1. Introduction

Aluminum alloys, with their favorable strength-to-mass ratio, excellent machinability, and relatively low cost, have been utilized across aerospace [

1,

2,

3,

4,

5], automotive [

6,

7,

8,

9,

10,

11,

12], marine [

13,

14,

15,

16,

17,

18], construction [

19,

20,

21,

22], and electronic industries [

23,

24]. In addition, aluminum alloys have found increasing applications in gear transmission systems, including wind turbine gearboxes and automotive transmissions, owing to their light weight and manufacturing advantages. In wind energy systems, the demand for high-efficiency and lightweight gearboxes drives the use of advanced aluminum alloys for components such as housings, gears, and bearing supports. Similarly, in automotive transmissions, aluminum alloy components contribute to vehicle weight reduction, improved fuel efficiency, and enhanced overall performance. However, as their application domains expand, aluminum alloy surfaces encounter numerous challenges under demanding operational conditions. Under high frictional stresses, aluminum alloy surfaces are susceptible to wear and increased energy consumption [

25,

26]; in corrosive environments, their corrosion resistance may be compromised [

27,

28]; in low-temperature and high-humidity settings, there is a potential for ice accumulation [

29]; and in complex operational environments, maintaining long-term optimal wettability and cleanliness proves challenging [

30,

31]. These issues become even more critical under extreme service conditions and stringent reliability requirements, limiting the wider adoption of aluminum alloys. In gear transmission systems, surface wear, pitting corrosion, lubrication degradation, and fatigue damage are critical issues that can shorten service life and reduce transmission efficiency. These problems are particularly pronounced under high load, high speed, and fluctuating temperature conditions, as commonly encountered in wind turbine gearboxes and automotive transmissions. These issues become even more critical under extreme service conditions and stringent reliability requirements, limiting the wider adoption of aluminum alloys.

To overcome these challenges, various surface treatments have been developed. These methods include surface coatings [

32,

33,

34], surface modification [

35,

36], surface alloying [

37], and surface texturing [

38,

39,

40]. Among these, surface texturing is particularly notable as a flexible microstructural design approach [

41,

42]. By incorporating a structured arrangement of microscopic/nanoscopic textures, such as indentations, channels, pores, and bio-inspired patterns, onto the outer layer of the material, it becomes possible to attain multiple functions simultaneously, such as controlling wettability [

43,

44], reducing friction and wear [

45,

46], improving corrosion resistance [

47,

48], and providing anti-icing [

49,

50] and anti-fouling properties [

13]. This strategy provides an effective solution to meet the demands of harsh operational conditions.

Recently, a variety of micro-manufacturing techniques have been utilized to create patterned surfaces on metals, including laser surface texturing (LST) [

51,

52], electrochemical machining (ECM) [

53,

54], chemical milling (CM) [

55], spark erosion machining (EMD) [

56], photolithographic etching (PLE) [

57], and ultrasonic-assisted machining (UAM) [

58]. Among these, LST has attracted considerable interest due to its precision, control, and process flexibility [

42,

59]. The main processing methods and functions of these techniques are summarized in

Table 1.

By modifying laser settings [

60]—including pulse length, power intensity, scanning rate, repetition frequency, and wavelength—coupled with post-treatment processes like thermal treatment, electrochemical passivation, surface modification, or film deposition, it is possible to fabricate multi-scale surface textures with high precision. When the surface features and dimensions are optimized, the textured surface can sustain stable lubricant films under sliding conditions, thereby minimizing friction and wear [

45,

61]. In corrosive environments, it can alter ion transport paths and stress distribution, thereby enhancing corrosion resistance [

62]. In terms of surface wettability and superhydrophobic characteristics, constructing hierarchical micro/nano textures can effectively regulate contact angles and sliding angles, enabling reversible transitions from superhydrophilic to superhydrophobic states [

43,

44,

63], thus providing self-cleaning and anti-fouling capabilities. In low-temperature and high-humidity settings, it facilitates droplet detachment, reducing ice adhesion [

64]. Furthermore, in composite material bonding applications [

65,

66,

67], the micro/nano-scale surface patterns promote mechanical interlocking with other materials, thereby enhancing the adhesive bond strength at the interface. Some research [

68,

69] has integrated patterned surfaces with functional coatings, dry lubricants, or ceramic coatings, resulting in combined enhancements in friction reduction, corrosion resistance, and wear durability, highlighting potential applications in marine, aerospace, and other high-demand industrial settings. The different surface functional applications enabled by LST are summarized in

Figure 1.

In conclusion, laser-based surface structuring shows considerable promise in enhancing the surface characteristics and multifunctional properties of alloys, although further in-depth research and analysis are required. This review will explore recent developments and uses of laser surface structuring on aluminum alloys, emphasizing various laser processing techniques, parameter optimization approaches, and the underlying mechanisms that influence surface wettability, frictional performance, corrosion resistance, anti-icing, and anti-fouling characteristics. Additionally, it outlines advancements in integrating coatings with textured surfaces and addresses the challenges and opportunities in key application fields, ultimately offering insights and recommendations for the effective design and industrial implementation of aluminum alloy surface treatments.

2. Surface Texturing Methods and Mechanisms

LST involves the rapid interaction between high-energy laser beams and the material surface, leading to the creation of micro- and nano-scale features [

70]. In very brief time intervals, laser pulses cause localized thermodynamic effects such as rapid melting, vaporization, plasma generation, and quick solidification. These phenomena create periodic or aperiodic indentations, ridges, protrusions, and intricate patterns on the surface [

71]. For aluminum alloys, ultra-short laser pulses help to minimize the heat-affected zone and reduce irregularities in solidification, leading to finer and more uniform micro- and nano-scale structures. The changes in surface texturing patterns caused by varying laser pulses provide a versatile method for achieving multifunctional control over surface properties.

2.1. Laser Surface Texturing Methods

Depending on differences in surface patterning mechanisms and laser-material interaction modes, LST techniques can be categorized into three types: direct laser ablation (DLA), direct laser interference patterning (DLIP), and laser shock processing (LSP). By choosing suitable processing techniques and parameter combinations, specific structural patterns that fulfil performance requirements can be created on aluminum.

2.1.1. Direct Laser Ablation

DLA utilizes the high energy density and short pulse characteristics of lasers to locally heat the target material surface through a focused beam. Within a short time, the laser energy rapidly heats the material to its melting or vaporization point, causing the material to transition directly from a solid state to vapor or plasma. This achieves material removal or shape modification. The process primarily relies on the photothermal and photochemical effects of the laser, without the need for additional masks or chemical solutions. DLA enables the rapid creation of regular arrays and multi-scale structures on materials.

Lopez et al. [

72] explored the impact of high-intensity ultrafast DLA on the surfaces of materials like aluminum, copper, molybdenum, and stainless steel. The tests employed a Yb-doped fiber laser with pulse lengths varying from 300 femtoseconds to 10 picoseconds, repetition frequencies from 200 kHz to 2 MHz, and a maximum output power of 5 W. The investigation highlighted considerable variations in the ablation patterns of different metals under identical conditions. Aluminum demonstrated enhanced etching efficiency, attaining an etch rate of 0.15 mm

3/min/W at a power density of 0.16 J/cm

2. When the laser power was boosted to 15 W, combined with a pulse frequency of 2 MHz and a scanning speed of 1000 mm/s, the rate at which aluminum was removed increased to 2.5 mm

3/min. Compared to stainless steel, aluminum’s material removal efficiency was approximately 50% higher, demonstrating superior etching capability and material response characteristics.

Eskandari et al. [

73] employed continuous-wave fiber lasers to generate composite structures containing Al

2O

3 and Au micro- and nanoparticles on aluminum surfaces covered with 15 nm and 40 nm thick gold nanolayers. With the growing thickness of the gold layer, the particle size on the eroded surface shrank, surface roughness decreased from 526 nm to 201 nm, and the oxygen content fell from 28% to 16%. The Al

2O

3 particles produced during DLA were round-shaped, averaging 45 nm in diameter, whereas the Au particles were predominantly irregular in shape, averaging 18 nm in size. DLA improved the wettability of the aluminum surface. The untreated aluminum had a water contact angle of 43°, while the sample coated with a 15 nm gold layer showed a contact angle of 112°, and the 40 nm gold-coated sample further enhanced the contact angle to 152°, resulting in superhydrophobicity. The results confirmed that changes in surface morphology and the distribution of micro- and nanoparticles are key factors in enhancing wettability.

The DLA process primarily depends on photothermal and photochemical effects. By adjusting the laser wavelength, power intensity, and processing trajectory, the removal of material can be executed across different types of substrates.

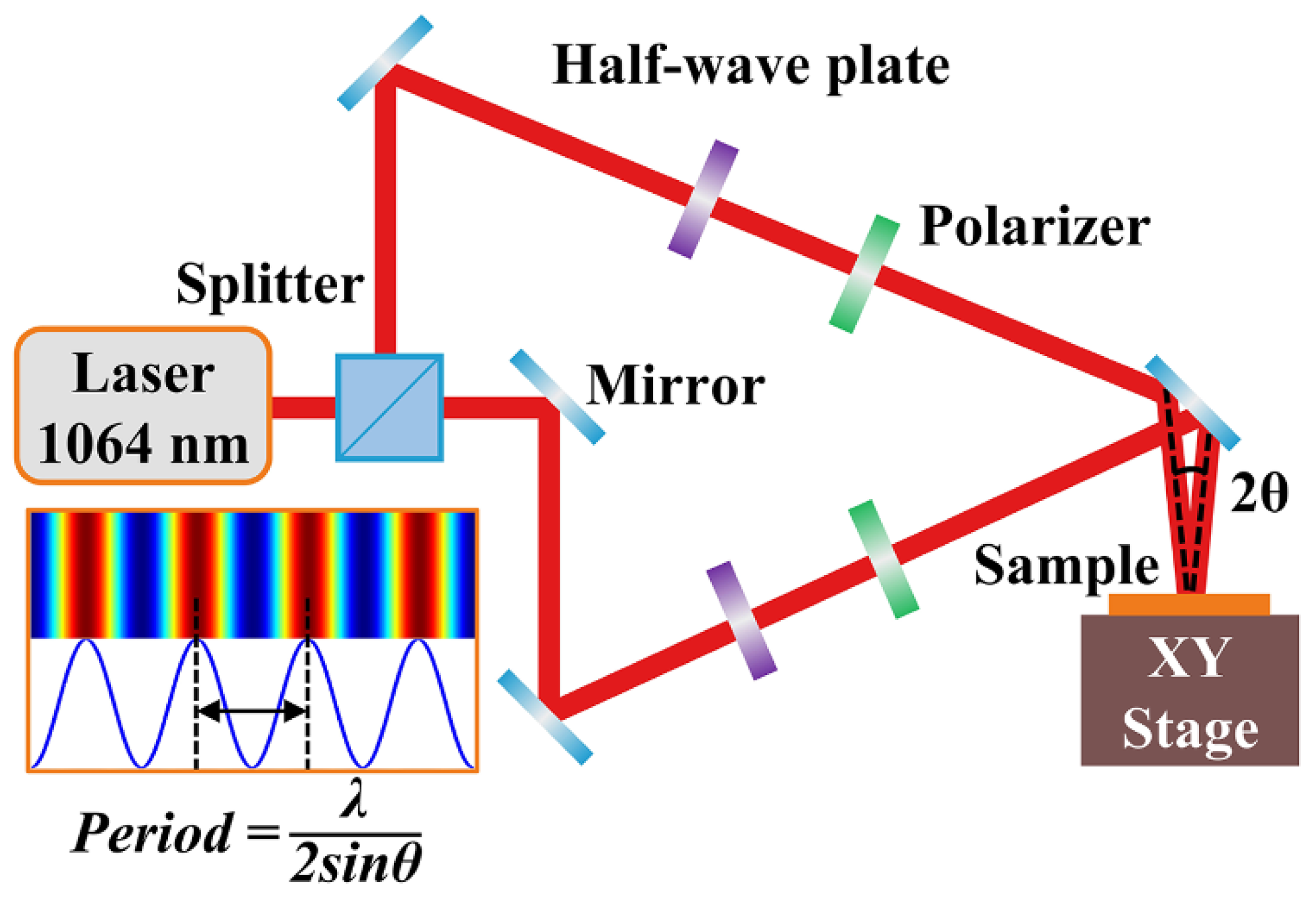

2.1.2. Laser Interference Patterning

DLIP facilitates the formation of regular microstructural patterns on metallic surfaces at both micron and submicron scales by combining several coherent laser beams, generating a spatially periodic light intensity distribution, commonly referred to as an interference pattern. The core principle involves transferring the spatially organized light field intensity from the interference pattern onto the material’s surface. Upon absorbing laser energy, the material experiences a localized rise in temperature, triggering photothermal phenomena such as melting, evaporation, and phase changes. Simultaneously, the molten layer undergoes flow and redistribution under the influence of surface tension gradients, known as the Marangoni effect, and evaporative recoil pressure. This procedure ultimately results in the material solidifying into well-organized periodic structures on the metal surface, as demonstrated in

Figure 2, which depicts the setup and operational principles.

This fabrication capability allows DLIP to create controlled micro-nanostructures, enabling studies on surface properties such as wettability. Alessandria et al. [

74], using a nanosecond Nd: YAG laser to generate interference patterns, demonstrated that the depth and morphology of the microstructures are highly sensitive to laser energy density and grating period. Milles et al. [

75] compared the microstructure fabrication capabilities of direct laser writing (DLW) and DLIP. DLW is a technique that uses a focused laser beam to directly write patterns onto material surfaces. It can produce relatively large structures, ranging from approximately 50 to 500 μm in size, with depths reaching up to 36.8 μm and a maximum Sq value of about 13 μm, but it offers relatively low resolution. In contrast, DLIP generates periodic columnar structures with finer resolution, achieving a minimum period of about 3 μm, shallower depths of up to 5.9 μm, and a lower Sq value of less than 2.2 μm. The symmetric columnar textures produced by DLIP enable a rapid transition to superhydrophobic states even at low surface roughness levels.

In subsequent studies, Milles et al. [

76] combined DLW and DLIP to create multi-scale micro-nanostructures. Using a combined DLW+DLIP technique to fabricate a grid pattern roughly 33.8 μm deep and dense columnar textures about 4.2 μm high on the aluminum surface, a contact angle of 161 degrees was attained, accompanied by a reduction in contact angle hysteresis to 36 degrees. In self-cleaning tests, when subjected to larger particles such as 100 micrometer MnO

2 and PA particles, the multi-scale structure achieved a cleaning efficiency close to that of the pure DLIP structure, with residual contamination rates below 10 percent. This indicates that rolling water droplets can effectively remove adhered particles. However, for smaller contaminants such as 1 micrometer MnO

2 particles, the cleaning efficiency was slightly lower than that of the pure DLIP structure, since the fine particles easily became trapped in deep grooves. Overall, the combination of DLW and DLIP leverages the benefits of multi-scale textures, achieving excellent droplet rolling behavior and high cleaning efficiency.

DLIP can regulate periodic micro-nanostructures on aluminum alloy surfaces, enabling wettability control through high-resolution textures. When combined with DLW, it improves the complexity and functionality of microstructures, offering a practical approach for engineering needs such as superhydrophobicity, self-cleaning, and anti-fouling.

2.1.3. Laser Shock Processing

Unlike DLA and DLIP, which primarily focus on constructing micro- and nano-scale morphologies, LSP utilizes ultrahigh-energy-density pulsed lasers to generate high-pressure plasma shock waves on the material surface. This induces a residual compressive stress field and forms specific micro-pits or ripple-like structures on the surface. This process significantly enhances surface mechanical properties and, to some extent, adjusts surface wettability and corrosion resistance.

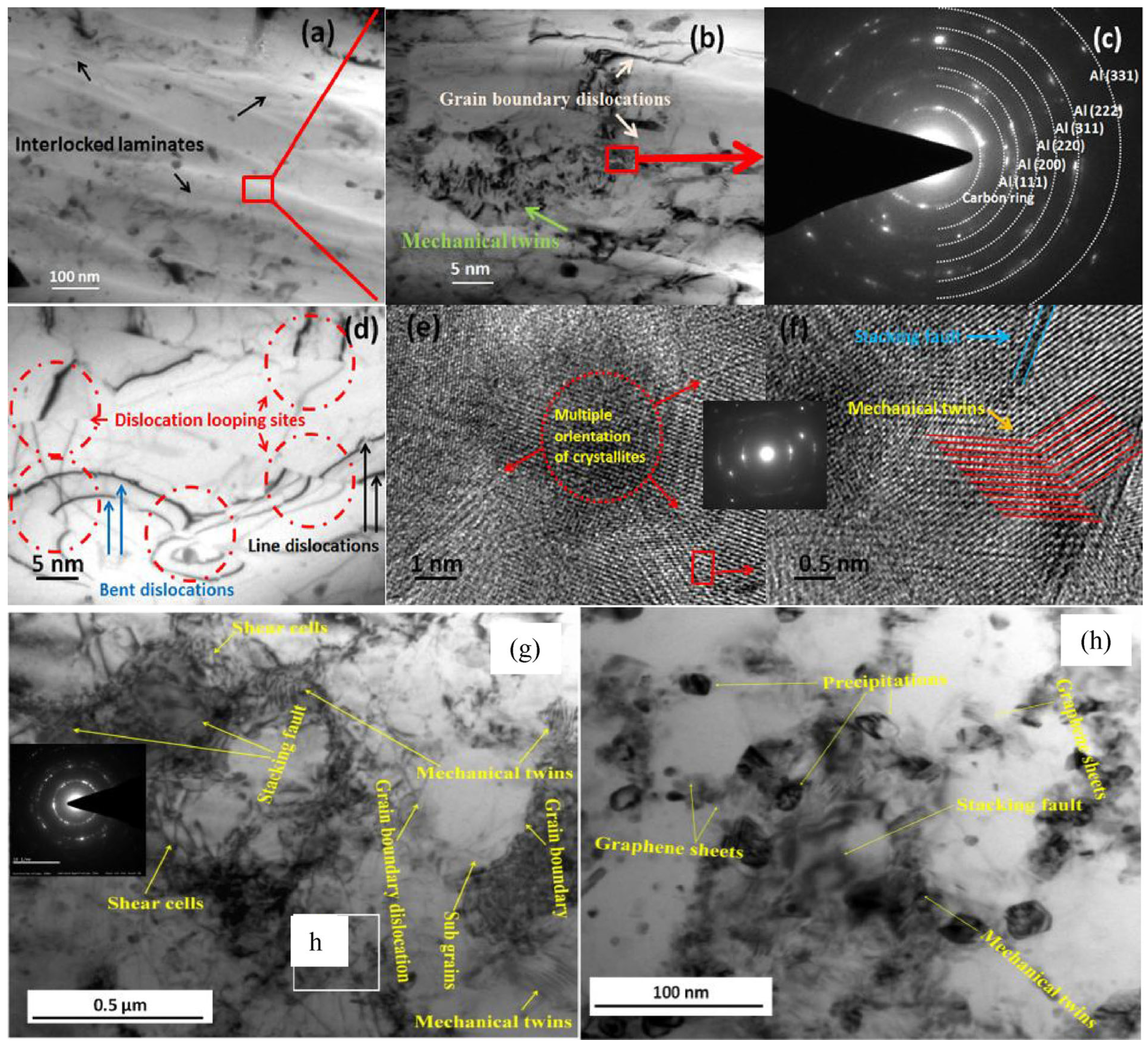

The superior strength of natural nacre primarily originates from its interlocked lamellar structure. Inspired by this, Kumar et al. [

77] developed a bioinspired nanolaminate graphene-aluminum alloy composite (AA-Gr). Initially, AA6061 aluminum alloy and graphene composite powders were prepared using ultrasonic dispersion and ball milling techniques, followed by cold pressing, sintering, and hot extrusion. Subsequently, the samples were subjected to LSP. After LSP treatment, the lamellar grains of the AA-Gr composites were further refined, forming an interlocked brick-and-mortar-like nanostructure similar to that of nacre, where graphene was positioned at the grain boundaries, effectively inhibiting grain growth and promoting lamellar arrangement. LSP also induced a high density of dislocations, leading to the formation of nano-scale stacking faults, micro shear cells, and other microstructural features, which significantly contributed to grain refinement.

Figure 3 illustrates the typical microstructural evolution of the AA-Gr nanocomposites after LSP treatment, with arrows in each subfigure indicating key features.

Figure 3a shows the formation of interlocked lamellar structures (indicated by arrows), highlighting the effective bonding and strengthening role of graphene at the grain boundaries. In

Figure 3b, the arrows point to regions with dense and uniformly distributed dislocation structures within the laminates.

Figure 3c presents the SAED pattern of a dislocation-rich area, where the arrows mark distinct diffraction spots corresponding to local lattice misorientations caused by high-density dislocations.

Figure 3d displays the suppression of large dislocation loops, with arrows indicating the role of graphene in hindering the expansion of Frank–Read dislocation sources and thereby reducing dislocation accumulation. In

Figure 3e,f, the arrows highlight the emergence of deformation twins and stacking faults, respectively, within the matrix after LSP.

Figure 3g,h further illustrate features of grain refinement, where arrows indicate the formation of ultrafine grains, dense dislocation walls, and low-angle grain boundaries.

Mechanical testing results demonstrated that LSP treatment led to a 24.55% increase in ultimate tensile strength, reaching 439 MPa, a 29.56% improvement in microhardness, and more than a twofold enhancement in fatigue life compared to the untreated samples. These findings confirm the synergistic effect of graphene reinforcement and laser shock processing in significantly enhancing the comprehensive performance of the composites.

Drawing inspiration from the layered structure of nacre, Kumar et al. [

77] utilized LSP to enhance the mechanical and surface characteristics of nanolayered graphene-aluminum alloy composites. After LSP treatment, the material’s ultimate tensile strength rose to around 439 MPa, reflecting a 24.55% increase; fatigue life extended to 2.3 × 10

5 cycles, more than double that of untreated samples; and hardness saw an enhancement of approximately 29.56%. The compressive stress field and grain refinement induced by LSP enhanced the stability of the layered structure and effectively inhibited crack propagation. This caused the surface contact angle to increase from 69.77° to 95.75°, indicating enhanced hydrophobic properties and improved corrosion resistance.

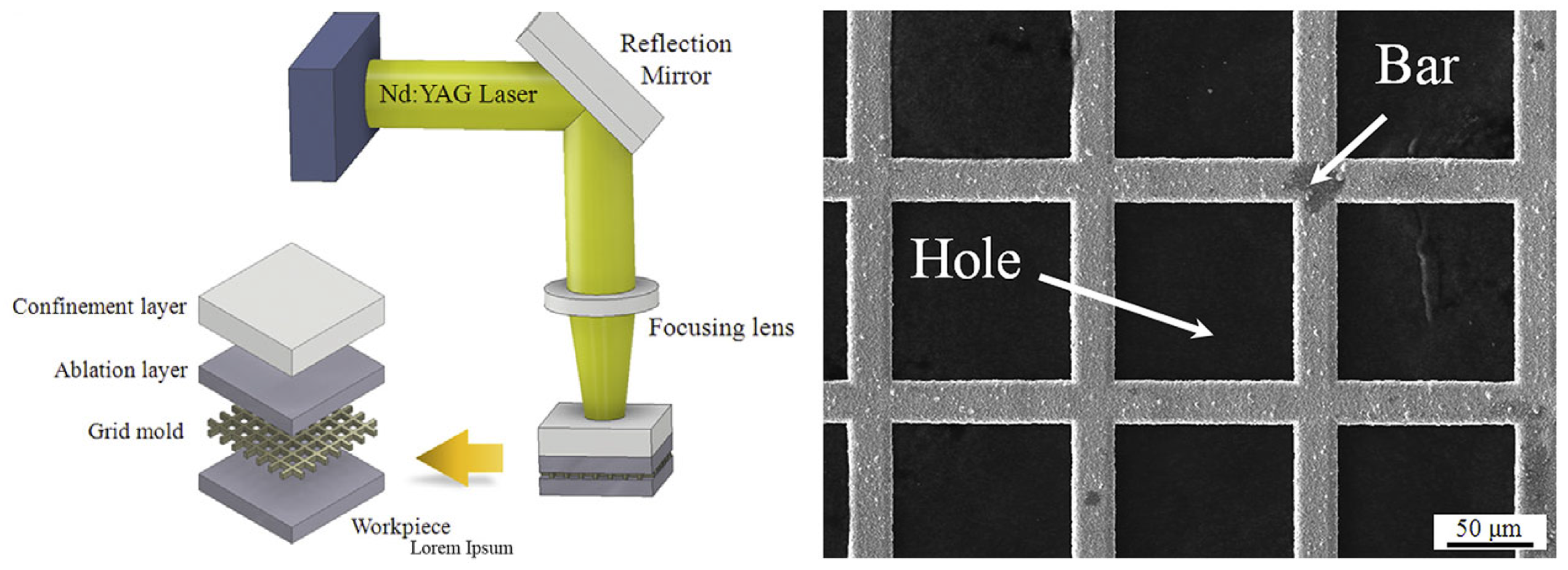

In another study, Koo et al. [

78] employed LSP to imprint a grid mold pattern onto the Al1050 alloy surface. A solitary laser pulse generated over 140 recurring micro-pattern units on the substrate, with a schematic of the equipment and grid displayed in

Figure 4. Hardness tests revealed that the plastic deformation caused by LSP significantly increased surface hardness in the striped regions. Under a 200 μm ablation layer condition, the average hardness in the striped areas reached 51.2 VHN, an increase of approximately 16.1% compared to the original surface’s 44.1 VHN, while the hardness in other regions showed minimal change, measured at 46.2 VHN and 44.6 VHN.

Choi’s research [

79] further elucidated the strengthening mechanism of LSP. High-intensity plastic deformation caused a marked rise in dislocation density, leading to the development of a hardened surface layer, which increased the Vickers hardness of aluminum alloys from an initial 43 HV to about 55 HV. Notably, the hardness increase was not limited to the areas directly impacted by the laser; regions indirectly affected also exhibited significant improvement, indicating that LSP loading effectively enhances overall surface properties.

LSP processing enhances the comprehensive performance of aluminum alloy surfaces by introducing beneficial residual compressive stresses, refining grains, and controlling microstructural morphology. While improving the hardness and fatigue life, the surface strengthening and moderate texturing induced by LSP also contribute to the regulation of wettability.

2.2. Effects of Laser Processing Conditions on Texture Morphology and Functionality

Laser processing alters surface structures and improves functionality through the focused interaction of a high-energy laser beam with the substrate. Adjusting laser processing parameters can affect the material’s surface energy absorption, melting, and evaporation behaviors, as well as material removal mechanisms, thereby determining the morphology, characteristic scale, and uniformity of the texture. This section will examine the combined effects of laser power and irradiation time, scanning speed and spacing, as well as scanning path and overlay strategies on surface texture and performance.

2.2.1. Effects of Laser Power and Irradiation Time

The power and duration of laser irradiation play key roles in determining how the laser interacts with the substrate, controlling the energy density delivered to the surface and influencing its morphology and functionality. Increased laser power enhances energy absorption, leading to vigorous molten flow and pronounced metal vaporization, which create deeper and wider surface patterns. Under high power, the material may undergo strongly localized evaporation, forming large droplets of splatter or deeper molten cavities, whereas lower power results in shallower molten pools and relatively smoother surface structures. For example, Yang et al. [

80] found that as laser power increased, the texture height, depth, and diameter on aluminum plates significantly increased. At 200 W, the texture height was 0.5 μm, the depth was 4.8 μm, and the diameter was 150 μm; at 400 W, the texture height increased to 1.2 μm, the depth to 7.0 μm, and the diameter to 190 μm. Higher power allows more laser energy absorption, causing more intense molten pool flow and metal evaporation phenomena, resulting in deeper and broader surface textures. Sharp’s study [

81] on controlling the wettability of aluminum via a 20 W fiber laser and an 800 W solid-state laser revealed that a 20 W laser produced contact angles between 0° and 162° on aluminum, while a 220 W laser reached angles up to 134°, showcasing the potential of high-power lasers to improve efficiency and fine-tune hydrophobicity.

Irradiation time determines the extent of laser energy accumulation per unit area. The combination of appropriate irradiation time and laser power can regulate the fineness and structural type of surface textures. Yang’s research [

80] also found that as laser irradiation time increased, the pressure and velocity of evaporated gases significantly rose. For instance, at 0.3 ms, the pressure of evaporated gases was 118,000 Pa, increasing to 610,000 Pa at 0.5 ms; at 400 W, the evaporation rate reached 0.89 m/s, which is 1.3 times that at 200 W. In pulse mode processing, the pulse frequency directly determines the irradiation relationship and also affects the formation of surface structures. Ahuir-Torres et al. [

63] studied the texturization process of AA2024-T3 aluminum alloy surfaces under different pulse energies and pulse numbers. Under a pulse frequency of 5 kHz, increasing the number of pulses led to a transition from shallow “dot” textures to deep pit textures on the surface. Under high energy and high pulse numbers, laser surface texturization altered the surface geometry and microstructure of the aluminum alloy.

2.2.2. Combined Effects of Scanning Speed and Spacing

The scanning speed and spacing of laser beams are key factors influencing processing results, collectively controlling how laser energy is distributed over the substrate and impacting texture uniformity and surface morphology. Scanning speed dictates how fast the laser beam moves across the material surface, directly affecting the energy input time per unit area. Higher scanning speeds shorten the energy input time, resulting in lower molten pool temperatures and a shallower melting process, typically producing finer and more uniform surface textures. Conversely, slower scanning speeds extend the laser’s interaction time with the substrate, deepening the molten pool and potentially causing rougher topographies or more pronounced textures.

Laser beam spacing refers to the distance between adjacent laser scanning paths. Smaller scanning spacing causes energy overlap between adjacent paths, increasing local heat accumulation and forming deeper, larger surface textures. Larger scanning spacing reduces the overlap area, making the surface morphology more uniform but potentially resulting in smaller or shallower textures. Cholkar et al. [

82] employed ultrafast femtosecond laser surface texturing technology to improve the hydrophobicity of 7075 aluminum alloy by generating periodic grooves and nano-scale textures. Using a 3 W laser, with 0.08 mm beam spacing and a scanning velocity of 3 mm/s, a water contact angle of 142° was achieved. The surface featured a mean roughness height (Sa) of 0.87 μm, a peak roughness height (Sz) of 19.4 μm, and a texture aspect ratio (Str) of 0.042.

Kuznetsov et al. [

83] studied how beam velocity and line density influence the development of surface textures. The results showed that as beam line speed increased and scanning line density decreased, the texture period enlarged from 67.3 μm to 198 μm. Roughness parameters decreased linearly, while the maximum height difference decreased exponentially. Under low line speed and high scanning line density, the resulting textures were denser with a higher degree of oxidation, achieving an oxygen content of up to 43% and exhibiting high contact angles (up to 131°).

The interplay between scan velocity and beam spacing dictates the precision and consistency of microstructures. High scanning speeds with small scanning spacing typically produce fine and uniform surface structures, while low scanning speeds with large scanning spacing facilitate the formation of larger-scale textures or pits. In practical applications, it is usually necessary to adjust the combination of these two parameters to achieve surface textures of varying scales and depths to meet different performance requirements.

2.2.3. Effects of Scanning Path and Overlay Strategy

The scan pattern defines the laser beam’s trajectory across the substrate, with distinct paths producing diverse energy profiles and microstructural attributes. For example, a linear scanning path typically generates uniform molten pools and surface textures, whereas spiral or wavy paths may result in directional or periodic texture structures. The selection of the scanning path should be optimized based on the desired surface structure to achieve the best processing results.

The overlay strategy refers to how the laser beam’s repetitive scanning is arranged on the surface during the laser processing. Through overlay strategies, higher energy input can be achieved, further affecting the depth and size of surface structures. Volpe et al. [

52] adjusted the geometric shape and density of textures and found that circular and triangular textures could achieve superhydrophobicity at lower texture densities with higher processing efficiency. This is because these shapes can capture more air at lower densities, forming an effective air cushion effect, thereby enhancing hydrophobicity and reducing processing time. Research indicates that adjusting the scan overlap and spot layout enables the creation of hierarchical roughness on AA2024-T3, enhancing the durability of its superhydrophobic properties.

In summary, laser processing parameters influence the texture morphology of aluminum alloy surfaces to varying degrees, thereby affecting their performance. Through systematic parameter optimization and multi-scale texture design, corrosion resistance, anti-fouling, and friction reduction properties can be achieved on aluminum alloy surfaces.

3. Surface Texture and Wettability Control

Controlling wettability on aluminum alloys unlocks versatile applications, including self-cleaning, anti-fouling, anti-icing, and optimized liquid dynamics. Nature provides examples like lotus leaves, butterfly wings, and insect exoskeletons, which inspire bio-inspired surface engineering due to their superhydrophobic and low-adhesion traits. By using laser surface texturing technology to precisely design micro- and nanostructures on aluminum alloy surfaces, and complementing this with chemical modifications or functional coatings, the wettability characteristics of the surface can be effectively regulated to meet specific application needs.

3.1. Wettability Control Mechanism and Surface Microstructure Design

Wettability refers to how liquids spread or accumulate when in contact with a solid substrate. The contact angle, measured between a liquid droplet and the solid interface, categorizes surfaces as hydrophilic (θ < 90°), hydrophobic (θ > 90°), superhydrophilic (θ < 10°), or superhydrophobic (θ > 150°). The texture of a surface affects how liquids interact with solids by altering its microstructure and roughness characteristics. The traditional Wenzel and Cassie–Baxter theories explain how surface roughness impacts wettability behavior.

In the Wenzel regime, liquid droplets infiltrate the surface’s rough features, expanding the contact area between the solid and liquid, thereby enhancing the material’s inherent wettability. Hydrophilic materials are more easily wetted in the Wenzel state, while hydrophobic materials exhibit higher contact angles. Under the Cassie–Baxter model, liquid droplets rest atop the surface features, substantially minimizing the real contact area with the solid, as air occupies the gaps within the texture. This decreases contact angle hysteresis and rolling angle, allowing droplets to roll off effortlessly, achieving superhydrophobicity and self-cleaning properties.

For aluminum surfaces, microstructures such as pits, grooves, and multi-level arrays can be fabricated on the micro- to nano-scale using lasers. With carefully engineered morphology (e.g., periodic grooves, lattices, or biomimetic patterns), water droplets may adopt the Cassie–Baxter regime, leading to superhydrophobicity. For instance, Li et al. [

84] fabricated textured surfaces based on the superhydrophobic properties of rice leaves.

Figure 5a illustrates a droplet resting on the rice leaf, exhibiting a contact angle close to 150°.

Figure 5b depicts evenly arranged micro-grooves and papillae on the leaf surface, with groove spacing ranging from 20–30 µm and papillae diameters between 4–20 µm.

Figure 5c shows the laser-treated aluminum alloy surface with multiple grooves, spaced about 48 µm, and widths of 35–40 µm, mimicking the microstructure of rice leaves. The detailed image of the grooves in

Figure 5d shows that the surface is covered with particles of 0.8–5.2 µm in diameter, enhancing the surface roughness.

Figure 5e reveals that particle accumulation shapes the groove gaps, while the dense particle arrangement traps air efficiently, minimizing the interaction area between the droplet and the substrate. The three-dimensional morphology of the grooves visually presents their structure and superhydrophobicity. Moreover, XPS analysis indicates that a silica layer generated post-laser treatment reduces surface energy further and enhances superhydrophobic stability. Compression experiments show that the water droplet maintains its shape under external force, with the contact angle only decreasing by about 1.1°, indicating good stability.

3.2. Achieving Superhydrophobic and Hydrophilic Properties

Earlier research demonstrated that with optimal laser parameters and texture designs, aluminum alloy surfaces can transition from hydrophilic to hydrophobic or superhydrophobic states. As discussed in

Section 2, ultrafast pulsed lasers were used to texture the AA7075 aluminum alloy surface. By optimizing the parameters, fine micro-nanostructures were achieved, significantly improving the surface hydrophobicity. After picosecond laser etching on AA2024-T3 aluminum alloy surfaces, multi-level roughness structures were built, and with appropriate chemical modification, the surface was transformed into a superhydrophobic state while maintaining stable corrosion resistance and controlled wettability. Using nanosecond laser processing, micro-sized pits or grooves were created on the aluminum alloy surface, and after subsequent low surface energy molecule modification, the liquid droplets formed a Cassie-Baxter state, achieving high contact angles and low rolling angles.

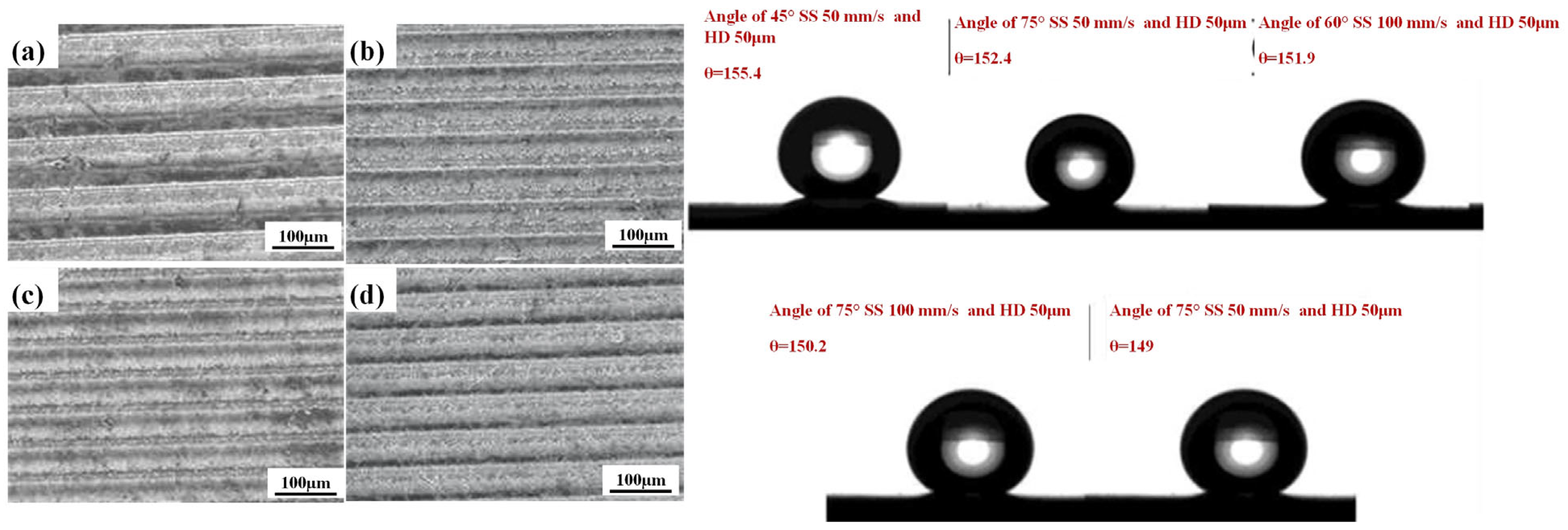

In enhancing superhydrophobicity, using suitable groove sizes is an effective strategy. Raja’s study [

85] found that untreated aluminum had hydrophilic characteristics, with a contact angle measured at 72°. Following laser texturing, the contact angle progressively increased as the inclined groove patterns were adjusted.

Figure 6 shows the groove patterns with different angles (30°, 45°, 60°, 75°). For the 30° inclined grooves, the contact angle increased from 87.6° to 127.4°, and by adjusting the laser parameters, the contact angle reached 151.2°. The 45° inclined groove design attained a peak angle of 155.5°, but this angle diminished as the etching distance and scanning speed varied. The 60° inclined groove configuration resulted in superhydrophobic behavior, characterized by a contact angle of 151.9°, but this effect weakened as the scanning speed was lowered. The 75° inclined groove pattern remained superhydrophobic regardless of laser parameter adjustments, with minimal contact angle variation, as shown in

Figure 4.

3.3. Synergistic Effect of Chemical Modification and Functional Coatings

The geometric configuration of micro-nanostructures can influence surface wettability, while introducing low surface energy substances, functional organic coatings, or nanoparticles can further stabilize the Cassie–Baxter state, enhancing the surface hydrophobicity or superhydrophobicity. Conradi et al. [

86] observed that laser-textured substrates initially displayed superhydrophilic traits, with a contact angle nearing 0°. However, after 6 months, the surface gradually transformed into a superhydrophobic state, with a contact angle of about 150°. This change was related to organic substances adsorbed on the surface, and XPS analysis showed an increase in non-polar carbon groups (C–C/C–H) and a decrease in metal oxides. When an epoxy coating was applied to the textured surface, it exhibited moderate hydrophobicity, with a contact angle ranging from 97.5° to 118.4°, and maintained good stability under long-term storage conditions with no significant changes. When the coating was replaced with a FAS-TiO

2/epoxy coating, superhydrophobicity was achieved, with a contact angle ranging from 143.4° to 156.3°, and after long-term storage for 1 year, the contact angle showed almost no change, indicating extremely high stability.

Samanta et al. [

87] introduced functional groups such as fluorinated (-CF

2- and -CF

3-), polar cyanide (-C≡N-), and sodium carboxyl (-COONa) to laser-fabricated micro-grooves, featuring a periodicity of around 250 μm and a width of approximately 100 μm. The fluorinated groups (-CF

2- and -CF

3-) have lower surface energy, which reduces surface energy and enhances superhydrophobic and superoleophobic properties. The polar cyanide groups (-C≡N-) attract water due to their strong polarity, enhancing surface hydrophilicity, while sodium carboxyl groups (-COONa) form hydrogen bonds with water molecules, further improving surface hydrophilicity and enhancing superoleophobicity. Through surface chemical treatment, superoleophobicity and superhydrophilicity were achieved simultaneously, effectively repelling oil while attracting water. Contact angle measurements revealed that the treated surface exhibited a contact angle exceeding 150°, with the droplet’s rolling angle kept minimal, showcasing exceptional liquid-repelling properties.

Furthermore, some studies have focused on the influence of graphene films on surface wettability. Yilbas et al. [

88] used laser gas-assisted texturing technology in a high-pressure nitrogen environment to fabricate micro-nanostructured pillar arrays on aluminum oxide surfaces and graphene oxide, generating aluminum nitride (AlN) in the process. The microstructures preserved droplet suspension under the Cassie–Baxter regime, drastically minimizing the solid-liquid interaction area, with air retained within the microstructural voids. Nitrogen treatment lowered the surface energy to approximately 38.3 mJ/m

2, and, in conjunction with the micro-nanostructures, rendered the surface superhydrophobic, with a contact angle reaching 155°. The introduction of the graphene film effectively improved the surface’s friction and wear resistance. However, the elevated energy level of graphene’s surface (63.8 mJ/m

2) caused the contact angle to drop noticeably to 75–85°, altering the surface characteristics from superhydrophobic to hydrophilic. This demonstrates that the introduced components must be coordinated with the original surface characteristics to avoid altering the inherent superhydrophobicity, especially when balancing wettability and friction performance for optimizing surface properties in practical applications.

4. Anti-Icing, Anti-Fouling, and Anti-Corrosion Properties

Improving properties like icing prevention, freezing resistance, fouling mitigation, and corrosion protection, along with other integrated functionalities of aluminum alloy surfaces, is key to their extensive use in aerospace, transportation, construction, electronics, and more. Through laser surface texturing technology, the micro-nano structures of the surface can be effectively improved, thereby endowing it with multifunctional characteristics. This chapter explores related research on anti-icing and anti-freezing, as well as anti-fouling and anti-corrosion properties.

4.1. Anti-Icing and Anti-Freezing Properties

Ice formation poses challenges in many engineering fields. For example, ice accumulation on aerospace vehicle surfaces can lead to degraded aerodynamic performance, ice buildup on offshore wind turbine blades can cause reduced energy efficiency and blade damage, and icing on power transmission lines can result in line breaks and power outages. Thus, creating aluminum alloy surfaces with reduced ice adhesion or ice-repellent characteristics has emerged as a critical area of study.

4.1.1. Mechanisms of Anti-Icing and Anti-Freezing

Anti-icing and anti-freezing refer to the ability of a material’s surface to prevent ice-layer formation or slow down ice-layer growth in low-temperature environments. The icing process on solid surfaces involves two stages: nucleation and growth. The nucleation stage is the initial formation of ice crystals on the surface, while the growth stage involves the gradual enlargement of these ice crystals. The nucleation stage is influenced by surface roughness, surface energy, and chemical properties. Rough surfaces provide more nucleation sites for ice crystals, thereby promoting ice formation, whereas smooth surfaces lack sufficient nucleation sites, making ice crystal formation more difficult. Materials with high surface energy are more prone to adsorbing water molecules, promoting ice nucleation. Conversely, low surface energy materials limit interaction with water molecules, effectively hindering ice crystal development.

4.1.2. Research on Anti-Icing, Anti-Fouling, and Anti-Corrosion Properties

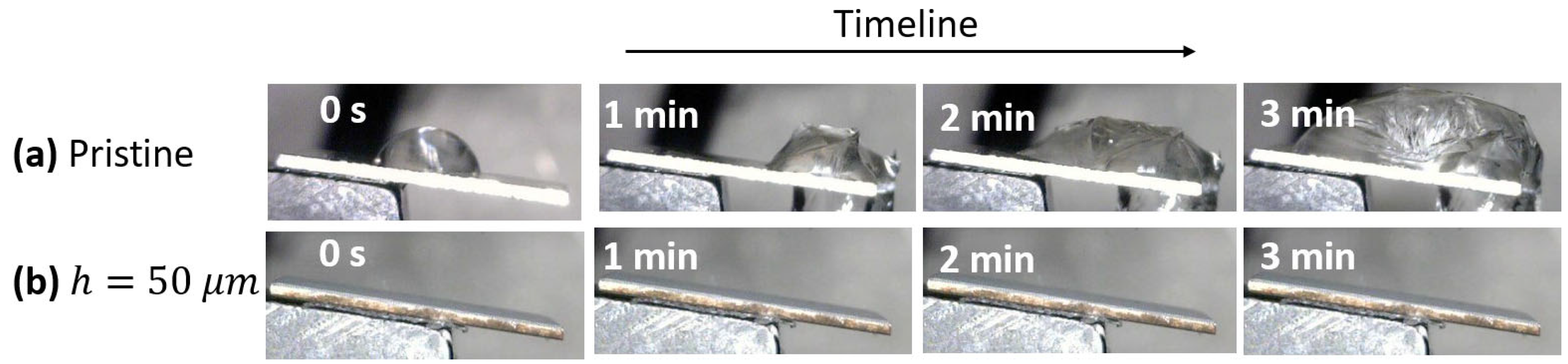

Laser texturing forms hierarchical micro-nano patterns on the substrate, creating an air-trapping interface that prevents direct contact between the surface and water droplets. On these surfaces, the effective contact area with the solid is minimized, significantly reducing ice adhesion. Hydrophobic and superhydrophobic surfaces encourage water droplets to roll off before freezing, shortening their contact duration and delaying the icing process. Surface roughness, chemical properties, and surface energy play crucial roles in ice nucleation and expansion. For example, Volpe et al. [

89] utilized femtosecond lasers to texture an aluminum alloy surface with a micro-grid structure 8 μm deep, as shown in

Figure 5. At −20 °C, the textured surface maintained good water repellency, with water droplets rapidly rebounding without forming strong adhesion to the surface. In contrast, untreated surfaces allowed water droplets to remain and spread, eventually freezing to form an ice layer.

Figure 7 shows a comparison of anti-icing performance between the textured and untreated surfaces at −20 °C. Within 3 min, ice fully covered the untreated surface, whereas the textured surface stayed free of ice.

In thermal cycling tests, water droplets were frozen to −20 °C and then heated to room temperature. The textured surface was able to restore its original superhydrophobicity, with water droplets returning to their initial shape and contact angle. In comparison, untreated surfaces accumulated ice layers during this process, resulting in complete wetting by water. During dynamic anti-icing tests, water droplets were added at a rate of 2 drops per second onto the substrate, and the samples were tested at −20 °C. Within 3 min, water droplets on the textured surface did not freeze, whereas untreated surfaces quickly accumulated ice layers.

Xing et al. [

49] employed three-level grid textures at the micron and nano scales, with each micro-grid texture ranging from 20 μm to 80 μm in width and forming cauliflower-like nano protrusions at the top and surrounding areas, spaced 5 to 10 μm apart. Multi-level micro-nano structures formed a trapped air interface, preventing direct contact between the surface and water droplets. On such surfaces, the effective contact area with the solid decreased significantly, reducing ice adhesion and weakening electrostatic and van der Waals forces. In studies on anti-freezing performance, untreated original surfaces began to freeze water droplets at −16 °C with a freezing time of 2879 s, while laser-treated surfaces extended the freezing time to 4015 s and lowered the freezing temperature to −23 °C, which is 6 °C lower than the original surface. Thermodynamic analysis showed that multi-layer micro-nano structures reduced thermal contact with the droplet, decreased heat transfer, and slowed its cooling rate, delaying freezing. These results demonstrate that optimizing surface structures can significantly enhance anti-freezing performance.

Future research should focus on improving the durability and environmental adaptability of these anti-icing surfaces to ensure they maintain excellent anti-icing performance under repeated freeze-thaw cycles, high wind speeds, high salt spray, and ultraviolet radiation conditions. Additionally, achieving large-scale industrial processing and cost control will be important topics for the practical application of anti-icing technologies.

4.2. Anti-Fouling and Anti-Corrosion Properties

Aluminum alloy surfaces used in extreme environments not only need to possess controllable wettability and anti-icing characteristics but also must maintain stable performance under complex conditions such as chemical corrosion, marine biofouling, and mechanical loads. By constructing multi-scale structures through laser texturing and combining them with appropriate post-treatment processes, corrosion and fouling resistance can be enhanced, ensuring the long-term serviceability of the material.

4.2.1. Mechanisms for Enhancing Anti-Fouling and Anti-Corrosion

Aluminum alloys are susceptible to corrosion in humid, salt spray, and acidic or alkaline environments. Surface texturing can effectively alter the diffusion and infiltration behavior of corrosive media (such as Cl− ions and corrosive solutions) on the surface. Constructing micro-nano structures and applying proper post-treatments can create a stable and dense “barrier layer”, effectively reducing electrochemical reaction rates. Laser texturing introduces residual stresses and phase distributions that delay corrosion crack initiation and propagation.

In marine environments, biofouling (such as algae, shellfish, and biofilm formation) can degrade material performance and increase maintenance costs. By creating specific micro-nano textures on aluminum alloy surfaces, the number of bio-adhesion points can be reduced, and the firm attachment of microorganisms to the surface can be weakened, achieving anti-fouling effects. When micro-nano structures are combined with hydrophobic surface chemistry, the surface free energy is further reduced, making biofouling more difficult and providing long-term protection for marine equipment.

4.2.2. Related Research

The micro-nano structures formed by laser texturing on material surfaces can effectively reduce the accumulation of corrosive media on the surface, improve electrode reaction kinetics, and slow down the corrosion process. Torres et al. [

90] demonstrated that laser-textured treatments could make the oxide layer on the substrate surface more uniform and stable. In electrochemical impedance spectroscopy (EIS) tests, the corrosion mechanism of textured samples remained stable, whereas the corrosion mechanism of untreated samples became unstable over time. Although the initial corrosion rate of textured samples was higher, their corrosion mechanisms were more stable, and after long-term immersion, they exhibited stronger corrosion resistance compared to untreated samples.

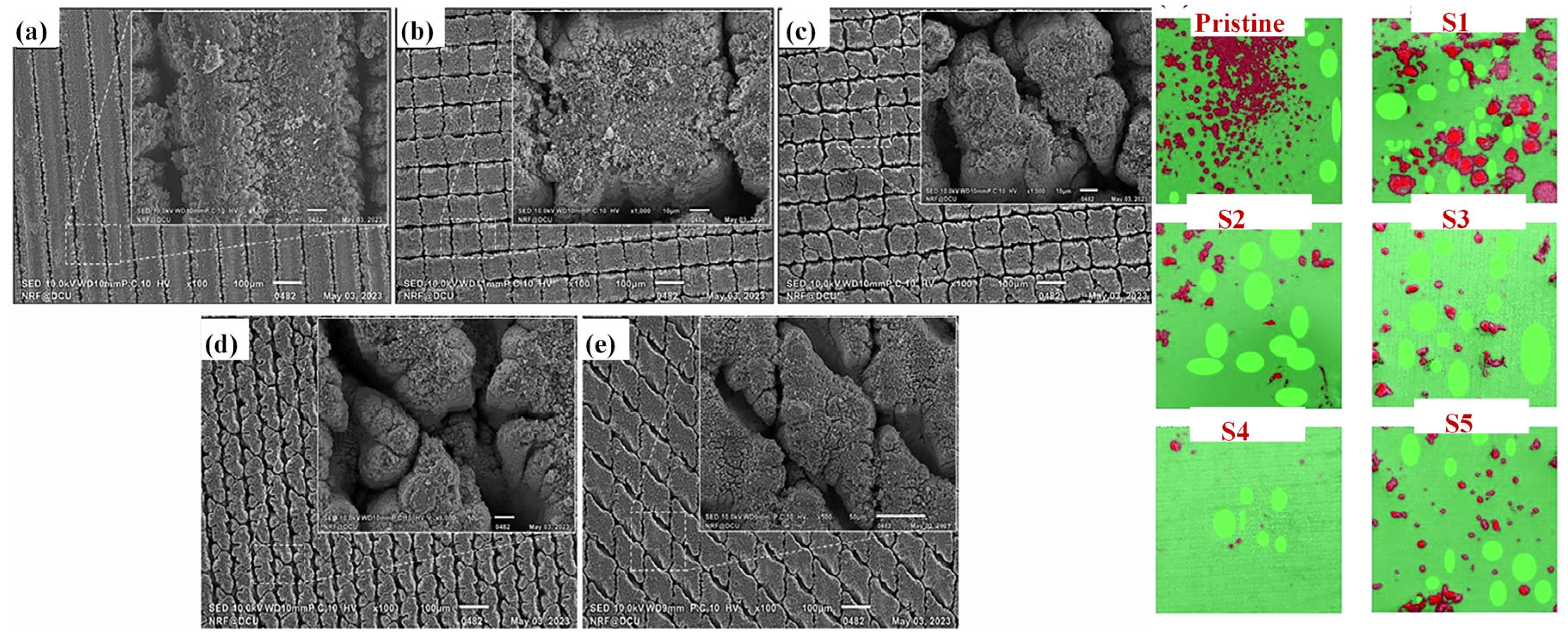

By constructing microstructure arrays and further reducing surface energy, the anti-fouling and anti-corrosion performance of materials can be enhanced. Cholkar et al. [

13] prepared five texture patterns: parallel lines (

Figure 8a), cross lines (

Figure 8b), triangles (

Figure 8c), stars (

Figure 8d), and diamonds (

Figure 8e). The parallel line pattern (S1) formed uniform lines with a relatively flat surface; the cross line pattern (S2) increased surface roughness and significantly enlarged the surface area; the triangle pattern (S3) exhibited sharp triangular structures that could affect liquid and material interactions; the star pattern (S4) featured strong periodicity and symmetry with complex structures; and the diamond pattern (S5) displayed regular geometric patterns with sharp edges. The star-shaped texture exhibited the highest surface roughness parameters (Sa = 37.4 μm, Sp = 13.45 μm), providing more effective anti-adhesion points.

Adhesion test results of the algae Nitzschia ovalis are illustrated in

Figure 8. The untreated sample had a marine microalgae coverage rate of 21.6%, S2 exhibited a biofilm coverage rate of 10.30%, and S4 only had 4.63%. Comparing various structures, it was found that larger grooves in surface textures allowed algae to easily adhere within these grooves, whereas smaller textures restricted algae to remain only on the surface with weaker adhesion. The star-shaped textured surface, due to its low surface energy, made it difficult for algae to adhere.

Corrosion tests revealed an open circuit potential (OCP) of −723 mV for untreated samples, with a corrosion potential (Ecorr) of −711 mV and a current density (Icorr) of 5.22 μA/cm2. In contrast, samples with star-shaped laser-textured surfaces had an OCP of −772 mV, an Ecorr of −763 mV, and an Icorr of 5.33 μA/cm2, indicating an approximate 25% improvement in corrosion performance.

After laser texturing, the pit-like textures formed on the aluminum alloy surface significantly affected its corrosion behavior. Misyura et al. [

91] found that when laser-textured aluminum alloys were exposed to corrosive solutions, the corrosion process changed noticeably over time. In the initial stage of corrosion, the oxide film began to dissolve, and the corrosion rate was relatively slow, mainly because the protective effect of the oxide film gradually weakened, exposing the metal surface to the solution. However, due to the relatively flat surface texture and fewer new corrosion points, the corrosion reaction remained in its initial stage.

Over time, new corrosion points became active, strongly influenced by the surface texture’s microstructure. The pit-like textures created by laser texturing formed tiny pits and cracks, which acted as “concentration points” for corrosion, providing more active areas for corrosion reactions. Consequently, as corrosion continued, the corrosion area expanded continuously, and the corrosion rate gradually accelerated.

Furthermore, during the droplet evaporation process, the formation of bubbles accelerated the corrosion process, especially where droplets contacted the surface. As water evaporates beneath corrosive droplets, the solution becomes saturated, concentrating salts and accelerating the corrosion reaction. In the textured areas, these pits and cracks caused changes in the droplet contact angle, altering the surface tension and concentration gradients in the droplet-surface contact area, thereby enhancing the dissolution and corrosion effects of the solution.

These processes indicate that laser-textured surfaces exhibit significantly different performance in corrosive solutions compared to untreated surfaces. The presence of surface textures not only provides more active areas for corrosion reactions but also alters the removal process of corrosion products. Tiny surface defects promote the removal of corrosion products via convection, dissolution, and diffusion, accelerating the corrosion reaction. These changes result in different corrosion kinetics compared to untreated surfaces, with noticeably faster corrosion rates and expansion of corrosion areas.

Combining oil film injection technology can effectively enhance the anti-corrosion ability of aluminum alloy surfaces, especially under continuous droplet impact conditions. Qin et al. [

92] combined oil film injection technology with laser texturing to treat aluminum alloy surfaces. The untreated aluminum alloy in a 3.5 wt% NaCl solution exhibited a corrosion current density of 10

−7 A·cm

2 and a corrosion potential of −733 mV. Laser texturing reduced the corrosion current density to 10

−10 A·cm

2 and raised the corrosion potential to −550 mV. Coating the textured surface with SiO

2 nanoparticles and a PFPE oil film decreased the corrosion current density to 10

−11 A·cm

2 and the corrosion potential to −600 mV, significantly enhancing corrosion resistance compared to untreated aluminum alloy. After 15 h of droplet impact, the water contact angle on the oil-treated surface rose slightly from 112° to 128°, while the untreated surface’s contact angle increased significantly from 106° to 143°, suggesting the oil film on the untreated surface was less durable. After 30 h of droplet impact, the oil film on the textured surface remained well-preserved, with the water contact angle stabilized around 130°, while the untreated surface’s contact angle slightly decreased to 136°, showing weaker oil film retention. In terms of corrosion morphology, after 15 h of droplet impact, the textured and oil-treated surfaces maintained an intact oil film, demonstrating better anti-corrosion properties, whereas the untreated surfaces exhibited oil film detachment and corrosion phenomena. These results indicate that the oil film can be retained through the micro-pits of the textured surface, thereby enhancing the anti-corrosion performance of aluminum alloy surfaces, especially under continuous droplet impact conditions.

5. Properties of Friction and Wear

Friction and wear critically influence material lifespan and energy efficiency. In mechanical systems like transmissions, bearings, and seals, reducing friction and wear is vital for enhancing energy efficiency, prolonging service life, and reducing maintenance costs. Micro-nano structures constructed using laser texturing can adjust the load distribution, lubrication film formation, and debris ejection on the contact surfaces, thereby imparting friction-reducing and wear-resistant characteristics to the surface.

5.1. Research on Tribology Related to Surface Texturing

Introducing regularly or periodically distributed micro-pits, micro-grooves, ripples, or nano-scale textures on material surfaces is a method to enhance the tribological performance of friction pairs. Microstructures like oil reservoirs and lubrication micro-pools help maintain or regenerate the lubrication film at the interface, lowering friction and contact temperature to improve tribological performance. Hamilton et al. [

93] were among the first to propose that appropriate micro-patterning can enhance friction performance and reduce wear by generating a hydrodynamic lubrication effect. During motion, lubricant flow through micro-pits generates pressure variations that boost the lubrication film’s load-bearing capacity, reducing friction and wear. Subsequent studies by Etsion et al. [

94] further validated this mechanism, confirming the positive impact of pressure variations at the micro-pit edges on the lubrication film’s load-bearing capacity.

Zhang et al. [

95] investigated a dual surface modification strategy combining biomimetic texturing and TiN coating to enhance the wear resistance of 20 Mn cast steel. In this study, microstructures mimicking the morphology of pangolin scales were first fabricated on the substrate surface using laser surface processing. Subsequently, a TiN coating was deposited on the surface via physical vapor deposition. The biomimetic texture effectively reduced the frictional contact area, dispersed frictional stress, and captured wear debris generated during the wear process, thereby suppressing local stress concentration and mitigating three-body wear. The TiN coating provided a hard and dense protective layer on the material surface, further enhancing scratch resistance and overall wear performance. Experimental results showed that the application of biomimetic texture alone reduced the friction coefficient by approximately 20%, while the TiN coating alone resulted in a reduction of about 30.9%. When both modifications were applied together, the friction coefficient decreased by 38.09%. The synergistic effect of biomimetic texturing and TiN coating significantly enhanced the wear resistance and service stability of 20 Mn cast steel under dry friction conditions.

Research highlights the link between surface texture geometry and friction performance, as studied by Andiry [

96], Andersson [

97], and Rahmani et al. [

98] found that geometric features like depth, area ratio, and shape significantly influence lubrication. For example, micro-pits with optimal dimensions can improve the lubrication film’s load-bearing capacity and lower friction. For instance, micro-pits with appropriate depth and shape can enhance the load-bearing capacity of the lubrication film and reduce the friction coefficient. Additionally, Fowell [

99] and Mourier al. [

100] demonstrated that optimized surface textures markedly improve tribological performance under high-viscosity lubricants, heavy loads, and high speeds.

Under different operating conditions, it is necessary to optimize surface texture design. Studies by Andersson [

97], Segu [

101], and Nacer al. [

102] indicated that optimized surface textures can significantly enhance tribological performance under conditions of high-viscosity lubricants, heavy loads, and high speeds. For example, Andersson al. [

97] noted that surface arrangements with deep pits, low density, and small openings perform particularly well with high-viscosity lubricants. Furthermore, Fatu’s research [

103] demonstrated the effectiveness of surface texturing in reducing power loss in sliding bearings, supporting the idea that texturing can improve load-bearing capacity and lower friction. Numerical simulations on surface texturing and lubrication friction continue to be an active area of research. Cupillard, Mourier [

100], and Fatu et al. [

101] examined the effects of surface textures in elastic flow lubrication and sliding bearings. Rahmani [

98] and Joshi et al. [

102] explored the roles of different shapes and types of textures in the tribological performance of bearings, providing a solid theoretical and experimental foundation for texture design. Researchers like Segu [

103], Nacer [

104], and Joshi et al. [

105] have demonstrated that surface texturing can notably enhance friction performance in conditions involving non-conformal point contact, dry friction, or heavy loads.

Clearly, surface texturing plays a significant role in enhancing tribological performance. Currently, there are numerous methods for fabricating microstructures, among which laser texturing technology is important in the field of surface wear resistance. Laser texturing enhances surface hardness under high temperatures and pressure, leading to improved tribological performance of friction pairs.

5.2. Research on Laser Surface Texturing Under Dry Friction Conditions

Surface texturing operates based on different friction-reduction mechanisms under various lubrication states. In dry friction conditions, the two surfaces of the friction pair are in direct contact with each other. Surface textures can capture and store wear debris, preventing its accumulation between the contact surfaces and thus reducing wear caused by debris buildup. Additionally, textures reduce the actual contact area, enhancing friction reduction and wear resistance. Li et al. [

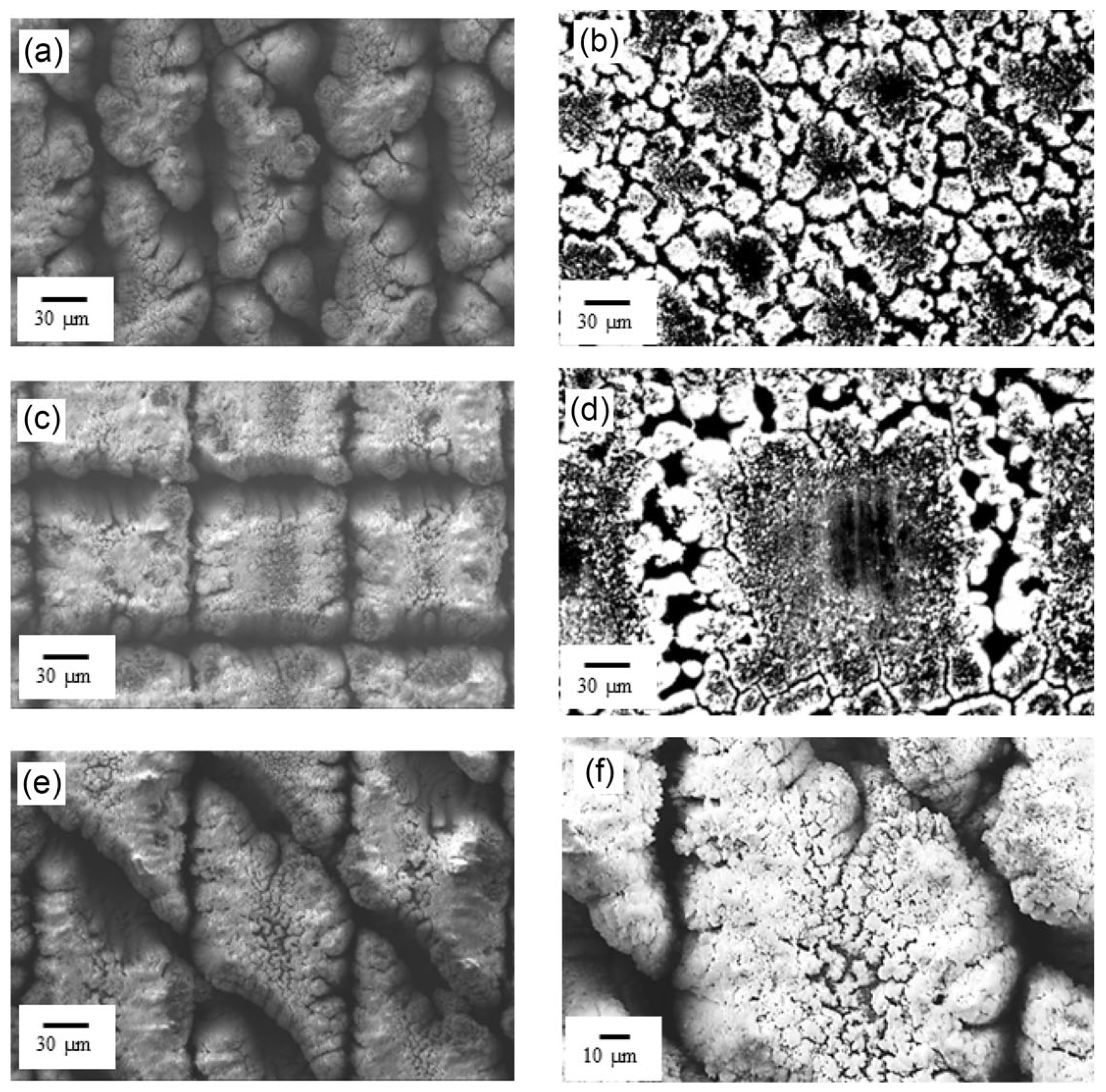

61] used femtosecond lasers to create triangular, as well as square, micro-pit textures on 7075 aluminum alloy and analyzed their influence on friction performance.

Figure 9a shows the worn surface of an untreated sample, featuring severe surface wear, rough morphology, distinct signs of wear, and damage. The worn region appears uniform and pronounced, lacking effective wear suppression.

Figure 9b shows the worn surface of a sample with triangular micro-pits, where the wear morphology is distinctly damaged, especially with significant grooves formed at the edges of the pits. Although it can provide some wear debris collection, the sharp shape leads to stress concentration, exacerbating wear.

Figure 9c displays the wear condition of a sample with square micro-pits, which shows slightly lighter wear but some damage at the pit edges.

Figure 9d shows the worn surface of a sample with circular micro-pits, where wear is minimal, and the morphology is well-preserved. This texture shape effectively reduces stress concentration by uniformly distributing stress, thereby minimizing wear. In terms of the friction coefficient, the circular textured sample exhibits the lowest and most stable COF, with the average COF reduction ranging from 46.41% to 81.92% and an average reduction of 61.84%. Additionally, textured samples exhibit lower wear rates compared to untextured ones, with circular textures showing a 60.30% reduction. Moreover, as the texture spacing increases, the wear rate rises slightly, primarily because larger spacing reduces the number of pits per unit area, affecting the lubricant retention capacity and debris accommodation, leading to insufficient lubrication.

In terms of post-processing surface texturing, research has been conducted on laser hardening. Cholkar et al. [

45] fabricated three different laser texture patterns—star-shaped, cross-textured, and diamond-shaped—and then subjected them to laser hardening treatment, as shown in

Figure 10. After laser hardening, the star-shaped texture exhibited the best wear resistance, with a significantly reduced friction coefficient and a substantial decrease in wear volume. Although the star-shaped texture had higher roughness, forming a hardened layer reduced the contact area and effectively enhanced wear resistance. Relative to untreated samples, the friction coefficient of laser-hardened star-shaped textures decreased by about 83%. The cross-textured samples showed moderate wear resistance after laser hardening, with improvements in friction coefficient and wear volume, but the enhancement was relatively small. In contrast, the diamond-shaped texture had the poorest wear resistance. Although the diamond texture had a more uniform surface structure, the friction coefficient did not significantly decrease, and the reduction in wear volume was not as pronounced as with the star and cross textures. Overall, laser hardening of star-shaped textures was the most effective in improving wear resistance.

5.3. Research on Laser Surface Texturing Under Lubricated Conditions

Under lubricated conditions, especially in fluid lubrication states, surface textures reduce wear through a hydrodynamic lubrication mechanism. In this state, the lubrication film’s thickness exceeds the friction pair’s roughness, keeping the solid surfaces separated by lubrication and preventing direct contact. This leads to reduced drag and minimal wear.

The hydrodynamic lubrication effect is the reason for the friction reduction provided by surface texturing. Tiny protrusions on the surface can generate additional fluid pressure between the friction pair surfaces. On one side of the protrusion, a converging wedge is formed, generating fluid pressure, while on the other side, a diverging wedge is created to limit the negative pressure effect. This structure reduces friction and wear, functioning similarly to miniature lubricated bearings by separating the friction surfaces with fluid pressure and lowering the friction coefficient. Optimizing surface structure enhances the oil film’s load-bearing ability, further minimizing friction.

Scaraggi et al. [

105] fabricated micro-pit and micro-groove textures on an aluminum alloy substrate using laser processing. In lubricated environments, the effectiveness of pit-shaped textures in reducing friction was markedly higher than that of groove-based designs. Segu et al. [

106] created multi-scale surface microtextures combining circular and elliptical shapes and analyzed their tribological performance under lubricated conditions using pin-disc friction and wear tests. They concluded that a texture density of 12% achieved optimal tribological performance. With increasing pit depth and sliding velocity, the frictional performance and durability of multi-scale textures showed notable enhancement. Hu et al. [

107] fabricated arrayed hole microstructures with varying densities on 2024 aluminum alloy, featuring 40 μm diameters. By examining hole-structured surfaces under varying pressures and lubricant viscosities, they observed that under 2.5 MPa pressure, smooth surfaces demonstrated superior low-speed friction characteristics. With increasing speed, coefficients of textured surfaces progressively outperformed those of smooth surfaces. At an applied pressure of 12 MPa, the microstructured surfaces consistently maintained lower friction coefficients, and changes in lubricant viscosity did not affect these results.

Kovalchenko et al. [

96] employed pin-disc tests to analyze how laser-textured surfaces influenced lubrication transitions during one-directional motion. Laser-textured surfaces broadened the scope of hydrodynamic lubrication states, spanning loads and speeds. Compared to rough untextured surfaces, microtextures reduced drag and minimized friction within boundary-lubricated states.

Beyond surface structure, material durability is further shaped by factors like lubricant characteristics, applied load, speed, and temperature. Hu et al. [

107] fabricated micro-pits with different densities (8.5%, 17%, and 35%) on the surface of 2024 aluminum alloy and tested their friction behavior under varying loads and sliding speeds using two different viscosity lubricants, PAO4 and PAO40.

Under high load and high sliding speed conditions, textured surfaces exhibited lower friction coefficients. At low loads, surfaces with an 8.5% texture density and low-viscosity lubricant exhibited minimal friction values. Under high loads, surfaces with an 8.5% texture density combined with high-viscosity oil PAO40 demonstrated the best friction performance. At low loads, surfaces with an 8.5% texture density and low-viscosity lubricant exhibited minimal friction values. Wear tests indicated that untextured surfaces underwent severe plastic deformation, while textured ones sustained lighter damage, preserved pit morphology, captured wear debris, and reduced damage to friction pairs. Laser micro-texturing stabilizes oil films by offering lubricant storage, reducing friction, and prolonging surface life, especially under high-viscosity oil and heavy-load scenarios.

Under certain oil temperature conditions, microtextured surfaces have better lubricant film retention capabilities. Janssen et al. [

108] tested the friction performance of aluminum-steel contact systems with different oil temperatures of 30 degrees Celsius and 90 degrees Celsius. The laser microstructure designs included diameters of 25 micrometers, 50 micrometers, and 100 micrometers, depths ranging from 2.5 micrometers to 40 micrometers, and coverage area ratios of 5%, 10%, and 20%. The experimental results showed that compared to untextured surfaces, laser microstructures significantly reduced the friction coefficient, especially at the higher oil temperature of ninety degrees Celsius. For instance, a structure with a 100 μm diameter, 20 μm depth, and 5% coverage could lower friction levels by as much as 64% at 30 K.

When the oil temperature increased to 90 degrees Celsius, the friction coefficient showed a more pronounced reduction under high-temperature conditions, particularly at high speeds, due to the decreased viscosity of the lubricant, which weakened the oil film’s load-bearing capacity. The study also revealed that small-diameter structures of 25 micrometers could cause micro-turbulence and oil film instability at high speeds, resulting in increased friction coefficients. In contrast, medium-diameter structures of 50 micrometers provided more stable friction behavior, especially at high temperatures, while large-diameter structures of 100 micrometers effectively reduced the friction coefficient at ninety degrees Celsius. At 30 degrees Celsius, large-diameter structures only showed some effectiveness within the medium-high speed range. The research also indicated that increasing the oil temperature significantly reduced the lubricant’s viscosity from 74.5 millimeters per second to 9 and 8 square millimeters per second, directly affecting the oil film thickness and friction behavior. Furthermore, laser microstructures significantly improved friction performance by optimizing the thickness and pressure distribution of the lubrication film. The study demonstrated that using laser surface microstructuring technology could effectively reduce friction losses, thereby enhancing the energy efficiency of internal combustion engines and potentially reducing automotive fuel consumption by approximately six percent.

6. Summary and Outlook

Recently, laser texturing techniques have advanced, improving aluminum alloy surfaces and other metals. This paper systematically reviews the research advancements in laser surface texturing across various domains, including wettability, tribological performance, corrosion resistance, anti-icing capability, and anti-fouling performance. It summarizes the impact of different texturing methods and their optimized parameters on surface microstructures and overall performance. By reviewing existing studies, a more comprehensive understanding of the advantages, limitations, and future development directions of laser texturing technology is achieved.

In the regulation of material surface wettability, laser surface texturing improves wettability by constructing multi-scale micro-nano hierarchical structures. Laser processing parameters and texture design play crucial roles in controlling surface wettability. By precisely designing the geometric shape, scale, and distribution of surface textures, it is possible to achieve reversible transitions between superhydrophobic and superhydrophilic states. The Wenzel–Cassie models explain surface effects on wettability, showing how textures modulate droplet behavior by trapping air or increasing liquid-solid contact. Studies have shown that well-designed surface textures can adjust wettability to meet various application requirements under different environmental conditions.

Regarding anti-icing, well-designed micro/nano-scale patterns significantly lower the interaction area with water droplets, reducing ice adhesion and delaying ice formation. These micro/nano features enhance anti-icing capabilities and reduce ice crystal adhesion under low-temperature conditions, preserving surface functionality. This is particularly valuable for applications in aviation and marine fields.

Regarding anti-fouling and corrosion resistance, laser surface texturing effectively lowers surface energy by constructing micro-nano structures and subsequent chemical modifications, thereby reducing the adhesion of corrosive media and biological fouling. Laser texturing alters the diffusion paths of corrosive agents and the distribution of electrochemical reactions, thereby enhancing the surface’s corrosion resistance. Research indicates that by creating complex microstructures and combining them with coating treatments, the corrosion rate of material surfaces is reduced, and corrosion mechanisms become more stable. For example, star-shaped and cross-linear textured surfaces exhibit remarkable corrosion resistance in salt spray tests and maintain low corrosion current densities even after prolonged immersion. This provides both theoretical and practical support for the application of aluminum alloys in harsh environments.

In frictional behavior, laser-generated textures like pits and grooves improve lubricant film distribution, reduce contact areas, and alleviate stress concentration. This results in minimized friction and significantly reduced wear. Under dry friction conditions, circular micro-pit textures effectively mitigate wear through uniform stress distribution. In lubricated conditions, these microstructures act as “lubrication reservoirs,” storing and redistributing lubricating oil to enhance the stability of the lubrication film. Studies reveal that optimized texture parameters excel in demanding conditions with high loads and speeds, effectively reducing friction and prolonging material life. This demonstrates that laser texturing enhances material properties, extends service life, and boosts suitability for challenging industrial applications.

Despite advancements in laser texturing for aluminum alloys, challenges persist in bridging research and real-world implementations.

Durability and environmental adaptability: Although laboratory studies confirm excellent anti-icing, corrosion resistance, and tribological performance, the long-term performance of laser-textured surfaces in various performance domains remains inadequately investigated. Roadblocks to these investigations primarily include the complexity and cost associated with long-duration testing under realistic operating conditions. Additionally, the inability to replicate exact industrial environments in laboratory settings further complicates obtaining representative long-term data. Addressing these issues requires collaborative efforts to establish standardized, scalable, and economically feasible testing methodologies.

Scalability for industrial applications: Current studies mostly focus on small-area samples. Scaling laser texturing technologies for large-scale industrial surfaces efficiently and cost-effectively remains challenging. Future research should focus on developing automated and high-speed laser processing systems to facilitate broader industrial applications.

Developing multifunctional composite surface structures: Future advancements require combining laser surface texturing with other surface treatment methods, such as plasma electrolytic oxidation, chemical modifications, and nano-coating deposition, to create composite protective layers. Integrating multiple functionalities like anti-corrosion and tribological performance on a single surface significantly enhances material performance under complex operating conditions. Additionally, developing intelligent, responsive textures that dynamically adapt surface properties to environmental changes will cater to diverse application requirements.

Advanced characterization and theoretical modeling: Fully understanding the intrinsic relationships between laser texturing and resultant material performance is crucial. Future research should employ advanced characterization techniques alongside multi-scale theoretical modeling methods such as molecular dynamics simulations and finite element analyses to elucidate structure-performance relationships. Applying machine learning and artificial intelligence to analyze extensive datasets can further identify complex interdependencies between processing parameters and performance outcomes, enabling intelligent and optimized texture designs.