Numerical Simulation of Cutting Performance of Coated Tools for Nickel-Based Superalloys

Abstract

1. Introduction

2. Establish a Two-Dimensional Cutting Finite Element Model

2.1. Constitutive Models for Superalloys and Physical Parameters of Coating Materials

2.2. Material Damage and Chip Separation Criterion

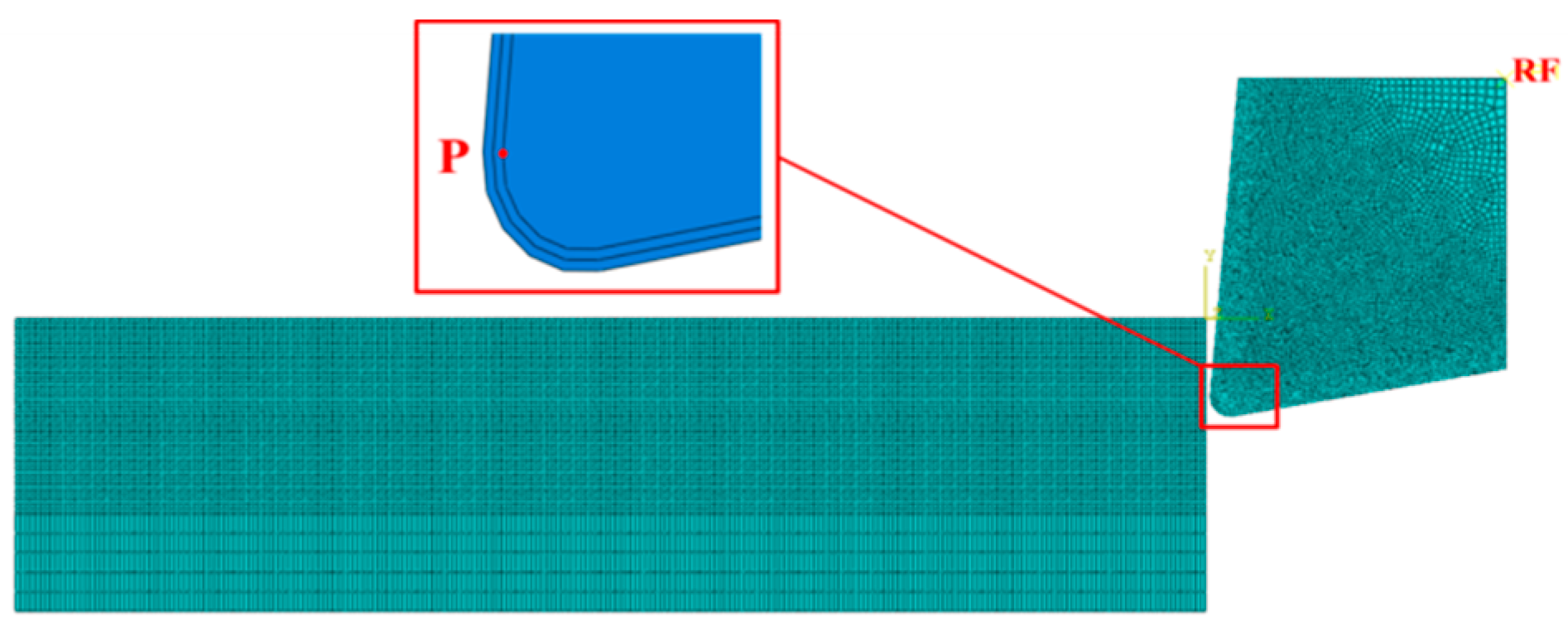

2.3. Finite Element Model

3. Cutting Simulation Results and Analysis

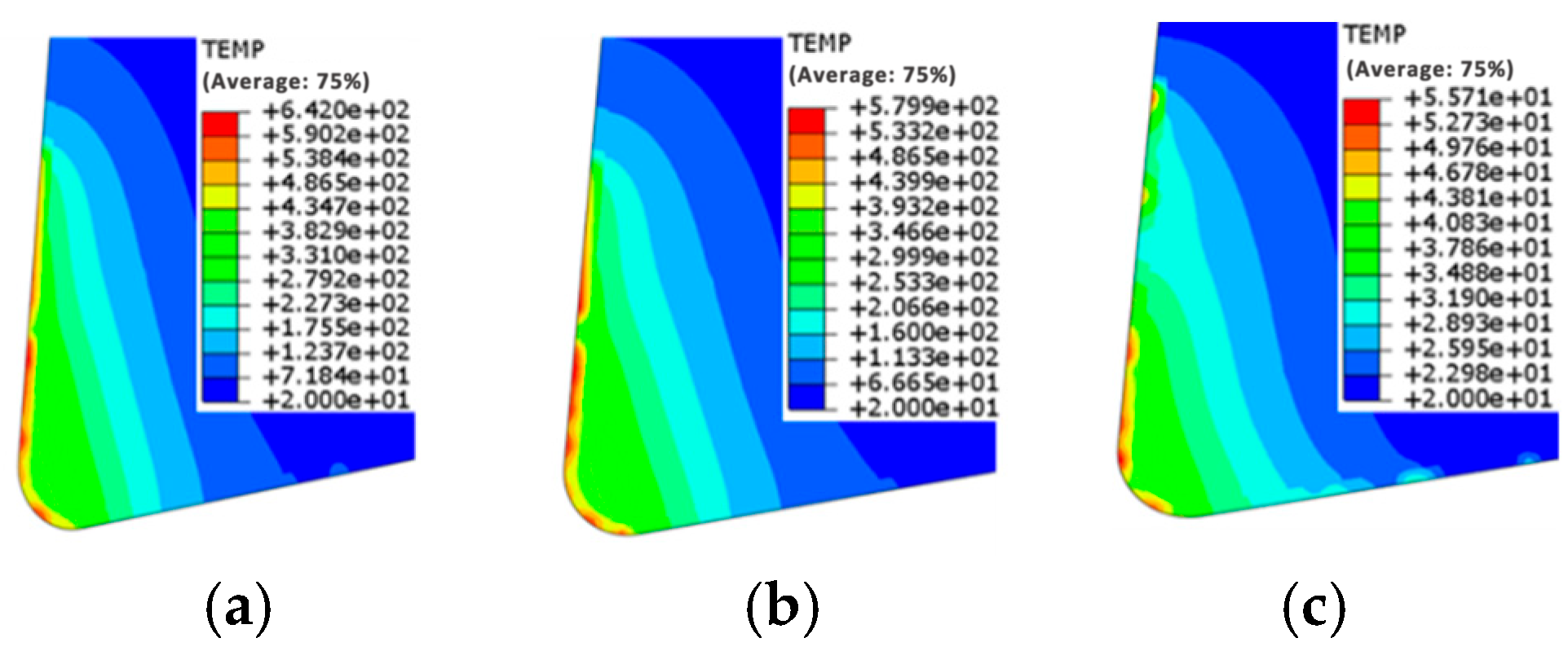

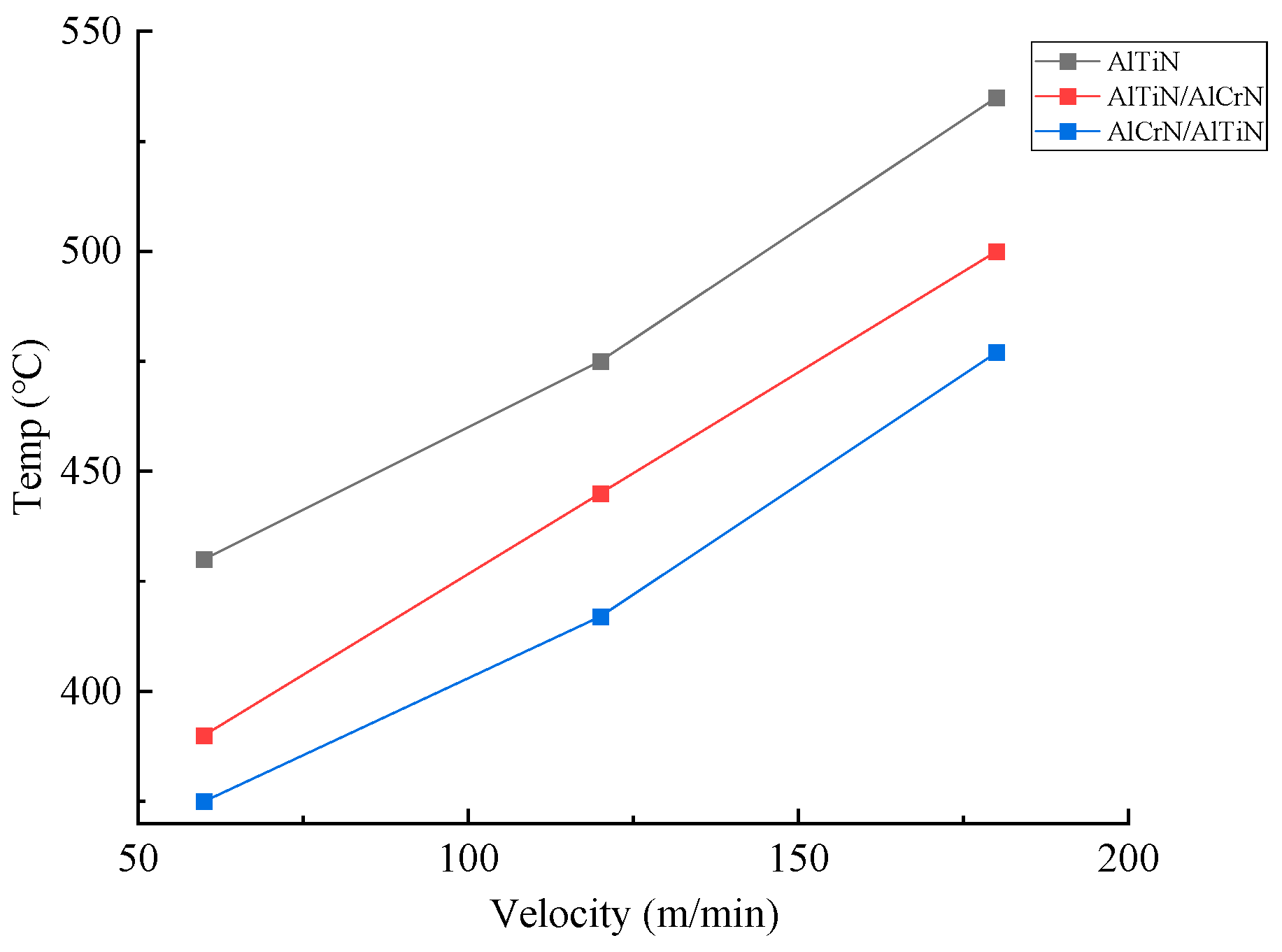

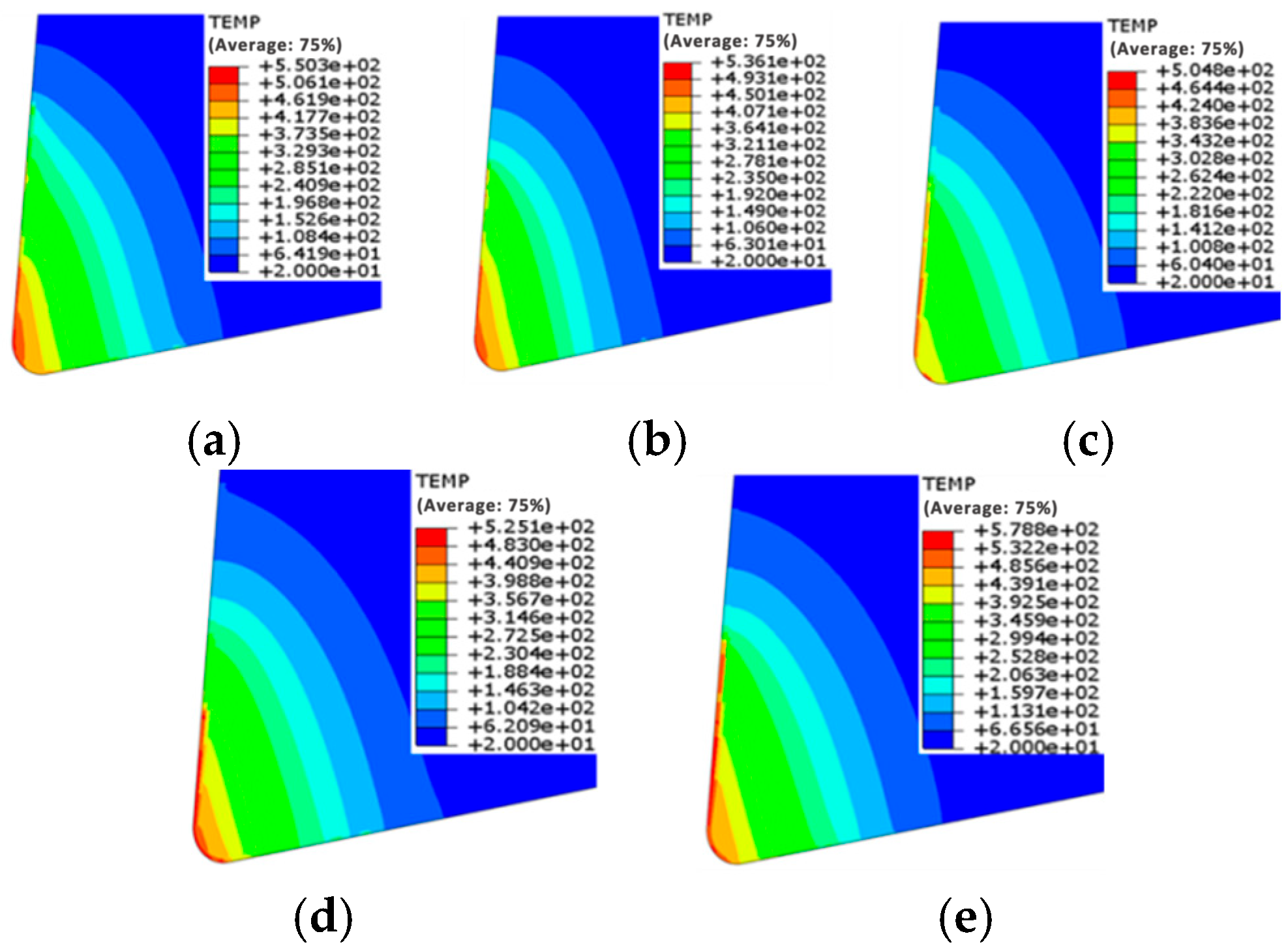

3.1. Effect of Coating Types on Cutting Temperature of Tools

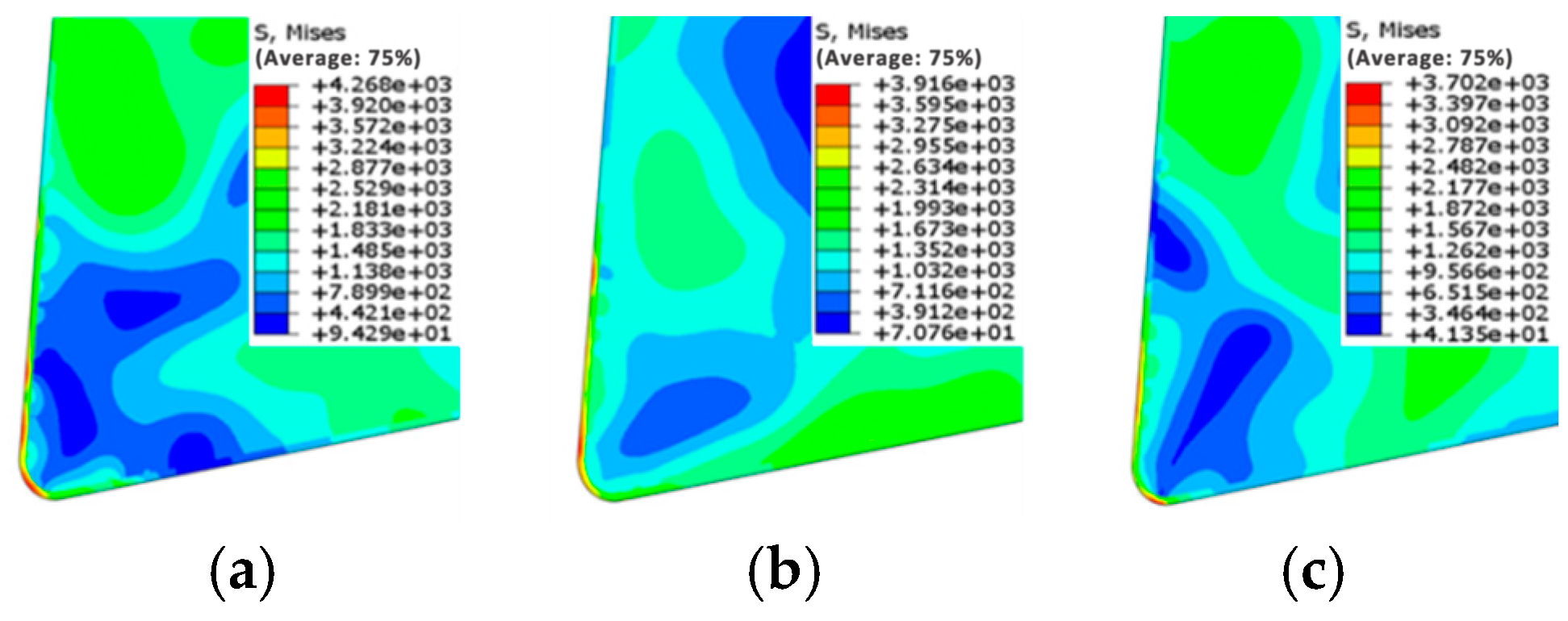

3.2. Effect of Coating Types on Cutting Stress of Tools

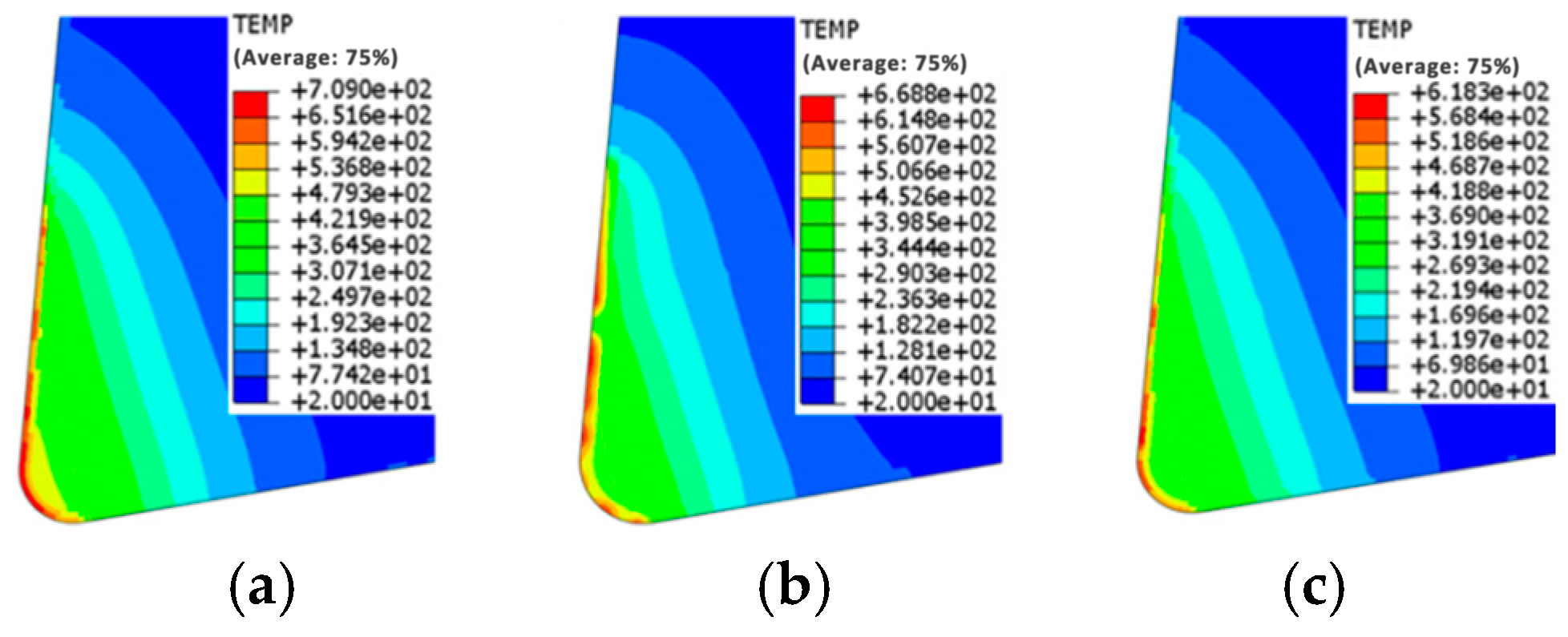

3.3. Effect of Coating Thickness Ratio on Cutting Temperature of Tools

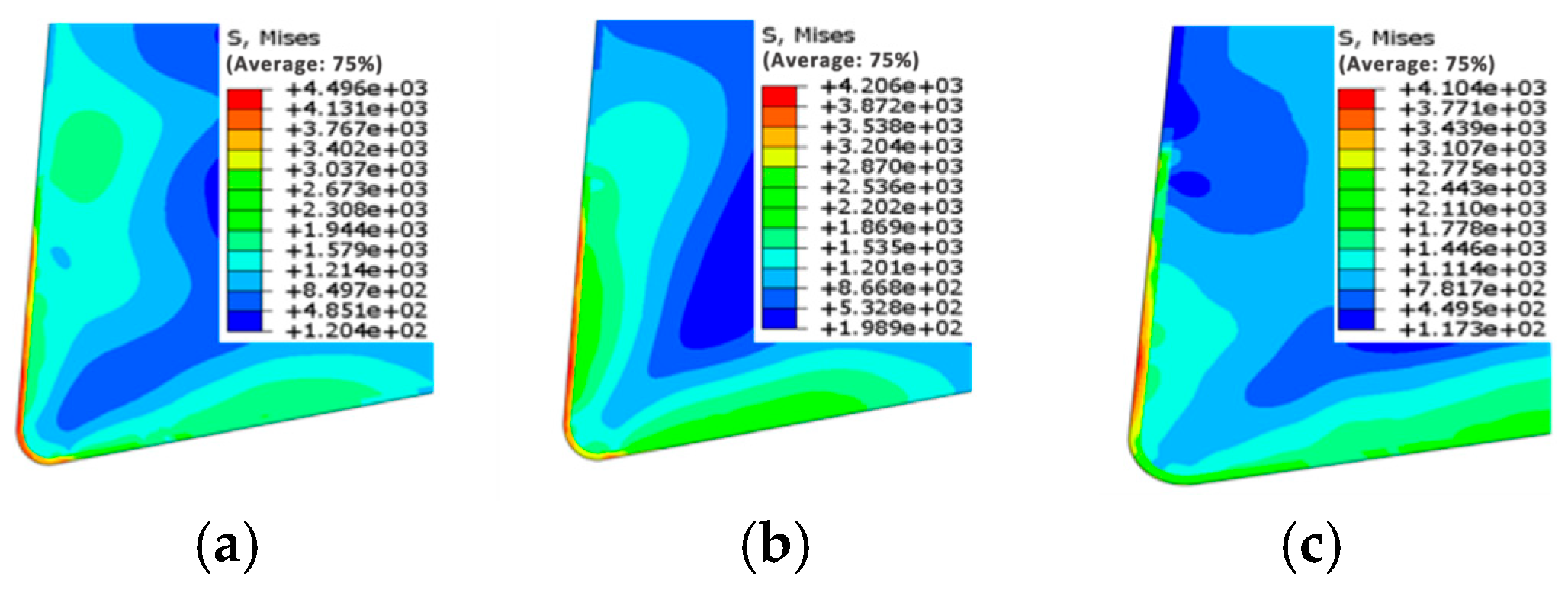

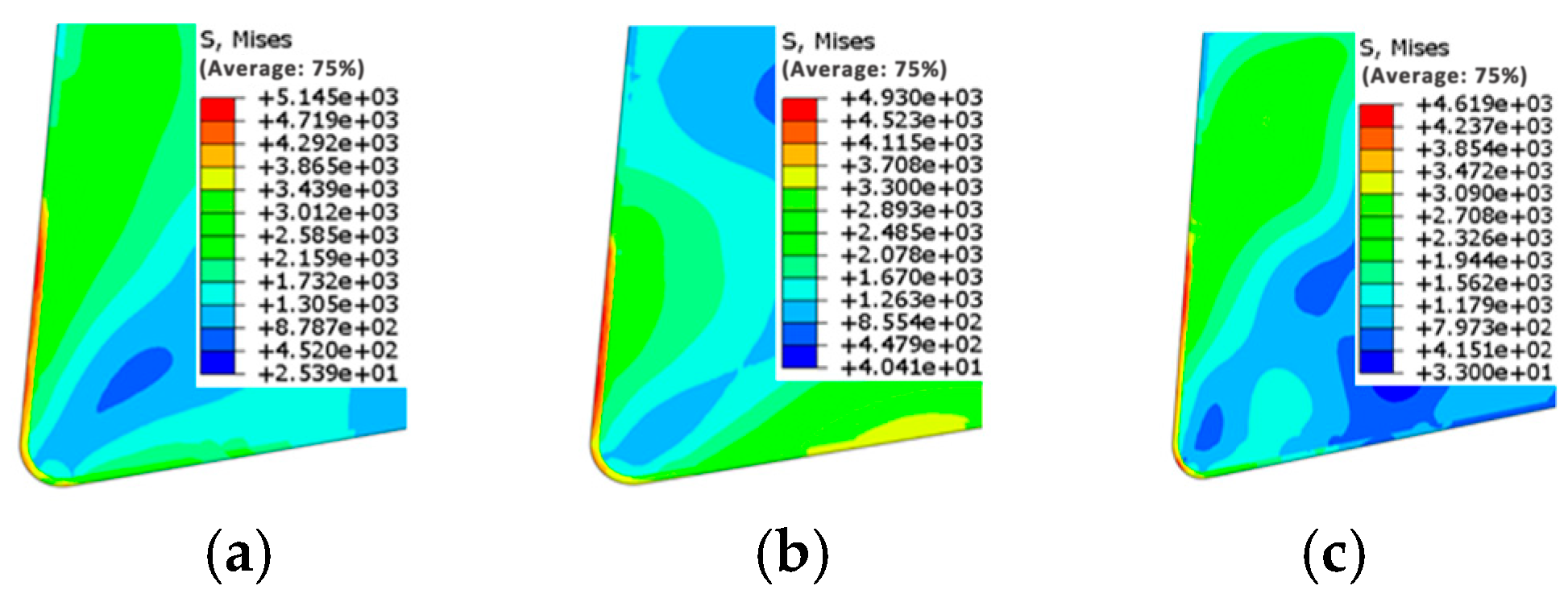

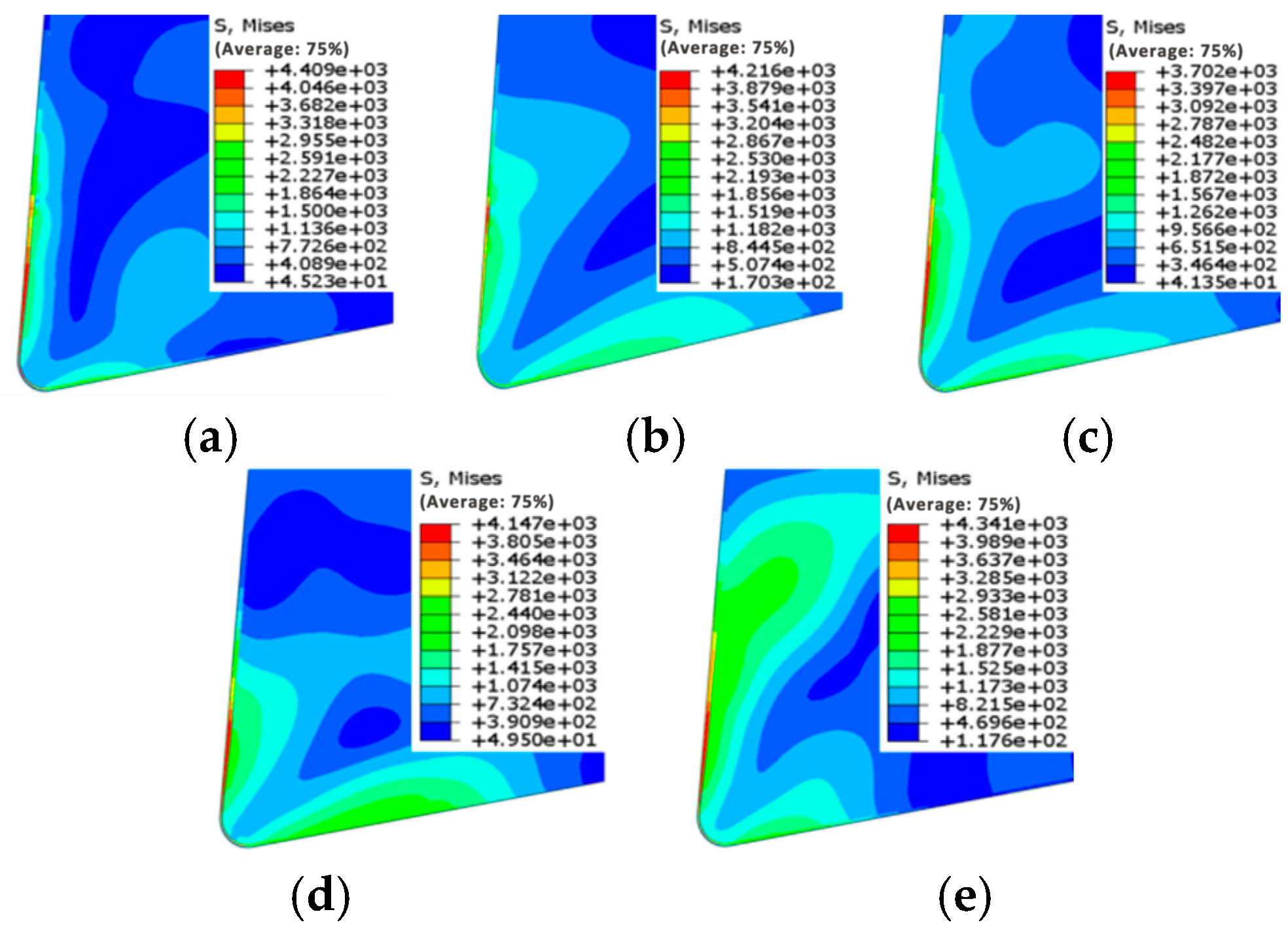

3.4. Effect of Coating Thickness on Cutting Stress of Tools

4. Conclusions

- (1)

- During the cutting process, the maximum cutting temperature and maximum cutting stress experienced by the three types of coated tools are primarily distributed at the tooltip and on the rake face. As the cutting speed increases, both the maximum temperature and maximum stress of the three coated tools show a significant upward trend. Additionally, the high-temperature and high-stress areas exhibit a slight shift from the tooltip toward the rake face. It can be predicted that the wear region of the coated tools will primarily manifest as crater wear on the rake face.

- (2)

- The double-layer AlCrN/AlTiN-coated tool exhibits the lowest maximum cutting temperature and cutting stress on both its rake face and tool substrate during machining compared to the other two types of coated tools (AlTiN and AlTiN/AlCrN).

- (3)

- When the AlCrN/AlTiN coating thickness ratio is 1.5:1 with a total thickness of 2.5 μm, the minimum values of maximum cutting temperature and maximum cutting stress are achieved, indicating the optimal cutting performance of the coated tool.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fu, Q.F.; Yang, X.L.; Liu, K.M. Current Status of Research and Prospect of High Temperature Materials for Aeroengine. Heat Treat. Technol. Equip. 2018, 39, 69–73. [Google Scholar]

- Xu, X.W.; Li, L.C.; Wu, A.J.; Chen, C.; Cui, J.B.; Xiong, J.; Liu, J.B. Research on Cutting Performance of High Performance Coated Tools for Cutting GH4169 High Temperature Alloy. Tool Eng. 2024. [Google Scholar]

- Zhang, E.G.; Zhu, Z.; Zhang, T.B. Research Progress and Application of Superhard Nano-Micron PVD Coating Technology in the Cutting Manufacturing Area. Surf. Technol. 2015, 44, 89–96+108. [Google Scholar]

- Song, X.H.; Gao, H.W.; Tian, Z.F.; Song, B. Numerical Simulation of Titanium Alloy Ti6Al4V in Cutting Proce. Tool Eng. 2020, 54, 40–43. [Google Scholar]

- Zhang, S.; Li, B.X.; Li, Q.H.; Man, J. Advances in Finite Element Simulation of the Cutting Process. Aeronaut. Manuf. Technol. 2019, 62, 14–28. [Google Scholar]

- Lu, T.; Xiang, G.Q.; Zhang, J.D. Analysis and Simulation of High—Speed Milling of Titanium Alloy Ti6Al4V. Modul. Mach. Tool Autom. Manuf. Tech. 2015, 149–151+160. [Google Scholar]

- Gao, D.Q.; Wang, J.J.; Wang, X.Y. Study on Cutting Process and Tool Parameter Finite Element Simulation of Nickel based Superalloy. Tool Eng. 2017, 51, 80–83. [Google Scholar]

- Sun, H.L.; Li, D.; Zhao, F.F.; Yu, X.X. Two-dimensional simulation on cutting process of aviation 7075 aluminum alloy based on ABAQUS. J. Tianjin Polytech. Univ. 2017, 36, 83–88. [Google Scholar]

- Wang, Z.; Li, L.; Shen, X.H. Analysis of Cutting Force and Cutting Temperature of Nickel-based Superalloy Inconel 718 Based on Grey Relational Analysis. Tool Eng. 2019, 53, 51–54. [Google Scholar]

- Lv, N. Research on Wear Mechanism of Cemented Carbide Tool Based on ABAQUS Finite Element Simulation. Mach. Tool Hydraul. 2021, 49, 164–168. [Google Scholar]

- Grzesik, W.; Bartoszuk, M.; Nieslony, P. Finite element modelling of temperature distribution in the cutting zone in turning processes with differently coated tools. J. Mater. Process. Technol. 2005, 164–165, 1204–1211. [Google Scholar] [CrossRef]

- Sadeghifar, M.; Sedaghati, R.; Jomaa, W. Finite element analysis and response surface method for robust multi performance optimization of radial turning of hard 300 M steel. Int. J. Adv. Manuf. Technol. 2018, 94, 2457–2474. [Google Scholar] [CrossRef]

- Qin, F.; Chou, Y.; Nolen, D. Coating thickness effects on diamond coated cutting tools. Surf. Coat. Technol. 2009, 204, 1056–1060. [Google Scholar] [CrossRef]

- Kumar, S.C.; Patel, K.S. Investigations on the effect of thickness and structure of AlCr and AlTi based nitride coatings during hard machining process. J. Manuf. Process. 2018, 31, 336–347. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, J.; Yi, M. Simulation study on influence of coating thickness on cutting performance of coated ceramic cutting tools. J. Phys. Conf. Ser. 2020, 1549, 032140. [Google Scholar] [CrossRef]

- Zhang, Y.; Mabrouki, T.; Nelias, D. Chip formation in orthogonal cutting considering interface limiting shear stress and damage evolution based on fracture energy approach. Finite Elem. Anal. Des. 2011, 47, 850–863. [Google Scholar] [CrossRef]

- He, Y.; Xu, Z.C.; Li, P.; Liu, M.; Gao, X.J.; Fan, L. Simulation Study on Cutting Titanium Alloy with Micro-Texture Tool Based on ABAQUS. J. Liaoning Petrochem. Univ. 2024, 44, 61–69. [Google Scholar]

- Kobayashi, T.; Simons, J.W.; Brown, C.S.; Shockey, D.A. Plastic flow behavior of Inconel 718 under dynamic shear loads. Int. J. Impact Eng. 2008, 35, 389–396. [Google Scholar] [CrossRef]

- Zhang, H.D.; Zhang, L.; Chen, Y.; Luo, G.K.; Xiao, Q.P.; Zhong, Z.Q. Failure modes of AlTiN coated alloys during scratch test and the related mechanism by finite element analysis. Powder Metall. Mater. Sci. Eng. 2018, 23, 445–453. [Google Scholar] [CrossRef] [PubMed]

- Bu, J.A.; Huang, S.T.; Yu, X.L.; Xu, L.F. Simulation of Residual Deformation and Cutting Force in High Speed Cutting of GH4169 Nickel-Based Superalloy. J. Aerosp. Mater. Technol. 2019, 49, 27–34. [Google Scholar]

| Yield Strength A | Strain Hardening Coefficient B | Strain Rate Hardening Coefficient C | Strain Hardening Exponent n | Coefficient of Thermal Softening m |

|---|---|---|---|---|

| 980 | 1370 | 17 | 0.02 | 1.03 |

| Coating Type | Density t/mm3 | Elasticity Modulus MPa | Poisson Rate | Conduction w/m·°C |

|---|---|---|---|---|

| AlCrN | 4.8 × 10−9 | 500,000 | 0.25 | 5 |

| AlTiN | 2.1 × 10−9 | 446,000 | 0.21 | 6 |

| d1 | d2 | d3 | d4 | d5 |

|---|---|---|---|---|

| 0.239 | 0.456 | −0.3 | 0.07 | 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dou, Z.; Zhao, L.; Yan, H.; Yang, Y.; Liu, F. Numerical Simulation of Cutting Performance of Coated Tools for Nickel-Based Superalloys. Coatings 2025, 15, 1275. https://doi.org/10.3390/coatings15111275

Dou Z, Zhao L, Yan H, Yang Y, Liu F. Numerical Simulation of Cutting Performance of Coated Tools for Nickel-Based Superalloys. Coatings. 2025; 15(11):1275. https://doi.org/10.3390/coatings15111275

Chicago/Turabian StyleDou, Zhaoliang, Liyang Zhao, Hongjuan Yan, Ye Yang, and Fengbin Liu. 2025. "Numerical Simulation of Cutting Performance of Coated Tools for Nickel-Based Superalloys" Coatings 15, no. 11: 1275. https://doi.org/10.3390/coatings15111275

APA StyleDou, Z., Zhao, L., Yan, H., Yang, Y., & Liu, F. (2025). Numerical Simulation of Cutting Performance of Coated Tools for Nickel-Based Superalloys. Coatings, 15(11), 1275. https://doi.org/10.3390/coatings15111275