1. Introduction

Lightweight alloys, like Al, Mg, and Ti alloys, can reduce energy waste and make a key role for mitigating greenhouse effect [

1,

2,

3]. Ti6Al4V titanium alloy has been widely used in the manufacturing of aerospace fuselage structures, compressor blades, and nozzle components because of its high strength, low density, and excellent thermal resistance [

3,

4,

5]. Nevertheless, Ti6Al4V components are highly vulnerable to multi-field coupling effects of stress corrosion and galvanic corrosion when they meet dissimilar materials under harsh service environments [

6,

7,

8]. These interactions give rise to cracking and corrosive defects, thus resulting in deteriorating the materials’ performance and the service life [

1,

9,

10]. To solve these issues, protective coatings (e.g., chromate compound coatings or polyurethane composite coatings) should be applied to the critical surfaces, thereby effectively providing a longer service life for the components [

11,

12,

13,

14]. However, these coatings may be partially damaged under complex alternating effects of wear, corrosion, and temperature, thus resulting in weak protective effectiveness. This deterioration should be inhibited using the removal of the coatings and followed by re-coating. Traditional removal methods mainly include mechanical abrasion, shot blasting, and chemical stripping. There is an operational challenge for the high-technology operator; Moreover, these methods exhibit suboptimal efficiency and significant amounts of environmental pollution [

15,

16]. By contrast, laser cleaning technology is gradually applied in surface treatment because of its controllability, high efficiency, and environmental friendliness [

17,

18].

Contemporary research was predominantly centered around pulsed laser surface cleaning technology. Paint removal experiments and thermodynamic analyses were performed to clarify the influence of laser energy density on removal efficiency and thermal stress on the surface of aluminum. The investigation uncovered that low-energy laser beams induce only minor surface ablation of the paint layer. The interfacial delamination could be attributed to increasing thermal stress caused by relatively high energy density. Furthermore, excessive energy input leads to the plasma ionization of the paint layer, generating shockwaves that cause mechanical damage to the substrates’ surface [

19]. G.D. Zhu conducted paint removal experiments on aircraft skin materials by modulating pulsed laser energy density, showing that exceeding threshold energy densities induces substrate ablation damage. However, the laser-cleaned surface maintains comparable friction/wear characteristics and corrosion resistance, with optimal parameters relative to untreated surface [

20]. Meanwhile, A. Moreno investigated the influence of pulsed laser incidence angle on ablation efficiency, demonstrating that ablation performance degrades with increasing angular deviation from normal incidence. This finding provides critical operational guidance for laser cleaning applications on geometrically complex surfaces [

21]. Q. Sun performed laser paint removal experiments using an IPG fiber laser, revealing significant improvements in surface properties of aluminum alloy post-treatment. The processed specimens exhibited higher surface roughness, hardness, tensile strength, yield strength, and toughness compared to pre-treatment baselines [

22]. Nanosecond-pulsed lasers were utilized for removing aerospace-grade inorganic thermal barrier coatings; the results indicated that removal efficiency increased with decreasing scanning speed, and the removal efficiency could be attributed to thermal stress rather than plasma action [

16]. A hybrid continuous-pulsed laser cleaning method was employed to address the issues of excessive removal intensity or inadequate thermomechanical effects. Experimental results demonstrated that increasing the inter-pulse delay duration enhances oxide layer removal [

23]. The study revealed that a micro-molten layer with refined grain structures was formed at the sub-surface when processed at optimal fluence levels, directly enhancing hardness and tensile properties of the surface layer [

24]. Conversely, excessive fluence induces the vaporization of the substrate accompanied by the generation of plasma shockwave, resulting in micro-crack formation due to thermomechanical stress concentrations [

25,

26].

Through the above literature review, it can be found that the current research mainly focuses on pulsed laser cleaning. There are relatively few studies in the field of continuous laser paint removal process optimization. The critical factor in laser cleaning lies in the appropriate parameter selection that ensures substrate integrity while maintaining cleaning efficiency. The main paint removal mechanisms of pulsed lasers include ablation, plasma impact, and thermal stress stripping [

16]. A continuous wave laser has higher energy efficiency compared to a pulsed laser. The resulting stronger ablation effect of continuous wave lasers allows for higher paint removal efficiency, but it may lead to excessive ablation depths, deeper surface remelting, and significant changes in the mechanical properties of the substrate [

27,

28]. Given the high paint removal efficiency demonstrated by the above-mentioned continuous-wave laser, as well as the substrate damage caused by unreasonable parameters, this study employed a continuous-wave optical-fiber laser to investigate paint removal on Ti6Al4V titanium alloy surfaces. The main laser paint removal parameters—laser power (100, 130, 150, and 200 W) and scanning speed (520, 550, 580, and 610 mm/min)—were optimized. The effect of microstructure evolution and dislocation accumulation on the changes in microhardness was analyzed. By combining EBSD detection, we discussed the effect of laser energy density on the heat accumulation of the substrate surface. Optimal paint removal parameters were determined, and substrate damage was avoided.

2. Materials and Methods

In this experiment, casting and rolling Ti6Al4V titanium alloy was used as the substrate, and its chemical composition includes 6 Al, 4 V, <0.2 O, <0.3 Fe, <0.1 C, <0.015 H, <0.05 N, and Bal. Ti (wt.%). The Ti6Al4V substrates were cut into cuboid blocks of 30 mm × 30 mm × 20 mm by wire cut electrical discharge machining. All surfaces of the substrate were polished with sandpaper of 180, 400, 800, 1500, and 2000 grit. Subsequently, referencing Boeing aircraft skin primer thickness dimensions [

20], a paint layer with a thickness of ~120 μm was sprayed on the surface of the substrate and cured for 72 h in a dry laboratory at room temperature. The coating material is a multi-component polymer system (Chengzhong Chemical Technology Co., Ltd., Zhongshan, China), with the main film-forming constituents being acrylic resin and waterborne amino resin. The cross-sectional morphology is shown in

Figure 1a. A laser cleaning system with a continuous fiber laser (XL-F1000, Guangzhou Xingrui Laser Technology Co., Ltd., Guangzhou, China) was employed in this work, and the laser parameters include mainly a defocusing amount of 250 mm, a laser spot diameter of 2.8 mm, a focal length of 220 mm, a laser power of 100~200 W, and a scanning speed of 520~610 mm/min. The process parameters are mainly determined by energy density calculation. At the same time, the energy intensity distribution of this laser beam uses an approximate Gaussian distribution. The schematic diagram is shown in

Figure 1b,c. For the continuous laser paint removal process, the main laser parameters affecting the paint removal effect are laser power, laser scanning speed, and the average energy density of the continuous laser E

d (J/mm

2), which can be expressed as follows:

where P is laser power (W), D is spot diameter (mm), and v is laser scanning speed (mm/s).

An optical microscope (OM, Axio Observer, Zeiss, Baden-Württemberg, Germany) was utilized to characterize the surface and cross-sectional morphology, the paint removal effect of the sample after paint removal was observed at a magnified scale, and the microstructure changes before and after paint removal were observed after cutting at 1/3 of the substrate, grinding, polishing, and etching (2 mL HF + 4 mL HNO3 + 100 mLH2O was used as the etching solution) the cut cross-section. SEM (Thermo Fisher Scientific, Waltham, MA, USA) was used to observe the microstructure changes in the heat-affected zone of the sample cross-section after paint removal, which facilitates the subsequent analysis of the degree of change in the heat-affected zone under different powers compared to the original substrate. In order to explore the influence of laser process parameters on the sub-surface of the substrate, an EDAX Velocity Super electron backscatter diffraction (EBSD, EDAX Inc., Mahwah, NJ, USA) scanner was used to analyze the grain size distribution, orientation difference, and texture of the heat-affected zones of the paint removal samples and the original substrates. The samples were recut to a thickness of about 2 mm and a length and width of about 8 mm, and in order to solve the effect of residual stress on the EBSD detection, the samples were roughly polished with sandpaper and then electrolytically polished for 2 h to meet the detection requirements. The main detection parameters were a sample diffraction angle of 70°, an accelerating voltage of 20 kV, and a scanning step size of 0.2–0.6 μm. Meanwhile, the HVS-1000AV microhardness tester (Shanghai Caikang Optical Instrument Co., Ltd., Shanghai, China) was used to measure the hardness of the cross-section of the substrate after paint removal, with a load application force of 10 g, a load application time of 10 s, and an experimental temperature of 25 °C. Indenter type was a tetragonal conical positive diamond indenter with a 136° apex angle.

3. Results and Discussion

Figure 2 shows the OM topography of the surface and cross-section at different scanning speeds under a power of 130 W. As the scanning speed gradually increases from 520 mm/min to 610 mm/min., according to Equation (1), it can be seen that the laser energy density gradually decreases. The ablation effect of the laser on the paint layer is gradually weakened. Ablation track width reduced from 3.56 mm to 3.24 mm. It can be seen in

Figure 2a that, when the laser scanning speed is 520 mm/min, black burns appear in the center of the cleaning path, and there are relatively clustered spots and strips of oxidation-induced bluing phenomenon. It can be seen in

Figure 2b that, when the laser scanning speed is 550 mm/min, the black burns in the cleaning path show a dilution, and the spot burning phenomenon is more dispersed, but the spot size is still large. As can be seen in

Figure 2c, when the laser scanning speed is 580 mm/min, the oxidation of the blue spot in the center of the track gradually disappears, but it still maintains a large area of black burns. As can be seen in

Figure 2d, when the laser scanning speed is 610 mm/min, the width of the black part in the middle decreases and fades, while no spot blue burning occurs. However, the reduction of laser energy density makes for uncomplete removal of the paint layer. As the laser beam used in this experiment is a Gaussian laser, its energy distribution shows that the energy in the center of the laser is the highest, and it decreases from the center to the periphery [

29]. Meanwhile, titanium alloy will form a sapphire blue oxidation color after oxidation at 600 °C [

30]. As a result, the middle part of the cleaning sample appears black and accompanied by blue spots. When the laser scanning speed increases, the heat accumulation between the paint layer and the substrate surface decreases. As a result, although the central part remains black at 610 mm/min, the blue burning spots disappear.

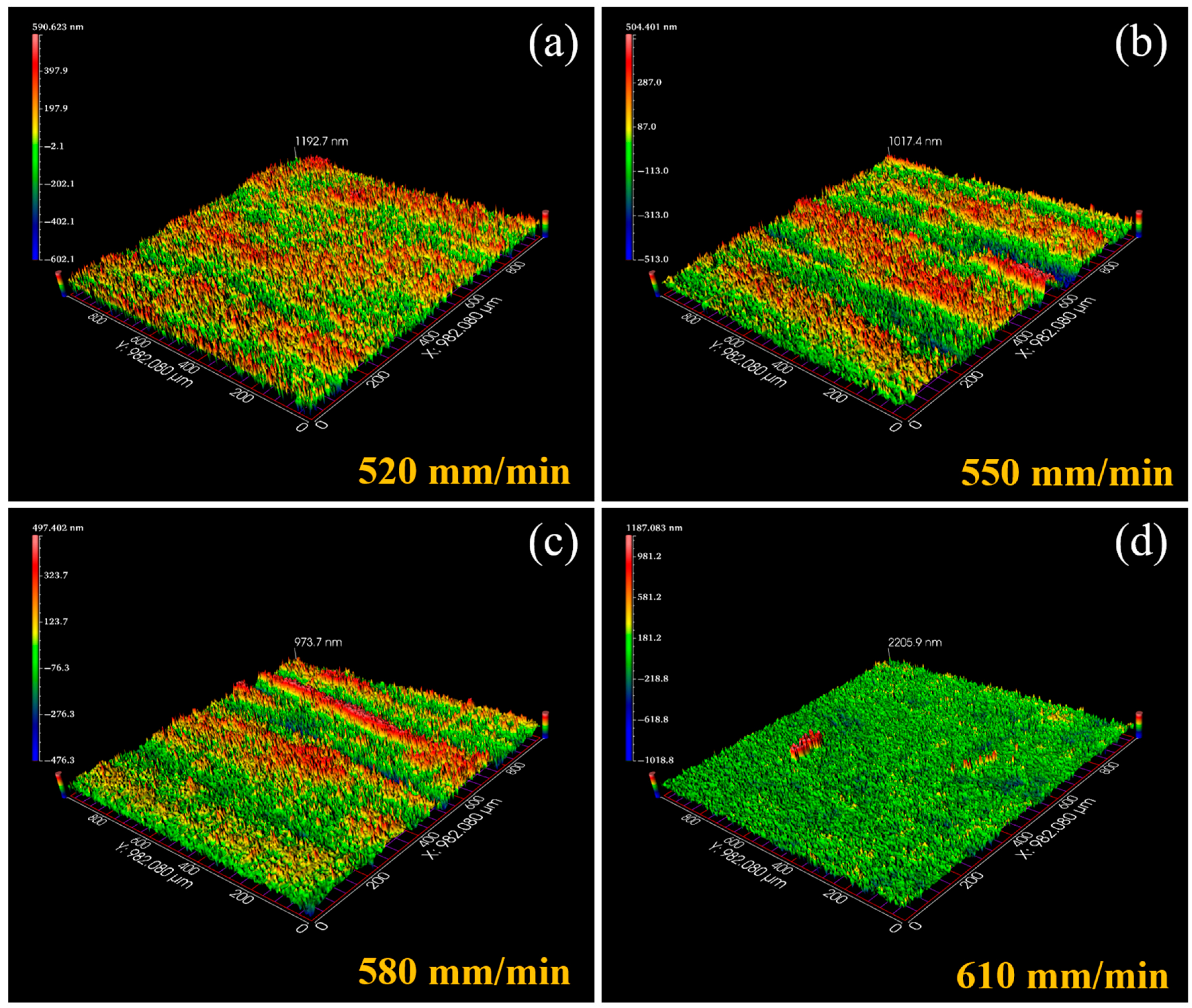

Figure 3 shows the three-dimensional morphology of the sample surface at different cleaning rates. At a constant power, increased scanning speed progressively flattens the sample’s surface morphology. However, at a 610 mm/min scanning speed (

Table 1), surface roughness exhibits an anomalous increase. As evidenced in

Figure 2d and

Figure 3d, the laser incompletely removes the paint layer at this scanning speed. The dot-like residual paint layer can be observed in

Figure 2d. Meanwhile, in

Figure 3d, the surface morphology of the sample shows point-like protrusions. Consequently, the observed roughness anomaly stems from inadequate laser energy density, resulting in incomplete paint ablation.

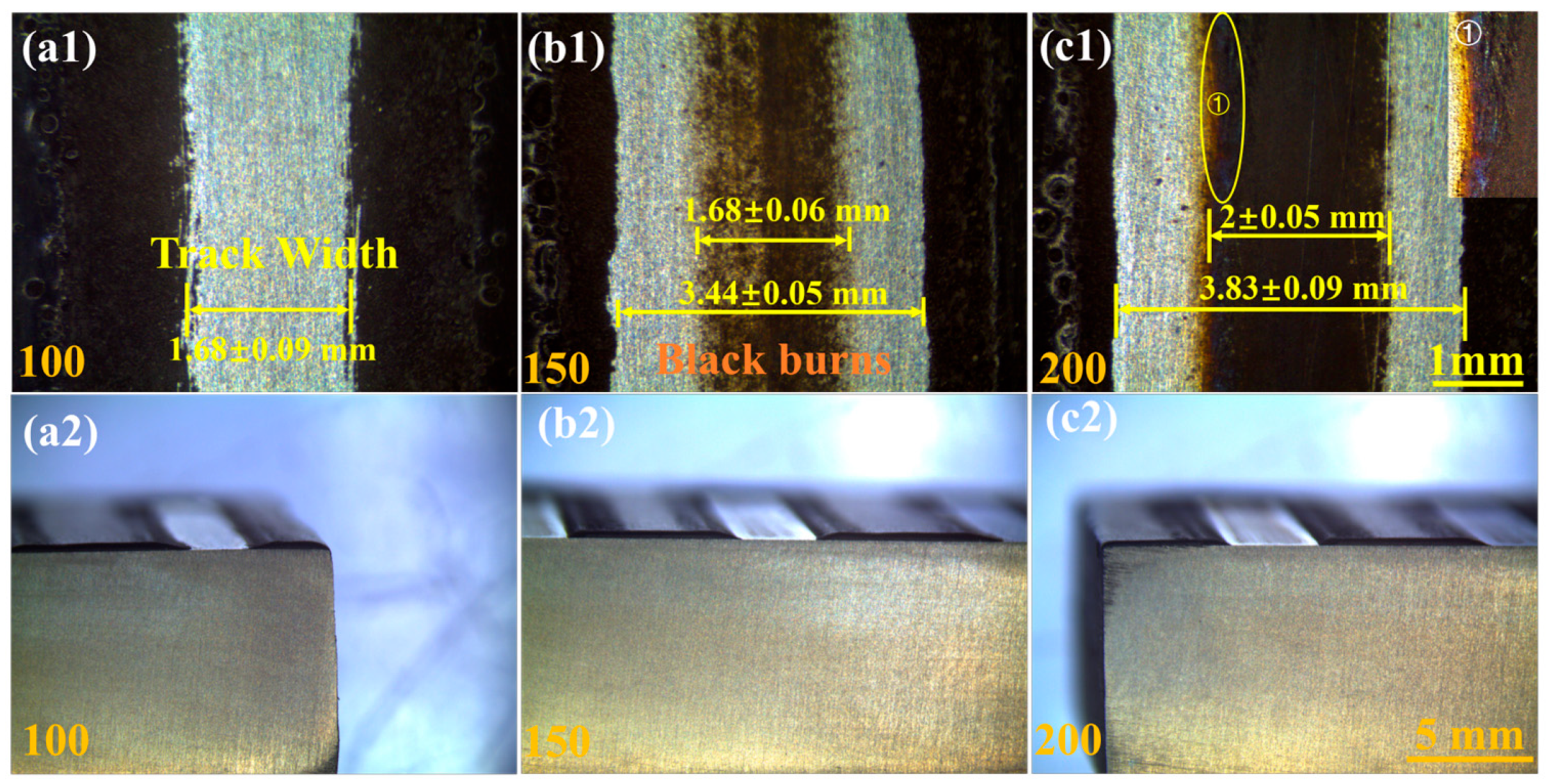

Figure 4 shows the influence of laser power on the width of the removal track. As can be seen in

Figure 4(a1), the paint layer on the surface of the sample is basically removed when the laser power is 100 W, and the base is exposed and presents a silver luster. When the laser power is 150 W, the excessive power causes an ablative effect on the substrate. The ablation effect is further increased as the laser power increases to 200 W, and a deep black and oxidation-induced bluing phenomenon can be clearly observed along the ablation edge. From Equation (1), it can be concluded that, when the spot diameter and laser scanning speed are fixed, the unit laser energy density increases with increasing laser power, and the ablation effect on the paint layer and substrate strengthens with increasing power. This results in greater substrate oxidation depth and oxidation width [

31]. At the same time, when the laser power is increased from 100 W to 150 W, the width of the ablation track is doubled, which can be summarized as follows: The higher laser energy density leads to a significant increase in the temperature of the paint layer during paint removal. When the laser power is 150 W, the removal threshold for paint ablation as well as thermal stress stripping is reached in the non-centered region of the laser energy. At the same time, the heat accumulation of the paint layer is higher. It makes the paint layer take longer to cool down. When the laser ends its action, the residual heat of the paint layer is still higher than the ignition points of the paint layer. Thus, a wider paint removal width is obtained. This results in the width of the cleaning track of 150 W increasing to approximately twice that of 100 W [

16]. The above explanation can be supported by observing the paint layer ablation air holes presented at the edges of the cleaning tracks of 150 W and 200 W. Experiments show that, when the laser power is 100 W, that is, the average energy density is 2.18 J/mm

2, the paint layer is basically removed, and the substrate shows a bright silver metallic luster after the paint removal. Compared with other parameters, this parameter presents the best paint removal effect.

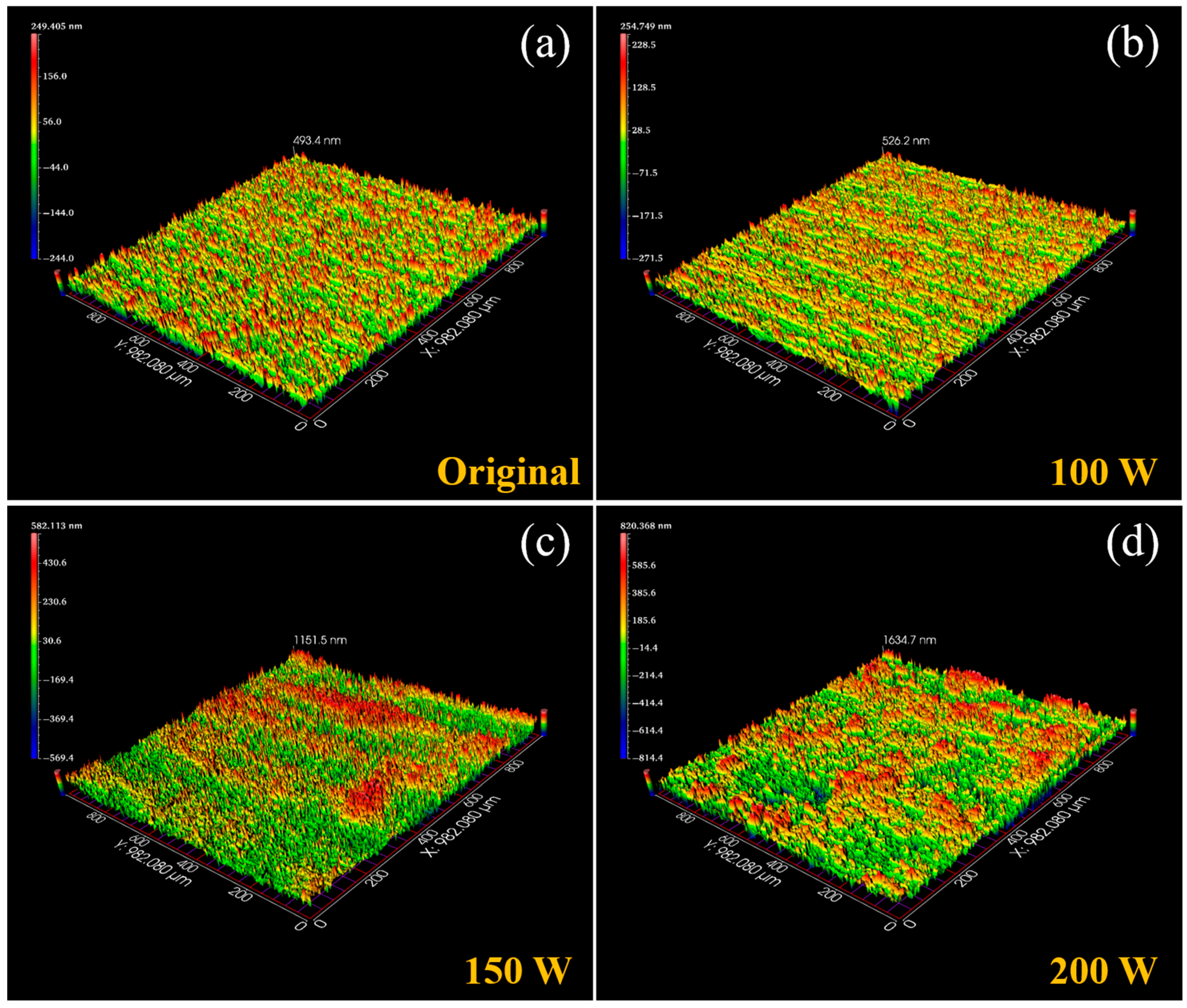

Figure 5 shows the 3D morphologies of the sample surface under different laser powers. By combining

Figure 4a and

Figure 5a,b, at 100 W laser power, the laser completely ablates the surface paint layer, ensuring a residue-free cleaned surface. At 100 W laser power (

Table 2), the sample’s surface roughness matches that of the bare substrate. This confirms that 100 W laser power avoids substrate surface remelting and oxide layer formation. At 150 W laser power, the sample’s surface roughness increased significantly. At 200 W laser power, the sample’s surface roughness (Sa) increased to 214 nm. Compared to the original surface roughness, it increased by four times. This phenomenon arises from surface remelting at 200 W, evidenced by striated ripples on the sample surface in

Figure 4(c1). Consequently, surface roughness increases significantly. Based on the OM image, 3D surface morphologies, and sample surface roughness, the cleaning effect on the sample surface is the best when the laser power is 100 W.

Under the metallographic microstructure, Ti6Al4V mainly consists of an α-phase with a white structure of densely arranged hexagonal structures and a β-phase with a black structure of body-centered cubic structure. As shown in

Figure 6a, there are no apparent changes observed in the metallographic microstructure. This is mainly due to the low laser energy density. The substrate is subjected to lower heat accumulation and thermal stress. Both do not allow the substrate to reach the phase transition point. The subsurface of the substrate in

Figure 6b shows a trace amount of grain refinement. At 150 W power, the increase in laser power leads to more heat accumulation per unit time. This results in a micro-solution phenomenon on the substrates subsurface. The alloy substrate’s high thermal conductivity accelerates the crystallization of the micro-molten layer grains, ultimately causing grain refinement. When the laser power rises to 200 W, this power has a stronger ablation effect.

Figure 6c demonstrates enhanced phase transition due to higher laser power, which intensifies coating and substrate ablation and promotes the pronounced precipitation of needle-like α phases. Concurrently, the continuous Gaussian laser beam induces significant fluctuations in the central micro-melt layer, while the periphery remains relatively smooth.

SEM analysis was conducted exclusively on the samples treated with 100 W (optimal parameters) and 200 W (worst parameter) laser powers, and their corresponding microstructures are shown in

Figure 7. In

Figure 7a, we can see that, at a power of 100 W, the subsurface of the substrate shows a needle-like α phase. Meanwhile, the phase transition is more obvious in

Figure 7b, and the main direction of the acicular α-phase shows a downward phenomenon. By comparing

Figure 7a,b, we know from Equation (1) that the unit laser energy density increases with increasing laser power, assuming other parameters are constant. This relationship leads to a more significant phase transition at 200 W due to excessive thermal buildup. Furthermore, by comparing

Figure 7b,c, the phase transition can be attributed to thermal accumulation on the substrate surface during laser paint removal. The shallow heat-affected zone and short laser exposure result in rapid cooling, promoting the formation of the acicular α-phase. The cooling direction is from the subsurface to the bottom of the substrate due to its higher thermal conductivity compared to air. This results in a downward orientation of the needle-like α-phase after paint removal. This phenomenon is consistent with the grain growth direction observed in the surface layer of the substrate during aluminum alloy surface cleaning studies [

26].

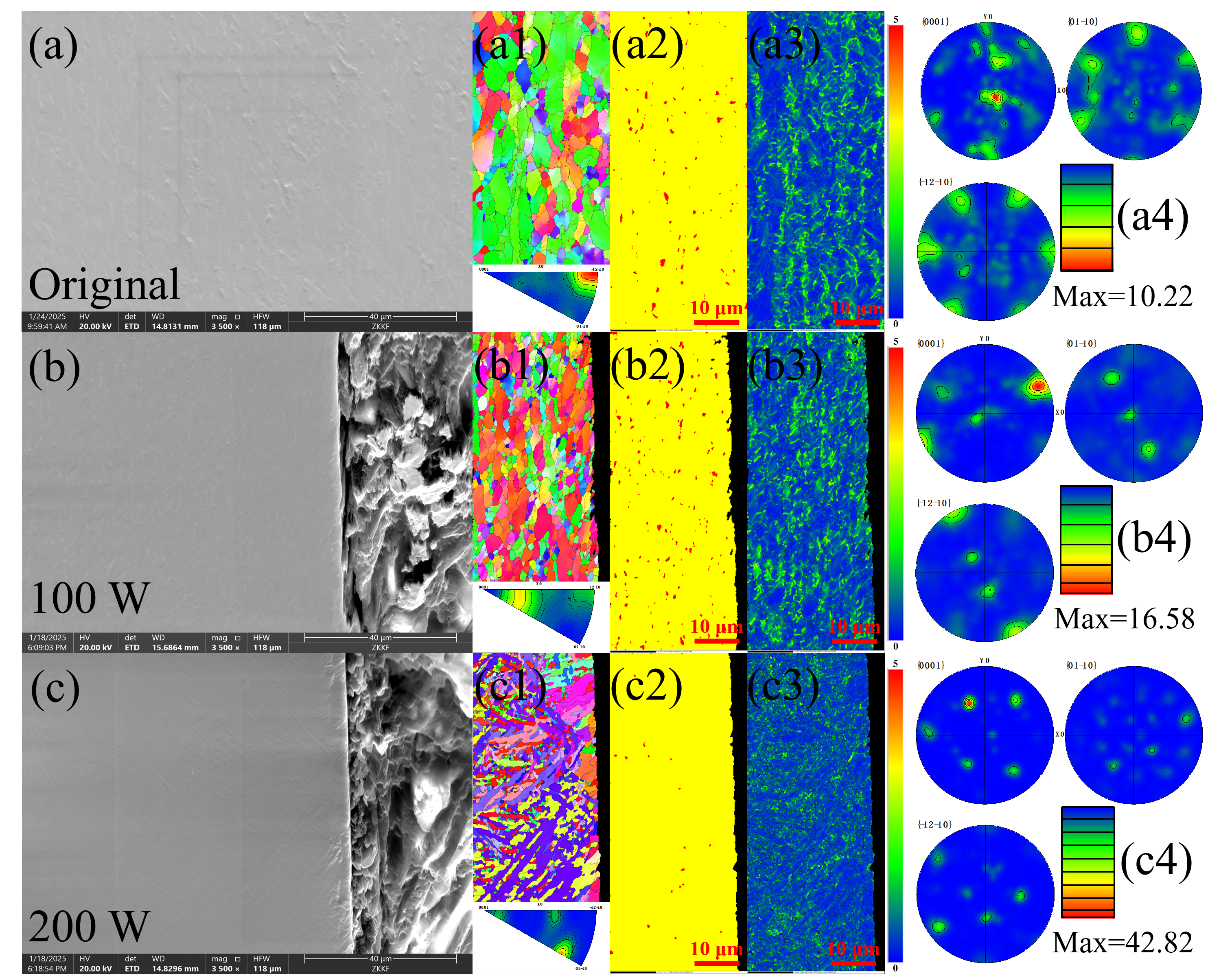

The EBSD results of the samples are shown in

Figure 8 and

Figure 9, revealing that the grains in the heat-affected zone at 100 W exhibit minor changes compared to the original substrate. The KAM plot in

Figure 8(b3) shows the internal dislocation distribution of the substrate at 100 W power. At this power, the main paint removal mechanism consists of thermal stress stripping and ablation. Lower heat accumulation produces small changes in substrate texture orientation, which can also be seen in the KAM plot. Due to thermal stresses and phase explosion, there is a large accumulation of dislocations on the substrate surface. Meanwhile, it can be seen in

Figure 9b that its grains show a certain degree of refinement. It can be seen in

Figure 8(c1) that, under 200 W laser power, the heat affected zone of the sample exhibits the same acicular α-phase observed in the SEM and OM. It is also interesting to note that the growth of the acicular α-phase tends significantly to extend inward from the edge of the sample, and the grain size (from small to large) follows a similar trend. The primary mechanism can be summarized as follows: Under high-energy laser irradiation, a micro-melting phenomenon occurs in the substrate’s surface layer, leading to microstructural changes in the heat-affected zone. Simultaneously, the significant difference in thermal conductivity between the substrate and the surrounding air drives heat transfer primarily from the surface toward the interior. This directional heat flux establishes a pronounced temperature gradient during cooling. This gradient results in faster cooling rates in the subsurface layer, promoting truncated grain nucleation and shorter growth periods. In contrast, regions farther from the surface experience prolonged cooling times, collectively causing the acicular α-phase to exhibit a pronounced preferential growth orientation. The longer the cooling time in the heat-affected zone, the more pronounced the acicular α-phase growth orientation becomes. Meanwhile, it can be seen in

Figure 8(c3) that dislocations mainly accumulate inside the grain boundaries. This is mainly due to the thermal stress gradient and phase transformation stress caused by rapid cooling after remelting. Meanwhile, during remelting, the formation energy of vacancies in the liquid-phase substrate is relatively low compared to the solid-phase substrate vacancy formation energy. After rapid cooling, it tends to retain a large number of vacancies at grain boundaries and form dislocation piled-up. This leads to the occurrence of dislocations [

32]. Meanwhile, it can be seen in

Figure 9c that the degree of grain refinement has been significantly improved, and the average grain size has decreased to 1.11 μm. Additionally, closer to the subsurface layer, grain refinement is significantly enhanced. However, the paint removal requirement in the aerospace field is to ensure that the paint layer is removed without changing the original substrate organization, so we can determine that the paint removal effect is better at 100 W laser power.

Based on the comparative analysis of paint removal effects under the two conditions (1) constant laser power with varying scanning speeds and (2) constant scanning speed with varying laser powers, the variation in laser power demonstrates a significantly greater impact on coating ablation efficiency compared to scanning speed adjustments. The optimal performance is achieved at 100 W laser power combined with a scanning speed of 550 mm/min. Therefore, the microhardness of the matrix cross-section after paint removal was investigated for the power change parameter group.

Figure 10 shows the microhardness variation lines of the cross-section at different depths before and after laser cleaning. The original microhardness is 335 HV (distance from treated surface 10 μm). It can be clearly seen that the microhardness of the substrate surface increases significantly after sample cleaning, and a gradual reduction was also observed in hardness as substrate cross-section increased depth. On the one hand, thermal stresses are generated during the cleaning process as well as evaporative recoil pressure from the vaporization of the paint layer [

33]. Both act simultaneously on the substrate surface, resulting in a hardening effect on the substrate surface. This shock effect diminishes with depth to the substrate. On the other hand, the grain refinement phenomenon produced by high-power laser ablation gradually weakens with the increase of depth. At the distance of 10 μm from the laser-treated surface, the microhardness of the substrate after laser cleaning at 100 W, 150 W, and 200 W measures 347 HV, 377 HV, and 391 HV, respectively. Compared to the untreated substrate (335 HV), these values represent increases of 3.41%, 12.42%, and 16.53%. Among the tested laser powers, only at 100 W does the hardness change after cleaning remains below 5%. This value falls within the acceptable hardness variation range for aerospace-grade substrates.

Combined with

Figure 6, when the laser power is 100 W, there are no obvious changes in the microstructure. However, the paint layer was vaporized by the laser ablation, creating a local evaporative recoil pressure. This recoil pressure results in a localized pressure gradient at the basal surface [

34]. This eventually led to the creation of a shockwave. It can be seen in

Figure 8(b3) that the shockwave acts on the surface of the substrate, resulting in the formation of a dense and stable dislocation structure on the surface, and it enhances the ability of the substrate to resist slip generation. As a result, the microhardness of the substrate surface is slightly increased [

35], and the impact effect decreases with the deepening of depth, making the hardness gradually return to the original base hardness [

36], thus resulting in a decreased service life caused by the formation of tensile stress and an increase in the possibility of cracking initiation [

37]. The main reason for the huge increase in microhardness at both 150 W and 200 W can be summarized as follows: Firstly, high-power laser cleaning generates high heat accumulation on the substrate surface. It makes the action area produce a heat-affected zone and even remelting phenomenon. At the same time, due to the short laser action time, it makes the substrate cool quickly, resulting in the heat-affected zone of the substrate surface showing grain refinement phenomenon. Thus, the substrate surface microhardness shows a significant increase [

38]. This can be clearly seen in

Figure 6c. At the same time, thermal stress, evaporation recoil pressure, and plasma ionization increase with laser energy density [

39]. In

Figure 6c, it can be seen that the substrate surface exhibits a wave-like morphology. This is mainly due to the remelting phenomenon when the substrate is subjected to a high-energy laser. Higher intensity thermal stresses, evaporative recoil pressure, and plasma impact effects act on the liquefied substrate. This ultimately leads to a wavy appearance on the substrate surface. This coupled impact effect refines the grains and thus increase the hardness of the substrate. In

Figure 6c, it can be clearly seen that there is a significant change in the metallographic phase due to the thermal effect of the laser at 200 W. The heat-affected zone (HAZ) is deepest at this power. However, the thermal effect will diminish with increasing depth. Its metallographic and microhardness will gradually return to the original substrate consistency. In this power, its microhardness at 35 μm measures 349 HV, compared to the original substrate microhardness of 337 HV at the same depth, representing a 3.78% increase.