Morphological Characterization of Fe2B Borided Layers on AISI 9254 Steel Using Reused Boron Paste: A Classical and Fractal Approach

Abstract

1. Introduction

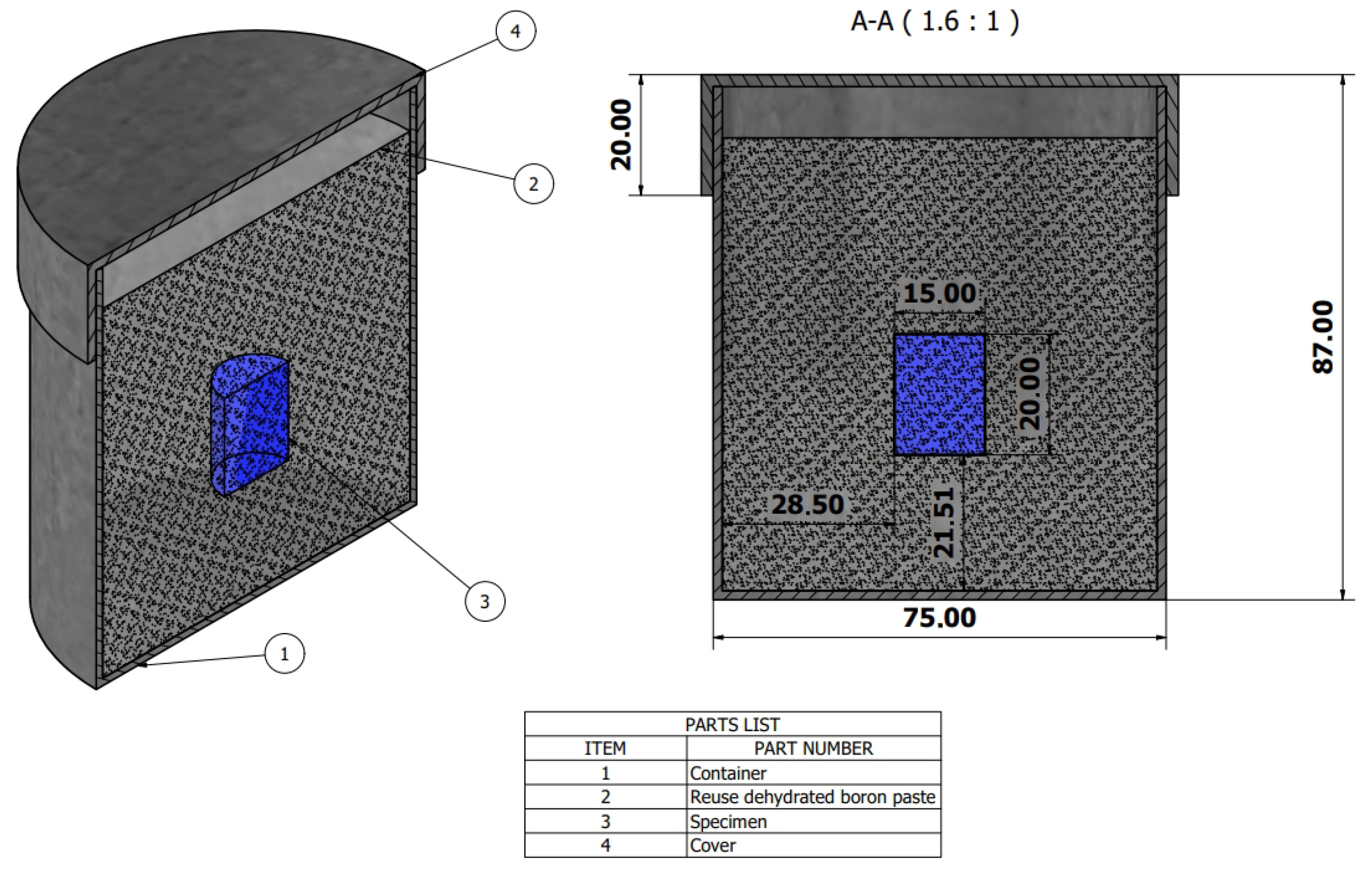

2. Materials and Methods

2.1. Mechanical Characterization

2.1.1. Materials and Surface Treatment

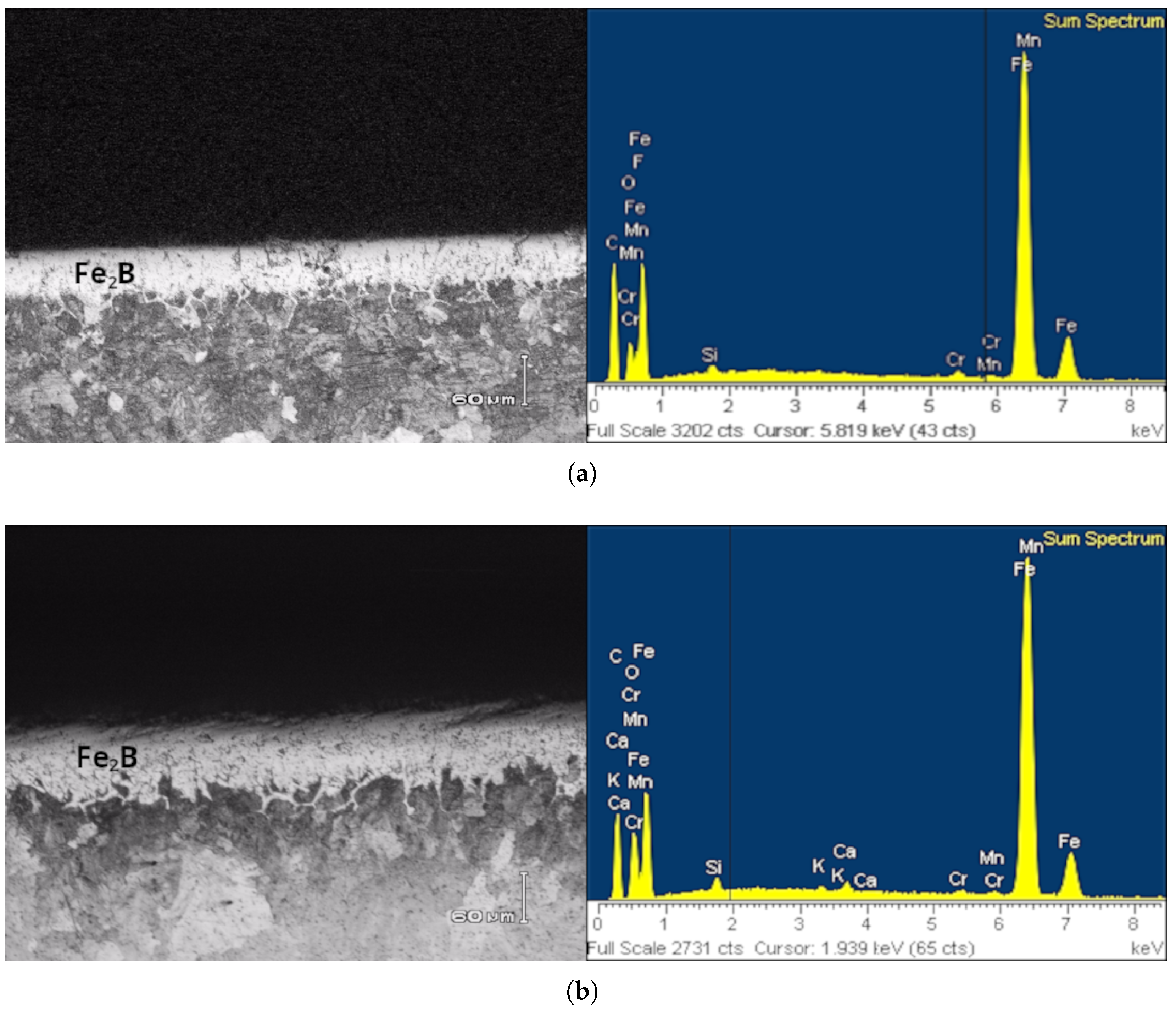

2.1.2. Characterization of Iron Boride

2.2. Fractal Statistical Characterization

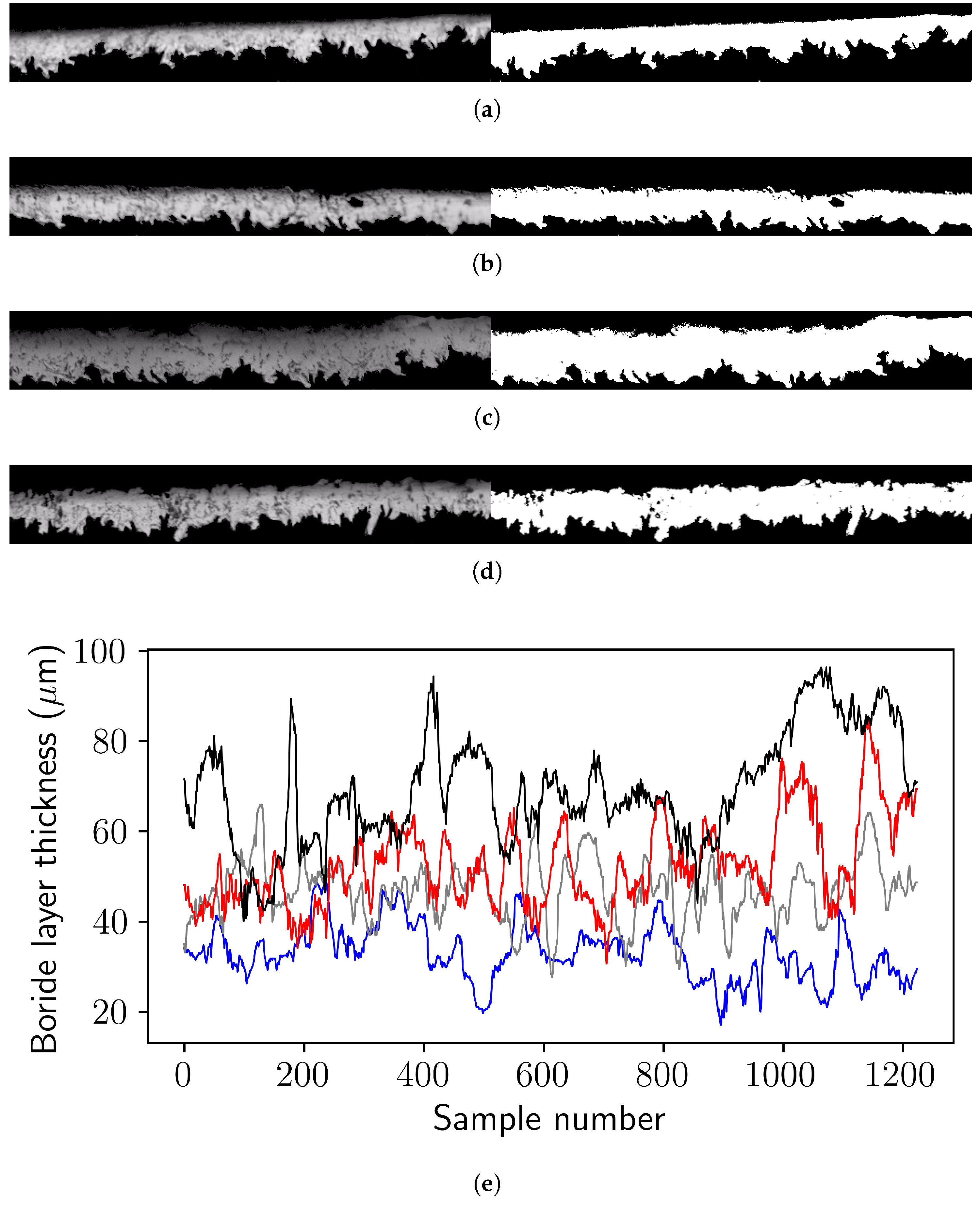

Characterization of Borided Layer Morphology

3. Results and Discussion

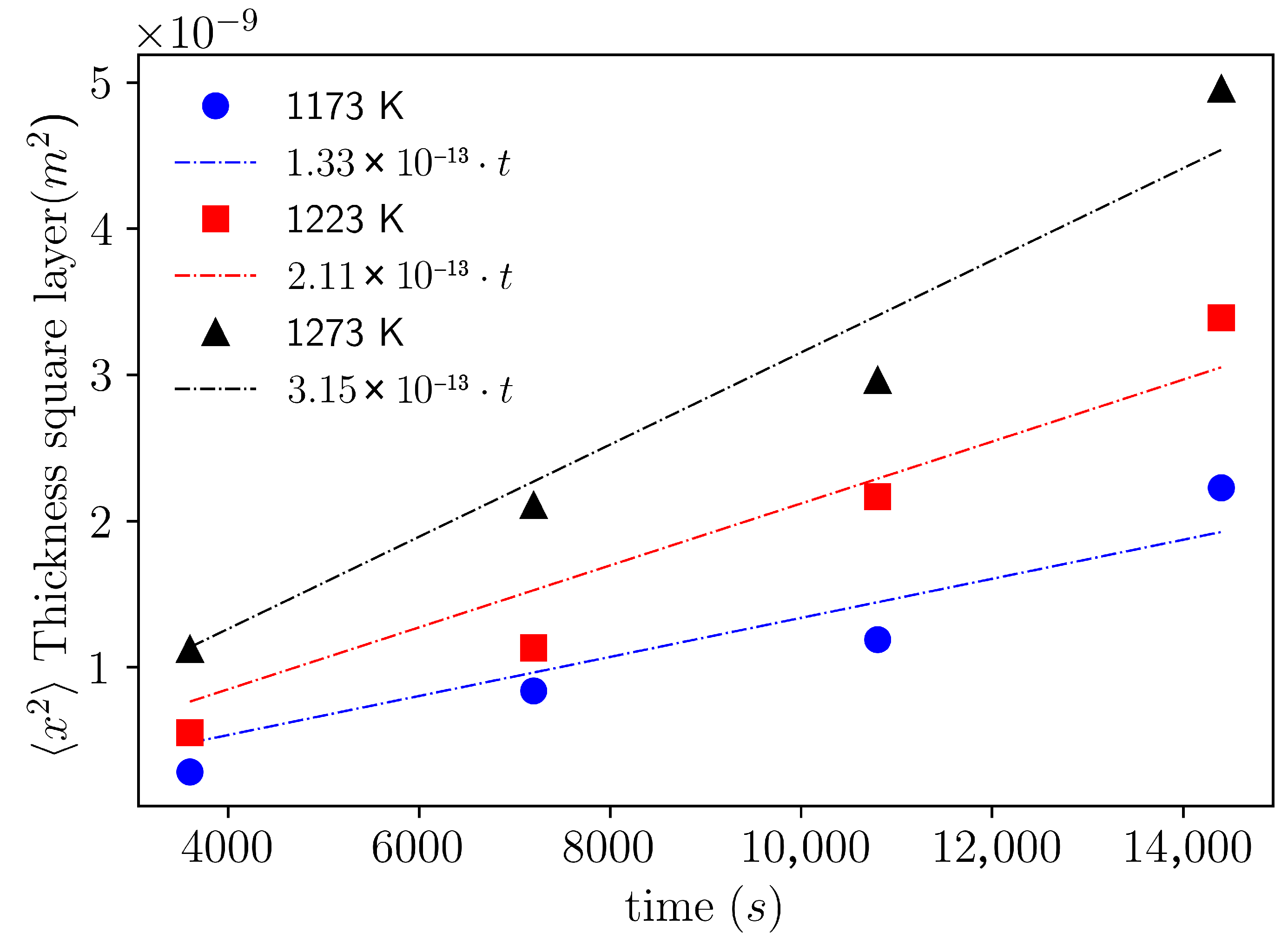

3.1. Thickness of the Iron Boride Layer

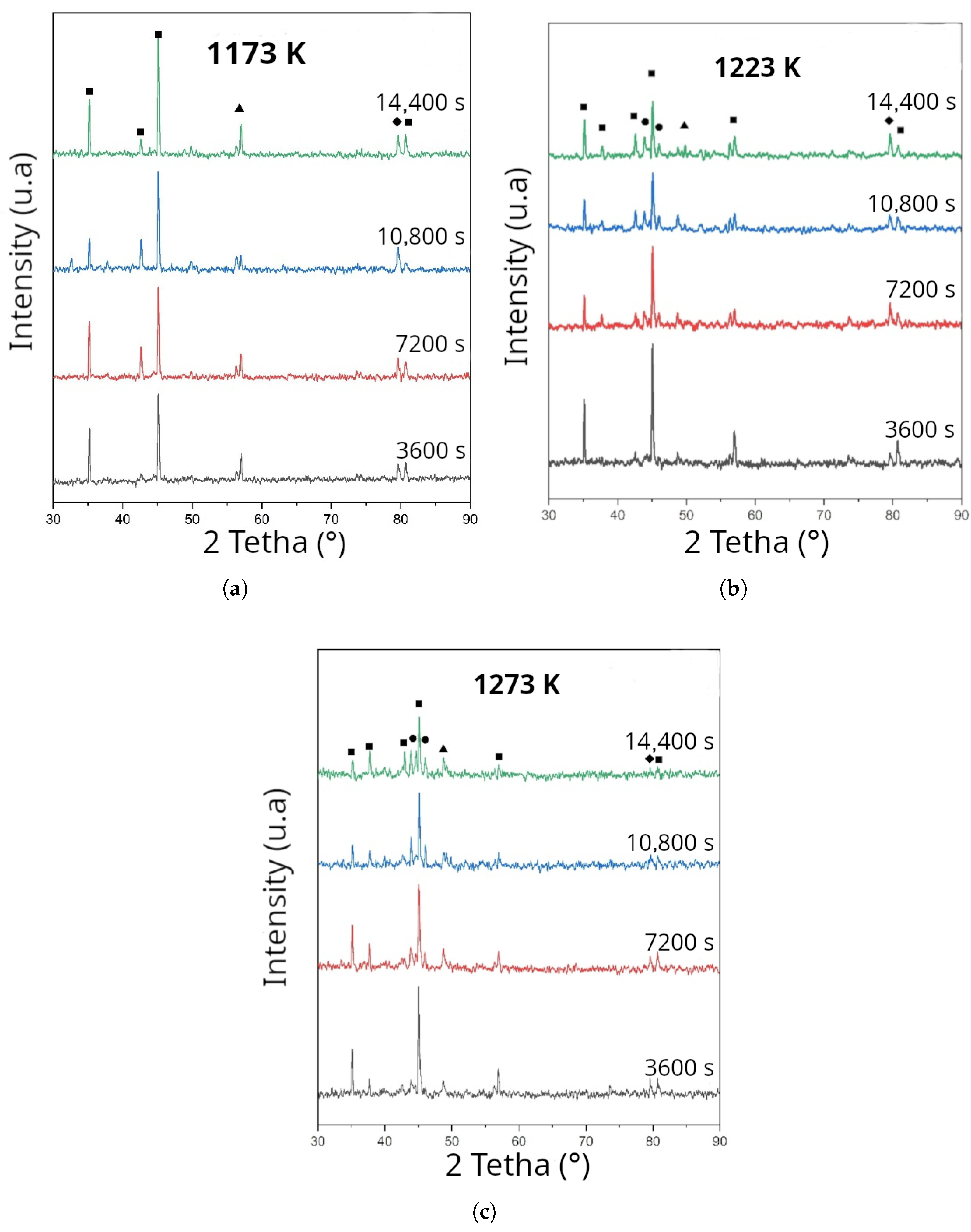

3.2. X-Ray Diffraction

3.3. Vickers Microhardness

3.4. Adhesion

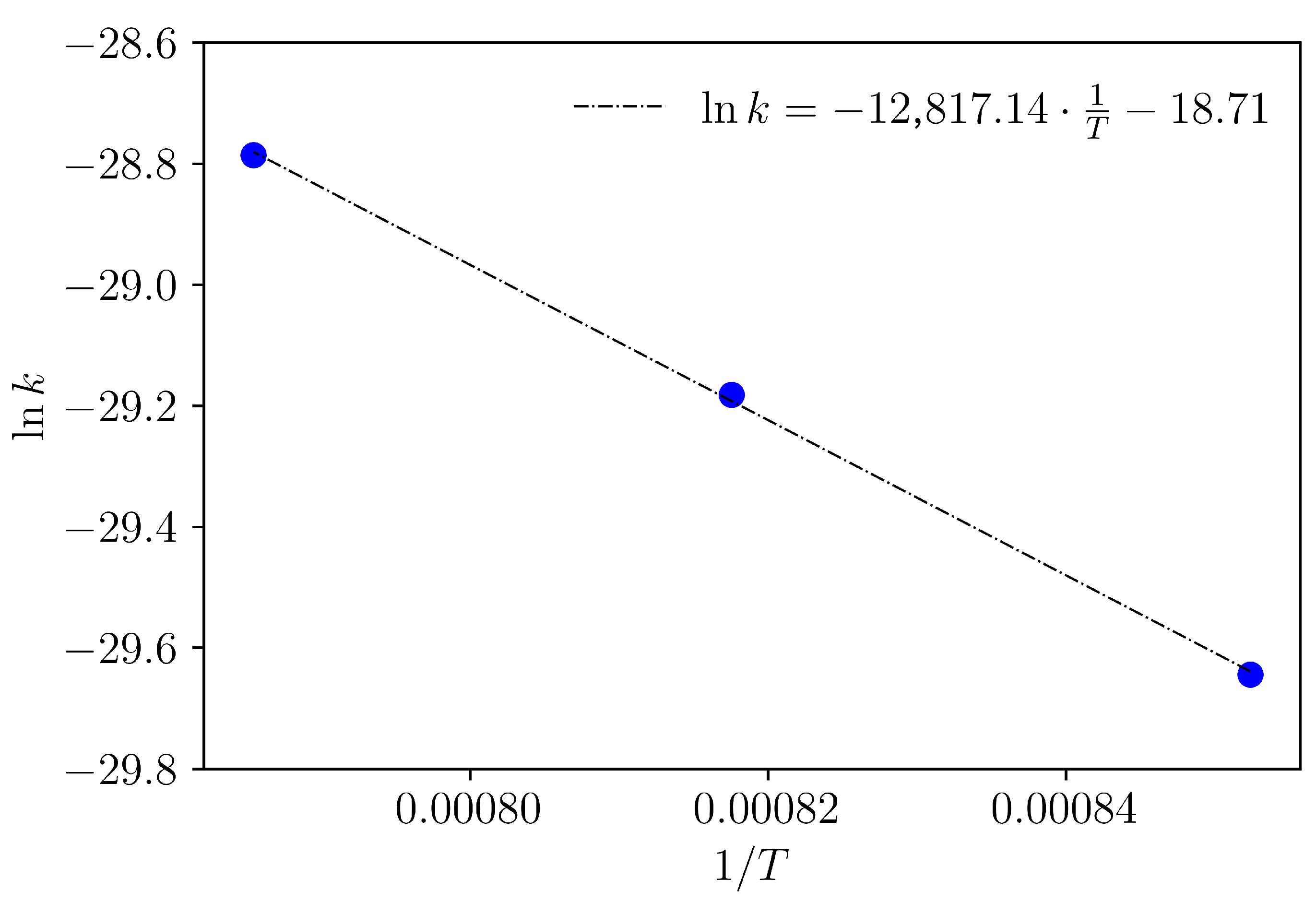

3.5. Activation Energy

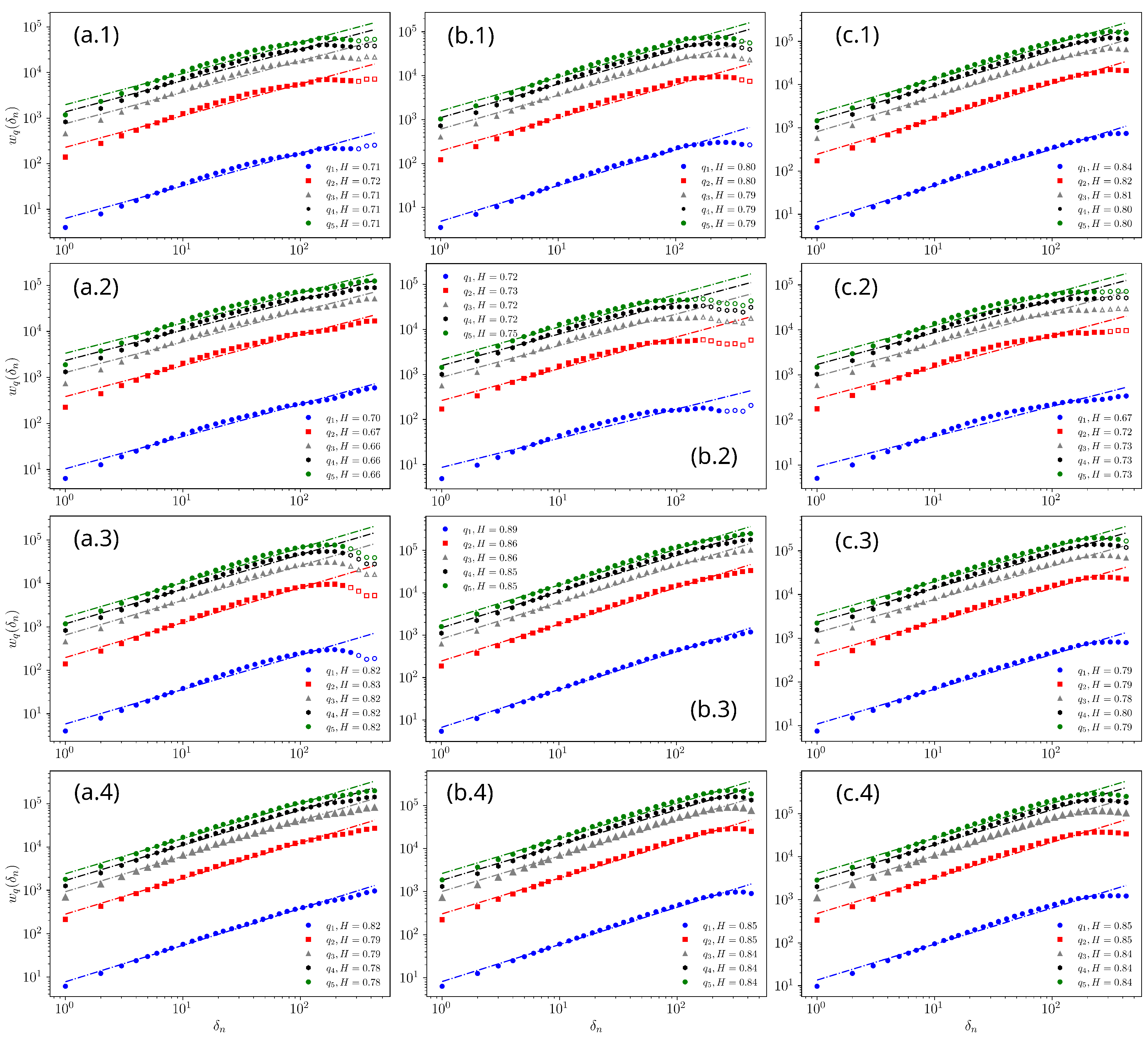

3.6. Fractal Characterization of the Morphology of Borided Layers

4. Conclusions

- The Fe2B layers developed on the steel surface exhibited a saw-tooth morphology, and their thickness increased with the boriding temperature. The maximum boride layer thickness was recorded in the sample subjected to boriding at 1273.15 K, with a measurement of 69.35

- X-ray diffraction analysis revealed the formation of borides under all treatment conditions, specifically Fe2B, CrB, and Mn2B. The hardness of the boride layer formed on AISI 9254 steel showed an increase up to 1620 HV. Additionally, localized hardness reduction was observed in the transition regions.

- The adhesion tests showed HF1 and HF2 failure modes for the iron boride layer, indicating good adhesion to the AISI 9254 substrate. Therefore, the coatings obtained may have applications in various manufacturing areas.

- The activation energy was evaluated using the traditional Arrhenius-type diffusion model, resulting in an estimated value of 106 kJ .

- Within the characterization of the saw-tooth type growth fronts, their roughness was assessed. These fronts were characterized by Hurst exponents within the range associated with statistical persistence, meaning that they are governed by long-range memory processes, which implies more homogeneous growth fronts.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Matuschka, A. Boronizing; Library of Congress: Philadelphia, PA, USA, 1980; p. 97. [Google Scholar]

- Fichtl, W. Boronizing and its practical applications. Mater. Des. 1981, 2, 276–286. [Google Scholar] [CrossRef]

- Prince, M.; Raj, G.S.; Kumar, D.Y.; Gopalakrishnan, P. Boriding of Steels: Improvement of Mechanical Properties-a Review. High Temp. Mater. Processes Int. Q. High-Technol. Plasma Processes 2022, 26, 43–89. [Google Scholar] [CrossRef]

- Dearnley, P.A.; Bell, T. Engineering the Surface with Boron Based Materials. Surf. Eng. 1985, 1, 203–217. [Google Scholar] [CrossRef]

- Campos-Silva, I.E.; Rodríguez-Castro, G.A. Boriding to improve the mechanical properties and corrosion resistance of steels. In Thermochemical Surface Engineering of Steels; Woodhead Publishing: Cambridge, UK, 2015; pp. 651–702. [Google Scholar] [CrossRef]

- Winter, K.M.; Kalucki, J.; Koshel, D. Process technologies for thermochemical surface engineering. In Thermochemical Surface Engineering of Steels; Woodhead Publishing: Cambridge, UK, 2015; pp. 141–206. [Google Scholar] [CrossRef]

- Murathan, Ö.F.; Davut, K.; Kilicli, V. Effect of austenitizing temperatures on the microstructure and mechanical properties of AISI 9254 steel. Mater. Test. 2021, 63, 48–54. [Google Scholar] [CrossRef]

- Charee, W.; Tangwarodomnukun, V. Experimental investigation and modeling of laser surface melting process for AISI 9254 commercially high silicon spring steel. Opt. Laser Technol. 2019, 115, 109–117. [Google Scholar] [CrossRef]

- Ortiz-Domínguez, M.; Morales-Robles, Á.; Gómez-Vargas, O.; Solis-Romero, J. Recycling of the Powder-pack Boriding Mixture: Microstructural Characterization of Fe2B Layers on ASTM A36 Steel. Microsc. Microanal. 2020, 26, 2220–2222. [Google Scholar] [CrossRef]

- Sinha, A. Metals Handbook, Volume 4: Heat Treating—Boriding (Boronizing) of Steels; ASM International: Materials Park, OH, USA, 1991; Volume 4, pp. 978–999. [Google Scholar]

- Perrusquia, N.L.; Ruiz, M.D.; Bustos, E.G.; Torres, C.R.; Miguel, S.; Domínguez, V.O. Microstructural Characterization on AISI 4140 Steel Boriding by New and Reused Dehydrated Boron Paste. Microsc. Microanal. 2020, 26, 1462–1463. [Google Scholar] [CrossRef]

- Kulka, M. Current Trends in Boriding; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Campos-Silva, I.; Balankin, A.S.; Sierra, A.H.; López-Perrusquia, N.; Escobar-Galindo, R.; Morales-Matamoros, D. Characterization of rough interfaces obtained by boriding. Appl. Surf. Sci. 2008, 255, 2596–2602. [Google Scholar] [CrossRef]

- Morales, O.; Campos, I.; Martínez, J.; Tejeida, R.; Balankin, A. Self-Affine Patterns of Boride Layers. Mater. Sci. Forum 2007, 553, 27–32. [Google Scholar] [CrossRef]

- Campos, I.; Ramírez, G.; VillaVelázquez, C.; Figueroa, U.; Rodríguez, G. Study of microcracks morphology produced by Vickers indentation on AISI 1045 borided steels. Mater. Sci. Eng. A 2008, 475, 285–292. [Google Scholar] [CrossRef]

- Olivares-Luna, M.; Rosales-Lopez, J.L.; Castillo-Vela, L.E.; Chaparro-Pérez, K.D.; Delgado-Brito, A.M.; Mejía-Caballero, I.; Campos-Silva, I. Insights on the pulsed-DC powder-pack boriding process: The role of the electric charge on the growth of the boride layer and the semiconductor behavior of the boriding media. Surf. Coatings Technol. 2024, 480, 130588. [Google Scholar] [CrossRef]

- Orihel, P.; Ptačinová, J.; Gogola, P.; Keddam, M.; Jurči, P. Pack-boriding of Sleipner steel: Microstructure analysis and kinetics modeling. Mater. Test. 2024, 66, 43–55. [Google Scholar] [CrossRef]

- Ortiz-Domínguez, M.; Morales-Robles, Á.J.; Gómez-Vargas, O.A.; de Jesús Cruz-Victoria, T. Analysis of Diffusion Coefficients of Iron Monoboride and Diiron Boride Coating Formed on the Surface of AISI 420 Steel by Two Different Models: Experiments and Modelling. Materials 2023, 16, 4801. [Google Scholar] [CrossRef] [PubMed]

- İpek Ayvaz, S. Growth Kinetics and Microstructure of Iron Boride Layers on AISI 1050 Steel. Met. Sci. Heat Treat. 2024, 65, 751–757. [Google Scholar] [CrossRef]

- Ortiz-Domínguez, M.; Keddam, M. Modelling boron diffusion for Fe2B layer formation: Comparative kinetics analysis in pack-boronized AISI 4147 steel. Mater. Test. 2023, 65, 1539–1550. [Google Scholar] [CrossRef]

- Ortiz-Dominguez, M.; Keddam, M. Diffusion Kinetics and Characterization of Fe2B Coatings Grown Thermochemically on Steel ASTM A709. Met. Sci. Heat Treat. 2024, 65, 538–546. [Google Scholar] [CrossRef]

- Wahl, G. Boronizing, a method for the production of hard surfaces for extreme wear. In Durferrit-Technical Information; Durferrit GmbH: Mannheim, Germany, 1975; pp. 785–789. [Google Scholar]

- Ruiz, M.A.D.; Perrusquia, N.L.; Huerta, D.S.; Miguel, C.R.T.S.; Calderón, G.M.U.; Moreno, E.A.C.; Suarez, J.V.C. Growth kinetics of boride coatings formed at the surface AISI M2 during dehydrated paste pack boriding. Thin Solid Film. 2015, 596, 147–154. [Google Scholar] [CrossRef]

- VDI 3198:1992-08; Beschichten von Werkzeugen der Kaltmassivumformung; CVD- und PVD-Verfahren. DIN: Berlin, Germany, 1992.

- Balankin, A.S.; Otamendi, E.G.; Samayoa, D.; Patiño, J.; Rodríguez, M.A. Depinning and creeplike motion of wetting fronts in weakly vibrated granular media. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2012, 85, 036313. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. Fractals and Scaling in Finance; Springer: New York, NY, USA, 1997. [Google Scholar] [CrossRef]

- Peitgen, H.O.; Jürgens, H.; Saupe, D. Chaos and Fractals; Springer: New York, NY, USA, 1992. [Google Scholar] [CrossRef]

- Xie, F.; juan Wang, X.; wei Pan, J. Accelerate pack boriding with reused boriding media by simultaneously employing Al and alternating current field. Vacuum 2017, 141, 166–169. [Google Scholar] [CrossRef]

- Sezgin, C.T.; Hayat, F. The effects of boriding process on tribological properties and corrosive behavior of a novel high manganese steel. J. Mater. Process. Technol. 2022, 300, 117421. [Google Scholar] [CrossRef]

- Neccaroglu, V.; Karademir, I.; Unal, O. Effects of pack boriding temperature on wear and corrosion performance of high-strength armor steel. Emerg. Mater. Res. 2025, 14, 83–97. [Google Scholar] [CrossRef]

- Laidler, K.J. The development of the Arrhenius equation. J. Chem. Educ. 1984, 61, 494. [Google Scholar] [CrossRef]

- Sánchez-Fuentes, Y.; Linares-Duarte, L.A.; Balderas-López, J.A.; Miranda-Hernández, J.G.; Tadeo-Rosas, R.; Proa-Coronado, C.; Hernández-Sánchez, E. Effect of boriding time on the effective thermal diffusivity of the borided AISI 1018 steel. Sci. Rep. 2025, 15, 19125. [Google Scholar] [CrossRef]

- Góral, M.; Kościelniak, B.; Ochał, K.; Kubaszek, T.; Jopek, J.; Drajewicz, M. The Structure of Boride Diffusion Coatings Produced on Selected Grades of Structural Steels. Solid State Phenom. 2024, 355, 95–100. [Google Scholar] [CrossRef]

- Omar, N.; Hassan, R.; Masripan, N. Kinetic study of boronized AISI 304 ball bearing using new and used boronizing powder. Proc. Mech. Eng. Res. Day 2017, 2017, 338–339. [Google Scholar]

- Fuentes, L.S.; Perrusquia, N.L.; Espinosa, M.C.E.; Máximo, D.V.M.; de la Mora Ramírez, T.; Domínguez, V.H.O.; Ruiz, M.A.D. Adhesion Characterization on AISI 9254 steel boriding. Microsc. Microanal. 2024, 30, 1273–1275. [Google Scholar] [CrossRef]

- Erdemir, A.; Eryillmaz, O.; Sista, V. Ultra-Fast Boriding for Improved Efficiency and Reduced Emissions in Materials Processing Industries; Argonne National Lab.: Argonne, IL, USA, 2012. [Google Scholar] [CrossRef]

- Daas, A.; Allaoui, L.A.; Zidelmel, S.; Allaoui, O. Paste Borided Layers Produced on XC38 Steel Using a New Activator. Mater. Perform. Charact. 2020, 9, 392–399. [Google Scholar] [CrossRef]

- Keddam, M.; Bouarour, B.; Abdellah, Z.N.; Chegroune, R. The effective diffusion coefficient of boron in the Fe2B layers formed on the iron substrate. MATEC Web Conf. 2013, 3, 01012. [Google Scholar] [CrossRef]

- Keddam, M.; Ortiz-Domínguez, M.; Elias-Espinosa, M.; Damián-Mejía, O.; Arenas-Flores, A.; Gómez-Vargas, O.A.; Abreu-Quijano, M.; Aldana-González, J.I.; Zuno-Silva, J. Growth Kinetics of the Fe2B Coating on AISI H13 Steel. Trans. Indian Inst. Met. 2015, 68, 433–442. [Google Scholar] [CrossRef]

- Chegroune, R.; Keddam, M.; Abdellah, Z.; Ulker, S.; Taktak, S.; Gunes, I. Characterization and kinetics of plasma-paste-borided AISI 316 steel. Mater. Technol. 2016, 50, 263–268. [Google Scholar] [CrossRef]

- Balankin, A.S. Dynamic scaling approach to study time series fluctuations. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2007, 76, 056120. [Google Scholar] [CrossRef]

- Barabási, A.L.; Vicsek, T. Multifractality of self-affine fractals. Phys. Rev. A 1991, 44, 2730–2733. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. Harold Edwin Hurst. In Statisticians of the Centuries; Springer: New York, NY, USA, 2001; pp. 335–338. [Google Scholar] [CrossRef]

| Temperature | ||||||

|---|---|---|---|---|---|---|

| 1173.15 (K) | 1223.15 (K) | 1273.15 (K) | ||||

| Time (s) |

Thickness Layer () |

Standard Deviation |

Thickness Layer () |

Standard Deviation |

Thickness Layer () |

Standard Deviation |

| 3600 | 16.07 | 4.9 | 23.07 | 4.44 | 32.93 | 6.11 |

| 7200 | 27.83 | 7.92 | 34.11 | 5.92 | 46.78 | 6.58 |

| 10,800 | 34.09 | 5.08 | 46.06 | 6.58 | 52.57 | 9.53 |

| 14,400 | 46.55 | 7.75 | 57.74 | 7.63 | 69.35 | 12.05 |

| Temperature (K) | |||

|---|---|---|---|

| 1173.5 | 1223.15 | 1273.15 | |

| Time (s) | Adhesion | ||

| 3600 | HF2 | HF1 | HF1 |

| 7200 | HF2 | HF1 | HF1 |

| 10,800 | HF2 | HF1 | HF1 |

| 14,400 | HF2 | HF1 | HF1 |

| Temperature (K) | ||||

|---|---|---|---|---|

| Time (s) | 1173 | 1223 | 1273 | |

| Hurst Exponent (H) | ||||

| 0.71 | 0.80 | 0.84 | ||

| 0.72 | 0.80 | 0.82 | ||

| 3600 s | 0.71 | 0.79 | 0.81 | |

| 0.71 | 0.79 | 0.80 | ||

| 0.71 | 0.79 | 0.80 | ||

| 0.70 | 0.72 | 0.67 | ||

| 0.67 | 0.73 | 0.72 | ||

| 7200 s | 0.66 | 0.72 | 0.73 | |

| 0.66 | 0.72 | 0.73 | ||

| 0.66 | 0.75 | 0.73 | ||

| 0.82 | 0.89 | 0.79 | ||

| 0.83 | 0.86 | 0.79 | ||

| 10,800 s | 0.82 | 0.86 | 0.78 | |

| 0.82 | 0.85 | 0.80 | ||

| 0.82 | 0.85 | 0.79 | ||

| 0.82 | 0.86 | 0.85 | ||

| 0.79 | 0.85 | 0.85 | ||

| 14,400 s | 0.79 | 0.85 | 0.84 | |

| 0.78 | 0.84 | 0.84 | ||

| 0.78 | 0.84 | 0.84 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez-Fuentes, L.; Matias-Gutierres, S.; García-Otamendi, E.I.; Sánchez-Chávez, H.D.; García-Bustos, E.D.; Doñu-Ruiz, M.A.; López-Perrusquia, N. Morphological Characterization of Fe2B Borided Layers on AISI 9254 Steel Using Reused Boron Paste: A Classical and Fractal Approach. Coatings 2025, 15, 1301. https://doi.org/10.3390/coatings15111301

Sánchez-Fuentes L, Matias-Gutierres S, García-Otamendi EI, Sánchez-Chávez HD, García-Bustos ED, Doñu-Ruiz MA, López-Perrusquia N. Morphological Characterization of Fe2B Borided Layers on AISI 9254 Steel Using Reused Boron Paste: A Classical and Fractal Approach. Coatings. 2025; 15(11):1301. https://doi.org/10.3390/coatings15111301

Chicago/Turabian StyleSánchez-Fuentes, Lizbeth, Sergio Matias-Gutierres, Edgar Israel García-Otamendi, Hugo David Sánchez-Chávez, Ernesto David García-Bustos, Marco Antonio Doñu-Ruiz, and Noé López-Perrusquia. 2025. "Morphological Characterization of Fe2B Borided Layers on AISI 9254 Steel Using Reused Boron Paste: A Classical and Fractal Approach" Coatings 15, no. 11: 1301. https://doi.org/10.3390/coatings15111301

APA StyleSánchez-Fuentes, L., Matias-Gutierres, S., García-Otamendi, E. I., Sánchez-Chávez, H. D., García-Bustos, E. D., Doñu-Ruiz, M. A., & López-Perrusquia, N. (2025). Morphological Characterization of Fe2B Borided Layers on AISI 9254 Steel Using Reused Boron Paste: A Classical and Fractal Approach. Coatings, 15(11), 1301. https://doi.org/10.3390/coatings15111301