1. Introduction

In recent years, the field of restorative dentistry has undergone significant development, particularly in the design and optimisation of dental composites. These materials must satisfy strict requirements regarding biocompatibility, mechanical performance, and clinical applicability [

1,

2,

3]. In recent decades, increasing attention was devoted to dental composites, which represent a unique class of biomaterials with severe restrictions on biocompatibility and curing behaviour, because these materials are often limited by shrinkage and polymerisation-induced shrinkage stress, limited toughness, and the presence of unreacted monomer that remains following the polymerisation [

4,

5,

6,

7]. Dental composites consisting of polymer matrices and inorganic fillers have been available for a very long time. Their versatility, ease of manipulation, and ability to mimic the natural appearance of teeth have made them indispensable in restorative procedures [

8,

9].

However, traditional resin composites still suffer limitations that reduce their long-term clinical performance, including shrinkage of the polymerisation, microleakage, insufficient wear resistance, and degradation over time in the oral environment. To address these issues, continuous research efforts have been directed toward the development of advanced fillers and resin systems. Among the most promising approaches is the incorporation of nanosized silica particles. Researchers have carried out many investigations on the potential of nanosilicas as reinforcements for dental composites, because the small size of filler particles can improve the optical properties of resin composites, their diameter is a fraction of the wavelength of visible light (0.4–0.8 µm), resulting in the inability of the human eye to detect the particles [

7,

10].

The performance of dental composites strongly depends on the type of filler, the volume fraction, and the number of nanoparticles, as well as on characteristics such as particle size, specific surface area, and compatibility with the matrix [

7,

11]. The use of nanofillers, such as silica, allows modification of the properties of the obtained composite, including control of water absorption, improvement of strength, and enhancement of thermal properties. Furthermore, silica can also serve as a carrier for antimicrobial agents, broadening the functional potential of dental composites, as it is considered safe for biomedical applications [

12,

13,

14].

In addition to fillers, the properties of dental composites are largely determined by the polymer matrix. Most of the widely used composite resins in restorative dentistry contain 2,2-bis-[4-(methacryloxypropoxy)-phenyl]-propane (Bis-GMA). This monomer plays a crucial role due to its low volatility and low polymerisation shrinkage [

15,

16]. Bis-GMA is a rigid, hydrophobic crosslinking monomer, where the link between the two aromatic rings restricts flexibility. However, because it is a very viscous liquid, a low-viscosity diluent monomer must be incorporated to facilitate resin handling and filler loading. Typically, triethylene glycol dimethacrylate (TEGDMA) is added for this purpose, which improves the flowability of resin loading [

16,

17]. Importantly, Bis-GMA helps limit photopolymerisation-induced volumetric shrinkage and enhances resin reactivity, while TEGDMA increases double bond conversion [

18]. When Bis-GMA is copolymerized with TEGDMA, a final conversion of 50%–75% can be achieved, depending on the monomer composition and the photopolymerisation conditions [

19].

Although several studies have investigated the effect of nanosilica on the polymerisation behaviour of dental materials, these reports are generally limited to simple observations of conversion or polymerisation rate using techniques such as FTIR, DSC, and NMR [

7]. To date, there has been a clear lack of detailed investigations addressing the broader aspects of polymerisation kinetics in silica-containing systems, particularly with respect to the determination of fundamental kinetic parameters such as propagation and termination rate coefficients and the post-curing effect. Moreover, the influence of these parameters on the physical, thermal, and mechanical properties of cured composites is poorly understood. In most studies, the polymerisation rate and final degree of conversion were monitored by FTIR analysis [

7,

20], near-infrared spectroscopy [

21], photodifferential scanning calorimetry (DSC) or other techniques such as NMR [

22,

23]. However, the degree of polymerisation reported in different studies frequently showed discrepancies, particularly between IR- and NMR-based analyses [

22]. This highlights the complexity of free-radical polymerisation of multifunctional methacrylates, which is governed not only by the concentration of reactants, but also by the evolving physical conditions in the reacting medium [

24,

25,

26]. A continuous increase in viscosity during polymerisation strongly influences both propagation and termination rates [

25]. Thus, the kinetics of these systems are not simply determined by the initial composition, but by mobility restrictions imposed on reactive species as the reaction progresses. Because the curing behaviour ultimately dictates the final network structure and, thereby, the performance of dental composites, a deeper understanding of polymerisation kinetics in the presence of nanosilica is crucial. In particular, clarifying how the type of nanosilica, the surface treatment, and the distribution affect the propagation and termination rate coefficients would provide essential insights for material design and optimisation.

The aim of this study is to systematically investigate the influence of different types of silica nanofillers (DT4, R709, OX50 and their OX50/R709 mixture) on the rheological, photopolymerisation, thermal, mechanical and sorption properties of Bis-GMA/TEGDMA-based dental composites. Special attention is given to the relationship between the physicochemical characteristics of the fillers (surface area, surface modification, particle size), their concentration, and the kinetics of the crosslinking process. A particularly important and distinctive aspect of the study is the analysis of the propagation and termination coefficients of the polymerisation reaction. This approach not only demonstrates how filler type and concentration affect composite performance but also highlights the exceptional role of kinetic parameters (propagation and termination) as key factors determining the efficiency and stability of the polymer network.

3. Results and Discussion

3.1. Viscosity

The photocurable formulations were characterised before curing (by viscosity measurements), during polymerisation (through curing kinetics), and after curing (by evaluation of the glass transition temperature and mechanical properties). The experimental composites were prepared by incorporating nanofillers into a mixture of Bis-GMA and TEGDMA (50:50) as the matrix phase. A series of formulations containing 0, 5, 10, 15, 20, 30, and 35–40 wt.% of the fillers was investigated.

Figure 1a presents representative relationships between formulation viscosity, shear rate, and DT4 filler content at 25 °C. Due to the very high viscosity of systems with higher filler loadings (25, 30, 35, and 40 wt.%), these formulations were not included in

Figure 1a. The dependence of viscosity (

η) on silica content for various types of silica (DT4, R709, OX50 and the R709/OX50 mixture) was determined at a constant cone rotation speed of 100 rpm (

Figure 1b). All measurements were carried out at 25 °C, corresponding to the temperature used for both kinetic investigations and composite preparation.

From a practical point of view, the rheological characteristics of the developed composites were compared with those typically required in restorative dentistry. The viscosities of the individual liquid components are as follows. Bis-GMA—approximately 600–1000 Pa·s, and TEGDMA—approximately 0.01–0.05 Pa·s [

31]. According to the literature, the viscosity of a Bis-GMA/TEGDMA mixture in a 1:1 ratio is 0.32 Pa·s [

31]. The viscosity measurement of the monomer mixture used in this study showed a value of approximately 0.25 Pa·s (

Figure 1a). Bis-GMA/TEGDMA-based systems investigated here exhibited viscosities between 0.25 and 300 Pa·s (depending on filler content), which correspond well to packable restorative materials (

Figure 1b). The viscosity of commercial light-cured resins used for posterior restorations usually lies in the range of 1000–100,000 Pa·s, allowing easy manipulation and cavity adaptation.

For the composite containing OX50, a steep increase in viscosity occurs above 15 wt.%, exceeding 150 Pa·s within 25–30 wt.%. This effect is related to the relatively high specific surface area of OX50 (~50 m2/g), which promotes the formation of an extensive filler-fill network. In contrast, the OX50/R709 mixture exhibits a sharp viscosity increase already at 10 wt.% of filler, reaching values above 104 Pa·s, followed by a subsequent decrease at higher loadings. This suggests that synergistic interactions between the unmodified hydrophilic OX50 and the silane-modified R709 facilitate the formation of a temporary percolated structure within the resin matrix, which becomes disturbed as the filler content increases further.

Composites containing DT4 exhibit more gradual viscosity growth. Although DT4 has the highest specific surface area (~160 m2/g) and the smallest particle size (~12 nm), its hydrophobic surface treatment reduces agglomeration and hydrogen bonding, allowing better dispersion and delaying the onset of a sharp increase in viscosity until higher filler loadings (>30 wt.%).

Formulations with R709 also show a steady increase in viscosity but maintain lower values compared to OX50 and OX50/R709. This is consistent with its lower specific surface area (~35 m2/g) and the modification of methacryloxy silane, which minimises filler-filler interactions and favours compatibility with the Bis-GMA/TEGDMA matrix.

These results demonstrate that the rheological performance of dental composites is strongly governed not only by filler concentration but also by the physicochemical properties of the silica nanofillers. The surface chemistry, particle size, and specific surface area play a decisive role in defining the degree of particle-particle and particle-matrix interactions, which ultimately control the viscosity of the systems.

3.2. Photopolymerisation Kinetics

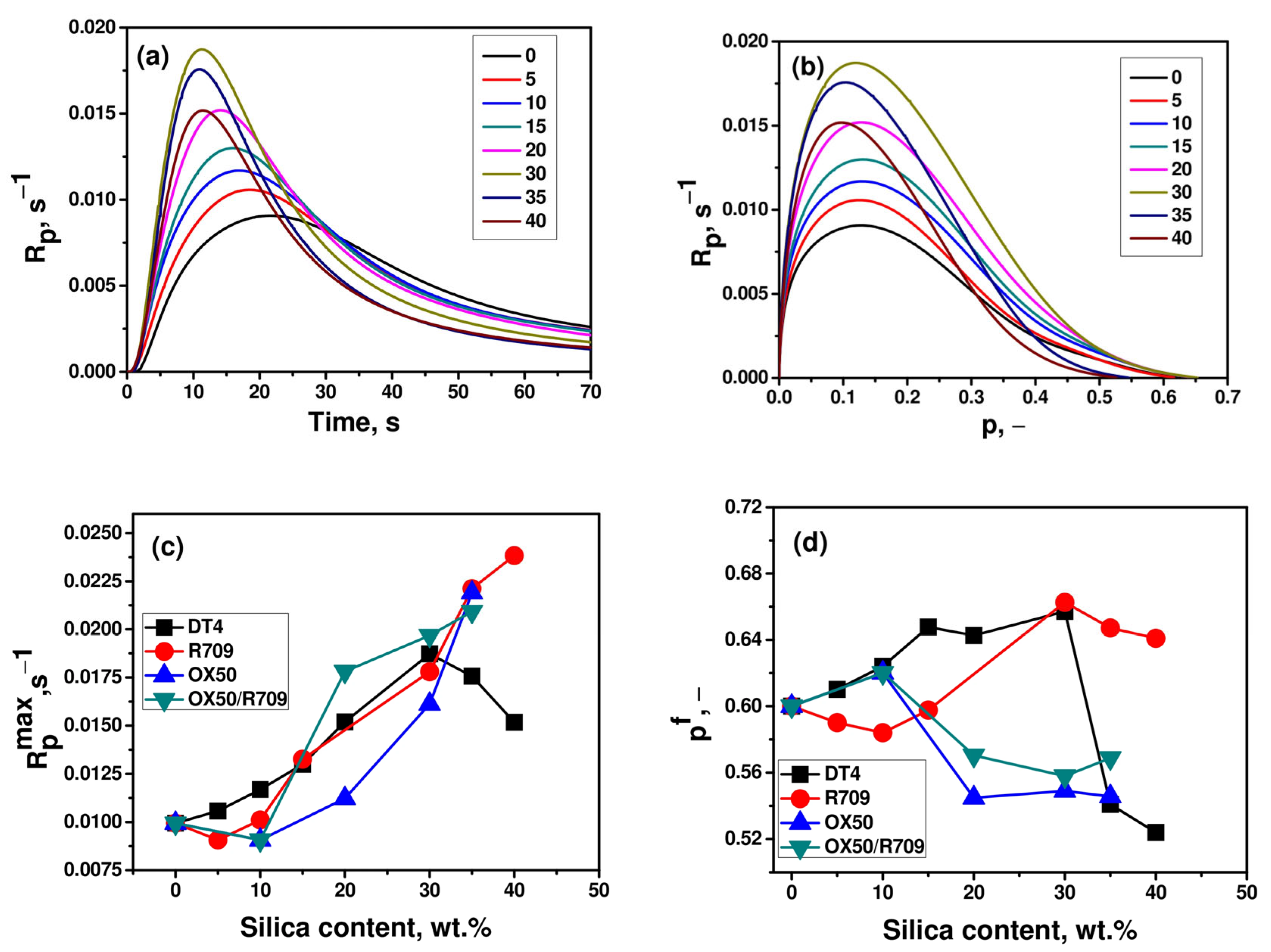

Figure 2a,b present exemplary effects of DT4 content on the polymerisation kinetics of Bis-GMA/TEGDMA-based composites. The unfilled resin matrix showed the lowest

Rpmax (maximum polymerisation rate, ~0.010 s

−1), indicating limited mobility and a relatively low monomer conversion. The shape of the curves corresponds to the kinetic curve of the polymerisation of multifunctional monomers with immediate autoacceleration, the occurrence of a maximum reaction rate (

Rpmax), and subsequent deceleration. Upon the addition of DT4,

Rp progressively increased to a filler content of 30–35 wt.%, reaching a value of approximately 0.018 s

−1. This enhancement is attributed to the increased light scattering caused by silica particles, which improves light penetration and initiator activation, as well as improved heat retention and viscosity-induced stabilisation of radical species. The time-dependent profiles of the polymerisation rate reveal that increasing DT4 concentration enhances the maximum polymerisation rate (

Rpmax), which shifts to earlier times (10–15 s) with filler loading. The conversion-dependent profiles (

Figure 2b) demonstrate that with increasing filler content, the maximum polymerisation rate occurs at progressively lower double bond conversions (~0.12–0.20), indicating faster network formation and the onset of gel points. At higher loadings, however, the final conversion is slightly reduced, most likely because of the restricted mobility of reactive species and enhanced light scattering caused by the nanofiller. These findings indicate that DT4, despite its very high specific surface area (~160 m

2/g) and small particle size (~12 nm), promotes rapid polymerisation kinetics at moderate concentrations, while excessive loading leads to reduced curing efficiency due to diffusional limitations and steric barriers.

At low filler contents (≤10 wt.%), a distinct difference in the polymerisation behaviour was observed among the systems studied. Only the composition containing DT4 exhibited an increase in

Rpmax, despite showing the lowest viscosity of the composition. This behaviour can be attributed to the efficient dispersion of the hydrophobically modified DT4 nanoparticles, which minimise filler–filler interactions and maintain high monomer mobility, thereby facilitating chain propagation. On the contrary, formulations containing OX50 or R709 showed a slight decrease in

Rpmax with increasing filler loading up to wt.%, and the extent of this decrease was correlated with the viscosity of the system (

Figure 2c). The higher viscosity of these systems likely limited the monomer and radical diffusion, resulting in a diffusion-controlled reduction in the overall polymerisation rate.

At higher filler loadings (>10 wt.%), the influence of viscosity on Rpmax became more complex and strongly dependent on the filler surface chemistry. Bis-GMA/TEGDMA/OX50 systems, characterised by the highest viscosities due to the hydrophilic and agglomeration-prone nature of OX50, showed only a minor increase in Rpmax with increasing silica content. On the contrary, composites containing the OX50/R709 mixture exhibited the most pronounced improvement in Rpmax, even though their viscosity remained relatively high. The strongest synergistic influence is observed at higher loading (>10 wt.%), while at lower concentrations the beneficial impact of combining both fillers decreases. This synergistic effect can be explained by interfacial interactions between the hydrophilic OX50 and the silane-modified R709 particles, which likely promote the formation of a transient percolated filler network. Such a structure may reduce the effective termination rate by limiting radical recombination while maintaining sufficient local monomer mobility, leading to a higher Rpmax.

However, at filler concentrations higher than 10 wt.% (

Figure 2d), all systems exhibited a reduction in the final double bond conversion

pf, indicating that increased viscosity and partial vitrification of the matrix restrict further chain growth. This confirms that, while moderate viscosity growth can enhance polymerisation kinetics through the Trommsdorff (gel) effect, excessive viscosity and network rigidity ultimately suppress monomer diffusion and limit the overall conversion.

3.3. Thermal Properties

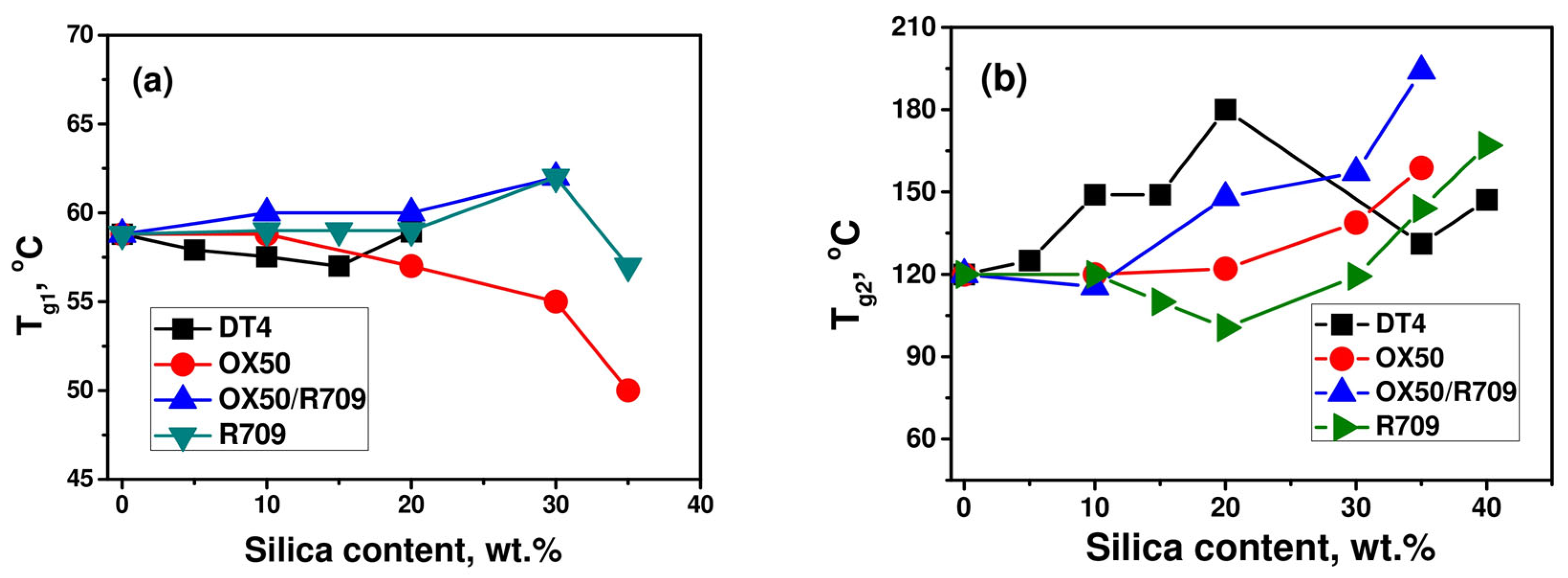

Figure 3 shows the dependence of

Tg on the silica content for each filler type. DSC analysis of the Bis-GMA/TEGDMA resin matrix revealed the presence of two distinct glass transition temperatures. The first transition was observed at approximately 60 °C, while the second occurred at approximately 120 °C. The appearance of two

Tg values indicates the presence of domains with different crosslink densities within the polymerised matrix and reflects the heterogeneous relaxation processes of the polymer network, which are strongly influenced by the filler–matrix interactions. The lower

Tg1 corresponds to more flexible regions enriched in TEGDMA, whereas the higher

Tg2 reflects the rigid Bis-GMA–rich network. Upon increasing the content of some silica fillers, the transition at ~60 °C progressively decreased and was no longer detectable at higher filler loadings. The composite then exhibited a single glass transition temperature at ~120 °C, which is attributed to the homogenised and stiffened polymer network resulting from filler–matrix interactions. This phenomenon originates from microphase separation and the heterogeneous course of photopolymerisation, where the more mobile TEGDMA chains react and organise differently from the highly crosslinked Bis-GMA regions, giving rise to domains with distinct segmental dynamics.

At low DT4 contents (≤15 wt.%), Tg1 exhibits a slight decrease. This effect is attributed to the formation of an interfacial layer around the silica nanoparticles, where the presence of silane coupling agents locally increases the mobility of the chain. The surface-bound methacrylate moieties and their interaction with TEGDMA create regions of reduced effective crosslink density and higher free volume, leading to a marginally lower Tg of the more flexible domains. Upon further addition of DT4 (>15 wt.%), the trend reverses: chain immobilisation at the filler interface becomes dominant and the interphase contributes to a reduction in segmental mobility, effectively increasing Tg1. In contrast, Tg2—associated with the rigid fraction of the network—increases strongly with filler loading up to ~20 wt.%. This pronounced increase (from ~120 °C to ~180 °C) reflects the efficient chemical integration of modified silica into the network, which enhances the effective crosslink density and restricts molecular motion in highly constrained domains. However, beyond 20 wt.% loading, Tg2 decreases again toward values characteristic of the neat matrix. This drop is attributed to particle agglomeration and incomplete silane coverage at high filler concentrations, which compromise the continuity of the filler–matrix coupling. The resulting defects and interfacial voids increase the local free volume, reducing the effective reinforcement of the rigid domains.

Incorporation of OX50 leads to a pronounced decrease in Tg1 with higher loadings. At 35 wt.%, Tg1 drops to ~50 °C, indicating enhanced segmental mobility. This effect likely arises from the poor compatibility of hydrophilic OX50 with the hydrophobic matrix, which promotes agglomeration and weakens interfacial adhesion. R709 and OX50/R709 show a stabilising effect on Tg1, with values slightly increasing at higher loadings. Modification of the methacrylate surface of R709 promotes chemical affinity to the resin matrix, improving interfacial bonding and reducing chain mobility compared to OX50 alone. The mixed OX50/R709 system behaves similarly, suggesting that the presence of R709 compensates for the weaker compatibility of OX50. Both systems also show a gradual increase in Tg2 with filler loading, with mixed filler producing the highest Tg2 (at 35–40 wt.%). This indicates that synergistic effects between hydrophilic and methacrylate-modified silica can optimise the filler dispersion and enhance crosslink density. These results demonstrate that surface modification and interfacial compatibility play a decisive role in controlling the low-temperature relaxation process. Poorly bonded OX50 particles act as mobility promoters, while reactive surfaces, such as in DT4 and R709, hinder segmental dynamics. In the case of R709, interfacial bonds appear less effective in restricting segmental dynamics, resulting in a reduced reinforcement of the rigid network domains.

3.4. Postpolymerisation

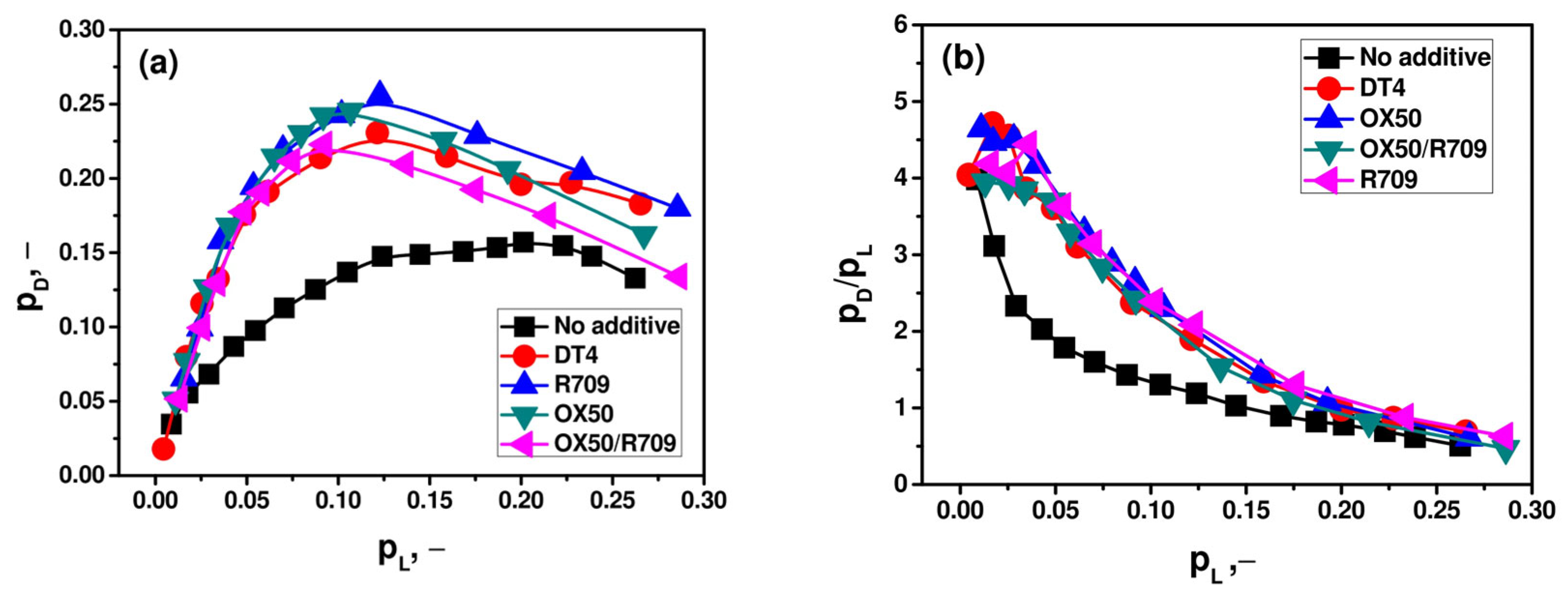

The post-curing effect was investigated using differential scanning calorimetry (DSC) at 25 °C. The study focused on composites containing 30 wt.% of silica fillers: DT4, R709, OX50, and the OX50/R709 mixture. The corresponding kinetic curves are presented in

Figure 4. Different irradiation times of the composites resulted in different degrees of double bond conversion (

pL). The relationship between the additional conversion that occurs after light exposure is stopped (

pD) and the degree of double bond conversion at the time of light interruption (

pL) is shown in

Figure 4b.

Figure 4 shows that the additional conversion of double bonds after termination of irradiation can be significant. The conversion at the moment of light interruption (

pL) initially increases until it reaches the value corresponding to the maximum polymerisation rate, after which it begins to decrease. The highest values of post-curing conversion (

pD) are obtained when irradiation is stopped at

Rpmax. This effect can be explained by the accumulation of a large number of active radicals generated during photopolymerisation up to the moment of light interruption.

Under continuous irradiation, the radical concentration increases steadily with reaction time since a stationary state is not established. After the light is switched off, the polymerisation proceeds in the dark until all active radicals are terminated. Consequently, the higher the conversion at which the irradiation is interrupted, the larger the additional conversion obtained during the dark reaction.

Beyond Rpmax, a decrease in radical activity is observed, which results from radical trapping within the forming polymer network. Under continuous irradiation, the radical concentration increases steadily with reaction time since a stationary state is not established. After the light is switched off, the polymerisation continues in the dark until all active radicals are terminated. Consequently, the higher the conversion at which the irradiation is interrupted, the larger the additional conversion obtained during the dark reaction.

The efficiency of the postpolymerisation process can be expressed by the ratio of pD to pL. This parameter reaches its highest values at the early stages of the reaction and gradually decreases with increasing pL. For all silica-filled composites, the post-curing effect follows a similar trend and is consistently higher than that of the neat monomer. The addition of surface-modified silica fillers enhances the magnitude of the dark reaction, which can be attributed to the stronger affinity of the fillers for the developing polymer matrix. This improved interaction likely facilitates radical stabilisation and prolongs their activity after light termination, thereby increasing the overall efficiency of postpolymerisation.

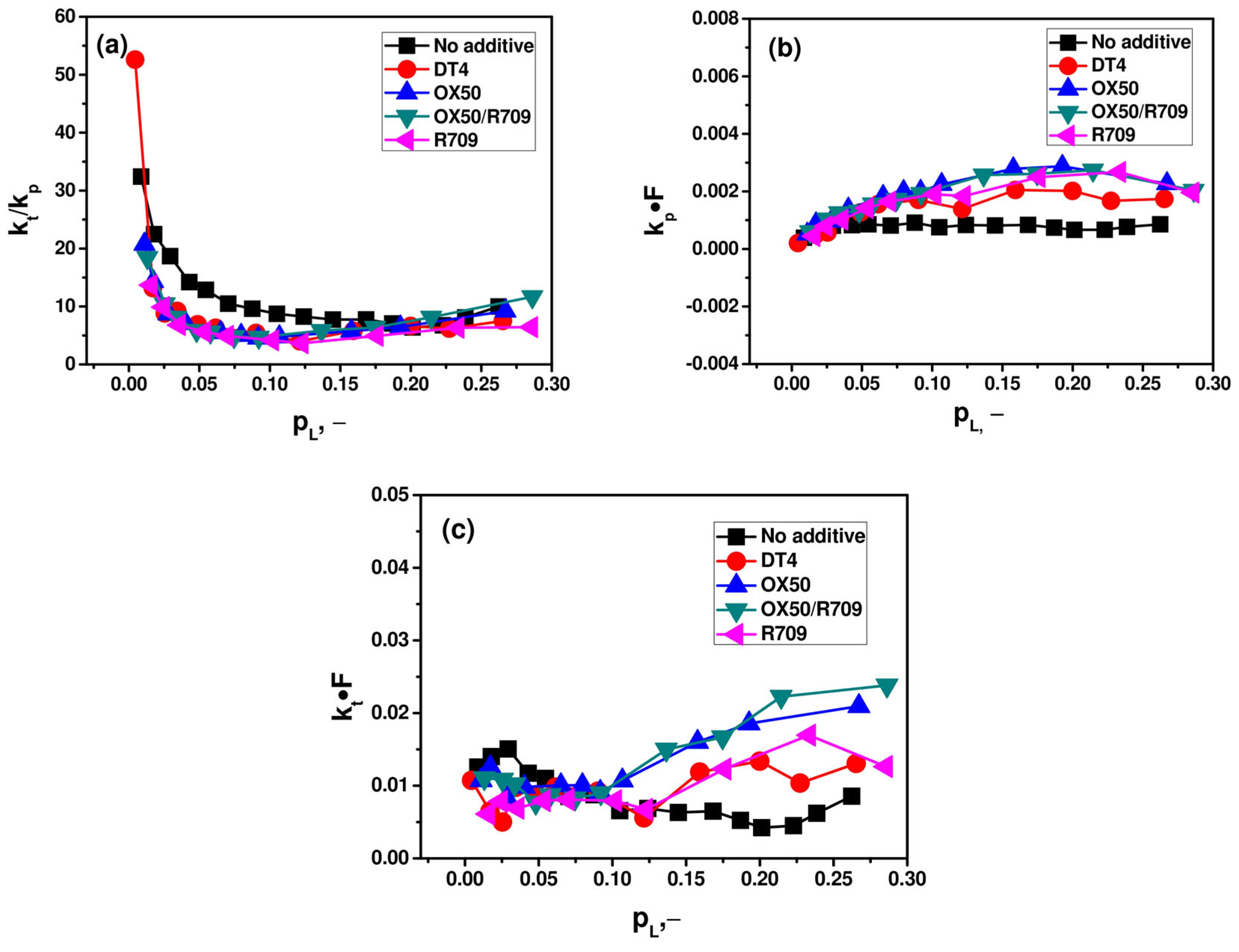

3.5. Propagation and Termination Rate Constant

Based on the interrupted irradiation experiments, the ratio

kt/

kp as well as the effective rate constants

kt·F and

kp·F were determined (

Figure 5). The dependence of

kt/

kp on the degree of double bond conversion is presented in

Figure 5a for the neat monomer mixture and for composites containing 30 wt.% of silica fillers DT4, OX50, R709 and OX50/R709.

At the early stages of polymerisation, the kt/kp ratio decreases with increasing conversion, and this decline is more pronounced for the composites compared to the neat Bis-GMA/TEGDMA mixture. A plateau is reached at approximately 5% conversion for the filled systems, while in the neat monomer, this point is shifted to around 10%. Beyond ~20% conversion, an apparent increase in the kt/kp ratio is observed in all systems.

Because a true increase in the bimolecular termination rate constant at higher conversions is physically implausible, the shape of the curves indicates the limitations of the applied kinetic model in this regime. The rise in the apparent kt/kp ratio after 20% conversion should therefore be interpreted as a manifestation of the dominant role of unimolecular termination. This effect originates from the significant slowing of macroradicals trapped within the developing polymer network, which prevents efficient bimolecular encounters under the experimental conditions.

For the systems analysed, individual values of the effective propagation and termination rate constants,

kp·F and

kt·F (where

F = Ia·ϕ,

ϕ—quantum yield of initiation,

Ia—absorbed light intensity) were determined. Their dependence on the degree of double bond conversion is shown in

Figure 5b,c.

For the neat monomer mixture, kp·F increases in the early stage of polymerisation and then reaches a stationary level. In contrast, silica-filled composites exhibit a different trend: kp·F continuously increases up to ~20% conversion, reaches a maximum and then decreases. Attainment of the stationary state at ~12% conversion corresponds to Rpmax. For the unfilled monomer, kt·F initially decreases, which may be attributed to the immediate onset of autoacceleration at the beginning of the reaction. This is followed by a plateau between 10% and 17% conversion, indicating that termination is diffusion-controlled within this range. Beyond 17% conversion, kt·F decreases further until ~20%, after which an increase is observed, consistent with the growing importance of unimolecular termination.

In composites containing silica fillers, kt·F shows an initial drop of up to ~7% conversion, followed by a continuous increase. This behaviour suggests that diffusion restrictions arising from the very high viscosity of the system strongly affect radical termination. As a result, the process becomes dominated by diffusion-controlled mechanisms and unimolecular termination. For 30 wt.% filler content, all silica-containing systems exhibited significantly higher values of the propagation rate constant (kp·F) compared to the unfilled monomer system. Kp·F increased with conversion up to approximately 0.15–0.20, with the most pronounced enhancement observed for the hybrid and R709 systems. Although the DT4-filled system displayed the lowest kp·F values among the composites, its performance was still superior to that of the neat resin. The silica-containing systems initially showed a decrease in kt·F up to approximately 0.07–0.10, followed by a marked increase at higher conversions. This trend was most pronounced for the R709 and OX50/R709 compounds, indicating dynamic changes in termination efficiency during network formation.

Since the termination rate coefficient (ktb) is inversely proportional to the viscosity of the system (ktb ~ 1/η), and the polymerisation rate (Rp) is related to the viscosity through Rp~1/(ktb)0.5, a higher initial viscosity of the formulation can lead to an increased polymerisation rate. Overall, the results clearly indicate that not only the filler content but also the physicochemical properties of the silica nanofillers (surface area, particle size, and surface chemistry) critically determine the rheological performance of the dental composites.

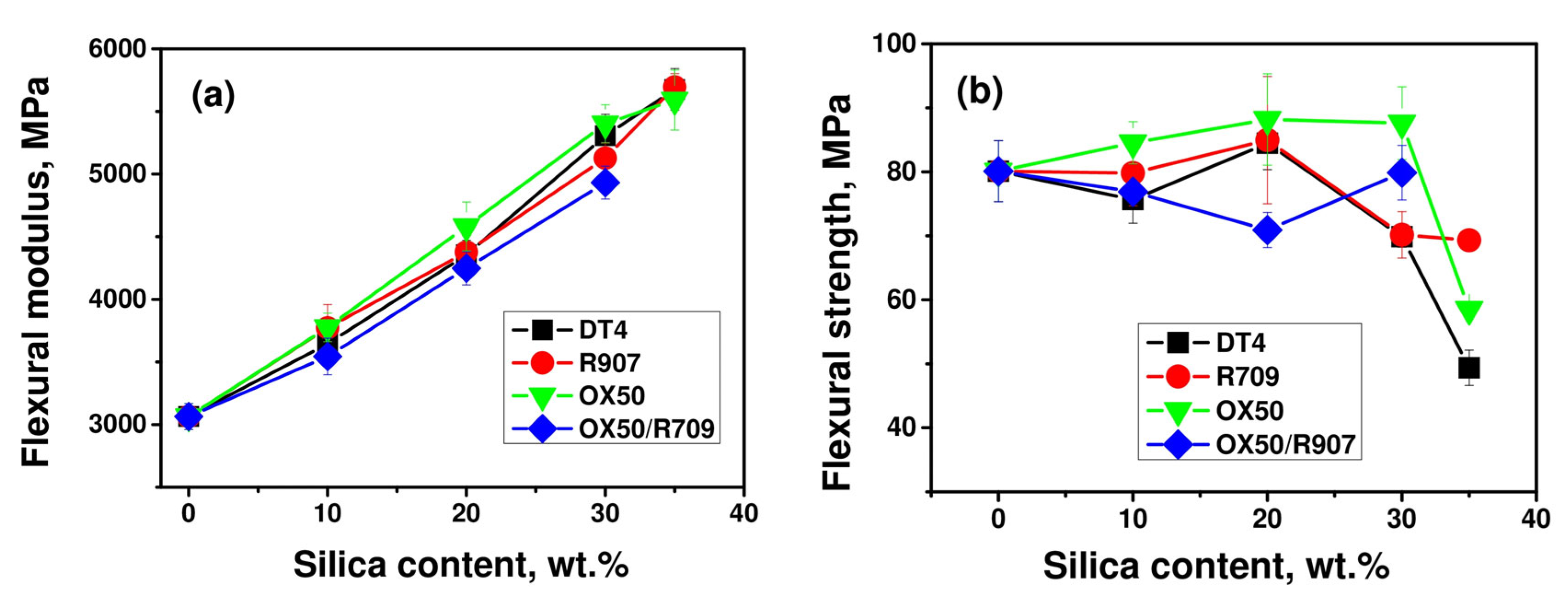

3.6. Mechanical Properties

Figure 6 shows the influence of filler loading on Young’s modulus for composites based on Bis-GMA/TEGDMA and different types of silica. In all cases, a clear increase in modulus was observed with increasing filler content in the 0–35 wt.% range. Already at 10 wt.% filler, all systems showed a noticeable increase in stiffness compared to the neat resin (~2900 MPa). As the filler content increased, the modulus continued to grow almost linearly, reaching values around 5400–5600 MPa at 35 wt.%. The highest modulus was obtained for the R709-filled composite, which slightly outperformed the others at the highest filler level. This could be due to an effective interaction between the methacrylated silica surface and the resin matrix, which improves stress transfer. The OX50 system also provided very good reinforcement, likely due to its fine dispersion, despite the lack of surface modification. Interestingly, the OX50/R709 system gave only slightly lower modulus values compared to the individual fillers, especially at low to moderate contents. At 35 wt.%, its performance became comparable, suggesting that hybridisation did not significantly enhance stiffness, although it may offer other benefits like better processability. DT4-filled composites gave slightly lower modulus values across all filler contents. This may result from higher surface activity and stronger chemical coupling, which limits local chain mobility but may not efficiently contribute to global stiffness due to possible filler clustering.

Figure 6b illustrates the dependence of flexural strength on filler content for composites containing different types of silica. DT4, OX50, R709, and a 1:1 mixture of OX50 and R709. For the unfilled resin, the flexural strength was approximately 80 MPa. Upon the addition of silica fillers, all systems initially showed an increase or retention of strength of up to 10–20 wt.%, indicating effective stress distribution and reinforcement at lower filler concentrations. The OX50-filled system exhibited the highest flexural strength values in this range, reaching a maximum of nearly 88 MPa at 20 wt.%.

However, with higher filler contents (≥30 wt.%), a pronounced decrease in flexural strength was observed across all formulations. This reduction is likely associated with increased filler-filler interactions, agglomeration, or microstructural defects that act as stress concentrators, compromising the mechanical integrity of the composite. The most significant drop was observed for the DT4 system, where strength fell below 50 MPa at 35 wt.% filler, possibly due to limited dispersion and strong chemical coupling that restricts matrix continuity.

The OX50/R709 and R709-alone systems maintained relatively better performance at higher loadings compared to DT4, suggesting more favourable dispersion and interface characteristics. However, even these systems demonstrated reduced strength at 35 wt.%, reinforcing the conclusion that excess filler content negatively impacts flexural performance, regardless of filler type. Experimental Bis-GMA/TEGDMA-based composites exhibited a linear increase in the flexural modulus from ~2900 MPa for neat resin to 5400–5600 MPa at 35 wt.% filler content. The flexural strength reached a maximum of ~88 MPa at 20 wt.% of filler, but decreased at higher filler loadings, probably due to filler agglomeration and reduced matrix continuity. Compared to commercial composites such as Filtek Z250, flexural strengths around 136–140 MPa and moduli of 7–8000 MPa, while Amelogen exhibits flexural strength up to 87 MPa [

32]. These results indicate that, although the experimental composites achieve competitive stiffness at moderate filler levels, further optimisation of filler dispersion and surface treatment is required to match the mechanical performance of commercial materials.

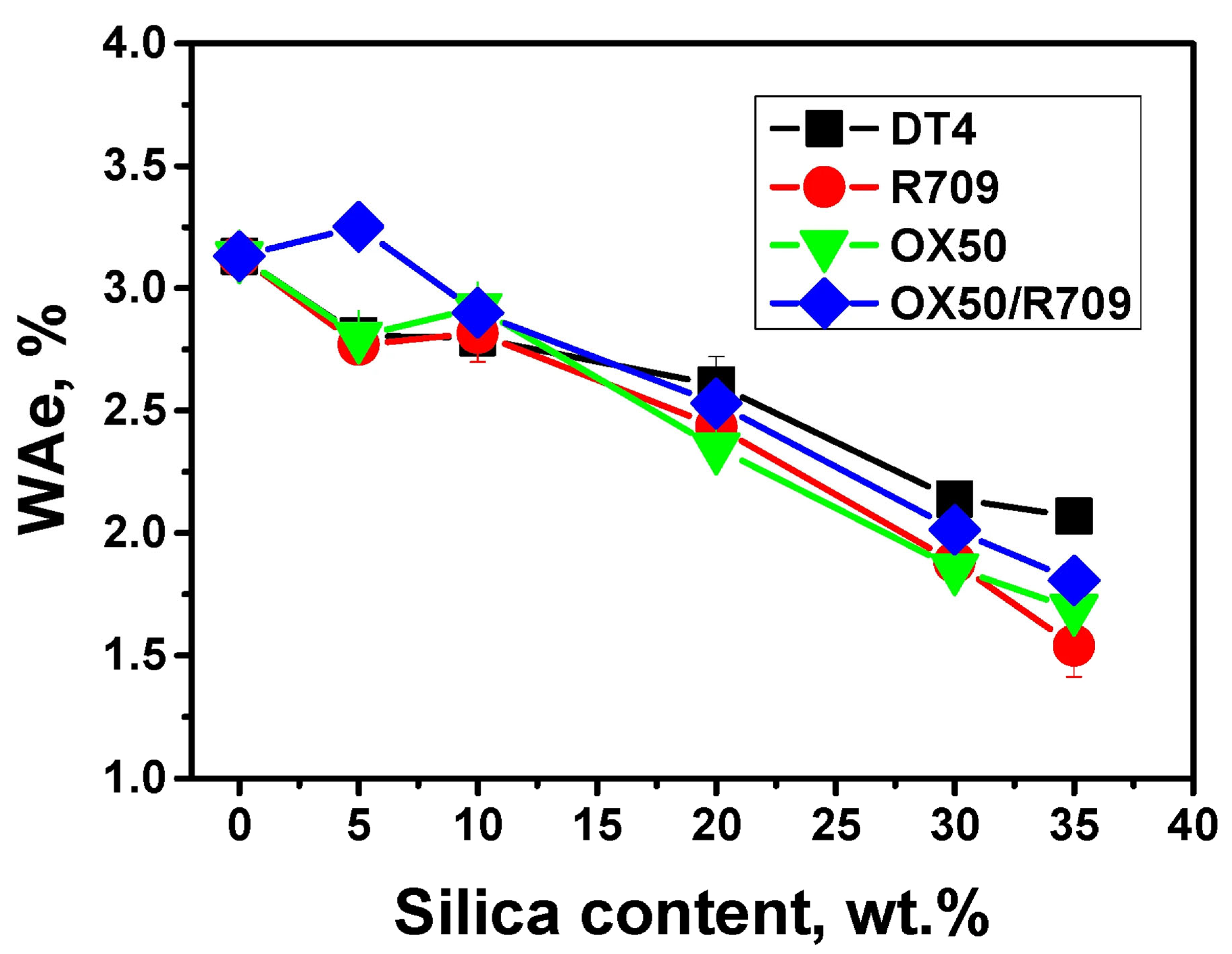

3.7. Water Sorption in the Swelling Equilibrium State

Figure 7 presents the relationship between water sorption in equilibrium swelling and the filler content for composites containing different types of silicas. Increasing the filler content resulted in a progressive decrease in water sorption, regardless of the filler type. For the unfilled system, the water uptake was approximately 3.2 wt.%, which is consistent with the known hydrophilic character of the Bis-GMA/TEGDMA resin matrix.

The highest water sorption was observed at low filler contents (0–5 wt.%), particularly for the OX50/R709 system, which showed a slight maximum near 5 wt.%, possibly due to increased surface area and limited network densification at this loading. This minor increase suggests that small amounts of filler can temporarily disrupt the matrix packing or create interfacial regions that facilitate water ingress. Beyond 10–15 wt.% filler, all systems exhibited a clear and nearly linear decline in water uptake, reaching values as low as 2.4–2.7 wt.% at 35 wt.% filler content. This trend can be attributed to the dilution of the hydrophilic organic matrix by the inorganic restricted mobility of the polymer chain. It can also lead to a denser network that limits water penetration or a physical blocking of diffusion pathways by well-dispersed filler particles.

Among the investigated composites containing different types of silicas, the systems filled with R709 and the OX50/R709 mixture exhibited the lowest water sorption values at high filler loadings. This behaviour can be attributed to the hydrophobic surface treatment of the R709 silica, which reduces its affinity for water, as well as to the improved particle packing in the OX50/R709 system that limits the formation of voids within the material. In contrast, the composites filled with DT4 consistently showed slightly higher water sorption across all filler contents, likely due to the high specific surface area of DT4 and its stronger chemical interaction with the resin matrix, which may lead to the formation of more extensive interfacial regions capable of retaining water molecules.

The composites cured with 30–35 wt.% of silica fillers exhibited water absorption of approximately 2 wt.%, which is within the acceptable limits defined by ISO 4049 for polymer-based dental restorative materials (40 μg/mm

3). In the literature, dental composites containing Bis-GMA and large amounts of TEGDMA as a diluent monomer have been reported to exhibit increased water sorption, sometimes reaching 3–6%, depending on monomer ratio, degree of conversion, network structure, and filler content. These findings were obtained based on studies of commercial composite formulations [

33].

4. Conclusions

This study systematically investigates the influence of different types of silica nanofillers (DT4, R709, OX50, and their OX50/R709 mixture) on the rheological, photopolymerisation, thermal, mechanical, and sorption properties of Bis-GMA/TEGDMA-based dental composites. The results reveal that both the physicochemical characteristics of the fillers (surface area, surface modification, particle size) and their concentration critically affect the overall performance of the composite systems.

Viscosity measurements demonstrated significant differences between fillers. OX50 and especially the OX50/R709 mixture led to rapid and nonlinear increases in viscosity due to the formation of extensive filler networks, even at moderate loadings. In contrast, DT4 and R709, both surface-modified, showed more gradual viscosity increases, indicating better dispersion and reduced filler–filler interactions. These rheological behaviours strongly correlated with photopolymerisation kinetics. DT4 promoted the highest polymerisation rates (Rpmax) and conversion at moderate filler contents, while excessive loading led to reduced final conversion due to mobility limitations. The OX50 system showed the lowest conversion values, attributed to its hydrophilic nature and high viscosity. Interestingly, the OX50/R709 mixture system exhibited a synergistic effect, with the highest increase in polymerisation rate at low filler contents (10 wt.%), outperforming both parent fillers used individually.

Thermal analysis revealed dual glass transitions in the base resin, associated with TEGDMA-rich and Bis-GMA-rich domains. The presence of fillers affected these transitions differently. At higher loadings, the lower transition (Tg1) disappeared, and a dominant higher Tg was observed, indicating a more homogeneous and rigid network. DT4 contributed to the highest Tg values due to its strong interfacial bonding, while OX50 caused a reduction in Tg1 and limited reinforcement. The OX50/R709 mixture improved Tg2 values most efficiently, suggesting synergistic network stiffening.

Post-curing studies confirmed that all fillers enhanced dark polymerisation efficiency, particularly when light exposure was stopped at the point of maximum polymerisation rate. Surface-modified fillers (R709, DT4) were more effective in stabilising active radicals, leading to greater postpolymerisation gains. Kinetic analysis of propagation and termination constants showed increased kp·F values for all filled systems, particularly for R709 and OX50/R709, correlating with better network formation. Termination became increasingly diffusion-controlled at higher conversions, especially in highly filled systems.

Mechanical testing revealed that filler addition significantly increased Young’s modulus across all systems, with R709-filled composites displaying the highest stiffness. However, flexural strength showed a peak at intermediate filler contents (10–20 wt.%) and declined at higher loadings due to agglomeration and network discontinuities. DT4-filled composites, while chemically active, exhibited the lowest flexural strength at 35 wt.%. The mixed filler system provided a balanced mechanical performance, combining stiffness and moderate strength retention.

Water sorption decreased with increasing filler content across all systems, due to matrix densification and reduced free volume. R709 and OX50/R709 systems showed the lowest equilibrium water uptake, benefiting from hydrophobic surface treatment and improved filler dispersion. DT4 and OX50 systems absorbed more water, attributed to their surface characteristics and less effective interfacial sealing.

Silica DT4 proved to be a highly effective nanosilica filler; however, its content should not exceed 20 wt.% as higher loadings lead to a deterioration of mechanical properties, increased water sorption, and a negative impact on polymerisation kinetics and the final double bond conversion. Silica R709 provided the highest mechanical stiffness and the lowest water sorption, making it the most suitable filler for applications requiring high dimensional stability, with an optimal OX50 loading of around 20 wt.%. Due to its hydrophilic surface and strong filler–filler interactions, it is less favourable for direct use in polymer matrices; however, it can effectively contribute to structural rigidity when combined with silane-modified fillers. The OX50/R709 mixed system exhibited a clear synergistic effect at low to moderate filler contents (around 10–15 wt.%), combining enhanced polymerisation kinetics and balanced mechanical performance. These findings suggest that mixing nanosilica fillers with complementary surface characteristics represents an effective strategy for optimising the performance of methacrylate-based dental composites, consistent with the design approach used in commercial restorative materials.