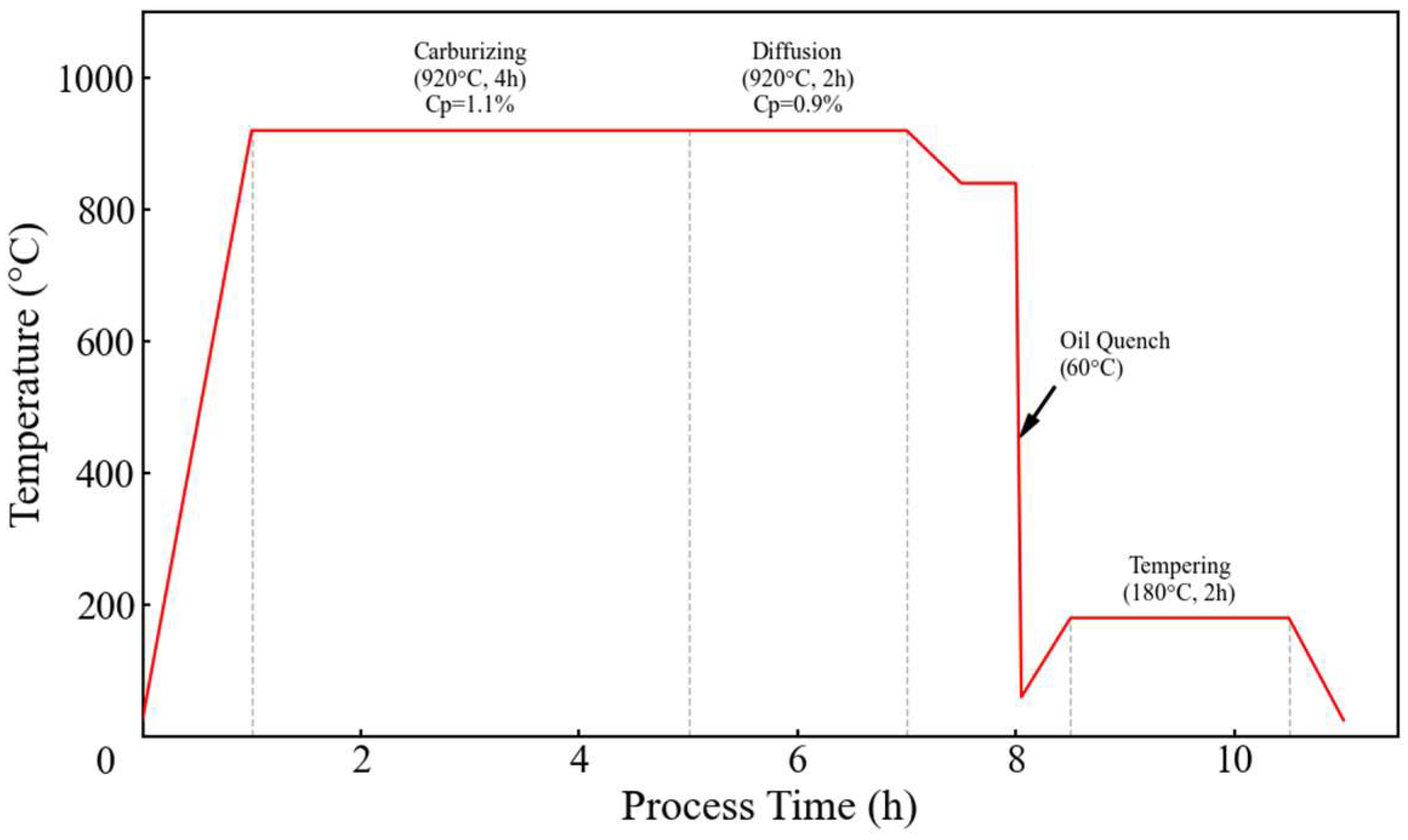

3.1. Characterization Result Analysis

3.1.1. Metallographic Analysis

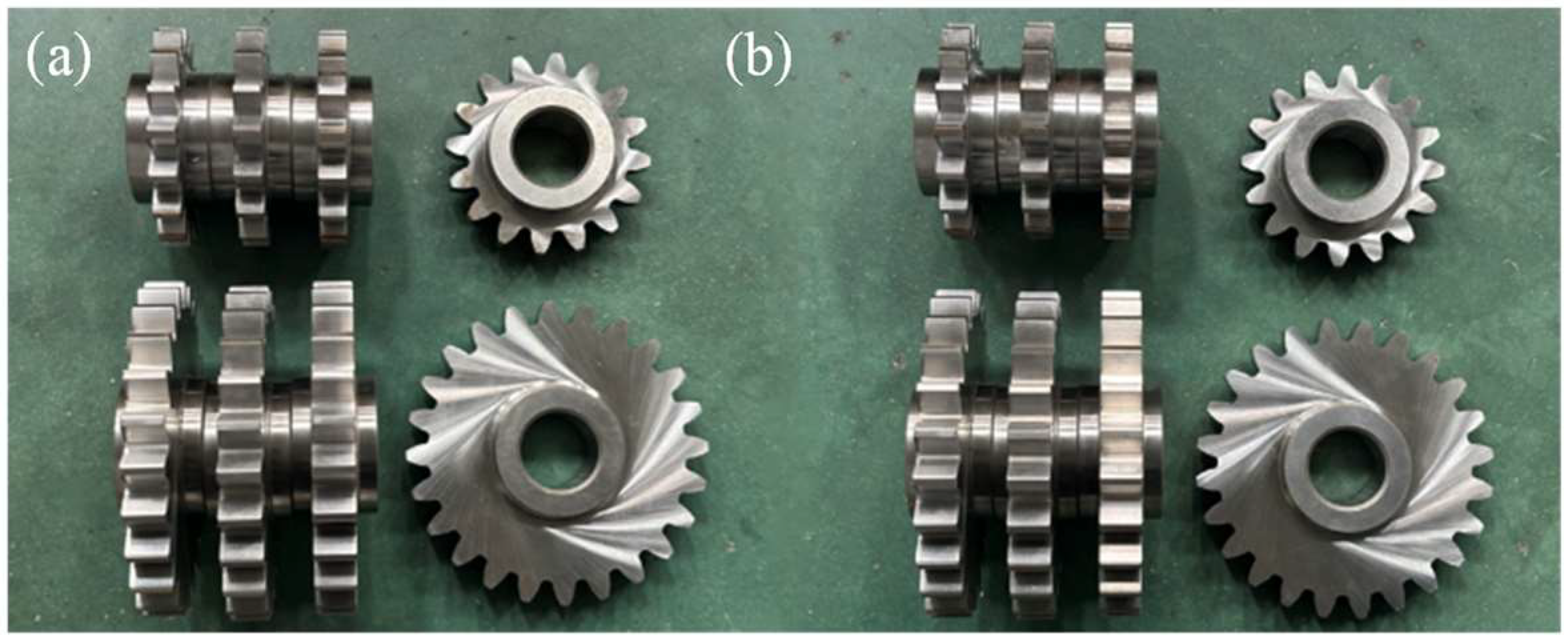

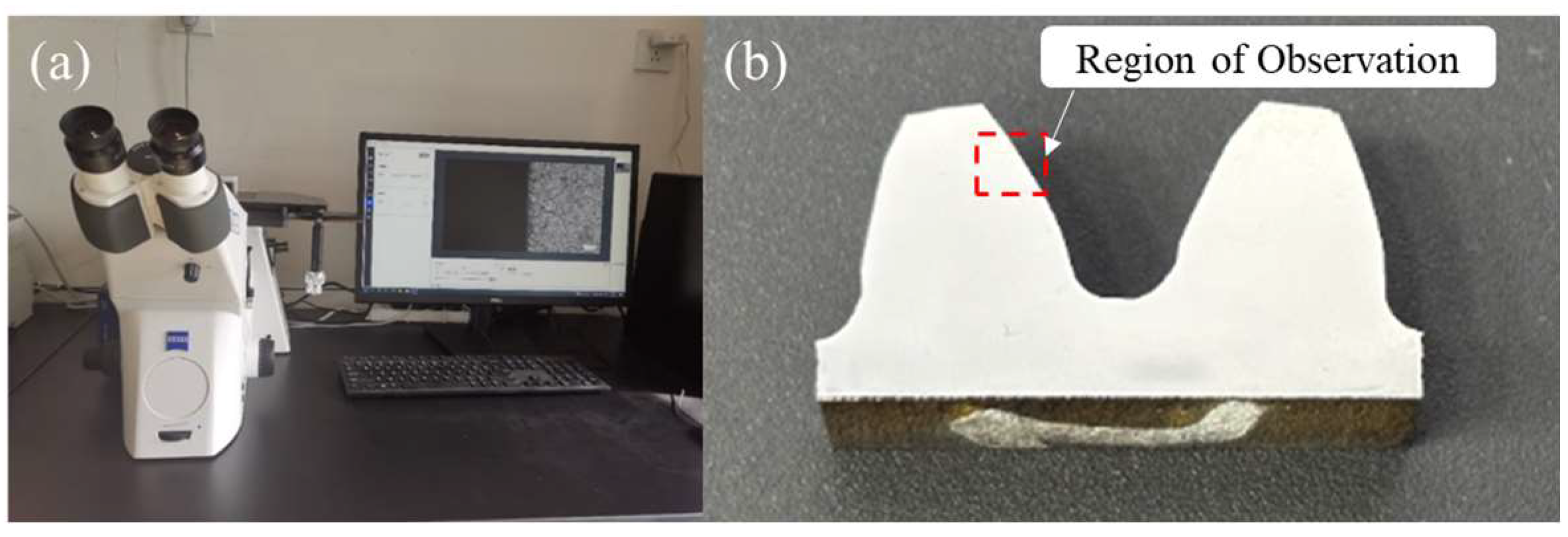

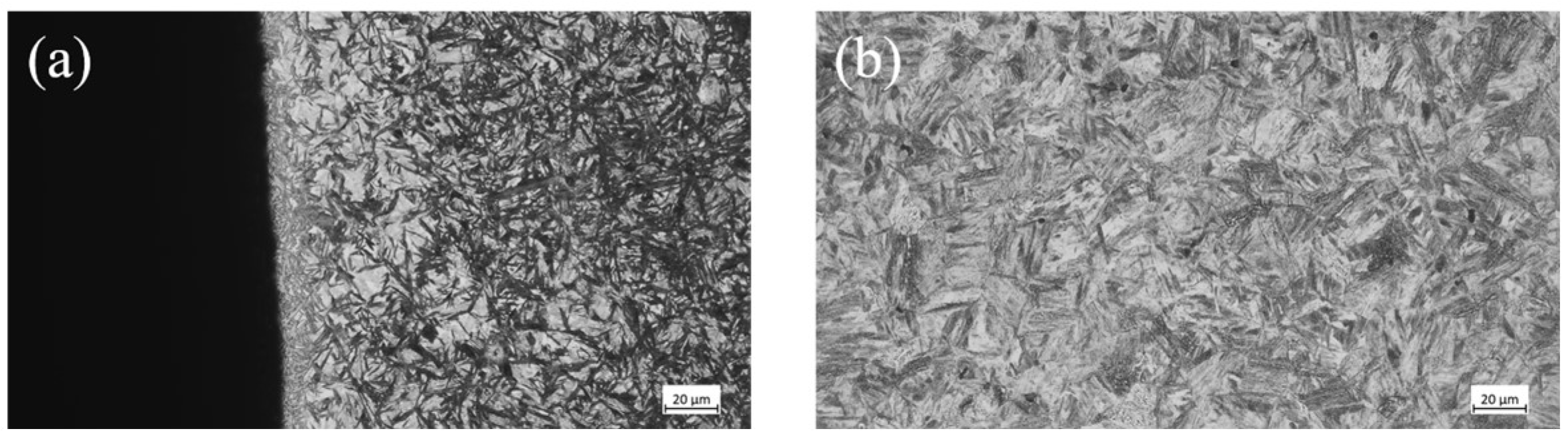

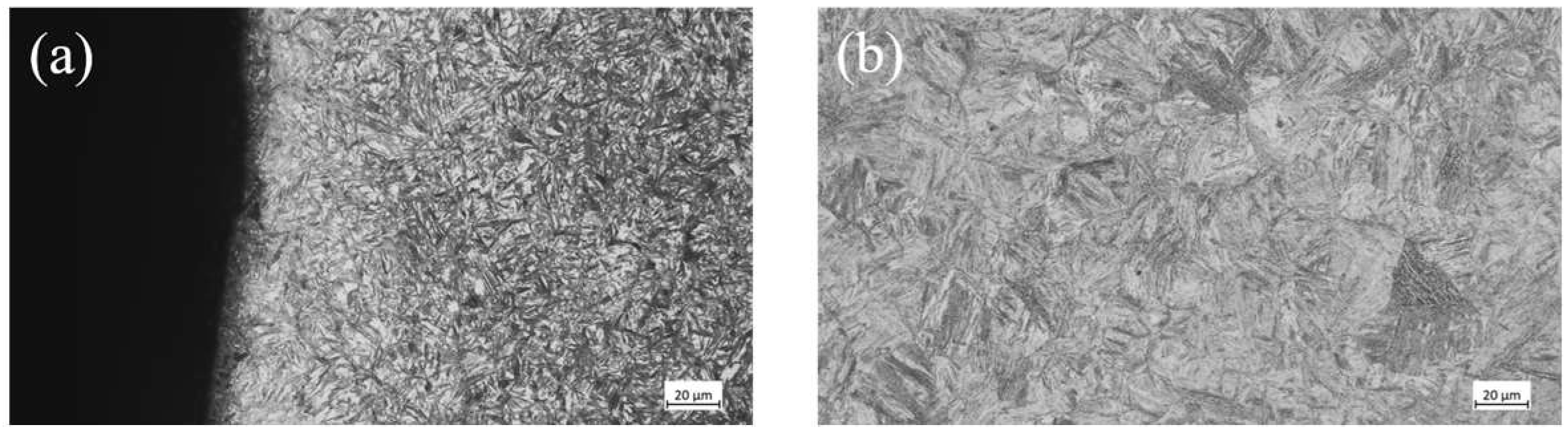

Figure 9 and

Figure 10 present the metallurgical structures of the 20MnCr5 and 20CrMoH gears in the surface and core regions, respectively. The microstructures were evaluated and graded in accordance with standards ISO 4967: 2013 and GB/T 25744-2010 [

38,

39], with the results summarized in

Table 5.

The carburized layers of both gear materials are predominantly composed of martensite, retained austenite, and carbides, while their core microstructures consist of uniform tempered sorbite with minor ferrite content. Both materials demonstrate carbide and core microstructure ratings of Grade 1, indicating comparable degrees of microstructural homogeneity and stability. Nevertheless, substantial differences emerge in the crucial microstructural features of the carburized layers. 20CrMoH exhibits martensite with a Grade 3 classification, characterized by finely distributed laths exhibiting blurred boundaries, indicative of a complete quenching transformation. Its retained austenite, similarly rated Grade 3, appears in relatively low concentration as isolated islands dispersed between martensite laths. In contrast, 20MnCr5 displays a coarser martensite structure achieving a Grade 4 rating with localized lath aggregation, along with retained austenite of Grade 4 classification that demonstrates significantly higher content and forms continuous thin films along martensite lath boundaries.

To address the need for quantitative microstructural metrics, the prior-austenite grain size and carbide distribution were further analyzed. The 20CrMoH gear exhibits a finer prior-austenite grain size average diameter ≈ 20 μm, attributed to the grain-refining effect of Molybdenum. In contrast, the 20MnCr5 gear shows a slightly coarser grain structure average diameter ≈ 30 μm. Regarding carbides, both materials exhibit a Grade 1 distribution, characterized by distinct, fine spherical carbides average diameter < 0.8 μm uniformly dispersed within the martensitic matrix. This microstructural difference has significant mechanical implications: the finer grain size and dispersed carbides in 20CrMoH contribute to its steeper hardness gradient and higher yield strength via the Hall-Petch effect. However, this Mo-driven strengthening creates a mechanistic trade-off. Unlike Manganese which strongly stabilizes austenite, Molybdenum promotes a more complete martensitic transformation, resulting in a lower retained austenite content. Consequently, the high-hardness matrix of 20CrMoH lacks the necessary ductility and transformation-toughening capacity to accommodate local stress concentrations. This inability to plastically relieve stress peaks explains the shift in failure mode from ductile micropitting to the catastrophic brittle spalling observed.

To quantify the microstructural evolution under cyclic contact loading, the retained austenite content was measured before and after testing using XRD. The XRD test was performed using the quasi-tilt fixed Ψ method, with the Gaussian function fitting adopted for peak positioning of both α-phase and γ-phase; the 2θ scanning range was set to 148.00–163.00° for α-phase and 125.00–132.00° for γ-phase. The results are presented in

Table 6.

To rigorously verify that the superior fatigue resistance of 20MnCr5 is dominantly governed by transformation toughening rather than differences in microstructural quality, we quantitatively compared the heterogeneity metrics. As shown in

Table 5, both alloys exhibit identical Grade 1 ratings for carbides, core microstructure, and non-metallic inclusions, indicating a comparable and high level of microstructural homogeneity. With heterogeneity ruled out as a differentiating factor, the dominant mechanism is identified through the XRD quantification: 20MnCr5 exhibits a significantly larger volume of transformed austenite (RA ≈ Δ16.9%) compared to 20CrMoH (RA ≈ Δ12%). This higher transformation volume provides superior energy absorption capability, directly correlating with the observed fatigue limit improvement.

Although EBSD (Electron Backscatter Diffraction) characterization was not performed in this study to visualize the local phase transformation at the crack tip, our quantitative XRD results provide robust macroscopic evidence. The retained austenite content in 20MnCr5 significantly decreased from 44.27% to 27.40% after fatigue testing. According to previous EBSD studies by Yan et al. [

40] and Liu et al. [

41], this reduction corresponds to the Strain-Induced Martensitic Transformation localized in the plastic deformation zone. While this transformation theoretically follows the subsurface shear stress gradient, depth-resolved quantification was precluded by the surface roughness of the fatigued samples; nonetheless, the aggregate reduction confirms the global toughening effect. This transformation absorbs deformation energy, introduces compressive residual stress, and relaxes local stress concentrations, thereby inhibiting crack propagation. This mechanism explains why 20MnCr5, despite having lower surface hardness than 20CrMoH, exhibits superior contact fatigue life.

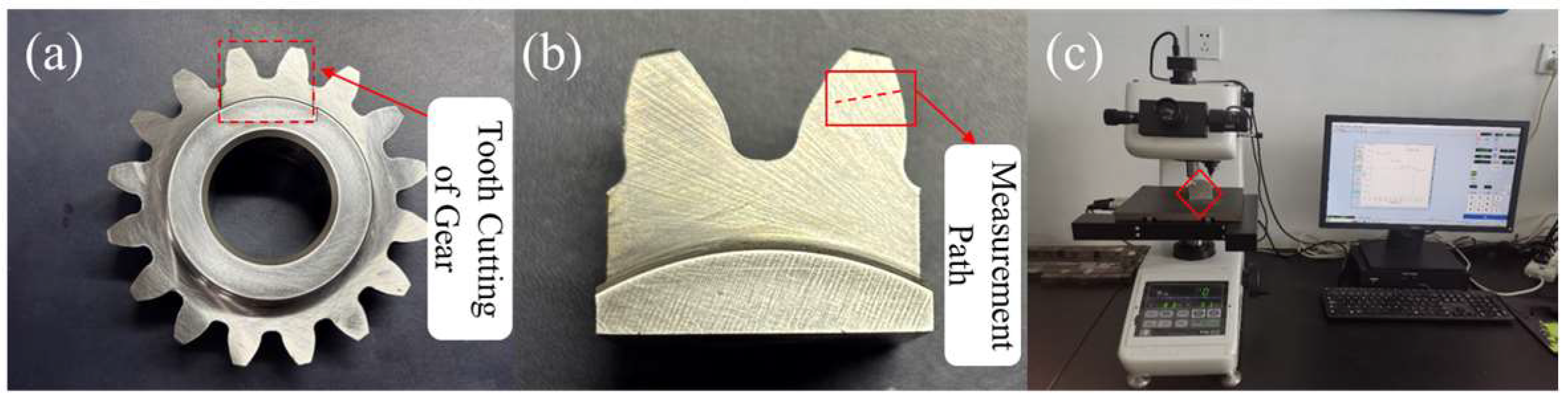

3.1.2. Microhardness Analysis

The hardness gradient distribution serves as a critical indicator for evaluating the contact fatigue performance of gears, as its variation characteristics directly influence the material’s stress response and crack initiation behavior under cyclic loading.

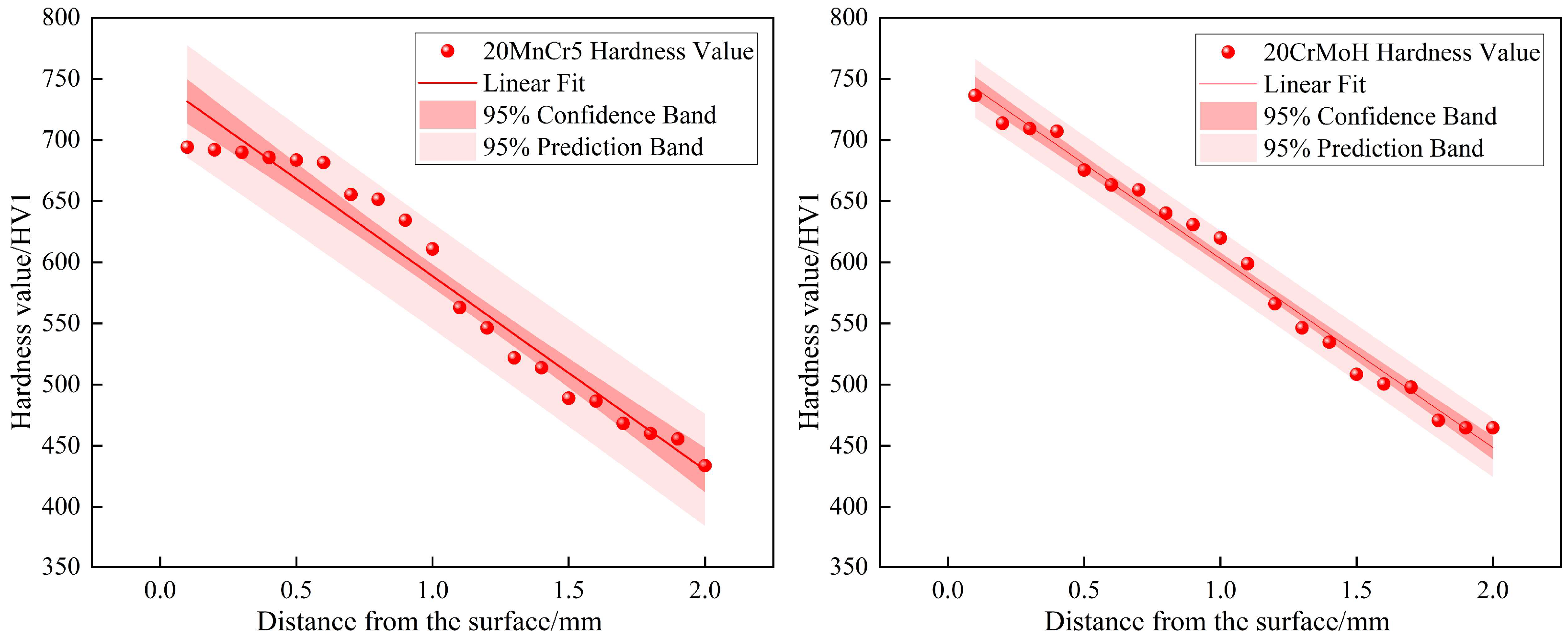

Figure 11 illustrates the hardness distribution profiles along the direction normal to the tooth surface for both 20MnCr5 and 20CrMoH gears (Statistical analysis and graphical plotting were performed using Origin 2024 (OriginLab Corporation, Northampton, MA, USA)). The results demonstrate that the two materials exhibit fundamentally distinct hardness decay behaviors from the surface to the core region, thereby providing a foundational explanation for their differing fatigue performance.

The 20CrMoH gear exhibits a surface hardness of 736.4 HV1.0, which is higher than the 694.1 HV1.0 measured for the 20MnCr5 gear. However, this higher initial hardness acts as a double-edged sword; without sufficient toughness (provided by retained austenite), the harder matrix becomes more notch-sensitive and prone to brittle cracking, proving that surface hardness alone is not the sole determinant of fatigue life. Furthermore, the 20CrMoH specimen demonstrates a more pronounced hardness degradation with increasing depth. At a depth of 0.5 mm, its hardness decreases to 675.4 HV1.0, corresponding to a hardness gradient of −122 HV/mm, with an effective case depth of 1.28 mm. This steep hardness transition suggests limited load-bearing capacity in the subsurface region, making it susceptible to plastic accumulation and crack initiation under contact stress.

It is acknowledged that the hardness profile of carburized layers typically follows a non-linear distribution. However, to quantitatively compare the property degradation rates, a linear regression analysis was performed on the high-density measurement data. The shaded regions in

Figure 11 represent the 95% confidence bands of the linear fit. The narrow width of these bands, combined with high coefficients of determination, statistically confirms that the calculated hardness gradients are robust descriptors of the subsurface material properties, effectively distinguishing the physical trend from measurement scatter. Crucially, this statistical stability extends specifically to the carburized–core transition zone, where the narrow confidence bands confirm that the gradient transition is a stable material property rather than an artifact of local heterogeneity.

In contrast, the 20MnCr5 gear, despite its marginally lower surface hardness, maintains a more gradual hardness distribution along the depth direction. At the 0.5 mm depth, the hardness remains at 683.6 HV1.0, with a minimal hardness gradient of −21 HV/mm and an effective case depth of 1.18 mm. Mechanistically, this gentler gradient is attributed to diffusion kinetics: unlike Molybdenum (in 20CrMoH) which strongly retards carbon diffusion leading to a steep concentration profile, Manganese (in 20MnCr5) facilitates a more uniform inward carbon penetration under the same carburizing potential.

It is crucial to note that the Effective Case Depth (ECD) of 20CrMoH is actually deeper than that of 20MnCr5. Typically, a deeper carburized case correlates with higher load-bearing capacity. The observation that 20CrMoH exhibits inferior fatigue life despite its deeper case serves as compelling evidence that the performance deficit is not due to insufficient carburizing depth or process inconsistency. Instead, it confirms that the failure is intrinsically governed by the material’s steeper hardness gradient and brittle microstructural response.

Studies have shown that the geometric characteristics of the hardness gradient exert a decisive influence on the fatigue life of gears. Compared with a steep hardness distribution, a gentle and convex hardness gradient can more effectively cover the subsurface Hertzian shear stress field, significantly inhibiting plastic deformation and the early initiation of cracks [

42]. In addition, the gentle gradient distribution can also effectively alleviate the stress concentration in the transition zone between the hardened layer and the core, reducing the risk of subsurface crack initiation in the transition zone [

43,

44]. Validated by analytical contact mechanics models [

23,

42], this link exists because the hardness gradient serves as a proxy for depth-dependent shear yield strength τ

yield. The gentler gradient in 20MnCr5 effectively maintains τ

yield above the theoretical subsurface Hertzian shear stress τ

max, whereas the steep gradient in 20CrMoH creates a weak zone vulnerable to shear yielding.

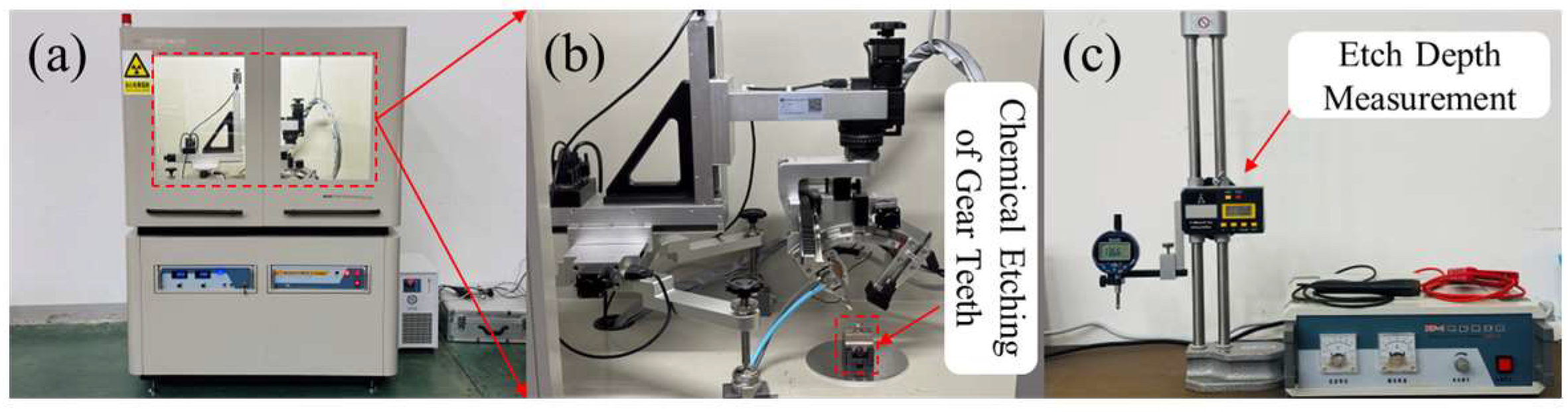

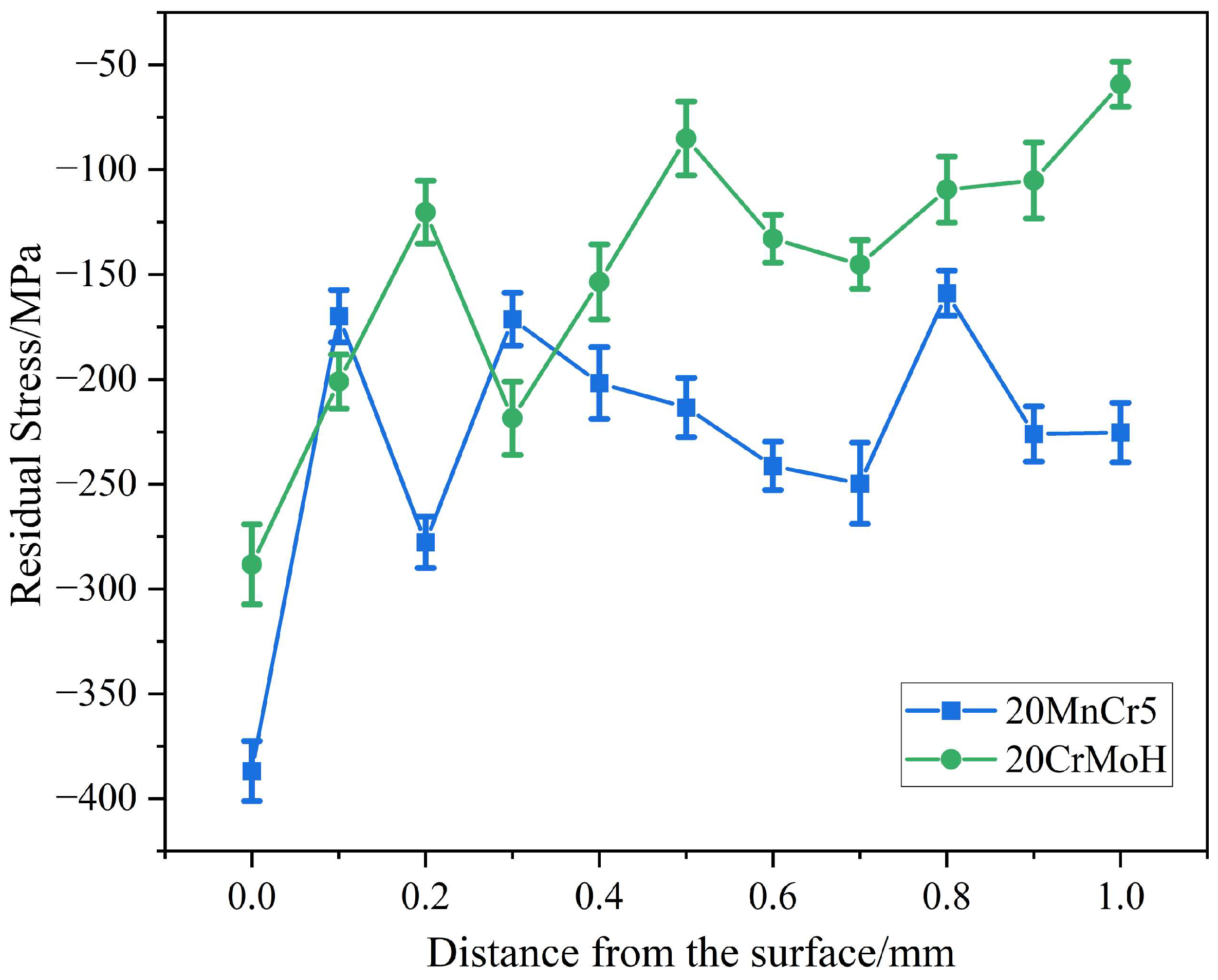

3.1.3. Residual Stress Analysis

The distribution of residual stress serves as a critical surface integrity parameter influencing the contact fatigue performance of gears. In this paper, the measurement parameters are summarized in

Table 7 and

Figure 12 presents the residual stress gradient profiles along the direction normal to the tooth surface for both 20MnCr5 and 20CrMoH gears.

Both gear materials exhibit compressive residual stress states at the surface, with the 20MnCr5 gear demonstrating a surface residual stress of −386.8 MPa, significantly higher than the −288.3 MPa measured for the 20CrMoH gear. The superior surface compressive stress in 20MnCr5 gear effectively counteracts tensile stresses induced by external loads, thereby enhancing resistance to fatigue crack initiation.

With increasing depth, the two materials display markedly different residual stress attenuation behaviors. The 20MnCr5 gear maintains relatively stable residual stress levels within the 0–0.5 mm depth range, fluctuating between −169.9 MPa and −386.8 MPa. At the 0.5 mm depth, the residual stress measures approximately −213.4 MPa, remaining at −225.3 MPa even at the 1.0 mm depth, indicating gradual attenuation throughout the subsurface region. In contrast, the 20CrMoH gear exhibits more rapid stress attenuation, with residual stress declining to −85.1 MPa at 0.5 mm depth and further diminishing to −59.3 MPa at 1.0 mm depth.

The gradual attenuation characteristics of residual stress in the 20MnCr5 gear correspond well with its hardness gradient behavior. This coordinated mechanical response establishes superior stability in the subsurface region, effectively suppressing both the initiation and propagation of contact fatigue cracks, thereby providing the mechanical foundation for its enhanced contact fatigue limit. Furthermore, regarding dynamic redistribution, the strain-induced transformation in 20MnCr5 generates compressive volume expansion, which effectively compensates for cyclic stress relaxation. In contrast, 20CrMoH lacks this compensation, implying that the performance gap inferred from pre-test profiles is likely amplified during actual service.

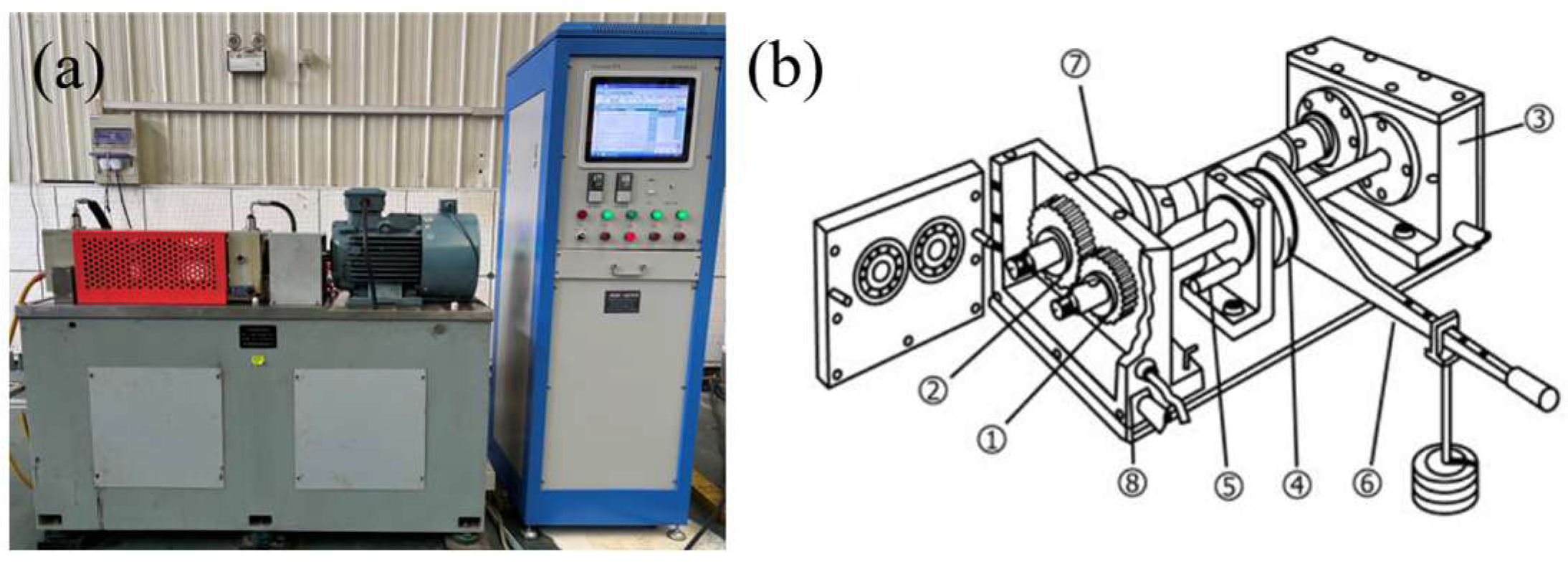

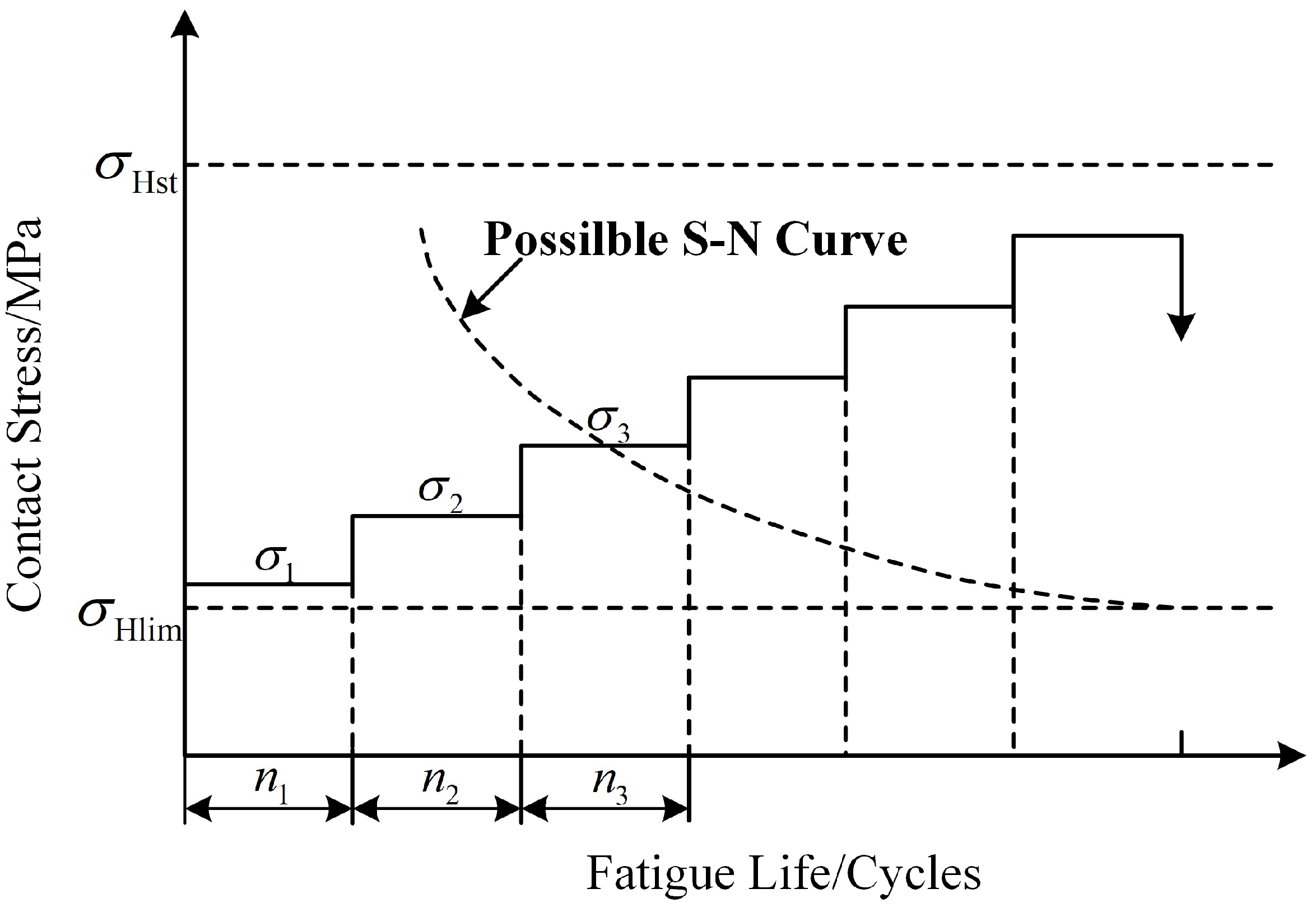

3.2. Fatigue Test Results Analysis

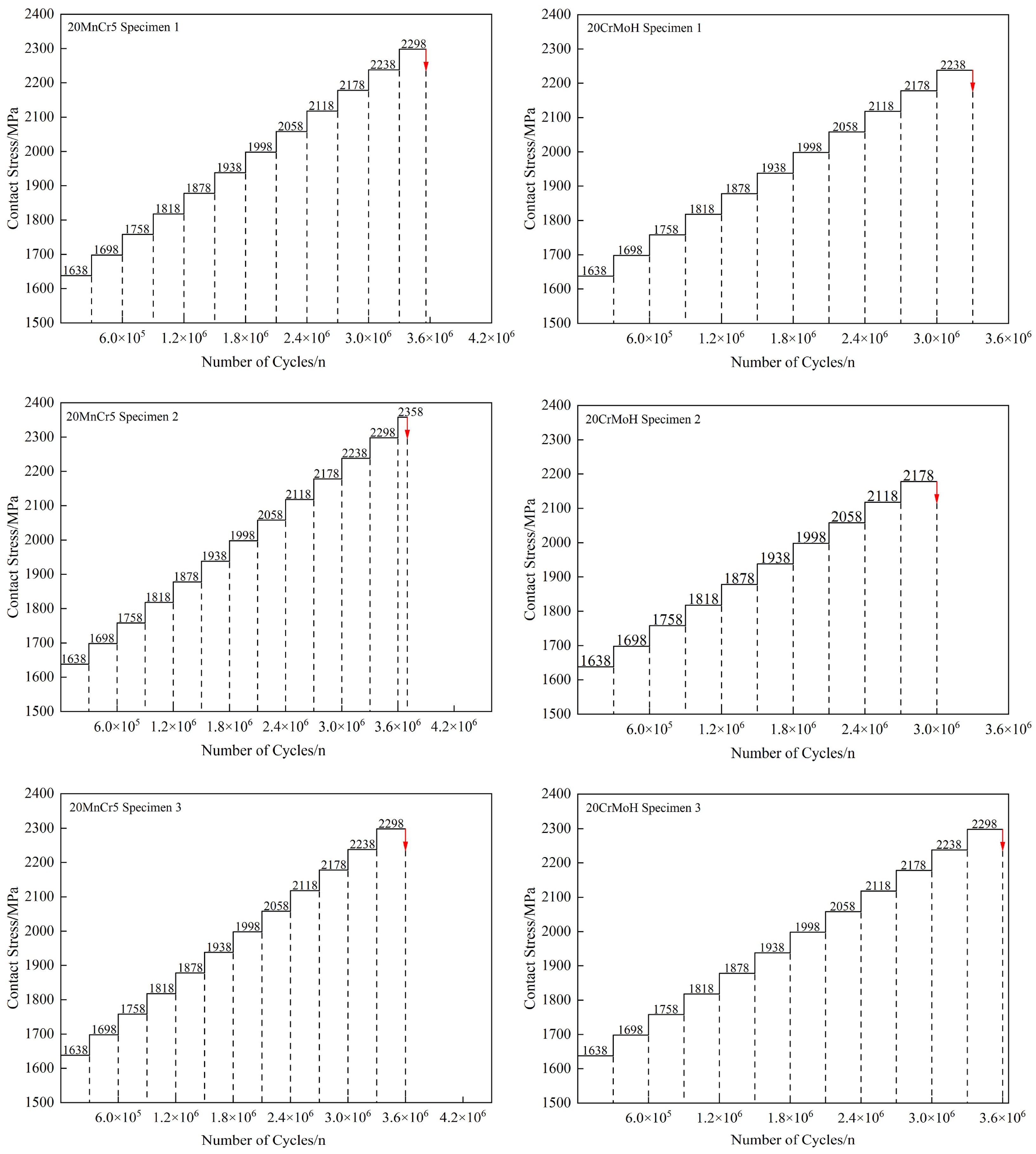

To systematically compare the contact fatigue performance of 20MnCr5 and 20CrMoH gears, contact fatigue tests were conducted using the step-loading method. Three valid specimens from each material were tested, yielding six sets of fatigue failure data. The processed experimental data are summarized in

Table 8, while the loading sequence during testing is illustrated in

Figure 13 (detailed data are listed in

Appendix A).

Upon obtaining the fatigue failure data points presented in

Table 6 and

Figure 12, the contact fatigue limit σ

Hlim was precisely determined using the three assumed S-N curves method combined with cumulative damage interpolation. The procedure was implemented as follows:

a. Three reference S-N curves were postulated, each characterized by distinct assumed fatigue limits designated as σ

Hlim1, σ

Hlim2, and σ

Hlim3. The S-N curve for σ

Hlim calculation was constructed based on the Basquin equation:

where

σ: Stress amplitude.

N: Fatigue life. m: Fatigue strength exponent.

C: Material fatigue constant. For the pitting failure of carburized and quenched gears, the value of m is taken as 13.22 [

45]. While m = 13.22 is selected based on the ISO 6336 standard for carburized gears, the sensitivity of the calculated fatigue limit to this assumed slope was further evaluated. A sensitivity analysis varying

m within the typical range for high-strength steels

m = 10 to 16 revealed that the variation in the calculated fatigue limit

σHlim is less than 3%. Crucially, regardless of the m value selected within this range, the relative performance ranking remains unchanged, with 20MnCr5 consistently exhibiting superior fatigue resistance compared to 20CrMoH. Thus, the standard value of 13.22 provides a robust and comparative basis for this study. Furthermore, potential calculation bias from tooth-to-tooth stress variability is minimized by the pre-test running-in process and the high-cycle averaging nature of the protocol (3.0 × 10

5 cycles per step), which homogenizes local geometric deviations.

b. Adopted as a standardized comparative metric, the cumulative damage index ∑(ni/Ni) was computed at every applied stress level, where n represents the actual number of cycles and N denotes the predicted fatigue life at the corresponding stress level according to the respective S-N curve.

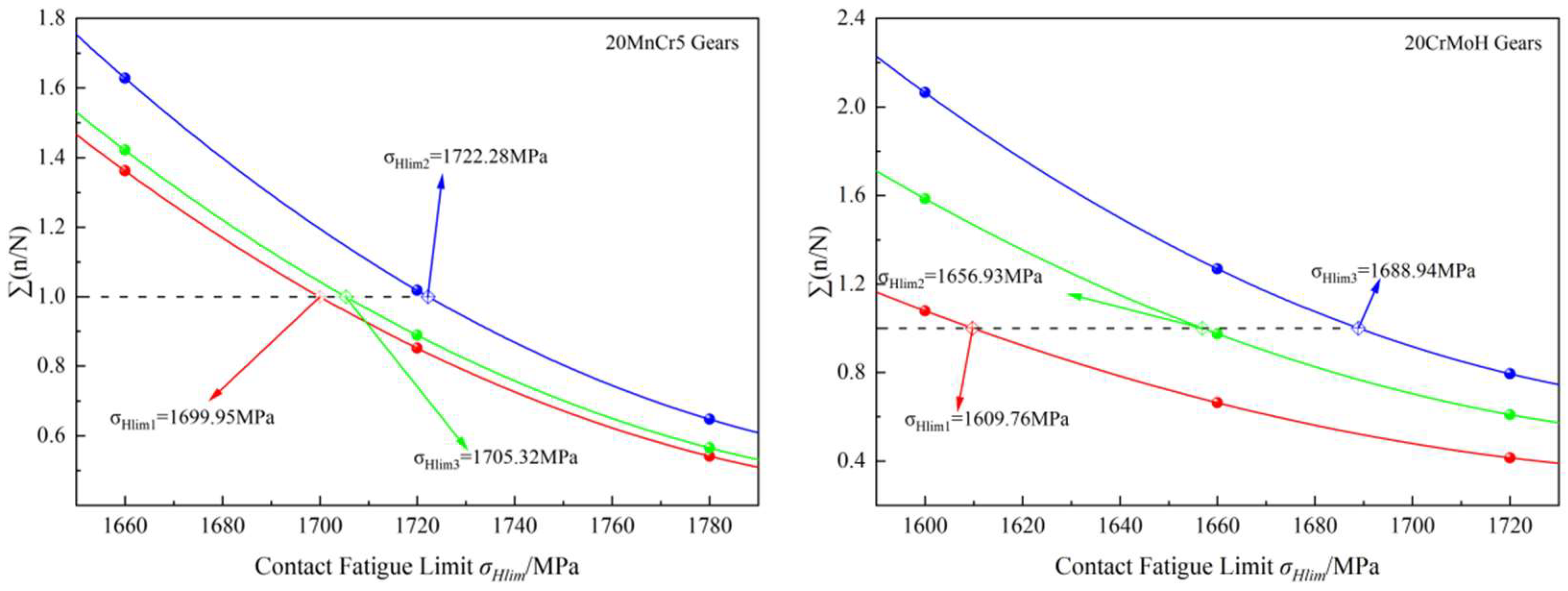

c. A relationship between the cumulative damage index and assumed fatigue limits was established by plotting ∑(ni/Ni) against σHlim, with the three assumed fatigue limits serving as abscissa values and their corresponding cumulative damage indices as ordinate values.

d. After obtaining three sets of data points with stress levels as the abscissa and cumulative damage values as the ordinate, a polynomial fitting was performed to construct a relationship curve. The stress value corresponding to the cumulative damage degree ∑(

ni/Ni) = 1 solved from this curve is defined as the contact fatigue limit

σHlim of the tested gear, and the data processing results are shown in

Figure 14.

The experimental results demonstrate that the three repeated tests for 20MnCr5 gears yield contact fatigue limits of 1699.95 MPa, 1705.32 MPa, and 1722.28 MPa, respectively, with a mean value of 1709.2 ± 12 MPa. In comparison, the corresponding values for 20CrMoH gears are 1609.76 MPa, 1656.93 MPa, and 1688.94 MPa, respectively, yielding a mean value of 1651.88 ± 40 MPa. The effect size corresponding to the difference between the two materials, Cohen’s d = 1.952, is classified as a very large effect, indicating that there are significant practical differences in the core service performance of the two materials. The independent samples t-test results show a p-value of 0.075, which is slightly higher than the conventional significance level of p < 0.05. The significantly higher contact fatigue limit of 20MnCr5 gears indicates superior fatigue resistance under identical cyclic contact loading conditions.

These findings are in strong agreement with the aforementioned surface integrity characterization. The enhanced subsurface mechanical properties of 20MnCr5 gears—attributed to their higher retained austenite content, gradual hardness gradient, and more stable residual stress distribution—collectively contribute to delayed fatigue crack initiation and propagation, thereby improving the overall fatigue limit. This study provides definitive experimental evidence for material selection between these two alloys in high-load gear applications.

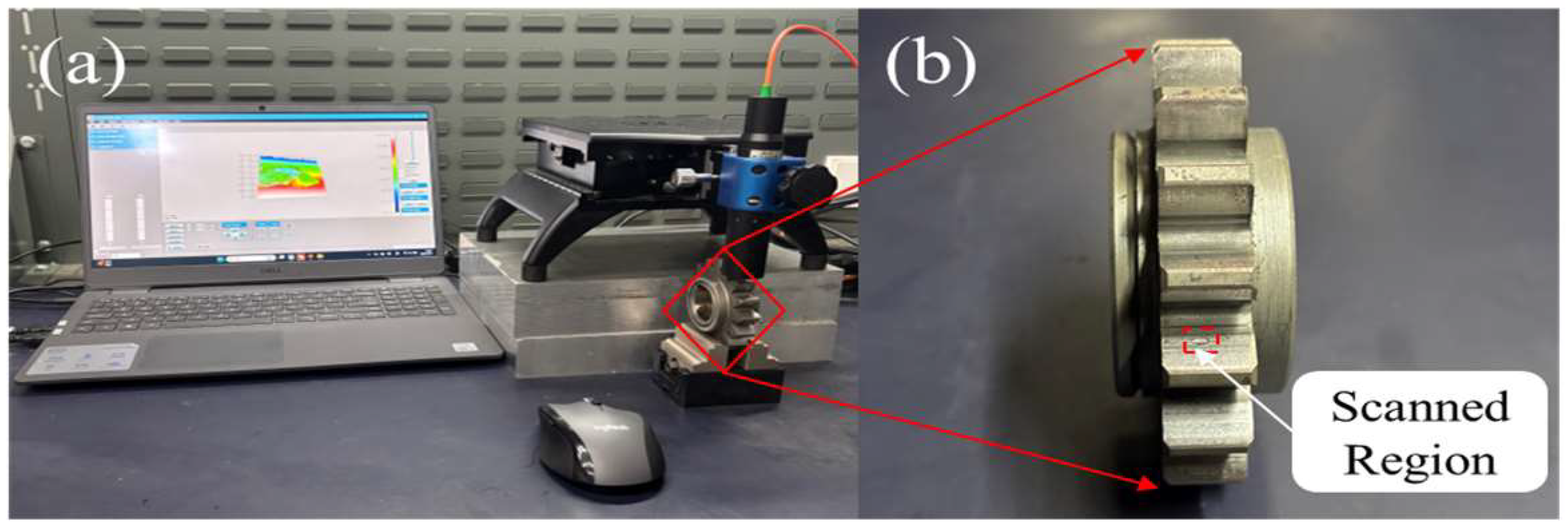

3.3. Damage Morphology Analysis

To further elucidate the damage evolution behavior of 20MnCr5 and 20CrMoH gears under cyclic contact loading, this section systematically compares the pitting initiation, propagation patterns, and morphological characteristics of the two materials through combined timed-shutdown observations and three-dimensional topography scanning.

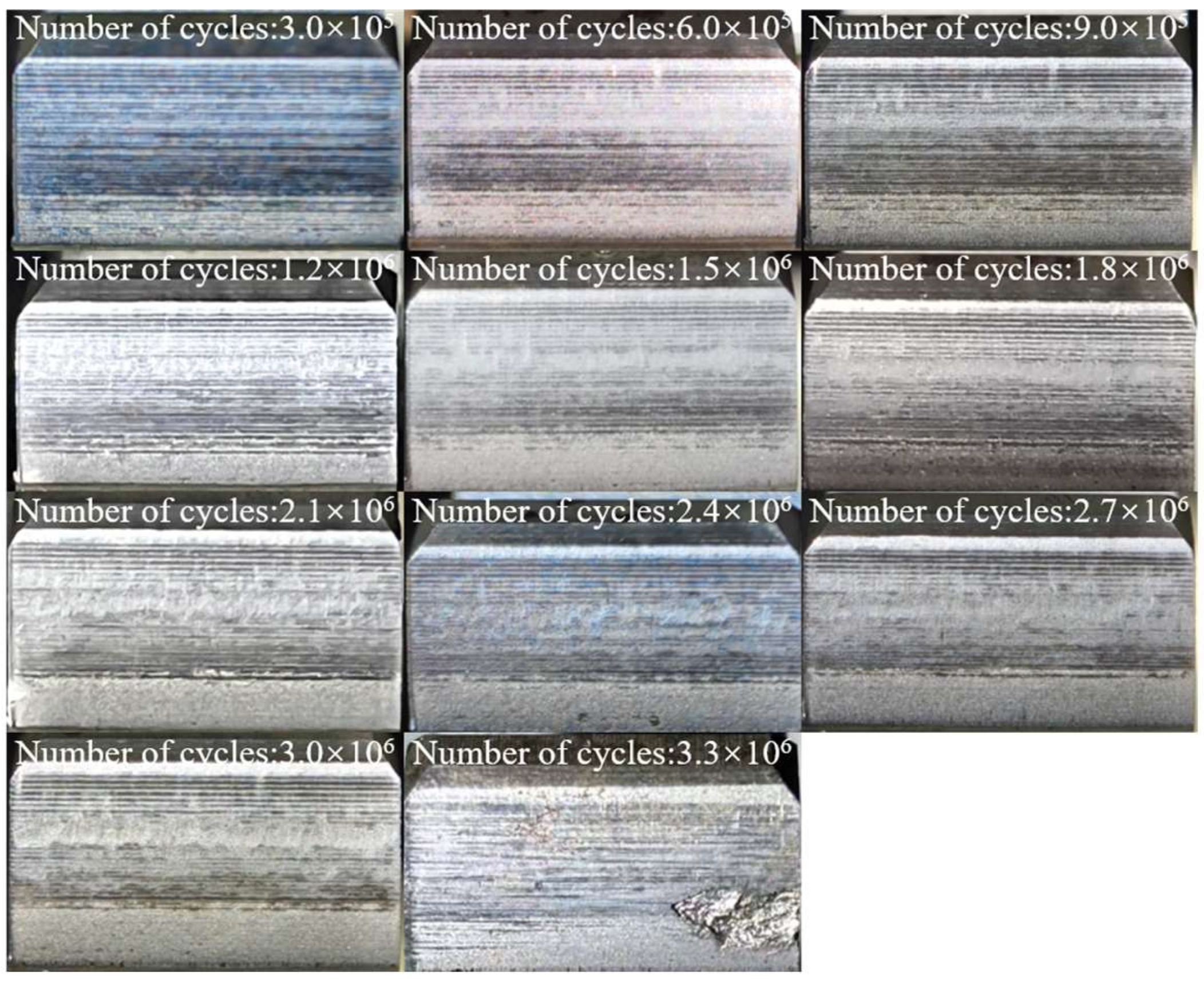

Scheduled shutdown observations reveal that pitting initiation in 20MnCr5 gears occurs relatively late, followed by a slow and uniform propagation process characterized by progressive damage features, as illustrated in

Figure 15. In contrast, 20CrMoH gears exhibit earlier pitting initiation with rapid propagation demonstrating a tendency toward sudden spalling, as shown in

Figure 16, indicating inferior fatigue resistance resulting from insufficient mechanical support capability in the subsurface region.

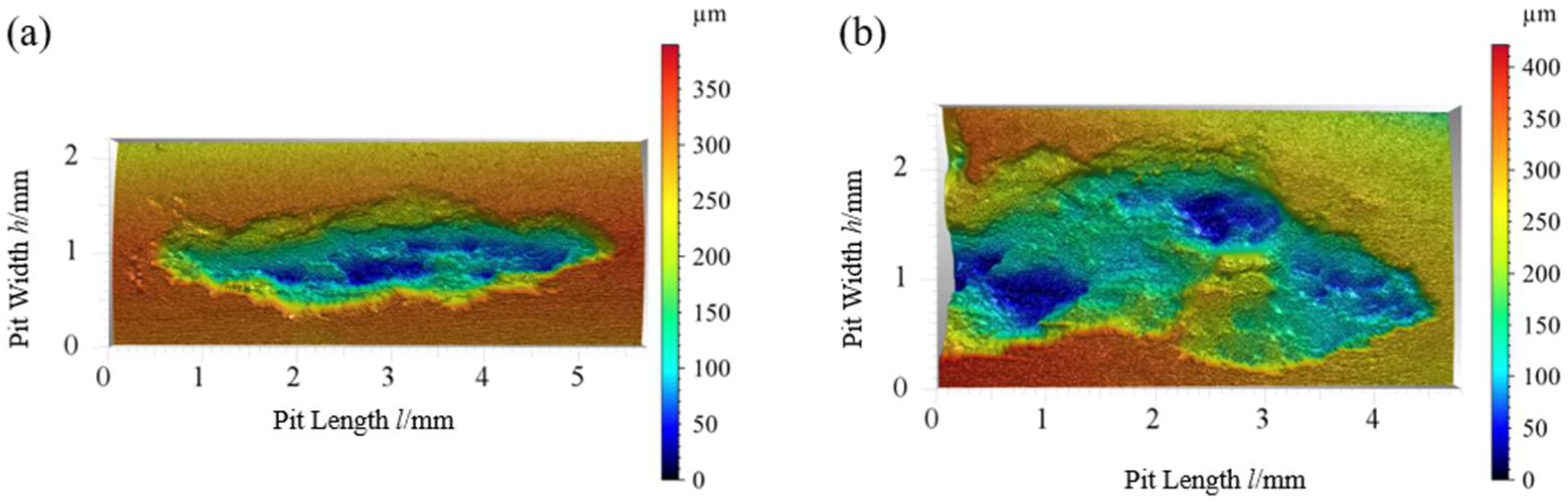

The specific pitting sites selected for 3D topography analysis in

Figure 17 were chosen based on their phenomenological representativeness of the global tooth-surface behavior. As observed in the macroscopic progression in

Figure 15, the 20MnCr5 gear surface exhibits uniform and widespread wear with small-scale material detachment. The selected 3D pit

Figure 17a, with its shallow depth and smooth profile, is characteristic of this micropitting mode dominating the entire surface. Conversely, the 20CrMoH gear in

Figure 16 displays localized, severe material removal. The selected 3D pit in

Figure 17, featuring steep edges and significant depth, typifies the spalling mechanism observed macroscopically. Therefore, these single-site 3D scans effectively capture the distinct failure characteristics inherent to each material’s surface integrity.

To quantitatively characterize the distinctions in pitting damage mechanisms, the specific pitting sites adjacent to the pitch line, whose damage evolution processes were tracked in

Figure 15 and

Figure 16, were selected for three-dimensional topography scanning. The resultant three-dimensional morphologies and corresponding key parameters are presented in

Figure 17 and

Table 9, respectively.

According to the standard classification of contact fatigue failures [

8], the damage morphology of 20MnCr5 gears is characterized by micropitting. The shallow U-shaped profile indicates a gradual material removal process dominated by surface plasticity. In contrast, 20CrMoH gears exhibit typical spalling features, where the steep, step-like edges suggest a brittle fracture mechanism driven by rapid subsurface crack propagation.

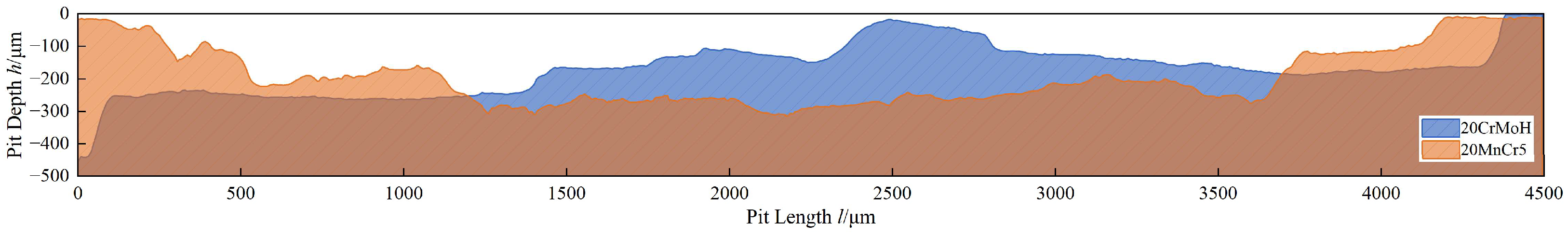

As illustrated in

Figure 17a, the pitting on the 20MnCr5 gear exhibits an elongated band-shaped distribution with a contour approximating a stretched ellipse. The maximum pitting depth measures 294.20 μm, with a projected area of 5.84 mm

2 and a relatively small volume of 4.893 × 10

8 μm

3. The surface roughness Sa is determined to be 60.01 μm. The pitting edges appear gradual without significant lip formation, while the pitting bottom maintains a relatively flat morphology.

In contrast,

Figure 17b reveals that the pitting on the 20CrMoH gear demonstrates a clustered and coalesced morphology. The maximum depth reaches 490.72 μm, with a projected area of 9.327 mm

2 and a volume exceeding twice that of 20MnCr5 at 1.016 × 10

9 μm

3. The surface roughness Sa increases to 73.13 μm. Pronounced lip formations are observed along the pitting edges, accompanied by a rough bottom topography, collectively indicating a stronger tendency toward localized brittle spalling. Moreover, the absence of adhesive scuffing characteristics on the flank surfaces rules out local lubrication starvation as a primary factor. Consequently, these significantly deeper pits are attributed to rapid brittle crack propagation facilitated by the material’s lower fracture toughness, rather than tribological insufficiency. To investigate the microscopic geometric characteristics and material removal mechanisms of the pitting damage, cross-sectional profiles were extracted through the deepest points of the two representative pits shown in

Figure 17, aligned parallel to the contact sliding direction. The resulting profiles, presented in

Figure 18, enable clear quantification of key morphological parameters including depth, sidewall inclination, and edge protrusion. These measurements provide direct visualization of the material failure mode under cyclic contact stress, distinguishing between preferential plastic detachment and brittle spalling mechanisms.

Figure 18 reveals that the pitting profile of the 20MnCr5 gear exhibits a characteristic shallow U-shaped contour. The transition from the pitting edge to the maximum depth occurs at a slope of approximately 15°, without abrupt step-like changes, indicating a uniform and progressive material removal process under cyclic contact stress. The pitting edges demonstrate symmetrical distribution with lip heights not exceeding 20 μm, remaining essentially flush with the tooth surface baseline and showing no significant plastic accumulation. The pitting bottom displays minimal contour fluctuation with near-horizontal characteristics, reflecting a fatigue spalling mechanism dominated by plastic deformation.

In contrast, the pitting cross-section of the 20CrMoH gear presents a steep stepped primary profile superimposed with multiple undulating secondary features. The main pit transitions from edge to maximum depth at slopes ranging from 40° to 50°, representing a significantly steeper gradient compared to the 20MnCr5 gear. Distinct asymmetric lip formations are observed at the pitting edges, with protrusion heights reaching 150–200 μm at both initiation and termination locations. From a fracture mechanics viewpoint, these high lips result from the rapid brittle fracture of the final surface ligament. Unlike 20MnCr5 where crack tip blunting suppresses upward deformation, the brittle matrix of 20CrMoH prevents plastic relaxation, causing the ligament to snap and protrude sharply. The contour at the initiation point exhibits a sharply ascending trend, indicating more severe brittle spalling behavior under cyclic contact stress.

To confirm that these brittle fracture features originate from the intrinsic material response rather than local defects, the non-metallic inclusion content was evaluated in

Table 5. Metallographic ratings of carburized 20MnCr5 and 20CrMoH steels. Both materials exhibit a Grade 1 inclusion rating, indicating high cleanliness with no significant stress-concentrating defects observed at the spalling sites. This scarcity of inclusions precludes a statistically meaningful quantitative correlation with pitting density, confirming that failure initiation is governed by the matrix microstructure rather than extrinsic defects. Consequently, the step-like crack path observed in the 20CrMoH profile in

Figure 18 is attributed to the intrinsic brittleness of the subsurface layer. Mechanistically, the significant depth of these pits serves as a morphological fingerprint of insufficient subsurface support. The steep hardness drop creates a hard-shell and soft-core mismatch; under cyclic loading, the yielding of the softer subsurface triggers the collapse of the overlying hard case, driving cracks vertically into the depth. The steep hardness gradient and low retained austenite content limit the local plastic deformation capacity, forcing the crack to propagate along low-energy crystallographic planes, thereby resulting in the characteristic steep, brittle edges.

Crucially, these specific damage profiles provide morphological evidence linking failure to interfacial cyclic plasticity. The distinct step-like edges observed in 20CrMoH in

Figure 18 spatially correspond to the geometric orientation of martensite lath boundaries. This implies that due to the low fraction of compliant retained austenite, strain incompatibility accumulates at the rigid martensite-austenite interfaces during cyclic loading, eventually triggering localized interface decohesion. In contrast, the smooth, shallow profile of 20MnCr5 suggests that the abundant film-like austenite facilitates strain accommodation through transformation at these interfaces, thereby preventing boundary decohesion and promoting a more homogeneous, transgranular plastic flow mode.

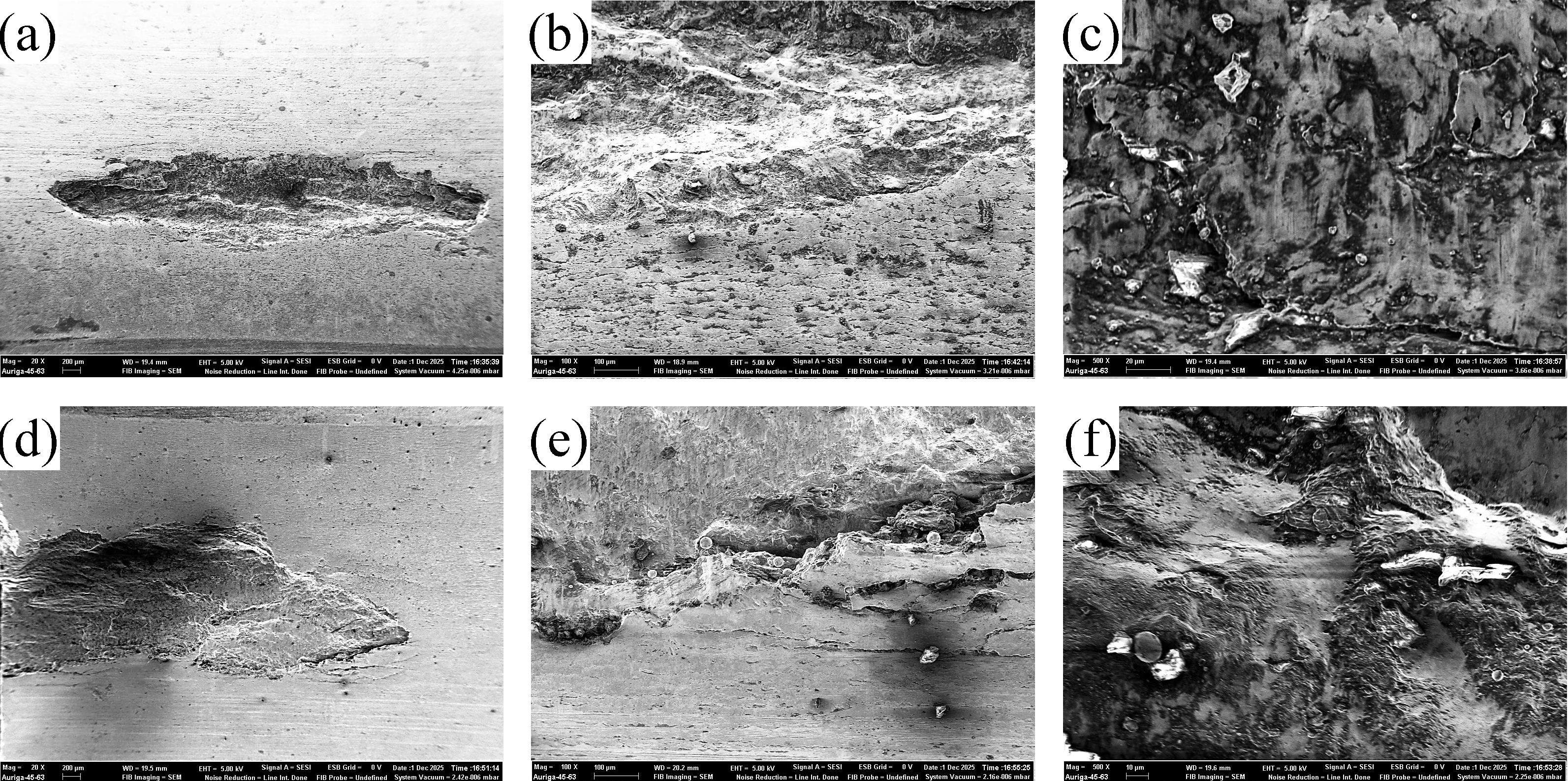

To further validate the fracture mechanisms at the micro-scale, Scanning Electron Microscopy (Carl Zeiss Microscopy GmbH, Oberkochen, Germany) analysis was performed on the representative pitting sites in

Figure 19. The 20MnCr5 gear exhibits typical ductile fracture characteristics. The pitting edge is smooth and rounded, showing clear evidence of plastic flow and shear lips without sharp discontinuities. The pit bottom is characterized by rough, torn textures reminiscent of shear dimples, confirming that the material underwent significant plastic deformation prior to detachment, driven by the high toughness of the austenite-rich matrix.

In stark contrast, the 20CrMoH gear displays distinct brittle fracture features. The overall morphology reveals a deep, blocky material removal. Crucially, the pitting edge exhibits sharp, step-like cleavage facets and secondary cracks propagating parallel to the edge, perfectly matching the steep profiles observed in the 3D scans. The pit bottom presents a rock-candy-like intergranular fracture appearance with distinct river patterns and cleavage steps. These microscopic features provide direct evidence that the failure in 20CrMoH is governed by rapid brittle crack propagation along weak boundaries, a consequence of its insufficient ductility and lack of transformation toughening.