Toughness Characterization Methods for Diamond-like Carbon Films

Abstract

1. Introduction

2. Conventional Toughness Testing Methods and Their Limitations for Thin Films

2.1. Bending Tests

2.2. Nanoindentation

2.3. Tensile Tests

2.4. Buckling Tests

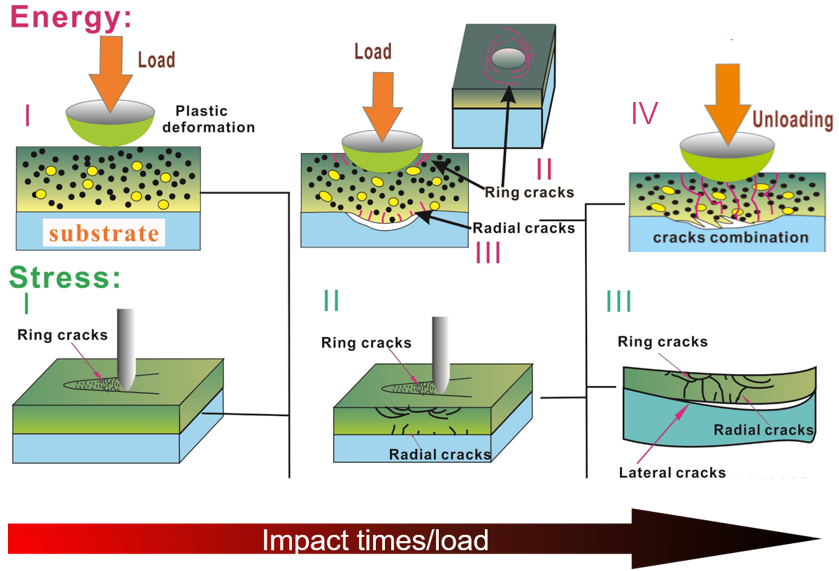

3. Impact Toughness Characterization

3.1. Principle of Impact Testing

3.2. Morphology Analysis: Cracks and Spallation Areas

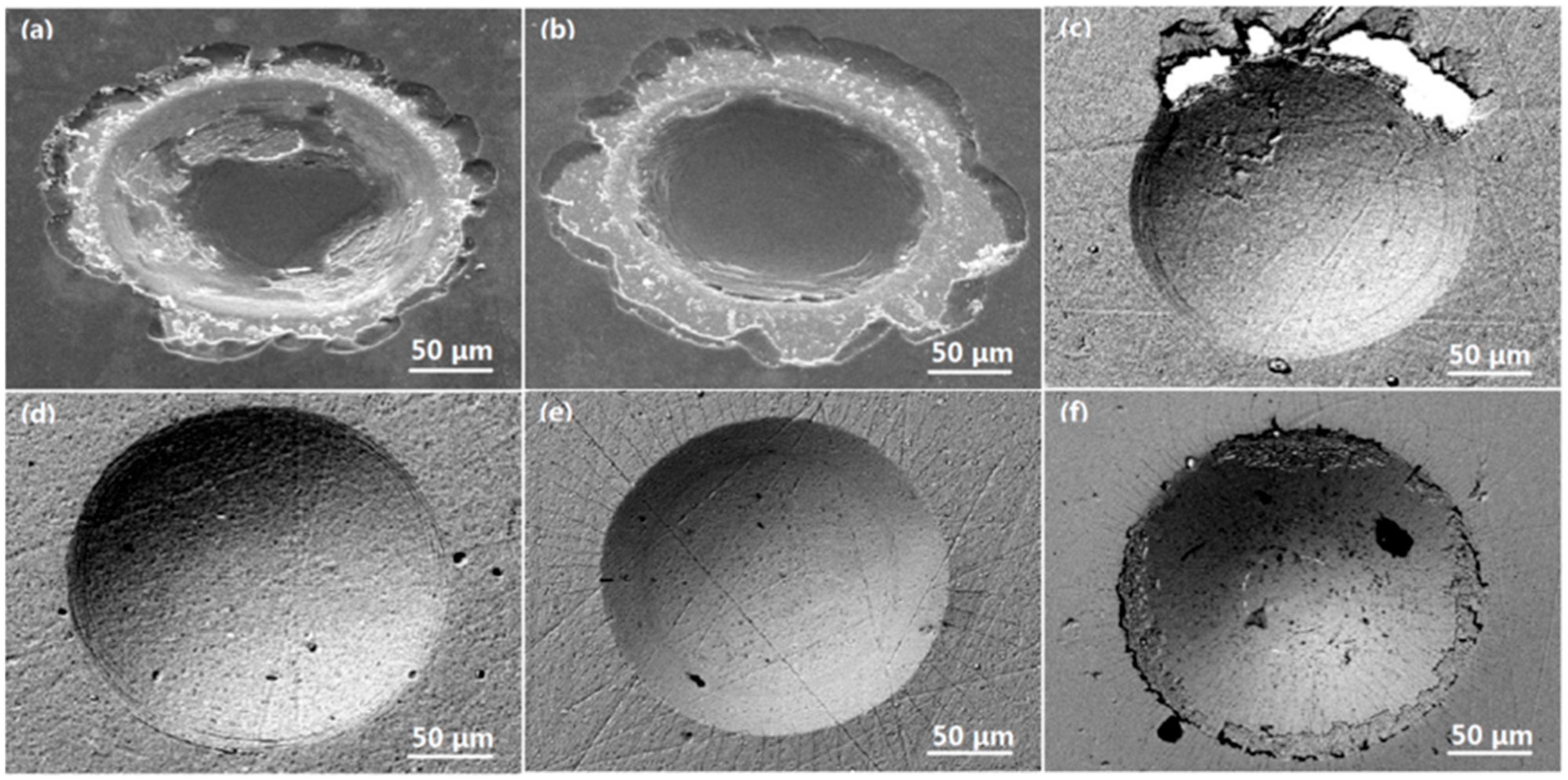

3.3. Case Study: Impact Morphology Comparison of Ag-DLC Films

- (i)

- Low/High Ag content (Figure 2a,b,f): Exhibited large white spallation zones around the crater, severe delamination, and extensive radial and circular cracking. This morphology indicates poor impact toughness, as cracks readily initiated and propagated through Stages I–III.

- (ii)

- Medium Ag content (Figure 2c–e): Showed significantly reduced spallation and cracking. The impact cavities had clearer profiles with minimal or no visible cracking, indicating that the films could absorb the impact energy through mechanisms other than brittle fracture, thus exhibiting good to excellent impact toughness.

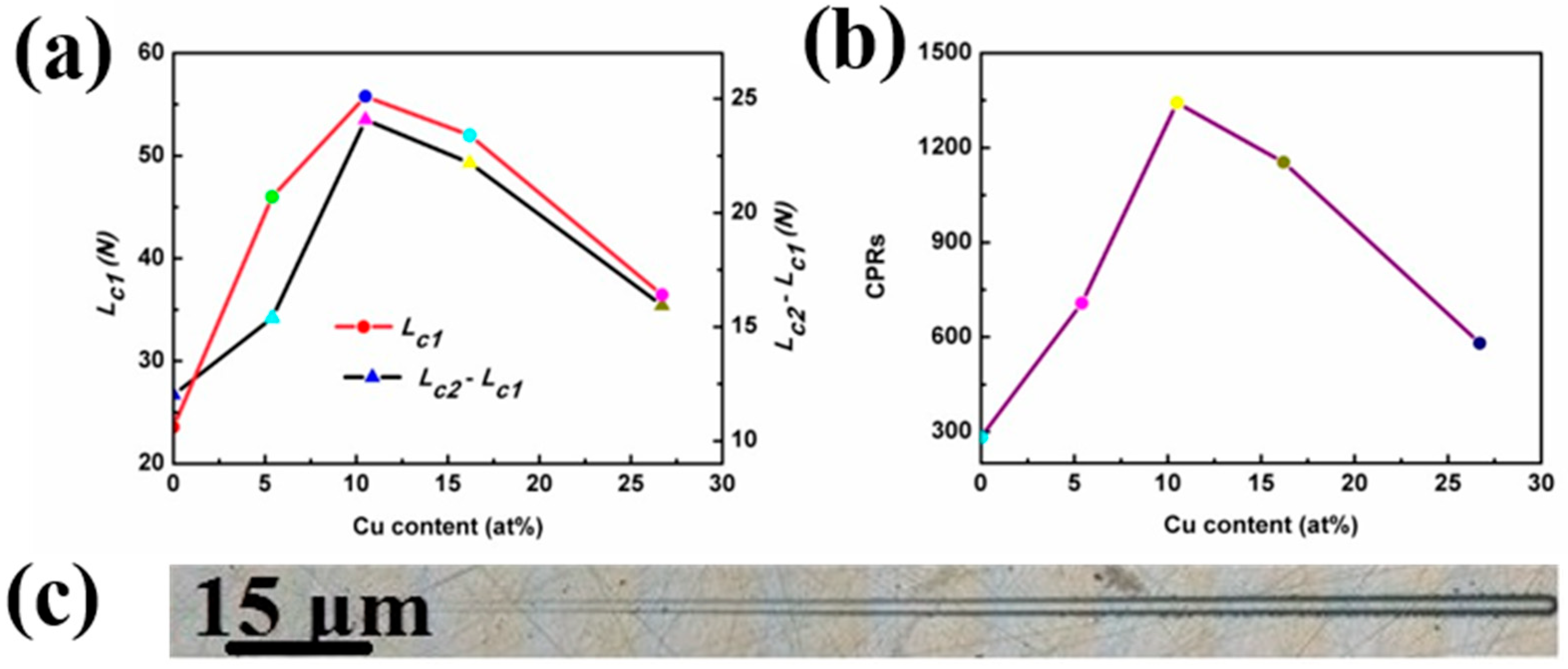

4. Scratch Toughness Characterization

4.1. Scratch Test and Critical Loads (Lc1, Lc2)

- (i)

- First Critical Load (Lc1): The load at which the first cohesive failures (e.g., conformal cracking, chipping) occur within the film.

- (ii)

- Second Critical Load (Lc2): The load at which the first adhesive failures (complete exposure of the substrate) occur.

4.2. Definition and Calculation of CPRS

4.3. Case Study: Scratch Morphology and CPRS Analysis of Cu-DLC and Ag-DLC

5. Combined Characterization Strategy

5.1. Complementarity of Impact and Scratch Methods

- (i)

- Impact Testing primarily assesses the film’s resistance to dynamic, repetitive normal loading and its ability to absorb energy over time. It is excellent for simulating and evaluating fatigue wear resistance and impact toughness. Its weakness lies in its qualitative nature and difficulty in distinguishing between films with similarly good (or poor) morphologies [39].

- (ii)

- Scratch Testing primarily assesses the film’s response to continuously increasing lateral shear stress and its resistance to crack initiation and propagation under a single pass. It provides quantitative parameters (Lc1, Lc2, CPRS) that are more readily comparable. Its weakness is that it is an indicative measure, and the stress field is complex, mixing compression, tension, and shear.

5.2. A Holistic Toughness Evaluation Framework

- •

- Step 1: Initial Quantitative Screening via Scratch Test

- •

- Step 2: Qualitative Fatigue Assessment via Impact Test

- •

- Step 3: Correlative Analysis and Final Decision-Making

- Scenario A: High SCRATCH performance (High CPRS/Lc1) & High IMPACT performance (Minimal Damage). The film possesses excellent overall toughness and is a prime candidate for demanding applications.

- Scenario B: High SCRATCH performance and Poor IMPACT performance. The film has good crack propagation resistance under sliding stress but poor energy absorption under impact. This indicates high brittleness, and strategies to improve ductility (e.g., doping, multilayer design) should be pursued.

- Scenario C: Poor SCRATCH performance and High IMPACT performance. The film is ductile and can absorb impact energy well but is susceptible to abrasive wear and scratch-induced damage. Enhancing hardness and cohesive strength may be required.

- Scenario D: Poor SCRATCH performance and Poor IMPACT performance. The film exhibits insufficient toughness. A fundamental reformulation of the coating composition or architecture is necessary [36].

6. Conclusions and Outlook

- (1)

- For hard DLC films on hard substrates (e.g., tool steels, cemented carbides), where cohesive fracture within the film often dominates failure, the combination of scratch testing (providing quantitative CPRS and Lc1) and impact testing (assessing fatigue crack resistance) is highly recommended. This duo effectively probes both the crack initiation/propagation resistance and the dynamic load-bearing capacity.

- (2)

- For hard DLC films on compliant substrates (e.g., aluminum, titanium alloys, or polymers), where interfacial adhesion and film flexibility are critical, the scratch test (for Lc2 and adhesion failure mode) is indispensable. This should be complemented by impact testing, which is particularly sensitive to the delamination driven by the large elastic mismatch in such systems.

- (3)

- When the primary concern is specifically interfacial adhesion, scratch testing should be the primary method, with buckling tests offering a valuable supplementary perspective on the interfacial fracture energy under a different stress state.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Du, N.; Wang, Y.; Wei, X.; Guo, P.; Chen, R.; Li, H.; Liu, C.; Lin, A.; Lee, K.R.; Li, X. Low-stress optimization and enhanced tribological properties of multilayer DLC films via alternating-energy deposition. Carbon 2025, 244, 120721. [Google Scholar] [CrossRef]

- Wood, R.J.K.; Lu, P. Coatings and Surface Modification of Alloys for Tribo-Corrosion Applications. Coatings 2024, 14, 99. [Google Scholar] [CrossRef]

- Beake, B.D.; Fox-Rabinovich, G.S. Progress in high temperature nanomechanical testing of coatings for optimising their performance in high speed machining. Surf. Coat. Technol. 2014, 255, 102–111. [Google Scholar] [CrossRef]

- Parvez, S.M.; Kumar, R.; Kumar, P.; Bonu, V.; Barshilia, H.C.; Mittal, R.K. Performance evaluation of DLC coated tools in high-speed micromilling of carbon fibre reinforced plastic. Diamond Relat. Mater. 2025, 157, 112505. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S.J. Approaches to investigate delamination and interfacial toughness in coated systems: An overview. J. Phys. D Appl. Phys. 2011, 44, 34001. [Google Scholar] [CrossRef]

- Sebastiani, M.; Johanns, K.E.; Herbert, E.G.; Pharr, G.M. Measurement of fracture toughness by nanoindentation methods: Recent advances and future challenges. Curr. Opin. Solid State Mater. Sci. 2015, 19, 324–333. [Google Scholar] [CrossRef]

- Zhu, X.; Dou, H.; Ban, Z.; Liu, Y.; He, J. Repeated impact test for characterization of hard coatings. Surf. Coat. Technol. 2007, 201, 5493–5497. [Google Scholar] [CrossRef]

- Albdiry, M.T.; Almensory, M.F. Failure analysis of drillstring in petroleum industry: A review. Eng. Fail. Anal. 2016, 65, 74–85. [Google Scholar] [CrossRef]

- Sharma, N.; Kumar, N.; Dash, S.; Das, C.R.; Rao, R.S.; Tyagi, A.K.; Raj, B. Scratch resistance and tribological properties of DLC coatings under dry and lubrication conditions. Tribol. Int. 2012, 56, 129–140. [Google Scholar] [CrossRef]

- Li, A.; Chen, Q.; Wu, G.; Huang, X.; Wang, Y.; Lu, Z.; Zhang, G.; Nie, X. Effect of the Variation of Film Thickness on the Properties of Multilayered Si-Doped Diamond-Like Carbon Films Deposited on SUS 304, Al and Cu Substrates. J. Mater. Eng. Perform. 2020, 29, 8473–8483. [Google Scholar] [CrossRef]

- Huang, T.; Yang, M.; Su, Y.; Han, Y.; Li, Q.; Zhang, S.; Goto, T.; Tu, R.; Zhang, L. Molecular dynamics study on nano sliding behavior at DLC/AISI 304 interface. Carbon 2025, 240, 120371. [Google Scholar] [CrossRef]

- Yu, X.; Ning, Z.W.; Hua, M.; Wang, C.B. Influence of silver incorporation on toughness improvement of diamond-like carbon film prepared by ion beam assisted deposition. J. Adhes. 2013, 89, 578–593. [Google Scholar] [CrossRef]

- Wu, L.; Bai, Z.; Hao, Q.; Qin, J. Improving Wear Resistance of DLC-Coated Metal Components During Service: A Review. Lubricants 2025, 13, 257. [Google Scholar] [CrossRef]

- Kumar, R.; Antonov, M. Self-lubricating materials for extreme temperature tribo-applications. Mater. Today Proc. 2021, 44, 4583–4589. [Google Scholar] [CrossRef]

- Rajak, D.; Kumar, A.; Behera, A.; Menezes, P.L. Diamond-Like Carbon (DLC) Coatings: Classification, Properties, and Applications. Appl. Sci. 2021, 11, 4445. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, Z. A new approach to cutting temperature prediction considering the diffusion layer in coated tools. Int. J. Mach. Tool. Manu. 2009, 49, 619–624. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, X. Toughness evaluation of hard coatings and thin films. Thin Solid Films 2012, 520, 2375–2389. [Google Scholar] [CrossRef]

- Xia, Y.; Zhang, L.; Hu, L.; Liu, Y.; He, L.; Tan, J.; Wang, Z. Investigation of fracture toughness and microstructure of micro-scaled multilayer-DLC/silicon system via pillar splitting method. Ceram. Int. 2023, 49, 38662–38671. [Google Scholar] [CrossRef]

- Yang, H.; Chen, X.; Sun, B.; Tang, J.; Vlassak, J.J. Fracture tolerance induced by dynamic bonds in hydrogels. J. Mech. Phys. Solids 2022, 169, 105083. [Google Scholar] [CrossRef]

- Pshyk, O.; Nakonechna, O.; Coy, E. Current View of Nanoindentation: Recent Developments and Application in Material Characterization. ACS Appl. Mater. Interfaces 2025, 17, 36275–36300. [Google Scholar] [CrossRef]

- McMaster, S.J.; Liskiewicz, T.W.; Neville, A.; Beake, B.D. Probing fatigue resistance in multi-layer DLC coatings by micro- and nano-impact: Correlation to erosion tests. Surf. Coat. Technol. 2020, 402, 126319. [Google Scholar] [CrossRef]

- Borrero-López, O.; Hoffman, M.; Bendavid, A.; Martin, P.J. Substrate effects on the mechanical properties and contact damage of diamond-like carbon thin films. Diamond Relat. Mater. 2010, 19, 1273–1280. [Google Scholar] [CrossRef]

- Xia, Y.; Liu, Y. Toughness Measurement of Micro-Scale Coating/Silicon MEMS System Using Pillar Splitting Method. IEEE Trans. Instrum. Meas. 2024, 73, 6008811. [Google Scholar] [CrossRef]

- Ben-David, E.; Tepper-Faran, T.; Rittel, D.; Shilo, D. A New Methodology for Uniaxial Tensile Testing of Free-Standing Thin Films at High Strain-Rates. Exp. Mech. 2014, 54, 1687–1696. [Google Scholar] [CrossRef]

- Chu, S.; Bai, J.; Zhao, Z.L.; Liu, Y.; Huang, D.; Li, B.; Li, Q.; Feng, X.Q. Peridynamic fracture analysis of film–substrate systems. J. Mech. Phys. Solids 2024, 191, 105757. [Google Scholar] [CrossRef]

- Cotterell, B.; Chen, Z. Buckling and cracking of thin films on compliant substrates under compression. Int. J. Fracture. 2000, 104, 169–179. [Google Scholar] [CrossRef]

- Beake, B.D.; Isern, L.; Endrino, J.L.; Fox-Rabinovich, G.S. Micro-impact testing of AlTiN and TiAlCrN coatings. Wear 2019, 418–419, 102–110. [Google Scholar] [CrossRef]

- Zak, S.; Trost, C.O.W.; Kreiml, P.; Cordill, M.J. Accurate measurement of thin film mechanical properties using nanoindentation. J. Mater. Res. 2022, 37, 1373–1389. [Google Scholar] [CrossRef]

- Kaygusuz, B.; Motallebzadeh, A.; Karadayı, Ö.; Kazmanlı, K.; Özerinç, S. Fracture toughness of AlTiN coatings investigated by nanoindentation and microcantilever bending. Thin Solid Films 2024, 790, 140199. [Google Scholar] [CrossRef]

- Amer, M.; Hayat, Q.; Janik, V.; Jennett, N.; Nottingham, J.; Bai, M. A Review on In Situ Mechanical Testing of Coatings. Coatings 2022, 12, 299. [Google Scholar] [CrossRef]

- Bouzakis, E. Fatigue Endurance Assessment of DLC Coatings on High-Speed Steels at Ambient and Elevated Temperatures by Repetitive Impact Tests. Coatings 2020, 10, 547. [Google Scholar] [CrossRef]

- Randall, N.X. The current state-of-the-art in scratch testing of coated systems. Surf. Coat. Technol. 2019, 380, 125092. [Google Scholar] [CrossRef]

- Wang, T.; Zha, X.; Chen, F.; Wang, J.; Li, Y.; Jiang, F. Mechanical impact test methods for hard coatings of cutting tools: A review. Int. J. Adv. Manuf. Technol. 2021, 115, 1367–1385. [Google Scholar] [CrossRef]

- Kleinbichler, A.; Pfeifenberger, M.J.; Zechner, J.; Wöhlert, S.; Cordill, M.J. Scratch induced thin film buckling for quantitative adhesion measurements. Mater. Des. 2018, 155, 203–211. [Google Scholar] [CrossRef]

- Liu, M.; Yan, F. Scratch-induced deformation and damage behavior of doped diamond-like carbon films under progressive normal load of Vickers indenter. Thin Solid Films 2022, 756, 139351. [Google Scholar] [CrossRef]

- Erdemir, A.; Martin, J. Superior wear resistance of diamond and DLC coatings. Curr. Opin. Solid. State Mater. 2018, 22, 243–254. [Google Scholar] [CrossRef]

- Zhou, Y.; Guo, P.; Sun, L.; Liu, L.; Xu, X.; Li, W.; Li, X.; Lee, K.R.; Wang, A. Microstructure and property evolution of diamond-like carbon films co-doped by Al and Ti with different ratios. Surf. Coat. Technol. 2019, 361, 83–90. [Google Scholar] [CrossRef]

- Fallqvist, M.; M’Saoubi, R.; Andersson, J.M.; Olsson, M. Mechanical and tribological properties of PVD-coated cemented carbide as evaluated by a new multipass scratch-testing method. Adv. Tribol. 2012, 2012, 305209. [Google Scholar] [CrossRef]

- Kolawole, F.O.; Kolade, O.S.; Bello, S.A.; Kolawole, S.K.; Ayeni, A.T.; Elijah, T.F.; Borisade, S.G.; Tschiptschin, A.P. The improvement of diamond-like carbon coatings for tribological and tribo-corrosion applications in automobile engines: An updated review study. Int. J. Adv. Manuf. Technol. 2023, 126, 2295–2322. [Google Scholar] [CrossRef]

- Gomez, I.J.; Wu, J.; Roper, J.; Beckham, H.; Meredith, J.C. High Throughput Screening of Mechanical Properties and Scratch Resistance of Tricomponent Polyurethane Coatings. ACS Appl. Polym. Mater. 2019, 1, 3064–3073. [Google Scholar] [CrossRef]

- Frutos, E.; González-Carrasco, J.L. A method to assess the fracture toughness of intermetallic coatings by ultramicroindentation techniques: Applicability to coated medical stainless steel. Acta Mater. 2013, 61, 1886–1894. [Google Scholar] [CrossRef]

- Anthymidis, K.G.; David, C.; Tsipas, D.N. Evaluation of the fatigue behavior of aluminide coating steel substrate compounds by means of the impact testing method. Mater. Manuf. Process. 2011, 26, 58–61. [Google Scholar] [CrossRef]

- ISO 20502:2005; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Adhesion of Ceramic Coatings by Scratch Testing. ISO: Geneva, Switzerland, 2005.

- ASTM E2546-15(2023); Standard Practice for Instrumented Indentation Testing. ASTM International: West Conshohocken, PA, USA, 2023.

| Method | Parameters | Main Advantages | Limitations for DLC Films | Refs. |

|---|---|---|---|---|

| Bending test | Critical strain (G c) | Mature model e.g., Suo-Hutchinson | Difficult pre-crack creation. Sensitive to substrate and residual stress. | [12,19] |

| Nanoindentation | Crack length (c), load (P) | Simple sample preparation | Inapplicable to tough DLCs (no cracks). Subjective crack measurement. | [20,21,22] |

| Tensile test | Crack density vs. strain | Well-defined stress state | Complex setup Challenging to isolate film fracture | [23,24] |

| Buckling test | Interfacial energy (γ) | Measures adhesion strength | Measures interface energy, not bulk film toughness | [25] |

| DLC Type | Scratch Test | Typical Parameters | References |

|---|---|---|---|

| Standard a-C:H or a-C | Lc1: 10–25 N CPRS: 50–200 μJ | Cycles to Failure 0: 104–105 | [35] |

| Metal-doped DLC (e.g., Cr-DLC) | Lc1: 20–40 N CPRS: 200–500 μJ | Cycles to Failure 0: 105–5 × 105 | [33] |

| Metal-doped DLC (e.g., Ag-DLC) Toughness Optimized | Lc1: 10–30 N CPRS: 150–400 μJ | Cycles to Failure 0: >106 | [28] |

| Multilayer/Graphitic DLC (Enhanced Toughness) | Lc1: 25–50 N CPRS: 300–800 μJ | Cycles to Failure 0: 5 × 105–>106 | [36] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Yang, Z.; Yu, X. Toughness Characterization Methods for Diamond-like Carbon Films. Coatings 2025, 15, 1302. https://doi.org/10.3390/coatings15111302

Liu J, Yang Z, Yu X. Toughness Characterization Methods for Diamond-like Carbon Films. Coatings. 2025; 15(11):1302. https://doi.org/10.3390/coatings15111302

Chicago/Turabian StyleLiu, Jiahao, Zhifang Yang, and Xiang Yu. 2025. "Toughness Characterization Methods for Diamond-like Carbon Films" Coatings 15, no. 11: 1302. https://doi.org/10.3390/coatings15111302

APA StyleLiu, J., Yang, Z., & Yu, X. (2025). Toughness Characterization Methods for Diamond-like Carbon Films. Coatings, 15(11), 1302. https://doi.org/10.3390/coatings15111302