Feasibility of Polyphosphoric Acid in Emulsified Asphalt Modification: Emulsification Characteristics, Rheological Properties, and Modification Mechanism

Abstract

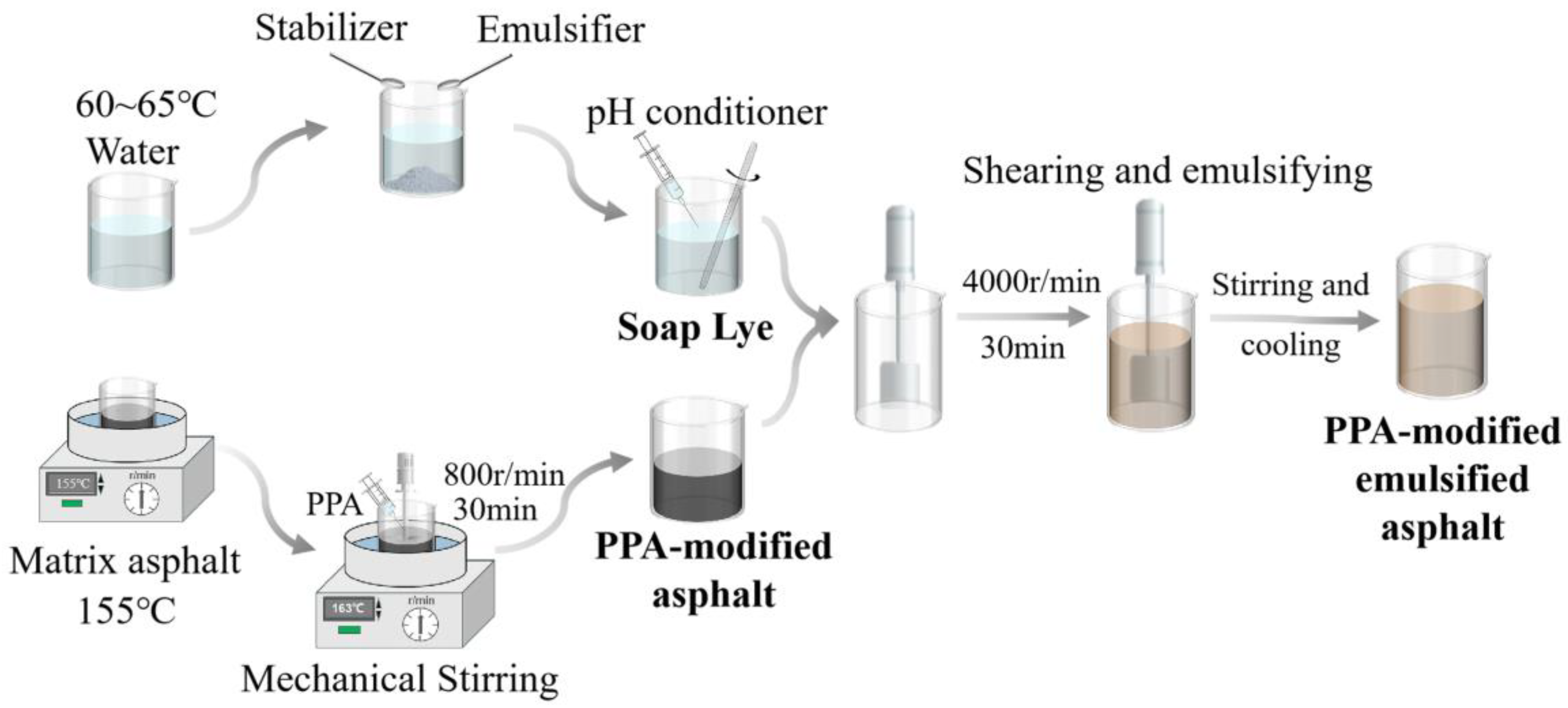

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Matrix Asphalt

2.1.2. PPA

2.1.3. Emulsifier and Other Additives

2.2. Preparation of PPA-Modified Emulsified Asphalt

2.3. Methods

2.3.1. Emulsification Characteristic Test

2.3.2. Dynamic Shear Rheological Test

2.3.3. Fourier Transform Infrared Spectroscopy Test

2.3.4. Fluorescence Microscope Test

3. Results and Discussion

3.1. Emulsification Characteristic Analysis

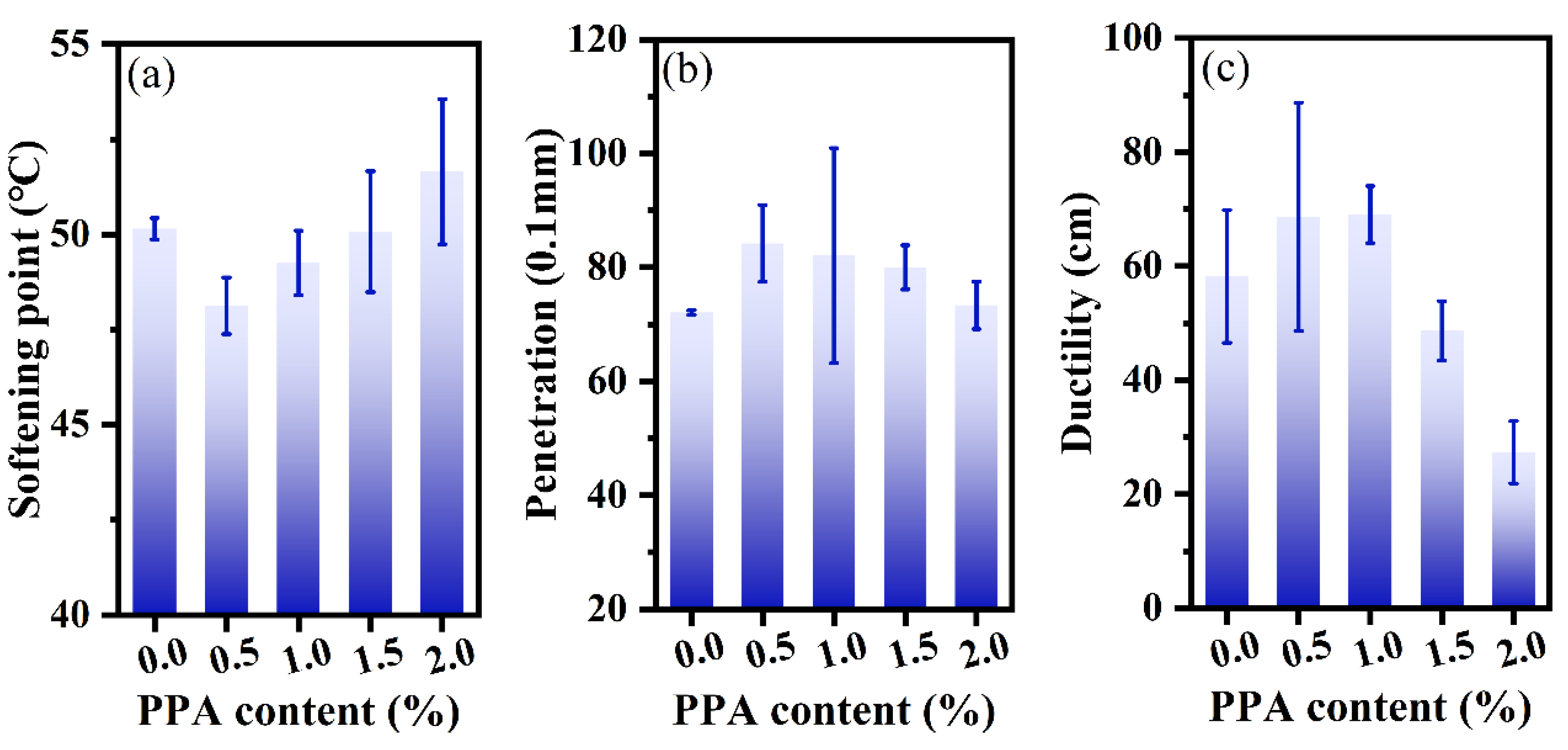

3.1.1. Effect of PPA on the Basic Physical Properties

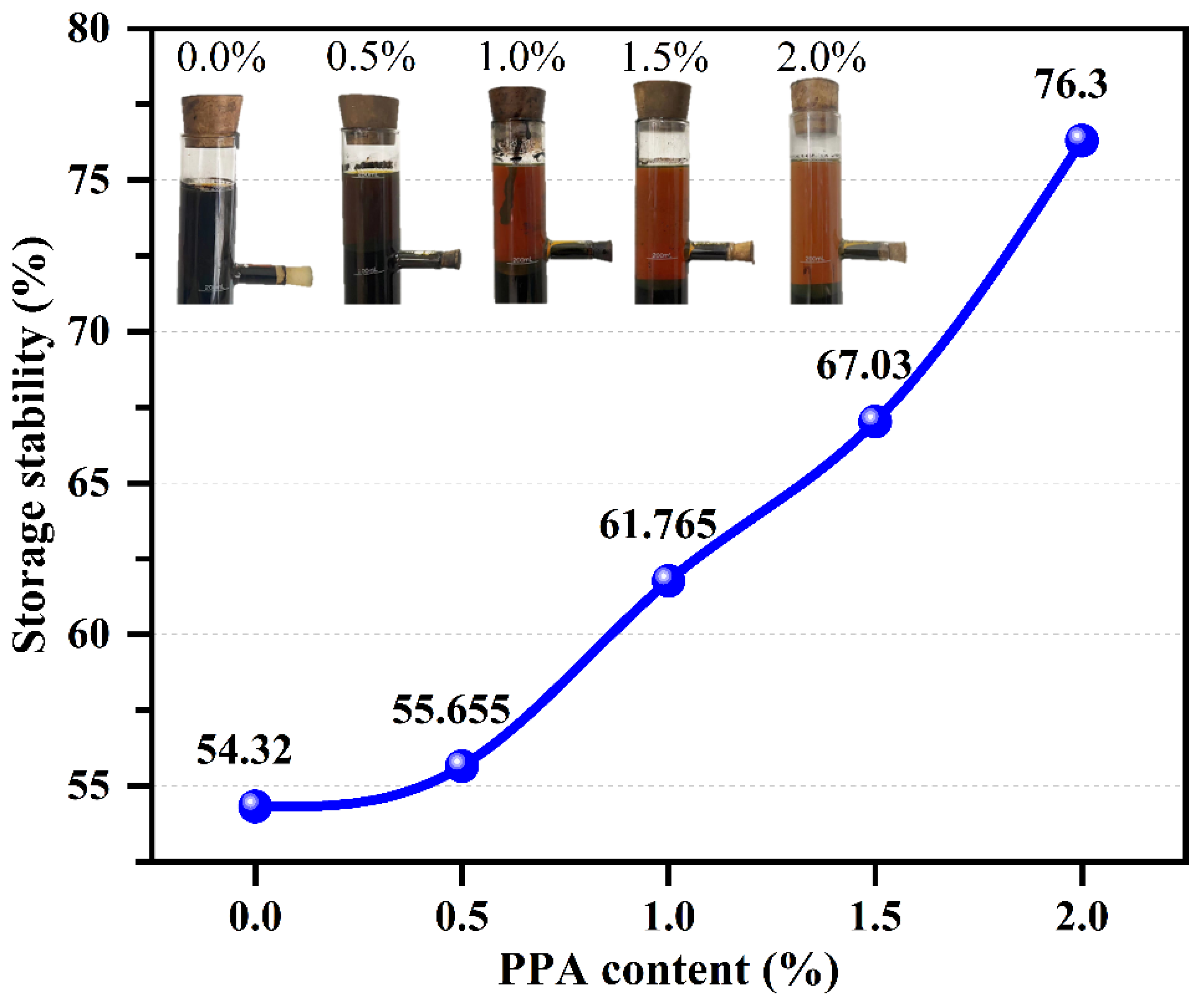

3.1.2. Effect of PPA on the Storage Stability

3.2. Rheological Properties of PPA-Modified Emulsified Asphalt

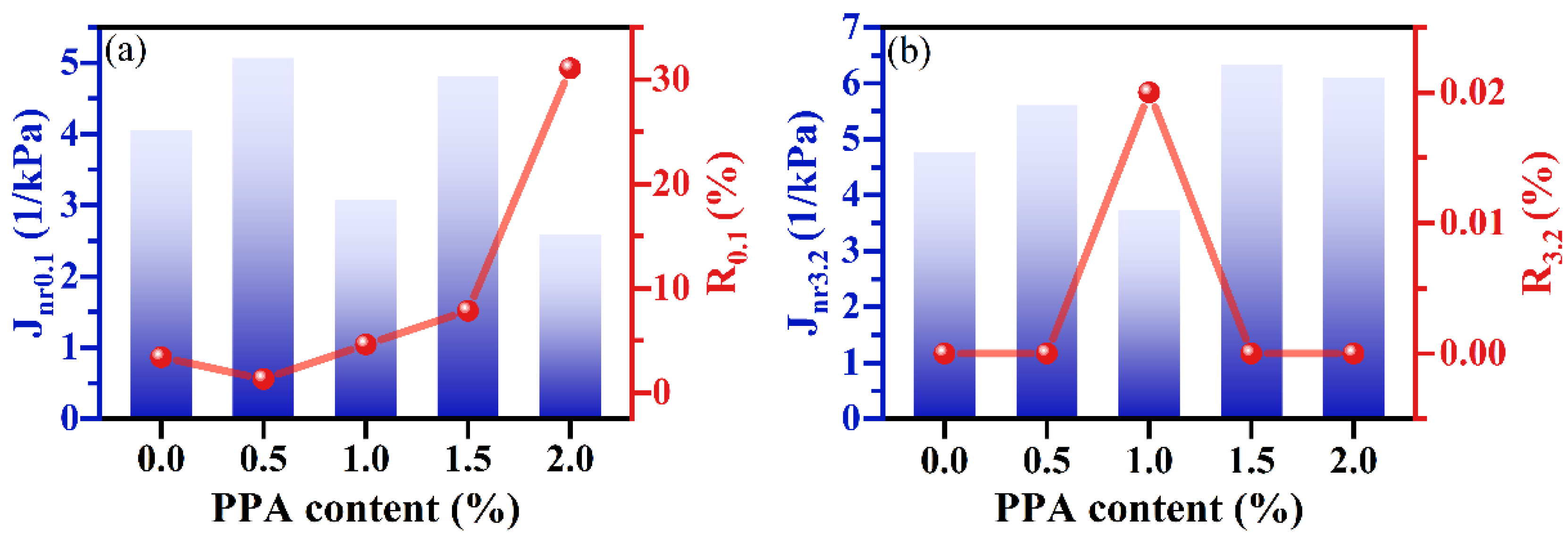

3.2.1. MSCR Analysis

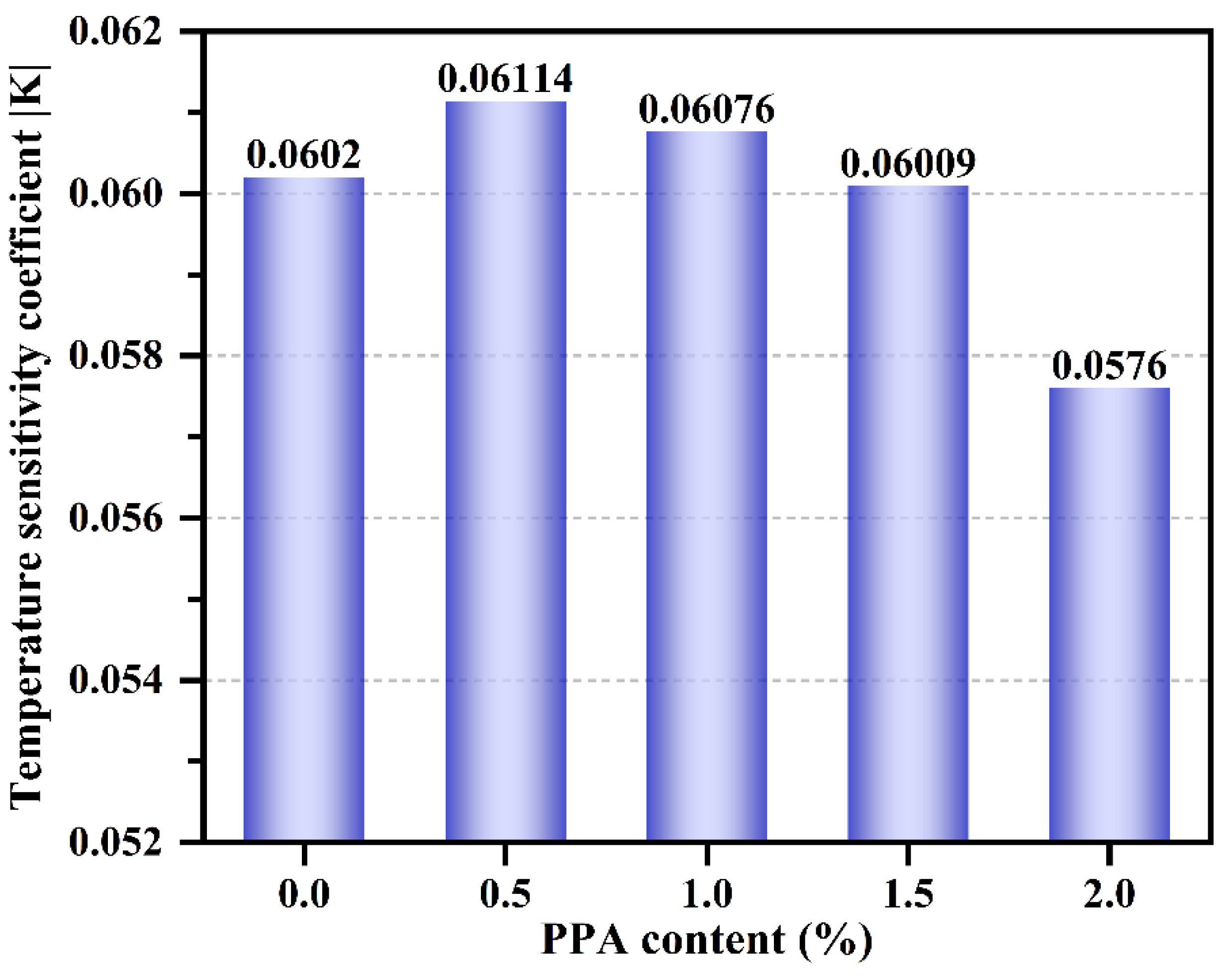

3.2.2. Temperature Sweep Analysis

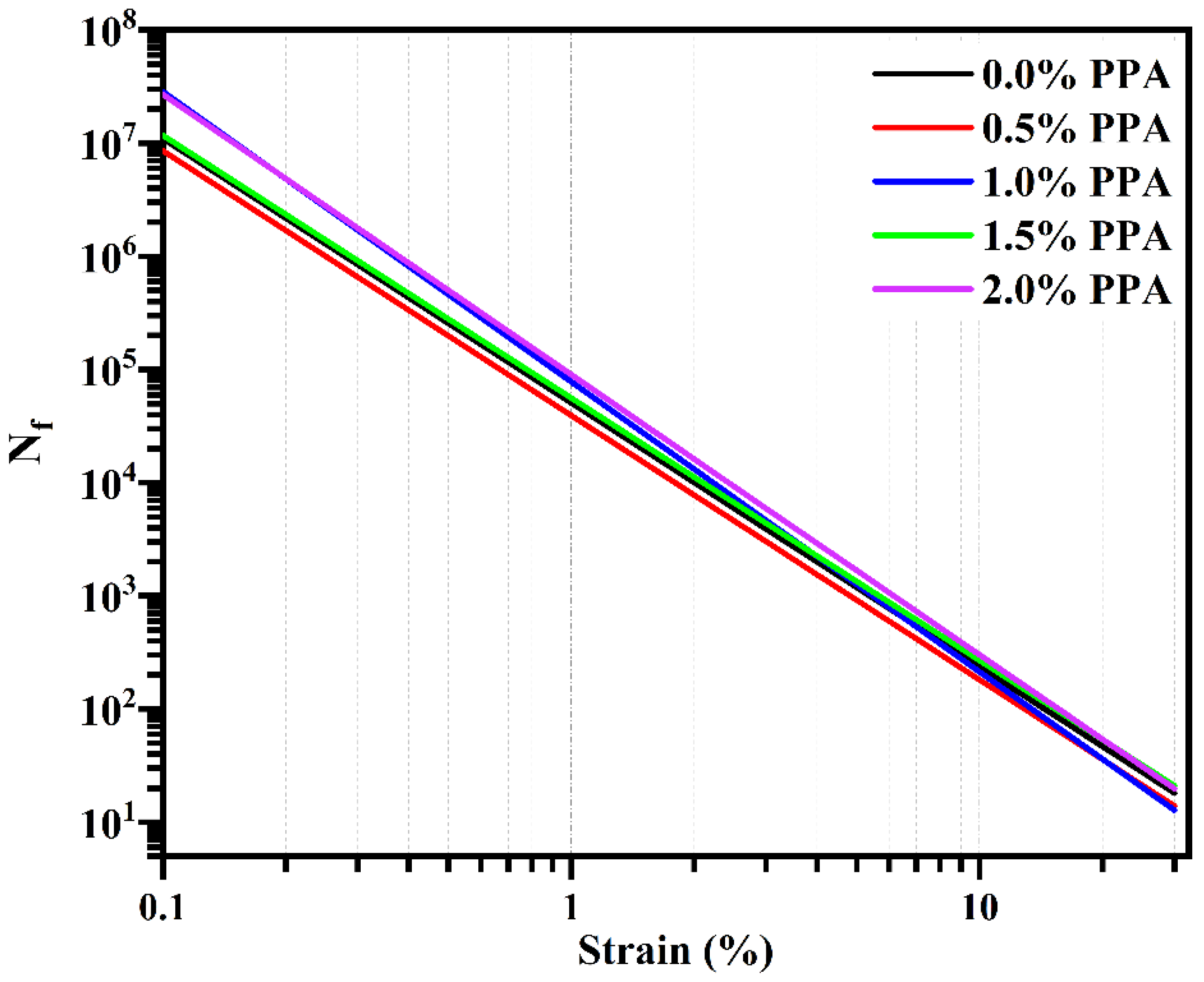

3.2.3. Fatigue Characteristic Analysis

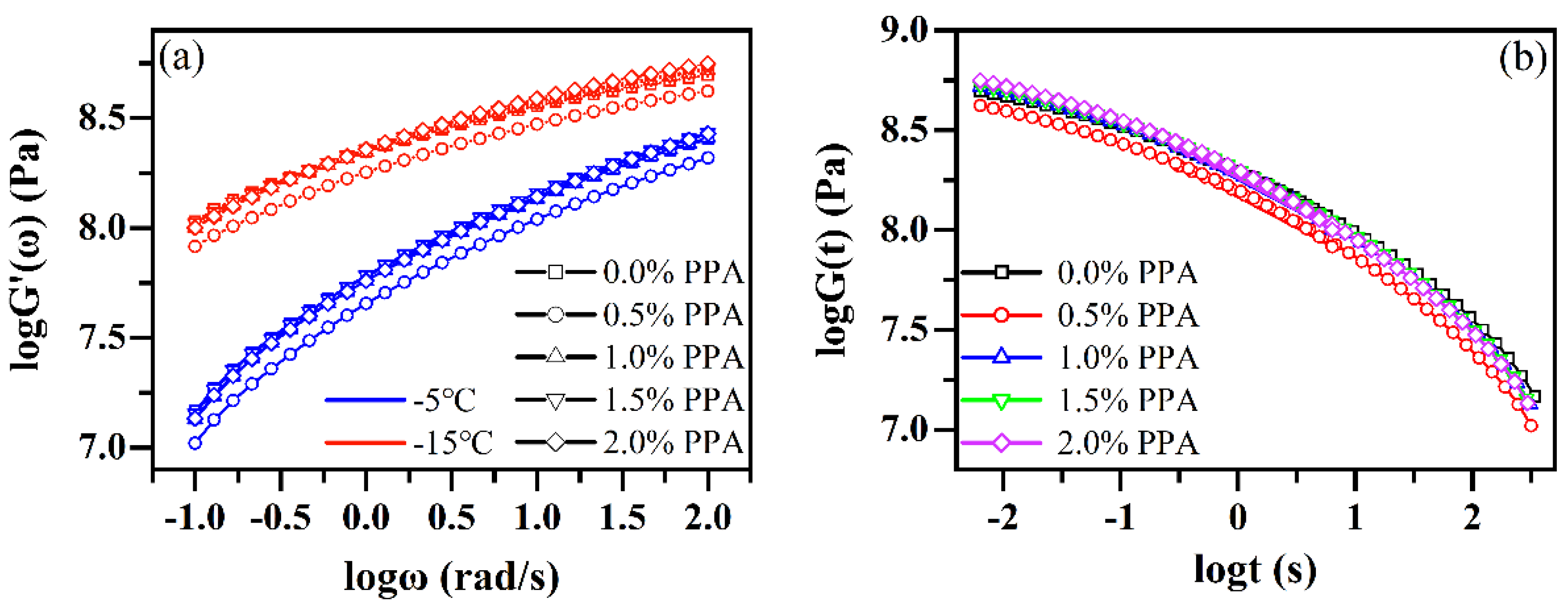

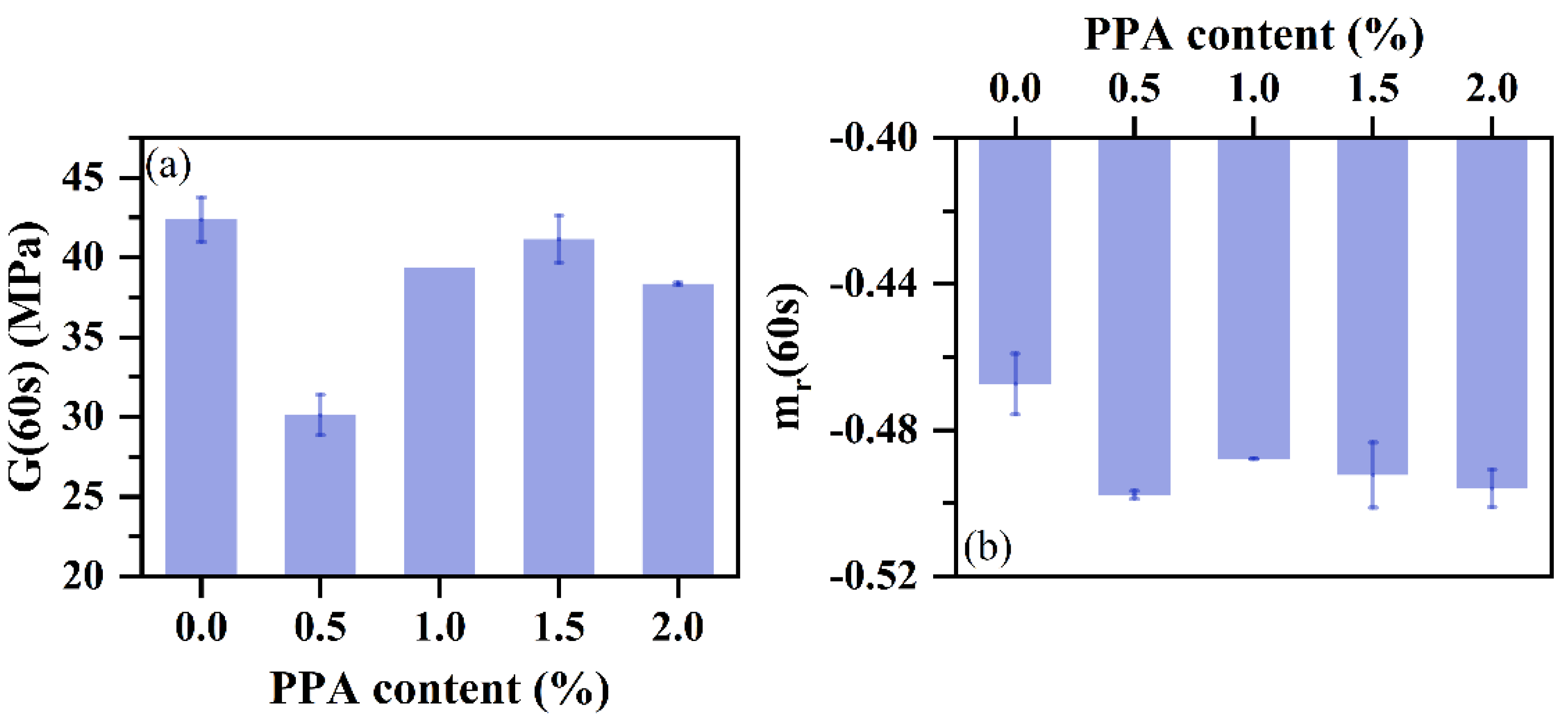

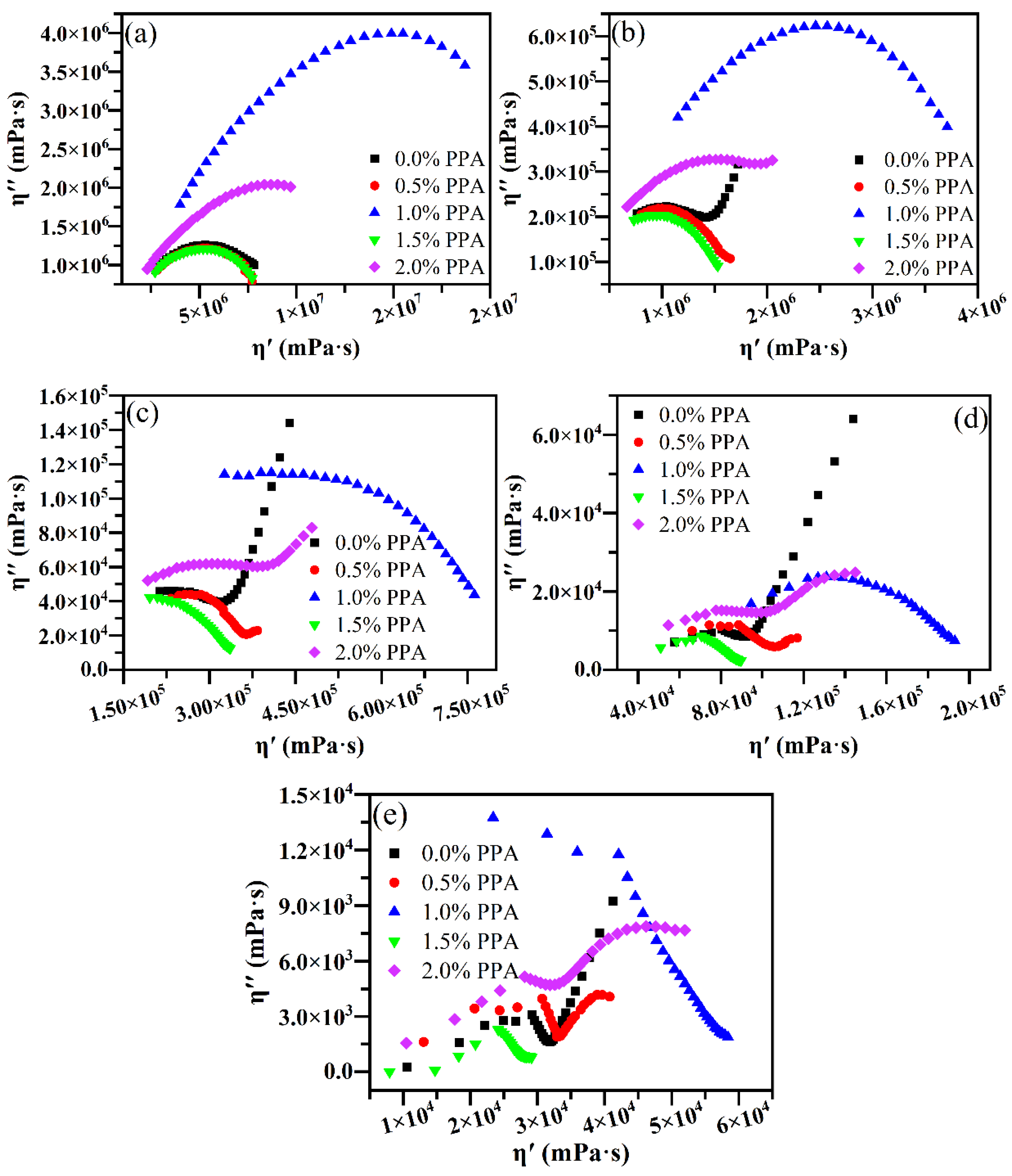

3.2.4. 4 mm DSR Analysis

3.3. Compatibilization Analysis

3.4. Analysis of Variance

3.5. Micro-Analysis of PPA-Modified Emulsified Asphalt

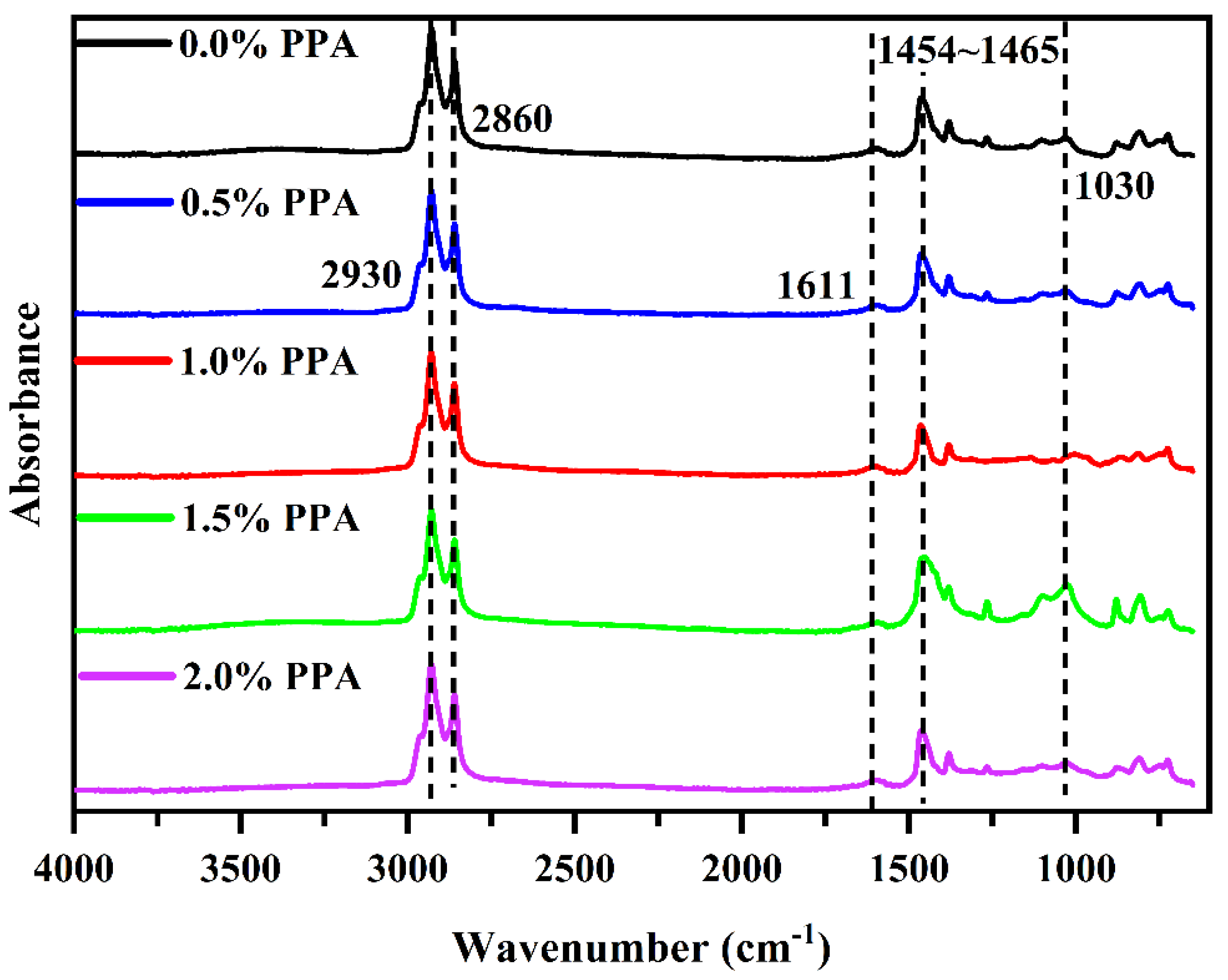

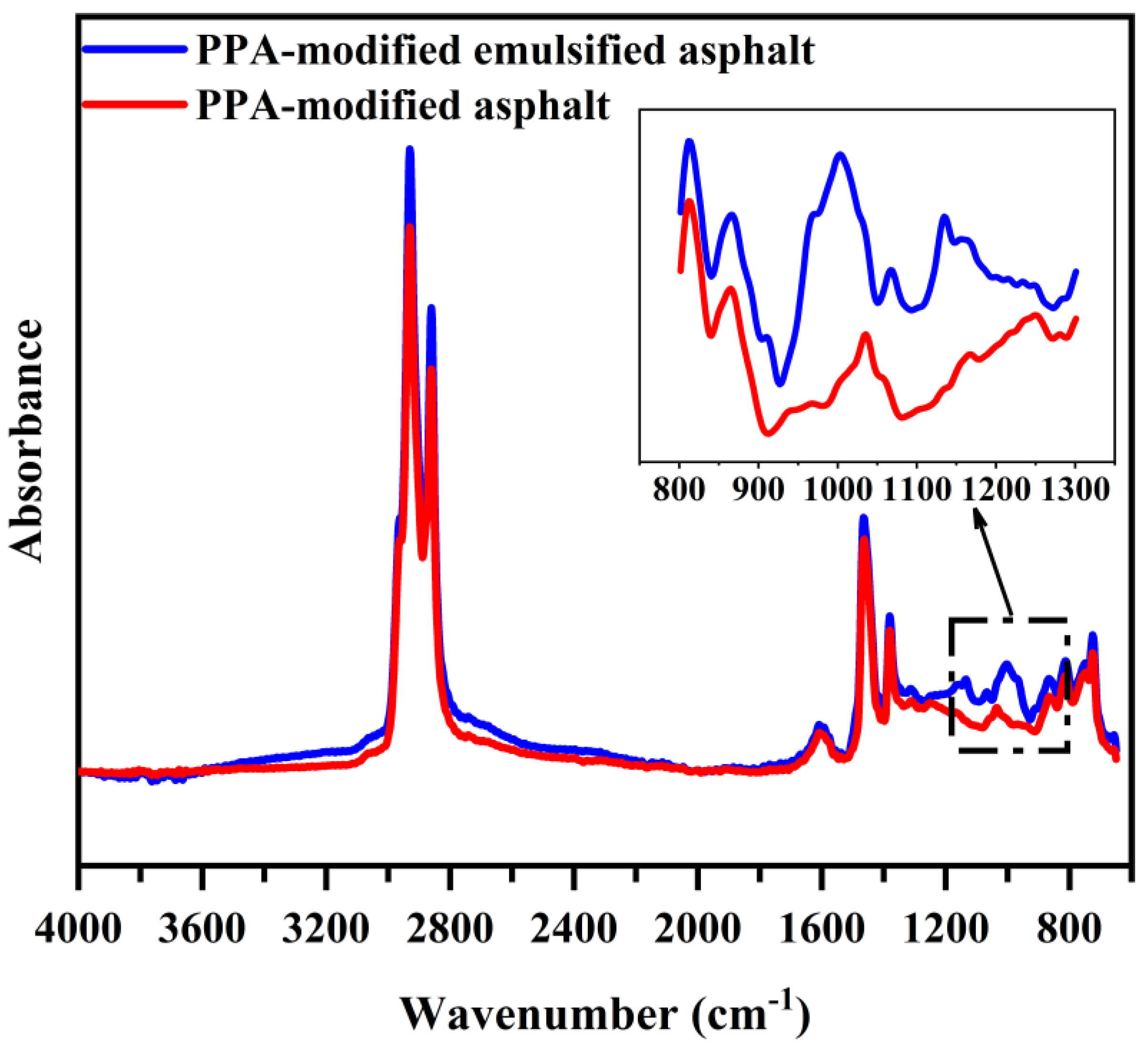

3.5.1. FTIR Analysis

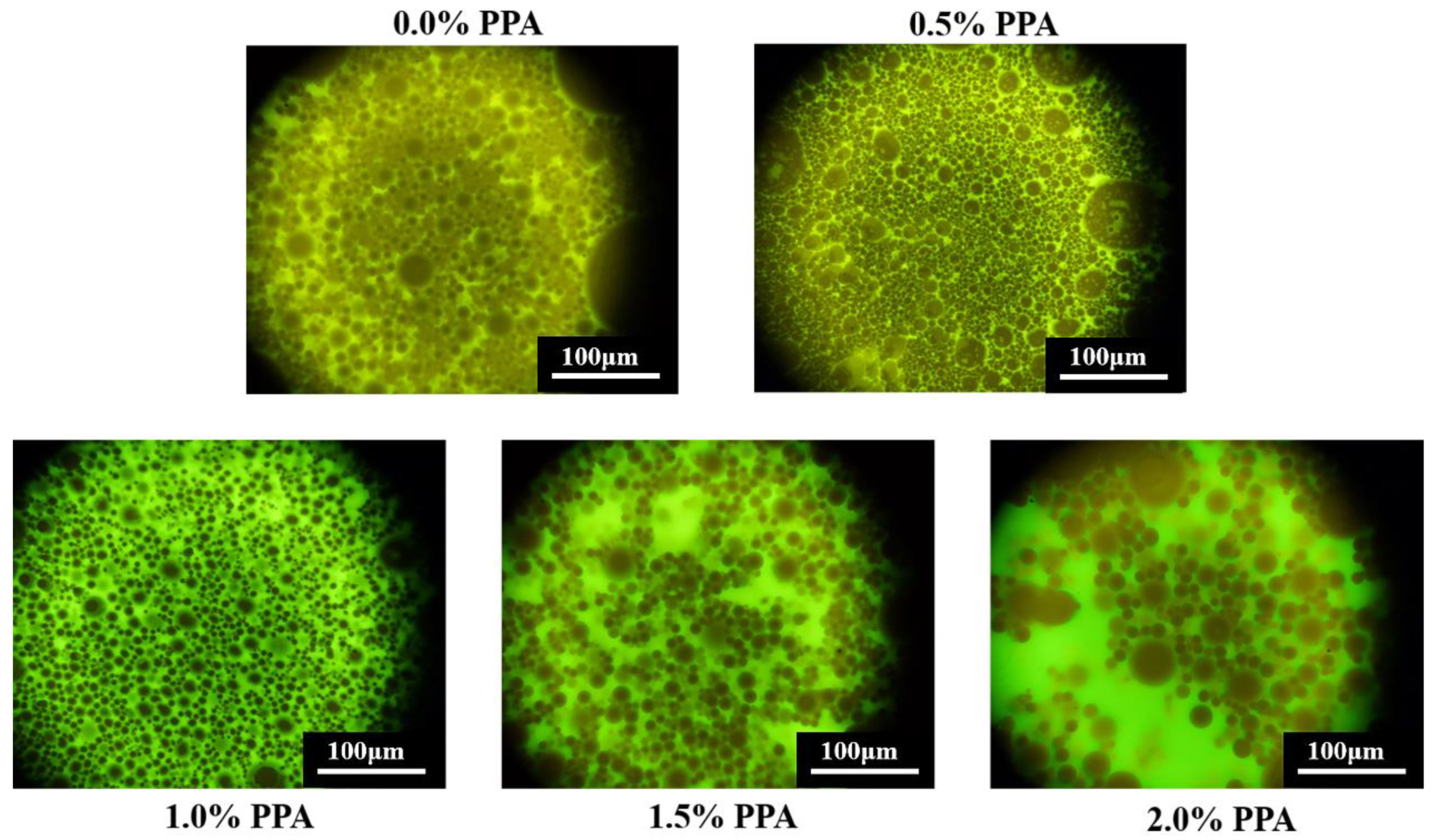

3.5.2. Fluorescent Microscope Analysis

4. Discussion

- As the PPA dosage increased, the softening point of evaporation residues from modified emulsified asphalt initially decreased and subsequently increased, whereas penetration and ductility exhibited an initial increase followed by a decrease. Additionally, incorporating PPA can reduce the storage stability of emulsified asphalt.

- PPA modification can improve the high-temperature stability of evaporation residues from emulsified asphalt, though the extent of improvement depends on the PPA dosage. The optimal high-temperature stability was achieved with a PPA dosage of 1.0%. Additionally, the temperature sensitivity of evaporation residues first decreased and then increased as the PPA content rose. When the dosage is 1.0% or more, PPA-modified emulsified asphalt shows better temperature sensitivity than unmodified emulsified asphalt.

- At a low PPA dosage (0.5%), the fatigue performance of emulsified asphalt decreased after modification. However, when the PPA content reached 1.0%, incorporation of PPA effectively enhanced fatigue resistance. Moreover, PPA enhanced low-temperature performance of evaporation residues, particularly when added at an appropriate dosage (e.g., 0.5%) where its effect is especially pronounced.

- The compatibility of PPA-modified emulsified asphalt initially increased and subsequently decreased as the PPA dosage increased. The optimal compatibility was observed at a PPA dosage of 1.0%.

- Hydrolysis of PPA in the emulsion system altered its chemical structure, resulting in a modification mechanism distinct from that in base asphalt. At a PPA dosage of 1.0%, asphalt particles exhibited a more uniform distribution. However, excessive PPA dosage (e.g., 2.0%) led to significant aggregation of asphalt particles, resulting in larger particle sizes and greater dispersion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PPA | Polyphosphoric acid |

| FTIR | Fourier transform infrared spectroscopy |

| FM | Fluorescence microscopy |

| SBR | Styrene–butadiene rubber |

| WER | Waterborne epoxy resin |

| SBS | Styrene–butadiene rubber |

| GPC | Gel permeation chromatography |

| CTAB | Hexadecyl trimethyl ammonium bromide |

| MSCR | Multistress creep test |

| LAS | Linear amplitude sweeping test |

| TS | Temperature sweeping test |

| FS | Frequency sweeping test |

| 4mmDSR | Frequency sweeping test in low temperature |

| DSR | Dynamic shear rheological test |

| ATR | Attenuated total reflection |

| R | recovery rate |

| Jnr | nonrecoverable creep compliance |

| G* | complex shear modulus |

| VECD | viscoelastic continuous damage theory |

| Nf | fatigue life |

| G′(ω) | low-temperature storage modulus |

| G(t) | relaxation modulus |

| G(60s) | |

| mr(60s) | |

| η* | complex viscosity |

| η′ | real part |

| η″ | imaginary part |

| ANOVA | variance analysis |

Appendix A

References

- Meng, Y.; Chen, J.; Kong, W.; Hu, Y. Review of emulsified asphalt modification mechanisms and performance influencing factors. J. Road Eng. 2023, 3, 141–155. [Google Scholar]

- Wu, J.; Zhang, Y.-X.; Zhang, C.-S. Research of In-situ Polymerization and Core-shell Structure Modified Emulsified Asphalt. In Proceedings of the International Conference on Green Building, Materials and Civil Engineering (GBMCE 2011), Shangri La, China, 22–23 August 2011; pp. 928–931. [Google Scholar]

- Hu, Z. Asphalt EMULSION and Slurry Surfacing; China Communication Press: Beijing, China, 2001. [Google Scholar]

- Zhang, S. Study on the Performance of High Viscosity Emulsified Asphalt Cold Recycled Mixture. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2024. [Google Scholar]

- Abedini, M.; Hassani, A.; Kaymanesh, M.R.; Yousefi, A.A. The rheological properties of a bitumen emulsion modified with two types of SBR latex. Pet. Sci. Technol. 2016, 34, 1589–1594. [Google Scholar] [CrossRef]

- Zhang, Q.; Fan, W.; Wang, T.; Nan, G. Studies on the temperature performance of SBR modified asphalt emulsion. In Proceedings of the 2011 International Conference on Electric Technology and Civil Engineering (ICETCE), Lushan, China, 22–24 April 2011; pp. 730–733. [Google Scholar]

- Cong, Y.; Liao, K.; Huang, W.; Zhai, Y. Performance of SBR-Modified Asphalt. Pet. Sci. Technol. 2006, 24, 1187–1194. [Google Scholar] [CrossRef]

- Zhang, F.; Yu, J. The research for high-performance SBR compound modified asphalt. Constr. Build. Mater. 2010, 24, 410–418. [Google Scholar] [CrossRef]

- Zhao, X. Research on Application of Cold In-Place Recycled Technology with Modified Emulsified Asphalt in Middle Surface Layer of Highway. Master’s Thesis, Southeast University, Nanjing, China, 2020. [Google Scholar]

- Xiang, Q.; Xiao, F. Applications of epoxy materials in pavement engineering. Constr. Build. Mater. 2020, 235, 117529. [Google Scholar] [CrossRef]

- He, L.; Hou, Y.; Yang, F. Study of the Properties of Waterborne Epoxy Resin Emulsified Asphalt and Its Modification Mechanism. J. Mater. Civ. Eng 2023, 35, 14627. [Google Scholar] [CrossRef]

- Wang, P.; Tian, X.; Zhang, R.; Zhen, S. Effect of Waterborne Epoxy Resin on Properties of Modified Emulsified Asphalt and Its Microstructure. J. Mater. Civ. Eng. 2021, 33, 0003793. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Z.; Wang, C.; She, Y. Investigation on Storage Stability of SBS Modified Asphalt Emulsion. Acta Pet. Sin. Pet. Process. Sect. 2013, 29, 1009–1014. [Google Scholar] [CrossRef]

- Wang, H.; Li, C.; Xu, G.; Zhou, Y.; Wang, R. Study of High-Temperature Rheological Properties of Emulsified Asphalt Residues. Coatings 2024, 14, 522. [Google Scholar] [CrossRef]

- Lei, L.; Gao, Y.; Zhang, X.; Cao, J.; Wang, X.; Zhao, X. Rheological mechanism and adhesion properties of SBS latex modified emulsified asphalt. J. Taiyuan Univ. Technol. 2024, 1–12. [Google Scholar]

- Wei, J.; Shi, S.; Zhou, Y.; Li, P.; Chen, Z.; Guan, Y. Rheological property of polyphosphoric acid modified asphalt. J. Traffic Transp. Eng. Engl. Ed. 2019, 19, 14–26. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Lupi, F.R.; Rossi, C.O.; Caputo, P.; Falvo, T. Rheological effects on bitumen of polyphosphoric acid (PPA) addition. Constr. Build. Mater. 2013, 40, 397–404. [Google Scholar] [CrossRef]

- Edwards, Y.; Tasdemir, Y.; Isacsson, U. Rheological effects of commercial waxes and polyphosphoric acid in bitumen 160/220—Low temperature performance. Fuel 2006, 85, 989–997. [Google Scholar]

- Wang, L.; Pei, K.; Li, C. Analysis of Chemical Modification Mechanism and Rheological Properties of Polyphosphoric Acid Modified Asphalt. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2022, 37, 876–884. [Google Scholar] [CrossRef]

- Aflaki, S.; Hajikarimi, P.; Fini, E.H.; Zada, B. Comparing Effects of Biobinder with Other Asphalt Modifiers on Low-Temperature Characteristics of Asphalt. J. Mater. Civ. Eng. 2014, 26, 429–439. [Google Scholar] [CrossRef]

- Sarnowski, M. Rheological properties of road bitumen binders modified with SBS polymer and polyphosphoric acid. RaBDiM 2015, 14, 47–65. [Google Scholar] [CrossRef]

- Baumgardner, G.L. Why and How of Polyphosphoric Acid Modification: An Industry Perspective. In Proceedings of the Asphalt Paving Technology, Sacramento, CA, USA, 7–10 March 2010; pp. 663–678. [Google Scholar]

- Dourado, E.R.; Pizzorno, B.S.; Motta, L.M.G.; Simao, R.A.; Leite, L.F.M. Analysis of asphaltic binders modified with PPA by surface techniques. J. Microsc. 2014, 254, 122–128. [Google Scholar] [CrossRef]

- Xu, Y.; Niu, K.; Zhu, H.; Chen, R.; Ou, L. Evaluating the Effects of Polyphosphoric Acid (PPA) on the Anti-Ultraviolet Aging Properties of SBR-Modified Asphalt. Materials 2023, 16, 2784. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, Y.; Li, C.; Chen, H.; Zhang, H.; Kuang, D. Preparation and performance evaluation of SBS/PPA composite modified emulsified asphalt. Appl. Chem. Ind. 2020, 49, 1438–1442. [Google Scholar] [CrossRef]

- JTG E20-2011E; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communication Press: Beijing, China, 2011.

- GB25592-2010; National Standard of Food Additives and Aluminum Ammonium Sulfate for Food Safety. National Health Commission of the PRC: Beijing, China, 2010.

- Fang, Y. Analysis on Permeability of High Permeability Layer-Penetration Oil Influencing Factors. Appl. Mech. Mater. 2014, 580–583, 2524–2527. [Google Scholar]

- Tang, Y. Study on the Preparation and Properties of High-performance Prime Coat and Tack Coat Materials. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2021. [Google Scholar]

- Han, Y. Study on the Raveling Resistance of Thin Friction Course (TFC) Based on the Modified Asphalt Emulsion. Master’s Thesis, Southeast University, Nanjing, China, 2019. [Google Scholar]

- ASTM-D7405; Standard Test Method for Multiple Stress Creep Recovery Test (MSCR) of Asphalt Binder Using Dynamic Shear Rheometer. ASTM: West Conshohocken, PE, USA, 2020.

- ASTM-D7175; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM: West Conshohocken, PE, USA, 2015.

- TP 101-14; Standard Method of Test for Estimating Damage Tolerance of Asphalt Binders Using the Linear Amplitude Sweep. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014.

- Sui, C.; Farrar, M.; Tuminello, W.H.; Turner, T. New Technique for Measuring Low-Temperature Properties of Asphalt Binders with Small Amounts of Material. Proc. Transp. Res. Rec. J. Transp. Res. Board 2010, 2179, 23–28. [Google Scholar] [CrossRef]

- Zhang, H.; Shi, C.; Yu, J.; Shen, J. Modification and Its Mechanism of Different Asphalts by Polyphosphorie Acid. J. Build. Mater. 2013, 16, 255–260. [Google Scholar]

- Liu, G.; Yang, X.; Zhu, X.; Rong, H. Characterising the modifying efficiency of polyphosphoric acid to bitumens with different oil sources. Int. J. Pavement Eng. 2024, 25, 2308170. [Google Scholar] [CrossRef]

- Qian, C.; Fan, W.; Yang, G.; Han, L.; Xing, B.; Lv, X. Influence of crumb rubber particle size and SBS structure on properties of CR/SBS composite modified asphalt. Constr. Build. Mater. 2020, 235, 117517. [Google Scholar] [CrossRef]

- Li, H.P.; Zhao, H.; Liao, K.J.; Li, Y.G.; Li, X.Q. A Study on the Preparation and Storage Stability of Modified Emulsified Asphalt. Pet. Sci. Technol. 2012, 30, 699–708. [Google Scholar] [CrossRef]

- Jiang, S.; Jiang, X.; Li, H.; Ding, Z.; Li, P.; Zhou, M. Experimental Study on Creep–Recovery Behavior of Polyphosphoric Acid (PPA) Modified Asphalt Binders under Multiple Factors. Materials 2023, 16, 2740. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Lyu, D.; Zhang, Z.; Chen, J. Differentiation Analysis of Viscoelastic Properties of High-ViscosityModified Asphalt at High Temperature. J. Build. Mater. 2020, 23, 692–699. [Google Scholar]

- Cai, Z. Temperature Sensitivity Evaluation of PPA Modified Asphalt. Highw. Eng. 2017, 42, 111–114. [Google Scholar]

- Kim, Y.R.; Little, D.N. Development of Specification-Type Tests to Assess the Impact of Fine Aggregate and Mineral Filler on Fatigue Damage; 0-1707-10; Texas Transportation Institute: Bryan, TX, USA, 2005. [Google Scholar]

- Johnson, C.M. Estimating Asphalt Binder Fatigue Resistance Using an Accelerated Test Method. Ph.D. Thesis, The University of Wisconsin, Madison, WI, USA, 2010. [Google Scholar]

- Liang, M.; Liang, P.; Fan, W.; Qian, C.; Nan, G. Thermo-rheological behavior and compatibility of modified asphalt with various styrene-butadiene structures in SBS copolymers. Mater. Des. 2015, 88, 177–185. [Google Scholar] [CrossRef]

- Dong, F.; Yu, X.; Liu, S.; Wei, J. Rheological behaviors and microstructure of SBS/CR composite modified hard asphalt. Constr. Build. Mater. 2016, 115, 285–293. [Google Scholar] [CrossRef]

- Kumar, A.; Choudhary, R.; Kumar, A. Storage Stability of Waste Tire Pyrolytic Char–Modified Asphalt Binders: Rheological and Chemical Characterization. J. Mater. Civ. Eng. 2022, 34, 0004129. [Google Scholar] [CrossRef]

- Corbridge, D.E.C. Phosphorus. An Outline of its Chemistry, Biochemistry and Technology; Elsevier Science Publishers: Amsterdam, The Netherlands, 1985. [Google Scholar] [CrossRef]

| Index | Test Result | Requirement (JTG E20-2011) | Test Method (JTG E20-2011) |

|---|---|---|---|

| Penetration (25 °C), 0.1 mm | 77 | 60~80 | T0604 |

| Durability (5 °C, 5 cm·min−1), cm | 25.03 | ≥25 | T0605 |

| Softening point, °C | 47.7 | >46 | T0606 |

| Flash point, °C | 300 | ≥260 | T0611 |

| Wax content (distillation method), % | 1.9 | ≤2.2 | T0615 |

| Density, (g·cm−3) | 1.03 | - | T0603 |

| Solubility (C2HCl3), % | 99.7 | ≥99.5 | T0607 |

| Index | Requirement | Value |

|---|---|---|

| Appearance, % | Colorless or light liquid | Colorless liquid |

| H3PO4, % | ≥115.0 | 115.8 |

| Fe, % | ≤0.002 | <0.002 |

| Heavy metal (Pb), % | ≤0.005 | <0.005 |

| Chloride (Cl), % | ≤0.0005 | <0.0005 |

| Index | Value | Reference | |

|---|---|---|---|

| Content | ≥99.0% | / | |

| HLB value | 15.8 | ||

| Melting point | 240 °C | ||

| Maximum content of impurities | Ethanol dissolution test | Qualified | GB25592 [27] |

| Ignition residue (sulfate) | 0.05 | ||

| Moisture | 0.5 | ||

| Fe | 0.001 | ||

| Heavy metal (meter Pb) | 0.001 | ||

| Test | MSCR | TS | LAS | 4 mm DSR | FS |

|---|---|---|---|---|---|

| Temperature, °C | 64 | 30~80 | 25 | −5, −15 | 40~80 |

| Temperature increment, °C | / | 10 | / | / | 10 |

| Parallel plate size, mm | 25 | 25 | 8 | 4 | 25 |

| Frequency | / | 10 rad/s | 0.2~30 Hz, 10 rad/s | 0.1~100 rad/s | 0.1~100 Hz |

| Load type | Stress control: 0.1 kPa, 3.2 kPa | Strain control: 1% | Strain control: 0.1% /0.1~30% | Strain control: 0.1% | Strain control: 0.1% |

| Test method | ASTM D7405 [31] | ASTM D7175 [32] | AASHTO TP 101-14 [33] | Literature [34] | ASTM D7175 [32] |

| Parameter | 0.0% PPA | 0.5% PPA | 1.0% PPA | 1.5% PPA | 2.0% PPA |

|---|---|---|---|---|---|

| A | 50,664.13 | 39,285.50 | 77,805.99 | 56,095.39 | 90,061.17 |

| B | 2.33 | 2.34 | 2.56 | 2.32 | 2.48 |

| Df | 59.67 | 50.91 | 61.17 | 63.21 | 71.21 |

| Cpeak | 0.50 | 0.54 | 0.46 | 0.50 | 0.46 |

| Stressmax | 2,570,712 | 211,588 | 254,443 | 267,318 | 237,446 |

| Index | Sum of Squares | Degree of Freedom | Root Mean Square | F | p-Value |

|---|---|---|---|---|---|

| Softening point | 13.432 | 4 | 3.358 | 2.231 | 0.201 |

| Penetration | 230.476 | 4 | 57.619 | 0.662 | 0.645 |

| R3.2 | 0.000 | 4 | 0.000 | 0.800 | 0.574 |

| Jnr3.2 | 9.591 | 4 | 2.398 | 141.040 | 0.000 |

| Nf2.5 | 300,079.078 | 4 | 75,019.770 | 0.294 | 0.871 |

| mr(60s) | 0.001 | 4 | 0.000 | 4.484 | 0.066 |

| G(60s) | 0.028 | 4 | 0.007 | 44.675 | 0.000 |

| Ductility | 3294.556 | 4 | 823.639 | 19.233 | 0.003 |

| Storage stability | 680.5434 | 4 | 170.136 | 22.795 | 0.002 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, S.; Liu, X.; Li, X.; Jia, J.; Yang, J. Feasibility of Polyphosphoric Acid in Emulsified Asphalt Modification: Emulsification Characteristics, Rheological Properties, and Modification Mechanism. Coatings 2025, 15, 471. https://doi.org/10.3390/coatings15040471

Pan S, Liu X, Li X, Jia J, Yang J. Feasibility of Polyphosphoric Acid in Emulsified Asphalt Modification: Emulsification Characteristics, Rheological Properties, and Modification Mechanism. Coatings. 2025; 15(4):471. https://doi.org/10.3390/coatings15040471

Chicago/Turabian StylePan, Simiao, Xiang Liu, Xiaolong Li, Jingpeng Jia, and Jun Yang. 2025. "Feasibility of Polyphosphoric Acid in Emulsified Asphalt Modification: Emulsification Characteristics, Rheological Properties, and Modification Mechanism" Coatings 15, no. 4: 471. https://doi.org/10.3390/coatings15040471

APA StylePan, S., Liu, X., Li, X., Jia, J., & Yang, J. (2025). Feasibility of Polyphosphoric Acid in Emulsified Asphalt Modification: Emulsification Characteristics, Rheological Properties, and Modification Mechanism. Coatings, 15(4), 471. https://doi.org/10.3390/coatings15040471