Influence of Gear Set Loading on Surface Damage Forms for Gear Teeth with DLC Coating

Abstract

1. Introduction

2. Materials and Methods

| Motor rotational speed | 3000 rpm; |

| Circumferential speed | 16.6 m/s; |

| Run duration | 7 min. 30 s; |

| Maximum load stage | 12; |

| Maximum loading torque | 535 N·m; |

| Maximum Hertzian stress | 2.6 GPa; |

| Initial lubrication oil temperature | 90 °C (uncontrolled after starting the run); |

| Type of lubrication | dip lubrication (oil quantity ca. 1.5 dm3). |

3. Results

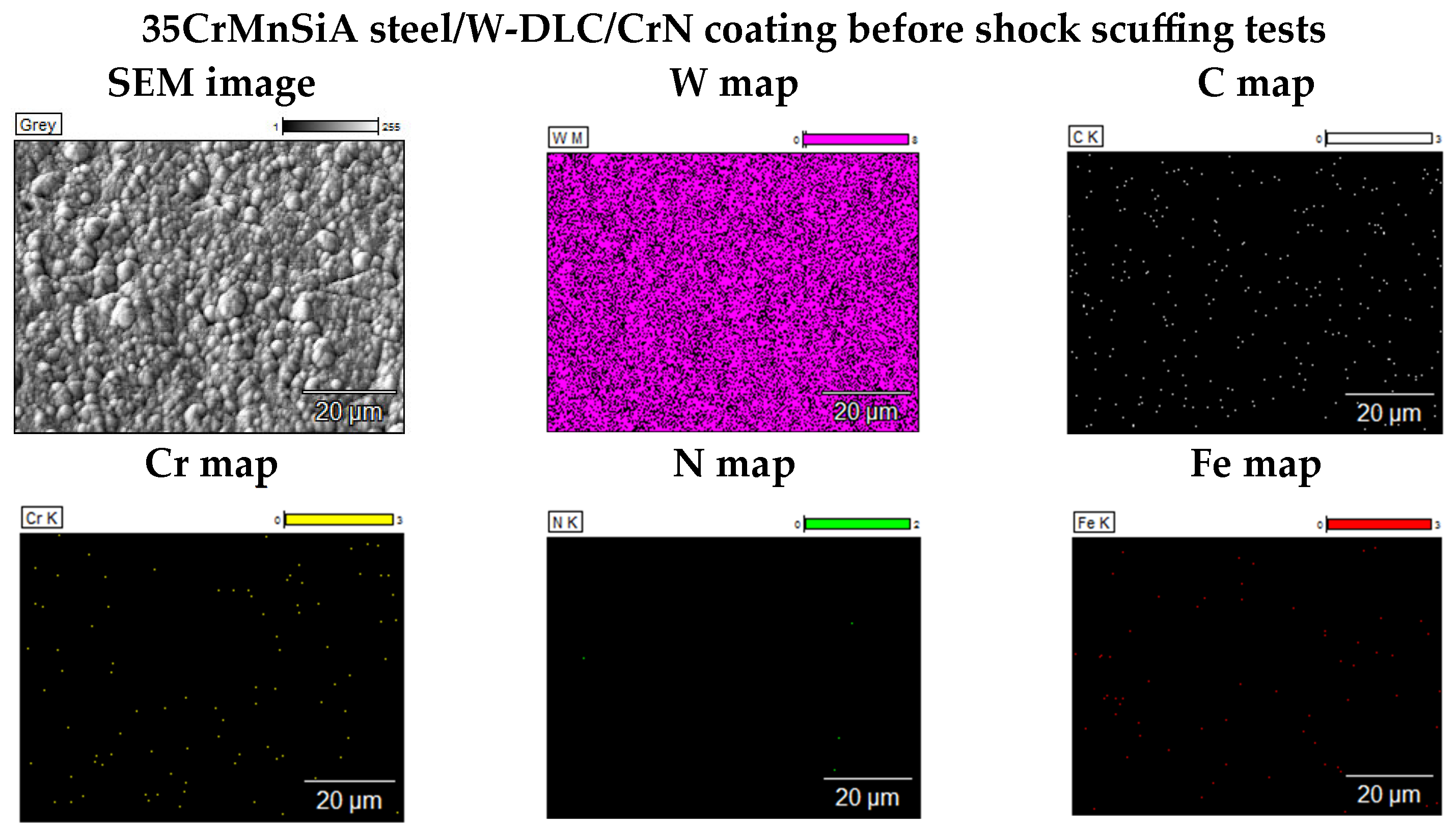

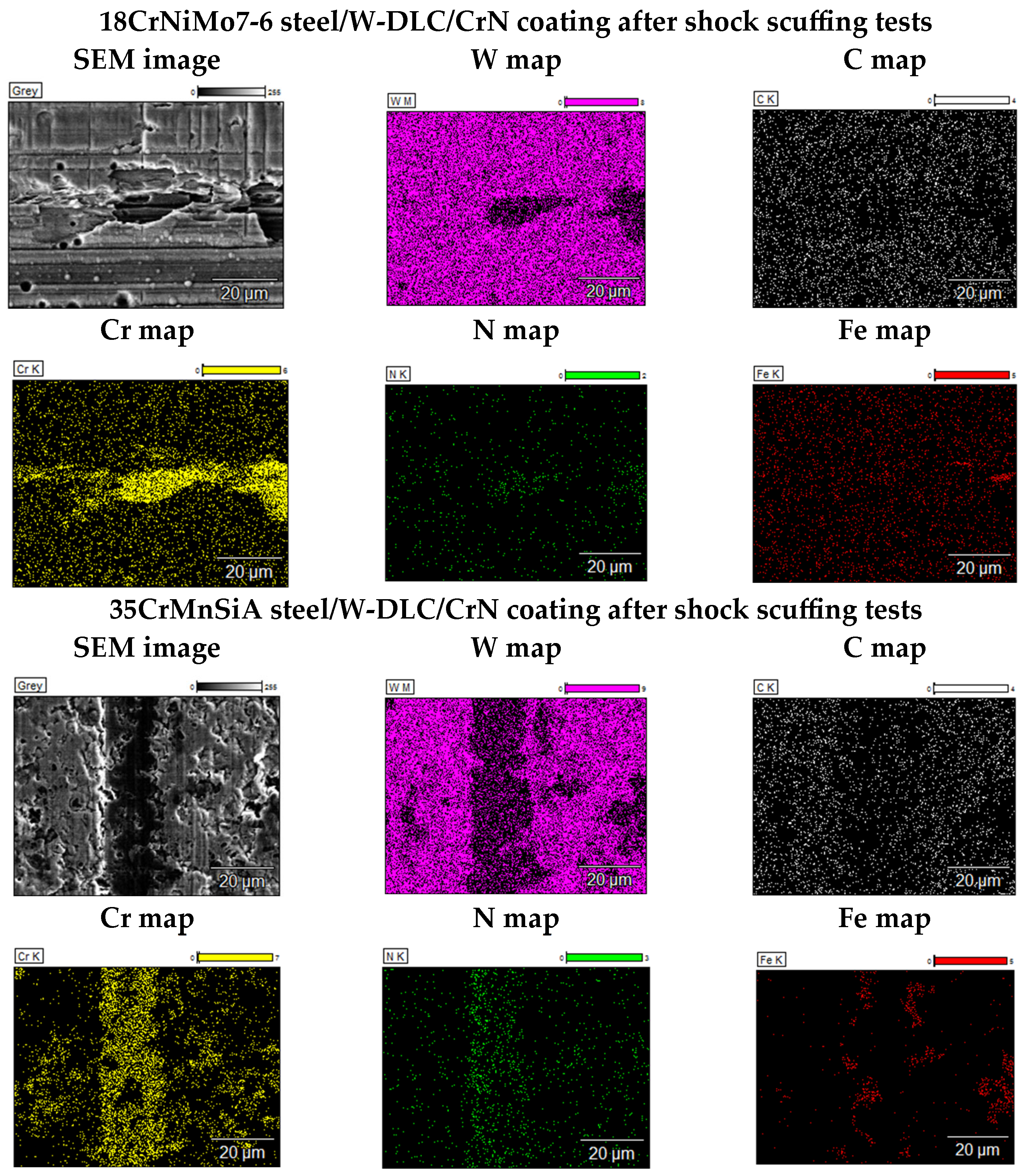

- A SU-70 field-emission scanning electron microscope (FE-SEM), produced by Hitachi, Tokyo, Japan, integrated with an NSS 312 energy dispersive spectrometer (EDS) produced by Thermo Scientific, Madison, WI, USA, for surface imaging in microscale and elemental analysis (acceleration voltage of 15 kV, take-off angle of 30, vacuum conditions 1 × 10−8 Pa, a secondary electron (SE) detector, and magnification for images-1000× for the elemental composition maps were acquired at 3000× magnification);

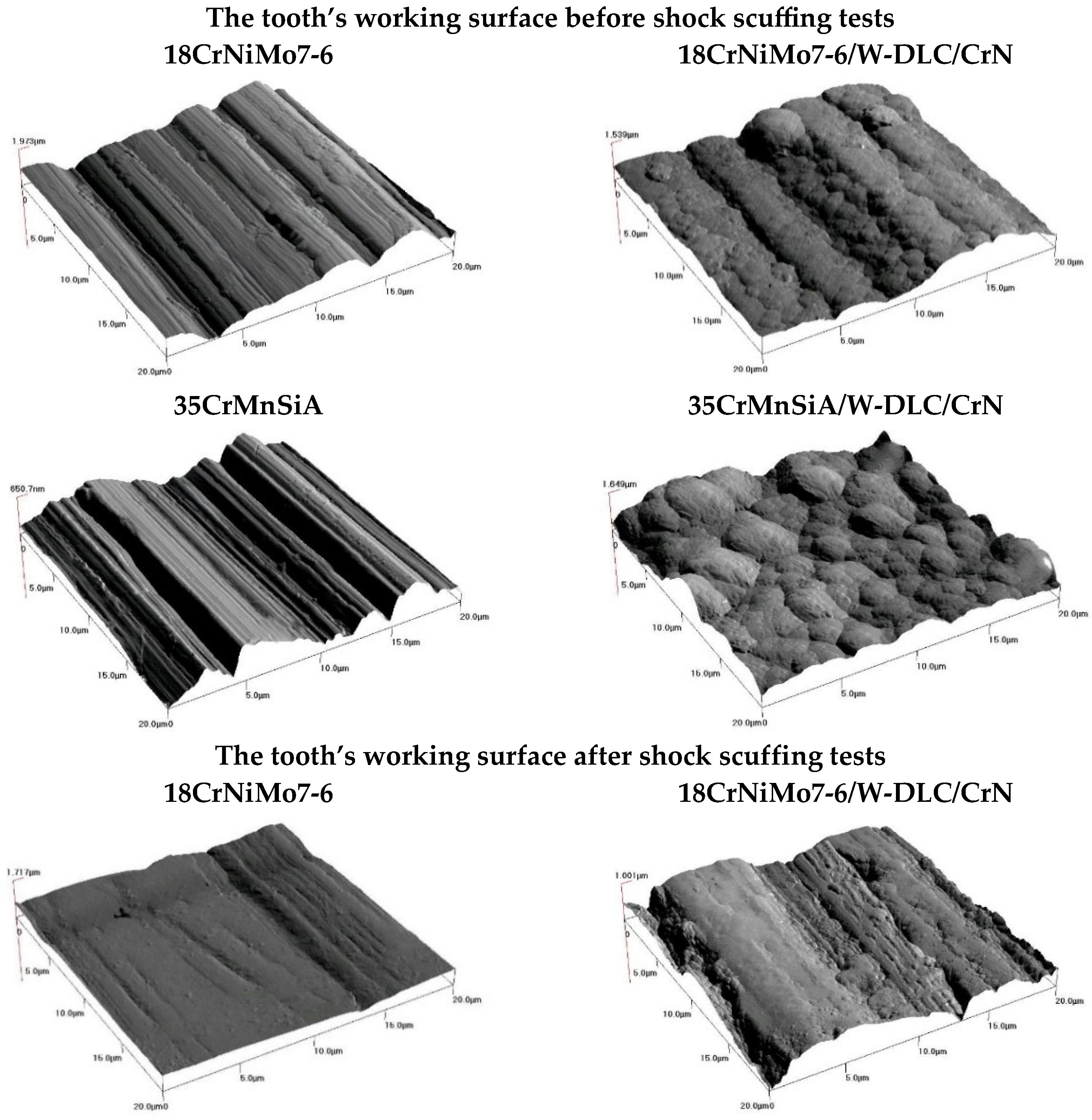

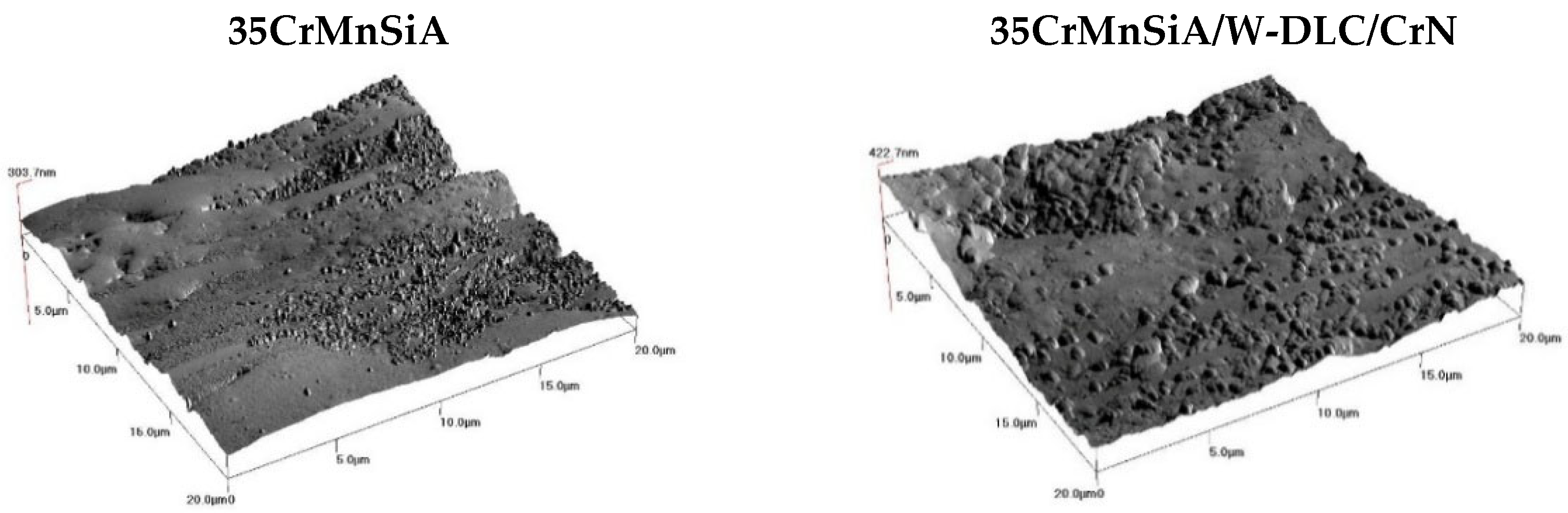

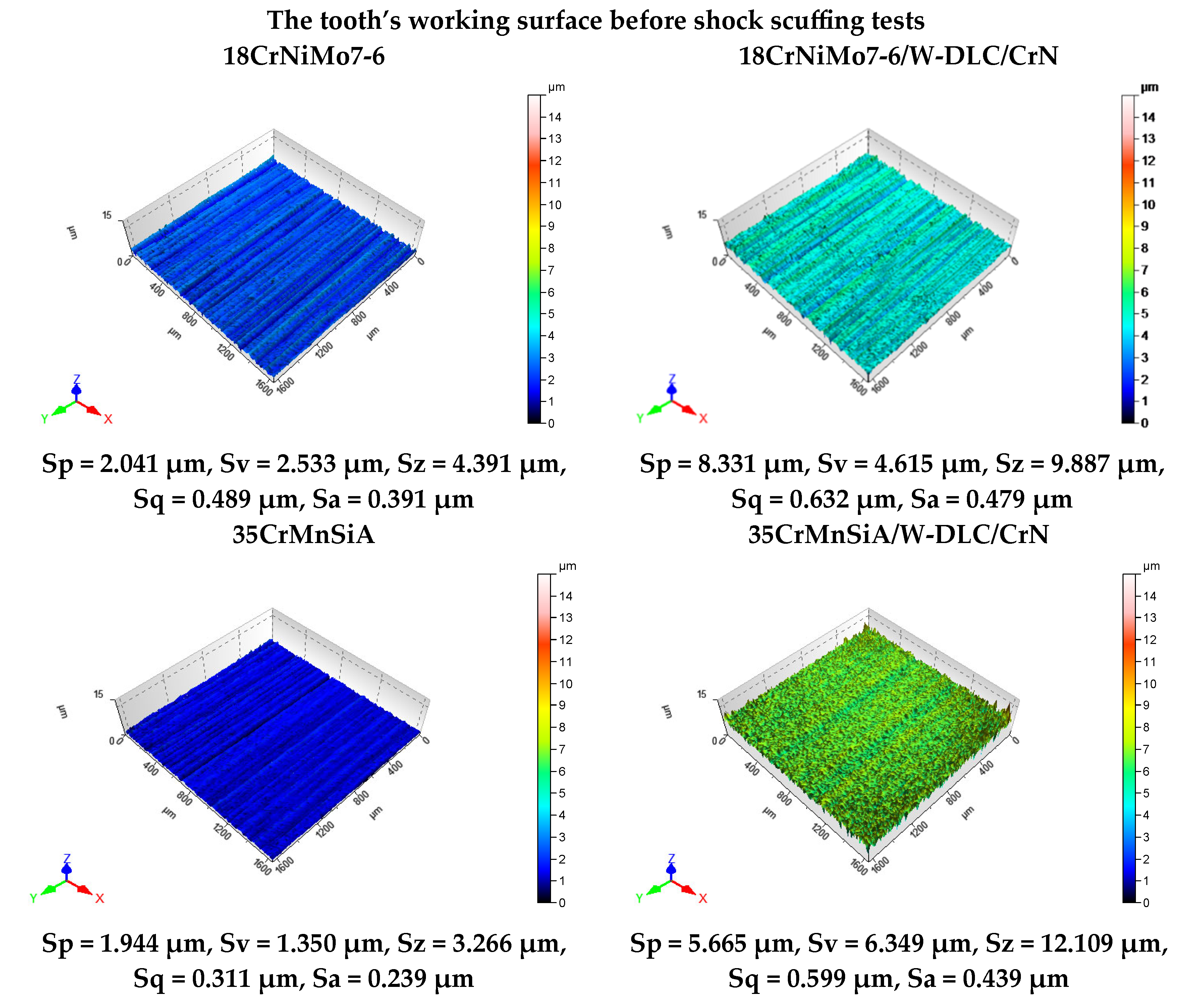

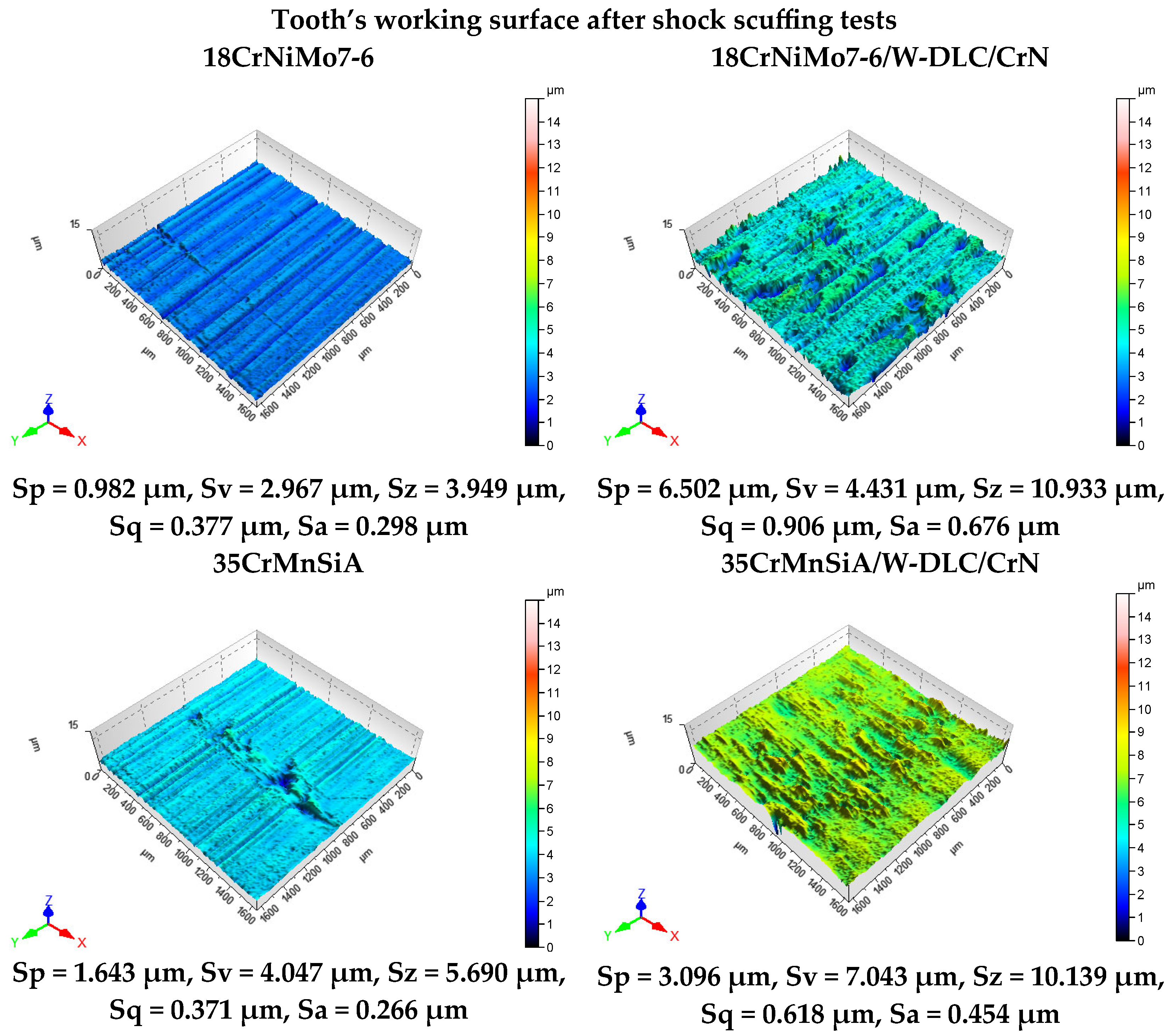

- A WLI optical profilometer, produced by Taylor Hobson, Leicester, UK, for 3D surface imaging at the micro scale and the measurement of surface roughness (10× magnification). The microscope is equipped with a set of Mirou objectives (5×, 10×, 20×, and 50×) and a CCD camera used for measurement data acquisition. The analysis of the measured dimensions is carried out using TalyMap v.7 software;

- A Q-scope 250 atomic force microscope (AFM) produced by the Quesant Instrument Corporation, Agoura Hills, CA, USA, for 3D surface imaging at the nano scale (contact mode measurement, and measurement head of the microscope: 20 × 20 μm);

- A MM-40 optical microscope produced by Nikon, Tokyo, Japan (50× magnification), equipped with the MultiScanBase v.8 system for image acquisition and digital processing, as well as a set of objectives with magnifications of 5×, 10×, 20×, and 50×.

4. Conclusions

- The 35CrMnSiA steel pinions with W-DLC/CrN coating were scuffing under shock loading. The coating proved insufficient under extreme overloading conditions.

- Scuffing areas were observed on the surface of the 35CrMnSiA steel tooth.

- The 18CrNiMo7-6 steel pinions without the coating were not scuffing even under the highest, 12th, stage of loading. This proves this steel has a much higher material resistance to scuffing compared with 35CrMnSiA steel.

- The surfaces of 18CrNiMo7-6 steel gear teeth, coated with DLC/CrN, showed no signs of scuffing even under maximum loading. The combination of a high-quality base material and the coating proved effective under shock scuffing conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FLS | failure load stage |

| FZG | the Gear Research Centre (Forschungsstelle fur Zahnrader und Getriebebau, FZG) of the Technical University of Munich |

| DLC | Diamond-like Carbon coating |

| SEM | Scanning Electron Microscope |

| EDS | Energy Dispersive Spectrometer |

| WLI | White Light Interferometer Microscope |

| AFM | Atomic Force Microscope |

| Ra | profile roughness [µm] |

| Sa | surface roughness [µm] |

| Sp | maximum peak height [µm] |

| Sv | maximum indentation depth [µm] |

| Sz | maximum surface height [µm] |

| Sq | mean square deviation of the surface roughness [µm] |

| Ap | wear surface area of the small gear teeth [mm2] |

References

- Evaristo, M.; Fernandes, F.; Cavaleiro, A. Influence of the alloying elements on thetribological performance of DLC coatings in different sliding conditions. Wear 2023, 526–527, 204880. [Google Scholar] [CrossRef]

- Forsberg, P.; Gustavsson, F.; Renman, V.; Hieke, A.; Jacobson, S. Performance of DLC coatings in heated commercial engine oils. Wear 2013, 304, 211–222. [Google Scholar] [CrossRef]

- Rincon, C.; Zambrano, G.; Carvajal, A.; Prieto, P.; Galindo, H.; Martinez, E.; Lousa, A.; Esteve, J. Tungsten carbide/diamond-like carbon multilayer coatings on steel for tribological applications. Surf. Coat. Technol. 2001, 148, 277–283. [Google Scholar] [CrossRef]

- Goti, E.; Mura, A.; di Confiengo, G.M.G.; Casalegno, V. The tribological performance of super-hard Ta:C DLC coatings obtained by low-temperature PVD. Ceram. Int. 2023, 49, 40193–40210. [Google Scholar] [CrossRef]

- Rajak, D.K.; Kumar, A.; Behera, A.; Menezes, P. Diamond-Like Carbon (DLC) Coatings: Classification, Properties, and Applications. Appl. Sci. 2021, 11, 4445. [Google Scholar] [CrossRef]

- Shaikh, S.; Sadeghi, M.; Cruz, S.; Ferreira, F. Recent Progress on the Tribology of Pure/Doped Diamond-like Carbon Coatings and Ionic Liquids. Coatings 2024, 14, 71. [Google Scholar] [CrossRef]

- Radoń-Kobus, K.; Madej, M.; Kowalczyk, J.; Piotrowska, K. Properties of Diamond-like Tungsten-Doped Carbon Coatings Lubricated with Cutting Fluid. Coatings 2024, 14, 342. [Google Scholar] [CrossRef]

- Martins, R.; Amaro, R.; Seabra, J. Influence of low friction coatings on the scuffing load capacity and efficiency of gears. Tribol. Int. 2008, 41, 234–243. [Google Scholar] [CrossRef]

- Vengudusamy, B.; Mufti, R.A.; Lamb, G.D.; Green, J.H.; Spikes, H.A. Friction properties of DLC/DLC contacts in base oil. Tribol. Int. 2011, 44, 922–932. [Google Scholar] [CrossRef]

- Kalin, M.; Vižintin, J. The tribological performance of DLC-coated gears lubricated with biodegradable oil in various pinion/gear material combinations. Wear 2005, 259, 1270–1280. [Google Scholar] [CrossRef]

- Tuszyński, W.; Michalczewski, R.; Osuch-Słomka, E.; Snarski-Adamski, A.; Kalbarczyk, M.; Wieczorek, A.; Nędza, J. Abrasive wear, scuffing and rolling contact fatigue of DLC-coated 18CrNiMo7-6 steel lubricated by a pure and contaminated gear oil. Materials 2021, 14, 7086. [Google Scholar] [CrossRef] [PubMed]

- Vicen, M.; Krajánek, D.; Trško, L.; Bokuvka, O.; Buchtík, M.; Florková, Z.; Frkán, M. Improving of 100Cr6 Steel Corrosion and Wear Properties in Simulted Sea Water Environment by Tungsten-Doped DLC Coating. Materials 2023, 16, 4334. [Google Scholar] [CrossRef] [PubMed]

- Barth, Y.J.; Sagraloff, N.; Egger, G.; Tobie, T.; Stahl, K. Investigations on Ways to Improve the Scuffing and Wear Behavior of Oil-Free Water-Based Lubricants for Gear Applications. J. Tribol. 2024, 146, 054601. [Google Scholar] [CrossRef]

- Ronkainen, H.; Elomaa, O.; Varjus, S.; Kilpi, L.; Jaatinen, T.; Koskinen, J. The influence of carbon based coatings and surface finishon the tribological performance in high-load contacts. Tribol. Int. 2016, 96, 402–409. [Google Scholar] [CrossRef]

- Beilicke, R.; Bobach, L.; Bartel, D. Transient thermal elastohydrodynamic simulation of a DLC coated helical gear pair considering limiting shear stress behavior of the lubricant. Tribol. Int. 2016, 97, 136–150. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, C.; Zhang, Y.; Wang, Z.; Song, C. Tribological evaluation of a coated spur gear pair. Tribol. Int. 2016, 99, 117–126. [Google Scholar] [CrossRef]

- Fujii, M.; Seki, M.; Yoshida, A. Surface durability of WC/C-coated case-hardened steel gear. J. Mech. Sci. Technol. 2010, 24, 103–106. [Google Scholar] [CrossRef]

- Wu, L.; Bai, Z.; Hao, Q.; Qin, J. Improving Wear Resistance of DLC-Coated Metal Components During Service: A Review. Lubricants 2025, 13, 257. [Google Scholar] [CrossRef]

- Osuch-Słomka, E.; Michalczewski, R.; Mańkowska-Snopczyńska, A.; Kalbarczyk, M.; Wieczorek, A.; Skołek, E. Wear mechanisms of the working surface of gears after scuffing tests. Materials 2024, 17, 3552. [Google Scholar] [CrossRef] [PubMed]

- Ríos-Diez, O.; Aristizábal-Sierra, R.; Serna-Giraldo, C.; Jimenez, J.A.; Garcia-Mateo, C. Development of nanobainitic microstructures in carbo-austempered cast steels: Heat treatment, microstructure and properties. Metals 2020, 10, 635. [Google Scholar] [CrossRef]

- Rementeria, R.; Morales-Rivas, L.; Kuntz, M.; Garcia-Mateo, C.; Kerscher, E.; Sourmail, T.; Caballero, F.G. On the role of microstructure in governing the fatigue behaviour of nanostructured bainitic steels. Mater. Scence Eng. A 2015, 630, 71–77. [Google Scholar] [CrossRef]

- Solano-Alvarez, W.; Pickering, E.; Bhadeshia, H.K. Degradation of nanostructured bainitic steel under rolling contact fatigue. Mater. Sci. Eng. A 2014, 617, 156–164. [Google Scholar] [CrossRef]

- Łukaszewicz, G.; Szczygieł, M.; Wesierska-Hinca, M.; Chmielarz, K.; Wierzbicka, E.; Wasiak, K. Interrupted quenching and bainitising below Ms temperature of EN X37CrMoV5-1 hot-work tool steel: Bainitic transformation kinetics, microstructure and mechanical properties. Mater. Sci. Eng. A 2023, 869, 144740. [Google Scholar] [CrossRef]

- Morales-Rivas, L.; Azadi, A.; Kerscher, E. Fatigue behavior of nanostructured bainite: A morphological study of crack path. Procedia Struct. Integr. 2022, 39, 515–527. [Google Scholar] [CrossRef]

- FVA Information Sheet no. 243, Status June 2000, Method to Assess the Scuffing Load Capacity of Lubricants with High EP Performance Using an FZG Gear Test Rig. 2000. Available online: https://hrcak.srce.hr/file/37724 (accessed on 10 July 2025).

- Höhn, B.R.; Michaelis, K.; Eberspächer, C.; Schlenk, L. A scuffing load capacity test with the FZG gear test rig for gear lubricants with high EP performance. Tribotest J. 1999, 5, 383–390. [Google Scholar] [CrossRef]

- Michaelis, K.; Höhn, B.R.; Graswald, C. Scuffing tests for API GL-1 to GL-5 gear lubricants. In Proceedings of the 13th International Colloquium Tribology, Esslingen, Alemanha, 17–15 January 2002; pp. 1133–1137. [Google Scholar]

- Michaelis, K.; Höhn, B.R.; Oster, P. Influence of lubricant on gear failures-test methods and application to gearboxes in practice. Tribotest J. 2004, 11, 43–56. [Google Scholar] [CrossRef]

- Van De Velde, F.; Willen, P.; De Baets, P.; Van Geetruyen, C. Substitution of inexpensive bench tests for the FZG scuffing test—Part I: Calculations. Tribol. Trans. 1999, 42, 63–70. [Google Scholar] [CrossRef]

- Van De Velde, F.; Willen, P.; De Baets, P.; Van Geeteruyen, C. Substitution of inexpensive bench tests for the FZG scuffing test—Part II: Oil tests. Tribol. Trans. 1999, 42, 71–75. [Google Scholar] [CrossRef]

- Michalczewski, R.; Kalbarczyk, M.; Mańkowska-Snopczyńska, A.; Osuch-Słomka, E.; Piekoszewski, W.; Snarski-Adamski, A.; Szczerek, M.; Tuszynski, W.; Wulczyński, J.; Wieczorek, A. The effect of a gear oil on abrasion, scuffing, and pitting of the DLC-coated 18CrNiMo7-6 steel. Coatings 2019, 9, 2. [Google Scholar] [CrossRef]

- Szczerek, M.; Kalbarczyk, M.; Mańkowska-Snopczyńska, A.; Osuch-Słomka, E.; Piekoszewski, W.; Snarski-Adamski, A.; Tuszyński, W.; Wieczorek, A.N. The correlated selection of a thin coating and gear oil to increase the resistance of 18CrNiMo7-6 gears to pitting—Part 1. In Proceedings of the ASIATRIB, Kuching, Malaysia, 17–20 September 2018; Volume 133, pp. 293–295, ISBN 978-967-13625-2-5. [Google Scholar]

- Tuszyński, W.; Michalczewski, R.; Osuch-Słomka, E.; Wieczorek, A.N.; Wulczyński, J. The correlated selection of a thin coating and gear oil to increase the resistance of 18CrNiMo7-6 gears to abrasion and scuffing—Part 2. In Proceedings of the ASIATRIB, Kuching, Malaysia, 17–20 September 2018; Volume 204, pp. 450–452, ISBN 978-967-13625-2-5. [Google Scholar]

| Polishing | Scratches | Scoring | Scuffing |

|---|---|---|---|

|  |  |  |

| Pinion Material | The Working Surface of the Pinion Gear After Scuffing Tests Under Shock Conditions | |||

|---|---|---|---|---|

| Test Gear | Modes of the Wear of the Test Pinion at Maximum Load Stage with the Total Area of Failures on the Pinion | Working Surface of the Pinion Tooth | Optical Microscope Image | |

| 17HNM steel |  |  Ap ≈ 32.0 mm2 |  |  |

| 17HNM/ W-DLC/CrN coating |  |  Ap ≈ 7.0 mm2 |  |  |

| 35HGSA steel |  |  Ap ≈ 59.0 mm2 |  |  |

| 35HGSA/ W-DLC/CrN coating |  |  Ap ≈ 106.0 mm2 |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osuch-Słomka, E.; Michalczewski, R.; Mańkowska-Snopczyńska, A.; Gibała, M.; Wieczorek, A.N.; Skołek, E. Influence of Gear Set Loading on Surface Damage Forms for Gear Teeth with DLC Coating. Coatings 2025, 15, 857. https://doi.org/10.3390/coatings15070857

Osuch-Słomka E, Michalczewski R, Mańkowska-Snopczyńska A, Gibała M, Wieczorek AN, Skołek E. Influence of Gear Set Loading on Surface Damage Forms for Gear Teeth with DLC Coating. Coatings. 2025; 15(7):857. https://doi.org/10.3390/coatings15070857

Chicago/Turabian StyleOsuch-Słomka, Edyta, Remigiusz Michalczewski, Anita Mańkowska-Snopczyńska, Michał Gibała, Andrzej N. Wieczorek, and Emilia Skołek. 2025. "Influence of Gear Set Loading on Surface Damage Forms for Gear Teeth with DLC Coating" Coatings 15, no. 7: 857. https://doi.org/10.3390/coatings15070857

APA StyleOsuch-Słomka, E., Michalczewski, R., Mańkowska-Snopczyńska, A., Gibała, M., Wieczorek, A. N., & Skołek, E. (2025). Influence of Gear Set Loading on Surface Damage Forms for Gear Teeth with DLC Coating. Coatings, 15(7), 857. https://doi.org/10.3390/coatings15070857