Investigation and Modelling of the Wear Resistance of Diamond Roller Dressers Made of Synthetic Diamonds with Mixed Grit Size

Abstract

1. Introduction

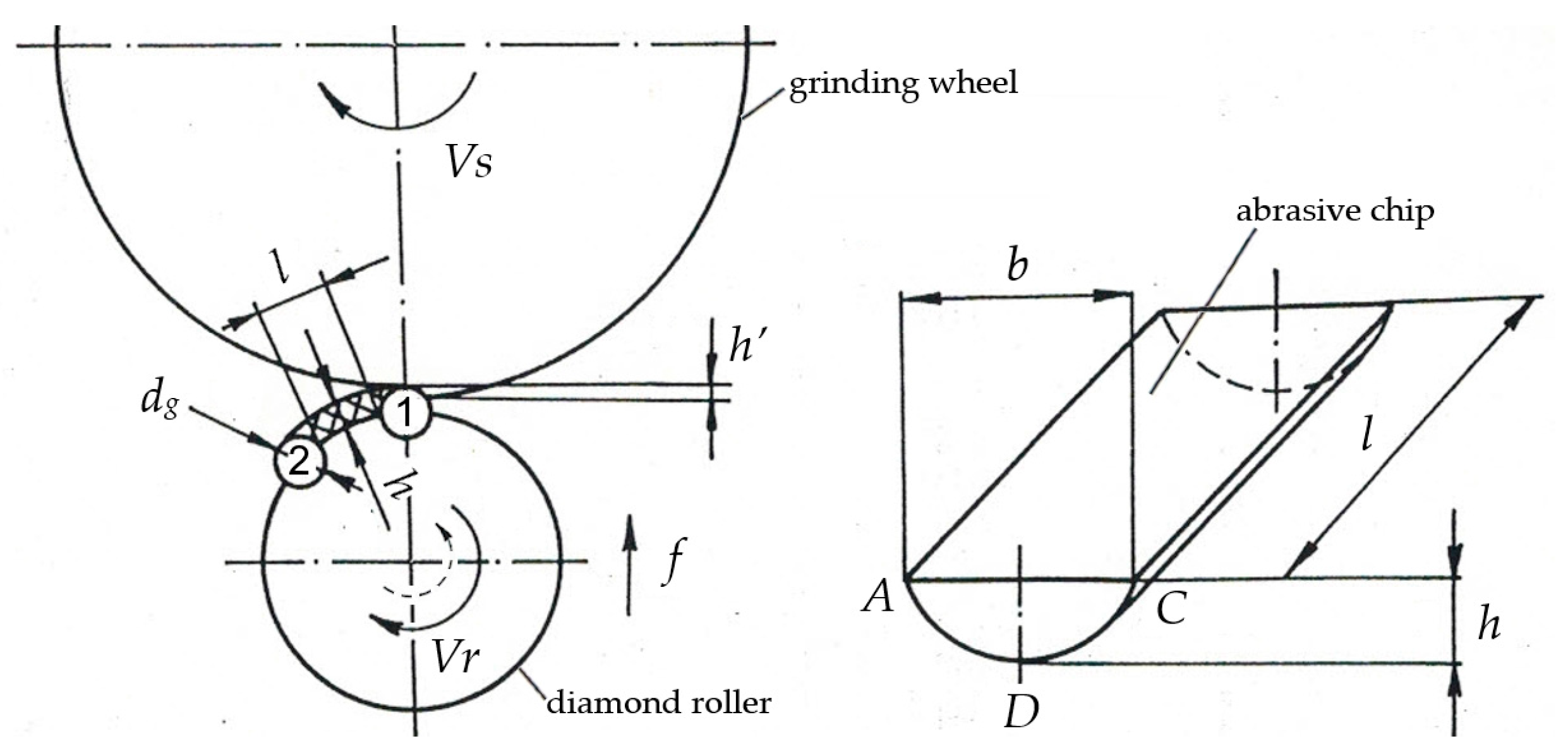

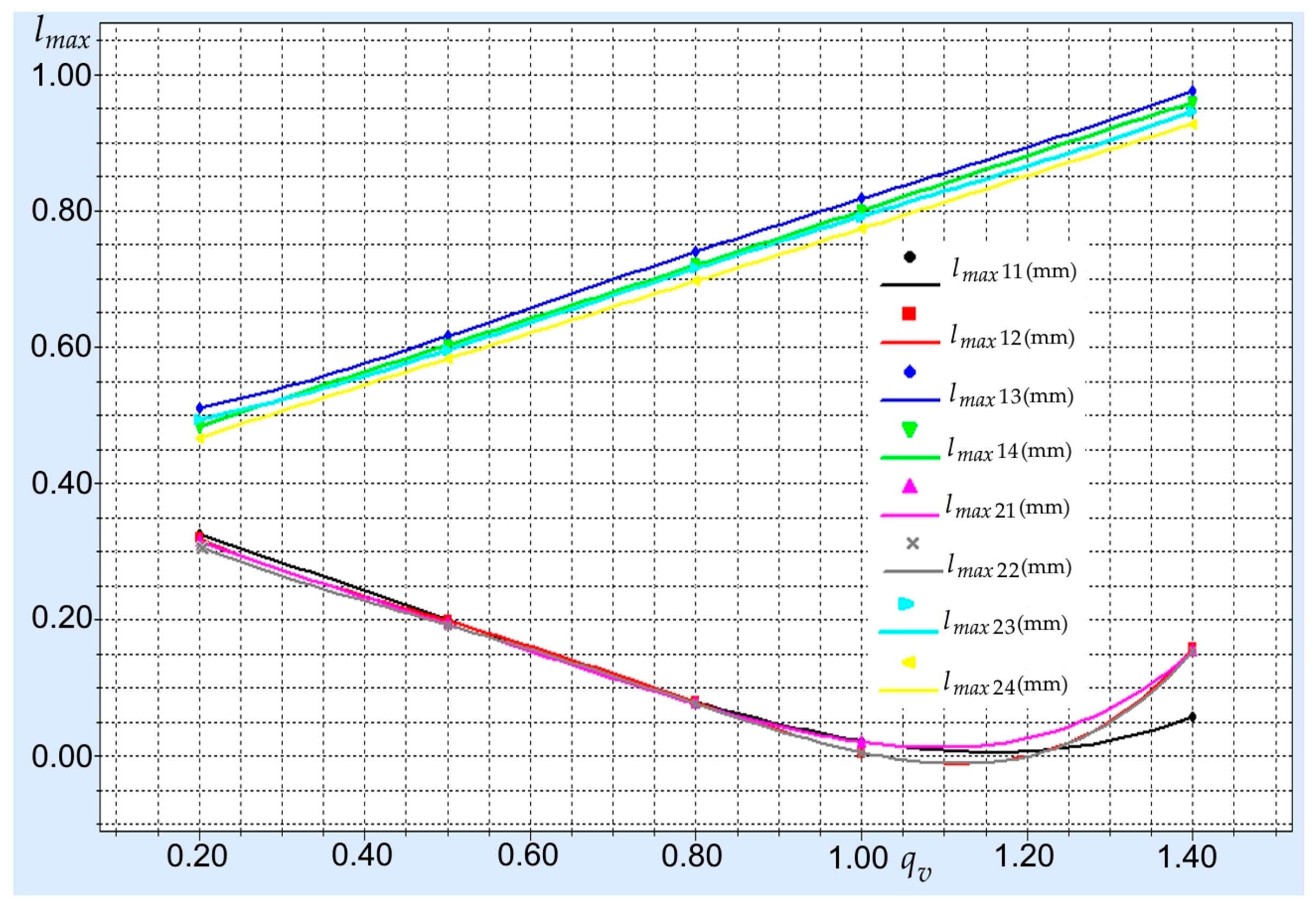

2. Theoretical Research of the Structure of the Working Layer of Diamond Rollers

3. Research and Modelling of the Wear Resistance of Diamond Roller Dressers

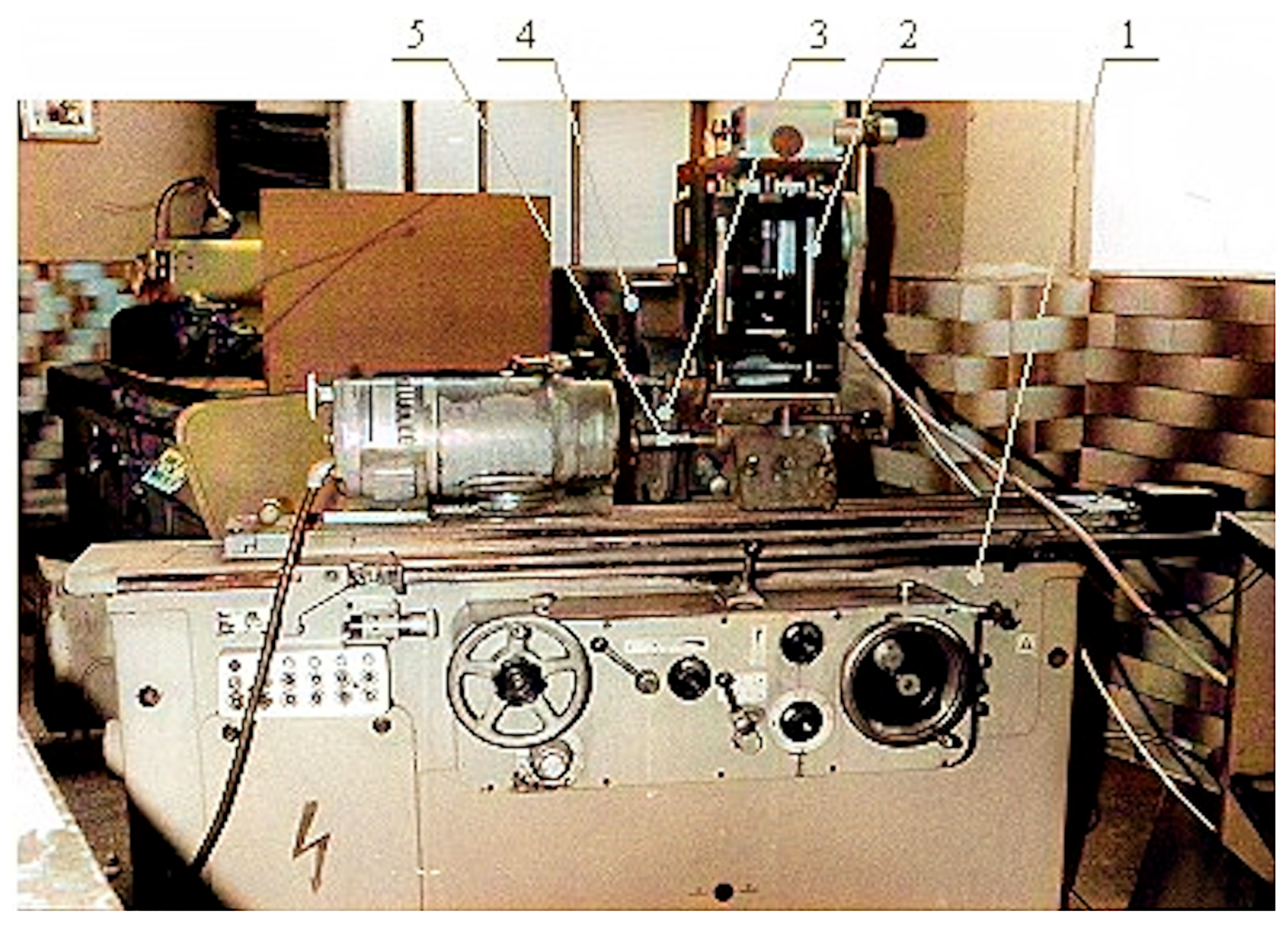

3.1. Equipment, Materials, and Methods

3.2. Results and Modelling

3.2.1. Experimental Results

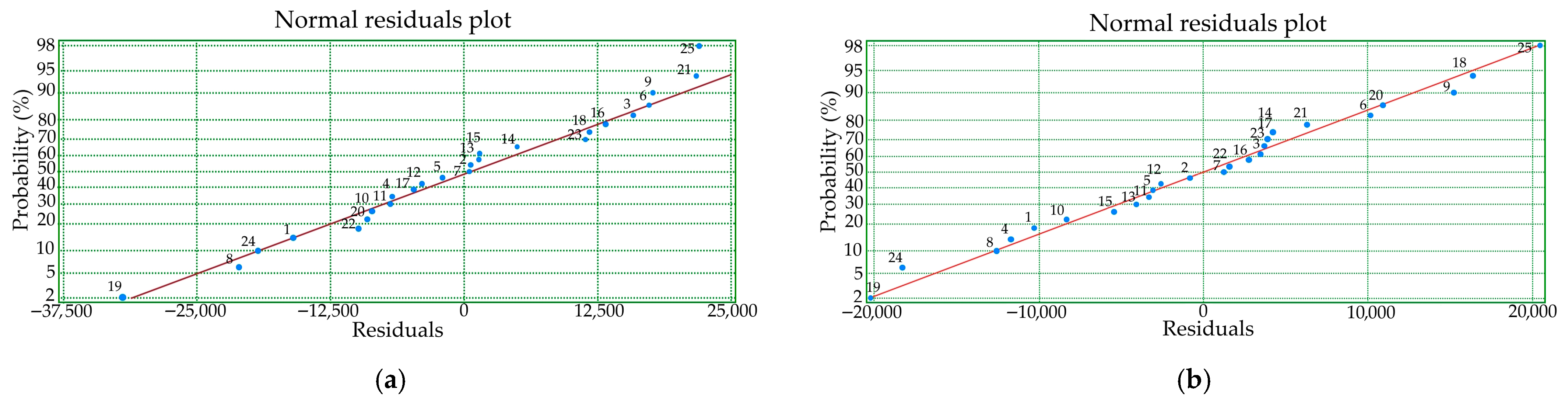

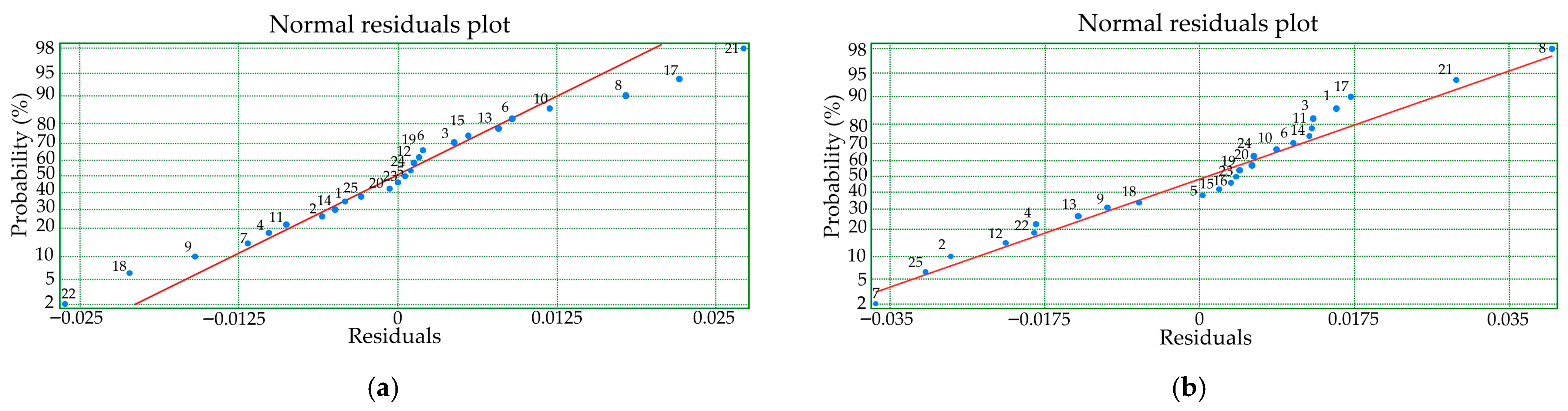

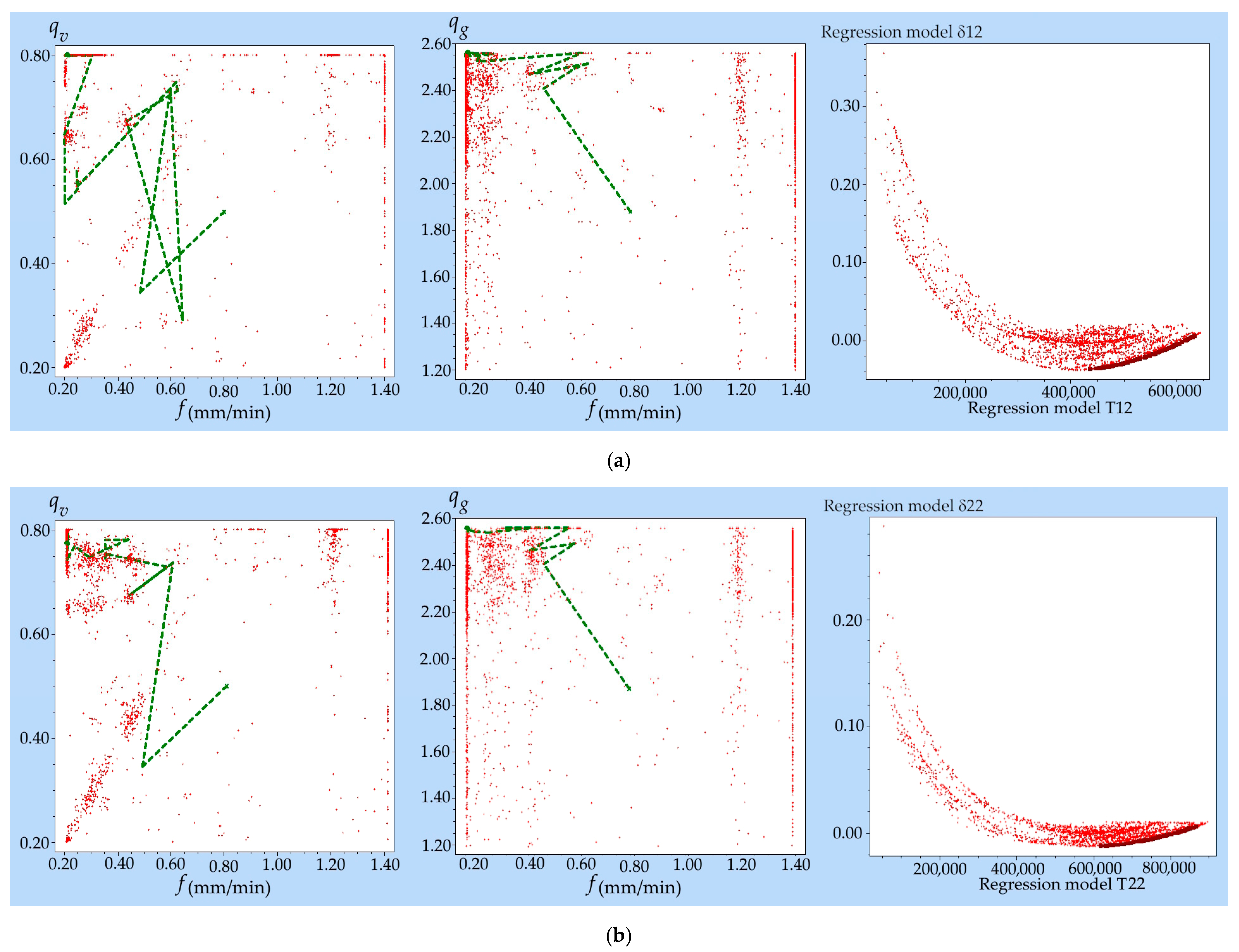

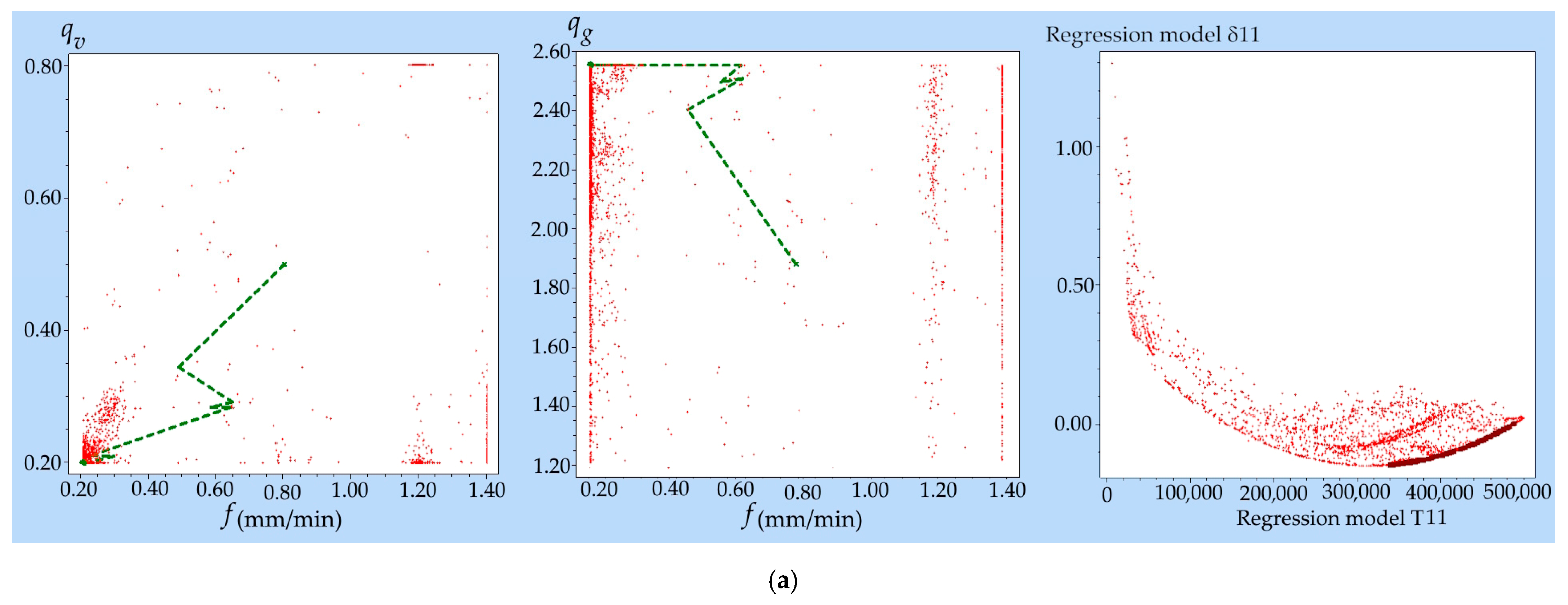

3.2.2. Statistical Modelling

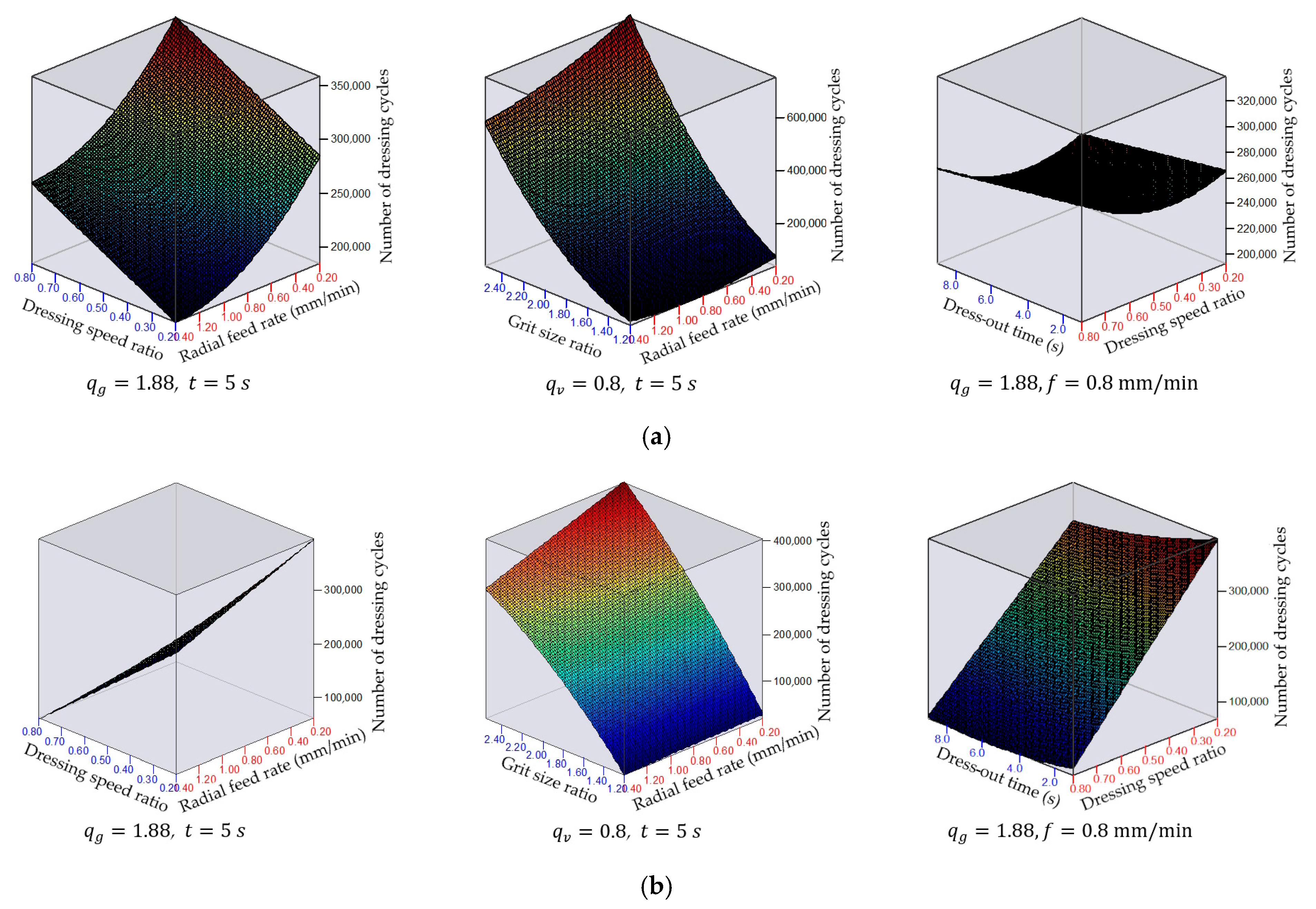

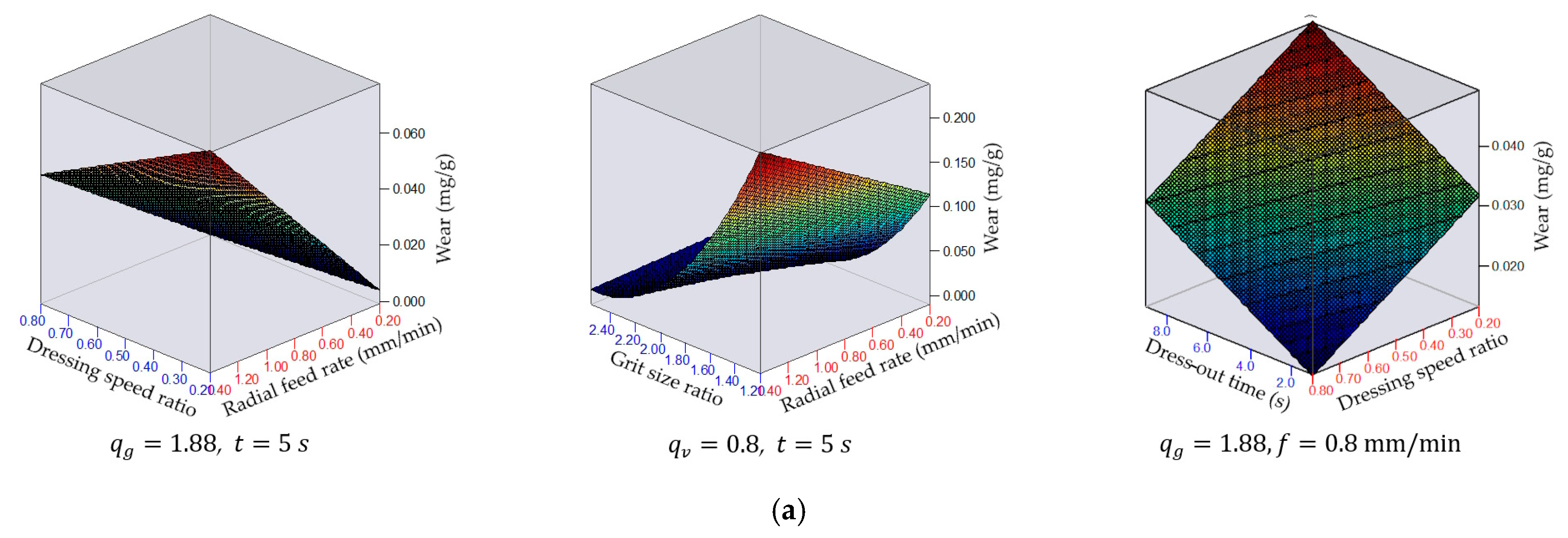

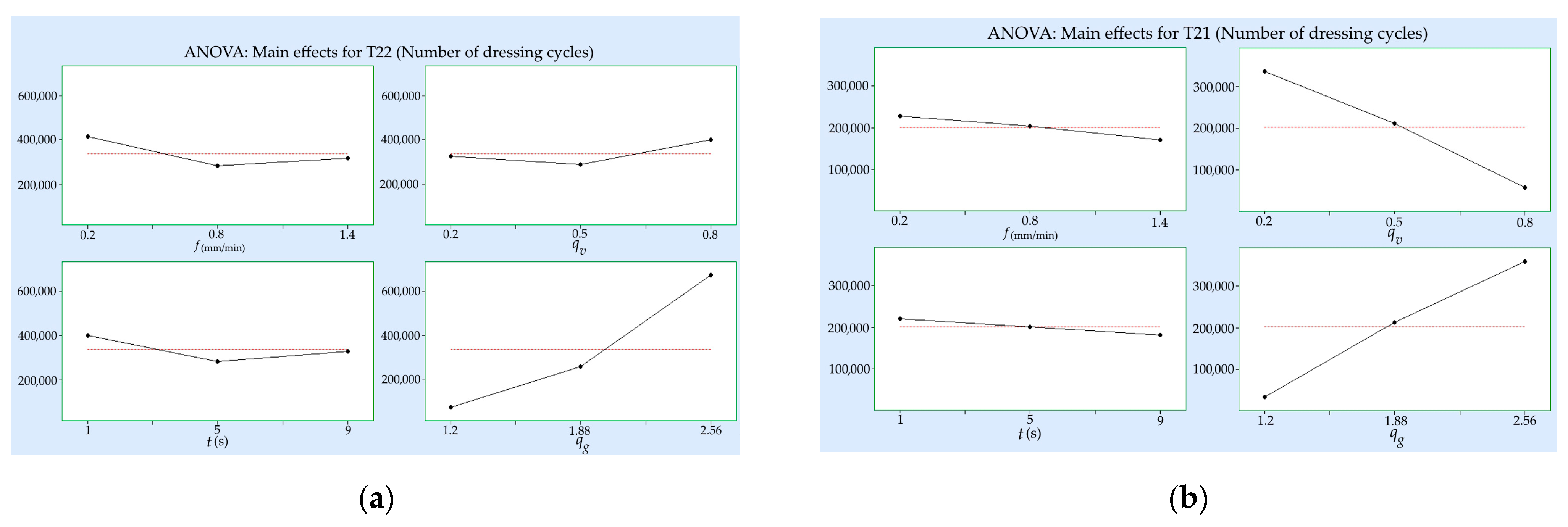

3.2.3. Analysis of the Experimental Results

- Of all the factors studied, the grit size ratio had the greatest influence on the lifetime and the wear of diamond rollers; as the increased, the lifetime increased from 5.8 to 11.6 times, and the wear decreased from 5 to 26 times. This trend remained the same for both uni-directional and counter-directional dressing with AC32 and AC80 DRs. The influence of on the lifetime of dressing tools was more pronounced for uni-directional dressing with diamond rollers made of high-strength synthetic diamonds, and increased with a decreasing dressing speed ratio. The wear of the diamond rollers, depending on the grit size ratio, changed most significantly during counter-directional dressing with AC32 DRs. The influence of the grit size ratio on the wear increased with an increasing radial feed rate during counter-directional dressing and with a decreasing dressing speed ratio during uni-directional dressing. The increase in the lifetime and decrease in the wear of the DRs, depending on the , were related to the reduction in the normal and tangential forces during dressing [19,20]. At a constant grain size of the grinding wheel, an increase in led to a decrease in the number of simultaneously cutting diamond grains. As a result, although the force acting on individual diamond grains during dressing with a coarser diamond roller increased, the total cutting force decreased. The dressing forces were significantly lower than those in grinding and were within the following ranges: and [43].

- The dressing conditions had a varying nature and degree of influence on the lifetime and wear of diamond rollers, which depended on the direction of dressing and the type of synthetic diamonds in the working layer of the diamond rollers. This was related to the change in force and heat load. The greatest influence was exerted by the dressing speed ratio, followed by the radial feed and the dress-out time.

- When dressing in the uni-direction, an increase in led to increased wear and a corresponding decrease in the lifetime of the DR, while when dressing in the counter-direction, these trends were reversed. This was related to the nature of the change in the length of the contact arc between the dressing and the dressed tools, the number of diamond grains simultaneously participating in the cutting, and the total cutting force [44,45]—they decreased with an increase in the dressing speed ratio during counter-directional dressing and increased during uni-directional dressing. Malkin and Murray [44] found that the components of the dressing force reached their maximum (approximately 14–16 N/mm) during uni-directional dressing when the dressing speed ratio was at unity, while during counter-directional dressing with , the normal force was minimal (approximately 3–8 N/mm). As a result, for uni-directional dressing with an increase in the , in the studied range, the lifetime of diamond rollers decreased by up to 7 times and the wear increased by up to 14 times, while for counter-directional dressing, an increase in the led to a maximum increase in the lifetime of the DR by 22% and a maximum decrease in the wear by 25%. The effect of was more pronounced for uni-directional dressing with diamond rollers made of AC32 synthetic diamonds, and increased with an increase in the radial feed rate and the grit size ratio.

- An increase in the radial feed rate led to a decrease in the lifetime of the diamond rollers by up to 38% and an increase in the wear by 2.2 times. This change in the studied parameters was related to an increase in the normal and tangential forces during dressing as a result of the increase in the cross-sectional area of the cut abrasive layer per revolution of the DR. At the same time, however, the specific dressing energy decreased when increasing the feed rate (from 15 J/mm3 to 2.5 J/mm3 at and from 2 J/m3 to 0.5 J/m3 at ) [44,45]. In this regard, the effect of the radial feed rate on the lifetime of the DR was more pronounced for uni-directional dressing with AC80 diamond rollers and increased with an increasing dressing speed ratio. The effect of the feed rate on the wear increased with a decreasing grit size ratio and was most pronounced for counter-directional dressing with AC80 DRs.

- With an increase in the dress-out time in the studied range, the lifetime of the diamond rollers decreased by a maximum of 26%, with the greatest impact on uni-directional dressing with AC32 synthetic diamond rollers. Increasing the dress-out time led to an increase in the wear by 23% to 61% and was most pronounced for uni-directional dressing with AC 32 and AC80 DRs with a high radial feed rate and dressing speed ratio values. This nature of change in the studied parameters was related to the greater friction forces arising between the DR and the grinding wheel during dressing with levelling.

- The lifetime of diamond rollers for counter-directional dressing was greater (up to 9.5 times) than the lifetime for uni-directional dressing, which was associated with less wear (up to 23 times) on the tools. This was due to the smaller number of simultaneously cutting diamond grains in the contact zone of the DR with the grinding wheel and the lower total cutting force. The difference in the lifetime and the wear of the DR was greater when dressing with diamond rollers made of AC32 synthetic diamonds, and increased with an increase in the grit size ratio, the dressing speed ratio, and the radial feed rate.

- At a grit size ratio , the lifetime of the diamond rollers made of high-strength synthetic diamonds was greater (up to 82%) than that of diamond rollers made of medium-strength diamond structures, and their wear was less (up to 27%). The difference in the lifetime and the wear was greater during uni-directional dressing and increased with an increasing dress-out time and an increasing grit size ratio.

4. Multi-Objective Optimisation of the Dressing System Parameters

5. Conclusions

- An approach was proposed for increasing the wear resistance of synthetic diamond rollers manufactured using the electroplating method by additionally treating the intergranular spaces of the diamond grains finer than those of the main fraction. For its application, analytical dependencies were derived for the maximum distance between the diamond grains; when this was exceeded, intensive wear of the diamond roller dresser bond was observed as a result of its contact with the abrasive grains of the grinding wheels. A ratio between the grain sizes of the main and additional diamond fractions is recommended depending on the dressing conditions.

- Diamond roller dressers with a working layer of synthetic diamonds of a medium and high strength and mixed grain sizes were created, and their lifetime and wear were studied during the dressing of electrocorundum grinding wheels using the plunge-grinding method. Theoretical–experimental models were constructed for the studied response variables, depending on the dressing direction, radial feed rate, dressing speed ratio, dressing out-time, and grit size ratio. The models were constructed using the planned experimental approach and the method of a multifactor regression analysis.

- Based on the analysis of the developed theoretical and experimental models and through the application of an ANOVA, the significant effect of the working conditions of the dressing process on the wear resistance of diamond rollers with a working layer of synthetic diamonds was demonstrated. It was proven that the grit size ratio has the greatest effect on the lifetime and wear of diamond rollers, with an increase in increasing the lifetime by up to 11.6 times and reducing the wear by up to 26 times as a result of the decrease in normal and tangential forces during dressing.

- Through multi-objective compromise optimisation and the application of a genetic algorithm, the Pareto-optimal dressing system parameters were determined, valid for uni-directional and counter-directional dressing with diamond rollers made of medium- and high-strength synthetic diamonds, as follows: radial feed rate ; dressing speed ratio ; dress-out time ; and grit size ratio . They provide the best combination between the maximum lifetime ( dressing cycles) and minimum wear () of the tested diamond roller dressers.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DR | Diamond roller dresser |

| ANOVA | Analysis of variance |

References

- Tung, L.A.; Pi, V.N.; Lien, V.T.; Hong, T.T.; Hung, L.X.; Long, B.T. Optimization of dressing parameters of grinding wheel for 9CrSi tool steel using the Taguchi method with grey relational analysis. In Proceedings of the 10th International Conference on Mechatronics and Manufacturing (ICMM 2019), Bangkok, Thailand, 21–23 January 2019; Volume 635, p. 012030. [Google Scholar] [CrossRef]

- Deresse, N.C.; Deshpande, V.; Taifa, I.W.R. Experimental investigation of the effects of process parameters on material removal rate using Taguchi method in external cylindrical grinding operation. Eng. Sci. Technol. Int. J. 2020, 23, 405–420. [Google Scholar] [CrossRef]

- Klocke, F.; Thiermann, J.; Mattfeld, P. Influence of the dressing process on grinding wheel wear. Prod. Eng. Res. Dev. 2015, 9, 563–568. [Google Scholar] [CrossRef]

- Linke, B. Dressing process model for vitrified bonded grinding wheels. CIRP Ann. Manuf. Technol. 2008, 57, 345–348. [Google Scholar] [CrossRef]

- Pombo, I.; Cearsolo, X.; Sánchez, J.A.; Cabanes, I. Experimental and numerical analysis of thermal phenomena in the wear of single point diamond dressing tools. J. Manuf. Process. 2017, 27, 145–157. [Google Scholar] [CrossRef]

- Le, H.-A.; Hoang, X.-T.; Trieu, Q.-H.; Pham, D.-L.; Le, X.-H. Determining the best dressing parameters for external cylindrical grinding using MABAC method. Appl. Sci. 2022, 12, 8287. [Google Scholar] [CrossRef]

- Wegener, K.; Hoffmeister, H.-W.; Karpuschewski, B.; Kuster, F.; Hahmann, W.-C.; Rabiey, M. Conditioning and monitoring of grinding wheels. CIRP Ann. Manuf. Technol. 2011, 60, 757–777. [Google Scholar] [CrossRef]

- Klocke, F.; Linke, B. Mechanisms in the generation of grinding wheel topography by dressing. Prod. Eng. Res. Dev. 2008, 2, 157–163. [Google Scholar] [CrossRef]

- Ding, W.; Li, H.; Zhang, L.; Xu, J.; Fu, Y.; Su, H. Diamond wheel dressing: A comprehensive review. J. Manuf. Sci. Eng. 2017, 139, 121006. [Google Scholar] [CrossRef]

- Daneshi, A.; Jandaghi, N.; Tawakoli, T. Effect of Dressing on Internal Cylindrical Grinding. Procedia CIRP 2014, 14, 37–41. [Google Scholar] [CrossRef]

- Krajnik, P.; Kopac, J.; Sluga, A. Design of grinding factors based on response surface methodology. J. Mater. Process. Technol. 2005, 162–163, 629–636. [Google Scholar] [CrossRef]

- Macerol, N.; Franca, L.F.P.; Drazumeric, R.; Krajnik, P. The effects of grit properties and dressing on grinding mechanics and wheel performance: Analytical assessment framework. Int. J. Mach. Tools Manuf. 2022, 180, 103919. [Google Scholar] [CrossRef]

- Godino, L.; Alvarez, J.; Muñoz, A.; Pombo, I. On the influence of rotary dresser geometry on wear evolution and grinding process. Materials 2019, 12, 3855. [Google Scholar] [CrossRef] [PubMed]

- Linke, B.; Klocke, F. Temperatures and wear mechanisms in dressing of vitrified bonded grinding wheels. Int. J. Mach. Tools Manuf. 2010, 50, 552–558. [Google Scholar] [CrossRef]

- Patil, P.P.; Jadhav, P.L. Optimization of Cylindrical Grinding Process—A Review. Int. Adv. Res. J. Sci. Eng. Technol. 2017, 4, 164–167. [Google Scholar] [CrossRef]

- Baseri, H. Simulated annealing based optimization of dressing conditions for increasing the grinding performance. Int. J. Adv. Manuf. Technol. 2012, 59, 531–538. [Google Scholar] [CrossRef]

- Khalilpourazari, S.; Khalilpourazary, S. Optimization of time, cost and surface roughness in grinding process using a robust multi-objective dragonfly algorithm. Neural Comput. Appl. 2020, 32, 3987–3998. [Google Scholar] [CrossRef]

- Tran, T.-H.; Hoang, X.-T.; Le, H.-K.; Nguyen, Q.-T.; Nguyen, T.-T.; Nguyen, T.-T.-N.; Jun, G.; Vu, N.-P. A study on cost optimization of external cylindrical grinding. Mater. Sci. Forum 2020, 977, 18–26. [Google Scholar] [CrossRef]

- Aleksandrova, I. Multi-Objective Optimization of the Dressing Parameters in Fine Cylindrical Grinding. SV-JME 2019, 65, 87–102. [Google Scholar] [CrossRef]

- Aleksandrova, I. Optimization of the dressing parameters in cylindrical grinding based on a generalized utility function. Chin. J. Mech. Eng. 2016, 29, 63–73. [Google Scholar] [CrossRef]

- Tawakoli, T.; Rasifard, A. Dressing of grinding wheels. In Machining with Abrasives; Jackson, M., Davim, J., Eds.; Springer: Boston, MA, USA, 2011. [Google Scholar] [CrossRef]

- Maksoud, T.M.A.; Atia, M.R. Review of intelligent grinding and dressing operations. Mach. Sci. Technol. 2004, 8, 263–276. [Google Scholar] [CrossRef]

- Godino, L.; Pombo, I.; Sanchez, J.A.; Mendez, I.; Cearsolo, X. Analysis of the dressing process using stationary dressing tools. Procedia Manuf. 2017, 13, 146–152. [Google Scholar] [CrossRef]

- Palmer, J.; Ghadbeigi, H.; Novovic, D.; Curtis, D. An experimental study of the effects of dressing parameters on the topography of grinding wheels during roller dressing. J. Manuf. Process. 2018, 31, 348–355. [Google Scholar] [CrossRef]

- Diamond Dressing Tools—Catalogue. Diamant Weber AG. Available online: https://cdn.website-editor.net/8303eeb1482c451eae632085b177d185/files/uploaded/Diamond%2520Dressing%2520Tools%2520Catalogue.pdf (accessed on 10 October 2025).

- Norton Winter Dressing Tools. Saint-Gobain Diamantwerkzeuge GmbH. Available online: https://www.nortonabrasives.com/sites/mac3-acs-norton/files/2024-07/NORTON_WINTER_catalogue_DressingTools_2021_EN_0.pdf (accessed on 10 October 2025).

- Prikhna, T.O.; Ilnytska, H.D.; Lavrinenko, V.I.; Zaitseva, I.N.; Sheiko, M.N.; Smokvyna, V.V.; Tymoshenko, V.V. Improvement of physical and mechanical characteristics of synthetic diamond powders synthesized from ferroalloys for increasing the wear resistance of the diamond dressing tool. J. Superhard Mater. 2022, 44, 139–150. [Google Scholar] [CrossRef]

- Korolev, A.V.; Korolev, A.A. Wear of diamond dressing tools at vibromechanical type of dressing abrasive discs. J. Frict. Wear 2016, 37, 415–418. [Google Scholar] [CrossRef]

- Lavrinenko, V.I.; Ilnitskaya, G.D.; Sheiko, M.N.; Dobroskok, V.L.; Ostroverh, Y.V.; Solod, V.Y. Improving the performance characteristics of synthetic diamonds for high-precision diamond dressing tool. Sci. Innov. 2021, 17, 72–82. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, Q.; Guo, B. Wear characteristics of electroplated diamond dressing wheels used for on-machine precision truing of arc-shaped diamond wheels. Diam. Relat. Mater. 2022, 129, 109372. [Google Scholar] [CrossRef]

- Spampinato, A.; Dragos, D.; Butler-Smith, P.; Novovic, D. On the performance of a novel dressing tool with controlled geometry and density of abrasive grits. CIRP Ann. Manuf. Technol. 2017, 66, 337–340. [Google Scholar] [CrossRef]

- Malkin, S.; Guo, C. Grinding Technology—Theory and Applications of Machining with Abrasives; Industrial Press: New York, NY, USA, 2008. [Google Scholar]

- Kolomiec, V.; Polupan, B. Diamond Dressing Rollers for Plunge Grinding of Machine Parts; Naukova Dumka: Kiev, Ucraine, 1983. (In Russian) [Google Scholar]

- Aleksandrova, I. Optimization of Dressing Process of Abrasive Tools with Diamond Profiling Rollers. Ph.D. Thesis, Technical University of Gabrovo, Gabrovo, Bulgaria, 1995. (In Bulgarian). [Google Scholar]

- Vuchkov, I.N.; Vuchkov, I.I. QStatLab Professional, Version 6.1.1.3. Statistical Quality Control Software; User’s Manual. QStatLab: Sofia, Bulgaria, 2009.

- Lubrica—Motor Oils, Industrial Oils, Greases—Catalogue. Available online: https://lubrica.com/wp-content/uploads/2015/05/lubrica_web_EN.pdf (accessed on 11 November 2025).

- ISO 6743/7:1986; Lubricants, Industrial Oils and Related Products (Class L)—Classification—Part 7: Family M (Metalworking). ISO: Geneva, Switzerland, 1986.

- Abrasive Tools and Materials, Disks for Cutting and Grinding. ZAI JSC-Bulgaria. Available online: https://zai-bg.com/en/ (accessed on 25 October 2025).

- ISO 525:2020; Bonded Abrasive Products—Shape Types, Designation and Marking. ISO: Geneva, Switzerland, 2020.

- GOST 9206-80; Diamond Powders. Technical Conditions. USSR State Committee for Standard: Moscow, Russia, 1980.

- DSTU 3292-95; Synthetic Diamond Powders. General Technical Conditions. State Standard of Ucraine: Kiev, Ucraine, 1995.

- A Review of Diamond Sizing and Standards. Industrial Diamond Association of America, INC. Available online: https://www.nationalresearchcompany.com/wp-content/uploads/2015/05/Diamond_Sizing_and_Standards.pdf (accessed on 25 October 2025).

- Rowe, W.B. Principles of Modern Grinding Technology; Elsevier Inc.: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Malkin, S.; Murray, T. Mechanics of rotary dressing of grinding wheels. J. Eng. Ind. 1978, 100, 95–102. [Google Scholar] [CrossRef]

- Baseri, H.; Rezaei, S.M.; Rahimi, A.; Rezaeian, M. Modelling of disc dressing forces. Mach. Sci. Technol. 2007, 11, 201–216. [Google Scholar] [CrossRef]

| Grit Size of Synthetic Diamonds | Dressing Method | Radial Feed Rate (mm/min) | Models |

|---|---|---|---|

| D107 | Uni-directional | 0.2 | |

| 1.4 | |||

| Counter-directional | 0.2 | ||

| 1.4 | |||

| D426 | Uni-directional | 0.2 | |

| 1.4 | |||

| Counter-directional | 0.2 | ||

| 1.4 |

| Dressing Method—h | Type of Synthetic Diamonds—p | |

|---|---|---|

| AC32 (p = 1) | AC80 (p = 2) | |

| Uni-directional (h = 1) | 11 | 21 |

| Counter-directional (h = 2) | 12 | 22 |

| Synthetic Diamonds | Static Compressive Strength (N) | Arithmetic Mean of the Compressive Strength for All Grit Sizes (N) | Micro-Hardness (GPa) | Heat Resistance (°C) | |

|---|---|---|---|---|---|

| Brand | Grit Size | ||||

| AC32 | D107 (110/80) | 18.4 | 32 | 86–101 | 700–900 |

| D251 (250/200) | 23.5 | ||||

| D426 (400/315) | 49.6 | ||||

| AC80 | D107 (110/80) | 40.0 | 80 | ||

| D251 (250/200) | 78.0 | ||||

| D426 (400/315) | 109.0 | ||||

| Factors | Factor Levels | |||

|---|---|---|---|---|

| −1 | 0 | +1 | ||

| X1 | f (mm/min) | 0.2 | 0.8 | 1.4 |

| X2 | 0.2 | 0.5 | 0.8 | |

| X3 | t (s) | 1 | 5 | 9 |

| X4 | 1.2 | 1.88 | 1.56 | |

| Control Factors | Response Variables | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Dressing Cycles | Wear of Diamond Roller Dresser | ||||||||||

| t | |||||||||||

| (mm/min) | (s) | (mg/g) | (mg/g) | (mg/g) | (mg/g) | ||||||

| 0.2 | 0.2 | 1 | 1.2 | 60,452 | 66,769 | 69,369 | 83,944 | 0.171 | 0.124 | 0.172 | 0.108 |

| 1.4 | 0.2 | 1 | 1.2 | 45,465 | 50,691 | 53,750 | 63,895 | 0.343 | 0.249 | 0.315 | 0.237 |

| 0.2 | 0.8 | 1 | 1.2 | 14,542 | 17,158 | 80,797 | 102,897 | 0.793 | 0.649 | 0.145 | 0.083 |

| 1.4 | 0.8 | 1 | 1.2 | 9382 | 10,638 | 62,611 | 78,331 | 1.142 | 0.852 | 0.265 | 0.182 |

| 0.2 | 0.2 | 9 | 1.2 | 45,338 | 55,587 | 56,608 | 68,865 | 0.224 | 0.179 | 0.221 | 0.140 |

| 1.4 | 0.2 | 9 | 1.2 | 34,098 | 42,201 | 43,866 | 52,423 | 0.450 | 0.361 | 0.405 | 0.304 |

| 0.2 | 0.8 | 9 | 1.2 | 10,906 | 14,284 | 65,940 | 84,415 | 1.042 | 0.941 | 0.187 | 0.107 |

| 1.4 | 0.8 | 9 | 1.2 | 7037 | 8856 | 51,098 | 64,260 | 1.499 | 1.235 | 0.342 | 0.234 |

| 0.2 | 0.2 | 1 | 2.56 | 514,371 | 772,896 | 577,290 | 764,900 | 0.011 | 0.009 | 0.009 | 0.008 |

| 1.4 | 0.2 | 1 | 2.56 | 386,853 | 586,777 | 447,352 | 582,276 | 0.016 | 0.013 | 0.012 | 0.0097 |

| 0.2 | 0.8 | 1 | 2.56 | 84,339 | 138,566 | 672,461 | 937,620 | 0.114 | 0.076 | 0.007 | 0.006 |

| 1.4 | 0.8 | 1 | 2.56 | 54,421 | 85,914 | 521,101 | 713,759 | 0.230 | 0.153 | 0.010 | 0.0074 |

| 0.2 | 0.2 | 9 | 2.56 | 385,771 | 644,555 | 426,599 | 627,501 | 0.013 | 0.011 | 0.011 | 0.0098 |

| 1.4 | 0.2 | 9 | 2.56 | 290,135 | 488,503 | 330,546 | 477,682 | 0.025 | 0.021 | 0.015 | 0.012 |

| 0.2 | 0.8 | 9 | 2.56 | 63,253 | 115,359 | 496,878 | 769,195 | 0.150 | 0.110 | 0.009 | 0.0075 |

| 1.4 | 0.8 | 9 | 2.56 | 40,815 | 71,525 | 385,039 | 585,546 | 0.302 | 0.220 | 0.013 | 0.0096 |

| 0.2 | 0.5 | 5 | 1.88 | 138,435 | 234,139 | 222,254 | 307,634 | 0.102 | 0.119 | 0.031 | 0.023 |

| 1.4 | 0.5 | 5 | 1.88 | 113,714 | 192,532 | 172,222 | 234,186 | 0.261 | 0.196 | 0.048 | 0.036 |

| 0.8 | 0.2 | 5 | 1.88 | 186,137 | 316,744 | 167,549 | 221,405 | 0.055 | 0.042 | 0.048 | 0.038 |

| 0.8 | 0.8 | 5 | 1.88 | 36,427 | 61,796 | 195,168 | 271,400 | 0.559 | 0.448 | 0.040 | 0.029 |

| 0.8 | 0.5 | 1 | 1.88 | 154,790 | 261,307 | 224,554 | 292,834 | 0.183 | 0.129 | 0.035 | 0.027 |

| 0.8 | 0.5 | 9 | 1.88 | 112,092 | 190,694 | 172,779 | 240,230 | 0.240 | 0.188 | 0.045 | 0.034 |

| 0.8 | 0.5 | 5 | 1.2 | 21,501 | 35,765 | 55,130 | 68,398 | 0.790 | 0.653 | 0.284 | 0.191 |

| 0.8 | 0.5 | 5 | 2.56 | 195,774 | 331,099 | 426,624 | 623,219 | 0.192 | 0.157 | 0.011 | 0.0091 |

| 0.8 | 0.5 | 5 | 1.88 | 136,379 | 231,845 | 185,328 | 253,298 | 0.223 | 0.210 | 0.042 | 0.032 |

| Models | Student Criterion | Fisher Criterion | Determination Coefficient | ||

|---|---|---|---|---|---|

| Calculated | Tabular | ||||

| 2.1448 | 241.0093 | 2.6022 | 0.9942 | 0.9799 | |

| 2.1448 | 323.6017 | 2.6022 | 0.9926 | 0.9926 | |

| 2.1098 | 688.7448 | 2.6143 | 0.9950 | 0.9925 | |

| 2.11991 | 903.4419 | 2.5911 | 0.9967 | 0.9945 | |

| Models | Student Criterion | Fisher Criterion | Determination Coefficient | ||

|---|---|---|---|---|---|

| Calculated | Tabular | ||||

| 2.2010 | 373.5344 | 2.7614 | 0.9951 | 0.9863 | |

| 2.2281 | 489.5465 | 2.8647 | 0.9965 | 0.9908 | |

| 2.1199 | 2.5911 | 202.9674 | 0.9854 | 0.9785 | |

| 2.1199 | 2.5911 | 151.1764 | 0.9804 | 0.9741 | |

| Synthetic Diamonds | Dressing Method | Control Factors | Number of Dressing Cycles | Wear of Diamond Roller Dresser | |||||

|---|---|---|---|---|---|---|---|---|---|

(mm/min) | (s) | ||||||||

| PV | EV | PV | EV | ||||||

| AC32 | Uni-directional | 0.2 | 0.2 | 1.0 | 2.56 | 499,073 | 514,371 | 0.0213 | 0.021 |

| Counter-directional | 0.2094 | 0.8 | 1.0087 | 2.56 | 644,445 | 672,200 | 0.0104 | 0.01 | |

| AC80 | Uni-directional | 0.2541 | 0.2002 | 1.0 | 2.56 | 740,401 | 762,690 | 0.0253 | 0.026 |

| Counter-directional | 0.2002 | 0.7733 | 1.0599 | 2.56 | 894,208 | 925,605 | 0.0104 | 0.01 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aleksandrova, I.; Mitev, H. Investigation and Modelling of the Wear Resistance of Diamond Roller Dressers Made of Synthetic Diamonds with Mixed Grit Size. Coatings 2025, 15, 1376. https://doi.org/10.3390/coatings15121376

Aleksandrova I, Mitev H. Investigation and Modelling of the Wear Resistance of Diamond Roller Dressers Made of Synthetic Diamonds with Mixed Grit Size. Coatings. 2025; 15(12):1376. https://doi.org/10.3390/coatings15121376

Chicago/Turabian StyleAleksandrova, Irina, and Hristian Mitev. 2025. "Investigation and Modelling of the Wear Resistance of Diamond Roller Dressers Made of Synthetic Diamonds with Mixed Grit Size" Coatings 15, no. 12: 1376. https://doi.org/10.3390/coatings15121376

APA StyleAleksandrova, I., & Mitev, H. (2025). Investigation and Modelling of the Wear Resistance of Diamond Roller Dressers Made of Synthetic Diamonds with Mixed Grit Size. Coatings, 15(12), 1376. https://doi.org/10.3390/coatings15121376