Microstructure Regulation and Optoelectronic Performance Optimization of Flexible CPI-Based ITO Thin Films Under Low-Temperature Heat Treatment Process

Abstract

1. Introduction

2. Experimental Methods

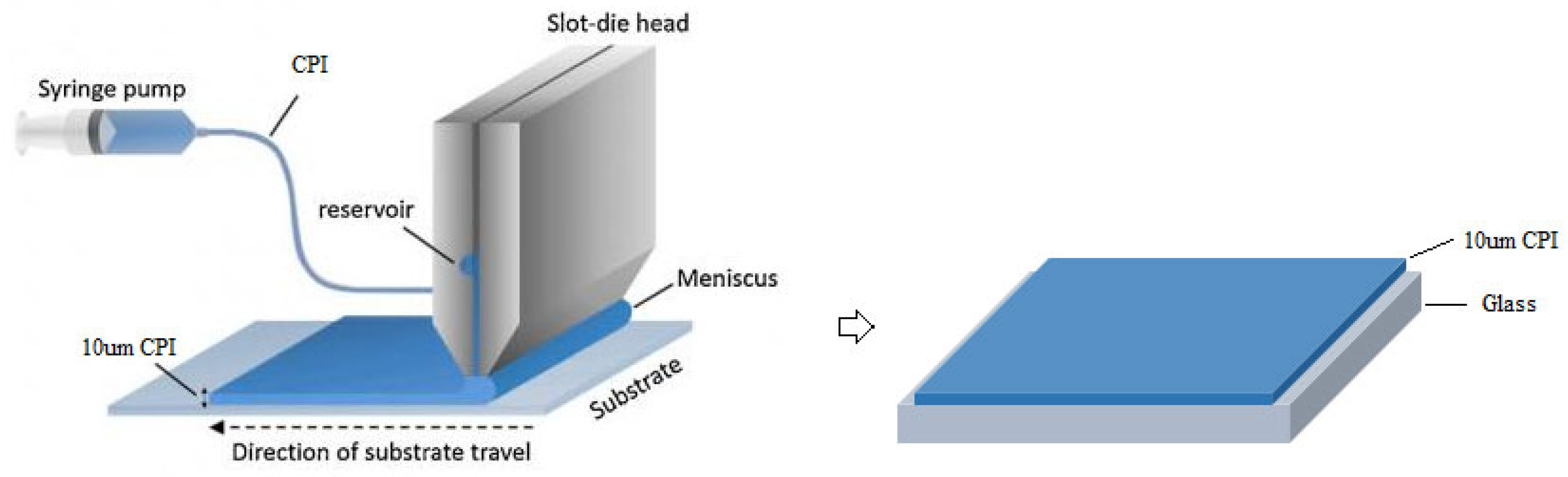

2.1. CPI Substrate and ITO Film Preparation

2.2. Heat Treatment Process

2.3. Performance Characterization

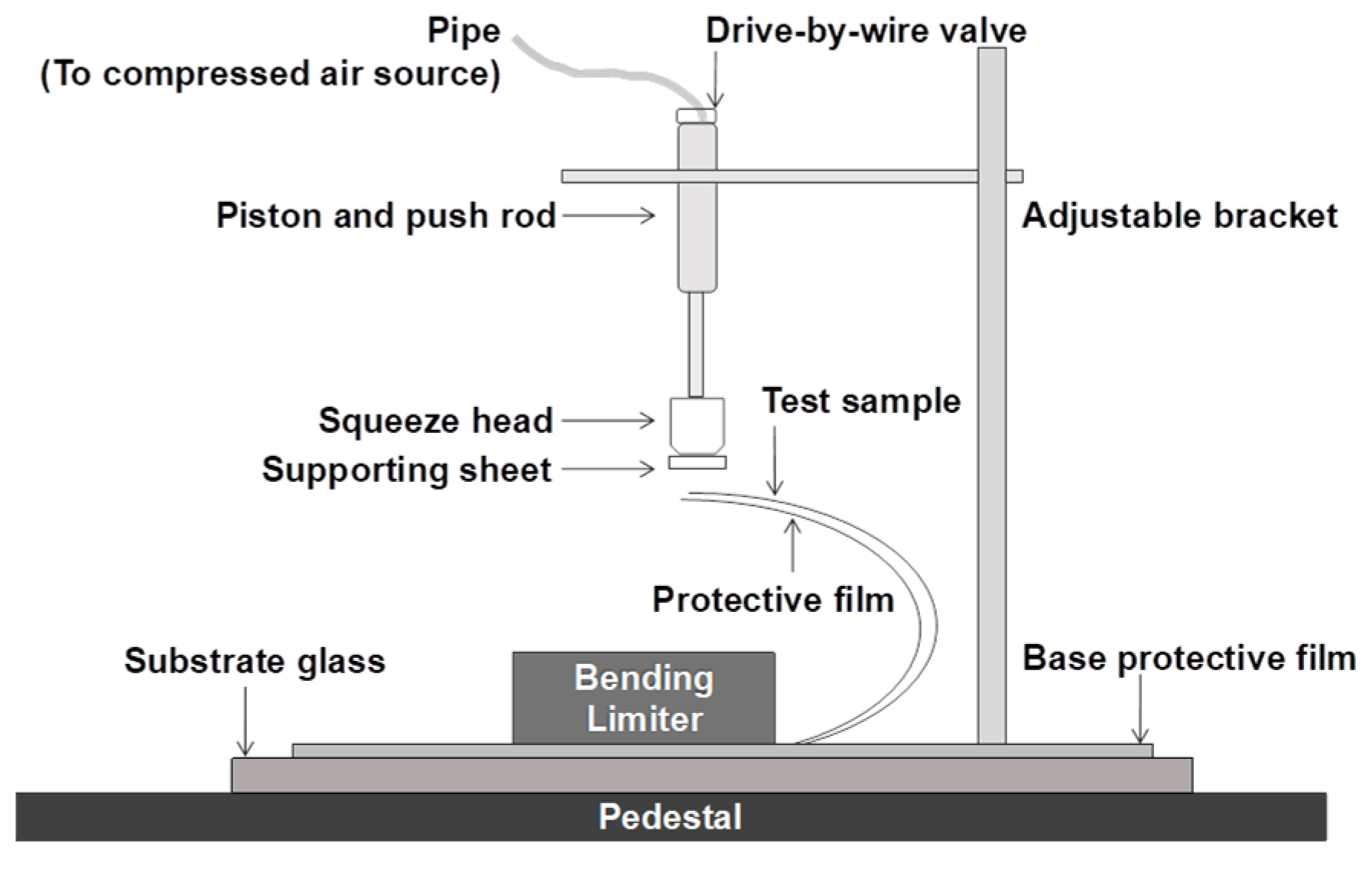

2.4. Bending Performance Test

3. Results and Discussion

3.1. Structural Properties

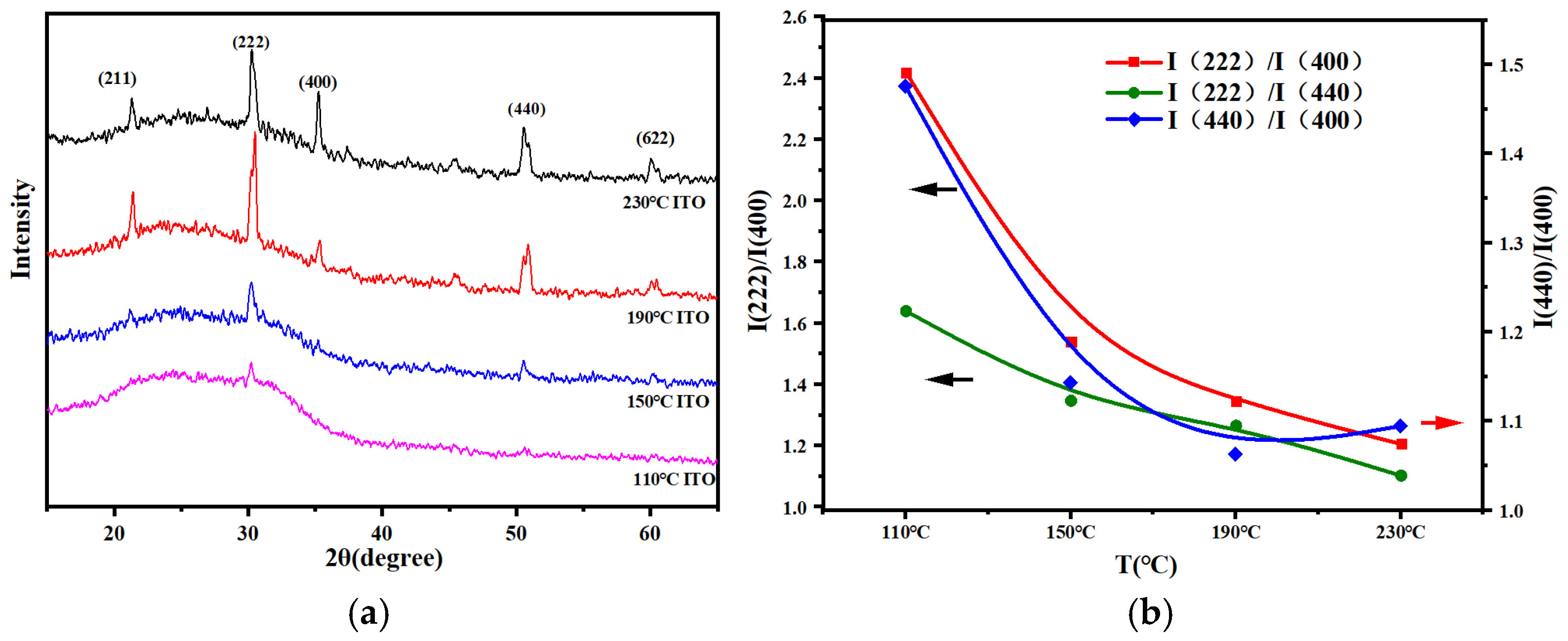

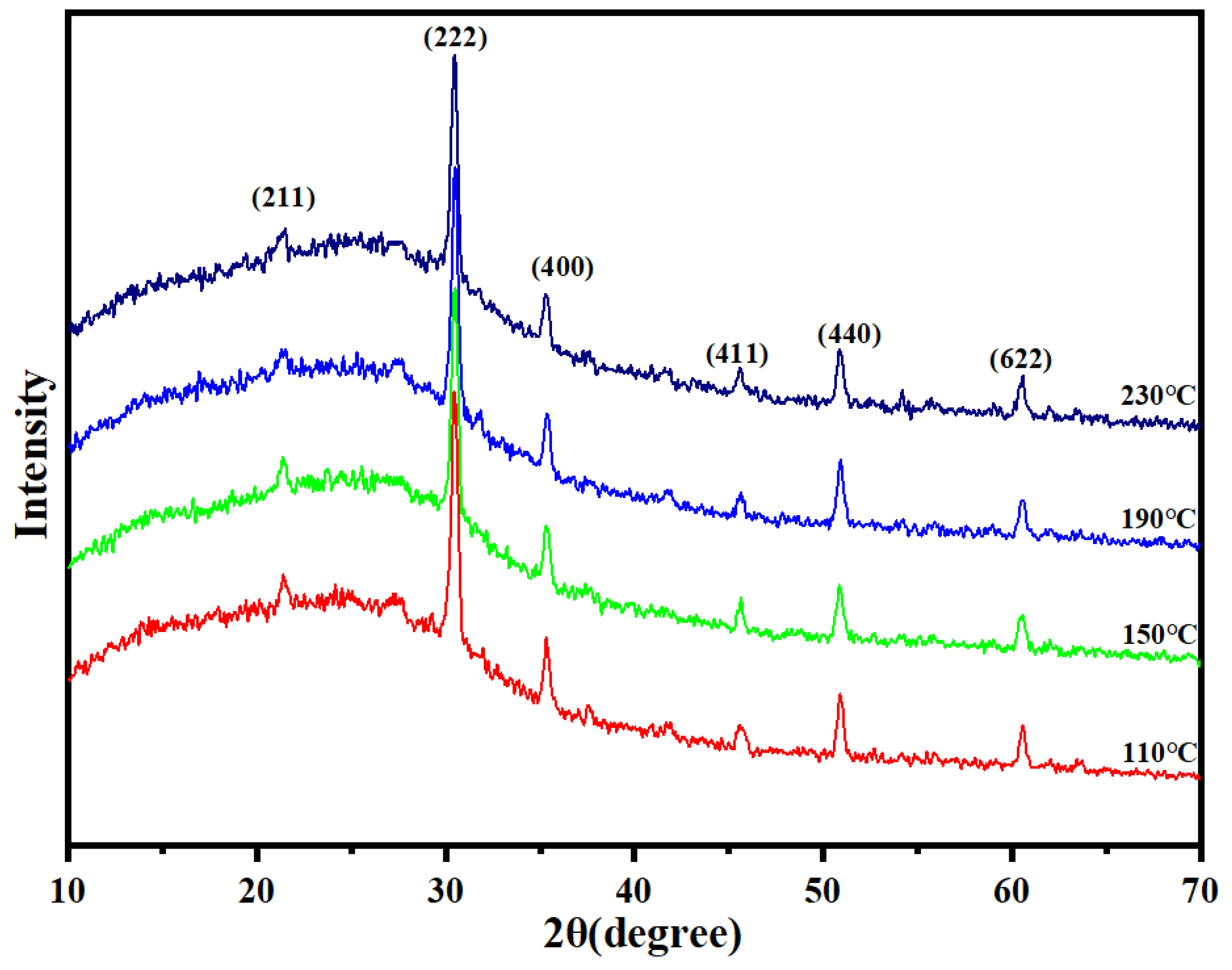

Crystal Structure and Microstructure Evolution

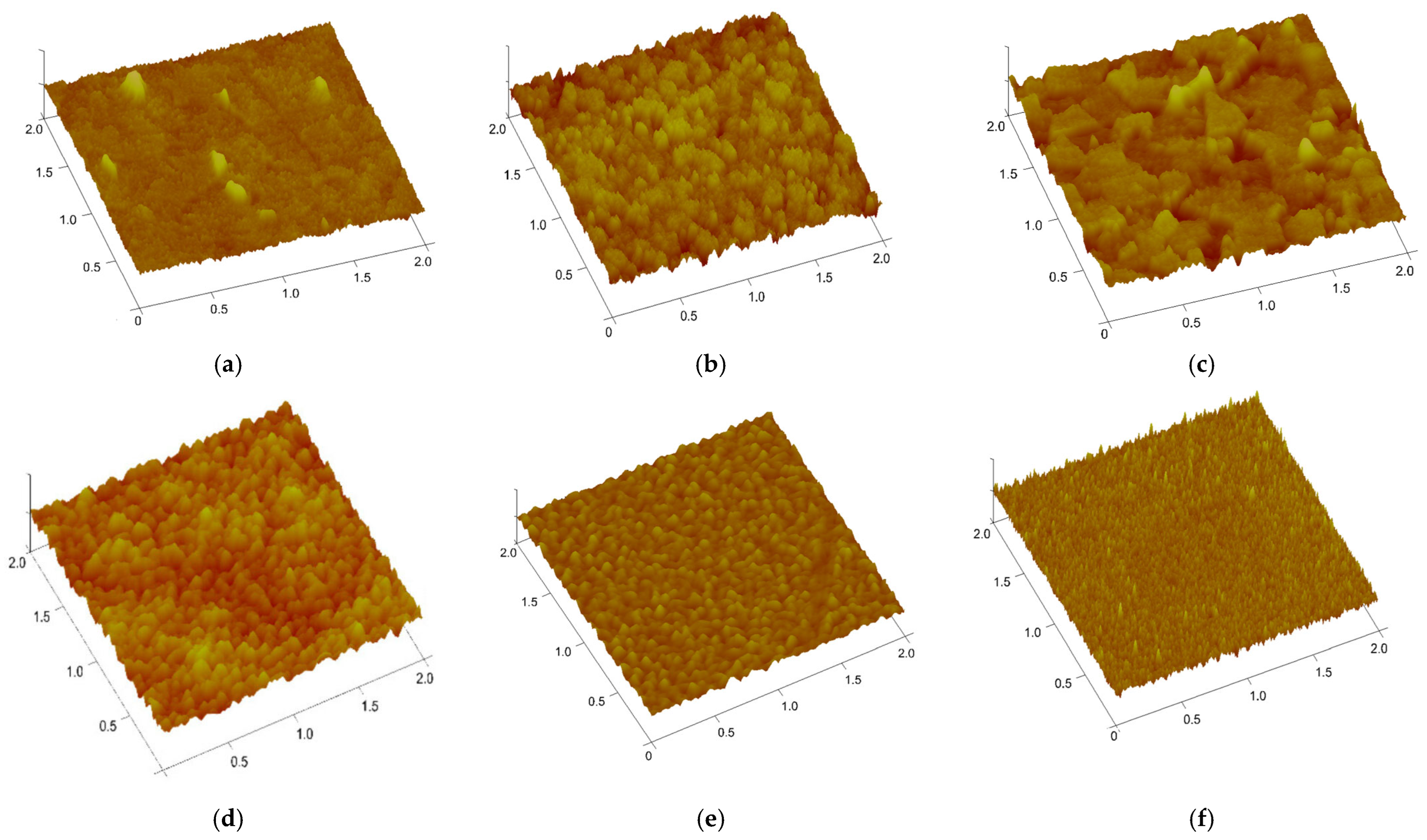

3.2. Surface Morphology

ITO Film Surface Morphology and Roughness Analysis

3.3. Optical Properties

3.4. Electrical Properties

3.4.1. Resistivity Analysis

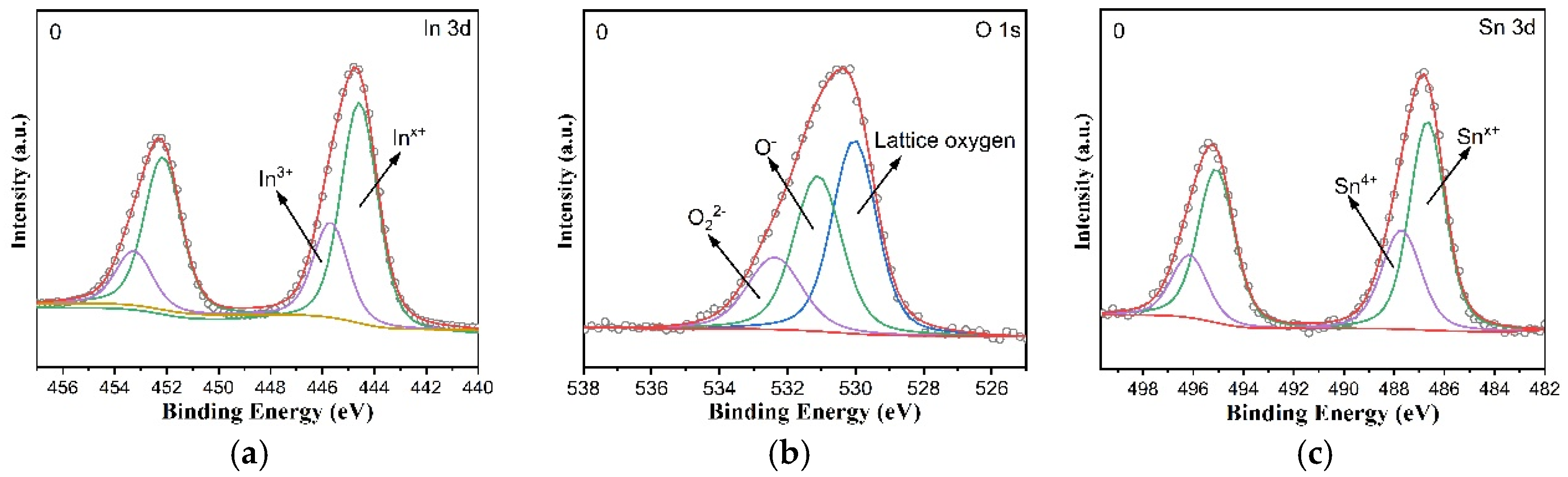

3.4.2. Chemical State and Doping Mechanism

In 3d Orbital Chemical State

Sn 3d Orbital Chemical State

O 1s Orbital Chemical State

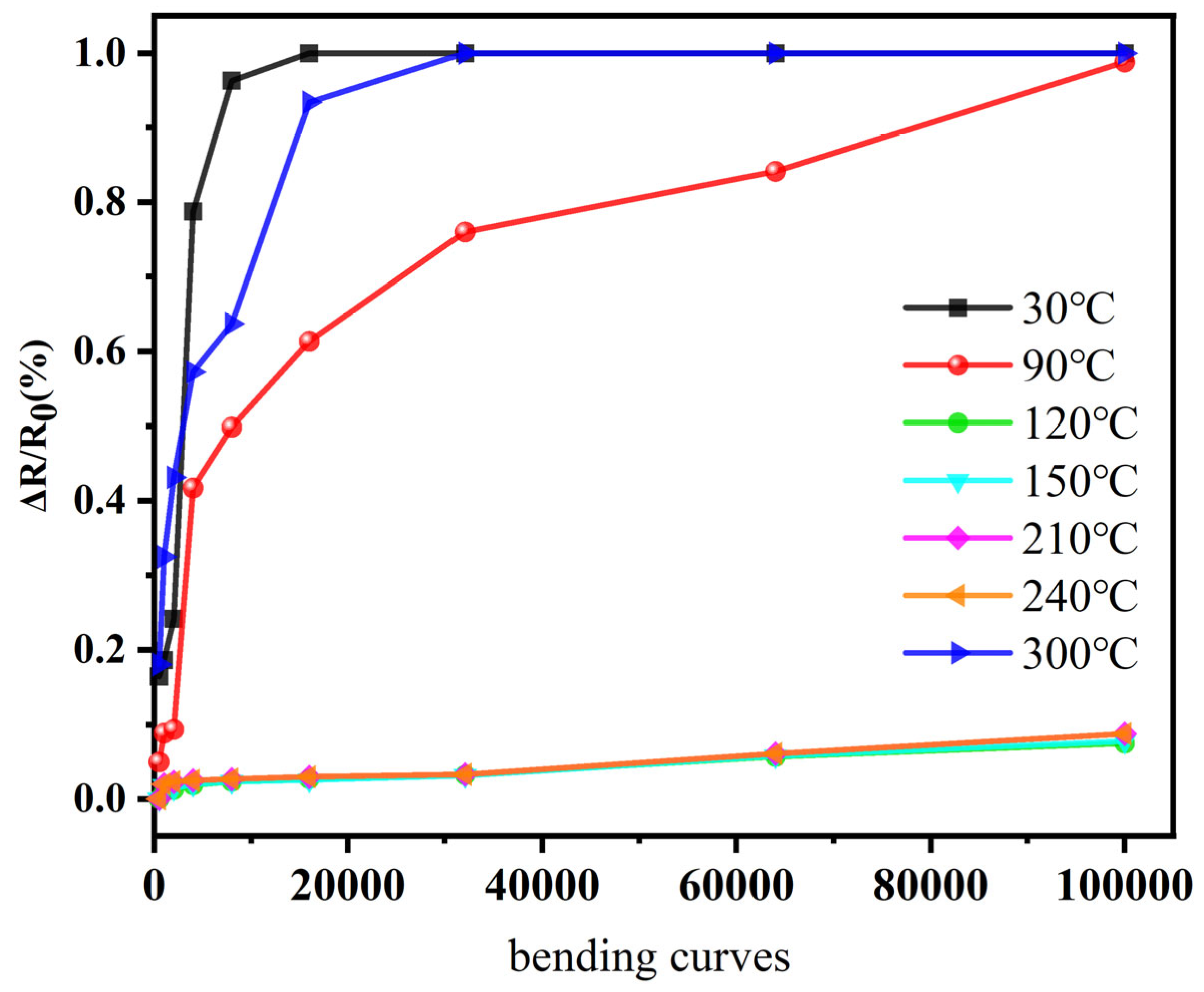

3.5. Bending Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chang, J.-H. Equibiaxially stretchable colorless and transparent polyimides for flexible display substrates. Rev. Adv. Mater. Sci. 2020, 59, 1–9. [Google Scholar] [CrossRef]

- Yang, L.; Huang, X.; Wu, H.; Liang, Y.; Ye, M.; Liu, W.; Li, F.; Xu, T.; Wang, H. Silver Nanowires: From Synthesis, Growth Mechanism, Device Fabrications to Prospective Engineered Applications. Eng. Sci. 2023, 23, 808. [Google Scholar] [CrossRef]

- Silveira, A.; Fuchs, M.; Pinheiro, D.; Tanabe, E.; Bertuol, D. Recovery of indium from LCD screens of discarded cell phones. Waste Manag. 2015, 45, 334–342. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, A.I.; Cloutet, E.; Hadziioannou, G. Materials for Transparent Electrodes: From Metal Oxides to Organic Alternatives. Adv. Electron. Mater. 2018, 4, 1700412. [Google Scholar] [CrossRef]

- Granqvist, C.G. Transparent conductors as solar energy materials: A panoramic review. Sol. Energy Mater. Sol. Cells 2007, 91, 1529–1598. [Google Scholar] [CrossRef]

- Lewis, B.G.; Paine, D.C. Applications and processing of transparent conducting oxides. MRS Bull. 2000, 25, 22–27. [Google Scholar] [CrossRef]

- Chen, Z.; Li, W.; Li, R.; Zhang, Y.; Xu, G.; Cheng, H. Fabrication of highly transparent and conductive indium-tin oxide thin films with a high figure of merit via solution processing. Langmuir 2013, 29, 13836–13842. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Gilmore, C.M.; Piqué, A.; Horwitz, J.S.; Mattoussi, H.; Murata, H.; Kafafi, Z.H.; Chrisey, D.B. Electrical, optical and structural properties of indium-tin-oxide thin Films for organic light-emitting devices. J. Appl. Phys. 1999, 86, 6451–6461. [Google Scholar] [CrossRef]

- Jung, Y.S.; Seo, J.Y.; Lee, D.W.; Jeon, D.Y. Influence of DC magnetron sputtering parameters on the properties of amorphous indium zinc oxide thin film. Thin Solid Film. 2003, 445, 63–71. [Google Scholar] [CrossRef]

- Shigesato, Y.; Takaki, S.; Haranoh, T. Electrical and structural properties of low resistivity tin-doped indium oxide films. J. Appl. Phys. 1992, 71, 3356–3364. [Google Scholar] [CrossRef]

- Ellmer, K. Resistivity of polycrystalline zinc oxide films: Current status and physical limit. J. Phys. D Appl. Phys. 2001, 34, 3097–3108. [Google Scholar] [CrossRef]

- Oh, M.J.; Son, G.C.; Kim, M.; Jeon, J.; Kim, Y.H.; Son, M. An Aqueous Process for Preparing Flexible Transparent Electrodes Using Non-Oxidized Graphene/Single-Walled Carbon Nanotube Hybrid Solution. Nanomaterials 2023, 13, 2249. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Jing, L.C.; Bao, Z.; Qian, P.; Geng, W.; Ethiraj, A.S.; Geng, W.H.; Chen, L.; Zhu, Q.; Geng, H.Z. Strong adhesion and high optoelectronic performance hybrid graphene/carbon nanotubes transparent conductive films for green-light OLED devices. Surf. Interfaces 2021, 24, 101137. [Google Scholar] [CrossRef]

- Slepchenkov, M.M.; Barkov, P.V.; Glukhova, O.E. Hybrid Films Based on Bilayer Graphene and Single-Walled Carbon Nanotubes: Simulation of Atomic Structure and Study of Electrically Conductive Properties. Nanomaterials 2021, 11, 1934. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Feng, Z.; Zhang, H. Study of indium tin oxide films deposited on colorless polyimide film by magnetron sputtering. Mater. Des. 2020, 193, 108809. [Google Scholar] [CrossRef]

- Cullity, B.D.; Stock, S.R. Elements of X-Ray Diffraction, 3rd ed.; Prentice Hall: Hoboken, NJ, USA, 2001. [Google Scholar]

- Ghorannevis, Z.; Akbarnejad, E.; Ghoranneviss, M. Structural and morphological properties of ITO thin films grown by magnetron sputtering. J. Theor. Appl. Phys. 2015, 9, 285–290. [Google Scholar] [CrossRef]

- Abdallah, A.A.; Bouten, P.C.P.; de With, G. Experimental study on buckle evolution of thin inorganic layers on a polymer substrate. Eng. Fract. Mech. 2010, 77, 2896–2905. [Google Scholar] [CrossRef]

- Yu, Z.; Li, Y.G.; Xia, F.; Zhao, Z.; Xue, W. Properties of indium tin oxide films deposited on unheated polymer substrates by ion beam assisted deposition. Thin. Solid Film. 2009, 517, 5395–5398. [Google Scholar]

- Cairns, D.R.; Witte, R.P., II; Sparacin, D.K.; Sachsman, S.M.; Paine, D.C.; Crawford, G.P.; Newton, R.R. Strain-dependent electrical resistance of tin-doped indium oxide on polymer substrates. Appl. Phys. Lett. 2000, 76, 1425. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Base Vacuum | 1.0 × 10−4 Pa |

| Process Pressure | 0.5 Pa |

| Power Density | 0.67 W/cm2 |

| Substrate Temperature | 30–300 °C |

| Ar Flow Rate | 120 sccm |

| Deposition Time | Controlled for 30 ± 2 nm thickness |

| Substrate Temperature | (222) Grain Size (nm) | (222) d-Spacing (nm) | (400) d-Spacing (nm) | Lattice Constant a (nm) |

|---|---|---|---|---|

| 110 °C | 5.41 | 0.2929 | 0.2537 | 1.01468 |

| 150 °C | 10.13 | 0.2926 | 0.2534 | 1.01347 |

| 190 °C | 18.97 | 0.2921 | 0.2530 | 1.01196 |

| 230 °C | 20.48 | 0.2921 | 0.2530 | 1.01193 |

| Substrate Temperature | (222) Grain Size (nm) | (222) d-Spacing (nm) | (440) d-Spacing (nm) | Lattice Constant a (nm) |

|---|---|---|---|---|

| 110 °C | 24.01 | 0.2921 | 0.2529 | 1.01188 |

| 150 °C | 23.63 | 0.2922 | 0.2530 | 1.01236 |

| 190 °C | 23.82 | 0.2921 | 0.2529 | 1.01193 |

| 230 °C | 24.51 | 0.2921 | 0.2529 | 1.0 |

| Substrate Temp. | Thickness (nm) | Resistivity (μΩ·cm) | Carrier Concentration (cm−3) | Mobility (cm2/V·s) |

|---|---|---|---|---|

| 110 °C | 30 ± 2 | 203 | 8.7 × 1020 | 35.2 |

| 150 °C | 30 ± 2 | 225 | 7.9 × 1020 | 35.1 |

| 230 °C | 30 ± 2 | 385 | 4.8 × 1020 | 33.8 |

| Sub. Temper | 30 °C | 90 °C | 120 °C | 150 °C | 210 °C | 240 °C | 300 °C |

|---|---|---|---|---|---|---|---|

| Bending Cycles | ΔR/R0 (%) | ΔR/R0 (%) | ΔR/R0 (%) | ΔR/R0 (%) | ΔR/R0 (%) | ΔR/R0 (%) | ΔR/R0 (%) |

| 500 | 0.164 | 0.05 | 0 | 0 | 0 | 0 | 0.18 |

| 1000 | 0.1863 | 0.0889 | 0.01 | 0.018 | 0.02 | 0.02 | 0.3245 |

| 2000 | 0.2412 | 0.0938 | 0.0125 | 0.0142 | 0.023 | 0.023 | 0.4312 |

| 4000 | 0.7874 | 0.4171 | 0.0189 | 0.0197 | 0.025 | 0.025 | 0.5721 |

| 8000 | 0.9627 | 0.4985 | 0.0235 | 0.0236 | 0.027 | 0.027 | 0.637 |

| 16,000 | 1 | 0.6136 | 0.0273 | 0.0256 | 0.03 | 0.03 | 0.934 |

| 32,000 | 1 | 0.76 | 0.0325 | 0.0315 | 0.033 | 0.033 | 1 |

| 64,000 | 1 | 0.841 | 0.0572 | 0.058 | 0.061 | 0.061 | 1 |

| 100,000 | 1 | 0.988 | 0.0752 | 0.078 | 0.088 | 0.088 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Yao, R.; Wu, W.; Shen, Y. Microstructure Regulation and Optoelectronic Performance Optimization of Flexible CPI-Based ITO Thin Films Under Low-Temperature Heat Treatment Process. Coatings 2025, 15, 1352. https://doi.org/10.3390/coatings15111352

Zhang H, Yao R, Wu W, Shen Y. Microstructure Regulation and Optoelectronic Performance Optimization of Flexible CPI-Based ITO Thin Films Under Low-Temperature Heat Treatment Process. Coatings. 2025; 15(11):1352. https://doi.org/10.3390/coatings15111352

Chicago/Turabian StyleZhang, Hanyan, Ruohe Yao, Weijing Wu, and Yi Shen. 2025. "Microstructure Regulation and Optoelectronic Performance Optimization of Flexible CPI-Based ITO Thin Films Under Low-Temperature Heat Treatment Process" Coatings 15, no. 11: 1352. https://doi.org/10.3390/coatings15111352

APA StyleZhang, H., Yao, R., Wu, W., & Shen, Y. (2025). Microstructure Regulation and Optoelectronic Performance Optimization of Flexible CPI-Based ITO Thin Films Under Low-Temperature Heat Treatment Process. Coatings, 15(11), 1352. https://doi.org/10.3390/coatings15111352