Effect of Graphene on Interfacial Microstructure and Thermal Conductivity in Copper/Aluminum Composite Plate

Abstract

1. Introduction

2. Methods

2.1. Experimental Materials

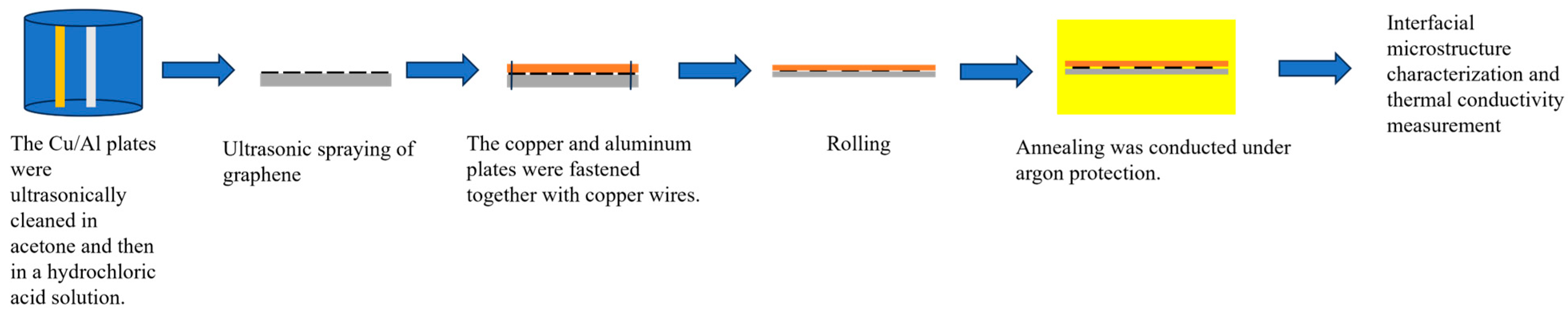

2.2. Experimental Methods

2.2.1. Pre-Rolling Treatment

2.2.2. Hot-Roll Bonding and Annealing

2.2.3. Interfacial Microstructure Characterization and Property Analysis

3. Results and Discussion

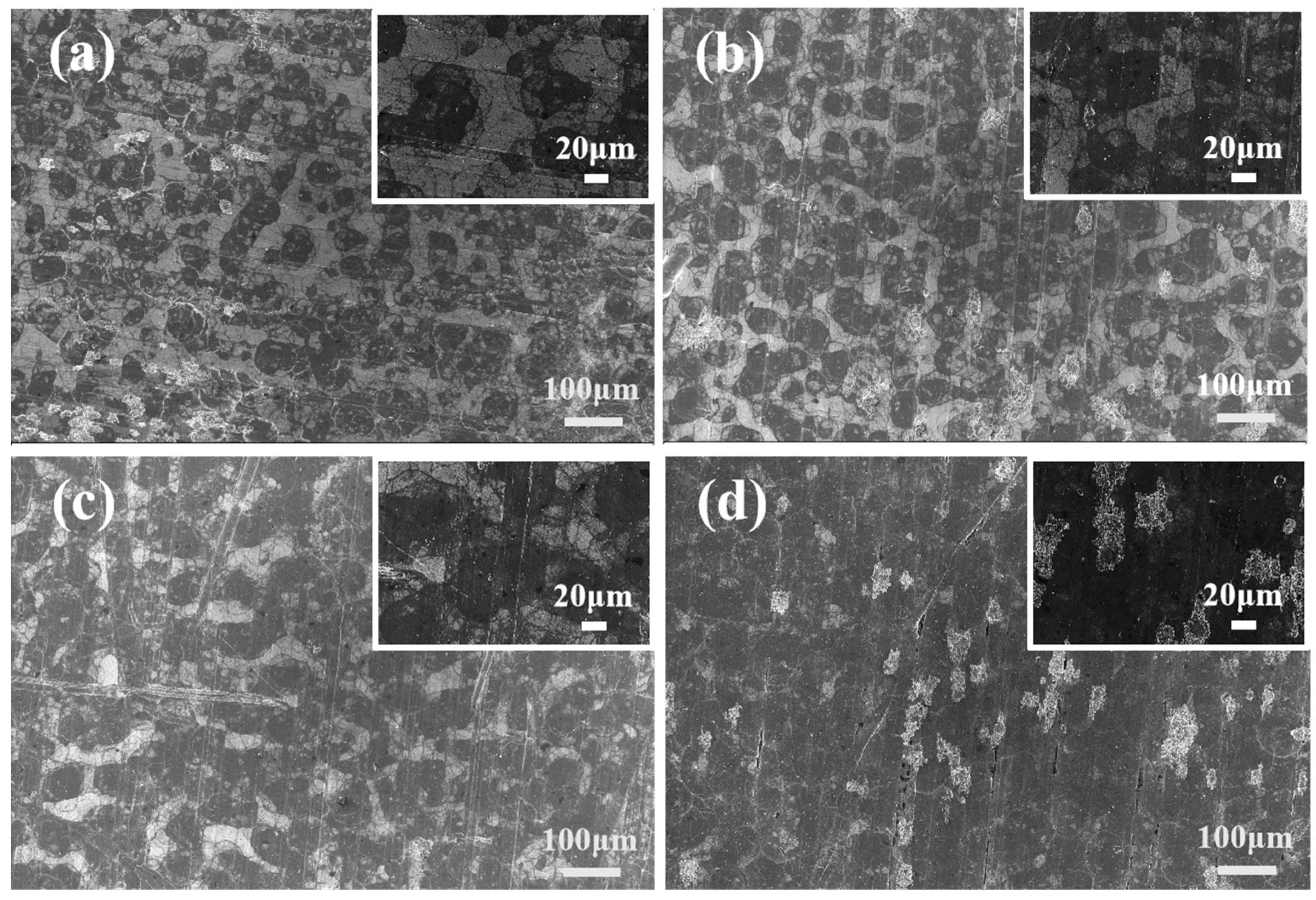

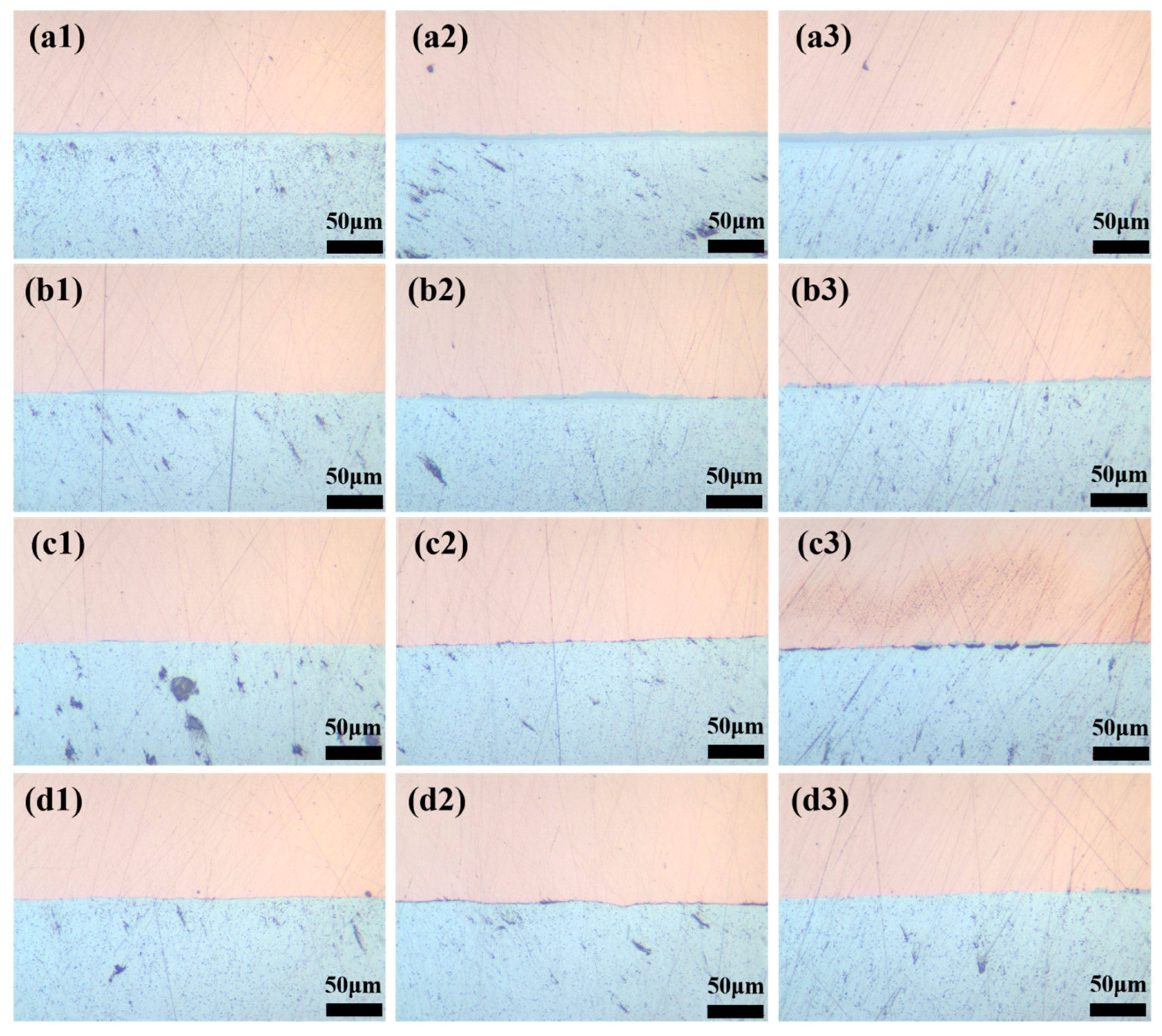

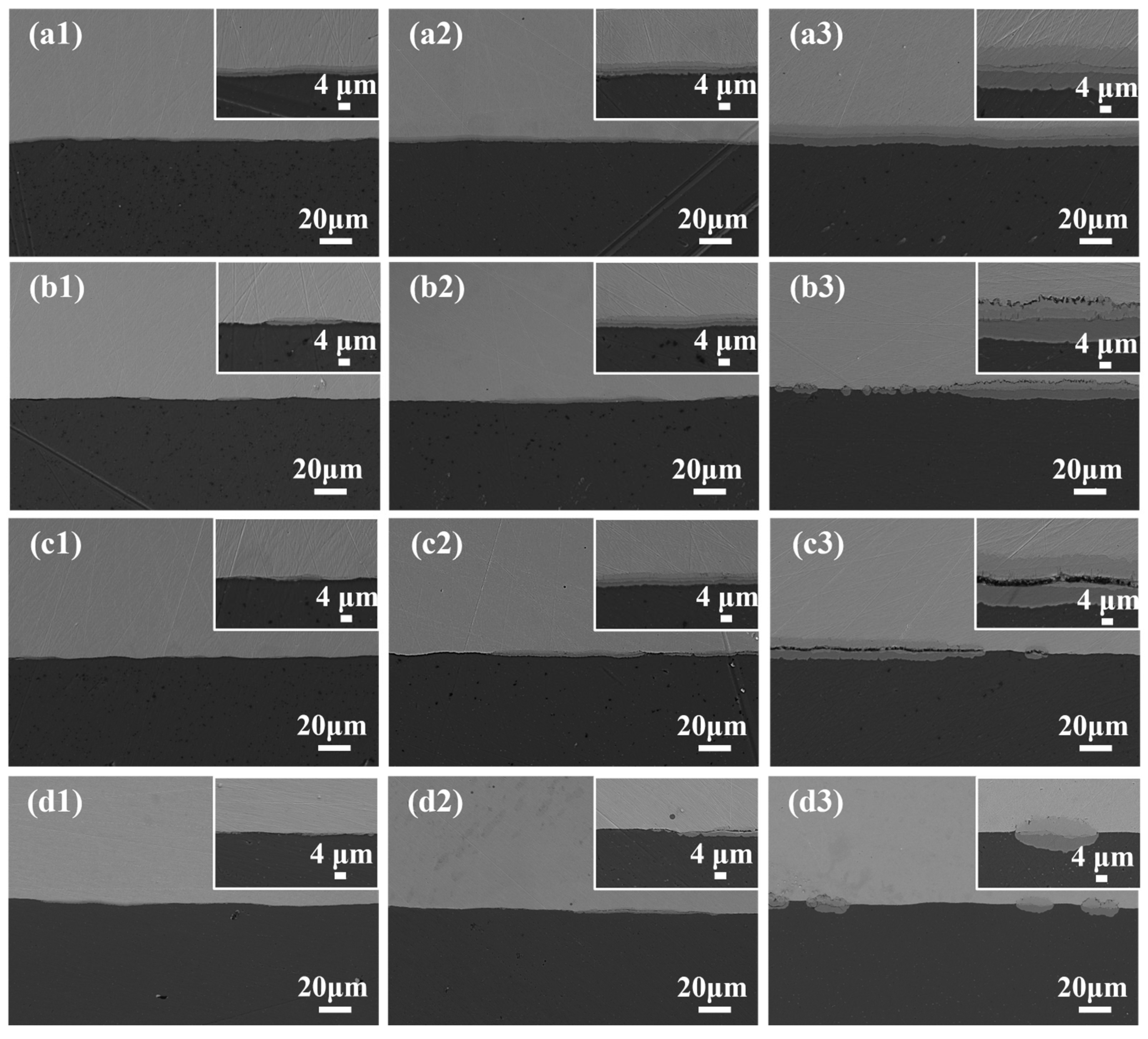

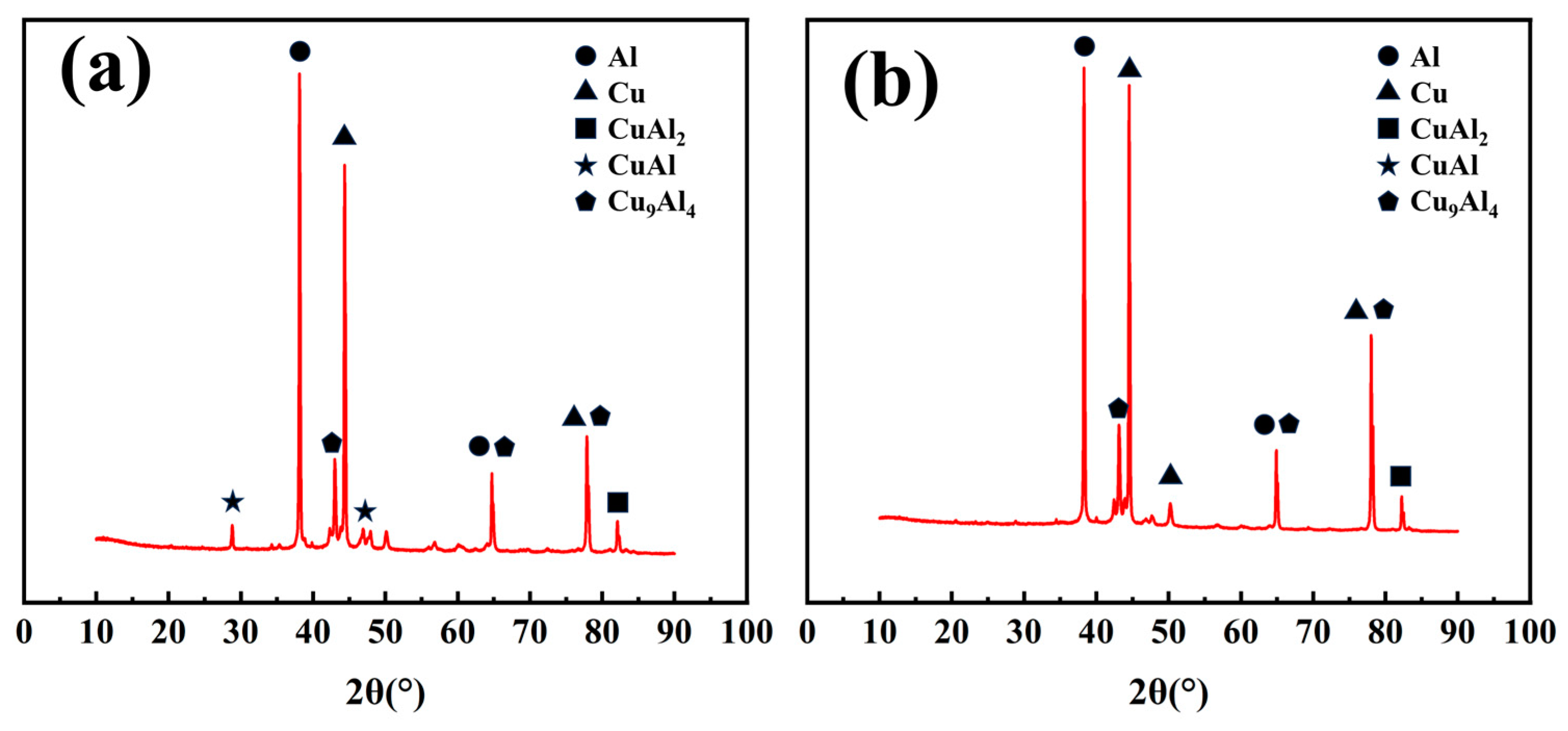

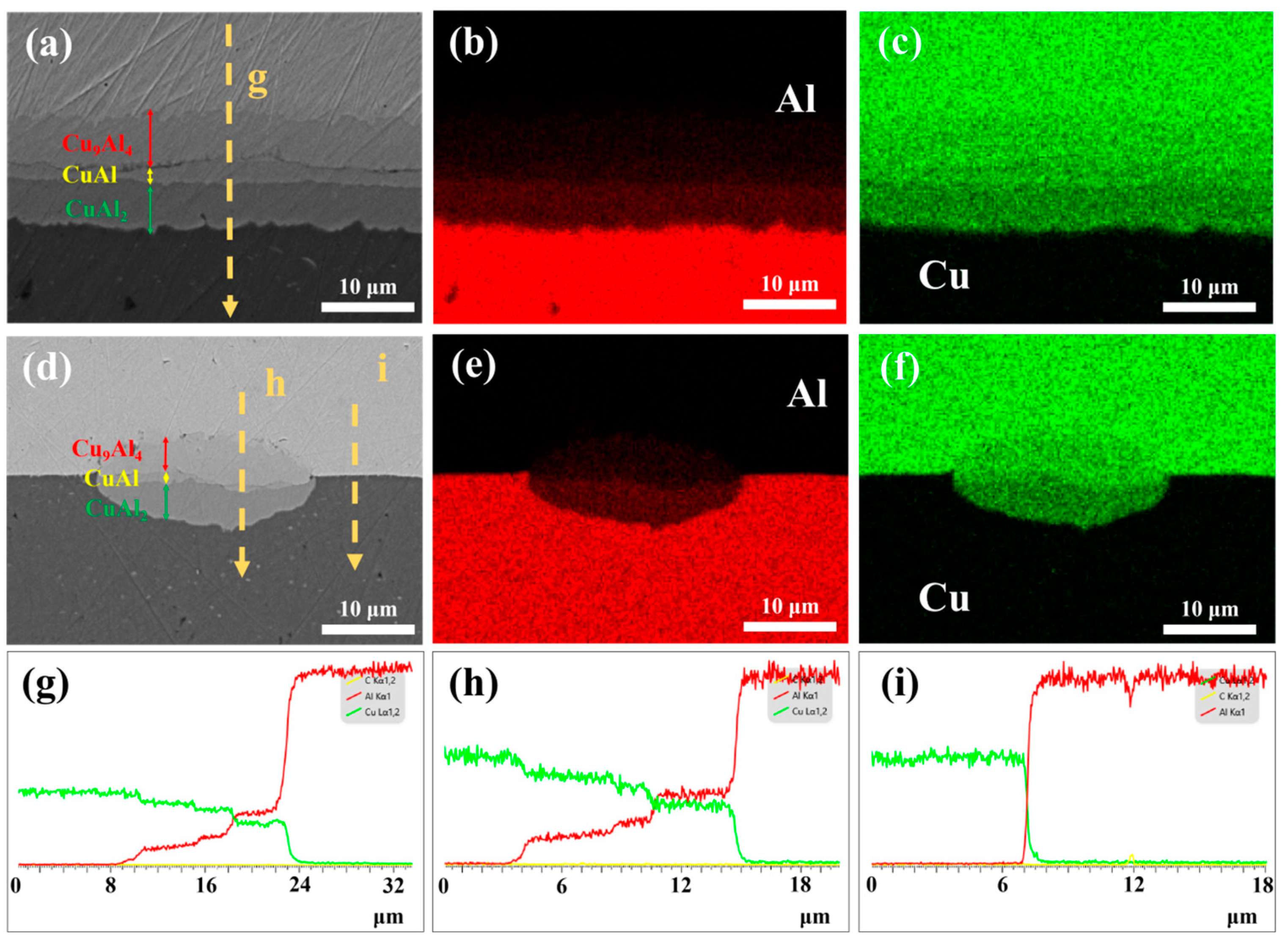

3.1. Interfacial Microstructural Characterization

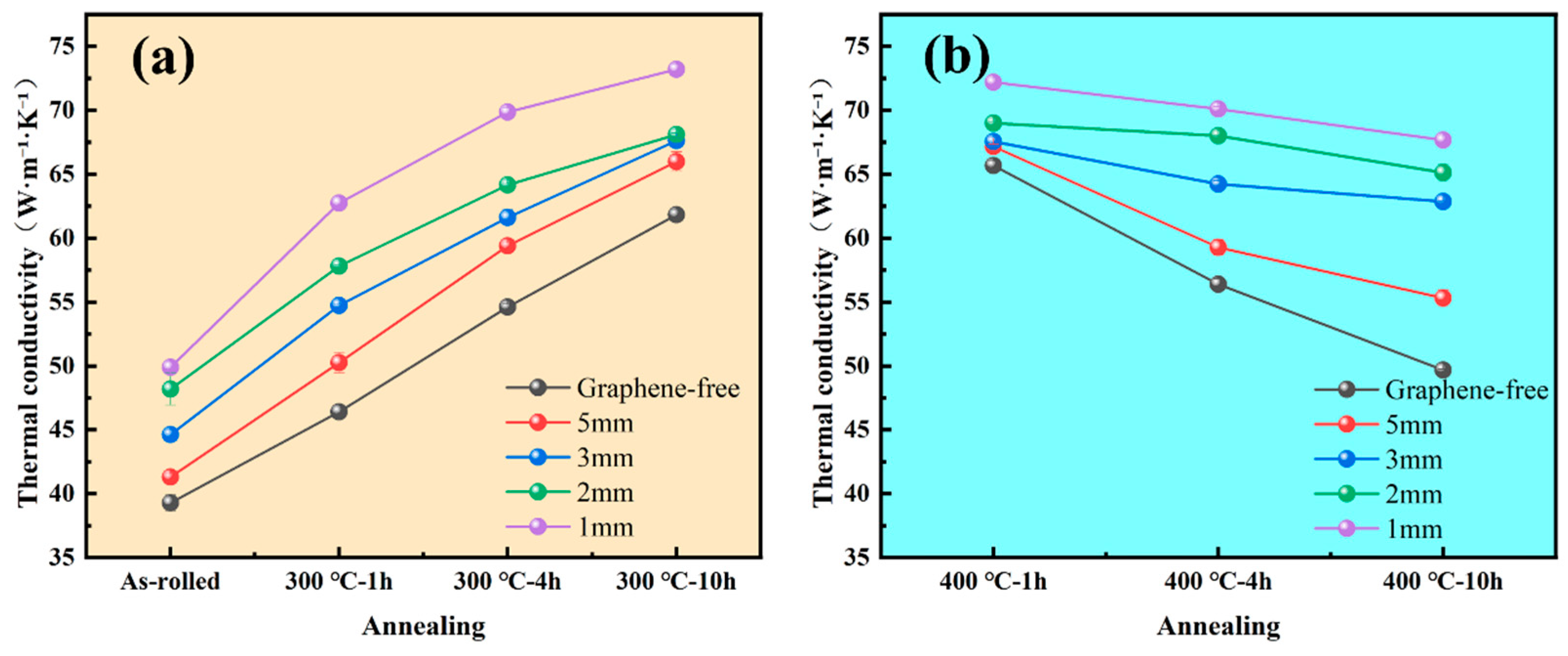

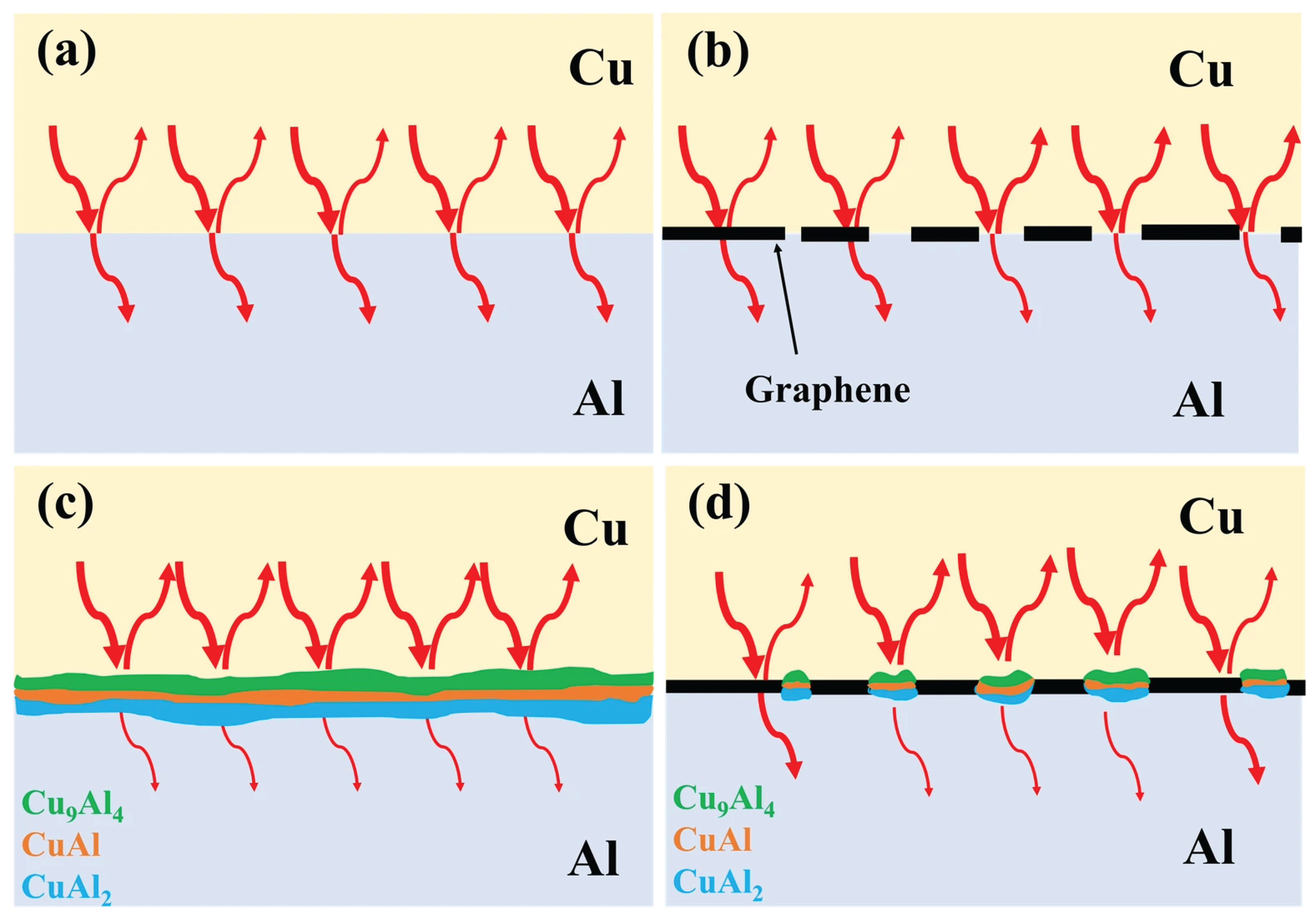

3.2. Thermal Conductivity of Cu/Al Composite Plate

4. Conclusions

- After heat treatment of the Cu/Al composite, intermetallic compounds (IMCs) form at the interface. With increasing temperature and holding time, IMC thickness progressively increases, with the primary phases sequenced from the Cu side to the Al side as: Cu9Al4, CuAl, and CuAl2.

- Annealing after graphene addition reveals that while intermetallic compound (IMC) thickness increases with elevated temperature/time, these IMCs exhibit a discontinuous morphology. This discontinuity arises from non-uniform graphene distribution induced by rolling deformation, leading to IMC growth exclusively within gaps of the graphene coating. Both the quantity and thickness of IMCs decrease proportionally with increasing graphene coverage percentage.

- During 300 °C annealing, the thermal conductivity of the Cu/Al composite plate increases with prolonged holding time, whereas at 400 °C annealing, conductivity decreases with extended holding time. Graphene-modified Cu/Al composite plate exhibit superior thermal conductivity compared to their graphene-free counterparts, with conductivity increasing proportionally to graphene coverage percentage. This enhancement primarily stems from graphene’s interfacial optimization: it restructures the interface morphology, suppresses intermetallic compound (IMC) formation, and provides high-speed thermal pathways, collectively elevating thermal conductivity beyond unmodified composites.

- Although the ultrasonic spraying parameters (e.g., distance, concentration) used in this study were optimized, their systematic effects across a wider range remain to be further investigated. Additionally, while the current work primarily evaluated performance through microstructure and thermal conductivity, other characterization methods could be employed in the future to enable a more in-depth analysis of the properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Madhusudan, S.; Sarcar, M.M.M.; Bhargava, N. Sliding Wear Studies on Aluminium–Copper Composites. Compos. Interfaces 2011, 18, 377–385. [Google Scholar] [CrossRef]

- Lin, Y.W.; Ke, W.B.; Wang, R.Y.; Wang, I.S.; Chiu, Y.T.; Lu, K.C.; Lin, K.L.; Lai, Y.S. The influence of Pd on the interfacial reactions between the Pd-plated Cu ball bond and Al pad. Surf. Coat. Technol. 2013, 231, 599–603. [Google Scholar] [CrossRef]

- Sapanathan, T.; Khoddam, S.; Zahiri, S.H.; Zarei-Hanzaki, A. Strength changes and bonded interface investigations in a spiral extruded aluminum/copper composite. Mater. Des. 2014, 57, 306–314. [Google Scholar] [CrossRef]

- Abbasi, M.; Taheri, A.K.; Salehi, M.T. Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process. J. Alloys Compd. 2001, 319, 233–241. [Google Scholar] [CrossRef]

- Kim, M.J.; Lee, K.S.; Han, S.H.; Hong, S.I. Interface strengthening of a roll-bonded two-ply Al/Cu sheet by short annealing. Mater. Charact. 2021, 174, 111021. [Google Scholar] [CrossRef]

- Eslami, P.; Karimi Taheri, A.; Zebardast, M. A comparison between cold-welded and diffusion-bonded Al/Cu bimetallic rods produced by ECAE process. J. Mater. Eng. Perform. 2013, 22, 3014–3023. [Google Scholar] [CrossRef]

- Hug, E.; Bellido, N. Brittleness study of intermetallic (Cu, Al) layers in copper-clad aluminium thin wires. Mater. Sci. Eng. A 2011, 528, 7103–7106. [Google Scholar] [CrossRef]

- Lee, T.H.; Lee, Y.J.; Park, K.T.; Jeong, H.G.; Lee, J.H. Mechanical and asymmetrical thermal properties of Al/Cu composite fabricated by repeated hydrostatic extrusion process. Met. Mater. Int. 2015, 21, 402–407. [Google Scholar] [CrossRef]

- Yan, W.; Wang, X.; Liu, M.; Ma, K.; Wang, L.; Liu, Q.; Wang, C.; Jiang, X.; Li, H.; Tang, Y.; et al. PCTS-controlled synthesis of L10/L12-typed Pt-Mn intermetallics for electrocatalytic oxygen reduction. Adv. Funct. Mater. 2024, 34, 2310487. [Google Scholar] [CrossRef]

- Zhang, B.; Fu, G.; Li, Y.; Liang, L.; Grundish, N.S.; Tang, Y.; Goodenough, J.B.; Cui, Z. General strategy for synthesis of ordered Pt3M intermetallics with ultrasmall particle size. Angew. Chem. Int. Ed. 2020, 59, 7857–7863. [Google Scholar] [CrossRef] [PubMed]

- Xiong, N.; Friedrich, S.; Friedrich, B. Purification of the Al2Cu intermetallic compound via zone melting crystallization technique. J. Mater. Res. Technol. 2023, 26, 973–983. [Google Scholar] [CrossRef]

- Mbayachi, V.B.; Ndayiragije, E.; Sammani, T.; Taj, S.; Mbuta, E.R. Graphene synthesis, characterization and its applications: A review. Results Chem. 2021, 3, 100163. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Sahoo, S.; Wang, N.; Huczko, A. Graphene research and their outputs: Status and prospect. J. Sci. Adv. Mater. Devices 2020, 5, 10–29. [Google Scholar] [CrossRef]

- Ge, X.; Chai, Z.; Shi, Q.; Liu, Y.; Wang, W. Graphene superlubricity: A review. Friction 2023, 11, 1953–1973. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Sharma, B.; Saju, B.R.; Shukla, A.; Saxena, A.; Maurya, N.K. Effect of Graphene nanoparticles on microstructural and mechanical properties of aluminum based nanocomposites fabricated by stir casting. World J. Eng. 2020, 17, 859–866. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669.8. [Google Scholar] [CrossRef] [PubMed]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Nieto, A.; Bisht, A.; Lahiri, D.; Zhang, C.; Agarwal, A. Graphene reinforced metal and ceramic matrix composites: A review. Int. Mater. Rev. 2017, 62, 241–302. [Google Scholar] [CrossRef]

- Yang, X.; Yang, L.; Zhu, D.; Wang, H.; Chen, T.; Chu, C.; Jiang, Z. Effect of graphene sheet diameter on the microstructure and properties of copper-plated graphene-reinforced 6061-aluminum matrix composites. J. Mater. Res. Technol. 2024, 28, 3286–3296. [Google Scholar] [CrossRef]

- Wang, J.; Guo, L.; Lin, W.; Chen, J.; Liu, C.; Chen, S.; Zhang, S.; Zhen, T. Effect of the graphene content on the microstructures and properties of graphene/aluminum composites. New Carbon Mater. 2019, 34, 275–285. [Google Scholar] [CrossRef]

| Fe | Si | Cu | Mn | Mg | Zn | V | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 0.14 | 0.12 | 0.03 | 0.01 | 0.02 | 0.03 | 0.03 | 0.02 | allowance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Yang, Z.; Shen, Y.; Wang, R.; Wang, L. Effect of Graphene on Interfacial Microstructure and Thermal Conductivity in Copper/Aluminum Composite Plate. Coatings 2025, 15, 1468. https://doi.org/10.3390/coatings15121468

Liu Y, Yang Z, Shen Y, Wang R, Wang L. Effect of Graphene on Interfacial Microstructure and Thermal Conductivity in Copper/Aluminum Composite Plate. Coatings. 2025; 15(12):1468. https://doi.org/10.3390/coatings15121468

Chicago/Turabian StyleLiu, Yifan, Zhaoyang Yang, Yusha Shen, Rui Wang, and Lianbo Wang. 2025. "Effect of Graphene on Interfacial Microstructure and Thermal Conductivity in Copper/Aluminum Composite Plate" Coatings 15, no. 12: 1468. https://doi.org/10.3390/coatings15121468

APA StyleLiu, Y., Yang, Z., Shen, Y., Wang, R., & Wang, L. (2025). Effect of Graphene on Interfacial Microstructure and Thermal Conductivity in Copper/Aluminum Composite Plate. Coatings, 15(12), 1468. https://doi.org/10.3390/coatings15121468