Improvement in the Polarization Fatigue Properties of PbZr0.50Ti0.50O3 Thick Film Using a Ba0.3Sr0.7Zr0.18Ti0.82O3 Buffer Layer

Abstract

1. Introduction

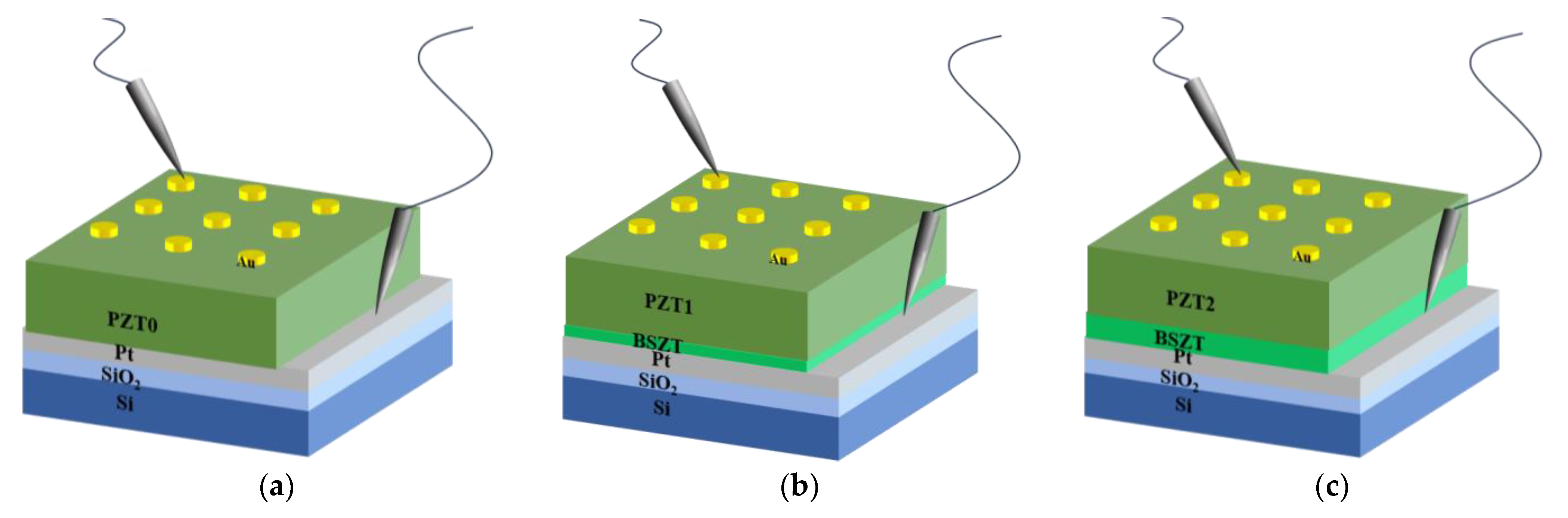

2. Materials and Methods

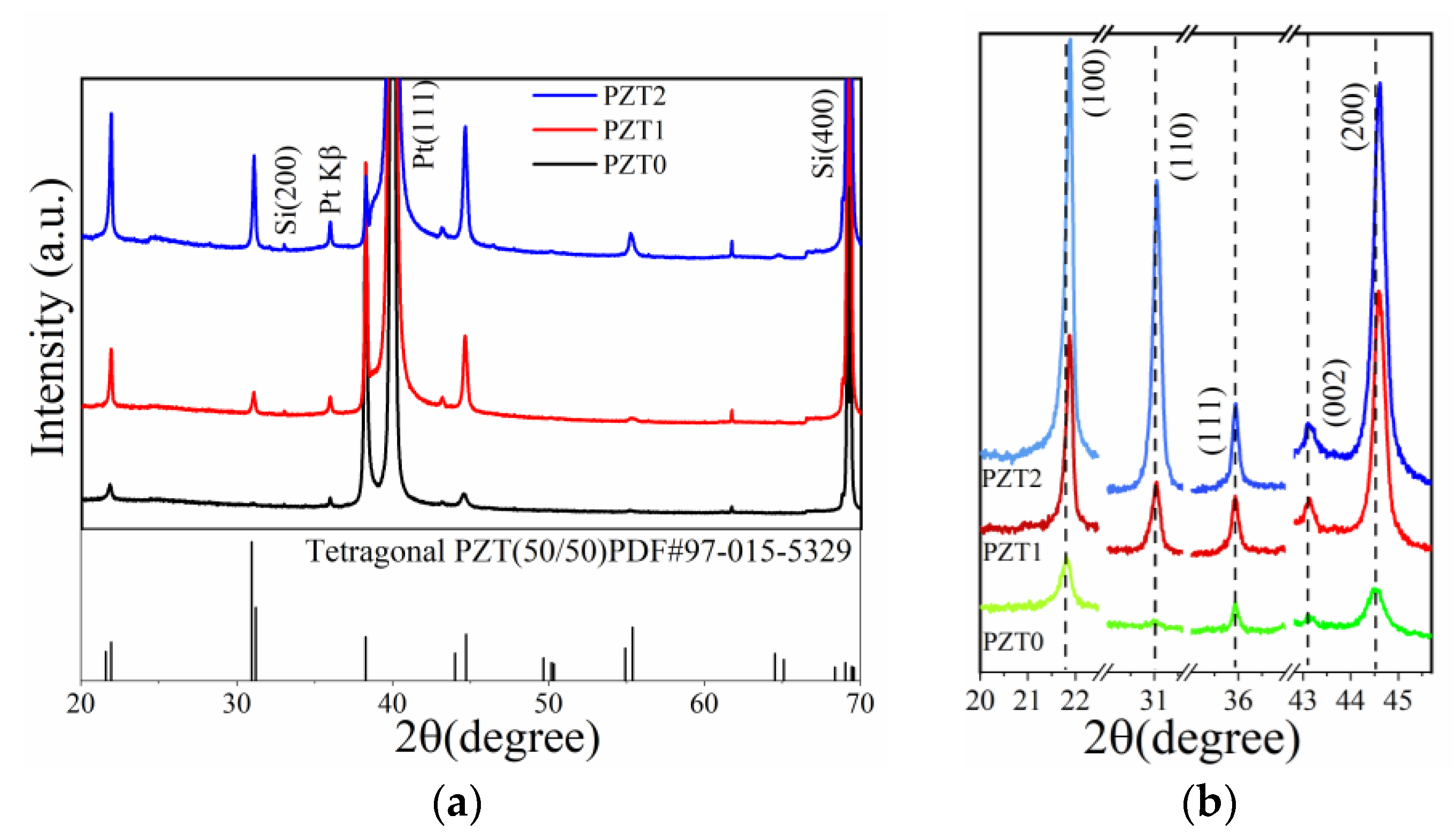

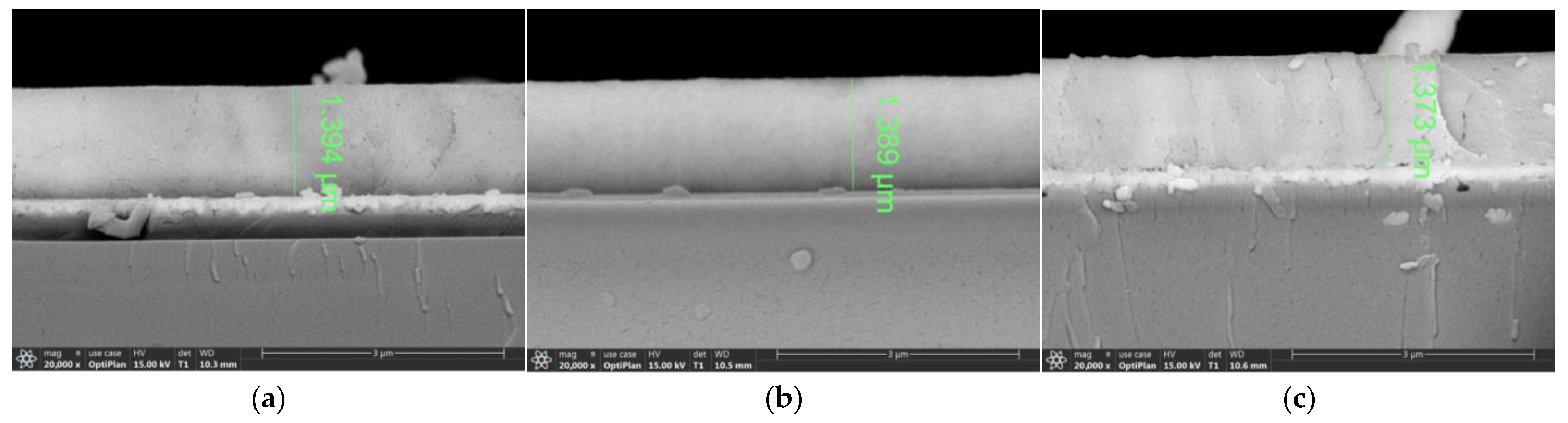

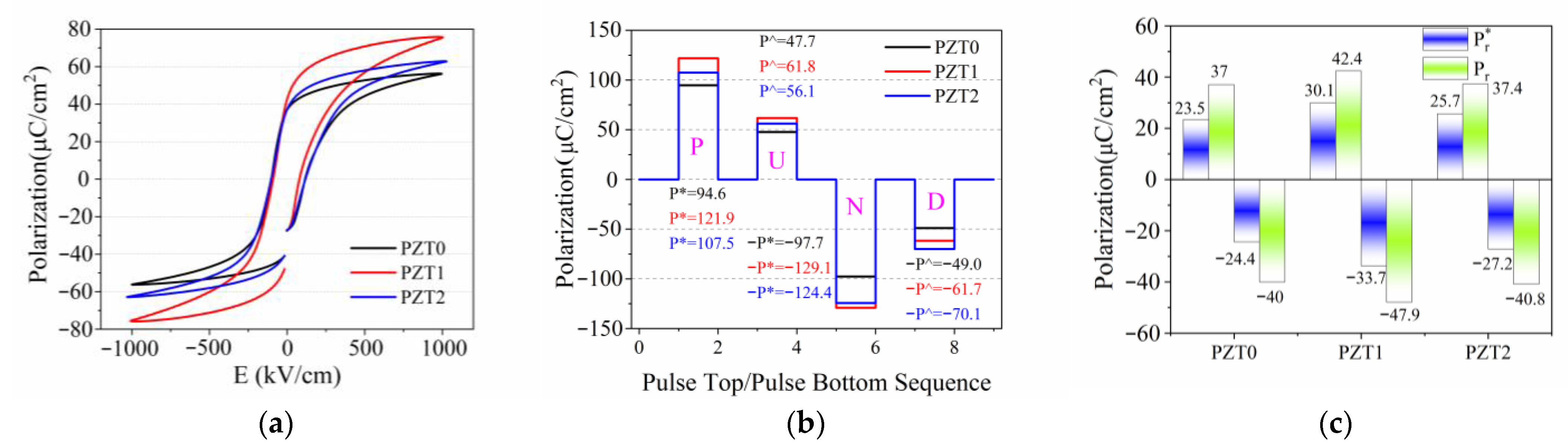

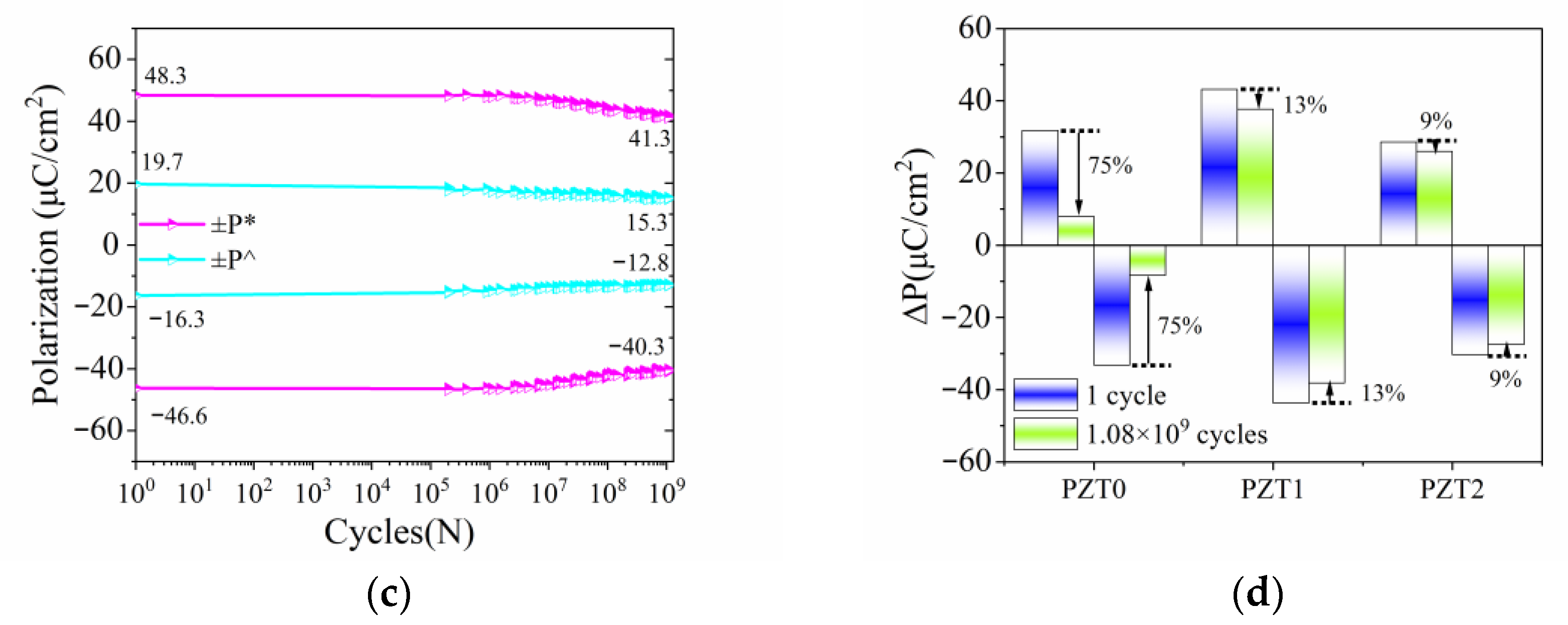

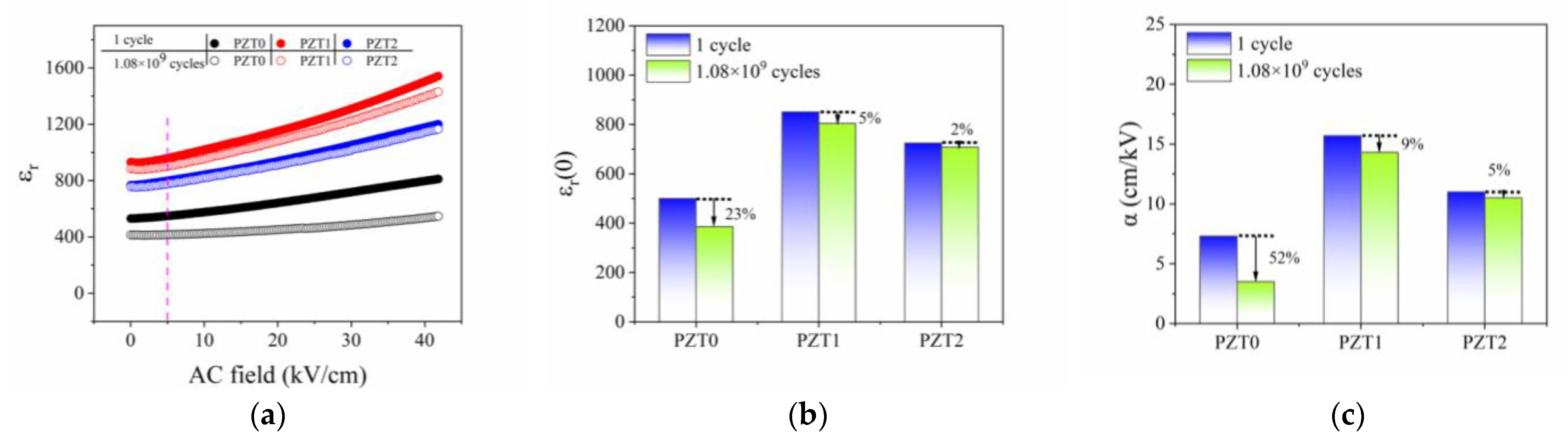

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lou, X.J.; Zhang, H.J.; Luo, Z.D.; Zhang, F.P.; Liu, Y.; Liu, Q.D.; Fang, A.P.; Dkhil, B.; Zhang, M.; Ren, X.B.; et al. Effect of polarization fatigue on the Rayleigh coefficients of ferroelectric lead zirconate titanate thin films: Experimental evidence and implications. Appl. Phys. Lett. 2014, 105, 102907. [Google Scholar] [CrossRef]

- Gerber, P.; Kügeler, C.; Ellerkmann, U.; Schorn, P.; Böttger, U.; Waser, R. Effects of ferroelectric fatigue on the piezoelectric properties (d33) of tetragonal lead zirconate titanate thin films. Appl. Phys. Lett. 2005, 86, 112908. [Google Scholar] [CrossRef]

- Wang, D.; Fotinich, Y.; Carman, G.P. Influence of temperature on the electromechanical and fatigue behavior of piezoelectric ceramics. J. Appl. Phys. 1998, 83, 5342–5350. [Google Scholar] [CrossRef]

- Zhu, H.; Chen, Y.; Chu, D.; Feng, S.; Zhang, Y.; Wang, P. Investigation of fatigue behavior of Pb (Zr0.45Ti0.55) O3 thin films under asymmetric polarization switching. Jpn. J. Appl. Phys. 2016, 55, 091501. [Google Scholar] [CrossRef]

- Lou, X.J. Polarization fatigue in ferroelectric thin films and related materials. J. Appl. Phys. 2009, 105, 024101. [Google Scholar] [CrossRef]

- Liu, Z.; Zhong, H.; Xie, D.; He, M.; Wang, C.; Lyu, H.; Yang, G.; Jin, K.; Ge, C. Reversible fatigue-rejuvenation procedure and its mechanism in Hf0.5Zr0.5O2 epitaxial films. J. Phys. Condens. Matter. 2023, 35, 204002. [Google Scholar] [CrossRef]

- Zhu, G.; Zeng, Z.; Zhang, L.; Yan, X. Polarization fatigue in ferroelectric vinylidene fluoride and trifluoroethylene copolymer films. Appl. Phys. Lett. 2006, 89, 102905. [Google Scholar] [CrossRef]

- Sidorkin, A.S.; Saint-Gregoire, P.; Nesterenko, L.P. Fatigue phenomena in thin ferroelectric films stimulated by repeated switching of the polarization. J. Adv. Dielectr. 2013, 3, 1350002. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, Q.; Huang, H.H.; Munroe, P.; Nagarajan, V.; Simons, H.; Hong, Z.; Chen, L.Q. Reversible polarization rotation in epitaxial ferroelectric bilayers. Adv. Mater. Interfaces 2016, 3, 1600444. [Google Scholar] [CrossRef]

- Do, M.T.; Gauquelin, N.; Nguyen, M.D.; Wang, J.; Verbeeck, J.; Blom, F.; Koster, G.; Houwman, E.P.; Rijnders, G. Interfacial dielectric layer as an origin of polarization fatigue in ferroelectric capacitors. Sci. Rep. 2020, 10, 7310. [Google Scholar] [CrossRef]

- Meng, X.; Song, J.; Wang, D.; Ma, H.; Liu, B.; Wang, Y. Impacts of light on switching properties of epitaxial (Pb0.9La0.1)(Zi0.4Ti0.6)O3 capacitor with Al2O3 doped ZnO top electrode. Optik 2021, 242, 167118. [Google Scholar] [CrossRef]

- Scott, J.F.; Dawber, M. Oxygen-vacancy ordering as a fatigue mechanism in perovskite ferroelectrics. Appl. Phys. Lett. 2000, 76, 3801. [Google Scholar] [CrossRef]

- Chang, L.W.; Alexe, M.; Scott, J.F.; Gregg, J.M. Settling the” dead layer” debate in nanoscale capacitors. Adv. Mater. 2009, 21, 4911. [Google Scholar] [CrossRef]

- Golonka, L.J.; Buczek, M.; Hrovat, M.; Belavič, D.; Dziedzic, A.; Roguszczak, H.; Zawada, T. Properties of PZT thick films made on LTCC. Microelectron. Int. 2005, 22, 13–16. [Google Scholar] [CrossRef]

- Tagantsev, A.K.; Stolichnov, I.; Colla, E.L.; Setter, N. Polarization fatigue in ferroelectric films: Basic experimental findings, phenomenological scenarios, and microscopic features. J. Appl. Phys. 2001, 90, 1387–1402. [Google Scholar] [CrossRef]

- Lou, X.J.; Wang, J. Bipolar and unipolar electrical fatigue in ferroelectric lead zirconate titanate thin films: An experimental comparison study. J. Appl. Phys. 2010, 108, 034104. [Google Scholar] [CrossRef]

- Du, X.; Chen, I.W. Fatigue of Pb(Zr0.53Ti0.47)O3 ferroelectric thin films. J. Appl. Phys. 1998, 83, 7789–7798. [Google Scholar] [CrossRef]

- Bao, D.; Wakiya, N.; Shinozaki, K.; Mizutani, N. Ferroelectric properties of sandwich structured (Bi, La)4T3O12/Pb(Zr, Ti)O3/(Bi, La)4Ti3O12 thin films on Pt/Ti/SiO2/Si substrates. J. Phys. D Appl. Phys. 2002, 35, L1–L5. [Google Scholar] [CrossRef]

- Wu, Z.; Zhou, J.; Chen, W.; Shen, J.; Hu, L.; Lv, C. Effects of Ba(Mg1/3Ta2/3)O3 buffer layer on the fatigue behavior in Pb (Zr0.52Ti0.48)O3 thin films. J. Sol-Gel Sci. Technol. 2015, 74, 234–239. [Google Scholar] [CrossRef]

- Mensur Alkoy, E.; Uchiyama, K.; Shiosaki, T.; Alkoy, S. Improving fatigue resistance of Pb (Zr, Ti) O3 thin films by using PbZrO3 buffer layers. J. Appl. Phys. 2006, 99, 106106. [Google Scholar] [CrossRef]

- Lou, X.J.; Zhang, M.; Redfern, S.A.T.; Scott, J.F. Fatigue as a local phase decomposition: A switching-induced charge-injection model. Phys. Rev. B 2007, 75, 224104. [Google Scholar] [CrossRef]

- Lou, X.J.; Zhang, M.; Redfern, S.A.T.; Scott, J.F. Local phase decomposition as a cause of polarization fatigue in ferroelectric thin films. Phys. Rev. Lett. 2006, 97, 177601. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Yu, S.; Sun, R.; Li, L.; Yin, Y.; Du, R. Microstructure and electrical properties of Ba0.7Sr0.3(Ti1−xZrx)O3 thin films prepared on copper foils with sol–gel method. Thin Solid. Film. 2010, 518, 3610–3664. [Google Scholar] [CrossRef]

- Jiang, L.L.; Tang, X.G.; Jiang, Y.P.; Liu, Q.X.; Ma, C.B.; Chan, H.L.W. Epitaxial growth and dielectric properties of BSZT thin films on SrTiO3: Nb single crystal substrate prepared by pulsed laser deposition. Surf. Coat. Technol. 2013, 229, 162–164. [Google Scholar] [CrossRef]

- Chan, N.Y.; Wang, D.Y.; Wang, Y.; Dai, J.Y.; Chan, H.L.W. The structural and in-plane dielectric/ferroelectric properties of the epitaxial (Ba, Sr)(Zr, Ti)O3 thin films. J. Appl. Phys. 2014, 115, 234102. [Google Scholar] [CrossRef]

- Chen, X.; Mo, T.; Huang, B.; Liu, Y.; Yu, P. Capacitance properties in Ba0.3Sr0.7Zr0.18Ti0.82O3 thin films on silicon substrate for thin film capacitor applications. Crystals 2020, 10, 318. [Google Scholar] [CrossRef]

- Chen, X.; Liu, Y.; Huang, B.; Yu, P. High energy storage efficiency and temperature stability realized in the Ba0.3Sr0.7Zr0.18Ti0.82O3/LaNiO3 heterostructure thin films directly deposited on the conductive Si substrate. Appl. Phys. Lett. 2022, 121, 122901. [Google Scholar] [CrossRef]

- Yang, C.; Yao, Q.; Guo, H.; Geng, F.; Lv, P.; Feng, C. Abnormal dielectric behavior induced by defect dipoles in aged Na0.5Bi0.5(Ti, Zr)O3 thin film. Mater. Lett. 2016, 164, 380–383. [Google Scholar] [CrossRef]

- Gharb, N.B.; Trolier-McKinstry, S. Dielectric nonlinearity of Pb (Yb1∕2Nb1/2) O3–PbTiO3 thin films with {100} and {111} crystallographic orientation. J. Appl. Phys. 2005, 97, 064106. [Google Scholar] [CrossRef]

- Mahmoud, A.E.R.; Parashar, S.K.S. Effect of domain switching contribution on polarization current, leakage current and switching charge density studied by PUND method in (Ba1−x, Cax)TiO3 ceramics. Mat. Sci. Eng. B 2019, 246, 13–20. [Google Scholar] [CrossRef]

- Shimura, R.; Tue, P.T.; Tagashira, Y.; Shimoda, T.; Takamura, Y. Solution-based process with thermal UV treatment for fabrication of piezoelectric PZT films for an actuator array at temperatures under 450 °C. Sens. Actuat. A-Phys. 2017, 267, 287–292. [Google Scholar] [CrossRef]

- Wang, J.; Nguyen, M.D.; Gauquelin, N.; Verbeeck, J.; Do, M.T.; Koster, G.; Rijnders, G.; Houwman, E. On the importance of the work function and electron carrier density of oxide electrodes for the functional properties of ferroelectric capacitors. Phys. Status Solidi-R. 2020, 14, 1900520. [Google Scholar] [CrossRef]

- Mihara, T.; Watanabe, H.; de Araujo, H.W.P. Characteristic change due to polarization fatigue of sol-gel ferroelectric Pb(Zr0.4Ti0.6)O3 thin-film capacitors. Jpn. J. Appl. Phys. 1994, 33, 5281. [Google Scholar] [CrossRef]

- Colla, E.L.; Kholkin, A.L.; Taylor, D.; Tagantsev, A.K.; Brooks, K.G.; Setter, N. Characterisation of the fatigued state of ferroelectric PZT thin-film capacitors. Microelectron. Eng. 1995, 29, 145–148. [Google Scholar] [CrossRef]

- Stolichnov, I.; Tagantsev, A.; Setter, N.; Okhonin, S.; Fazan, P.; Cross, J.S.; Tsukada, M. Dielectric breakdown in (Pb, La)(Zr, Ti)O3 ferroelectric thin films with Pt and oxide electrodes. J. Appl. Phys. 2000, 87, 1925–1931. [Google Scholar] [CrossRef]

- Scott, J.F.; Araujo, C.A.; Melnick, B.M.; McMillan, L.D.; Zuleeg, R. Quantitative measurement of space-charge effects in lead zirconate-titanate memories. J. Appl. Phys. 1991, 70, 382–388. [Google Scholar] [CrossRef]

- Wang, J.L.; Lai, Y.S.; Chiou, B.S.; Tseng, H.Y.; Tsai, C.C.; Juan, C.P.; Jan, C.K.; Cheng, H.C. Study on fatigue and breakdown properties of Pt/(Pb,Sr)TiO3/Pt capacitors. J. Phys. Condens. Matter. 2006, 18, 10457. [Google Scholar] [CrossRef][Green Version]

| Sample | FWHM(100) (°) | FWHM(110) (°) | FWHM(111) (°) | FWHM(200) (°) |

|---|---|---|---|---|

| PZT0 | 0.242 | \ | 0.251 | 0.387 |

| PZT1 | 0.158 | 0.193 | 0.161 | 0.253 |

| PZT2 | 0.186 | 0.196 | 0.168 | 0.275 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, K.; Zhang, J.; Fan, Z.; Yu, P. Improvement in the Polarization Fatigue Properties of PbZr0.50Ti0.50O3 Thick Film Using a Ba0.3Sr0.7Zr0.18Ti0.82O3 Buffer Layer. Coatings 2025, 15, 568. https://doi.org/10.3390/coatings15050568

Wu K, Zhang J, Fan Z, Yu P. Improvement in the Polarization Fatigue Properties of PbZr0.50Ti0.50O3 Thick Film Using a Ba0.3Sr0.7Zr0.18Ti0.82O3 Buffer Layer. Coatings. 2025; 15(5):568. https://doi.org/10.3390/coatings15050568

Chicago/Turabian StyleWu, Kefan, Junxi Zhang, Zhiyang Fan, and Ping Yu. 2025. "Improvement in the Polarization Fatigue Properties of PbZr0.50Ti0.50O3 Thick Film Using a Ba0.3Sr0.7Zr0.18Ti0.82O3 Buffer Layer" Coatings 15, no. 5: 568. https://doi.org/10.3390/coatings15050568

APA StyleWu, K., Zhang, J., Fan, Z., & Yu, P. (2025). Improvement in the Polarization Fatigue Properties of PbZr0.50Ti0.50O3 Thick Film Using a Ba0.3Sr0.7Zr0.18Ti0.82O3 Buffer Layer. Coatings, 15(5), 568. https://doi.org/10.3390/coatings15050568