Investigation of Fatigue Performance for In-Service Asphalt Pavement Mixtures Using Push-Pull Fatigue Test

Abstract

1. Introduction

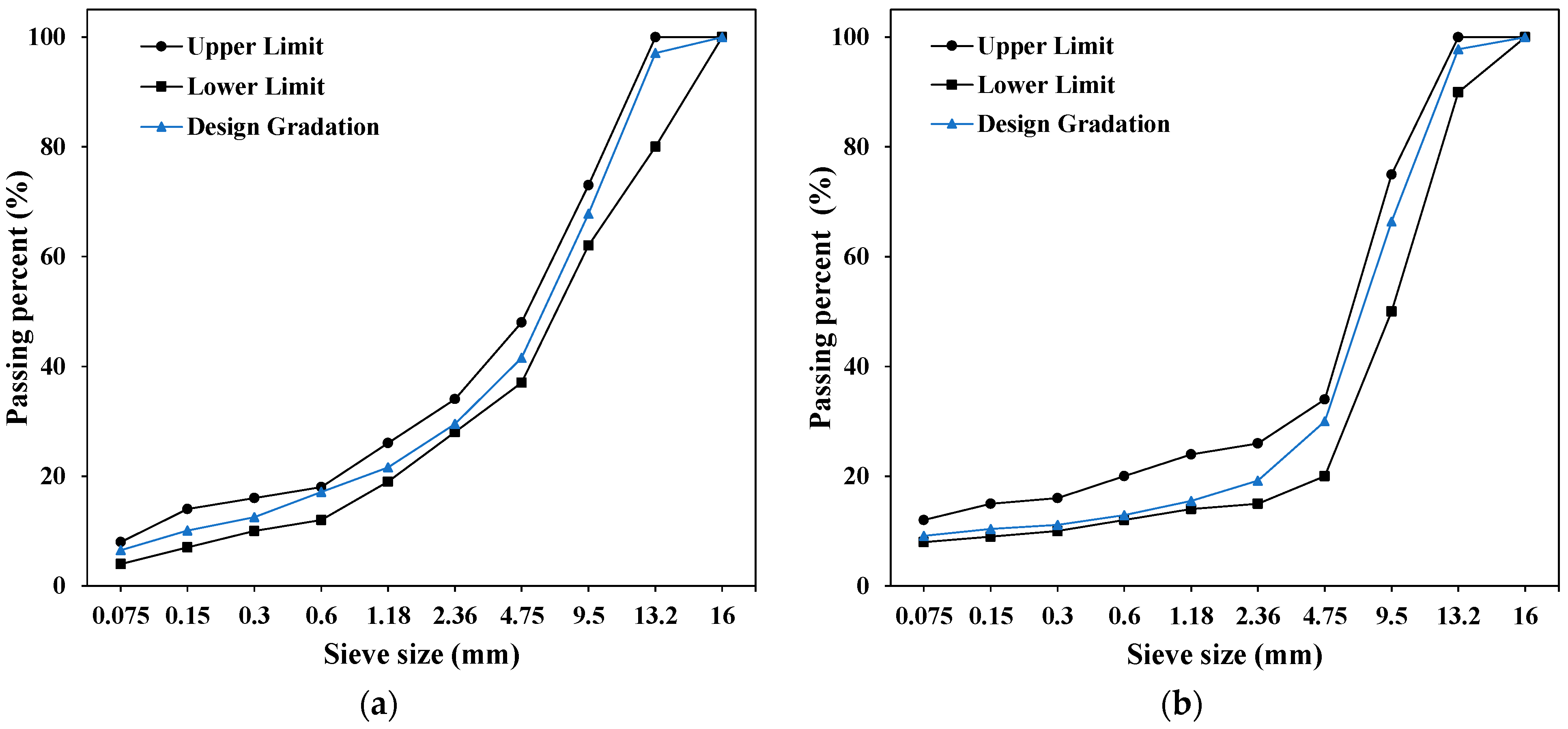

2. Materials and Methods

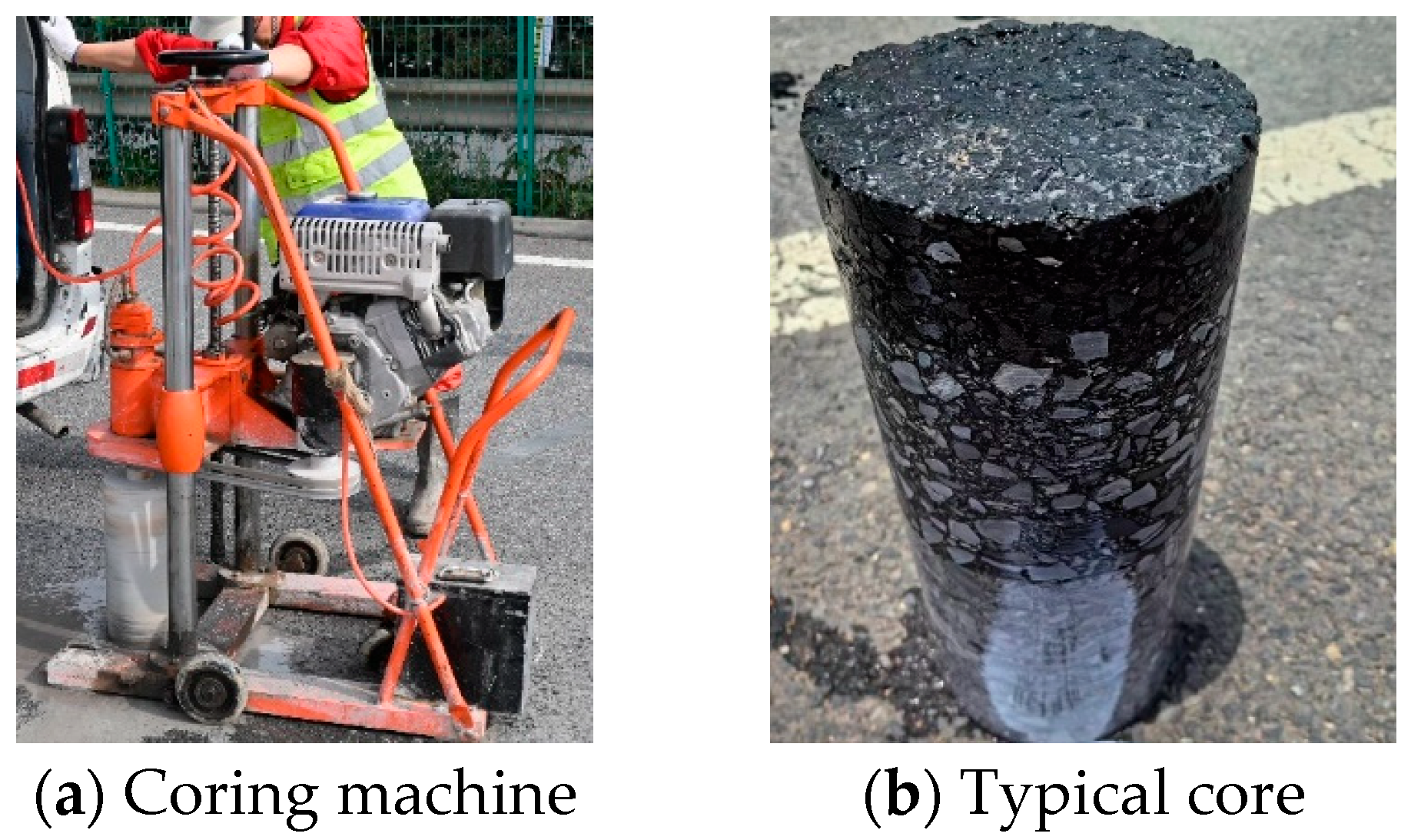

2.1. Field Core Sampling

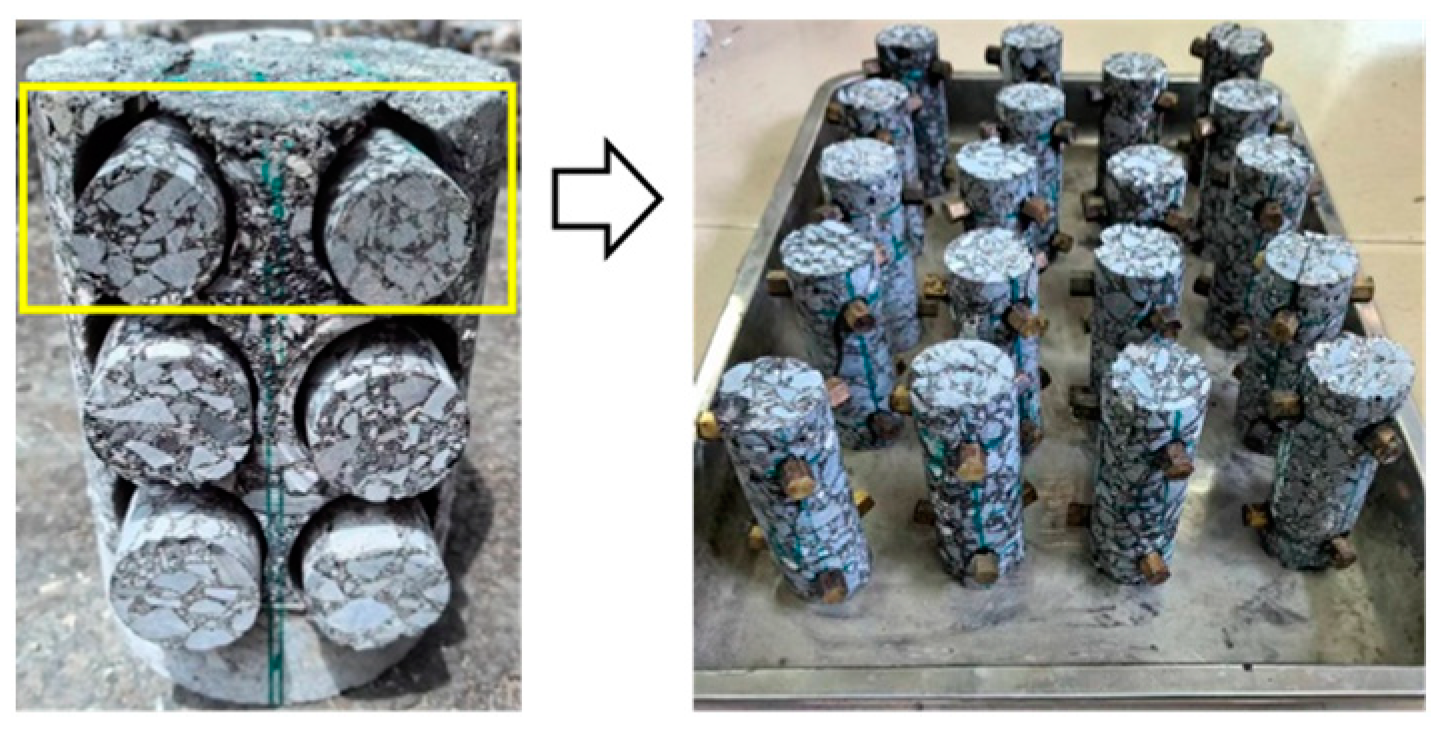

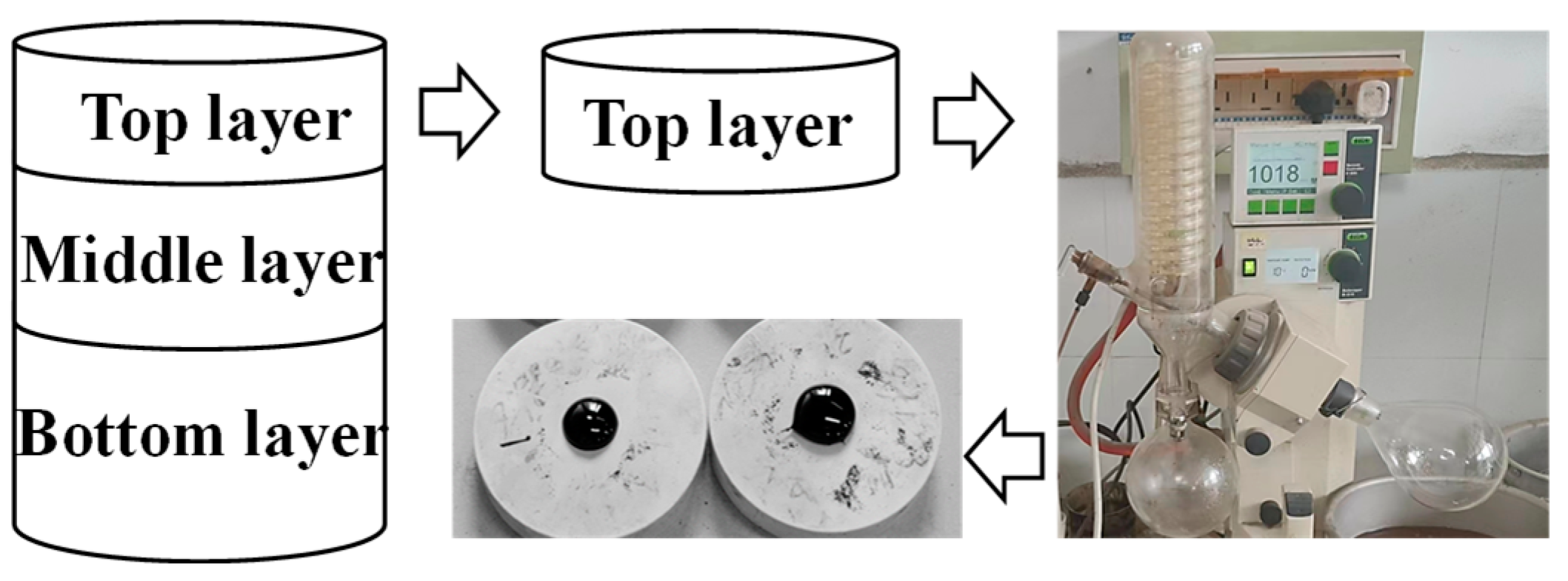

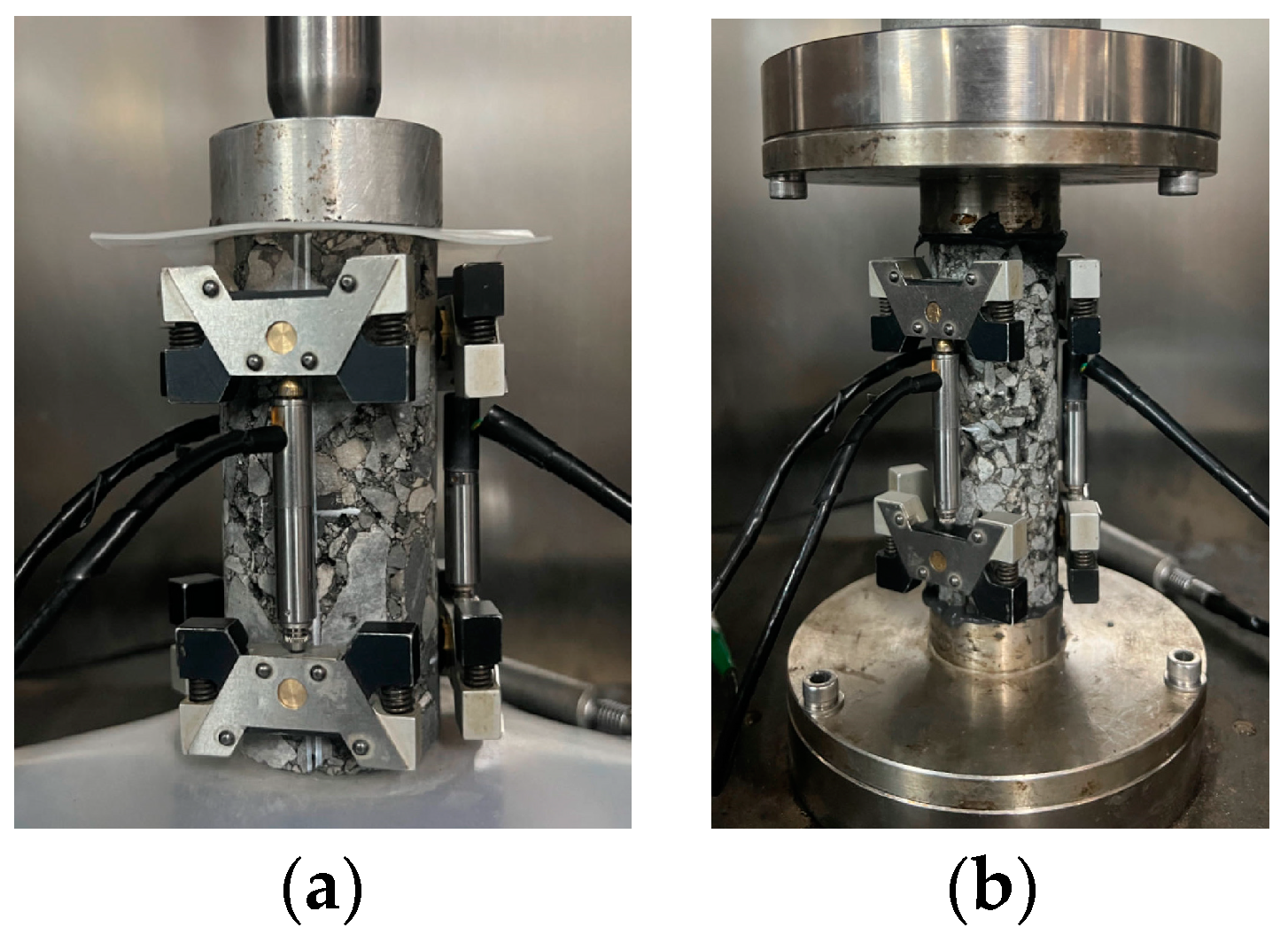

2.2. Specimen Preparation

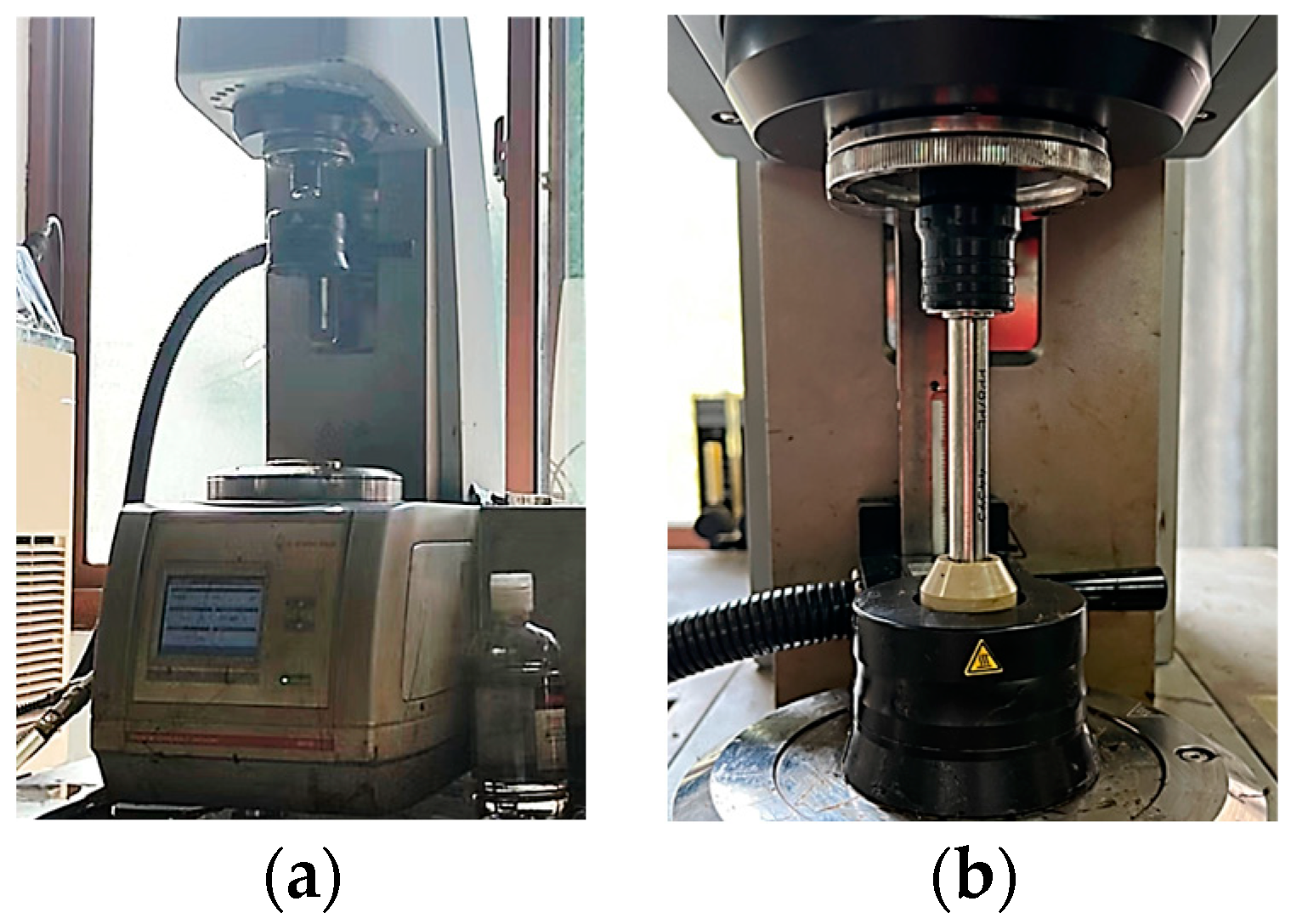

2.3. Testing Method

3. Results and Discussion

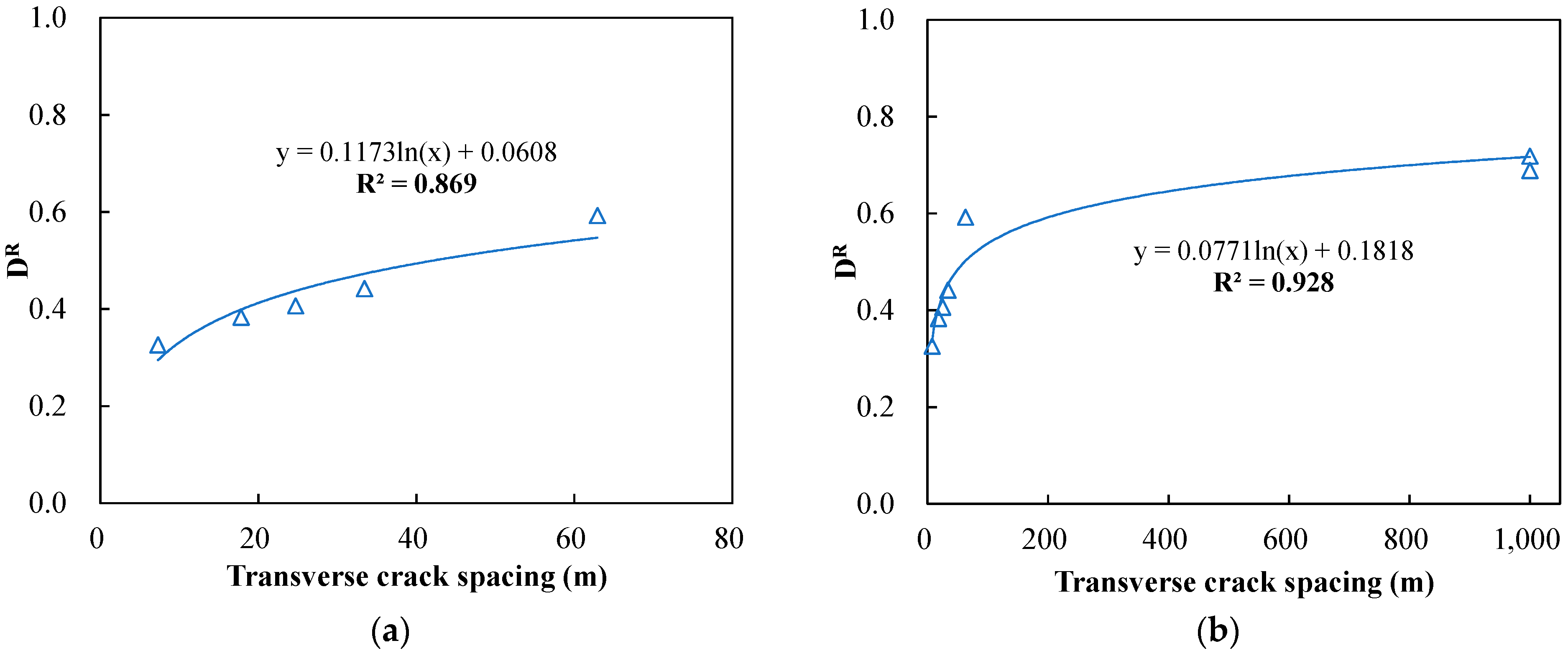

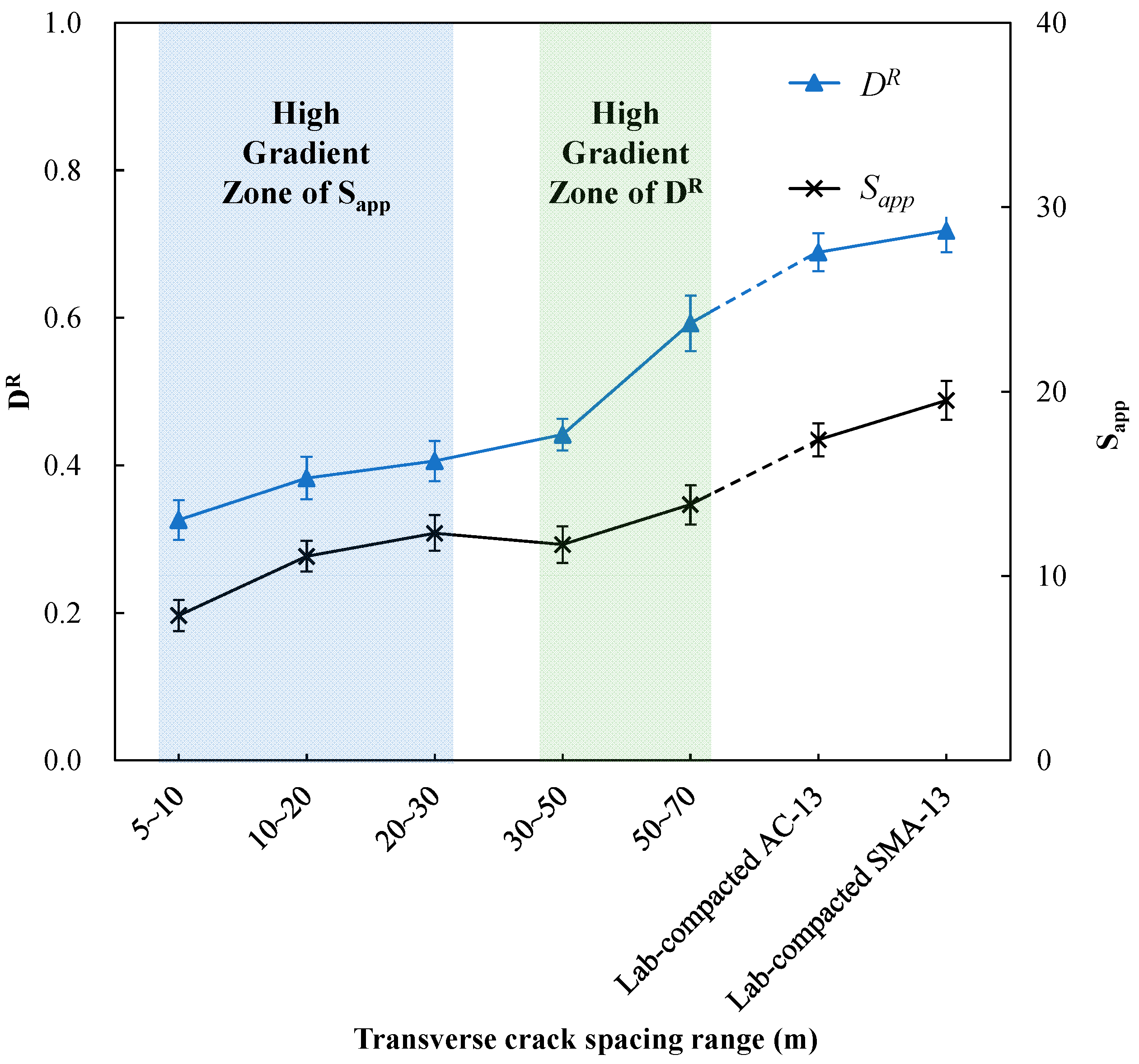

3.1. Push-Pull Fatigue Test

3.2. Validation Using Asphalt Binder LAS Test

4. Conclusions

- The push-pull fatigue test method based on the S-VECD model provides reliable fatigue performance evaluation indicators, effectively assessing the intermediate-temperature fatigue damage characteristics of in-service asphalt mixtures. The fatigue indicators demonstrate a strong correlation with the actual cracking conditions of the pavement.

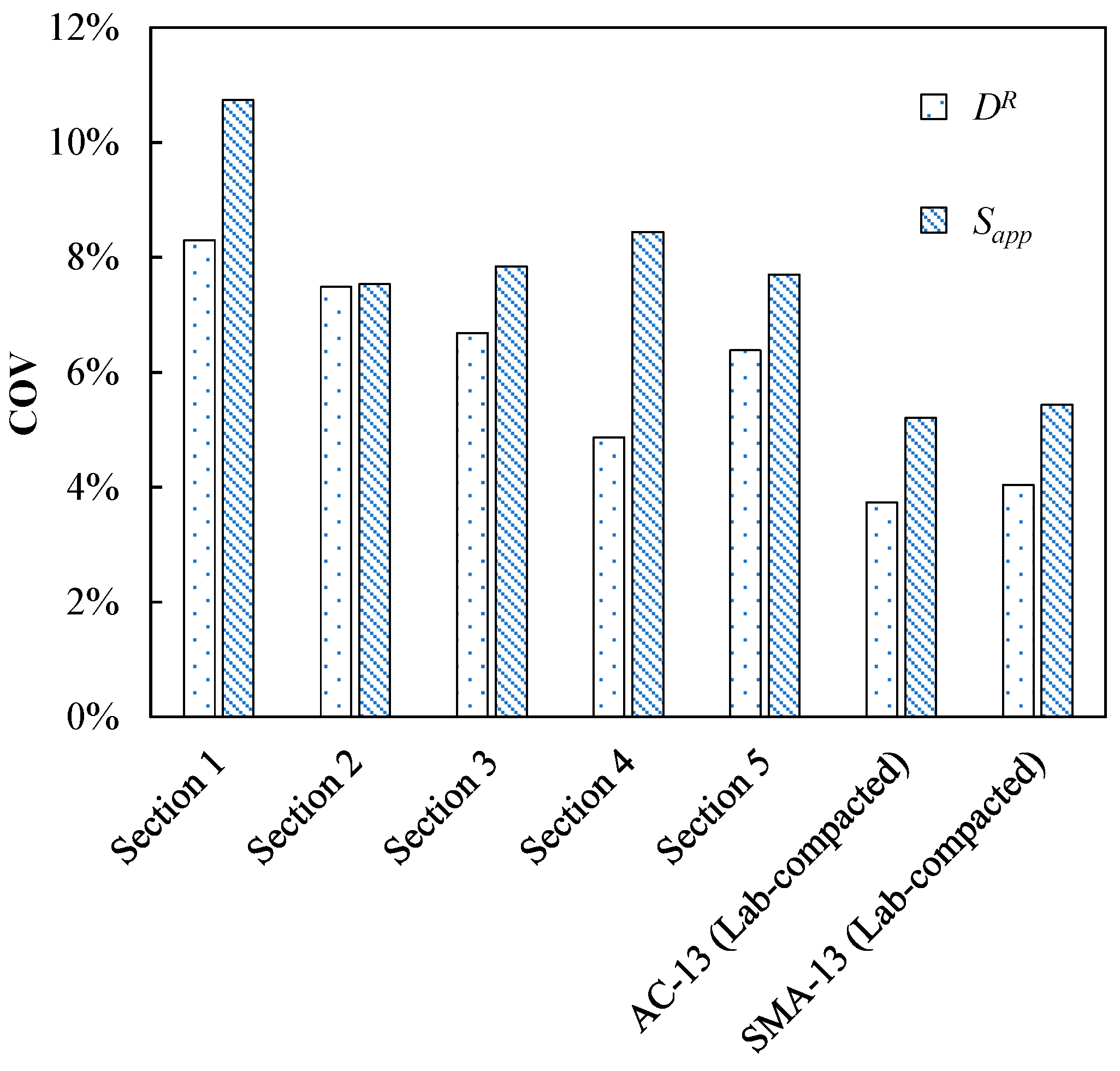

- The apparent damage capacity indicator, Sapp, accounts for both the modulus and toughness of the material, showing higher sensitivity to the fatigue performance of asphalt mixtures in heavily cracked pavement sections compared to the average pseudo-stiffness degradation rate (DR). Additionally, Sapp demonstrates superior differentiation in performance among mixtures with different gradation types. Based on extensive test results, its coefficient of variation remains below 11%, indicating good stability and repeatability.

- The top layer gradation type significantly impacts the fatigue performance of asphalt mixtures. SMA-13 mixtures, with their more stable skeleton structure and higher binder content, exhibit superior fatigue performance than AC-13, as reflected by larger pavement crack spacing. In sections with smaller crack spacing, the fatigue performance of the mixtures deteriorates significantly, indicating that high stress concentrations and frequent loading intensify pavement damage.

- The LAS test results further revealed the significant contribution of asphalt binder fatigue performance deterioration to the overall degradation of mixture performance. Across highway sections with varying cracking conditions, the fatigue life of asphalt binder demonstrated consistent trends with the fatigue parameters from mixture push-pull fatigue tests. This indicates that the decline in binder fatigue performance is the primary cause of the reduction in asphalt mixture fatigue performance, effectively validating the correlation between push-pull fatigue test results and pavement cracking severity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lyu, S.; Liu, C.; Qu, F.; Zheng, J. Test Methods and Characterization of Fatigue Performance of Asphalt Mixtures: A Review. China J. Highw. Transp. 2020, 33, 67–75. [Google Scholar]

- Wu, S.; Wen, H.; Zhang, W.; Shen, S.; Mohammad, L.N.; Faheem, A.; Muhunthan, B. Field performance of top-down fatigue cracking for warm mix asphalt pavements. Int. J. Pavement Eng. 2016, 20, 33–43. [Google Scholar] [CrossRef]

- Luo, X.; Luo, R.; Lytton, R.L. Energy-based mechanistic approach for damage characterization of pre-flawed visco-elasto-plastic materials. Mech. Mater. 2014, 70, 18–32. [Google Scholar] [CrossRef]

- Ziari, H.; Aliha, M.R.M.; Mojaradi, B.; Sarbijan, M.J. Investigating the effects of loading, mechanical properties and layers geometry on fatigue life of asphalt pavements. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1563–1577. [Google Scholar] [CrossRef]

- Fang, C.; Guo, N.; Li, H.; Chu, Z.; Liu, T. Investigating the characterization of fatigue damage process for asphalt based on kinetics theory. China J. Highw. Transp. 2024, 1–13. [Google Scholar]

- Sagnol, L.; Quezada, J.C.; Chazallon, C.; Stoeckner, M. Effect of glass fibre grids on the bonding strength between two asphalt layers and its Contact Dynamics method modelling. Road Mater. Pavement Des. 2019, 20, 1164–1181. [Google Scholar] [CrossRef]

- Sabouri, M.; Kim, Y.R. Development of a Failure Criterion for Asphalt Mixtures Under Different Modes of Fatigue Loading. Transp. Res. Rec. 2014, 2447, 117–125. [Google Scholar] [CrossRef]

- Ozer, H.; Al-Qadi, I.L.; Lambros, J.; El-Khatib, A.; Singhvi, P.; Doll, B. Development of the fracture-based flexibility index for asphalt concrete cracking potential using modified semi-circle bending test parameters. Constr. Build. Mater. 2016, 115, 390–401. [Google Scholar] [CrossRef]

- Manh Tuan, N.; Lee, H.J.; Baek, J. Fatigue Analysis of Asphalt Concrete under Indirect Tensile Mode of Loading Using Crack Images. J. Test. Eval. 2013, 41, 148–158. [Google Scholar] [CrossRef]

- Cheng, H.L.; Liu, J.N.; Sun, L.J.; Liu, L.P. Critical position of fatigue damage within asphalt pavement considering temperature and strain distribution. Int. J. Pavement Eng. 2021, 22, 1773–1784. [Google Scholar] [CrossRef]

- Yuan, F.; Cheng, L.; Shao, X.; Dong, Z.; Zhang, L.; Wu, G.; He, X. Full-field measurement and fracture and fatigue characterizations of asphalt concrete based on the SCB test and stereo-DIC. Eng. Fract. Mech. 2020, 235, 107127. [Google Scholar] [CrossRef]

- Du, H.; Ni, F.; Ma, X. Crack Resistance Evaluation for In-Service Asphalt Pavements by Using SCB Tests of Layer-Core Samples. J. Mater. Civ. Eng. 2021, 33, 04020418. [Google Scholar] [CrossRef]

- Xu, D.; Ding, J.; Shu, L.; Ni, F.; Jiang, J.; Zhang, Z. In-situ tracking of multiscale fatigue degradation in the wearing course of asphalt pavement. Constr. Build. Mater. 2024, 441, 137588. [Google Scholar] [CrossRef]

- Feng, D.; Cui, S.; Yi, J.; Chen, Z.; Qin, W. Evaluation Index of Low-temperature Asphalt Mixture Performance Based on Semi-circular Bending Test. China J. Highw. Transp. 2020, 33, 50–57. [Google Scholar]

- Zhou, D.; Ma, Z.; Liu, L.; Sun, L. Study on Fatigue Performance of In-service Asphalt Pavement Based on Full-scale Accelerated Loading Test. J. Highw. Transp. Res. Dev. 2020, 37, 17–24. [Google Scholar]

- Schapery, R.A. Correspondence principles and a generalized J integral for large deformation and fracture analysis of viscoelastic media. Int. J. Fract. 1984, 25, 195–223. [Google Scholar] [CrossRef]

- Underwood, B.S.; Baek, C.; Kim, Y.R. Simplified Viscoelastic Continuum Damage Model as Platform for Asphalt Concrete Fatigue Analysis. Transp. Res. Rec. J. Transp. Res. Board 2012, 2296, 36–45. [Google Scholar] [CrossRef]

- Wang, Y.; Kim, Y.R. Development of a pseudo strain energy-based fatigue failure criterion for asphalt mixtures. Int. J. Pavement Eng. 2019, 20, 1182–1192. [Google Scholar] [CrossRef]

- Wang, Y.D.; Keshavarzi, B.; Kim, Y.R. Fatigue Performance Analysis of Pavements with RAP Using Viscoelastic Continuum Damage Theory. KSCE J. Civ. Eng. 2018, 22, 2118–2125. [Google Scholar] [CrossRef]

- Shen, J. Climate zoning for road asphalt and asphalt mixture and the key technical index. China J. Highw. Transp. 1997, 10, 1–9. [Google Scholar]

- Zhang, Q.; Xiao, X. Research review on constitutive model and micro structure of asphalt and asphalt mixture. China J. Highw. Transp. 2016, 29, 26–33. [Google Scholar]

- Zeiada, W.A.; Underwood, B.S.; Pourshams, T.; Stempihar, J.; Kaloush, K.E. Comparison of conventional, polymer, and rubber asphalt mixtures using viscoelastic continuum damage model. Road Mater. Pavement Des. 2014, 15, 588–605. [Google Scholar] [CrossRef]

- Li, H.; Luo, X.; Zhang, Y. Pseudo Energy-based Kinetic Characterization of Fatigue in Asphalt Binders. China J. Highw. Transp. 2020, 33, 115–124. [Google Scholar]

- Bahia, H.U.; Zhai, H.; Zeng, M.; Hu, Y.; Turner, P. Development of binder specification parameters based on characterization of damage behavior (with discussion). Assoc. Asph. Paving Technol.-Proc. Tech. 2001, 70, 442–470. [Google Scholar]

- Hintz, C.; Velasquez, R.; Johnson, C.; Bahia, H. Modification and Validation of Linear Amplitude Sweep Test for Binder Fatigue Specification. Transp. Res. Rec. 2011, 2207, 99–106. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, G.; Chen, X.; Wang, R.; Zhou, W. Fatigue Property of Aged Asphalt Binders Using Different Experimental Methods. J. Build. Mater. 2020, 23, 168–175. [Google Scholar]

- Li, J. Effect of wax-based warm mix on rutting and fatigue properties of waste rubber powder modified asphalt. J. China Foreign Highw. 2023, 43, 230–235. [Google Scholar]

- Zhang, R.; Sias, J.E.; Dave, E.V. Development of new performance indices to evaluate the fatigue properties of asphalt binders with ageing. Road Mater. Pavement Des. 2022, 23, 377–396. [Google Scholar] [CrossRef]

- Cao, W.; Mohammad, L.N.; Barghabany, P. Use of Viscoelastic Continuum Damage Theory to Correlate Fatigue Resistance of Asphalt Binders and Mixtures. Int. J. Geomech. 2018, 18, 04018151. [Google Scholar] [CrossRef]

- Safaei, F.; Castorena, C.; Kim, Y.R. Linking asphalt binder fatigue to asphalt mixture fatigue performance using viscoelastic continuum damage modeling. Mech. Time-Depend. Mater. 2016, 20, 299–323. [Google Scholar] [CrossRef]

- Lee, K.C.; Pape, S.; Castorena, C.; Underwood, B.S.; Kim, Y.R. Strain-Level Determination Procedure for Small-Specimen Cyclic Fatigue Testing in the Asphalt Mixture Performance Tester. Transp. Res. Rec. 2019, 2673, 824–835. [Google Scholar] [CrossRef]

- Kutay, M.E.; Gibson, N.; Youtcheff, J.; Dongre, R. Use of Small Samples to Predict Fatigue Lives of Field Cores Newly Developed Formulation Based on Viscoelastic Continuum Damage Theory. Transp. Res. Rec. 2009, 2127, 90–97. [Google Scholar] [CrossRef]

- Ding, J.; Jiang, J.; Ni, F.; Dong, Q.; Zhao, Z. Correlation investigation of fatigue indices of fine aggregate matrix (FAM) and asphalt mixture containing reclaimed asphalt pavement materials. Constr. Build. Mater. 2020, 262, 120646. [Google Scholar] [CrossRef]

- Wang, Y.D.; Underwood, B.S.; Kim, Y.R. Development of a fatigue index parameter, Sapp, for asphalt mixes using viscoelastic continuum damage theory. Int. J. Pavement Eng. 2022, 23, 438–452. [Google Scholar] [CrossRef]

- Guo, X. Local Calibration of the MEPDG Using Test Track Data. Master’s Thesis, Auburn University, Auburn, AL, USA, 2013. [Google Scholar]

| No. | Service Age (Year) | Type of Top Layer Mixture | Transverse Crack Spacing (m) | Transverse Crack Spacing Range (m) |

|---|---|---|---|---|

| Section 1 | 18 | AC-13 1 | 7.32 | 5~10 |

| Section 2 | 13 | AC-13 | 17.83 | 10~20 |

| Section 3 | 13 | SMA-13 2 | 24.72 | 20~30 |

| Section 4 | 21 | AC-13 | 33.44 | 30~50 |

| Section 5 | 5 | SMA-13 | 62.92 | 50~70 |

| Lab-compacted group 1 | / | AC-13 | / | / |

| Lab-compacted group 2 | / | SMA-13 | / | / |

| Basic Technical Indicators | SBS Modified Asphalt |

|---|---|

| Penetration/(25 °C, 0.1 mm) | 54 |

| Ductility/(5 °C, cm) | 29 |

| Softening Point/°C | 77 |

| Dynamic Viscosity/(60 °C, Pa·s) | 3982 |

| Elastic Recovery/(25 °C, %) | 91 |

| No. | Transverse Crack Spacing (m) | DR | ||

|---|---|---|---|---|

| Mean | Standard Deviation | Coefficient of Variation | ||

| Section 1 | 7.32 | 0.33 | 0.027 | 8.3% |

| Section 2 | 17.83 | 0.38 | 0.029 | 7.5% |

| Section 3 | 24.72 | 0.41 | 0.027 | 6.7% |

| Section 4 | 33.44 | 0.44 | 0.021 | 4.9% |

| Section 5 | 62.92 | 0.59 | 0.038 | 6.4% |

| AC-13 (Lab-compacted) | / | 0.69 | 0.026 | 3.7% |

| SMA-13 (Lab-compacted) | / | 0.72 | 0.029 | 4.0% |

| No. | Transverse Crack Spacing (m) | Sapp | ||

|---|---|---|---|---|

| Mean | Standard Deviation | Coefficient of Variation | ||

| Section 1 | 7.32 | 7.86 | 0.843 | 10.7% |

| Section 2 | 17.83 | 11.07 | 0.834 | 7.5% |

| Section 3 | 24.72 | 12.33 | 0.967 | 7.8% |

| Section 4 | 33.44 | 11.72 | 0.989 | 8.4% |

| Section 5 | 62.92 | 13.87 | 1.068 | 7.7% |

| AC-13 (Lab-compacted) | / | 17.39 | 0.904 | 5.2% |

| SMA-13 (Lab-compacted) | / | 19.53 | 1.060 | 5.4% |

| Mixture Type | DR | Sapp | ||

|---|---|---|---|---|

| Top Layer of Cores | Lab-Compacted Mixtures | Top Layer of Cores | Lab-Compacted Mixtures | |

| AC-13 (Section 2) | 0.38 | 0.69 | 11.07 | 17.39 |

| SMA-13 (Section 3) | 0.41 | 0.72 | 12.33 | 19.53 |

| AC-13/SMA-13 | 94.3% | 95.9% | 89.8% | 89.0% |

| No. | Transverse Crack Spacing (m) | Nf_5% | ||

|---|---|---|---|---|

| Mean | Standard Deviation | Coefficient of Variation | ||

| Section 1 | 7.32 | 226 | 13 | 5.8% |

| Section 2 | 17.83 | 603 | 28 | 4.7% |

| Section 3 | 24.72 | 737 | 32 | 4.3% |

| Section 4 | 33.44 | 425 | 21 | 4.9% |

| Section 5 | 62.92 | 1659 | 76 | 4.6% |

| Short-term aged SBS-modified asphalt | / | 2352 | 75 | 3.2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Xu, D.; Fan, Y.; Ma, H.; Ding, Z.; Jiang, J.; Li, J.; Ma, T. Investigation of Fatigue Performance for In-Service Asphalt Pavement Mixtures Using Push-Pull Fatigue Test. Coatings 2025, 15, 178. https://doi.org/10.3390/coatings15020178

Zhang Z, Xu D, Fan Y, Ma H, Ding Z, Jiang J, Li J, Ma T. Investigation of Fatigue Performance for In-Service Asphalt Pavement Mixtures Using Push-Pull Fatigue Test. Coatings. 2025; 15(2):178. https://doi.org/10.3390/coatings15020178

Chicago/Turabian StyleZhang, Zhanming, Duo Xu, Yunlong Fan, Hui Ma, Zihao Ding, Jiwang Jiang, Jie Li, and Tao Ma. 2025. "Investigation of Fatigue Performance for In-Service Asphalt Pavement Mixtures Using Push-Pull Fatigue Test" Coatings 15, no. 2: 178. https://doi.org/10.3390/coatings15020178

APA StyleZhang, Z., Xu, D., Fan, Y., Ma, H., Ding, Z., Jiang, J., Li, J., & Ma, T. (2025). Investigation of Fatigue Performance for In-Service Asphalt Pavement Mixtures Using Push-Pull Fatigue Test. Coatings, 15(2), 178. https://doi.org/10.3390/coatings15020178