Functional Coatings for Fiber Bragg Gratings: A Critical Review of Deposition Techniques for Embedded and Harsh-Environment Applications

Abstract

1. Introduction

1.1. Review Scope and Method

1.2. Position of This Review Within Existing Literature

2. Fundamentals and Performance Metrics for Coated FBGs

2.1. Thermo-Mechanical Coupling Induced by Coatings

2.2. Normalized Temperature Sensitivity and Key Metrics

- Spectral centroid shift (for mean λ stability);

- FWHM (for spectral broadening);

- SNR (for reflectivity quality);

- Hysteresis between heating/cooling;

- Drift per thermal cycle;

- Response time to step changes in temperature.

2.3. Reporting Conventions and Comparison Framework

3. Coating Materials and Design Constraints

3.1. Material Families and Functional Roles

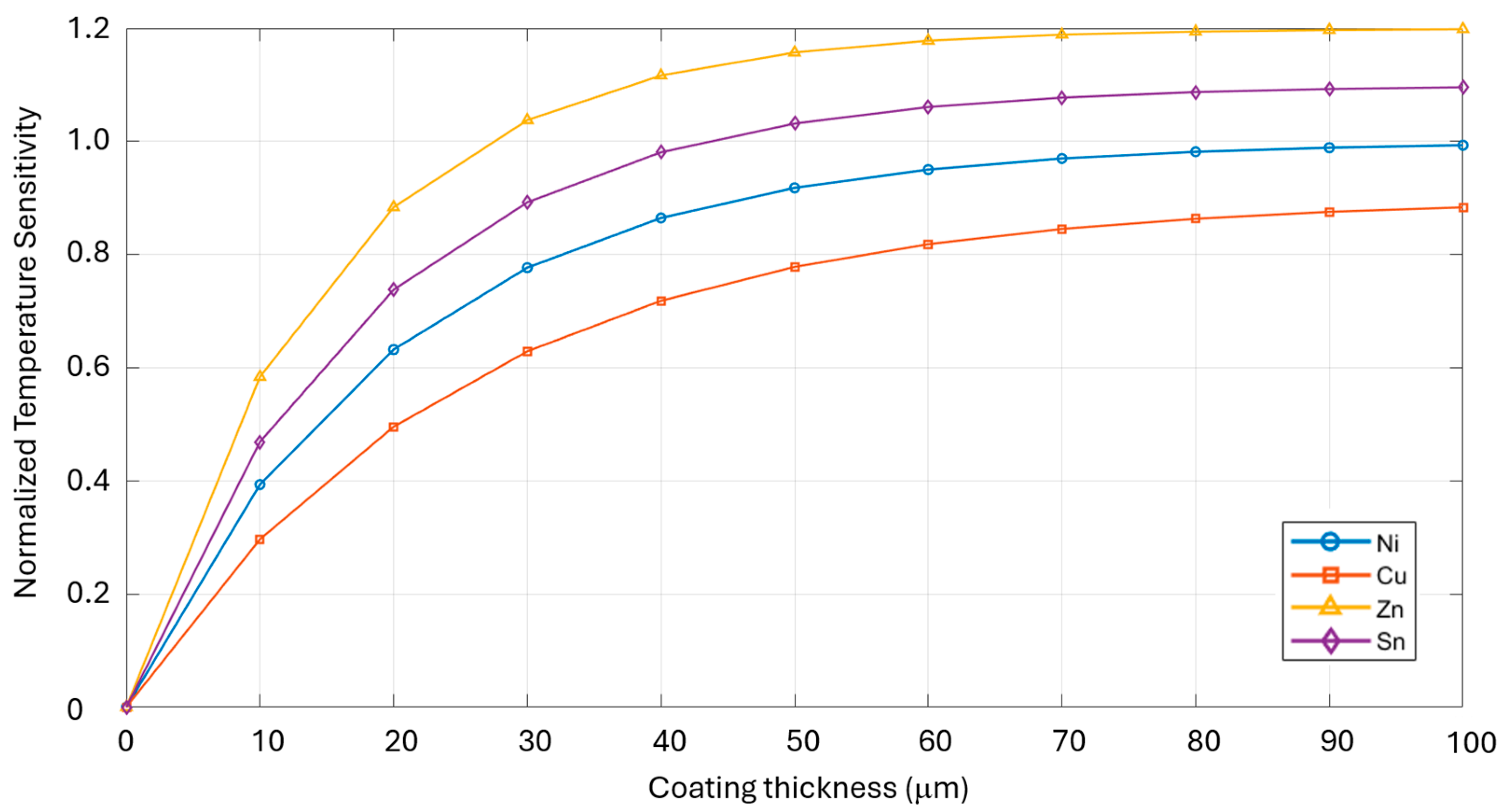

3.2. Thickness Dependence and Optimal Ranges

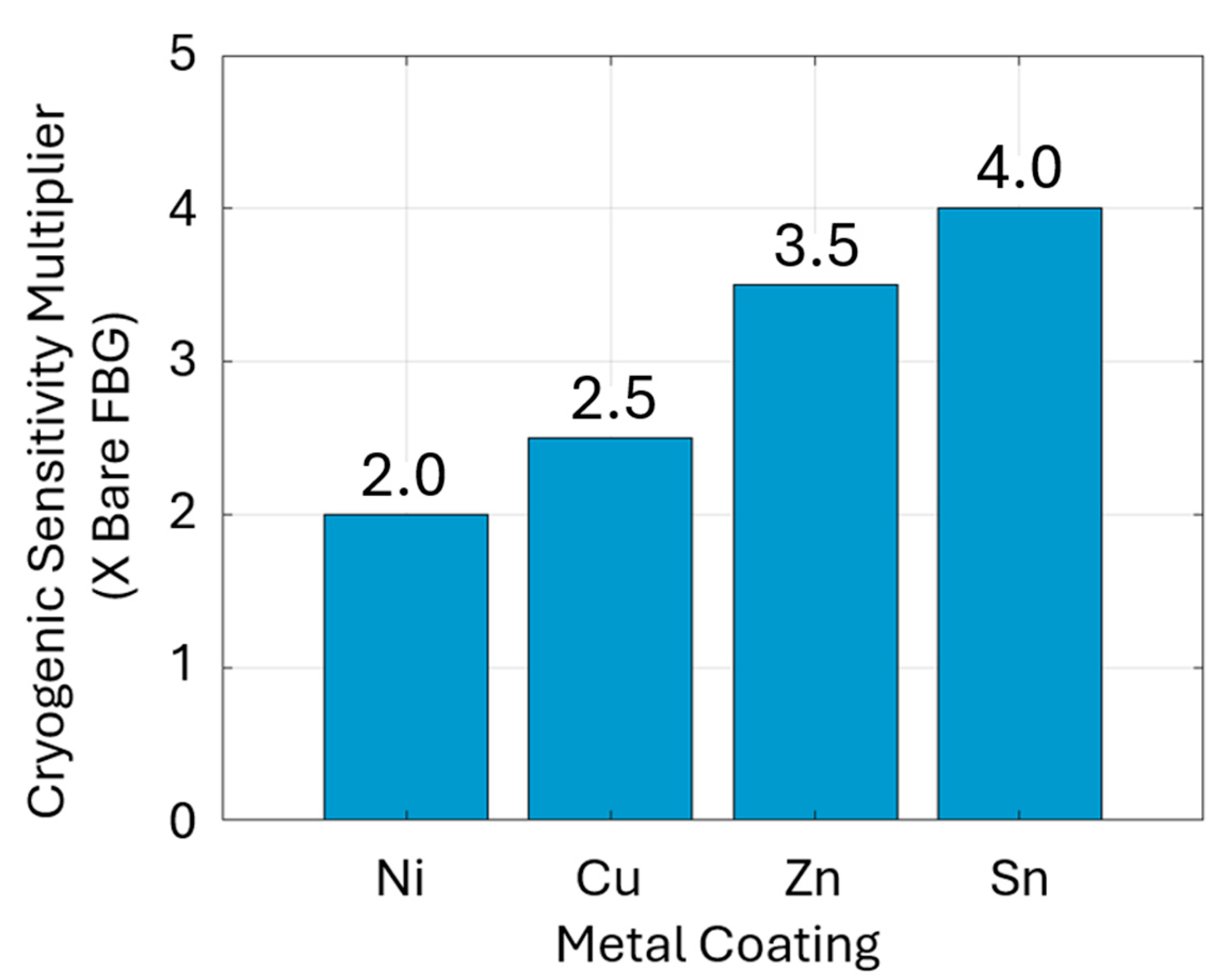

3.3. Cryogenic Behavior and Transients

3.4. Deposition Route, Microstructure, and Post-Treatments

3.5. Adhesion, Interfaces, and Seeding

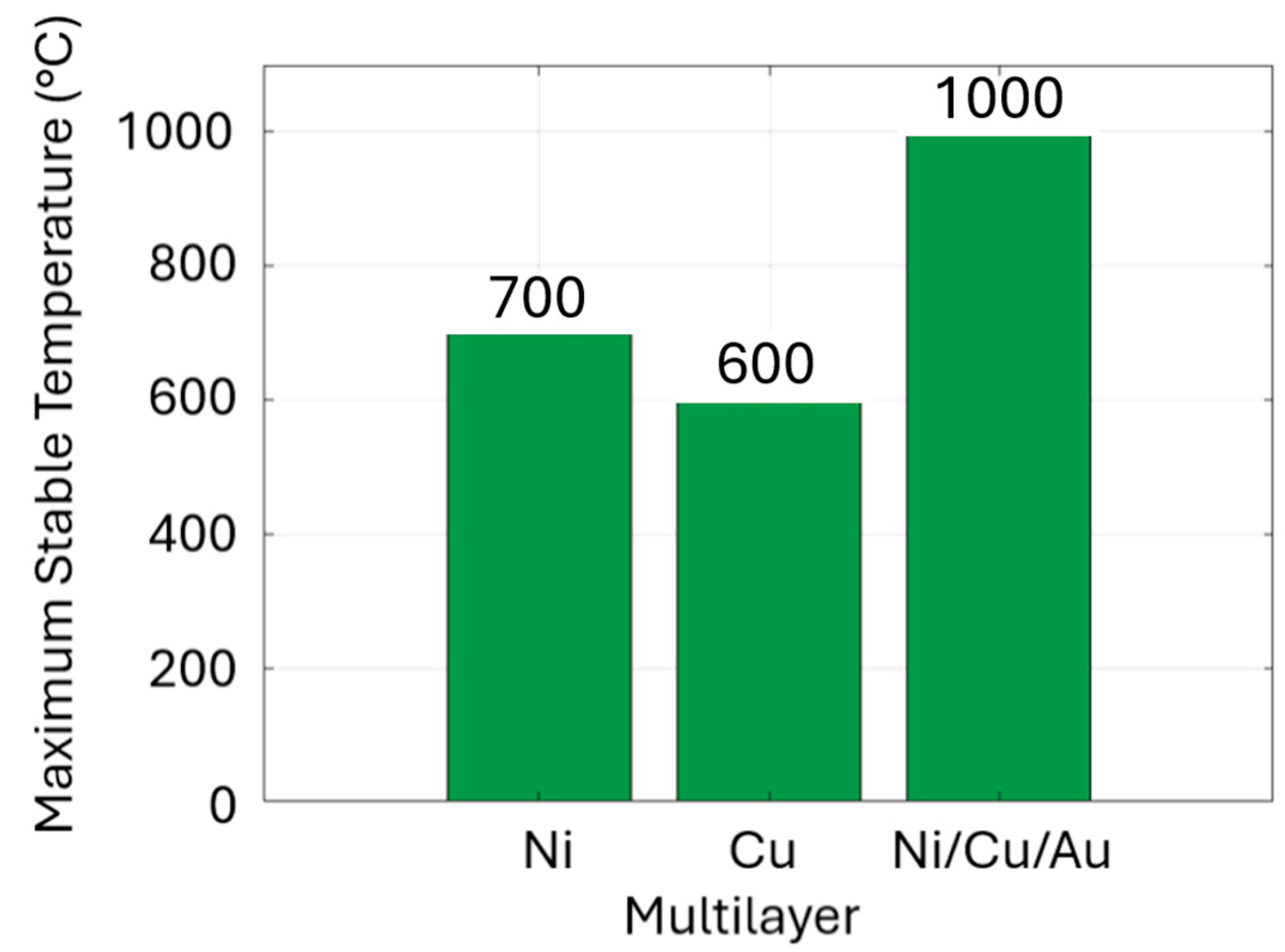

3.6. High-Temperature Stability, Diffusion, and Barriers

3.7. Practical Selection Rules

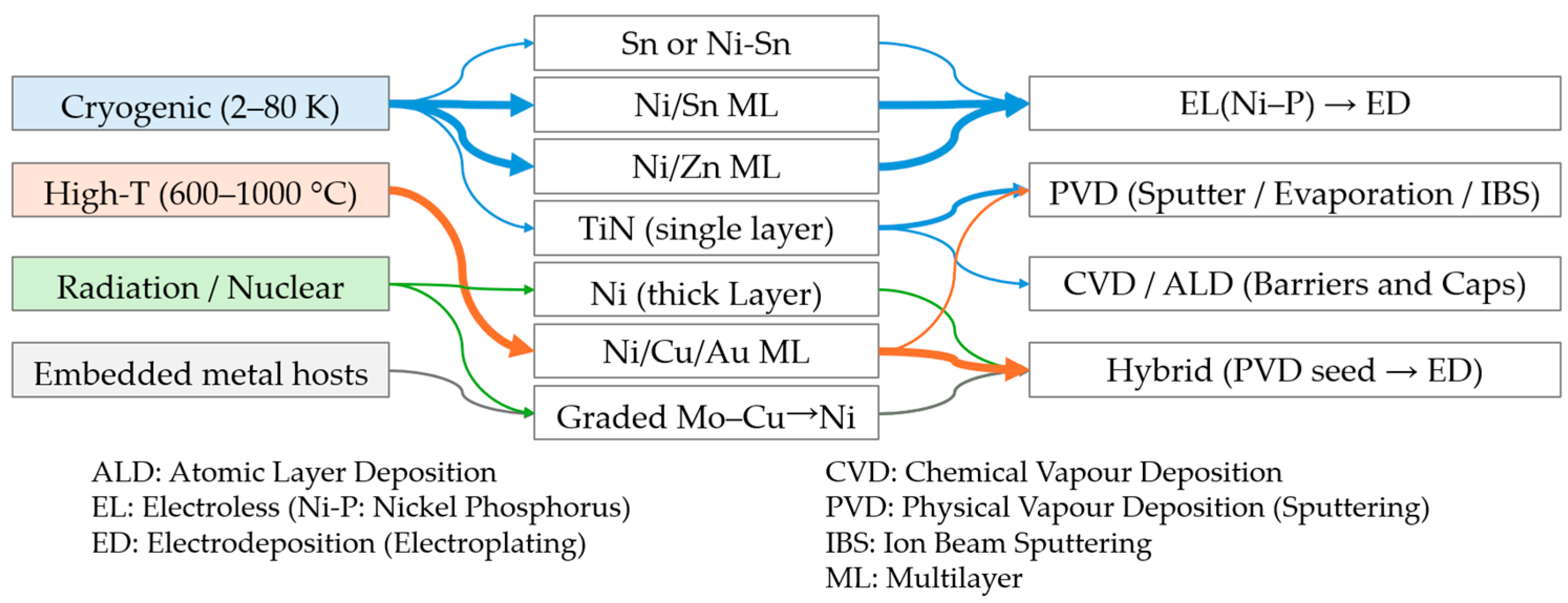

4. Deposition Techniques

4.1. Top-Down: PVD

4.2. Bottom-Up: CVD and ALD

4.3. Wet-Chemical Routes: EL and ED

4.4. Hybrid and Combination Strategies

4.5. Fusion-Based Approaches and Integration into Metals

5. Surface Preparation and Activation

6. Comparative Synthesis and Qualification

7. Design Recommendations and Outlook

8. Conclusions and Outlook

Recommendations for Coating Selection and Future Development

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ALD | Atomic Layer Deposition |

| CTE | Coefficient of Thermal Expansion |

| CVD | Chemical Vapor Deposition |

| ED | Electrodeposition |

| EL | Electroless |

| FBG | Fiber Bragg Grating |

| FWHM | Full-Width at Half Maximum |

| IBS | Ion Beam Sputtering |

| ML | Multilayer |

| PMMA | Poly(Methyl MethAcrylate) |

| PVD | Physical Vapor Deposition |

| QA | Quality Assurance |

| SNR | Signal-to-Noise Ratio |

References

- Lo Presti, D.; Massaroni, C.; D’Abbraccio, J.; Saccomandi, P.; Caponero, M.A.; Polimadei, A.; Schena, E. Fiber Bragg Gratings for Medical Applications and Future Challenges: A Review. IEEE Access 2020, 8, 156863–156888. [Google Scholar] [CrossRef]

- Xie, J.F.; Zhang, H.; Zhu, Z.; Xu, J.N.; Hu, R.H.; Song, L.F. A Study of the Temperature Sensitivity of Fiber Bragg Gratings after Metallization. Smart Mater. Struct. 2007, 16, 1837–1842. [Google Scholar] [CrossRef]

- Lupi, C.; Montinaro, N.; Paolozzi, A.; Giordano, M.; Russo, S.; Mastrogiacomo, F.; Campopiano, S.; Cutolo, A.; Cusano, A. Critical Issues of Double-Metal Layer Coating on FBG for Applications at High Temperatures. Sensors 2019, 19, 3824. [Google Scholar] [CrossRef]

- Liu, Y.; Fang, J.; Jia, D.; Li, W. Temperature Characteristics of FBG Sensors with Different Coatings for High Temperature Superconductor Application. In Proceedings of the 2019 IEEE 3rd International Electrical and Energy Conference (CIEEC 2019), Beijing, China, 7–9 September 2019; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2019; pp. 1546–1550. [Google Scholar] [CrossRef]

- Pendão, C.; Silva, I. Optical Fiber Sensors and Sensing Networks: Overview of the Main Principles and Applications. Sensors 2022, 22, 7554. [Google Scholar] [CrossRef]

- Vendittozzi, C.; Felli, F.; Lupi, C. Modeling FBG Sensors Sensitivity from Cryogenic Temperatures to Room Temperature as a Function of Metal Coating Thickness. Opt. Fiber Technol. 2018, 42, 84–91. [Google Scholar] [CrossRef]

- Mishra, V.; Lohar, M.; Amphawan, A. Improvement in Temperature Sensitivity of FBG by Coating of Different Materials. Optik 2016, 127, 825–828. [Google Scholar] [CrossRef]

- Wang, X.D.; Wolfbeis, O.S. Fiber-Optic Chemical Sensors and Biosensors (2015–2019). Anal. Chem. 2020, 92, 397–428. [Google Scholar] [CrossRef] [PubMed]

- Ramakrishnan, M.; Rajan, G.; Semenova, Y.; Farrell, G. Overview of Fiber Optic Sensor Technologies for Strain/Temperature Sensing Applications in Composite Materials. Sensors 2016, 16, 99. [Google Scholar] [CrossRef] [PubMed]

- Wen, C.; Li, Y. Effects of Metal Coating on the Fiber Bragg Grating Temperature Sensing Characteristics. J. Mod. Opt. 2016, 63, 762–770. [Google Scholar] [CrossRef]

- Campanella, C.E.; Cuccovillo, A.; Campanella, C.; Yurt, A.; Passaro, V.M.N. Fibre Bragg Grating Based Strain Sensors: Review of Technology and Applications. Sensors 2018, 18, 3115. [Google Scholar] [CrossRef]

- Wang, X.; Wang, W.; Li, Q.; Xie, C.; Luo, G.N. Application of FBG sensors in tokamak tungsten divertor, component for strain and temperature monitoring. In Optics and Photonics for Energy and the Environment; ET5A.6. 10.1364/EE.2018.ET5A.6; Optica Publishing Group: Washington, DC, USA, 2018. [Google Scholar]

- Hegde, G.; Asokan, S.; Hegde, G. Fiber Bragg grating sensors for aerospace applications: A review. ISSS J. Micro Smart Syst. 2022, 11, 257–275. [Google Scholar] [CrossRef]

- Yassin, M.H.; Farhat, M.H.; Soleimanpour, R.; Nahas, M. Fiber Bragg grating (FBG)-based sensors: A review of technology and recent applications in structural health monitoring (SHM) of civil engineering structures. Discov. Civ. Eng. 2024, 1, 151. [Google Scholar] [CrossRef]

- Lupi, C.; Vendittozzi, C.; Ciro, E.; Felli, F. FBG Spectrum Regeneration by Ni-Coating and High-Temperature Treatment. Sensors 2022, 22, 7255. [Google Scholar] [CrossRef]

- Nogueira, R.; Oliveira, R.; Bilro, L.; Heidarialamdarloo, J. New advances in polymer fiber Bragg gratings. Opt. Laser Technol. 2015, 78, 104–109. [Google Scholar] [CrossRef]

- Mihailov, S.J.; Grobnic, D.; Hnatovsky, C.; Walker, R.B.; Lu, P.; Coulas, D.; Ding, H. Extreme Environment Sensing Using Femtosecond Laser-Inscribed Fiber Bragg Gratings. Sensors 2017, 17, 2909. [Google Scholar] [CrossRef]

- Leal-Junior, A.; Frizera, A.; Marques, C. Development and Characterization of UV-Resin Coated Fiber Bragg Gratings. Sensors 2020, 20, 3026. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Sun, X.; Hu, Y.; Zeng, L.; Liu, Q.; Duan, J. Highly-Sensitive Fiber Bragg Grating Temperature Sensors with Metallic Coatings. Optik 2022, 262, 169337. [Google Scholar] [CrossRef]

- Deng, Y.; Jiang, J. Optical Fiber Sensors in Extreme Temperature and Radiation Environments: A Review. IEEE Sens. J. 2022, 22, 11145–11161. [Google Scholar] [CrossRef]

- Stephen, J.; Pal, P.; Mathew, J. Advances in Cryogenic Temperature Sensing Using Fiber Bragg Grating: A Review. IEEE Sens. J. 2025, 25, 12345–12360. [Google Scholar] [CrossRef]

- Zaynetdinov, M.; See, E.M.; Geist, B.; Ciovati, G.; Robinson, H.D.; Kochergin, V. A Fiber Bragg Grating Temperature Sensor for 2–400 K. IEEE Sens. J. 2015, 15, 1908–1912. [Google Scholar] [CrossRef]

- Hisham, H. Fiber Bragg Grating Sensors: Development and Applications; Taylor & Francis Group, LLC: Boca Raton, FL, USA, 2019; ISBN 978-0-367-22485-1. [Google Scholar] [CrossRef]

- Ciotti, M.; Nardelli, V.; Caponero, M.A.; Felli, F.; Lupi, C.; Ippoliti, L. An Optical System for Cryogenic Temperature Measurements. Smart Mater. Struct. 2007, 16, 1708–1711. [Google Scholar] [CrossRef]

- Soman, A.C.; Chalackal, A.T.; Kanakambaran, S. Design of Cryogenic Temperature Sensors Using Copper-Coated Fiber Bragg Gratings. In Proceedings of the 2022 IEEE Region 10 Symposium (TENSYMP 2022), Kolkata, India, 29–31 May 2022; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2022. [Google Scholar] [CrossRef]

- Chiuchiolo, A.; Bracco, C.; Rossi, F.; Bianchi, L.; Verdi, M. Cryogenic Test Facility Instrumentation with Fiber Optic and Fiber Optic Sensors for Testing Superconducting Accelerator Magnets. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2017; Volume 278, p. 012082. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, H.; Li, Y.L.; Rao, C.F. Temperature Sensing of Metal-Coated Fiber Bragg Grating. IEEE/ASME Trans. Mechatron. 2010, 15, 511–519. [Google Scholar] [CrossRef]

- Sugino, M.; Ogata, M.; Mizuno, K.; Hasegawa, H. Development of Zinc Coating Methods on Fiber Bragg Grating Temperature Sensors. IEEE Trans. Appl. Supercond. 2016, 26, 9000606. [Google Scholar] [CrossRef]

- Wang, X.; Sun, X.; Hu, Y.; Duan, J. Multilayer Metal-Coated Fiber Bragg Grating for High-Temperature Sensing. Measurement 2024, 226, 114132. [Google Scholar] [CrossRef]

- Shiue, S.T.; Yang, C.H.; Chu, R.S.; Yang, T.J. Effect of the Coating Thickness and Roughness on the Mechanical Strength and Thermally Induced Stress Voids in Nickel-Coated Optical Fibers Prepared by Electroless Plating Method. Thin Solid Films 2005, 485, 169–175. [Google Scholar] [CrossRef]

- Butt, M.A. Thin-Film Coating Methods: A Successful Marriage of High-Quality and Cost-Effectiveness—A Brief Exploration. Coatings 2022, 12, 1115. [Google Scholar] [CrossRef]

- Muench, F. Electroless Plating of Metal Nanomaterials. ChemElectroChem 2021, 8, 3591–3600. [Google Scholar] [CrossRef]

- Barhoum, A.; García-Betancourt, M.L.; Jeevanandam, J.; Hussien, E.A.; Mekkawy, S.A.; Mostafa, M.; Omran, M.M.; Abdalla, M.S.; Bechelany, M. Review on Natural, Incidental, Bioinspired, and Engineered Nanomaterials: History, Definitions, Classifications, Synthesis, Properties, Market, Toxicities, Risks, and Regulations. Nanomaterials 2022, 12, 177. [Google Scholar] [CrossRef] [PubMed]

- Elsherif, M.; Salih, A.E.; Muñoz, M.G.; Alam, F.; AlQattan, B.; Savariraj, A.D.; Zaki, M.F.; Yetisen, A.K.; Park, S.; Wilkinson, T.D.; et al. Optical Fiber Sensors: Working Principle, Applications, and Limitations. Adv. Photonics Res. 2022, 3, 2100371. [Google Scholar] [CrossRef]

- Grandal, T.; Piñeiro, E.; Asensio, A.; Rodriguez, F. Metallic Coating Techniques for Fiber Bragg Grating Sensors. In Proceedings of the 8th Iberoamerican Optics Meeting and 11th Latin American Meeting on Optics, Lasers, and Applications, Porto, Portugal, 22–26 July 2013; SPIE: Bellingham, WA, USA, 2013; p. 878538. [Google Scholar] [CrossRef]

- Majumder, M.; Gangopadhyay, T.K.; Chakraborty, A.K.; Dasgupta, K.; Bhattacharya, D.K. Fibre Bragg Gratings in Structural Health Monitoring—Present Status and Applications. Sens. Actuators A 2008, 147, 150–164. [Google Scholar] [CrossRef]

- Kern, W.; Schuegraf, K.K. Deposition Technologies and Applications: Introduction and Overview. In Handbook of Thin Film Deposition Processes and Techniques, 1st ed.; Noyes Publications: Park Ridge, NJ, USA, 1988; pp. 1–44. [Google Scholar]

- Rao, C.; Zhang, H.; Feng, Y.; Xiao, L.; Ye, Z. Thick Metal Coating Long-Period Fiber Grating. In Proceedings of the 6th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Design, Manufacturing, and Testing of Smart Structures, Micro- and Nano-Optical Devices, and Systems, Xiamen, China, 26–29 April 2012; SPIE: Bellingham, WA, USA, 2012; p. 84181Q. [Google Scholar] [CrossRef]

- Koo, K.N.; Lee, J.H.; Kim, S.H.; Park, J.; Lee, S.H. Fabrication and Modification of Temperature FBG Sensor: Role of Optical Fiber Type and Cu Sputtered Thickness. Phys. Scr. 2020, 95, 095602. [Google Scholar] [CrossRef]

- Tang, A.Q.; Fang, L.; Xue, S.J.; Yin, B.; Liu, L.; Zhang, P. Ni-P Coating Metallization on Fiber Bragg Grating without Fiber Coarsening and Its Temperature Sensing Property. In Proceedings of the 2011 International Conference on Optical Instruments and Technology: Optical Sensors and Applications, Beijing, China, 6–9 November 2011; SPIE: Bellingham, WA, USA, 2011; p. 819907. [Google Scholar] [CrossRef]

- Zhao, Z.B.; Gillispie, B.A.; Smith, J.R. Coating Deposition by the Kinetic Spray Process. Surf. Coat. Technol. 2006, 200, 4746–4754. [Google Scholar] [CrossRef]

- Scurti, F.; McGarrahan, J.; Schwartz, J. Effects of Metallic Coatings on the Thermal Sensitivity of Optical Fiber Sensors at Cryogenic Temperatures. Opt. Mater. Express 2017, 7, 1754–1764. [Google Scholar] [CrossRef]

- Li, Y.; Yang, K.; Li, X. Temperature Sensing Characteristics of Metal Coated FBG during Dynamic Cooling Process. Opt. Fiber Technol. 2018, 45, 368–375. [Google Scholar] [CrossRef]

- Sengupta, D.; Sai Shankar, M.; Saidi Reddy, P.; Sai Prasad, R.L.N.; Narayana, K.S.; Kishore, P. An Improved Low-Temperature Sensing Using PMMA Coated FBG. In Optics InfoBase Conference Papers, Proceedings of the Asia Communications and Photonics Conference and Exhibition 2011, Shanghai China, 13–16 November 2011; SPIE: Bellingham, WA, USA, 2011. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, W.; Zhang, H.; Liu, B.; Zhao, J.; Tu, Q.; Kai, G.; Dong, X. An embedded FBG sensor for simultaneous measurement of stress and temperature. IEEE Photonics Technol. Lett. 2006, 18, 154–156. [Google Scholar] [CrossRef]

- Mattox, D.M. Arc Vapor Deposition. In Handbook of Physical Vapor Deposition (PVD) Processing; Elsevier: Amsterdam, The Netherlands, 2010; pp. 287–300. [Google Scholar] [CrossRef]

- Pawar, K.; Dixit, P. A critical review of copper electroless deposition on glass substrates for microsystems packaging applications. Surf. Eng. 2022, 38, 576–617. [Google Scholar] [CrossRef]

- Prasad, R.D.; Teli, B.; Prasad, R.S.; Prasad, R.B.; Prasad, S.R.; Sinha, P.; Sinha, A.; Sinha, P.; Saxena, M.; Prasad, R.R.; et al. A Review on Thin Film Technology and Nanomaterial Characterization Techniques. ES Mater. Manuf. 2024, 25, 1198. [Google Scholar] [CrossRef]

- Li, C.; Liu, M.; Song, H.; Wang, J.; Wu, Y.; Chen, X. Thermal Sensing Performance Analysis, Preparation and Application of Bimetallic Layer MFBG. Int. J. Heat Mass Transf. 2023, 215, 124514. [Google Scholar] [CrossRef]

- Listewnik, P. Temperature Fiber-Optic Sensor with ZnO ALD Coating. Eng. Proc. 2021, 2, 99. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, X.; Guan, M.; Xin, C.; Wu, W.; Lin, X.; Pei, B. Enhanced Strain and Temperature Sensing in Copper-Coated Fiber Bragg Grating Sensors across a Wide Temperature Range from Cryogenic to Elevated Levels. Cryogenics 2024, 139, 103834. [Google Scholar] [CrossRef]

- Perry, M.; Niewczas, P.; Johnston, M.; Mackersie, J. Nickel plating of FBG strain sensors for nuclear applications. In Proceedings of the 21st International Conference on Optical Fiber Sensors, Ottawa, ON, Canada, 15–19 May 2011; Bock, W.J., Albert, J., Bao, X., Eds.; SPIE: Bellingham, WA, USA, 2011; Volume 7753. Article 77530C. [Google Scholar] [CrossRef]

- Shen, R.-S.; Teng, R.; Li, X.-P.; Zhang, J.; Xia, D.-C.; Fan, Z.-Q.; Yu, Y.-S.; Zhang, Y.-S.; Du, G.-T. Electroless Nickel Plating and Electrodeposition on FBG Temperature Sensor. Chem. Res. Chin. Univ. 2008, 24, 635–639. [Google Scholar] [CrossRef]

- Wang, Y.L.; Tu, Y.; Tu, S.T. Development of Highly-Sensitive and Reliable Fiber Bragg Grating Temperature Sensors with Gradient Metallic Coatings for Cryogenic Temperature Applications. IEEE Sens. J. 2021, 21, 4652–4663. [Google Scholar] [CrossRef]

- Li, Y.; Wen, C.; Zhang, H.; Yang, J.; Yan, M.; Jiang, J. An Electrodeposition Method for Surface Mounting Optical Fiber Sensors on the Metal Substrate. IEEE Photonics Technol. Lett. 2016, 28, 1811–1814. [Google Scholar] [CrossRef]

- Tu, Y.; Qi, Y.H.; Tu, S.T. Fabrication and thermal characteristics of multilayer metal-coated regenerated grating sensors for high-temperature sensing. Smart Mater. Struct. 2013, 22, 075026. [Google Scholar] [CrossRef]

- Li, Y.; Hua, Z.; Yan, F.; Gang, P. Metal coating of fiber Bragg grating and the temperature sensing character after metallization. Opt. Fiber Technol. 2009, 15, 391–397. [Google Scholar] [CrossRef]

- Mansor, N.F.; Raja Ibrahim, R.K. Temperature sensitivity of FBG coating with zinc oxide and silicon carbide. J. Phys. Conf. Ser. 2021, 1892, 012033. [Google Scholar] [CrossRef]

- Kesavan, K.; Ravisankar, K.; Senthil, R.; Sundaram, B.A.; Parivallal, S. Studies on Apparent Strain Using FBG Strain Sensors for Different Structural Materials. Exp. Tech. 2014, 38, 31–38. [Google Scholar] [CrossRef]

- Lindner, M.; Gaßmann, S.; Klein, T.; Roeser, F.; Möllmann, M.; Lerch, R. Fiber Bragg Sensors Embedded in Cast Aluminum Parts: Axial Strain and Temperature Response. Sensors 2021, 21, 1680. [Google Scholar] [CrossRef] [PubMed]

- Freitas, R.; Araujo, F.; Araujo, J.; Neumann, H.; Ramalingam, R. A Study on Intermediate Buffer Layer of Coated Fiber Bragg Grating Cryogenic Temperature Sensors. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2015; Volume 101, p. 012154. [Google Scholar] [CrossRef]

- He, J.; Ding, L.; Cai, J.; Zhu, W.; Dai, J. A Novel High Temperature Resistant Mo-Cu Functional Gradient Coating for Optic Fiber Bragg Grating. Results Phys. 2019, 14, 102456. [Google Scholar] [CrossRef]

- Weraneck, K.; Lee, S.W.; King, N.; Ward, A.D.; Haynes, M.; Sampson, P.; Allwood, D. Strain Measurement in Aluminium Alloy during the Solidification Process Using Embedded Fibre Bragg Gratings. Sensors 2016, 16, 1853. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wang, Y.; Wen, C. Temperature and Strain Sensing Properties of the Zinc Coated FBG. Optik 2016, 127, 6463–6469. [Google Scholar] [CrossRef]

- Kok, S.P.; Go, Y.I.; Wang, X.; Wong, M.D. Advances in Fiber Bragg Grating (FBG) Sensing: A Review of Conventional and New Approaches and Novel Sensing Materials in Harsh and Emerging Industrial Sensing. IEEE Sens. J. 2024, 24, 29485–29505. [Google Scholar] [CrossRef]

- Hokkanen, A.; Salmi, A.; Vashistha, V.; Nyman, M.; Nielsen, S.K.; Jensen, T.; Jessen, M.; Wälchli, B.; Kapulainen, M.; Naulin, V.; et al. A Panda fiber temperature sensor up to 900°C. J. Instrum. 2022, 17, P07031. [Google Scholar] [CrossRef]

- Lupi, C.; Felli, F.; Brotzu, A.; Caponero, M.A.; Paolozzi, A. Improving FBG Sensor Sensitivity at Cryogenic Temperature by Metal Coating. IEEE Sens. J. 2008, 8, 1299–1304. [Google Scholar] [CrossRef]

- Listewnik, P.; Hirsch, M.; Struk, P.; Weber, M.; Bechelany, M.; Jędrzejewska-Szczerska, M. Preparation and Characterization of Microsphere ZnO ALD Coating Dedicated for the Fiber-Optic Refractive Index Sensor. Nanomaterials 2019, 9, 306. [Google Scholar] [CrossRef]

- Sandlin, S.; Kinnunen, T.; Rämö, J.; Sillanpää, M. A Simple Method for Metal Re-Coating of Optical Fibre Bragg Gratings. Surf. Coat. Technol. 2006, 201, 3061–3065. [Google Scholar] [CrossRef]

- Silva, D.; da Silva, L.F.; de Souza, R.F.; de Almeida, D.L.; de Oliveira, M.M. Sputtering Deposition of TiO2 Thin Film Coatings for Fiber Optic Sensors. Photonics 2022, 9, 342. [Google Scholar] [CrossRef]

- Lou, H.H.; Huang, Y. Electrodeposition. In Encyclopedia of Chemical Processing; Lee, S., Ed.; Taylor & Francis: New York, NY, USA, 2006. [Google Scholar]

- Chan, T.H.T.; Seah, L.K.; Leung, A.Y.T.; Li, H.-N.; Lam, H.F. Fiber Bragg Grating Sensors for Structural Health Monitoring of Tsing Ma Bridge: Background and Experimental Observation. Eng. Struct. 2006, 28, 648–659. [Google Scholar] [CrossRef]

- Hsu, C.Y.; Chiang, C.C.; Hsieh, T.S.; Hsu, H.C.; Tsai, L.; Hou, C.H. Study of Fiber Bragg Gratings with TiN-Coated for Cryogenic Temperature Measurement. Opt. Laser Technol. 2021, 136, 106768. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, H.; Li, Y.-L.; Peng, G. Highly Sensitive Ni-Cu Duplex Metal Coated Fiber Bragg Grating Temperature Sensor. In Proceedings of the 2009 Symposium on Photonics and Optoelectronics, Wuhan, China, 14–16 August 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Feng, Y.; Peng, G. A Plating Method for Metal Coating of Fiber Bragg Grating. Chin. Opt. Lett. 2009, 7, 115–117. [Google Scholar] [CrossRef]

- Kok, S.; Go, Y.; Wang, X.; Wong, D. A Review of Nanostructure Coating Techniques to Achieve High-Precision Optical Fiber Sensing Applications. Nanomanufacturing 2024, 4, 214–240. [Google Scholar] [CrossRef]

- Wright, R.F.; Buric, M.; Egbu, J.; Ziomek-Moroz, M.; Lu, P.; Ohodnicki, P.R. Electrolessly Coated Optical Fibers for Distributed Corrosion Monitoring. In Proceedings of the CORROSION 2019, Nashville, TN, USA, 24–28 March 2019; pp. 1–12. [Google Scholar] [CrossRef]

- Rajini-Kumar, R.; Suesser, M.; Narayankhedkar, K.G.; Krieg, G.; Atrey, M.D. Performance Evaluation of Metal-Coated Fiber Bragg Grating Sensors for Sensing Cryogenic Temperature. Cryogenics 2008, 48, 142–147. [Google Scholar] [CrossRef]

- Chanet, N.; Frigione, D.; Imbeaux, F.; Debieu, J.; Jacquet, P.; Mazon, D. Design and Integration of Femtosecond Fiber Bragg Gratings Temperature Probes inside Actively Cooled IT-ER-Like Plasma-Facing Components. Fusion Eng. Des. 2021, 166, 112376. [Google Scholar] [CrossRef]

- Sala, G.; Di Landro, L.; Airoldi, A.; Bettini, P. Fibre Optics Health Monitoring for Aeronautical Applications. Meccanica 2015, 50, 2547–2567. [Google Scholar] [CrossRef]

- Caloud, J.; Imbeaux, F.; Frigione, D.; Boulbe, C.; Jacquet, P.; Mazon, D. Conceptual Design of Fiber Bragg Grating Temperature Sensors for Heat Load Measurements in COMPASS-U Plasma-Facing Components. Fusion Eng. Des. 2023, 193, 113608. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Li, H.; Li, S.; Huang, Y.; Liu, Y. R&D of a Strain Monitoring System for the EAST Tungsten Divertor. Nucl. Mater. Energy 2019, 19, 498–502. [Google Scholar] [CrossRef]

- Chang, T.; Jia, L.; Sui, Q.; Cui, H.-L. High-Temperature Measurement Using Cu-Plating Fiber Bragg Grating for Metal Smart Structure Applications. In Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2014; SPIE: Bellingham, WA, USA, 2014; p. 90613P. [Google Scholar] [CrossRef]

| Environment | Dominant Degradation Drivers | Recommended Coating Stack | Deposition Route | Key Parameters/Post-Treatments | (×Bare) * | Trade-Offs/Notes | Refs. |

|---|---|---|---|---|---|---|---|

| Cryogenic (2–80 K) | Low thermo-optic slope of silica, thermal shock, brittleness | Ni → Zn duplex/Ni/Sn multilayer/Ni–P + Sn | EL Ni–P → ED Zn/Sn (or alternating Ni/Sn plating) | 5–30 µm total; anneal 250 °C; H2 bake | 1.5–5× | Highest ηᵀ gain; moderate transient penalty (~2× slower step); stress-balancing needed in multilayers | [27,29,38,41] |

| High- temperature (600–1000 °C) | Oxidation, interdiffusion, drift | Ni/Cu/Au multilayer ± TiN/Al2O3 cap | PVD seed → ED Ni/Cu → PVD Au (+CVD/ALD cap) | ~1–10 µm each; H2 bake before use | ≈1× (stable slope) | Excellent stability to 1000 °C; diffusion control via multilayers | [30,31,40] |

| Radiation/nuclear | Embrittlement, hydrogen accumulation, adhesion loss | Thick Ni | Evap seed → ED Ni | ≥10 µm; post-plating bake mandatory | ≈1× | Robust, but prone to H2 blisters if unbaked | [45] |

| Embedded/CTE-matched | Thermal-shock delamination, CTE mismatch | Graded Mo–Cu → Ni | Sputtered gradient → ED Ni | – | 1–2× | Stress-relieved interface; process complex | [46,47] |

| Corrosive/chemical | Bath attack, oxidation in service | Ni–P or Ni–P + Zn | EL Ni–P or EL → ED | – | 1–2× | Low-cost route; limited cryo-stability | [48,49] |

| Parameter | Symbol/Expression | Physical Meaning | Typical Range or Trend |

|---|---|---|---|

| Temperature sensitivity | Apparent shift in wavelength per unit temperature | 8–12 pm K−1 (bare), 12–50 pm K−1 (coated) | |

| Normalized sensitivity | Sensitivity amplification due to coating | 1–5 depending on material | |

| Strain transfer efficiency | Degree of strain coupling between coating and fiber | 0.5–1 | |

| Hysteresis | Δλ (heating vs. cooling) | Indicates elastic recovery and adhesion stability | <10 pm preferred |

| Drift | Δλ per cycle or time | Measures long-term thermal stability | <1 pm cycle−1 typical |

| FWHM | Spectral width at ½ max | Indicates spectral broadening from strain gradients | 0.1–0.3 nm typical |

| SNR | Peak reflectivity/noise | Evaluates spectral quality | >20 dB desirable |

| Response time | Time to 95% of Δλ after ΔT | Measures coating thermal inertia | 0.1–5 s depending on thickness |

| Stage | Params | QA | Notes | Refs |

|---|---|---|---|---|

| Clean/etch | Solvent clean; acid/alkali etch | No residue; microscope | Avoid over-etching | [38,48] |

| Sensitize/activate | SnCl2 → PdCl2 | pH/time control | Foundation for EL nucleation | [48] |

| EL Ni–P seed | ~90 °C; pH 4.5–5.0 | Continuity; spectral check | Anneal removes λ(T) hysteresis | [38,53] |

| Electroplate build | Ni/Cu/Zn/Sn plating | Thickness per step; centroid drift | Bake Ni to outgas H2 | [39,40,51] |

| Barriers/caps | Thin TiN/oxides or Au | Adhesion; diffusion tests | Needed for Cu/Ni stacks | [30,54,55] |

| Post-treatments | Ni–P anneal; H2 bake | Hysteresis removed; drift stabilized | Mandatory before qualification | [38,56] |

| Metal | Bath | Current | Temp | Agitation | Notes | Refs |

|---|---|---|---|---|---|---|

| Ni | Watts/sulfamate | 1–5 A/dm2 | 45–60 °C | Moderate | H2 uptake → bake | [40,51] |

| Cu | Acid sulfate | 1–4 A/dm2 | 20–30 °C | Moderate | Needs barriers/caps | [30,51] |

| Zn | Acid chloride/alkaline | 0.5–2 A/dm2 | 20–35 °C | Gentle | Recipe discipline for λ0 | [29,57,58] |

| Sn | Methanesulfonate/stannous | 0.4–0.6 A/dm2 | 20–30 °C | Gentle | Whisker mitigation | [51] |

| Route | Thick | Conform | Stress | Rate | Complex | Defects | Best | Refs |

|---|---|---|---|---|---|---|---|---|

| PVD | 0.01–2 µm | Good (LOS) | Low–Med | Low–Med | Med–High | Particles, stress | Seeds, TiN, thin Cu | [45,59,60] |

| CVD/ALD | 0.005–0.2 µm | Excellent | Low | Low | High | Complex precursors | Barriers/caps | [54,55,61] |

| EL (Ni-P) | 0.05–1 µm | Excellent | Med (anneal) | Med | Low | Nodules if bath aged | Uniform seeds | [40,62] |

| ED (Ni/Cu/Zn/Sn) | 1–100 µm | Excellent (rotation) | Process-dependent | High | Low–Med | H2, non-uniformity | Thick builds, duplex | [41,51] |

| Hybrid (PVD → ED) | 0.1–50 µm | Good–Excellent | Balanced | Med–High | Med–High | Interface issues | Ni/Cu/Au multilayers | [30,31,63] |

| Graded interlayer | ~1–10 µm | Good | Reduced | Med | High | Process complexity | Stress relief/embedding | [46] |

| Regime | Stack | Depo | Treat | Caps | Notes | Refs |

|---|---|---|---|---|---|---|

| Deep cryo (≤80 K) | Ni → Zn duplex | Sn → Pd → EL Ni-P → Zn ED | Ni-P anneal; H2 bake | — | Large slope, slower transient | [27,29,41,62] |

| 80–300 K | Ni/Cu duplex or TiN | PVD seed → Ni/Cu ED | H2 bake | TiN or Au | Balanced properties | [59,63,64] |

| High-T (600–1000 °C) | Ni/Cu/Au multilayer | PVD seed → ED → PVD cap | H2 bake | Ni barrier + Au cap | Diffusion/oxidation control | [30,31,40] |

| Radiation/nuclear | Thick Ni | Evap Cr/Au → Ni ED | H2 bake | — | Adhesion robustness | [45] |

| Embedded in metal host | Graded Mo–Cu → Ni | Sputter gradient → Ni ED | Stress-relief soaks | As needed | Shock survival | [46,64] |

| Field | Desc | Refs |

|---|---|---|

| Specimen ID | ID, grating type | Example: FBG-01 |

| Pre-coat spectral | λ0, FWHM, SNR | 1549.876 nm, 0.18 nm, 28 dB |

| Surface prep | Clean/etch details | Acetone/IPA, HF 0.5% |

| Activation/seed | SnCl2 → PdCl2; EL Ni-P | 90 °C, pH 4.8, 0.15 µm |

| ED | Metal, current, thickness | Zn 0.6 A/dm2, 8 min, +3 µm |

| Barriers/caps | Material, thickness | Au 80 nm PVD |

| Post-treatments | Anneal, bake | 300 °C 60 min |

| Qualification | LN2 cycles; soaks | 5× 293↔77 K |

| Result summary | Slope, hysteresis | +2.3× bare |

| Failure mode | Adhesion, cracking | None after 10 cycles |

| Coating Type | Representative Materials | Typical Application Range | Main Advantages | Main Limitations | Typical Temperature Sensitivity/Accuracy * |

|---|---|---|---|---|---|

| Metallic (single-layer) | Ni, Cu, Al | Cryogenic (2–300 K), moderate thermal cycling | Strong strain transfer, easy deposition | Residual stress, oxidation | ηT ≈ 1.5–3; ±0.5 K stability |

| Duplex/multilayer | Ni → Zn, Ni/Cu/Au, Ni/Sn | Cryogenic to 800 °C | Enhanced adhesion, tunable sensitivity | Complexity, interdiffusion | ηT ≈ 2–5; ±0.3 K typical |

| Ceramic/oxide | TiO2, SiO2, Al2O3 | 600–1000 °C (oxidizing atmospheres) | High-T stability, oxidation resistance | Brittle, limited strain transfer | ηT ≈ 1–1.5; ±1 K typical |

| Composite/ hybrid | Metal + polymer, Metal + oxide | 100–500 °C, humidity/corrosion protection | Mechanical resilience, environmental sealing | Aging of polymer layers | ηT ≈ 1.2–2; ±0.5 K |

| Polymeric/UV-resin | Acrylate, polyimide | <150 °C, low-cost use | Flexible, easy handling | Thermal degradation, poor uniformity | ηT ≈ 1; ±1–2 K |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vendittozzi, C.; Di Micco, E.; Caponero, M.A.; D’Amato, R. Functional Coatings for Fiber Bragg Gratings: A Critical Review of Deposition Techniques for Embedded and Harsh-Environment Applications. Coatings 2025, 15, 1268. https://doi.org/10.3390/coatings15111268

Vendittozzi C, Di Micco E, Caponero MA, D’Amato R. Functional Coatings for Fiber Bragg Gratings: A Critical Review of Deposition Techniques for Embedded and Harsh-Environment Applications. Coatings. 2025; 15(11):1268. https://doi.org/10.3390/coatings15111268

Chicago/Turabian StyleVendittozzi, Cristian, Emilia Di Micco, Michele A. Caponero, and Rosaria D’Amato. 2025. "Functional Coatings for Fiber Bragg Gratings: A Critical Review of Deposition Techniques for Embedded and Harsh-Environment Applications" Coatings 15, no. 11: 1268. https://doi.org/10.3390/coatings15111268

APA StyleVendittozzi, C., Di Micco, E., Caponero, M. A., & D’Amato, R. (2025). Functional Coatings for Fiber Bragg Gratings: A Critical Review of Deposition Techniques for Embedded and Harsh-Environment Applications. Coatings, 15(11), 1268. https://doi.org/10.3390/coatings15111268