Structural and Phase Characteristics and Properties of Multilayer Cr/CrN Coatings Obtained by Magnetron Sputtering

Abstract

1. Introduction

2. Materials and Methods

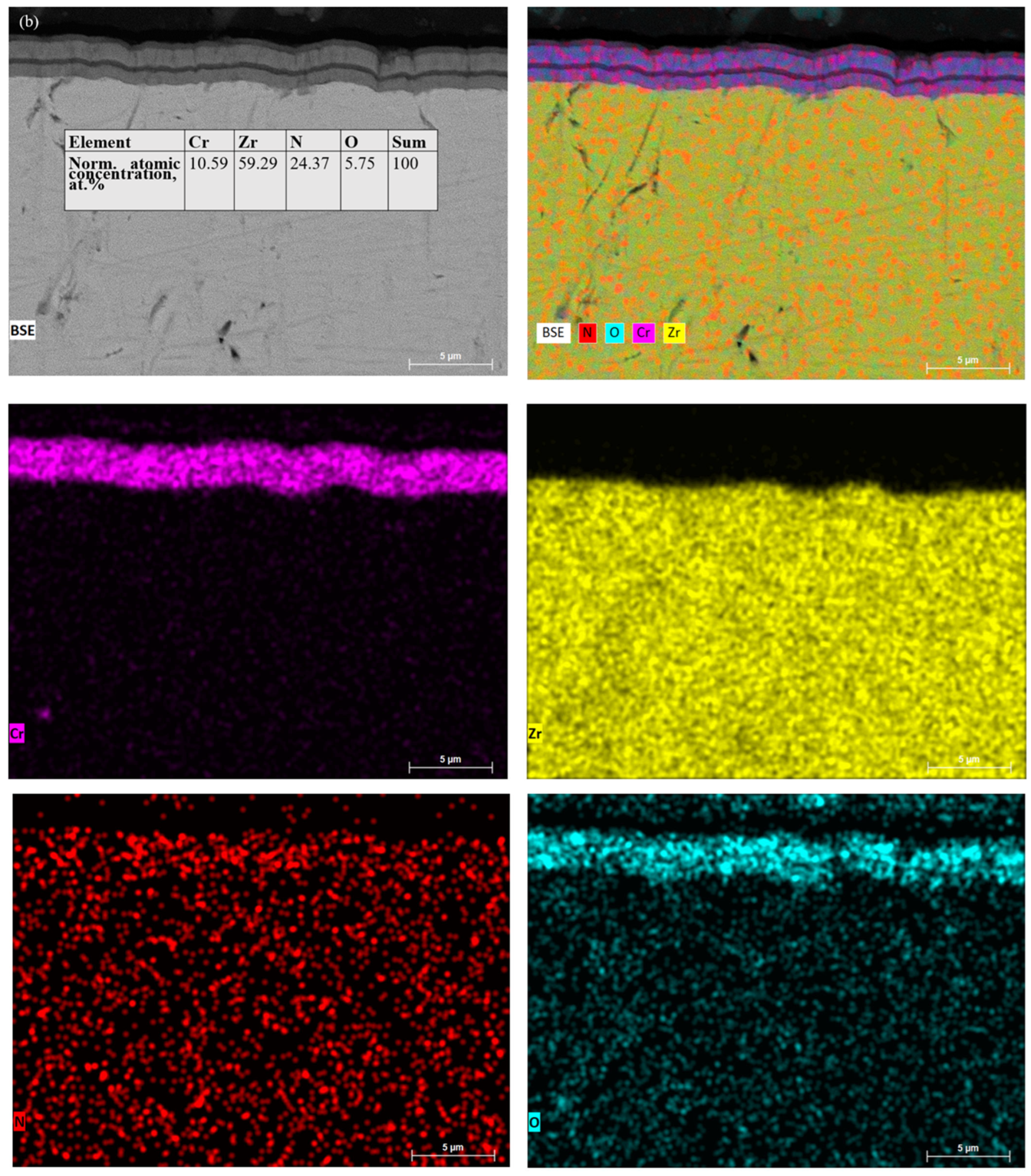

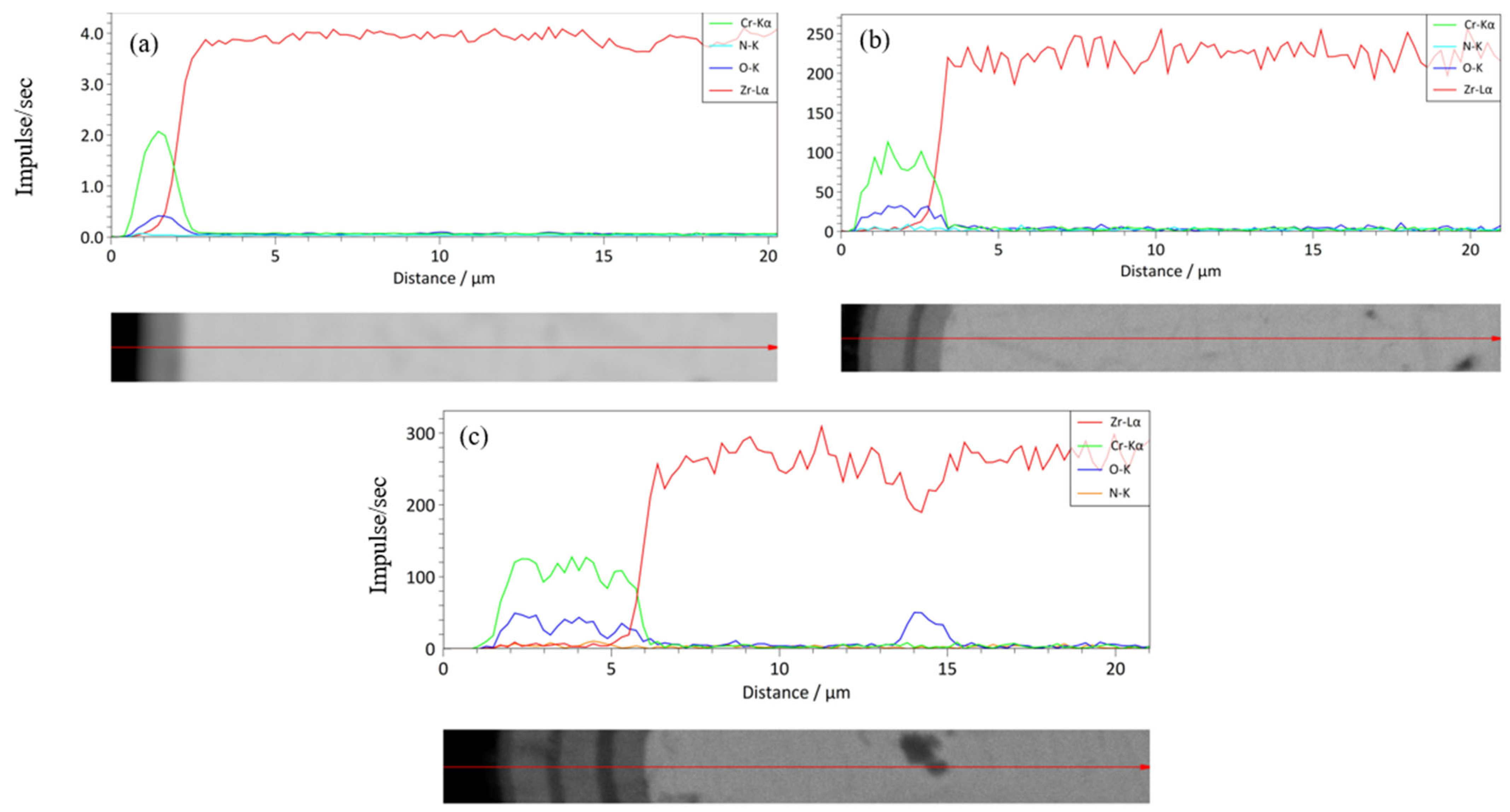

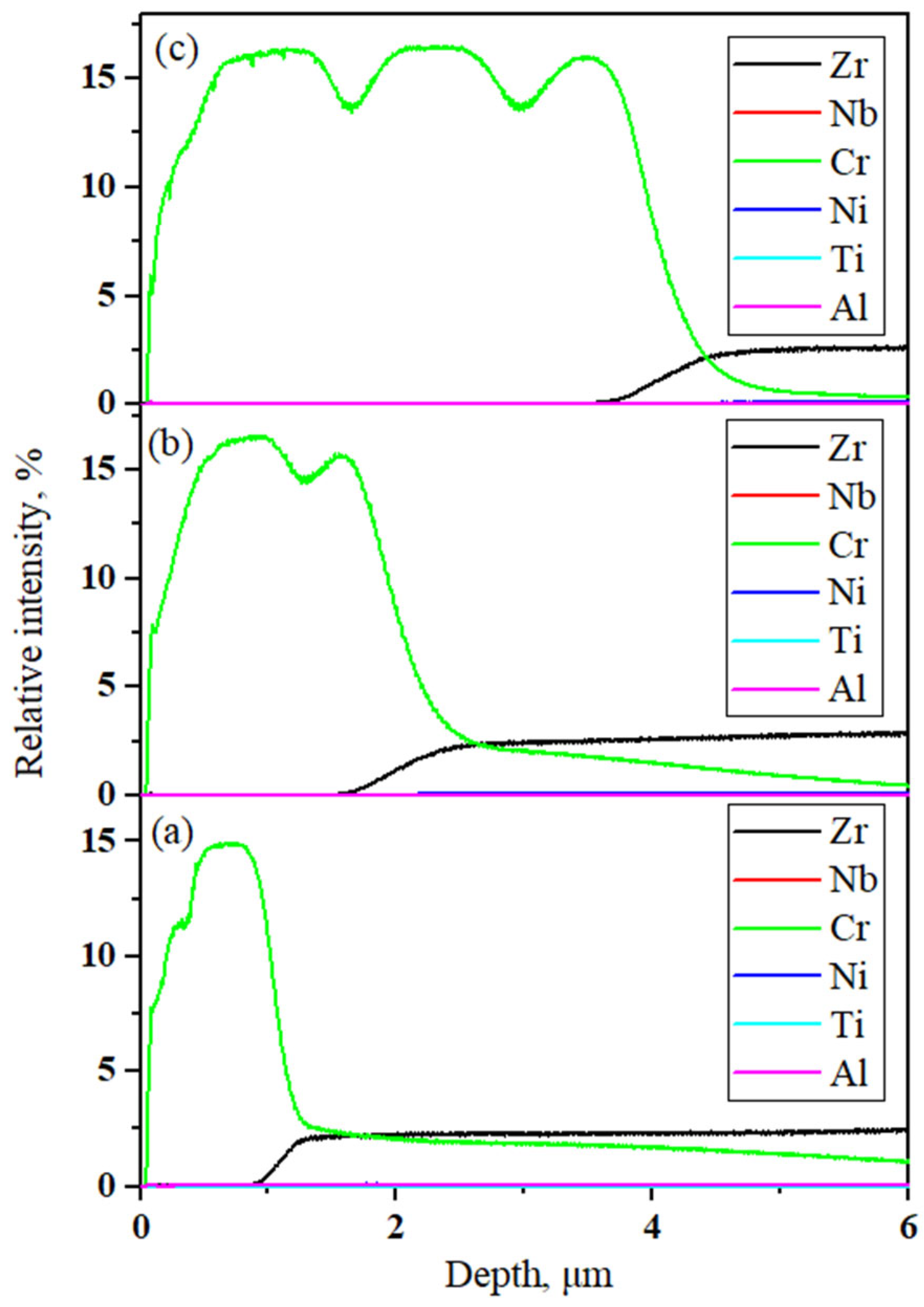

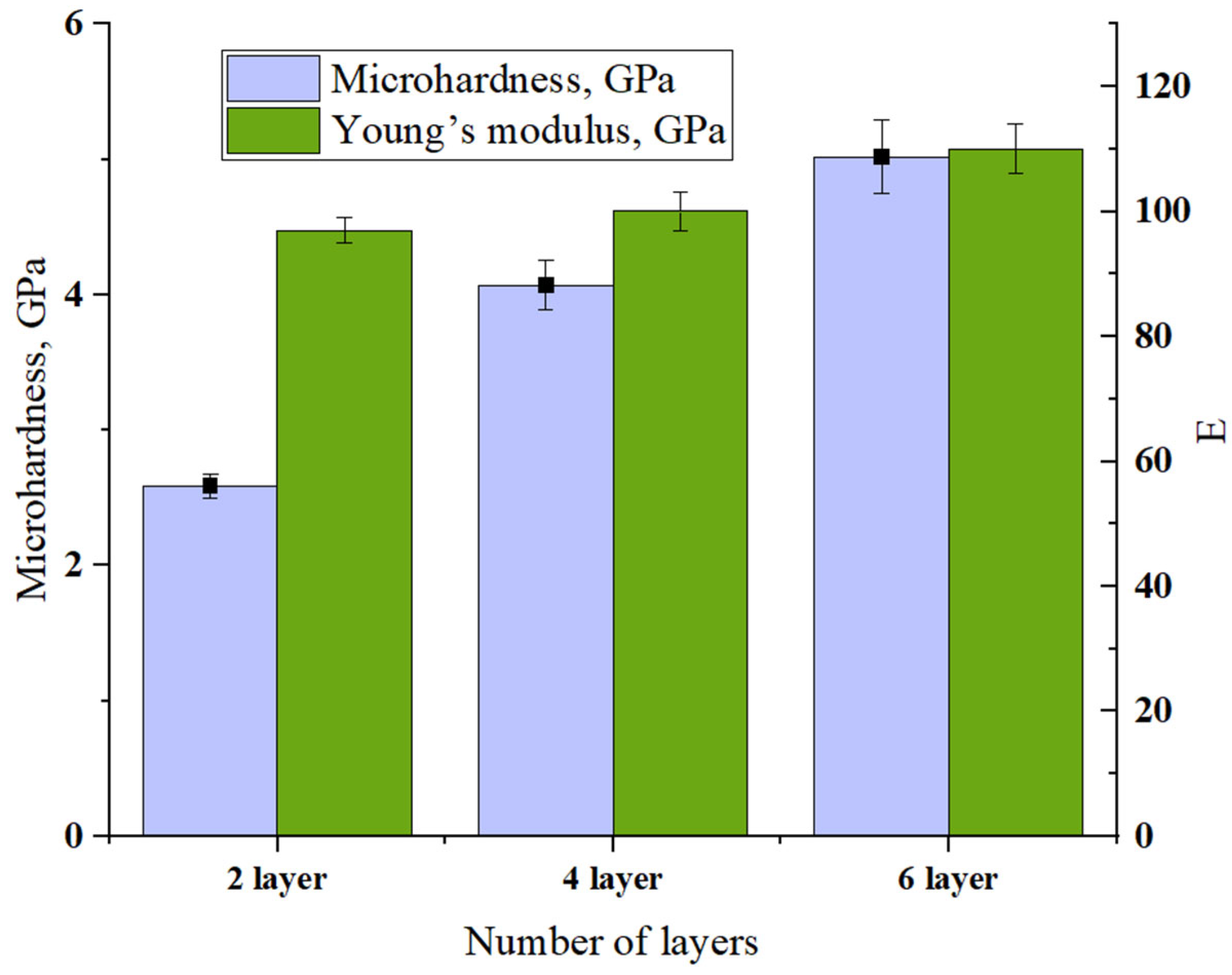

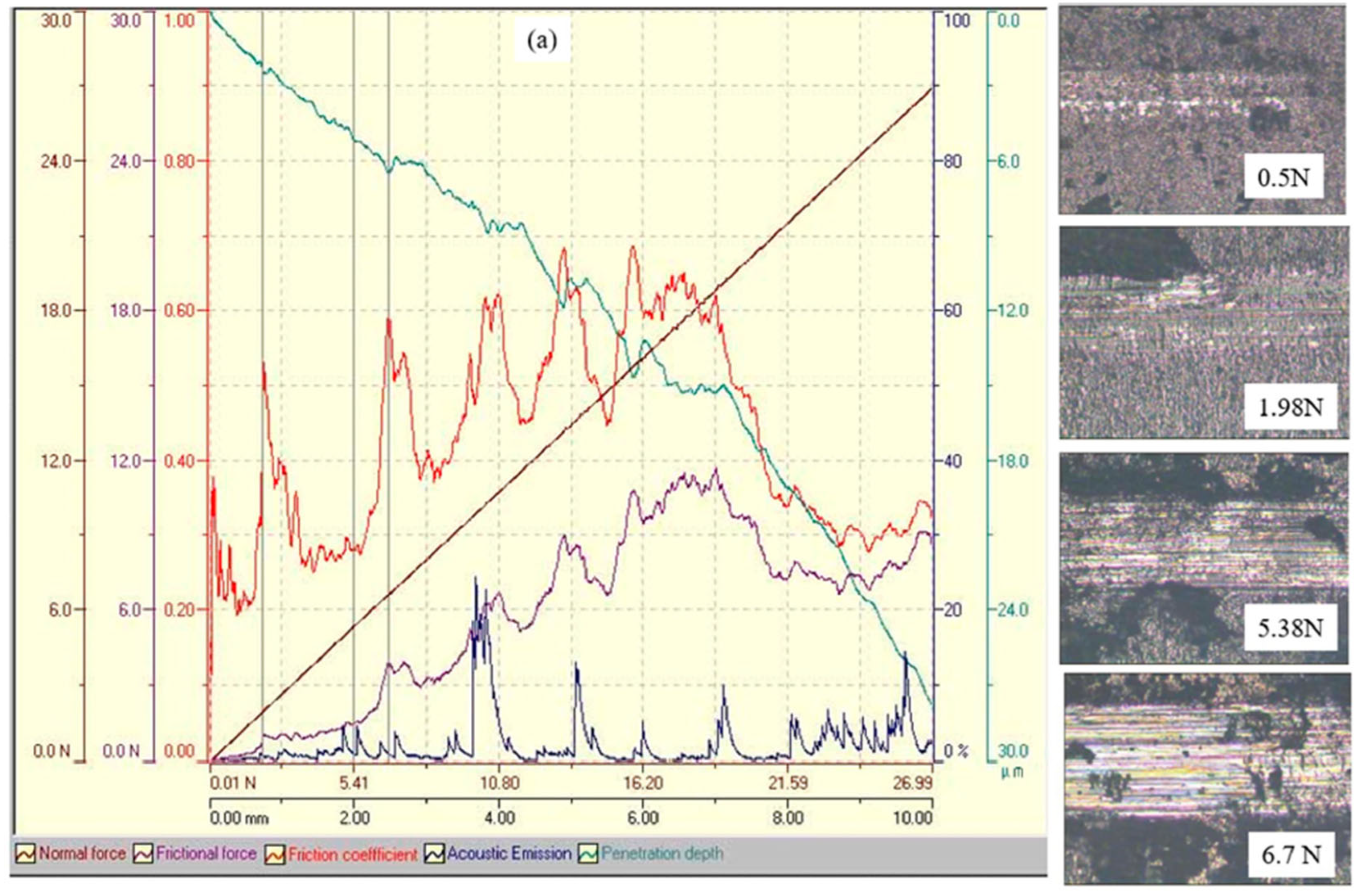

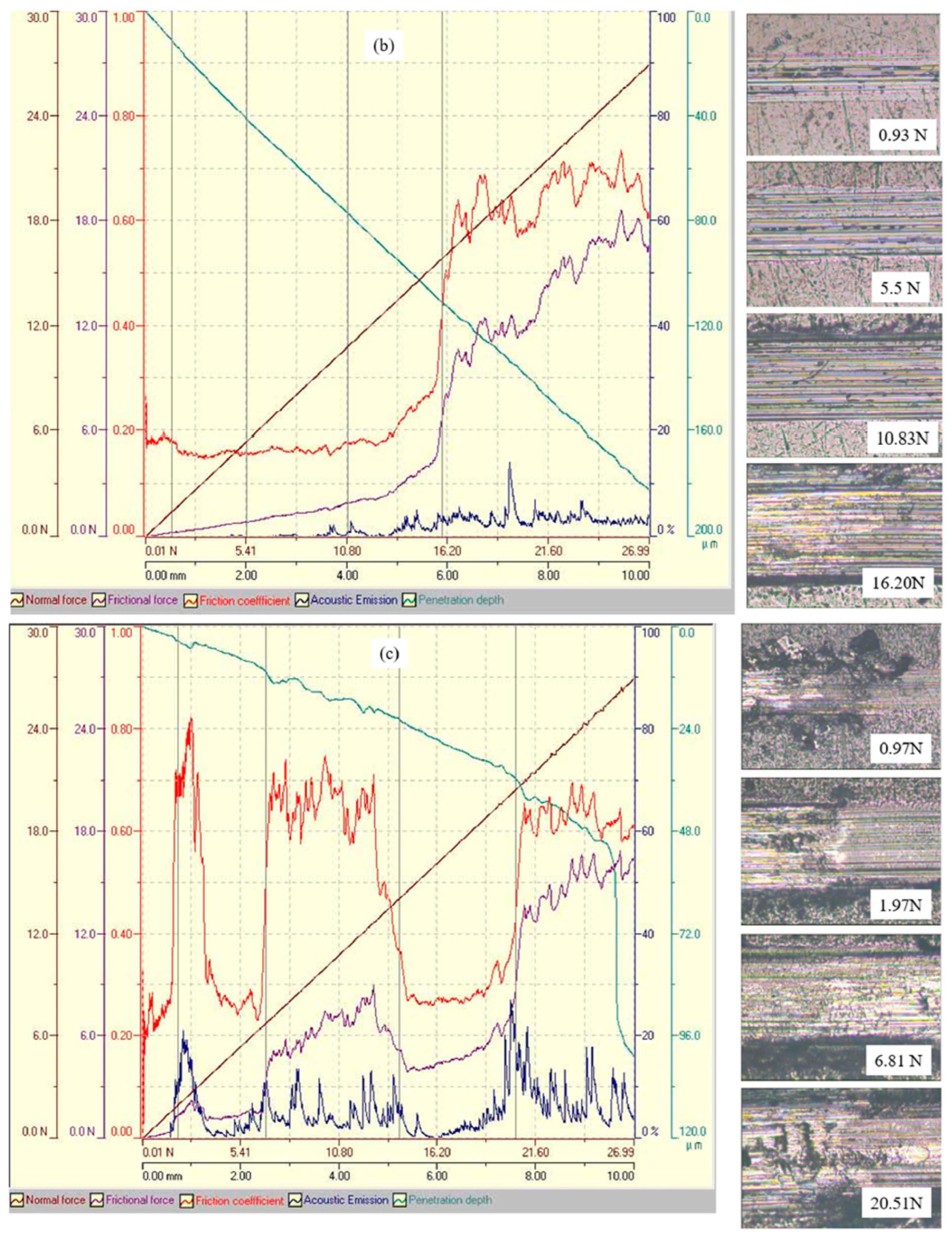

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, Z.; Dailey, R.; Feng, T.; Zhou, Y.; Sun, Z.; Corradini, M.L.; Wang, J. Uncertainty Analysis of ATF Cr-Coated-Zircaloy on BWR in-Vessel Accident Progression during a Station Blackout. Reliab. Eng. Syst. Saf. 2021, 213, 107770. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, X.; Yun, D. A complete review and a prospect on the candidate materials for accident-tolerant fuel claddings. Mater. Rev. 2018, 32, 1757–1778. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Terrani, K.A.; Gehin, J.C.; Ott, L.J.; Snead, L.L. Accident Tolerant Fuels for LWRs: A Perspective. J. Nucl. Mater. 2014, 448, 374–379. [Google Scholar] [CrossRef]

- Bragg-Sitton, S.M.; Todosow, M.; Montgomery, R.; Stanek, C.R.; Montgomery, R.; Carmack, W.J. Metrics for the technical performance evaluation of light water reactor accident-tolerant fuel. Nucl. Technol. 2016, 195, 111–123. [Google Scholar] [CrossRef]

- Tang, C.; Stueber, M.; Seifert, H.J.; Steinbrueck, M. Protective Coatings on Zirconium-Based Alloys as Accident-Tolerant Fuel (ATF) Claddings. Corros. Rev. 2017, 35, 141–165. [Google Scholar] [CrossRef]

- Brachet, J.-C.; Idarraga-Trujillo, I.; Flem, M.L.; Saux, M.L.; Vandenberghe, V.; Urvoy, S.; Rouesne, E.; Guilbert, T.; Toffolon-Masclet, C.; Tupin, M.; et al. Early Studies on Cr-Coated Zircaloy-4 as Enhanced Accident Tolerant Nuclear Fuel Claddings for Light Water Reactors. J. Nucl. Mater. 2019, 517, 268–285. [Google Scholar] [CrossRef]

- Maier, B.; Yeom, H.; Johnson, G.; Dabney, T.; Walters, J.; Xu, P.; Romero, J.; Shah, H.; Sridharan, K. Development of Cold Spray Chromium Coatings for Improved Accident Tolerant Zirconium-Alloy Cladding. J. Nucl. Mater. 2019, 519, 247–254. [Google Scholar] [CrossRef]

- Ševeček, M.; Gurgen, A.; Seshadri, A.; Che, Y.; Wagih, M.; Phillips, B.; Champagne, V.; Shirvan, K. Development of Cr cold-spray-coated fuel cladding with enhanced accident tolerance. Nucl. Eng. Technol. 2018, 50, 229–236. [Google Scholar] [CrossRef]

- Kim, H.-G.; Kim, I.-H.; Jung, Y.-I.; Park, D.-J.; Park, J.-Y.; Koo, Y.-H. Adhesion Property and High-Temperature Oxidation Behavior of Cr-Coated Zircaloy-4 Cladding Tube Prepared by 3D Laser Coating. J. Nucl. Mater. 2015, 465, 531–539. [Google Scholar] [CrossRef]

- Kashkarov, E.; Afornu, B.; Sidelev, D.; Krinitcyn, M.; Gouws, V.; Lider, A. Recent advances in protective coatings for accident tolerant Zr-based fuel claddings. Coatings 2021, 11, 557. [Google Scholar] [CrossRef]

- Schuster, F.; Lomello, F.; Billard, A.; Velisa, G.; Monsifrot, E.; Bischoff, J.; Ambard, A.; Brachet, J.-C.; Lesaux, M.; Leflem, M.; et al. On-Going Studies at CEA on Chromium Coated Zirconium Based Nuclear Fuel Claddings for Enhanced Accident Tolerant LWRS Fuel. In Proceedings of the TopFuel 2015—Reactor Fuel Performance Meeting 2015, Zürich, Switzerland, 13–19 September 2015. [Google Scholar]

- Park, D.J.; Kim, H.G.; Jung, Y.I.; Park, J.H.; Yang, J.H.; Koo, Y.H. Behavior of an Improved Zr Fuel Cladding with Oxidation Resistant Coating under Loss-of-Coolant Accident Conditions. J. Nucl. Mater. 2016, 482, 75–82. [Google Scholar] [CrossRef]

- Brachet, J.-C.; Rouesne, E.; Ribis, J.; Guilbert, T.; Urvoy, S.; Nony, G.; Toffolon-Masclet, C.; Le Saux, M.; Chaabane, N.; Palancher, H.; et al. High Temperature Steam Oxidation of Chromium-Coated Zirconium-Based Alloys: Kinetics and Process. Corros. Sci. 2020, 167, 108537. [Google Scholar] [CrossRef]

- Umretiya, R.V.; Vargas, S.; Galeano, D.; Mohammadi, R.; Castano, C.E.; Rojas, J.V. Effect of Surface Characteristics and Environmental Aging on Wetting of Cr-Coated Zircaloy-4 Accident Tolerant Fuel Cladding Material. J. Nucl. Mater. 2020, 535, 152163. [Google Scholar] [CrossRef]

- Bischoff, J.; Vauglin, C.; Delafoy, C.; Barberis, P.; Perche, D.; Guerin, B.; Schuster, F.; Monsifrot, E.; Brachet, J.-C. Development of Cr-Coated Zirconium Alloy Cladding for Enhanced Accident Tolerance. In Proceedings of the TopFuel 2016—Reactor Fuel Performance Meeting 2016, Boise, ID, USA, 11–15 September 2016. [Google Scholar]

- Bischoff, J.; Delafoy, C.; Vauglin, C.; Barberis, P.; Roubeyrie, C.; Perche, D.; Duthoo, D.; Schuster, F.; Brachet, J.-C.; Schweitzer, E.W.; et al. AREVA NP’s Enhanced Accident-Tolerant Fuel Developments: Focus on Cr-Coated M5 Cladding. Nucl. Eng. Technol. 2018, 50, 223–228. [Google Scholar] [CrossRef]

- Bono, M.; Pham, T.-H.; Courcelle, A.; Mallet, C.; Pegaitaz, J.; Sibille, Y.; Bossu, D.; Wu, A.; Rouesne, E.; Brachet, J.-C.; et al. Mechanical Testing of Irradiated ATF Chromium-coated Zr-based Claddings. In Proceedings of the Nuclear Materials Conference 2020, Ghent, Belgium, 26–29 October 2020. [Google Scholar] [CrossRef]

- Guo, Z.; Dailey, R.; Zhou, Y.; Sun, Z.; Wang, J.; Corradini, M.L. Effect of ATF Cr-Coated-Zircaloy on BWR In-Vessel Accident Progression during a Station Blackout. Nucl. Eng. Des. 2021, 372, 110979. [Google Scholar] [CrossRef]

- Jiang, J.; Zhai, H.; Gong, P.; Zhang, W.; He, X.; Ma, X.; Wang, B. In-Situ Study on the Tensile Behavior of Cr-Coated Zircaloy for Accident Tolerant Fuel Claddings. Surf. Coat. Technol. 2020, 394, 125747. [Google Scholar] [CrossRef]

- Yeom, H.; Maier, B.; Mariani, R.; Bai, D.; Xu, P.; Sridharan, K.; Hwasung, Y. Development of Zirconium–Silicide Coatings for Accident Tolerant Zirconium-Alloy Fuel Cladding. In Proceedings of the ICAPP 2016—International Congress on Advances in Nuclear Power Plants 2016, San Francisco, CA, USA, 17–20 April 2016; p. 2126. [Google Scholar]

- Song, L.; Huang, B.; Li, J.; Ma, X.; Liu, M.; Jiang, J.; Hu, Y. Effects of Ion Irradiation on Cr, CrN, and TiAlCrN Coated Zircaloy-4 for Accident Tolerant Fuel Claddings. Ann. Nucl. Energy 2021, 156, 108206. [Google Scholar] [CrossRef]

- Yang, J.; Steinbrück, M.; Tang, C.; Große, M.; Liu, J.; Zhang, J.; Yun, D.; Wang, S. Review on Chromium Coated Zirconium Alloy Accident Tolerant Fuel Cladding. J. Alloys Compd. 2022, 895, 162450. [Google Scholar] [CrossRef]

- Rivai, A.K.; Aziz, F.; Panitra, M.; Insani, A. Neutronic Investigation of a Light Water Reactor with SiC Ceramic as Accident Tolerant Fuel Cladding (ATFC) Material. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2022; Volume 2663, p. 070004. [Google Scholar] [CrossRef]

- Kim, S.-K.; Bang, J.-G.; Kim, D.-H.; Lim, I.-S.; Yang, Y.-S.; Song, K.-W.; Kim, D.-S. Hoop Strength and Ductility Evaluation of Irradiated Fuel Cladding. Nucl. Eng. Des. 2009, 239, 254–260. [Google Scholar] [CrossRef]

- Dabney, T.; Johnson, G.; Yeom, H.; Maier, B.; Walters, J.; Sridharan, K. Experimental evaluation of cold spray FeCrAl alloys coated zirconium-alloy for potential accident tolerant fuel cladding. Nucl. Mater. Energy 2019, 21, 100715. [Google Scholar] [CrossRef]

- Feng, T.; Wang, J.; Zhou, Y.; Song, P.; Wang, M.; Dailey, R.; Tian, W.; Corradini, M.L. Quantification of the Effect of Cr-Coated-Zircaloy Cladding during a Short Term Station Black Out. Nucl. Eng. Des. 2020, 363, 110678. [Google Scholar] [CrossRef]

- Kashkarov, E.B.; Sidelev, D.V.; Pushilina, N.S.; Yang, J.; Tang, C.; Steinbrueck, M. Influence of Coating Parameters on Oxidation Behavior of Cr-Coated Zirconium Alloy for Accident Tolerant Fuel Claddings. Corros. Sci. 2022, 203, 110359. [Google Scholar] [CrossRef]

- Červenka, P.; Krejčí, J.; Cvrček, L.; Rozkošný, V.; Manoch, F.; Rada, D.; Kabátová, J. Experimental study of damaged Cr-coated fuel cladding in post-accident conditions. Acta Polytech. CTU Proc. 2020, 28, 1–7. [Google Scholar] [CrossRef]

- Yokosuka, M.; Mishima, Y.; Muto, H.; Others, A. Experimental study on mechanical strength of fuel cladding tube under the loss of coolant accident. Nippon. Genshiryoku Gakkai-Shi 1963, 5, 510–519. [Google Scholar] [CrossRef]

- Pint, B.A.; Terrani, K.A.; Brady, M.P.; Cheng, T.; Keiser, J.R. High Temperature Oxidation of Fuel Cladding Candidate Materials in Steam–Hydrogen Environments. J. Nucl. Mater. 2013, 440, 420–427. [Google Scholar] [CrossRef]

- Sawarn, T.K.; Shriwastaw, R.S.; Banerjee, S.; Samanta, A.; Kumar, S.; Sunil, S.; Shah, P.K.; Singh, R.N. Influence of Temperature and Hydrogen Content on the Transverse Mechanical Properties of Zircaloy-4 Fuel Cladding. Prog. Nucl. Energy 2022, 153, 104439. [Google Scholar] [CrossRef]

- Moreira, T.A.; Lee, D.; Anderson, M.H. Critical Heat Flux on Zircaloy and Accident Tolerant Fuel Cladding under Prototypical Conditions of Pressurized and Boiling Water Reactors. Appl. Therm. Eng. 2022, 213, 118740. [Google Scholar] [CrossRef]

- He, X.; Tian, Z.; Shi, B.; Xu, X.; Meng, C.; Dang, W.; Tan, J.; Ma, X. Effect of Gas Pressure and Bias Potential on Oxidation Resistance of Cr Coatings. Ann. Nucl. Energy 2019, 132, 243–248. [Google Scholar] [CrossRef]

- Ma, X.-F.; Wu, Y.-W.; Tan, J.; Meng, C.-Y.; Yang, L.; Dang, W.-A.; He, X.-J. Evaluation of Corrosion and Oxidation Behaviors of TiAlCrN Coatings for Nuclear Fuel Cladding. Surf. Coat. Technol. 2019, 358, 521–530. [Google Scholar] [CrossRef]

- Han, X.; Chen, C.; Tan, Y.; Feng, W.; Peng, S.; Zhang, H. A Systematic Study of the Oxidation Behavior of Cr Coatings on Zry4 Substrates in High Temperature Steam Environment. Corros. Sci. 2020, 174, 108826. [Google Scholar] [CrossRef]

- Gautier, C.; Machet, J. Effects of Deposition Parameters on the Texture of Chromium Films Deposited by Vacuum Arc Evaporation. Thin Solid Film. 1996, 289, 34–38. [Google Scholar] [CrossRef]

- Chen, Q.S.; Liu, C.H.; Zhang, R.Q.; Yang, H.Y.; Wei, T.G.; Wang, Y.; Li, Z.; He, L.X.; Wang, J.; Wang, L.; et al. Microstructure and High-Temperature Steam Oxidation Properties of Thick Cr Coatings Prepared by Magnetron Sputtering for Accident Tolerant Fuel Claddings: The Role of Bias in the Deposition Process. Corros. Sci. 2020, 165, 108378. [Google Scholar] [CrossRef]

- ASTM E2546-07; Standard Practice for Instrumented Indentation Testing. ASTM International: West Conshohocken, PA, USA, 2007.

- Ning, C.; Li, K.; Tang, G.; Xie, Y.; Shang, L.; Zhang, G.; Cai, Z. Fretting Wear Performance of CrN Coating after Laser Shock Peening. Chin. J. Mech. Eng. 2025, 38, 96. [Google Scholar] [CrossRef]

- Singh, S.K.; Chattopadhyaya, S.; Pramanik, A.; Kumar, S.; Basak, A.K.; Pandey, S.M.; Litak, G. Tribological Properties of Chromium Nitride on the Cylinder Liner under the Influence of High Temperature. Materials 2020, 13, 4497. [Google Scholar] [CrossRef]

- Jasempoor, F.; Elmkhah, H.; Imantalab, O.; Fattah-Alhosseini, A. Improving the Mechanical, Tribological, and Electrochemical Behavior of AISI 304 Stainless Steel by Applying CrN Single Layer and Cr/CrN Multilayer Coatings. Wear 2022, 504–505, 204425. [Google Scholar] [CrossRef]

- Stachowiak, G.; Batchelor, A.W. Engineering Tribology, 5th ed.; Butterworth-Heinemann: Oxford, UK, 2025; ISBN 9780323858291. [Google Scholar]

- Bhushan, B.; Ko, P.L. Introduction to Tribology. Appl. Mech. Rev. 2003, 56, B6–B7. [Google Scholar] [CrossRef]

- Taylor, C.M.; Childs, P.R.N.; Berthier, Y.; Flamand, L.; Dalmaz, G.; Dowson, D.; Georges, J.M. (Eds.) The Third Body Concept: Interpretation of Tribological Phenomena; Elsevier: Amsterdam, The Netherlands, 1996; Volume 31. [Google Scholar]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Analysis of Surface Texture of Plateau-Honed Cylinder Liner—A Review. Precis. Eng. 2021, 72, 807–822. [Google Scholar] [CrossRef]

- Martinez, E.; Romero, J.; Lousa, A.; Esteve, J. Wear Behavior of Nanometric CrN/Cr Multilayers. Surf. Coat. Technol. 2003, 163–164, 571–577. [Google Scholar] [CrossRef]

- Lackner, J.M.; Waldhauser, W.; Major, L.; Kot, M. Tribology and Micromechanics of Chromium Nitride-Based Multilayer Coatings on Soft and Hard Substrates. Coatings 2014, 4, 121–138. [Google Scholar] [CrossRef]

- Polcar, T.; Martinez, R.; Vítů, T.; Kopecký, L.; Rodriguez, R.; Cavaleiro, A. High Temperature Tribology of CrN and Multilayered Cr/CrN Coatings. Surf. Coat. Technol. 2009, 203, 3254–3259. [Google Scholar] [CrossRef]

- Lu, B.; Ma, F.; Ma, D. Microstructure and Mechanical Properties of Thick Cr/CrN Multilayer Coatings by Multi-Arc Ion Plating. Rare Metal Mater. Eng. 2022, 51, 1558–1564. [Google Scholar]

- Kot, M.; Rakowski, W.A.; Major, R.; Morgiel, J. Effect of Bilayer Period on Properties of Cr/CrN Multilayer Coatings Produced by Laser Ablation. Surf. Coat. Technol. 2008, 202, 3501–3506. [Google Scholar] [CrossRef]

| Zr | Be | Nb | Hf | Ni | Cr | Ti | Al | O | Pb |

|---|---|---|---|---|---|---|---|---|---|

| 99.5 | 0.003 | 0.9–1.1 | 0.01 | 0.02 | 0.02 | 0.007 | 0.008 | 0.1 | 0.005 |

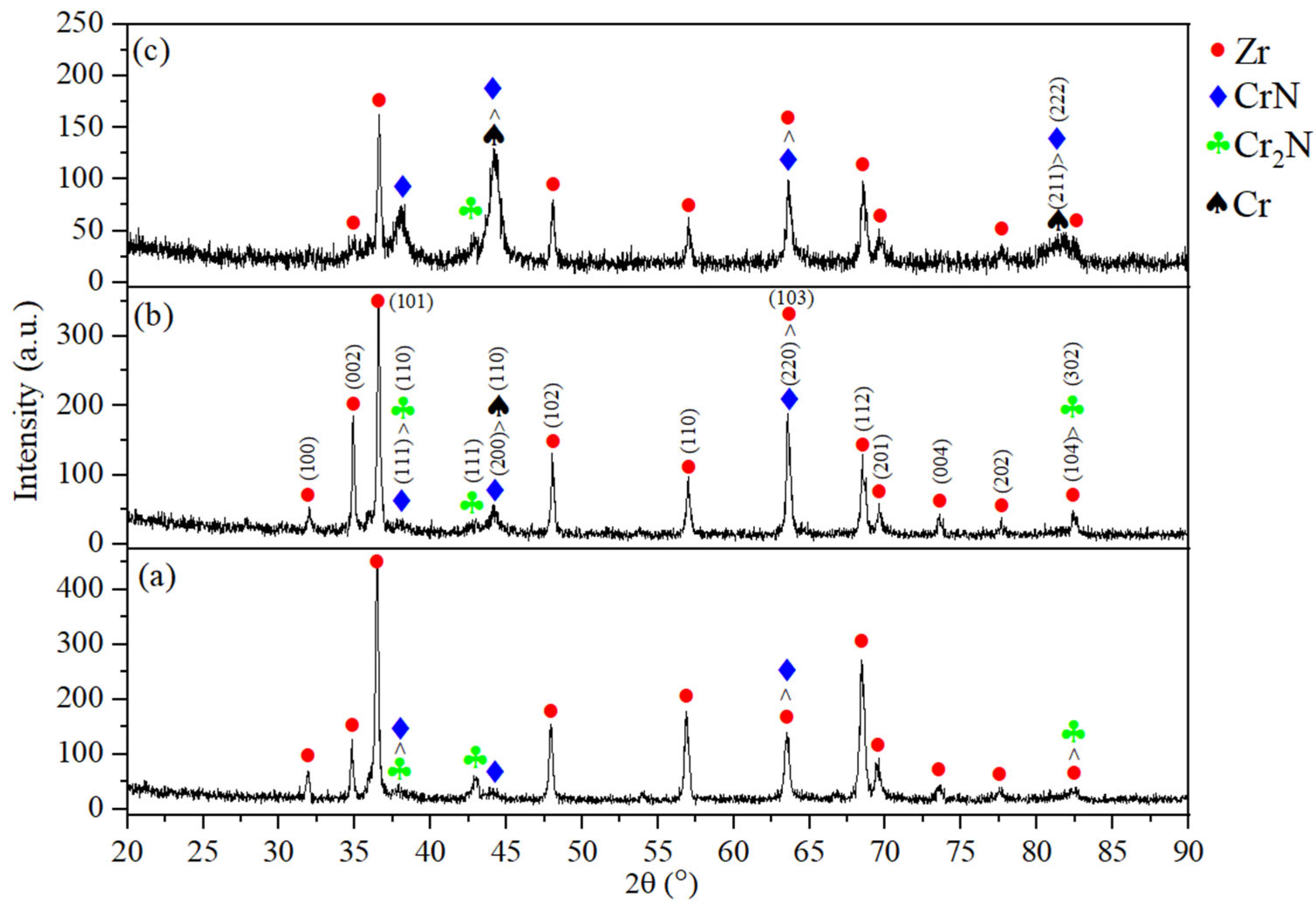

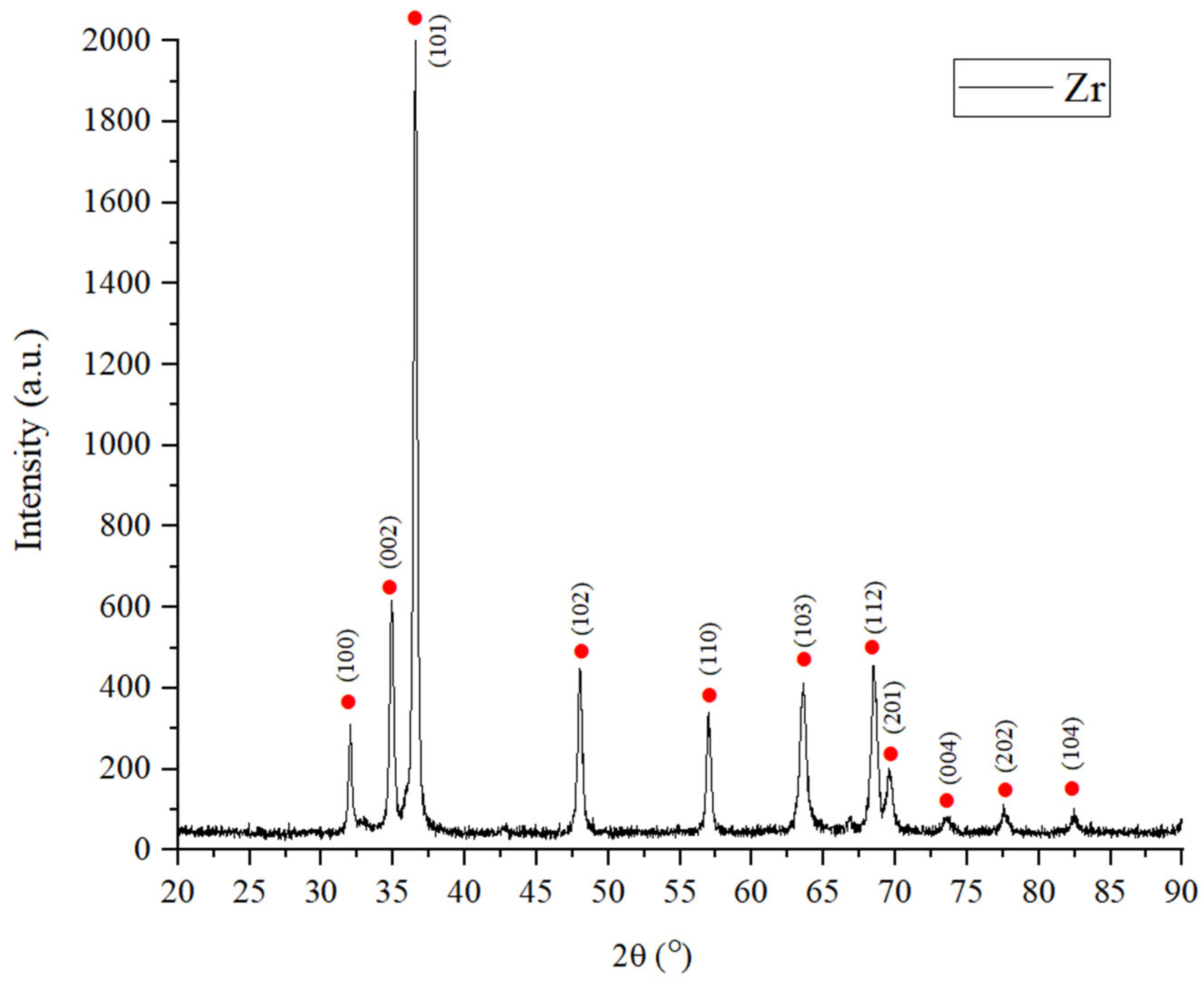

| Number of Layers | Detected Phases | Lattice Parameters, Å | Coherent Scattering Region (CSR) Size, nm | Microstrain Value, Δd/d × 10−3 |

|---|---|---|---|---|

| 2 layers | Zr | a = 3.2328 c = 5.1484 | 39.14 | 0.570 |

| CrN | a = 4.1448 | 18.22 | 1.313 | |

| Cr2N | a = 4.7474 c = 4.4353 | 14.73 | 0.287 | |

| Cr | a = 2,8840 | 11.38 | 6.152 | |

| 4 layers | Zr | a = 3.2309 c = 5.1496 | 35.45 | 1.160 |

| CrN | a = 4.1348 | 17.51 | 2.176 | |

| Cr2N | a = 4.7531 c = 4.4724 | 16.10 | 2.304 | |

| Cr | a = 2.8872 | 18.03 | 1.444 | |

| 6 layers | Zr | a = 3.2382 c = 5.1616 | 23.61 | 1.595 |

| CrN | a = 4.1310 | 13.83 | 1.034 | |

| Cr2N | a = 4.7396 c = 4.5180 | 23.83 | 1.900 | |

| Cr | a = 2.8959 | 19.10 | 0.570 |

| Phase | Crystal Lattice | File | Space Group |

|---|---|---|---|

| Zr | Hexagonal | 00-005-0665 | P63/mmc |

| CrN | Cubic | 00-011-0065 | Fm3m |

| Cr2N | Hexagonal | 01-079-2159 | P-31m |

| Cr | Cubic | 01-085-1336 | Im-3m |

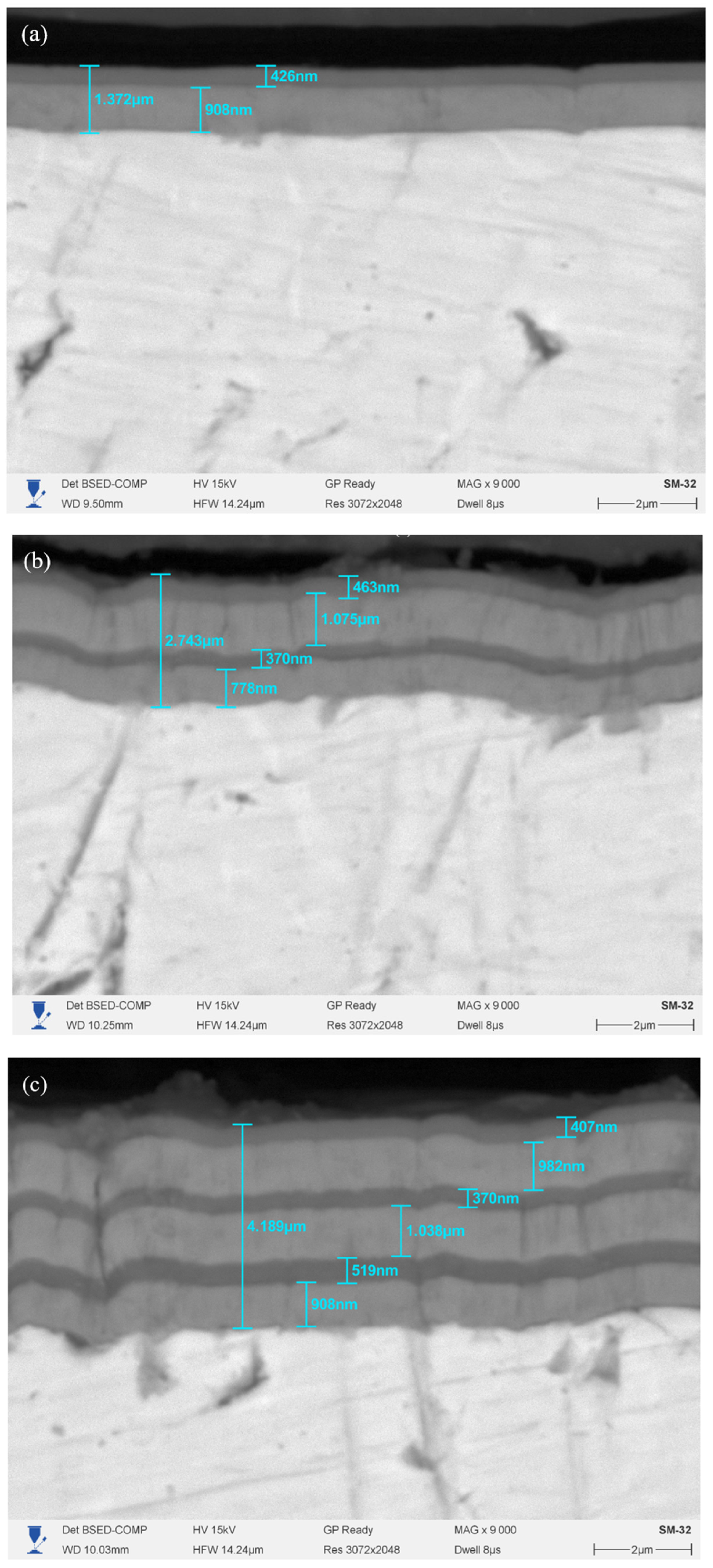

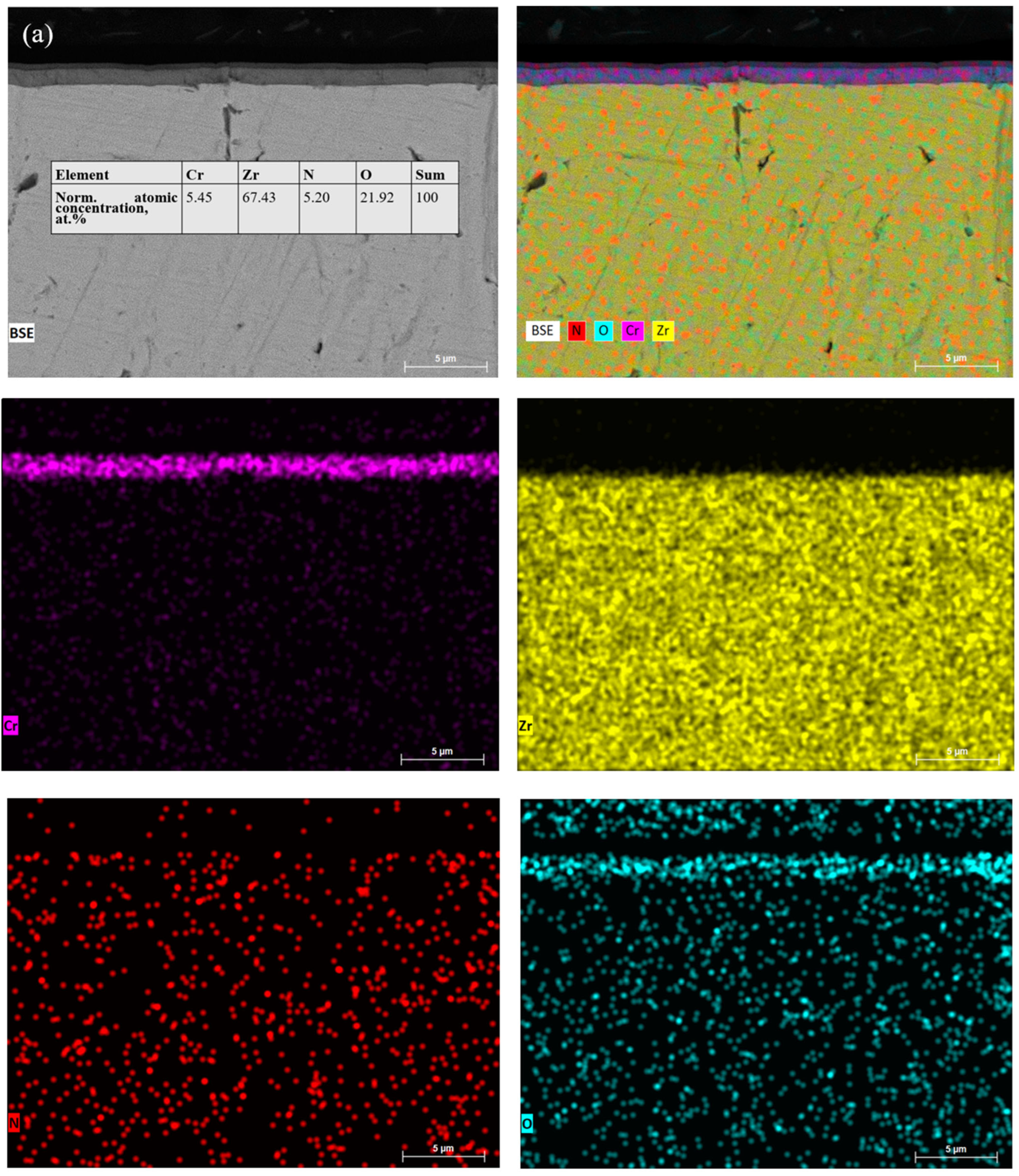

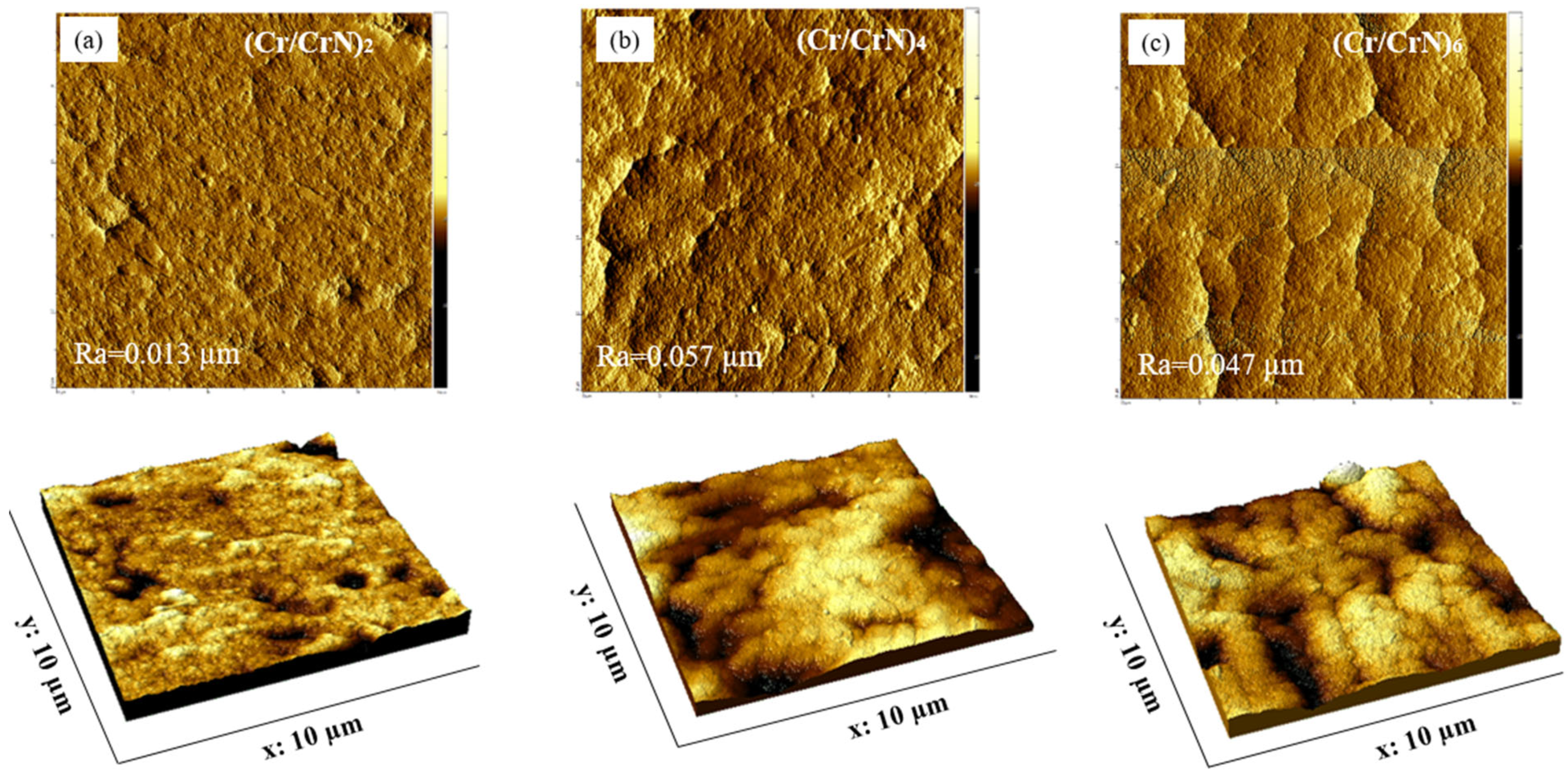

| Number of Layers | Ra, nm (µm) | Rq, nm | Max, nm | Skew | Kurtosis | Surface Slope Angle, φ, ° |

|---|---|---|---|---|---|---|

| 2 layers | 12.7 (0.013) | 18.7 | 54.4 | −2.01 | 9.24 | 26.93 |

| 4 layers | 57.4 (0.057) | 70.9 | 190.9 | −0.41 | −0.14 | 26.73 |

| 6 layers | 47.8 (0.047) | 62.4 | 316.6 | −0.39 | 1.66 | 12.33 |

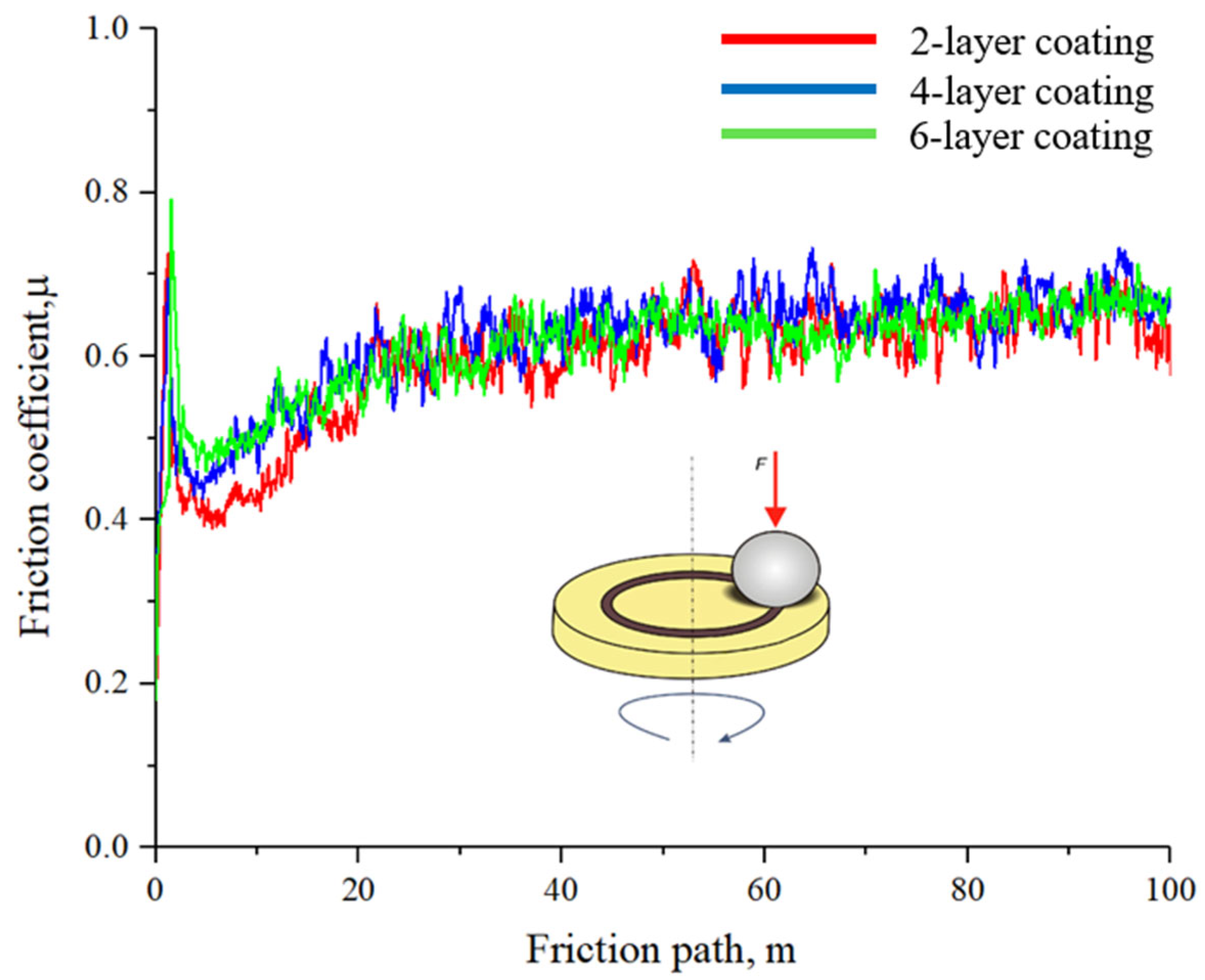

| № | Number of Layers | µ (Average) | Wear Rate, mm3·N−1·m−1 | Wear Volume, mm3 |

|---|---|---|---|---|

| 1 | 2 layers | 0.595 | 6.20 × 10−4 | 0.186 |

| 2 | 4 layers | 0.620 | 8.64 × 10−4 | 0.259 |

| 3 | 6 layers | 0.610 | 2.26 × 10−4 | 0.068 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muktanova, N.; Rakhadilov, B.; Naimankumaruly, E.; Kalitova, A. Structural and Phase Characteristics and Properties of Multilayer Cr/CrN Coatings Obtained by Magnetron Sputtering. Coatings 2025, 15, 1375. https://doi.org/10.3390/coatings15121375

Muktanova N, Rakhadilov B, Naimankumaruly E, Kalitova A. Structural and Phase Characteristics and Properties of Multilayer Cr/CrN Coatings Obtained by Magnetron Sputtering. Coatings. 2025; 15(12):1375. https://doi.org/10.3390/coatings15121375

Chicago/Turabian StyleMuktanova, Nazerke, Bauyrzhan Rakhadilov, Erasyl Naimankumaruly, and Aisulu Kalitova. 2025. "Structural and Phase Characteristics and Properties of Multilayer Cr/CrN Coatings Obtained by Magnetron Sputtering" Coatings 15, no. 12: 1375. https://doi.org/10.3390/coatings15121375

APA StyleMuktanova, N., Rakhadilov, B., Naimankumaruly, E., & Kalitova, A. (2025). Structural and Phase Characteristics and Properties of Multilayer Cr/CrN Coatings Obtained by Magnetron Sputtering. Coatings, 15(12), 1375. https://doi.org/10.3390/coatings15121375