Nb Microalloying Enhances the Grain Stability of SAE8620H Gear Steel During High-Temperature Carburizing

Abstract

1. Introduction

2. Experimental Methods

2.1. Material Preparation

2.2. Microstructural Characterization

3. Results and Discussion

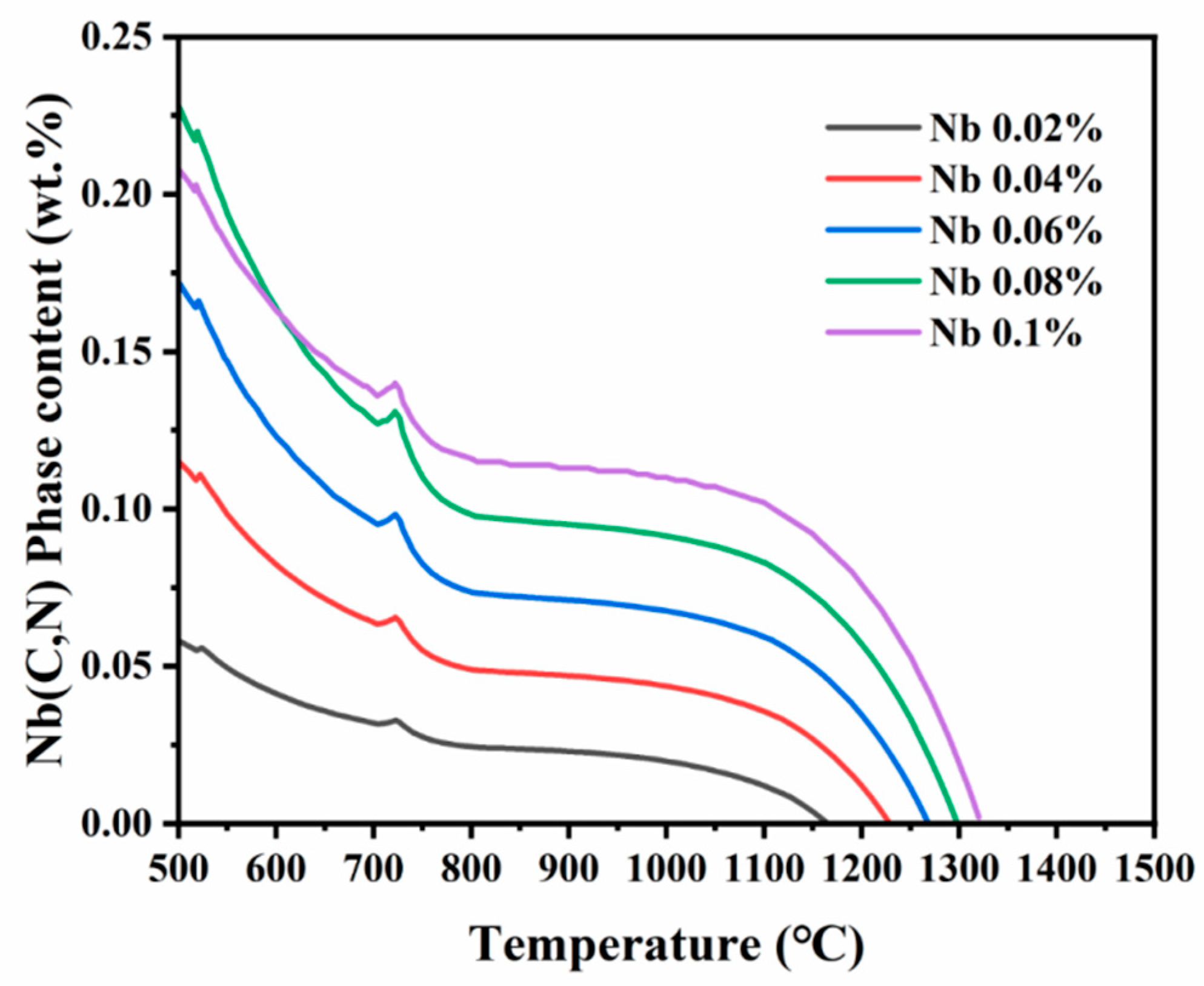

3.1. Thermodynamic Calculations

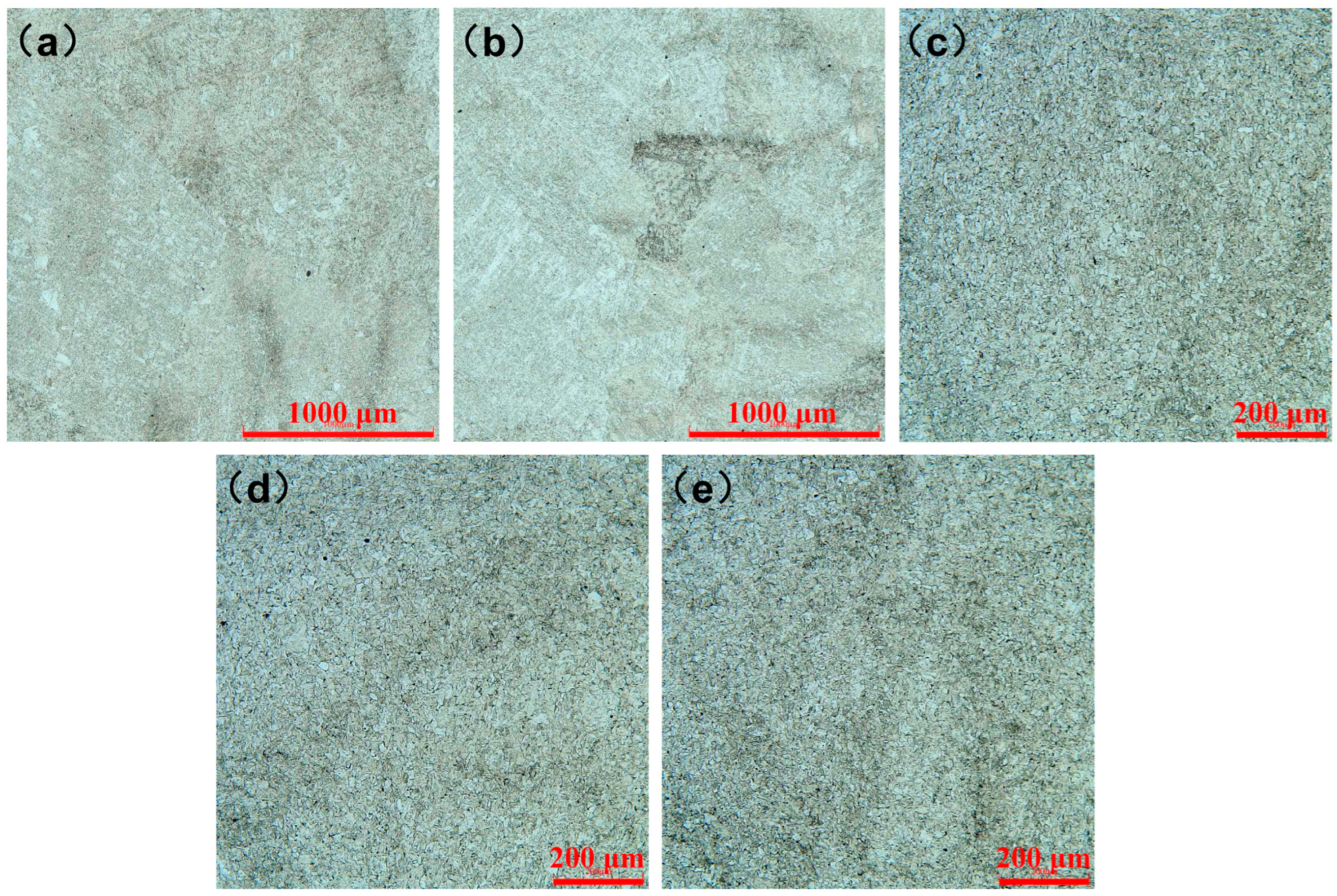

3.2. Grain Growth Behavior Without Pre-Heating

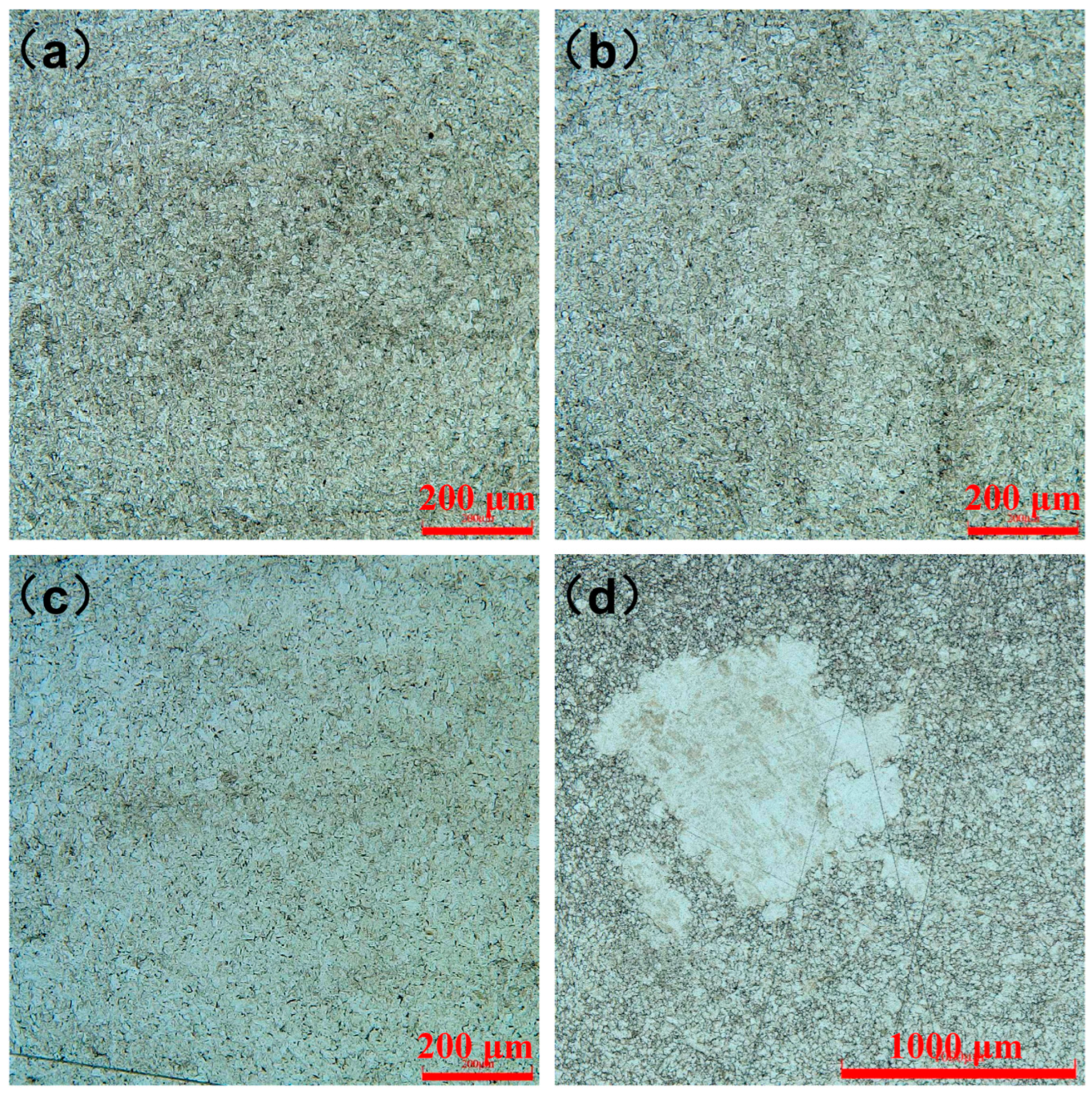

3.3. Grain Growth Behavior After Pre-Heating

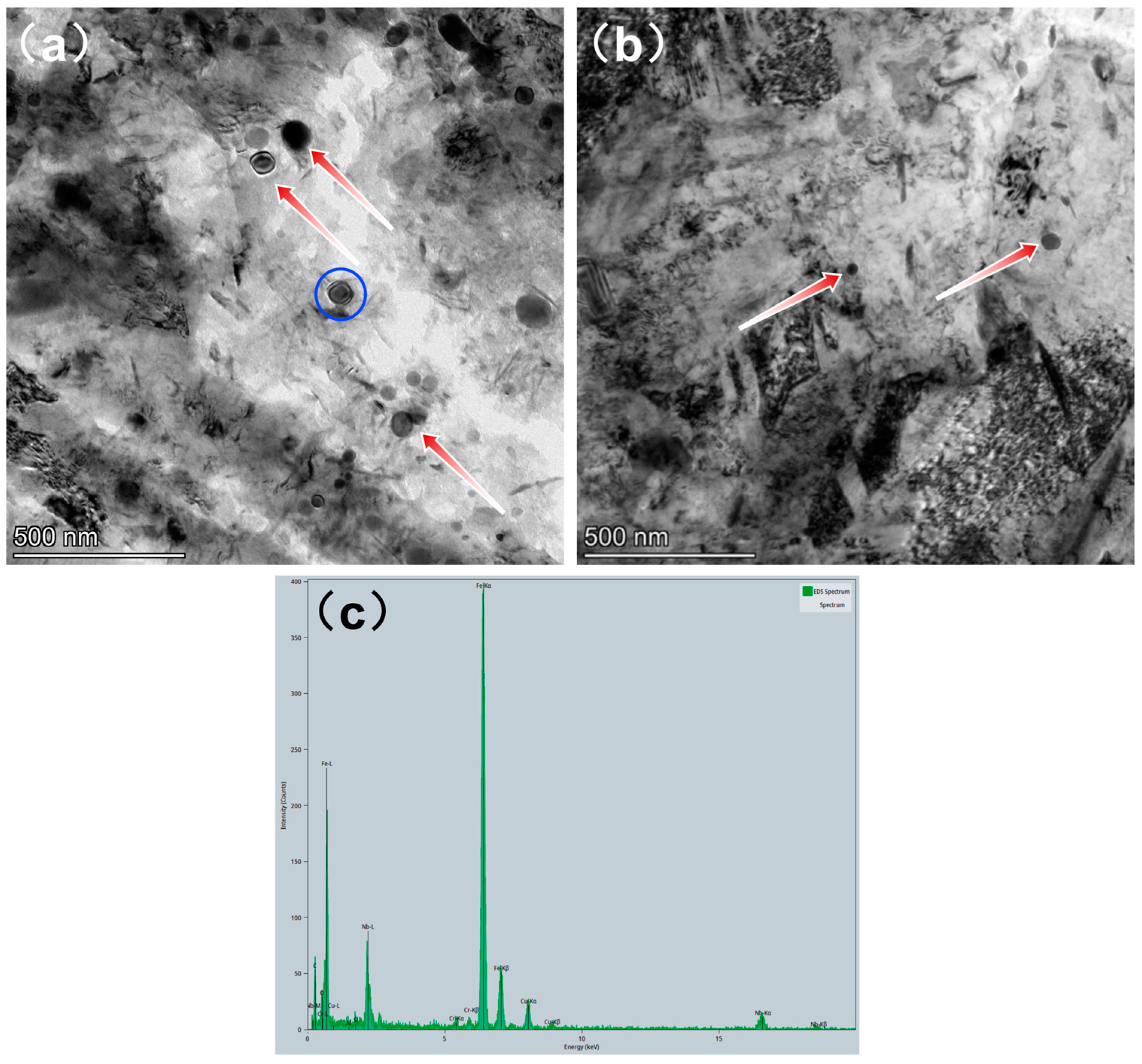

3.4. Analysis and Discussion

4. Conclusions

- (1)

- Thermodynamic calculations show that, with the increase in temperature, the Nb(C, N) phase content in SAE8620H test steels with different Nb contents decreases. The higher the Nb content, the relatively higher the Nb(C, N) phase content at the same temperature. A higher Nb content can maintain a certain amount of Nb(C, N) phase at high temperatures, which is of great significance for suppressing austenite grain coarsening during high-temperature carburizing.

- (2)

- Without pre-heat treatment, during pseudo-carburizing at 980–1050 °C, Nb microalloying can refine the grains of SAE8620H gear steel. The higher the Nb content, the more obvious the grain refinement effect. However, as the temperature increases, the grain growth trend intensifies, and relying solely on Nb for grain refinement is limited. At 1050 °C, even with 0.1% Nb addition, it is difficult to maintain a fine-grained state.

- (3)

- By using the pre-heat treatment process of maintaining the solution at 1330 °C for 10 min + water quenching, the Nb(C, N) precipitated phase particles can be made uniform and fine. When the Nb content is not less than 0.053%, the grains can be ensured not to coarsen under the 1050 °C × 2 h carburizing regime. When the Nb content is 0.1%, a fine-grained state can be maintained under the 1050 °C × 4 h carburizing regime.

- (4)

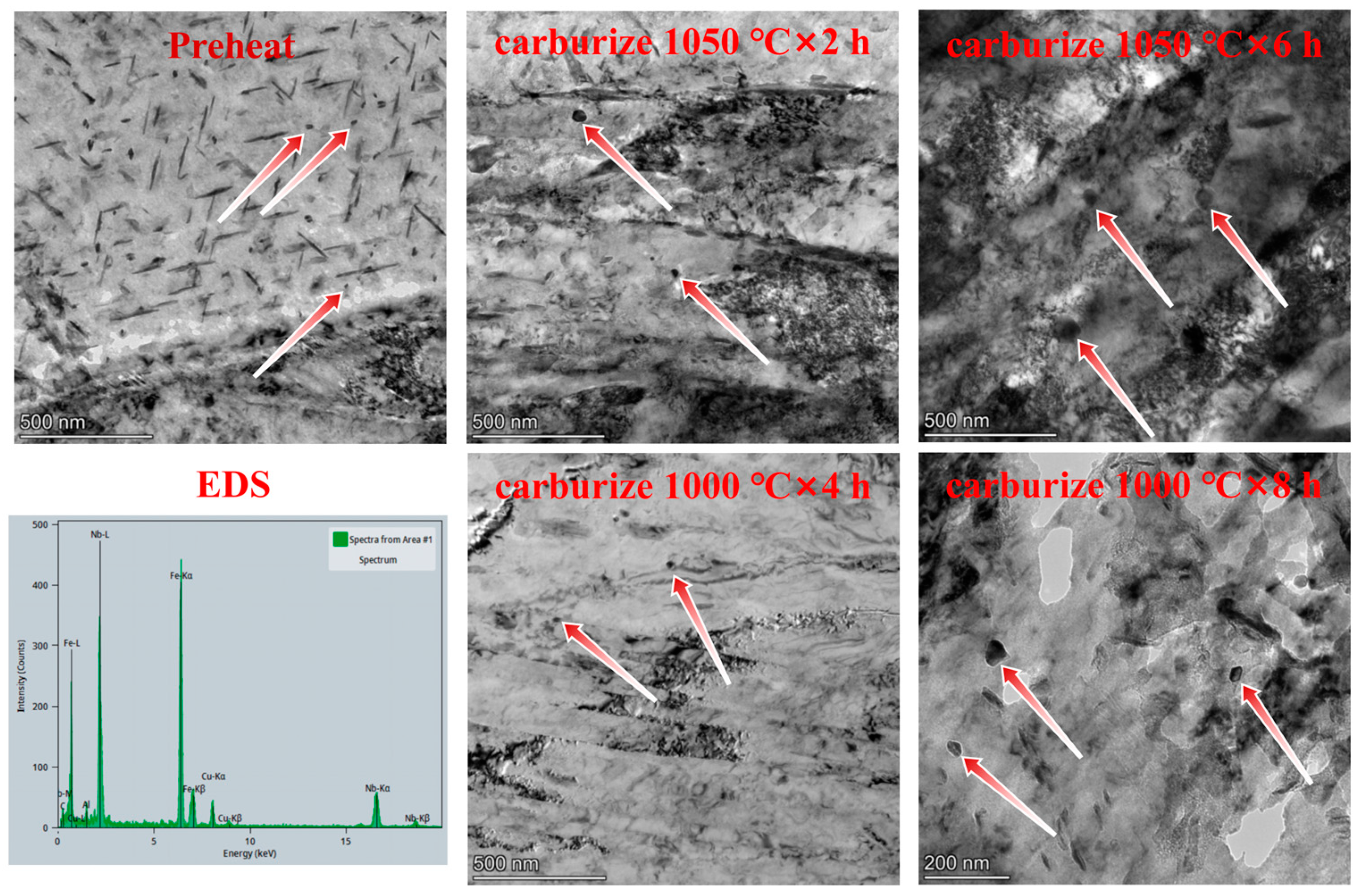

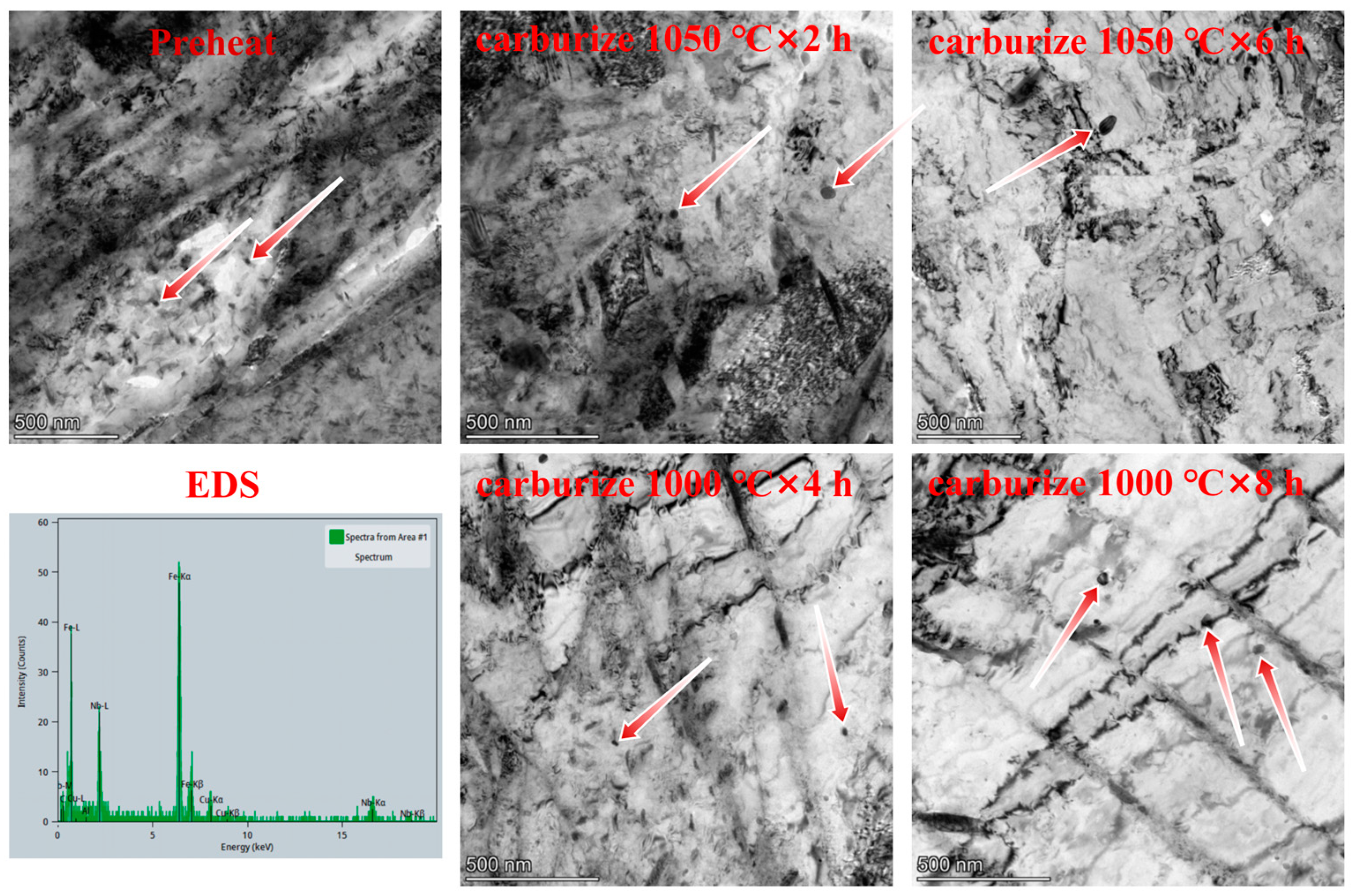

- After pre-heat treatment, the precipitated phase particles in the high-temperature carburizing state are more uniform and fine, with a greater pinning force, which is more conducive to suppressing grain coarsening. The coarsening trend of the precipitated phase particles is in good agreement with the DICTRA simulation results, indicating that the precipitated phases coarsen in accordance with the Ostwald theory.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gupta, K.; Laubscher, R.F.; Paulo Davim, J.; Jain, N.K. Recent developments in sustainable manufacturing of gears: A review. J. Clean. Prod. 2016, 112, 3320–3330. [Google Scholar] [CrossRef]

- Guerrini, G.; Lerra, F.; Fortunato, A. The effect of radial infeed on surface integrity in dry generating gear grinding for industrial production of automotive transmission gears. J. Manuf. Processes 2019, 45, 234–241. [Google Scholar] [CrossRef]

- Tobie, T.; Hippenstiel, F.; Mohrbacher, H. Optimizing gear performance by alloy modification of carburizing steels. Metals 2017, 7, 415. [Google Scholar] [CrossRef]

- Parrish, G. Carburizing: Microstructures and Properties; Asm International: Materials Park, OH, USA, 1999; pp. 6–10. [Google Scholar]

- Shi, L.; Cui, X.; Li, J.; Jin, G.; Liu, J.; Tian, H. Improving the wear resistance of heavy-duty gear steels by cyclic carburizing. Tribo. Int. 2022, 171, 107576. [Google Scholar] [CrossRef]

- Rakhit, A.K. Heat Treatment of Gears: A Practical Guide for Engineers; ASM international: Materials Park, OH, USA, 2000; pp. 50–55. [Google Scholar]

- Asi, O.; Can, A.C.; Pineault, J.; Belassel, M. The effect of high temperature gas carburizing on bending fatigue strength of SAE 8620 steel. Mater. Des. 2009, 30, 1792–1797. [Google Scholar] [CrossRef]

- Kim, D.W.; Cho, H.H.; Lee, W.B.; Cho, K.T.; Cho, Y.G.; Kim, S.J.; Han, H.N. A finite element simulation for carburizing heat treatment of automotive gear ring incorporating transformation plasticity. Mater. Des. 2016, 99, 243–253. [Google Scholar] [CrossRef]

- Alogab, K.A.; Matlock, D.K.; Speer, J.G.; Kleebe, H.J. The influence of niobium microalloying on austenite grain coarsening behavior of Ti-modified SAE 8620 steel. ISIJ Int. 2007, 47, 307–316. [Google Scholar] [CrossRef]

- Yang, Y.H.; Wang, M.Q.; Chen, J.C.; Dong, H. Microstructure and mechanical properties of gear steels after high temperature carburization. J. Iron Steel Res. Int. 2013, 20, 140–145. [Google Scholar] [CrossRef]

- Vinogradov, A.; Hashimoto, S. Multiscale phenomena in fatigue of ultra-fine grain materials—An overview. Mater. Trans. 2001, 42, 74–84. [Google Scholar] [CrossRef]

- Hamada, A.S.; Karjalainen, L.P.; Surya, P.V.; Misra, R.D.K. Fatigue behavior of ultrafine-grained and coarse-grained Cr–Ni austenitic stainless steels. Mater. Sci. Eng. A 2011, 528, 3890–3896. [Google Scholar] [CrossRef]

- He, G.; Zhang, N.; Wan, S.; Zhao, H.; Jiang, B.; Liu, Y.; Wu, C. The Carburizing behavior of high-temperature short-time carburizing gear steel: Effect of Nb microalloying. Steel Res. Int. 2022, 93, 2200427. [Google Scholar]

- An, X.; Tian, Y.; Wang, H.; Shen, Y.; Wang, Z. Suppression of austenite grain coarsening by using Nb–Ti microalloying in high temperature carburizing of a gear steel. Adv. Eng. Mater. 2019, 21, 1900132. [Google Scholar]

- Chen, W.; He, X.; Yu, W.; Wang, M.; Yao, K. Microstructure, hardness, and tensile properties of vacuum carburizing gear steel. Metals 2021, 11, 300. [Google Scholar] [CrossRef]

- Tang, E.; Yuan, Q.; Zhang, R.; Zhang, Z.; Mo, J.; Liang, W.; Xu, G. On the grain coarsening behavior of 20CrMnTi gear steel during pseudo carburizing: A comparison of Nb-Ti-Mo versus Ti-Mo microalloyed steel. Mater. Charact. 2023, 203, 113138. [Google Scholar]

- He, G.; Feng, Y.; Jiang, B.; Wu, H.; Wang, Z.; Zhao, H.; Liu, Y. Corrosion and abrasion behavior of high-temperature carburized 20MnCr5 gear steel with Nb and B microalloying. J. Mater. Res. Technol. 2023, 25, 5845–5854. [Google Scholar]

- Liu, H.; Dong, Y.; Zheng, H.; Liu, X.; Lan, P.; Tang, H.; Zhang, J. Precipitation criterion for inhibiting austenite grain coarsening during carburization of Al-containing 20Cr gear steels. Metals 2021, 11, 504. [Google Scholar] [CrossRef]

- De Morais, R.F.; Reguly, A.; De Almeida, L.H. Transmission electron microscopy characterization of a Nb microalloyed steel for carburizing at high temperatures. J. Mater. Eng. Perform. 2006, 15, 494–498. [Google Scholar]

- Gong, S.; Wang, F.; Chen, K. AlN and Nb (C, N) Composite Precipitation Behaviors and Their Effects on Austenite Grain Growth in SCr420H High-Temperature Carburized Gear Steel. Steel Res. Int. 2024, 95, 2400080. [Google Scholar] [CrossRef]

- Zhang, G.Q.; He, X.F.; Zhang, Q.Z.; Wang, W.J.; Wang, M.Q. Comparison of microstructure and heat treatment distortion of gear steels with and without Nb addition. J. Iron Steel Res. Int. 2021, 28, 488–495. [Google Scholar] [CrossRef]

- Nes, E.; Ryum, N.; Hunderi, O.J.A.M. On the Zener drag. Acta Metall. 1985, 33, 11–22. [Google Scholar]

- Yong, Q. Second Phases in Structural Steels, 2nd ed.; Metallurgical Industry Press: Beijing, China, 2006; p. 249. [Google Scholar]

- Tao, S.; Wang, F.; Sun, G.; Yang, Z.; Li, C. DICTRA simulation of holding time dependence of NbC size and experimental study of effect of NbC on austenite grain growth. Metall. Mater. Trans. A 2015, 46, 3670. [Google Scholar] [CrossRef]

- Enloe, C.M.; Findley, K.O.; Speer, J.G. Austenite grain growth and precipitate evolution in a carburizing steel with combined niobium and molybdenum additions. Metall. Mater. Trans. A 2015, 46, 5308–5328. [Google Scholar] [CrossRef]

- Gong, S.; Su, L.; Wang, F. Nucleation and coarsening behavior of aluminum nitride and its effect on abnormal grain growth in high-temperature carburizing process. Metall. Mater. Trans. A 2024, 55, 910–922. [Google Scholar]

| No. | C (wt.%) | Si (wt.%) | Mn (wt.%) | Cr (wt.%) | Mo (wt.%) | Ni (wt.%) | Cu (wt.%) | Als (wt.%) | N (wt.%) | Nb (wt.%) | Fe (wt.%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1# | 0.21 | 0.27 | 0.79 | 0.60 | 0.18 | 0.59 | 0.014 | 0.021 | 0.011 | 0.02 | Bal. |

| 2# | 0.20 | 0.26 | 0.67 | 0.59 | 0.19 | 0.58 | 0.013 | 0.023 | 0.012 | 0.04 | Bal. |

| 3# | 0.18 | 0.26 | 0.68 | 0.62 | 0.20 | 0.61 | 0.012 | 0.020 | 0.013 | 0.053 | Bal. |

| 4# | 0.20 | 0.26 | 0.75 | 0.61 | 0.19 | 0.59 | 0.013 | 0.021 | 0.012 | 0.08 | Bal. |

| 5# | 0.19 | 0.27 | 0.71 | 0.60 | 0.19 | 0.59 | 0.013 | 0.022 | 0.010 | 0.1 | Bal. |

| Solution + Quenching | Carburizing 1050 °C × 2 h | Carburizing 1050 °C × 6 h | Carburizing 1000 °C × 4 h | Carburizing 1000 °C × 8 h | ||

|---|---|---|---|---|---|---|

| Nb 0.04% | Size | 22.1 nm | 27.3 nm | 60.3 nm | 27.7 nm | 46.6 nm |

| Number density | 13.1 × 1012 m−2 | 7.5 × 1012 m−2 | 4.9 × 1012 m−2 | 7.1 × 1012 m−2 | 11.7 × 1012 m−2 | |

| Nb 0.08% | Size | 18.4 nm | 38.0 nm | 67.8 nm | 29.6 nm | 34.4 nm |

| Number density | 13.8 × 1012 m−2 | 11.3 × 1012 m−2 | 3.0 × 1012 m−2 | 16.1 × 1012 m−2 | 8.4 × 1012 m−2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Liu, H.; Lu, B.; Zhang, Y.; Zhao, Q.; Yan, Z.; Gong, S.; Guo, X.; Pan, D.; Xu, P.; et al. Nb Microalloying Enhances the Grain Stability of SAE8620H Gear Steel During High-Temperature Carburizing. Coatings 2025, 15, 423. https://doi.org/10.3390/coatings15040423

Zhang X, Liu H, Lu B, Zhang Y, Zhao Q, Yan Z, Gong S, Guo X, Pan D, Xu P, et al. Nb Microalloying Enhances the Grain Stability of SAE8620H Gear Steel During High-Temperature Carburizing. Coatings. 2025; 15(4):423. https://doi.org/10.3390/coatings15040423

Chicago/Turabian StyleZhang, Xiangyu, Huasong Liu, Bingjun Lu, Yu Zhang, Qianshui Zhao, Zhiran Yan, Shuo Gong, Xiaodong Guo, Dong Pan, Pei Xu, and et al. 2025. "Nb Microalloying Enhances the Grain Stability of SAE8620H Gear Steel During High-Temperature Carburizing" Coatings 15, no. 4: 423. https://doi.org/10.3390/coatings15040423

APA StyleZhang, X., Liu, H., Lu, B., Zhang, Y., Zhao, Q., Yan, Z., Gong, S., Guo, X., Pan, D., Xu, P., Wang, Y., & Wang, K. (2025). Nb Microalloying Enhances the Grain Stability of SAE8620H Gear Steel During High-Temperature Carburizing. Coatings, 15(4), 423. https://doi.org/10.3390/coatings15040423