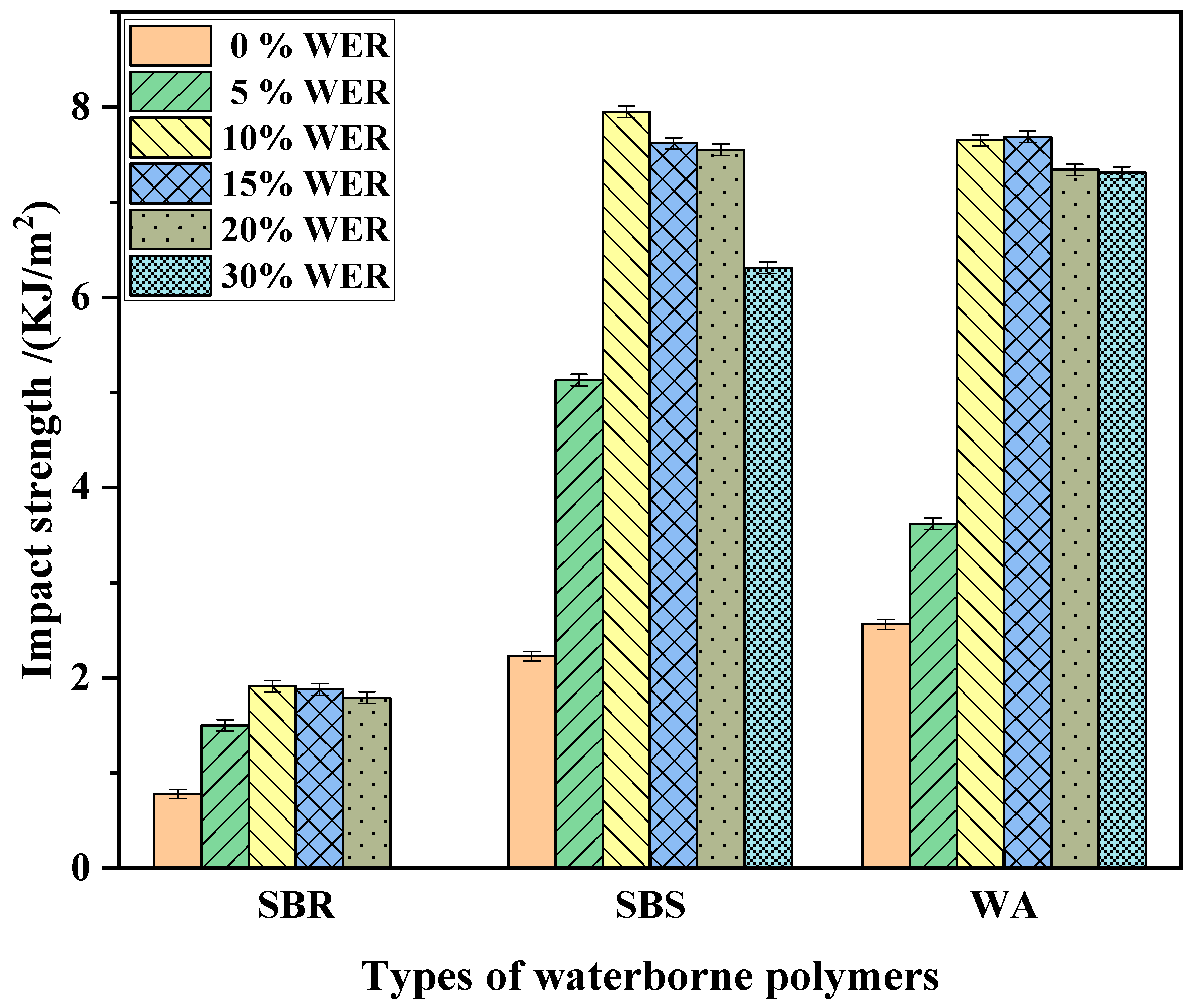

3.1.3. Impact Resistance

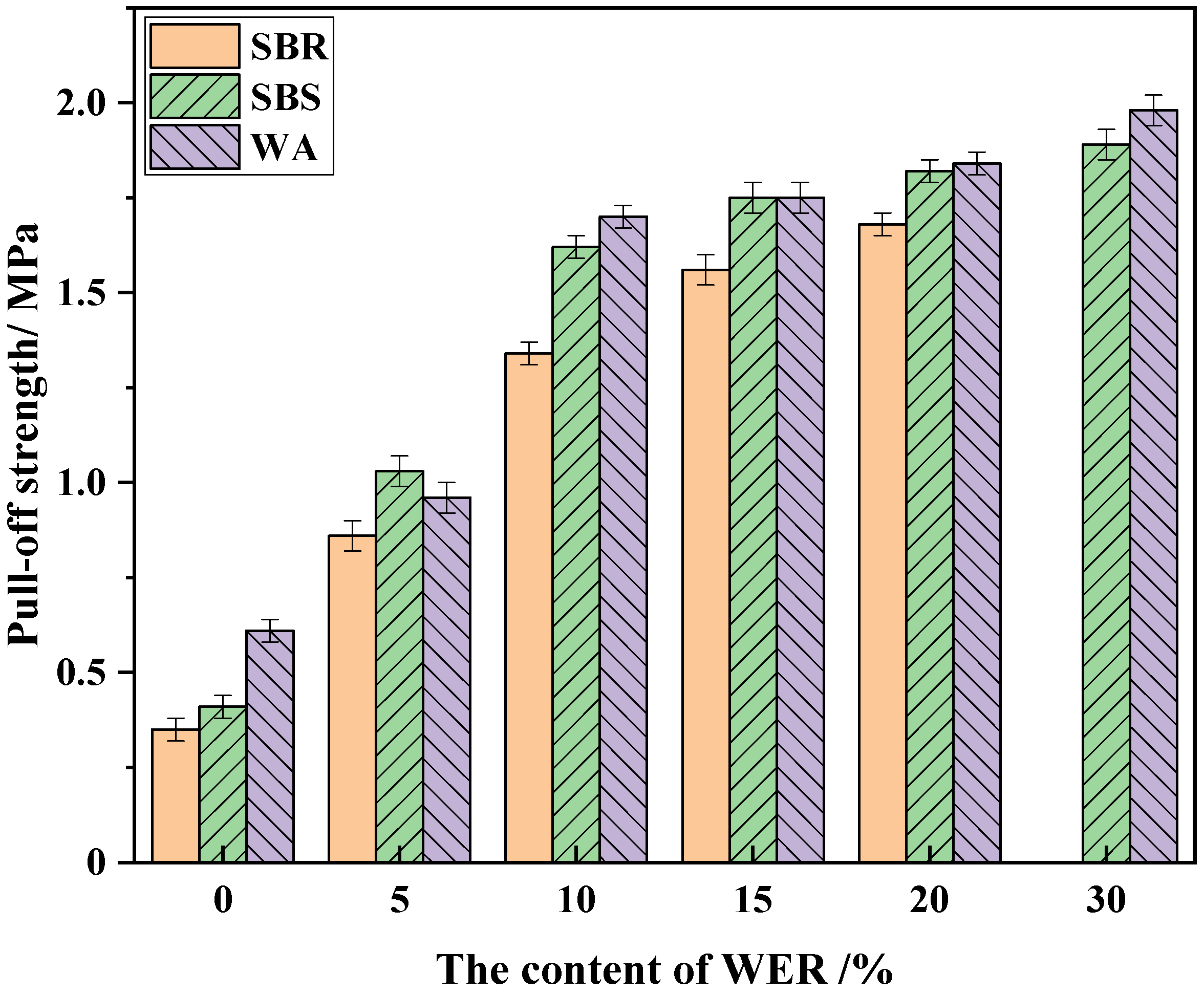

3.1.4. Bonding Performance

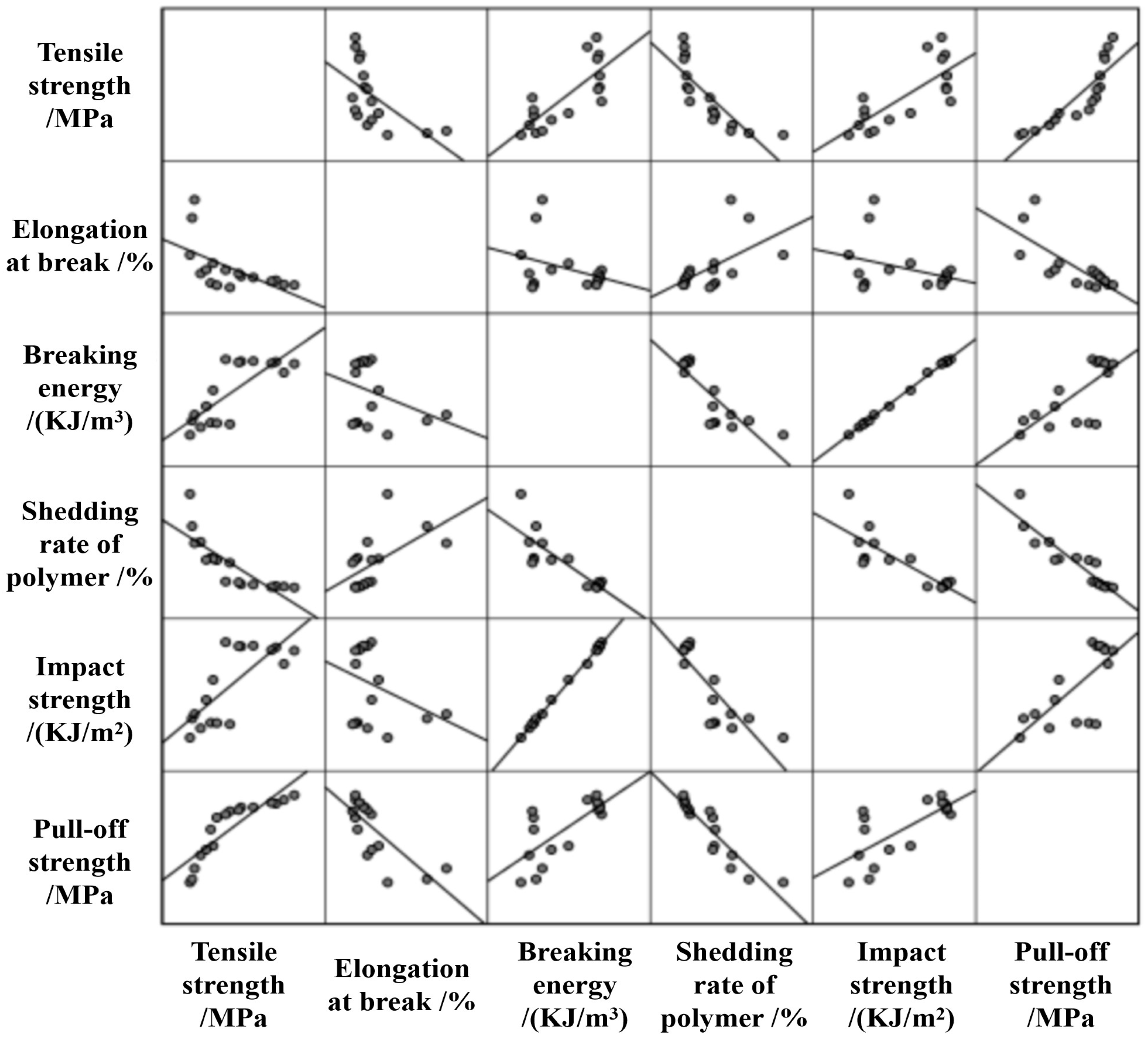

3.2. Correlation Analysis Between Various Performances

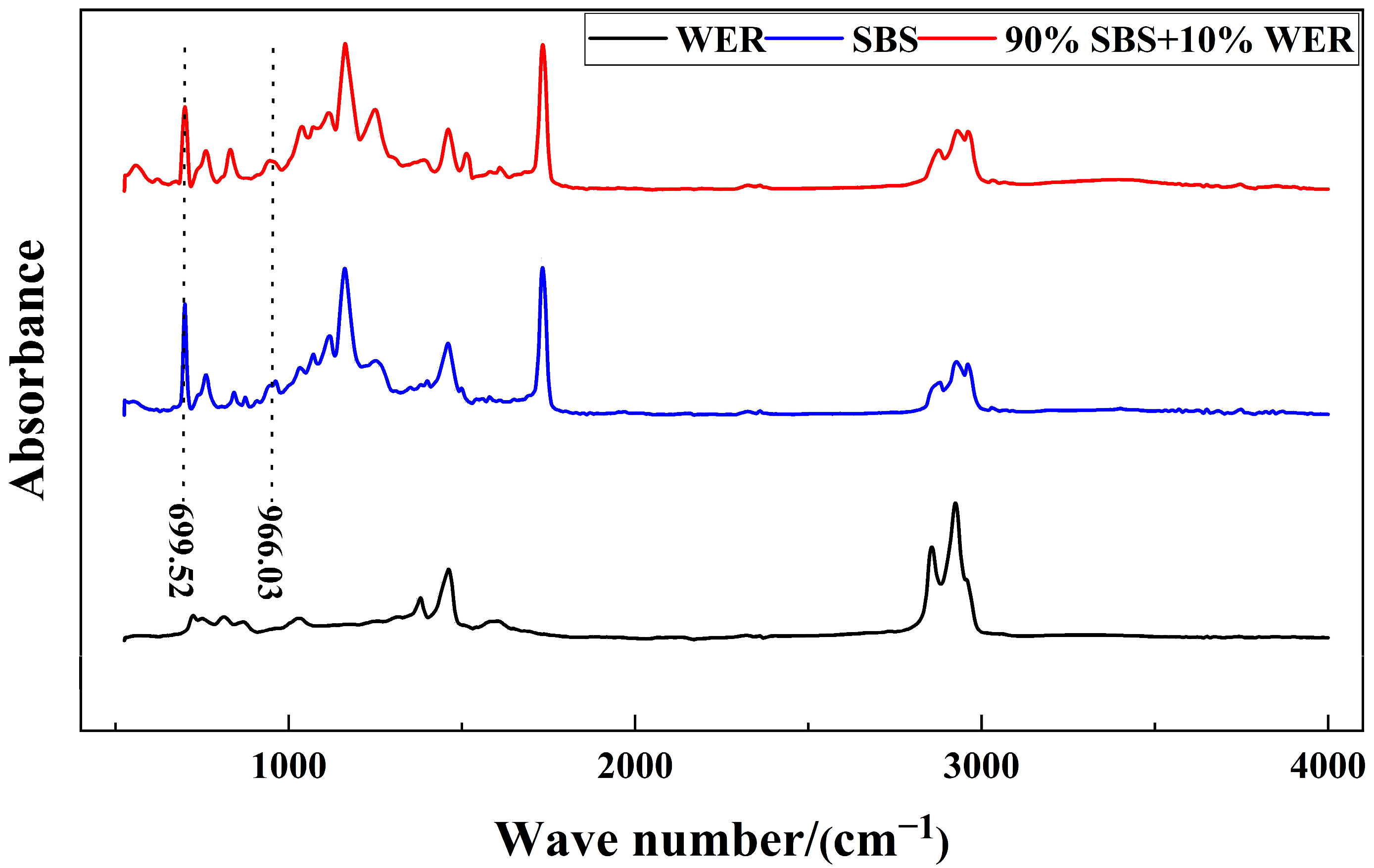

3.3. FTIR and TG Analysis of WER-Modified SBS or WA

3.3.1. FTIR Analysis

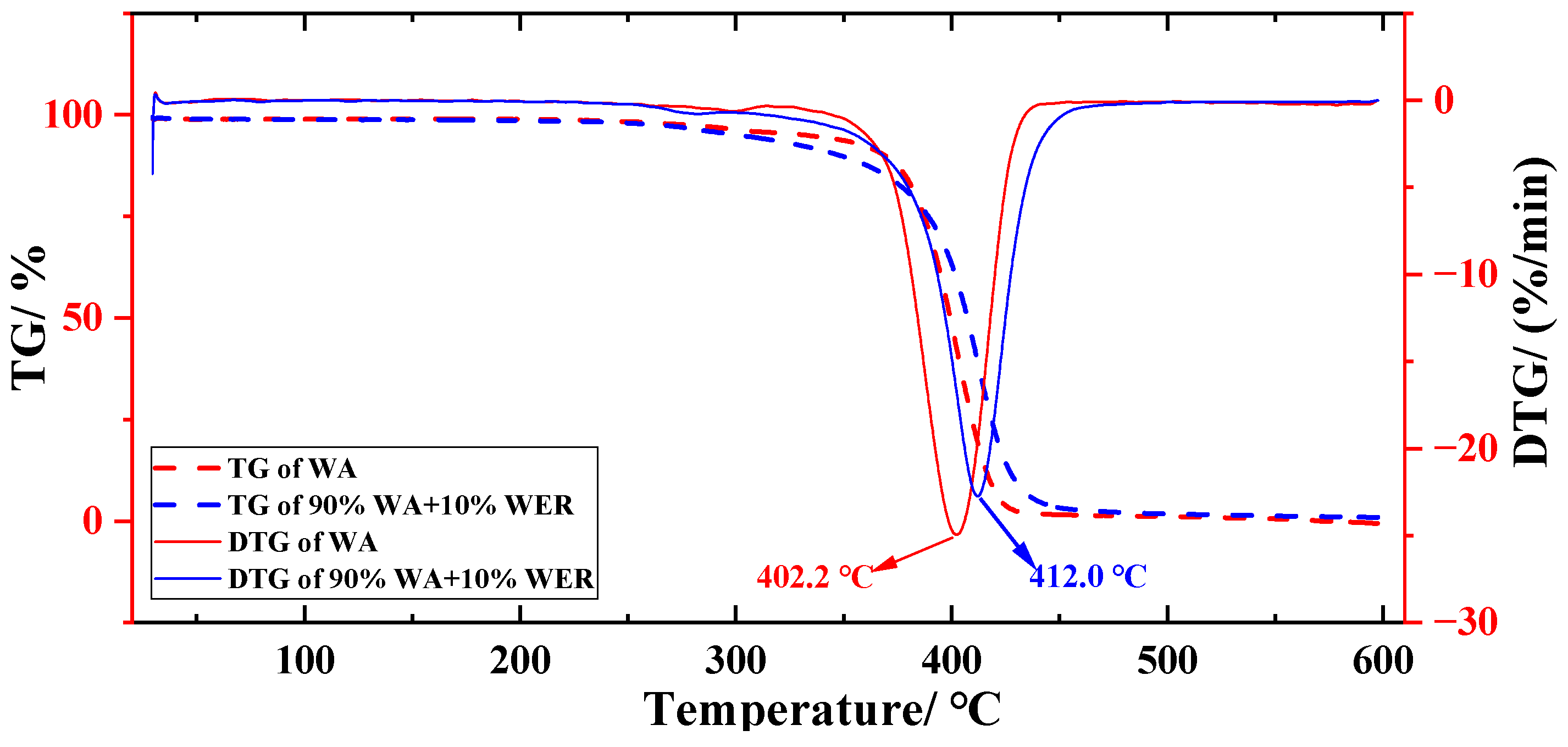

3.3.2. TG Analysis

4. Conclusions

- Adding an appropriate content of WER can significantly improve the mechanical strength, tensile modulus and toughness of SBS, WA and SBR, and increase its ability to resist deformation and damage. The content of WER is suggested to be 10%–15%.

- There is a certain correlation between the adhesion, bonding and mechanical strength of the waterborne polymers, and the impact resistance is related to their breaking energy. The application properties of adhesion, bonding and impact resistance can be further improved by improving the mechanical strength and breaking energy of the waterborne polymers.

- FTIR and TG analyses indicate that the modification process involving WER-modified SBS or WA prepared via emulsion blending primarily involves physical changes. WER enhances the thermal stability of SBS and WA while promoting crosslinking and curing. This study compares the performance differences among WER-reinforced SBS, WA, and SBR. Further investigation into the performance variations of these modified emulsified asphalts is warranted.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, L.; Li, X.R.; Zong, Q.D.; Xiao, F.P. Chemical, morphological and rheological investigations of SBR/SBS modified asphalt emulsions with waterborne acrylate and polyurethane. Constr. Build. Mater. 2021, 272, 121972. [Google Scholar] [CrossRef]

- Yang, F.; Zhou, Q.; Yang, L.M.; He, L.H.; Chen, Q.; Tang, S.G. Preparation and performance evaluation of waterborne epoxy resin modified emulsified asphalt binder. Case Stud. Constr. Mater. 2024, 21, e03548. [Google Scholar] [CrossRef]

- Xu, L.; Zhao, Z.F.; Li, X.R.; Yuan, J.; Zhou, Q.Y.; Xiao, F.P. Cracking investigation on fog seal technology with waterborne acrylate and polyurethane as a clean modification approach. J. Clean. Prod. 2021, 329, 129751. [Google Scholar] [CrossRef]

- Wang, H.Z.; Li, C.X.; Xu, G.; Zhou, Y.X.; Wang, R. Study of high-temperature rheological properties of emulsified asphalt residues. Coatings 2024, 14, 522. [Google Scholar] [CrossRef]

- Hu, F.G.; Tian, X.G.; Hu, H.L.; Li, G.Y.; Guo, C.H. Effect of SBR latex content on performance of modified emulsified asphalt. J. Build. Mater. 2021, 24, 895–900. (In Chinese) [Google Scholar] [CrossRef]

- Song, W.M.; Chen, D.W.; Wu, H.; Wu, Z.Z.; Wada, S.A.; Yuan, H. Preparation and performance characterization of waterborne epoxy resin modified asphalt emulsion for tack coat. J. Clean. Prod. 2024, 475, 143715. [Google Scholar] [CrossRef]

- Huang, S.L.; Jin, F.; Chen, D.D.; Xiao, Q.; Ding, Q.J. Study on modification mechanism and performance of waterborne epoxy resin Micro-surfacing. Coatings 2023, 13, 504. [Google Scholar] [CrossRef]

- Lu, C.; Zheng, M.L.; Gao, Y.; Ding, X.Y.; Zhang, W.W.; Chen, W. Study of long-term skid and wear resistance of waterborne epoxy resin-SBR compound modified emulsified asphalt microsurfacing. J. Appl. Polym. Sci. 2024, 141, 54937. [Google Scholar] [CrossRef]

- Zeng, Q.W.; Yang, S.X.; Cui, Q.X.; Luan, D.X.; Xiao, F.; Xu, C. Prediction of moisture content ratio of emulsified asphalt chip seal based on machine learning and electrical parameters. Constr. Build. Mater. 2024, 450, 138633. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Yang, J.H.; Fang, Y.; Luo, Y.F. Design and performance of waterborne epoxy-SBR asphalt emulsion (WESE) slurry seal as under-seal coat in rigid pavement. Constr. Build. Mater. 2020, 270, 121467. [Google Scholar] [CrossRef]

- Chen, Q.; Lan, X.; Li, A.Q.; Sun, X.L.; Wang, C.H. The novel rapid curing pavement maintenance seal with a low environmental impact: Preparation and performance evaluation. Wear 2025, 566–567, 205919. [Google Scholar] [CrossRef]

- Yan, K.Z.; Shi, J.Y.; Shi, K.X.; Wang, M.; Li, G.K.; Hong, Z. Effects of the chemical structure of curing agents on rheological properties and microstructure of WER emulsified asphalt. Constr. Build. Mater. 2022, 347, 128531. [Google Scholar]

- Fu, H.; Wang, C.H.; Niu, L.L.; Yang, G.L.; Liu, L.Q. Composition optimisation and performance evaluation of waterborne epoxy resin emulsified asphalt tack coat binder for pavement. Int. J. Pavement Eng. 2022, 23, 4034–4048. [Google Scholar] [CrossRef]

- Gu, Y.; Tang, B.M.; He, L.H.; Yang, F.; Wang, H.; Ling, J.M. Compatibility of cured phase-inversion waterborne epoxy resin emulsified asphalt. Constr. Build. Mater. 2019, 229, 116942. [Google Scholar] [CrossRef]

- Li, R.; Leng, Z.; Zhang, Y.; Ma, X. Preparation and characterization of waterborne epoxy modified bitumen emulsion as a potential high-performance cold binder. J. Clean. Prod. 2019, 235, 1265–1275. [Google Scholar] [CrossRef]

- Li, R.; Leng, Z.; Partl, M.N.; Raab, C. Characterization and modelling of creep and recovery behaviour of waterborne epoxy resin modified bitumen emulsion. Mater. Struct. 2021, 54, 8. [Google Scholar] [CrossRef]

- Ji, J.; Yao, H.; Zheng, W.H.; Suo, Z.; Xu, Y.; Han, S.; Xu, S.F.; You, Z.P. Preparation and properties of waterborne epoxy–modified emulsified asphalt binder (WEMEAB). J. Test. Eval. 2018, 48, 3172–3187. [Google Scholar] [CrossRef]

- Yao, X.G.; Tan, L.Z.; Xu, T. Preparation, properties and compound modification mechanism of waterborne epoxy resin/styrene butadiene rubber latex modified emulsified asphalt. Constr. Build. Mater. 2022, 318, 126178. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, Y.H.; Wen, Z.G. Influence of water-borne epoxy resin content on performance of waterborne epoxy resin compound SBR modified emulsified asphalt for tack coat. Constr. Build. Mater. 2017, 153, 774–782. [Google Scholar] [CrossRef]

- Liu, F.Q.; Zheng, M.L.; Liu, X.; Ding, X.Y.; Wang, F.; Wang, Q.Q. Performance evaluation of waterborne epoxy resin-SBR composite modified emulsified asphalt fog seal. Constr. Build. Mater. 2021, 301, 124106. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Z.Q.; Zhao, Q.S. Laboratory performance evaluation of a waterborne epoxy-modified asphalt mixture with styrene-butadiene rubber for cold patching applications. J. Mater. Civ. Eng. 2022, 34, 04022111. [Google Scholar] [CrossRef]

- Li, X.L.; Yang, L.; Luo, S.; Song, X.J.; Fan, L.; Chen, J.J.; Diab, A.; Ye, J.H.; Ning, Z.F. Aging characteristics of a colored ultrathin overlay. J. Transp. Eng. Part B Pavements 2022, 148, 04022009. [Google Scholar] [CrossRef]

- Yao, X.G.; Xu, H.Y.; Xu, T. Syncretization mechanism between emulsified asphalt and aged asphalt in cold recycled asphalt mixture using developed demulsification-dehydration method. Constr. Build. Mater. 2022, 326, 126860. [Google Scholar] [CrossRef]

- Wang, F.; Fu, H.; Liu, G.X.; Wang, C.H.; Yu, S.X. Preparation optimization and performance evaluation of waterborne epoxy resin for roads. Adv. Civ. Eng. 2021, 2021, 8977674. [Google Scholar] [CrossRef]

- JT/T 535-2015; Water Quality Asphalt Waterproof Coating for Highway. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015. (In Chinese)

- Wang, Y.L.; Hou, L.J.; Liu, Z.Y.; Li, S.Y.; Li, Z.H. Study on coating properties of waterborne polyurethane modified epoxy resin latex. Mater. Rep. 2019, 33, 2456–2460. (In Chinese) [Google Scholar]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011. (In Chinese)

- GB/T 2567-2021; Test Methods for Properties of Resin Casting Body. Standardization Administration of China: Beijing, China, 2021. (In Chinese)

| No. | Materials | Basic Performance Indices |

|---|---|---|

| 1 | SBS | Milky white viscous liquid; solid content, 48%–52%; density, ≥1.10 g/cm3; viscosity, 10–40 mPa.s; pH, 6–7 |

| 2 | WA | Milky translucent liquid; solid content, 46%–48%; density, ≥1.05 g/cm3; viscosity, 350–500 mPa.s; pH, 7–8 |

| 3 | SBR | Milky white viscous liquid; solid content, 49%–51%; density, ≥1.10 g/cm3; viscosity, 50–350 mPa.s; pH, 7–9 |

| 4 | E-51 epoxy resin | Transparent liquid; molecular weight, 350–400; epoxy value, 0.48–0.54 (mol/100 g) |

| 5 | WER curing agent | Non-ionic yellowish transparent liquid; solid content, 48%–52%; density, 1.05–1.10 g/cm3; active hydrogen equivalent (solids), 291; viscosity, 10 Pa·s; pH, 11–13 |

| Pearson Correlation Coefficient R2 | Tensile Strength /MPa | Elongation at Break /% | Breaking Energy /(KJ/m3) | Shedding Rate of Polymer /% | Impact Strength /(KJ/m2) | Pull-Off Strength /MPa |

|---|---|---|---|---|---|---|

| Tensile strength /MPa | - | - | - | - | - | - |

| Elongation at break /% | −0.586 * | - | - | - | - | - |

| Breaking energy /(KJ/m3) | 0.781 ** | −0.348 | - | - | - | - |

| Shedding rate of polymer /% | −0.815 ** | 0.573 * | −0.843 ** | - | - | - |

| Impact strength /(KJ/m2) | 0.762 ** | −0.343 | 0.959 ** | −0.837 ** | - | - |

| Pull-off strength /MPa | 0.870 ** | −0.760 ** | 0.739 ** | −0.924 ** | 0.727 ** | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, H.; Wang, C. Performance Evaluation of Waterborne Epoxy Resin-Reinforced SBS, Waterborne Acrylate or SBR Emulsion for Road. Coatings 2025, 15, 787. https://doi.org/10.3390/coatings15070787

Fu H, Wang C. Performance Evaluation of Waterborne Epoxy Resin-Reinforced SBS, Waterborne Acrylate or SBR Emulsion for Road. Coatings. 2025; 15(7):787. https://doi.org/10.3390/coatings15070787

Chicago/Turabian StyleFu, Hao, and Chaohui Wang. 2025. "Performance Evaluation of Waterborne Epoxy Resin-Reinforced SBS, Waterborne Acrylate or SBR Emulsion for Road" Coatings 15, no. 7: 787. https://doi.org/10.3390/coatings15070787

APA StyleFu, H., & Wang, C. (2025). Performance Evaluation of Waterborne Epoxy Resin-Reinforced SBS, Waterborne Acrylate or SBR Emulsion for Road. Coatings, 15(7), 787. https://doi.org/10.3390/coatings15070787