The Amorphous Carbon Layers Deposited by Various Magnetron Sputtering Techniques

Abstract

1. Introduction

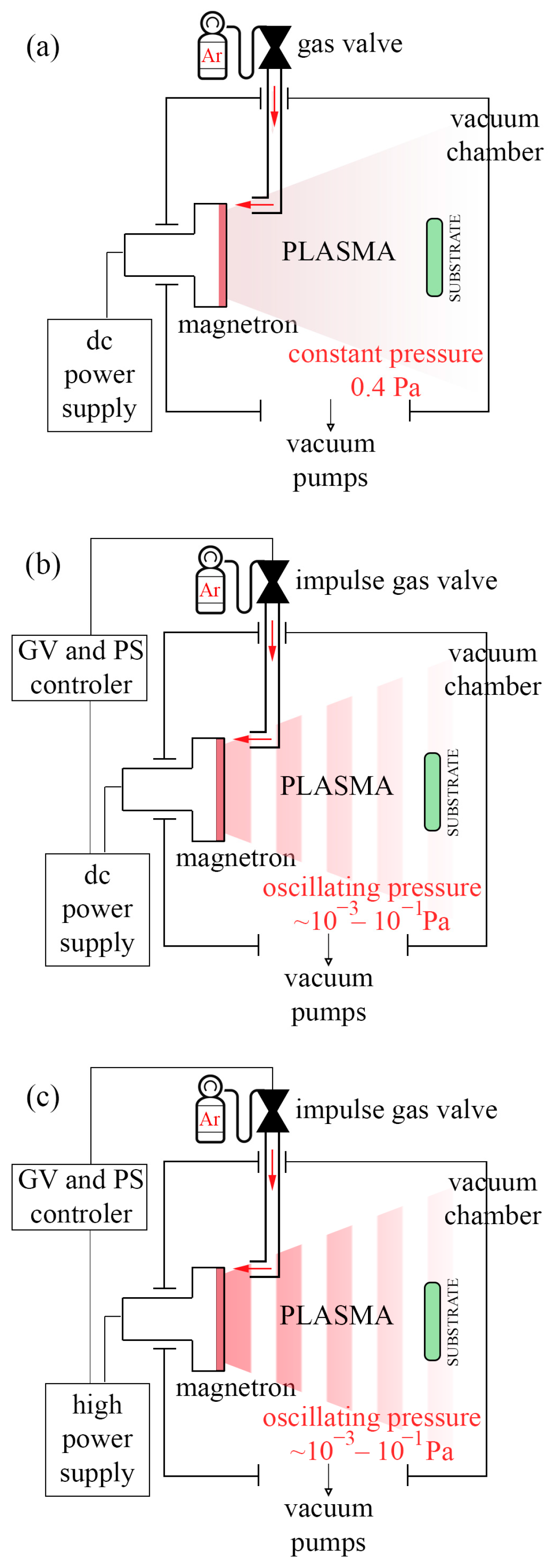

- Gas Injection Magnetron Sputtering (GIMS)—a technique that uses power pulses with a density characteristic of the PMS technique but coupled with the operation of pulsed valves supplying working gas [44,45]. Thanks to this, the generated plasma pulses have a chance to propagate in an environment with a lower concentration of gas molecules, which leads to limiting the dissipation of plasma particle energy [46,47];

2. Materials and Methods

2.1. Sputtering the Graphite Targets

2.2. Examination Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rajak, D.K.; Kumar, A.; Behera, A.; Menezes, P.L. Diamond-Like Carbon (DLC) Coatings: Classification, Properties, and Applications. Appl. Sci. 2021, 11, 4445. [Google Scholar] [CrossRef]

- Kulkarni, A.V.; Bhushan, B. Nanoindentation measurements of amorphous carbon coatings. J. Mater. Res. 1997, 12, 2707–2714. [Google Scholar] [CrossRef]

- Li, L.; Song, W.; Ovcharenko, A.; Xu, M.; Zhang, G. Effects of atomic structure on the frictional properties of amorphous carbon coatings. Surf. Coat. Technol. 2015, 263, 8–14. [Google Scholar] [CrossRef]

- Bhushan, B. Chemical, mechanical and tribological characterization of ultra-thin and hard amorphous carbon coatings as thin as 3.5 nm: Recent developments. Diam. Relat. Mater. 1999, 8, 1985–2015. [Google Scholar] [CrossRef]

- Grill, A. Diamond-like carbon coatings as biocompatible materials—An overview. Diam. Relat. Mater. 2003, 12, 166–170. [Google Scholar] [CrossRef]

- Kim, I.-S.; Shim, C.-E.; Kim, S.W.; Lee, C.-S.; Kwon, J.; Byun, K.-E.; Jeong, U. Amorphous Carbon Films for Electronic Applications. Adv. Mater. 2023, 35, 2204912. [Google Scholar] [CrossRef]

- Robertson, J. Structure and Electronic Properties of Diamond-Like Carbon. In Diamond and Diamond-like Films and Coatings; Clausing, R.E., Horton, L.L., Angus, J.C., Koidl, P., Eds.; Springer: New York, NY, USA, 1991; pp. 331–356. [Google Scholar] [CrossRef]

- Saparina, S.V.; Kharintsev, S.S. Amorphous Carbon Thin Films for Optical Sensing of Humidity. Bull. Russ. Acad. Sci. Phys. 2022, 86, S187–S190. [Google Scholar] [CrossRef]

- Zhou, J.; Guo, P.; Cui, L.; Yan, C.; Xu, D.; Li, F.; Zhang, C.; Wang, A. Wrinkled and cracked amorphous carbon film for high-performance flexible strain sensors. Diam. Relat. Mater. 2023, 132, 109619. [Google Scholar] [CrossRef]

- Silva, S.R.P.; Carey, J.D. Enhancing the electrical conduction in amorphous carbon and prospects for device applications. Diam. Relat. Mater. 2003, 12, 151–158. [Google Scholar] [CrossRef]

- Yaroslavtsev, A.B.; Stenina, I.A. Carbon coating of electrode materials for lithium-ion batteries. Surf. Innov. 2020, 9, 92–110. [Google Scholar] [CrossRef]

- Guo, T.; Hu, P.; Li, L.; Wang, Z.; Guo, L. Amorphous materials emerging as prospective electrodes for electrochemical energy storage and conversion. Chem 2023, 9, 1080–1093. [Google Scholar] [CrossRef]

- Yin, P.; Liu, Z.; Cao, X.; Lu, Z.; Zhang, G. Evaluation of the corrosion protection effect of amorphous carbon coating through the corrosion behaviors on different substrates. Diam. Relat. Mater. 2024, 142, 110771. [Google Scholar] [CrossRef]

- Li, S.; Li, H.; Guo, P.; Li, X.; Yang, W.; Ma, G.; Nishimura, K.; Ke, P.; Wang, A. Enhanced Long-Term Corrosion Resistance of 316L Stainless Steel by Multilayer Amorphous Carbon Coatings. Materials 2024, 17, 2129. [Google Scholar] [CrossRef]

- Roy, R.K.; Lee, K.-R. Biomedical applications of diamond-like carbon coatings: A review. J. Biomed. Mater. Res. Part B Appl. Biomater. 2007, 83B, 72–84. [Google Scholar] [CrossRef] [PubMed]

- Tiainen, V.-M. Amorphous carbon as a bio-mechanical coating—Mechanical properties and biological applications. Diam. Relat. Mater. 2001, 10, 153–160. [Google Scholar] [CrossRef]

- Robertson, J. Preparation and properties of amorphous carbon. J. Non-Cryst. Solids 1991, 137–138, 825–830. [Google Scholar] [CrossRef]

- Savvides, N.; Window, B. Diamond-like amorphous carbon films prepared by magnetron sputtering of graphite. J. Vac. Sci. Technol. A 1985, 3, 2386–2390. [Google Scholar] [CrossRef]

- Vetter, J.; Stüber, M.; Ulrich, S. Growth effects in carbon coatings deposited by magnetron sputtering. Surf. Coat. Technol. 2003, 168, 169–178. [Google Scholar] [CrossRef]

- Yáñez-Hernández, L.A.; Bonilla-Gameros, L.; Chevallier, P.; Sarkissian, A.; Mantovani, D. Plasma-Based Amorphous Carbon Coatings on Polymeric Substrates for Biomedical Applications: A Critical Review Focused on Adhesion. Appl. Sci. 2025, 15, 9968. [Google Scholar] [CrossRef]

- Che, J.; Yi, P.; Peng, L.; Lai, X. Impact of pressure on carbon films by PECVD toward high deposition rates and high stability as metallic bipolar plate for PEMFCs. Int. J. Hydrog. Energy 2020, 45, 16277–16286. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Donley, M.S. Preparation of amorphous diamond-like carbon by pulsed laser deposition: A critical review. Surf. Coat. Technol. 1996, 82, 199–213. [Google Scholar] [CrossRef]

- Gaudiuso, R. Pulsed Laser Deposition of Carbon-Based Materials: A Focused Review of Methods and Results. Processes 2023, 11, 2373. [Google Scholar] [CrossRef]

- Hakovirta, M.; Tiainen, V.-M.; Pekko, P. Techniques for filtering graphite macroparticles in the cathodic vacuum arc deposition of tetrahedral amorphous carbon films. Diam. Relat. Mater. 1999, 8, 1183–1192. [Google Scholar] [CrossRef]

- Polo, M.C.; Andújar, J.L.; Hart, A.; Robertson, J.; Milne, W.I. Preparation of tetrahedral amorphous carbon films by filtered cathodic vacuum arc deposition. Diam. Relat. Mater. 2000, 9, 663–667. [Google Scholar] [CrossRef]

- Schultrich, B. Structure and Characterization of Vacuum Arc Deposited Carbon Films—A Critical Overview. Coatings 2022, 12, 109. [Google Scholar] [CrossRef]

- Schultrich, B.; Scheibe, H.-J.; Drescher, D.; Ziegele, H. Deposition of superhard amorphous carbon films by pulsed vacuum arc deposition. Surf. Coat. Technol. 1998, 98, 1097–1101. [Google Scholar] [CrossRef]

- Liu, J.Q.; Li, L.J.; Wei, B.; Wen, F.; Cao, H.T.; Pei, Y.T. Effect of sputtering pressure on the surface topography, structure, wettability and tribological performance of DLC films coated on rubber by magnetron sputtering. Surf. Coat. Technol. 2019, 365, 33–40. [Google Scholar] [CrossRef]

- Nguyen, T.; Ulrich, S.; Bsul, J.; Beauvais, S.; Burger, W.; Albers, A.; Stüber, M.; Ye, J. Influence of argon gas pressure and target power on magnetron plasma parameters. Diam. Relat. Mater. 2009, 18, 995–998. [Google Scholar] [CrossRef]

- Chowdhury, S.; Laugier, M.T.; Rahman, I.Z. Characterization of DLC coatings deposited by rf magnetron sputtering. J. Mater. Process. Technol. 2004, 153–154, 804–810. [Google Scholar] [CrossRef]

- Chowdhury, S.; Laugier, M.T.; Rahman, I.Z. Effects of substrate temperature on bonding structure and mechanical properties of amorphous carbon films. Thin Solid Film. 2004, 447–448, 174–180. [Google Scholar] [CrossRef]

- Ahmad, I.; Roy, S.S.; Maguire, P.D.; Papakonstantinou, P.; McLaughlin, J.A. Effect of substrate bias voltage and substrate on the structural properties of amorphous carbon films deposited by unbalanced magnetron sputtering. Thin Solid Film. 2005, 482, 45–49. [Google Scholar] [CrossRef]

- Nakamura, M.; Takagawa, Y.; Miura, K.; Kobata, J.; Zhu, W.; Nishiike, N.; Arao, K.; Marin, E.; Pezzotti, G. Structural alteration induced by substrate bias voltage variation in diamond-like carbon films fabricated by unbalanced magnetron sputtering. Diam. Relat. Mater. 2018, 90, 214–220. [Google Scholar] [CrossRef]

- Dai, W.; Gao, X.; Wang, Q.; Xu, A. Influence of Ne sputtering gas on structure and properties of diamond-like carbon films deposited by pulsed-magnetron sputtering. Thin Solid Film. 2017, 625, 163–167. [Google Scholar] [CrossRef]

- Sahu, B.B.; Kim, S.I.; Lee, M.W.; Han, J.G. Effect of helium incorporation on plasma parameters and characteristic properties of hydrogen free carbon films deposited using DC magnetron sputtering. J. Appl. Phys. 2020, 127, 14901. [Google Scholar] [CrossRef]

- Dai, W.; Li, X.; Wu, L.; Wang, Q. Influences of target power and pulse width on the growth of diamond-like/graphite-like carbon coatings deposited by high power impulse magnetron sputtering. Diam. Relat. Mater. 2021, 111, 108232. [Google Scholar] [CrossRef]

- Skowronski, L.; Chodun, R.; Trzcinski, M.; Zdunek, K. Optical Properties of Amorphous Carbon Thin Films Fabricated Using a High-Energy-Impulse Magnetron-Sputtering Technique. Materials 2023, 16, 7049. [Google Scholar] [CrossRef] [PubMed]

- Lifshitz, Y.; Kasi, S.R.; Rabalais, J.W.; Eckstein, W. Subplantation model for film growth from hyperthermal species. Phys. Rev. B 1990, 41, 10468–10480. [Google Scholar] [CrossRef] [PubMed]

- Lifshitz, Y.; Lempert, G.D.; Grossman, E.; Avigal, I.; Uzan-Saguy, C.; Kalish, R.; Kulik, J.; Marton, D.; Rabalais, J.W. Growth mechanisms of DLC films from C+ ions: Experimental studies. Diam. Relat. Mater. 1995, 4, 318–323. [Google Scholar] [CrossRef]

- Sokołowska, A.; Zdunek, K.; Grigoriew, H.; Romanowski, Z. The structure and mechanical properties of carbon layers formed by crystallization from pulse plasma. J. Mater. Sci. 1986, 21, 763–767. [Google Scholar] [CrossRef]

- Sokołowski, M. Influence of the pulse plasma chemical content on the crystallization of diamond under conditions of its thermodynamic instability. J. Cryst. Growth 1981, 54, 519–522. [Google Scholar] [CrossRef]

- Belkind, A.; Freilich, A.; Lopez, J.; Zhao, Z.; Zhu, W.; Becker, K. Characterization of pulsed dc magnetron sputtering plasmas. New J. Phys. 2005, 7, 90. [Google Scholar] [CrossRef]

- Vlček, J.; Pajdarová, A.D.; Musil, J. Pulsed dc Magnetron Discharges and their Utilization in Plasma Surface Engineering. Contrib. Plasma Phys. 2004, 44, 426–436. [Google Scholar] [CrossRef]

- Zdunek, K.; Nowakowska-Langier, K.; Chodun, R.; Dora, J.; Okrasa, S.; Talik, E. Optimization of gas injection conditions during deposition of AlN layers by novel reactive GIMS method. Mater. Sci.-Pol. 2014, 32, 171–175. [Google Scholar] [CrossRef]

- Skowronski, L.; Zdunek, K.; Nowakowska-Langier, K.; Chodun, R.; Trzcinski, M.; Kobierski, M.; Kustra, M.K.; Wachowiak, A.A.; Wachowiak, W.; Hiller, T.; et al. Characterization of microstructural, mechanical and optical properties of TiO2 layers deposited by GIMS and PMS methods. Surf. Coat. Technol. 2015, 282, 16–23. [Google Scholar] [CrossRef]

- Chodun, R.; Nowakowska-Langier, K.; Wicher, B.; Okrasa, S.; Minikayev, R.; Dypa, M.; Zdunek, K. TiO2 coating fabrication using gas injection magnetron sputtering technique by independently controlling the gas and power pulses. Thin Solid Films 2021, 728, 138695. [Google Scholar] [CrossRef]

- Chodun, R.; Nowakowska-Langier, K.; Wicher, B.; Okrasa, S.; Kwiatkowski, R.; Zaloga, D.; Dypa, M.; Zdunek, K. The state of coating–substrate interfacial region formed during TiO2 coating deposition by Gas Injection Magnetron Sputtering technique. Surf. Coat. Technol. 2020, 398, 126092. [Google Scholar] [CrossRef]

- Alami, J.; Bolz, S.; Sarakinos, K. High power pulsed magnetron sputtering: Fundamentals and applications. J. Alloys Compd. 2009, 483, 530–534. [Google Scholar] [CrossRef]

- Ehiasarian, A.P.; New, R.; Münz, W.-D.; Hultman, L.; Helmersson, U.; Kouznetsov, V. Influence of high power densities on the composition of pulsed magnetron plasmas. Vacuum 2002, 65, 147–154. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Posadowski, W.M.; Wiatrowski, A.; Dora, J.; Radzimski, Z.J. Magnetron sputtering process control by medium-frequency power supply parameter. Thin Solid Film. 2008, 516, 4478–4482. [Google Scholar] [CrossRef]

- Cui, W.G.; Lai, Q.B.; Zhang, L.; Wang, F.M. Quantitative measurements of sp3 content in DLC films with Raman spectroscopy. Surf. Coat. Technol. 2010, 205, 1995–1999. [Google Scholar] [CrossRef]

- Woollam, J.A. Guide to Using WVASE32®; Wextech Systems Inc.: Mendota Heights, MN, USA, 2010. [Google Scholar]

- Fujivara, H. Spectroscopic Ellipsometry. In Principles and Applications; John Wiley and Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Tauc, J. Optical properties and electronic structure of amorphous Ge and Si. Mater. Res. Bull. 1968, 3, 37–46. [Google Scholar] [CrossRef]

- Tauc, J.; Grigorovici, R.; Vancu, A. Optical Properties and Electronic Structure of Amorphous Germanium. Phys. Status Solidi (B) 1966, 15, 627–637. [Google Scholar] [CrossRef]

- Ganesan, R.; Murdoch, B.J.; Treverrow, B.; Ross, A.E.; Falconer, I.S.; Kondyurin, A.; McCulloch, D.G.; Partridge, J.G.; McKenzie, D.R.; Bilek, M.M.M. The role of pulse length in target poisoning during reactive HiPIMS: Application to amorphous HfO2. Plasma Sources Sci. Technol. 2015, 24, 35015. [Google Scholar] [CrossRef]

- Kadlec, S.; Čapek, J. Return of target material ions leads to a reduced hysteresis in reactive high power impulse magnetron sputtering: Model. J. Appl. Phys. 2017, 121, 171910. [Google Scholar] [CrossRef]

- Brenning, N.; Huo, C.; Lundin, D.; Raadu, M.A.; Vitelaru, C.; Stancu, G.D.; Minea, T.; Helmersson, U. Understanding deposition rate loss in high power impulse magnetron sputtering: I. Ionization-driven electric fields. Plasma Sources Sci. Technol. 2012, 21, 25005. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Libassi, A.; Tanner, B.K.; Stolojan, V.; Yuan, J.; Brown, L.M.; Rodil, S.E.; Kleinsorge, B.; Robertson, J. Density, sp3 fraction, and cross-sectional structure of amorphous carbon films determined by x-ray reflectivity and electron energy-loss spectroscopy. Phys. Rev. B 2000, 62, 11089–11103. [Google Scholar] [CrossRef]

- Tuinstra, F.; Koenig, J.L. Raman Spectrum of Graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Raman spectroscopy of amorphous, nanostructured, diamond–like carbon, and nanodiamond. Philos. Trans. R. Soc. A 2004, 362, 2477–2512. [Google Scholar] [CrossRef]

- Zdunek, K.; Chodun, R.; Wicher, B.; Nowakowska-Langier, K.; Okrasa, S. Characterization of sp3 bond content of carbon films deposited by high power gas injection magnetron sputtering method by UV and VIS Raman spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2018, 194, 136–140. [Google Scholar] [CrossRef] [PubMed]

- Wiatrowski, A.; Kijaszek, W.; Posadowski, W.M.; Oleszkiewicz, W.; Jadczak, J.; Kunicki, P. Deposition of diamond-like carbon thin films by the high power impulse magnetron sputtering method. Diam. Relat. Mater. 2017, 72, 71–76. [Google Scholar] [CrossRef]

- Eliasson, H.; Rudolph, M.; Brenning, N.; Hajihoseini, H.; Zanáška, M.; Adriaans, M.J.; Raadu, M.A.; Minea, T.M.; Gudmundsson, J.T.; Lundin, D. Modeling of high power impulse magnetron sputtering discharges with graphite target. Plasma Sources Sci. Technol. 2021, 30, 115017. [Google Scholar] [CrossRef]

- Streletskiy, O.A.; Zavidovskiy, I.A.; Balabanyan, V.Y.; Tsiskarashvili, A.V. Antibacterial properties of modified a-C and ta-C coatings: The effects of the sp2/sp3 ratio, oxidation, nitridation, and silver incorporation. Appl. Phys. A 2022, 128, 929. [Google Scholar] [CrossRef]

- Kovtun, A.; Jones, D.; Dell’Elce, S.; Treossi, E.; Liscio, A.; Palermo, V. Accurate chemical analysis of oxygenated graphene-based materials using X-ray photoelectron spectroscopy. Carbon 2019, 143, 268–275. [Google Scholar] [CrossRef]

- Rabchinskii, M.K.; Dideikin, A.T.; Kirilenko, D.A.; Baidakova, M.V.; Shnitov, V.V.; Roth, F.; Konyakhin, S.V.; Besedina, N.A.; Pavlov, S.I.; Kuricyn, R.A.; et al. Facile reduction of graphene oxide suspensions and films using glass wafers. Sci. Rep. 2018, 8, 14154. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Fang, D. A review on C1s XPS-spectra for some kinds of carbon materials. Fuller. Nanotub. Carbon Nanostructures 2020, 28, 1048–1058. [Google Scholar] [CrossRef]

- Prenzel, M.; de los Arcos, T.; Kortmann, A.; Winter, J.; von Keudell, A. Embedded argon as a tool for sampling local structure in thin plasma deposited aluminum oxide films. J. Appl. Phys. 2012, 112, 103306. [Google Scholar] [CrossRef]

- Tiron, V.; Bulai, G.; Costin, C.; Velicu, I.-L.; Dincă, P.; Iancu, D.; Burducea, I. Growth and characterization of W thin films with controlled Ne and Ar contents deposited by bipolar HiPIMS. Nucl. Mater. Energy 2021, 29, 101091. [Google Scholar] [CrossRef]

- Akhavan, B.; Ganesan, R.; Matthews, D.T.A.; McKenzie, D.R.; Bilek, M.M.M. Noble gas control of diamond-like content and compressive stress in carbon films by arc-mixed mode high power impulse magnetron sputtering. Surf. Coat. Technol. 2021, 427, 127785. [Google Scholar] [CrossRef]

- Zheng, G.; Xiang, Y.; Xu, L.; Luo, H.; Wang, B.; Liu, Y.; Han, X.; Zhao, W.; Chen, S.; Chen, H.; et al. Controlling Surface Oxides in Si/C Nanocomposite Anodes for High-Performance Li-Ion Batteries. Adv. Energy Mater. 2018, 8, 1801718. [Google Scholar] [CrossRef]

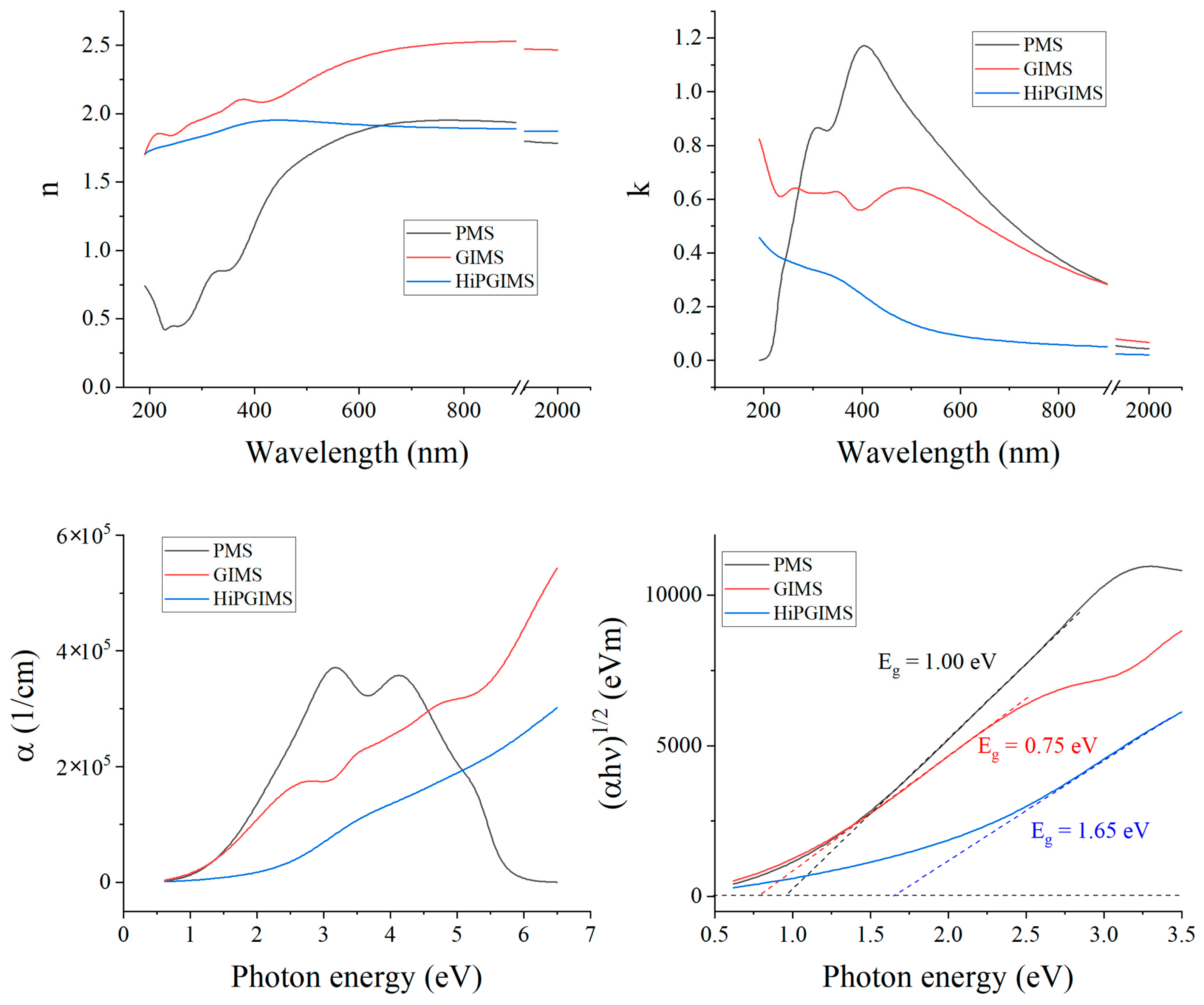

- Liu, L.; Lu, F.; Tian, J.; Xia, S.; Diao, Y. Electronic and optical properties of amorphous carbon with different sp3/sp2 hybridization ratio. Appl. Phys. A 2019, 125, 366. [Google Scholar] [CrossRef]

- Kassavetis, S.; Patsalas, P.; Logothetidis, S.; Robertson, J.; Kennou, S. Dispersion relations and optical properties of amorphous carbons. Diam. Relat. Mater. 2007, 16, 1813–1822. [Google Scholar] [CrossRef]

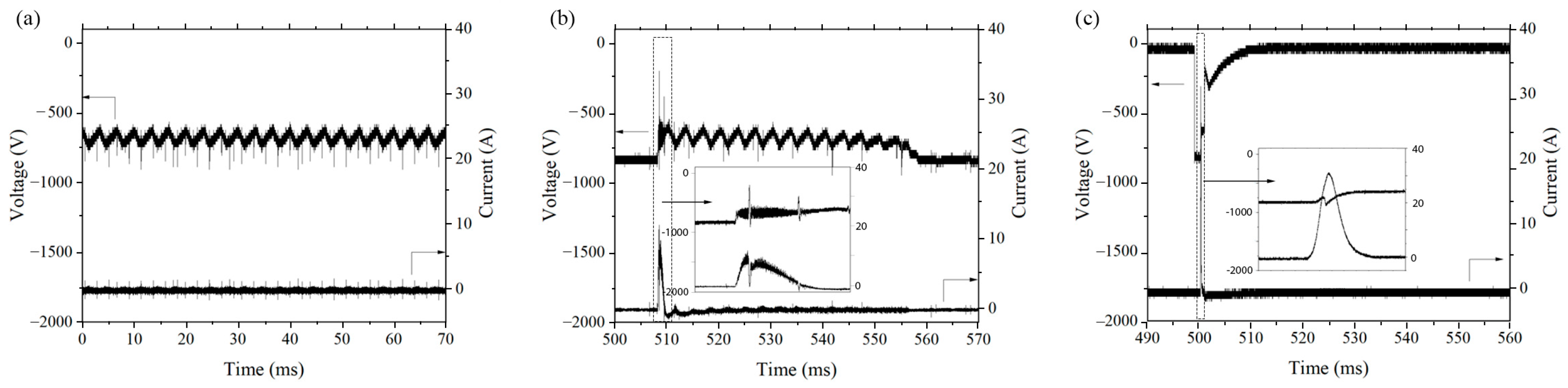

| PMS | GIMS | HiPGIMS | |

|---|---|---|---|

| tAr (ms) | - | 4 | 4 |

| T (Hz) | - | 2 | 2 |

| D (%) | 100 | 10 | 0.2 |

| Jdmean (mA/cm2) | 14 | 23 | 74 |

| Pdmean (W/cm2) | 10 | 18 | 6 |

| pAr (Pa) | 0.4 (steady) | 10−3–10−1 (oscillating) | 10−3–10−1 (oscillating) |

| tpulse (ms) | - | 50 | 1 |

| tproc (min) | 10 | 120 | 120 |

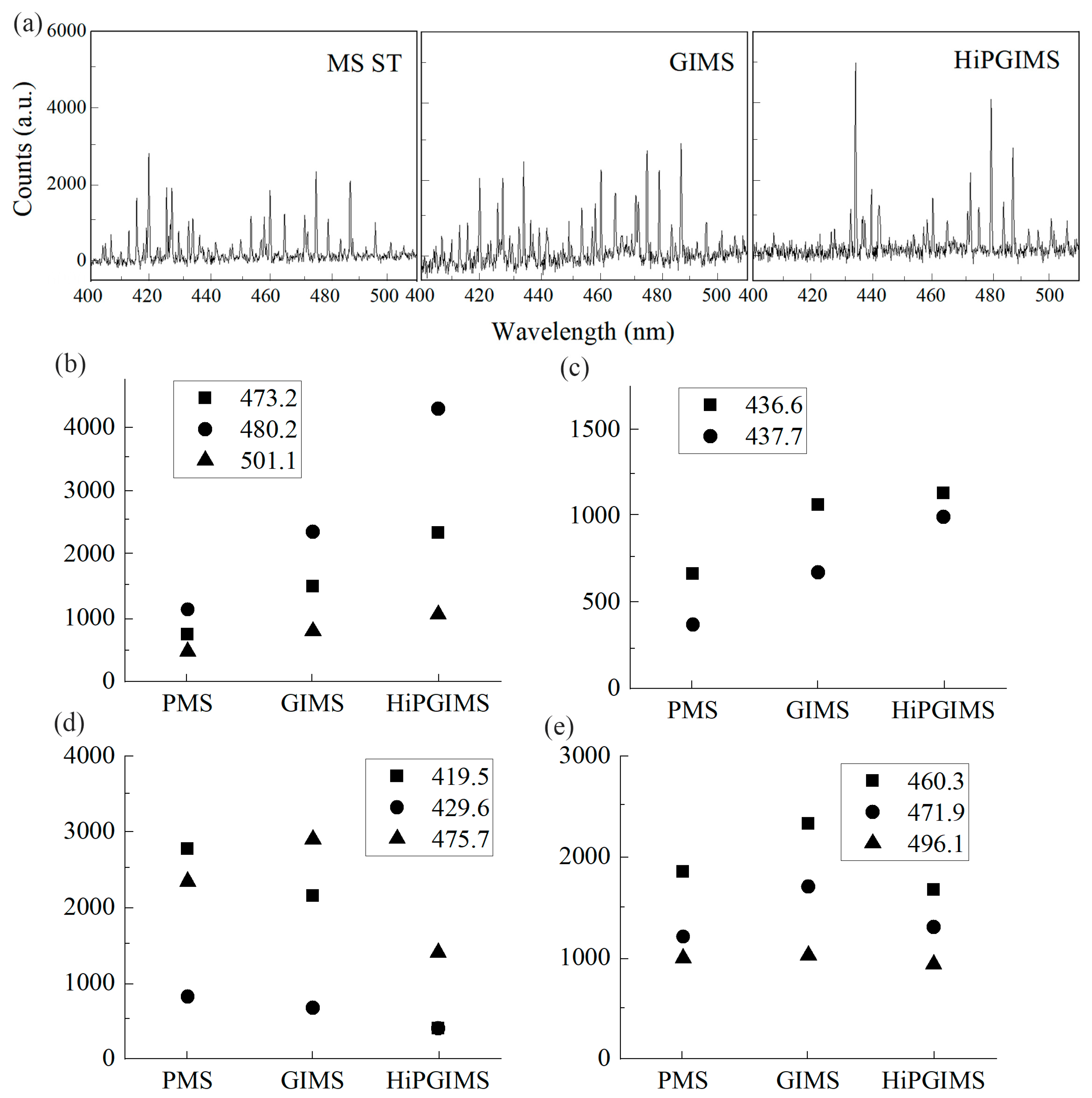

| Observed Wavelength (nm) | Species | Lower Level | Upper Level | Intensity (arb. u.) | ||

|---|---|---|---|---|---|---|

| PMS | GIMS | HiPGIMS | ||||

| 403.7 | C I | 2s22p3s | 2s22p5p | 430 | 340 | in noise |

| 405.1 | Ar II | 3s23p4(1D)4s | 3s23p4(1D)4p | 390 | 301 | in noise |

| 406.7 | C I | 2s22p3s | 2s22p5p | 625 | 671 | 778 |

| 410.2 | Ar II | 3s23p4(3P)4p | 3s23p4(3P)5s | 233 | 515 | in noise |

| 412.8 | Ar II | 3s23p4(1D)4s | 3s23p4(1D)4p | 760 | 924 | in noise |

| 415.5 | C I | 2s2p3 | 2s22p7p | 1597 | 963 | in noise |

| 418.3 | Ar I | 3s23p5(2P°3/2)4s | 3s23p5(2P°3/2)5p | 878 | 401 | in noise |

| 419.5 | Ar I | 3s23p5(2P°3/2)4s | 3s23p5(2P°3/2)5p | 2769 | 2153 | in noise |

| 422.6 | C I | 2s2p3 | 2s22p(2P°1/2)6f | 329 | 475 | in noise |

| 425.3 | Ar I | 3s23p5(2P°1/2)4s | 3s23p5(2P°1/2)5p | 1929 | 1569 | 778 |

| 427.4 | C I | 2s22p3s | 2s22p5p | 1929 | 2192 | 856 |

| 429.6 | Ar I | 3s23p5(2P°3/2)4s | 3s23p5(2P°3/2)5p | 817 | 671 | in noise |

| 432.9 | Ar II | 3s23p4(3P)4s | 3s23p4(3P)4p | 1031 | 946 | 1401 |

| 434.4 | C I | 2s2p3 | 2s22p6p | 1092 | 2602 | 5145 |

| 436.6 | C II | 2s2p(3P°)3d | 2s2p(3P°)4f | 664 | 1063 | 1131 |

| 437.7 | C II | 3s23p4(3P)4s | 3s23p4(3P)4p | 369 | 671 | 992 |

| 439.7 | Ar II | 3s23p4(3P)4p | 3s23p4(3P)5s | 294 | 906 | 1872 |

| 441.9 | Ar II | 3s23p4(3P)4d | 3s23p4(3P)4p | 486 | 867 | 1480 |

| 446.7 | C I | 2s2p3 | 2s22p(2P°3/2)5f | 329 | 223 | in noise |

| 447.7 | C I | 2s2p3 | 2s22p(2P°3/2)5f | 468 | 458 | in noise |

| 450.5 | Ar I | 3s23p5(2P°1/2)4s | 3s23p5(2P°3/2)5p | 604 | 401 | in noise |

| 454.1 | Ar II | 3s23p4(3P)4s | 3s23p4(3P)4p | 1149 | 1433 | 682 |

| 457.3 | Ar II | 3s23p4(3P)4s | 3s23p4(3P)4p | 525 | 924 | 896 |

| 458.5 | Ar II | 3s23p4(1D)4s | 3s23p4(1D)4p | 1188 | 1512 | 1092 |

| 460.3 | Ar II | 3s23p4(1D)3d | 3s23p4(1D)4p | 1850 | 2327 | 1676 |

| 465.6 | Ar II | 3s23p4(3P)4s | 3s23p4(3P)4p | 1266 | 1765 | 1149 |

| 471.9 | Ar II | 3s23p4(3P)4s | 3s23p4(3P)4p | 1209 | 1704 | 1305 |

| 473.2 | C I | 2s2p3 | 2s22p5p | 739 | 1490 | 2338 |

| 475.7 | Ar I | 3s23p5(2P°3/2)4p | 3s23p5(2P°3/2)8d | 2338 | 2894 | 1401 |

| 480.2 | C I | 2s2p3 | 2s22p5p | 1131 | 2349 | 4286 |

| 484.3 | C I | 2s22p3p | 2s22p(2P°1/2)16d | 586 | 906 | 1519 |

| 487.5 | C I | 2s22p3s | 2s22p4p | 2103 | 3090 | 3001 |

| 493.1 | C I | 2s22p3s | 2s22p4p | 369 | 536 | 817 |

| 496.1 | Ar II | 3s23p4(3P)4s | 3s23p4(3P)4p | 995 | 1024 | 935 |

| 501.1 | C I | 2s22p3p | 2s22p(2P°1/2)10d | 468 | 789 | 1052 |

| 505.4 | C I | 2s22p3p | 2s22p(2P°3/2)7d | 447 | 732 | 1092 |

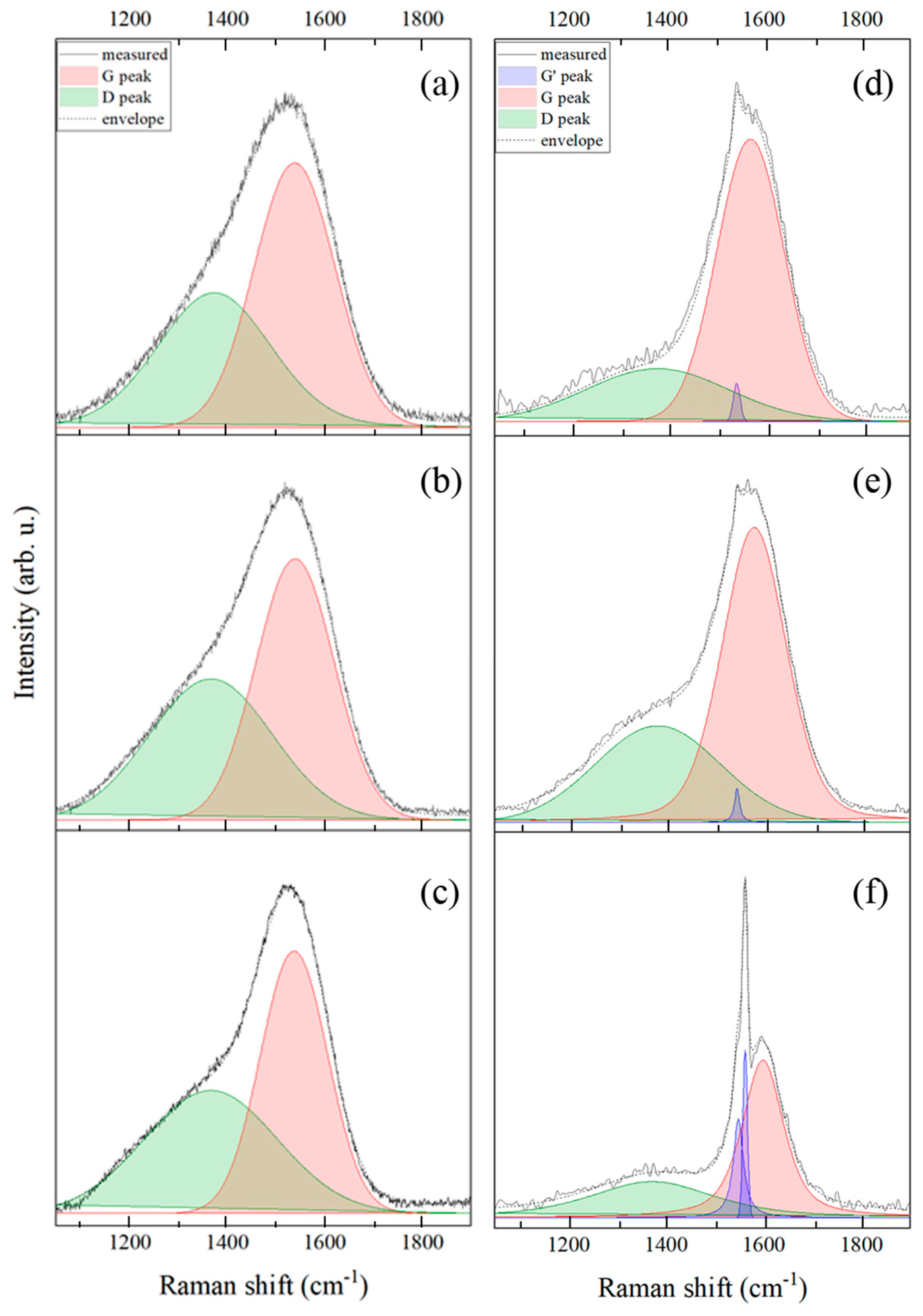

| G peak | D peak | ||||||

|---|---|---|---|---|---|---|---|

| Position (cm−1) | FWHM (cm−1) | Intensity (arb. u.) | Position (cm−1) | FWHM (cm−1) | Intensity (arb. u.) | ||

| 266 nm | PMS | 1572.8 | 162.1 | 288.0 | 1381.9 | 342.9 | 53.7 |

| GIMS | 1580.4 | 154.9 | 594.9 | 1383.1 | 300.4 | 194.7 | |

| HiPGIMS | 1598.3 | 100.4 | 220.5 | 1371.2 | 303.2 | 50.6 | |

| 532 nm | PMS | 1538.5 | 195.5 | 347.2 | 1373.6 | 273.7 | 176.7 |

| GIMS | 1539.4 | 188.2 | 488.0 | 1366.7 | 296.9 | 263.5 | |

| HiPGIMS | 1537.3 | 162.2 | 1026.8 | 1366.4 | 320.8 | 481.1 | |

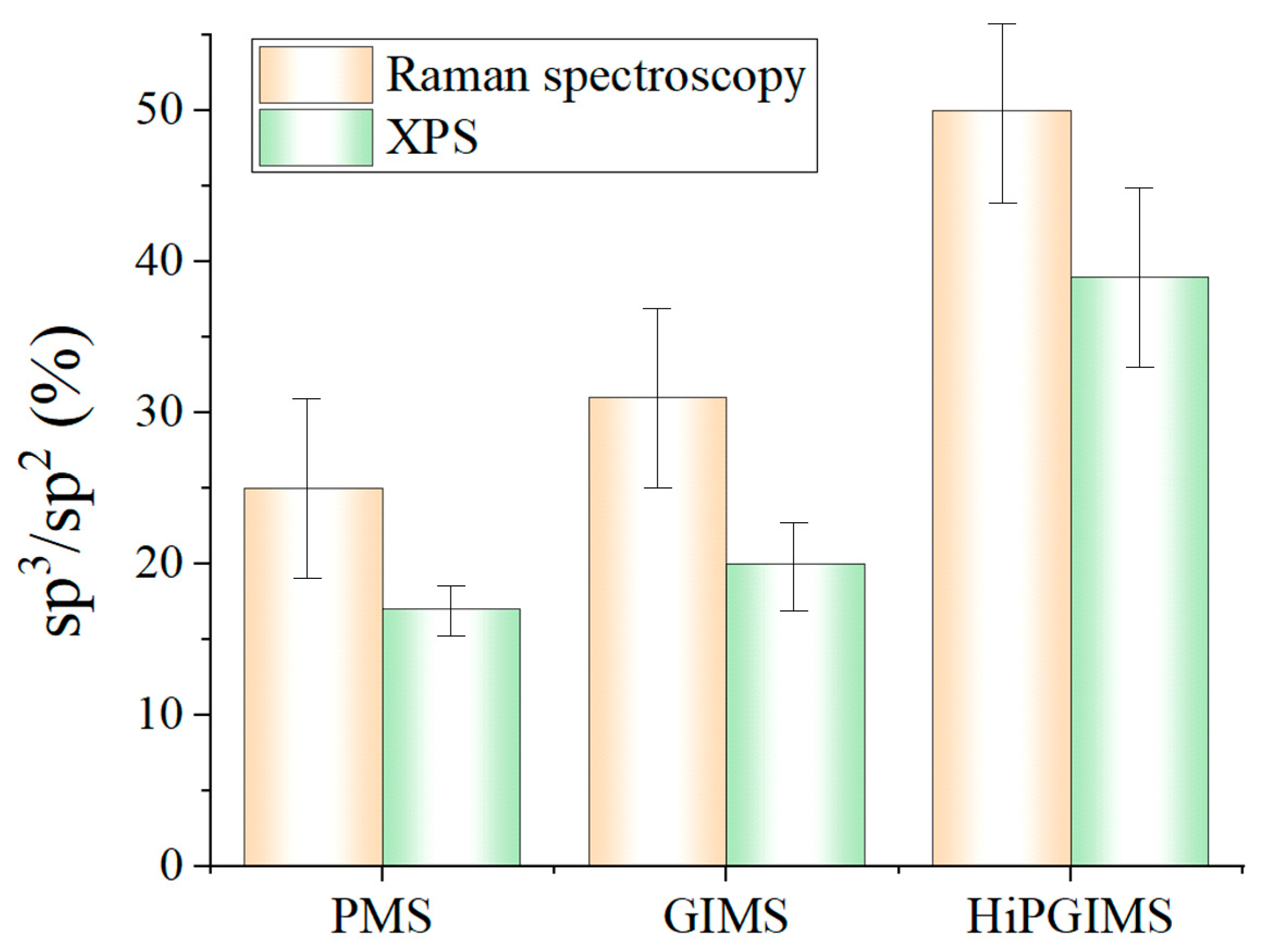

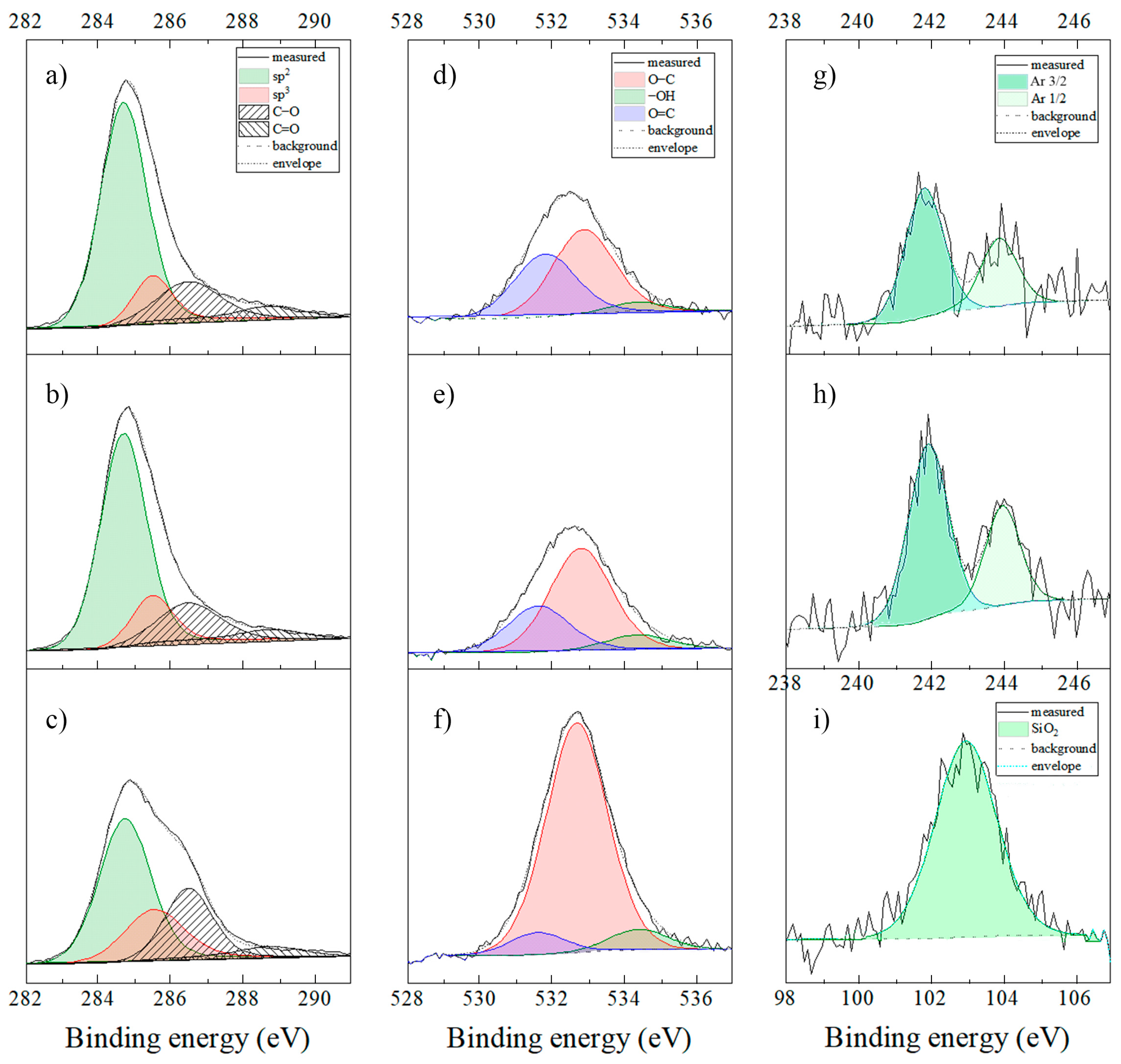

| C (sp2) | C (sp3) | C (C–O) | C (C=O) | O-C | OH | O=C | SiO2 | Ar | %C | %O | %Si | %Ar | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PMS | 63.72 | 10.68 | 14.19 | 4.34 | 3.66 | 0.31 | 2.74 | - | 0.36 | 92.93 | 6.71 | 0 | 0.36 |

| GIMS | 62.13 | 12.22 | 14.44 | 3.54 | 4.51 | 0.62 | 2.03 | - | 0.51 | 92.33 | 7.16 | 0 | 0.51 |

| HiPGIMS | 45.09 | 17.77 | 19.87 | 3.49 | 9.88 | 0.79 | 0.82 | 2.29 | - | 86.22 | 11.49 | 2.29 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chodun, R.; Skowronski, L.; Trzcinski, M.; Zaloga, D.; Nowakowska-Langier, K.; Domanowski, P.; Zdunek, K. The Amorphous Carbon Layers Deposited by Various Magnetron Sputtering Techniques. Coatings 2025, 15, 1367. https://doi.org/10.3390/coatings15121367

Chodun R, Skowronski L, Trzcinski M, Zaloga D, Nowakowska-Langier K, Domanowski P, Zdunek K. The Amorphous Carbon Layers Deposited by Various Magnetron Sputtering Techniques. Coatings. 2025; 15(12):1367. https://doi.org/10.3390/coatings15121367

Chicago/Turabian StyleChodun, Rafal, Lukasz Skowronski, Marek Trzcinski, Dobromil Zaloga, Katarzyna Nowakowska-Langier, Piotr Domanowski, and Krzysztof Zdunek. 2025. "The Amorphous Carbon Layers Deposited by Various Magnetron Sputtering Techniques" Coatings 15, no. 12: 1367. https://doi.org/10.3390/coatings15121367

APA StyleChodun, R., Skowronski, L., Trzcinski, M., Zaloga, D., Nowakowska-Langier, K., Domanowski, P., & Zdunek, K. (2025). The Amorphous Carbon Layers Deposited by Various Magnetron Sputtering Techniques. Coatings, 15(12), 1367. https://doi.org/10.3390/coatings15121367