The Influence Mechanism of the Hardness Homogeneity of the Grind-Hardening Layer on Its Wear Resistance

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Condition

2.2. Grind-Hardening Experiment

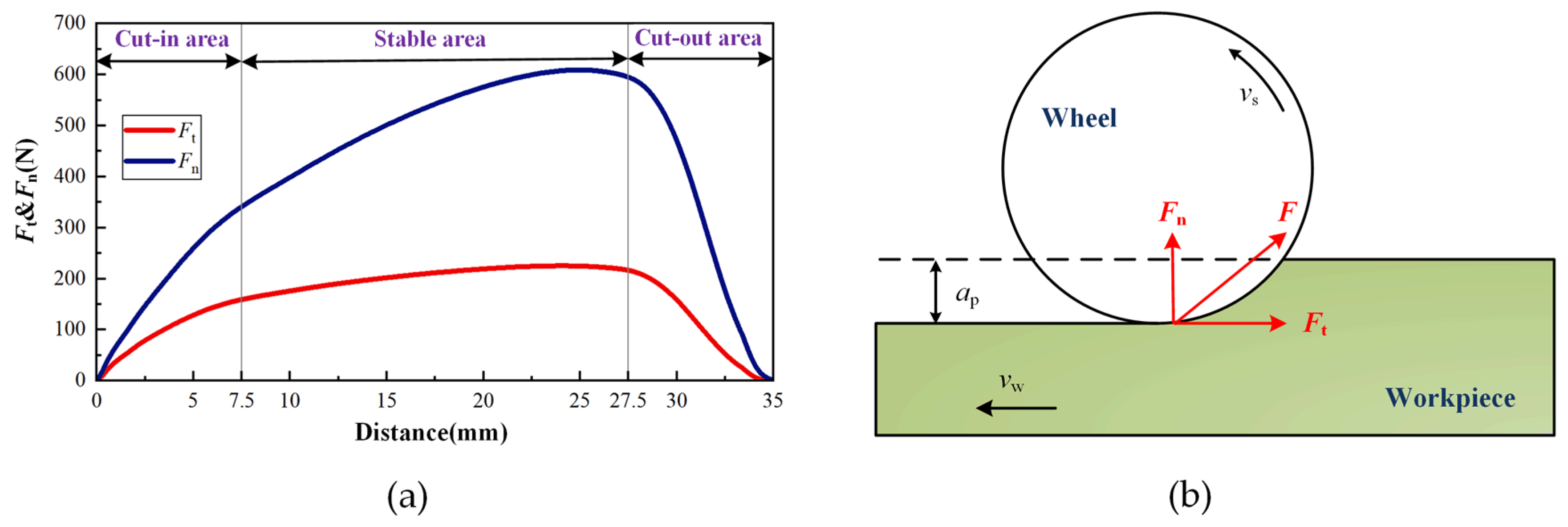

2.2.1. Grinding Force

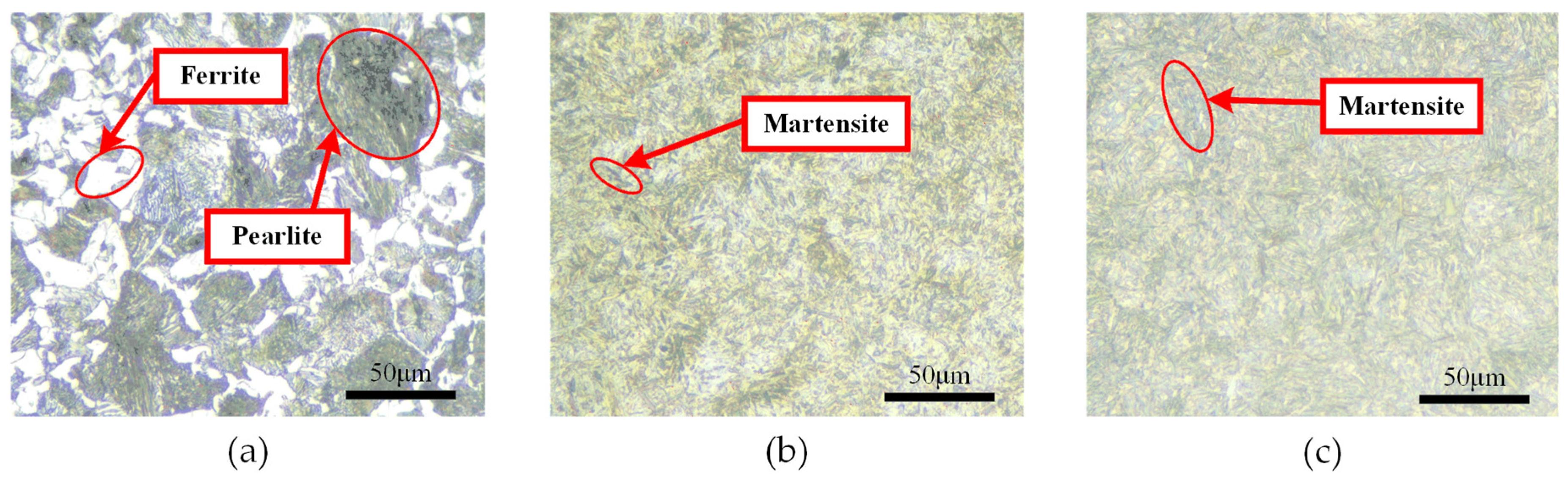

2.2.2. Microstructure

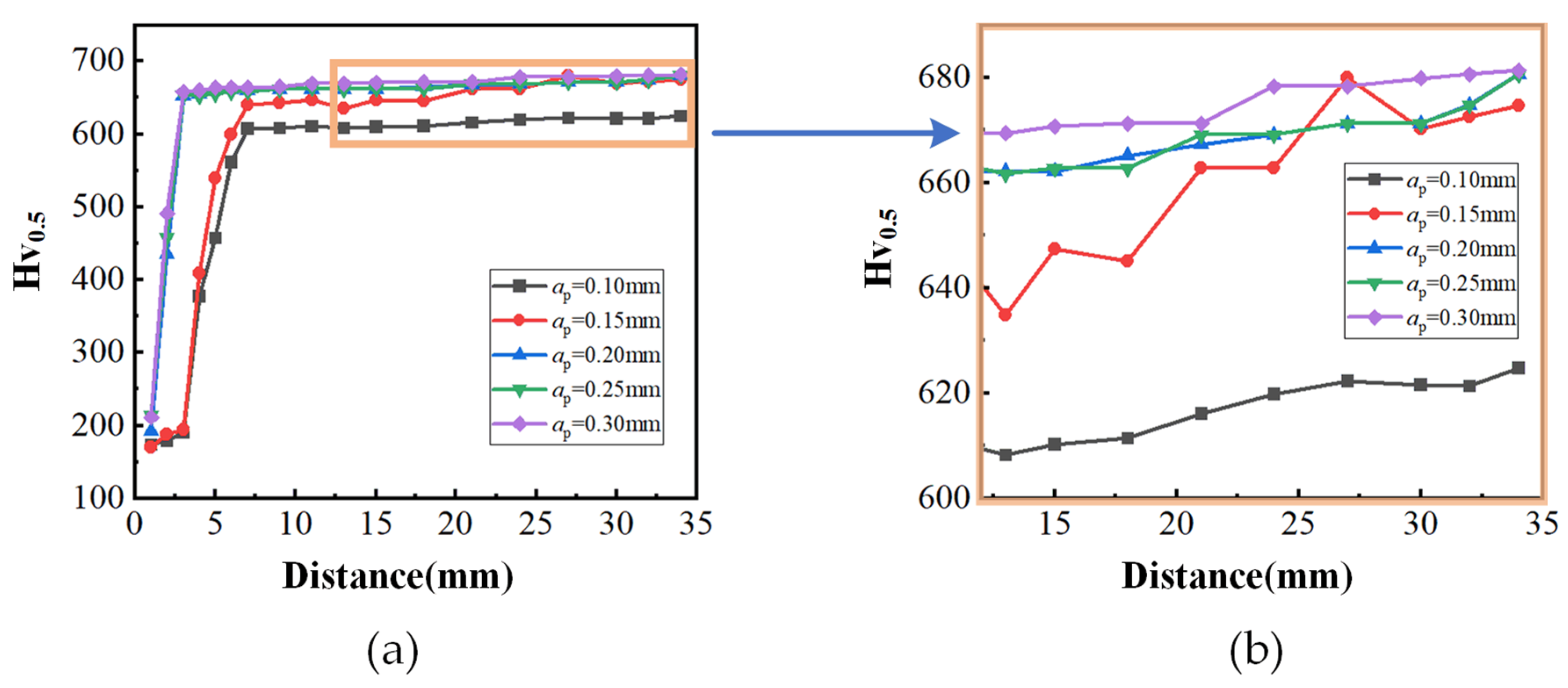

2.2.3. Hardness

2.3. Friction Experiment

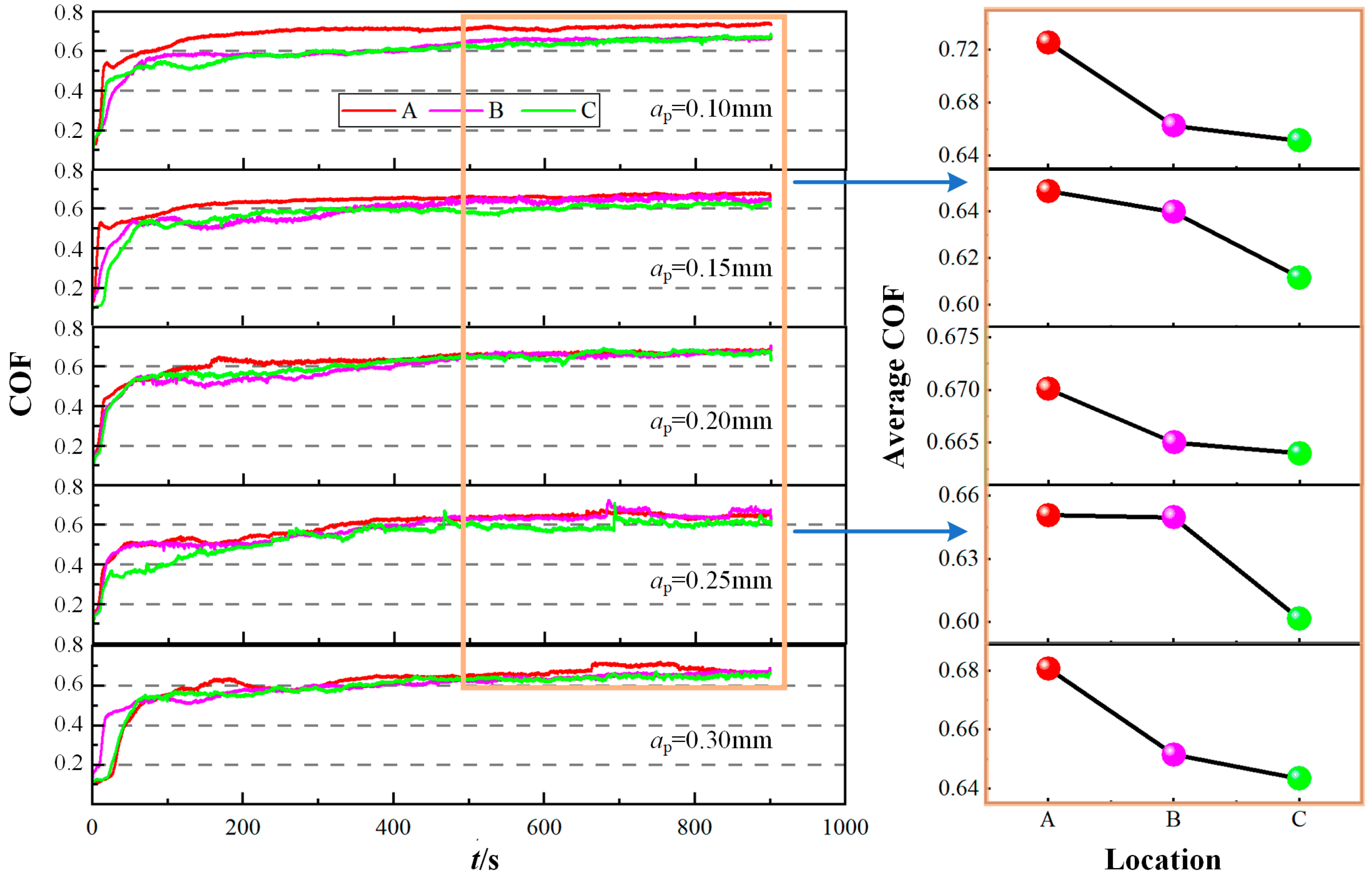

2.3.1. COF

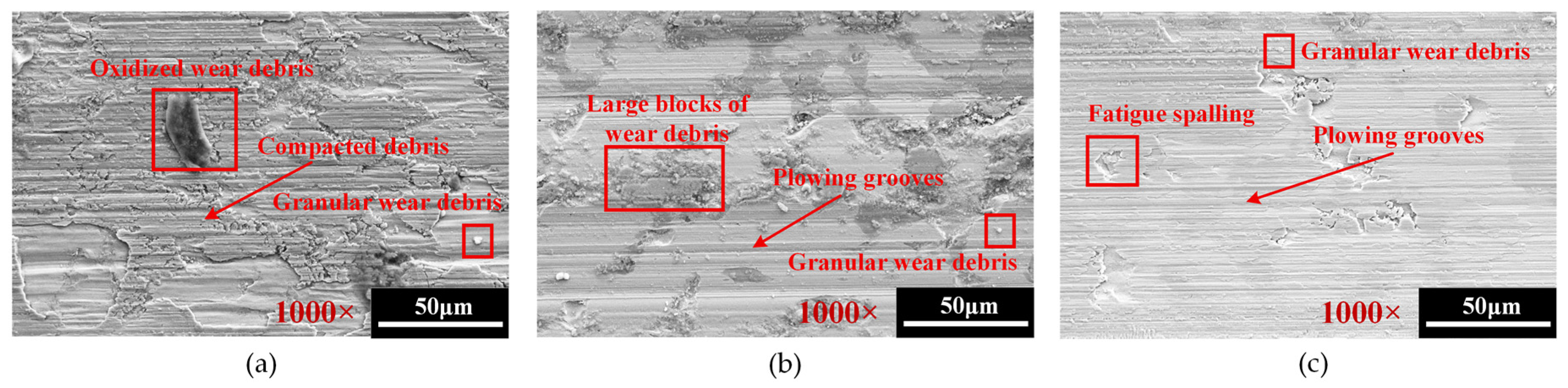

2.3.2. Wear Morphology

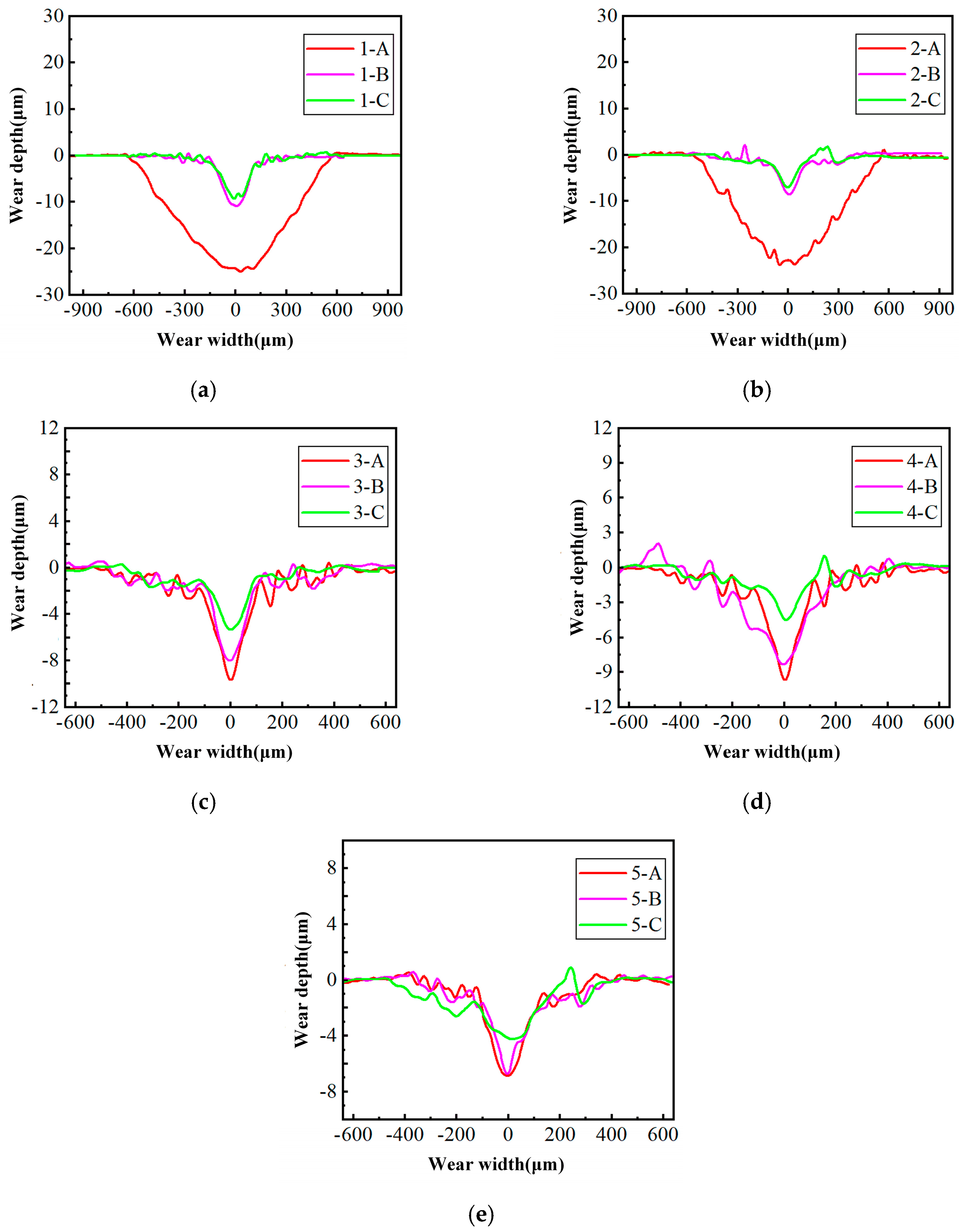

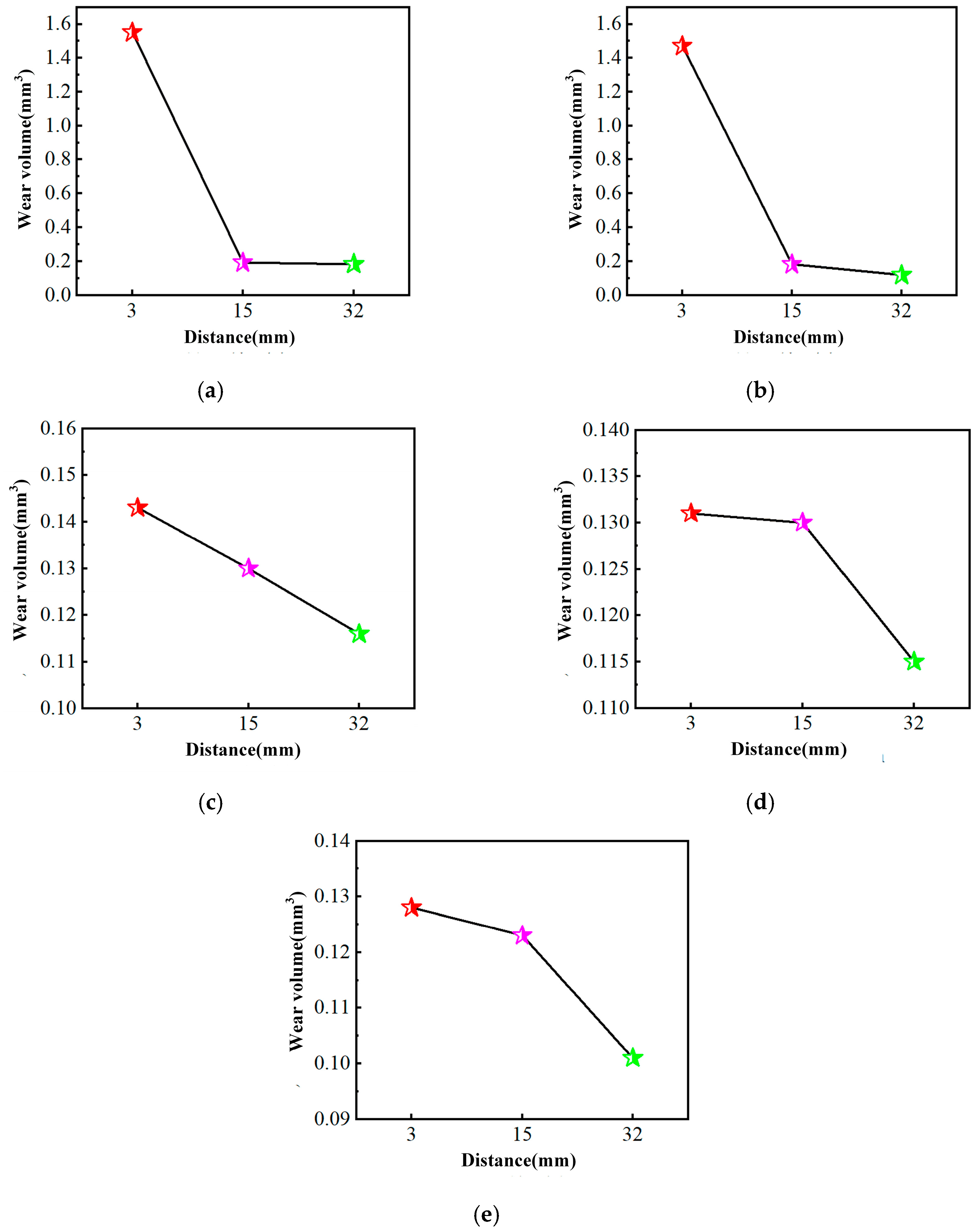

2.3.3. Wear Profile and Amount

3. Simulation and Results

3.1. Wear Model and Simulation Procedure

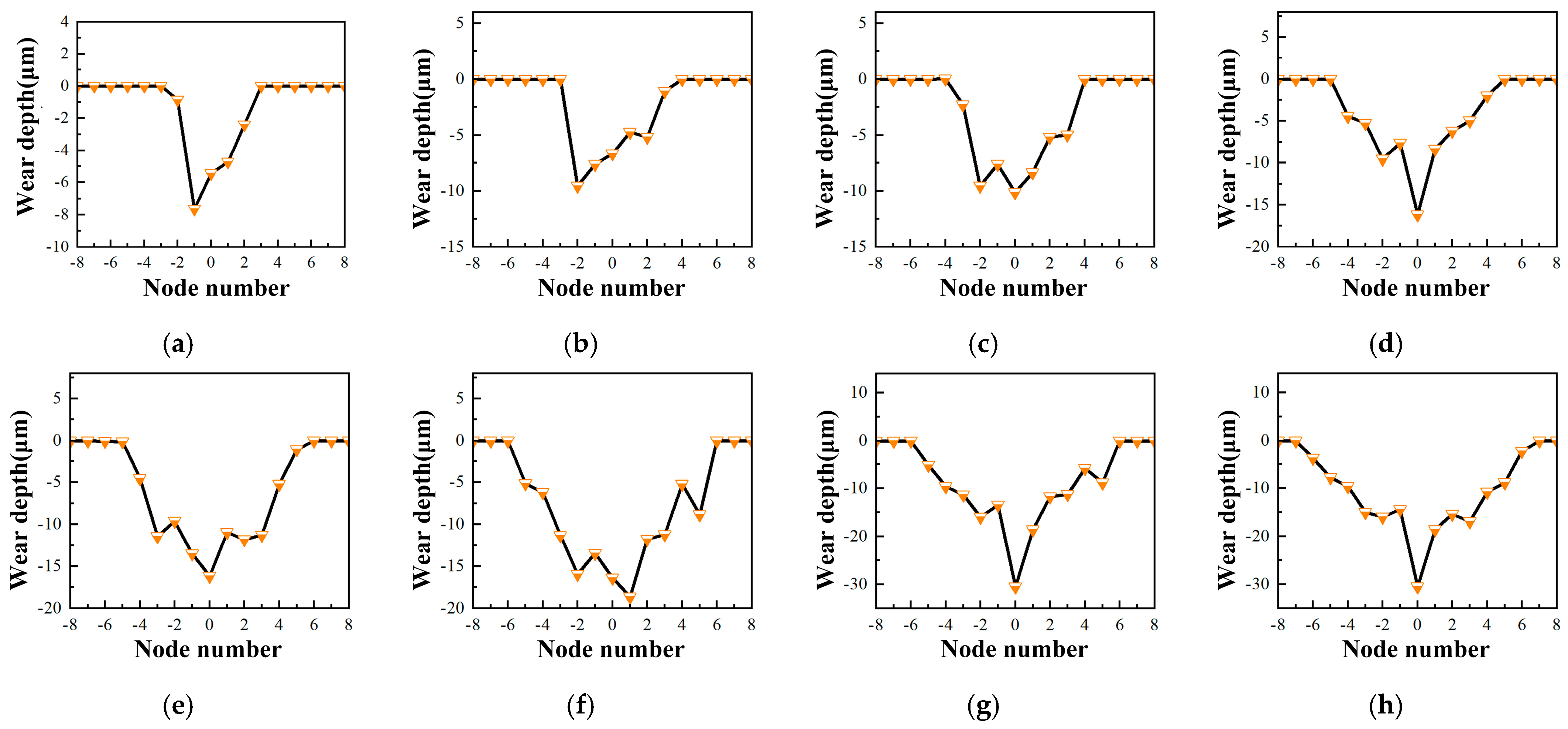

3.2. Results and Discussion

4. Conclusions

- (1)

- An experimental study on grind-hardening of AISI 1045 steel is carried out. The results show that the instantaneous grinding force appears to be a nonlinear change during the grinding process. According to the variation characteristics of the grinding force over time, the workpiece surface can be divided into the cut-in area, the stable area and the cut-out area. Combined with microstructure observation, the change in grinding force is the fundamental reason for inhomogeneous hardness distribution of hardened layer.

- (2)

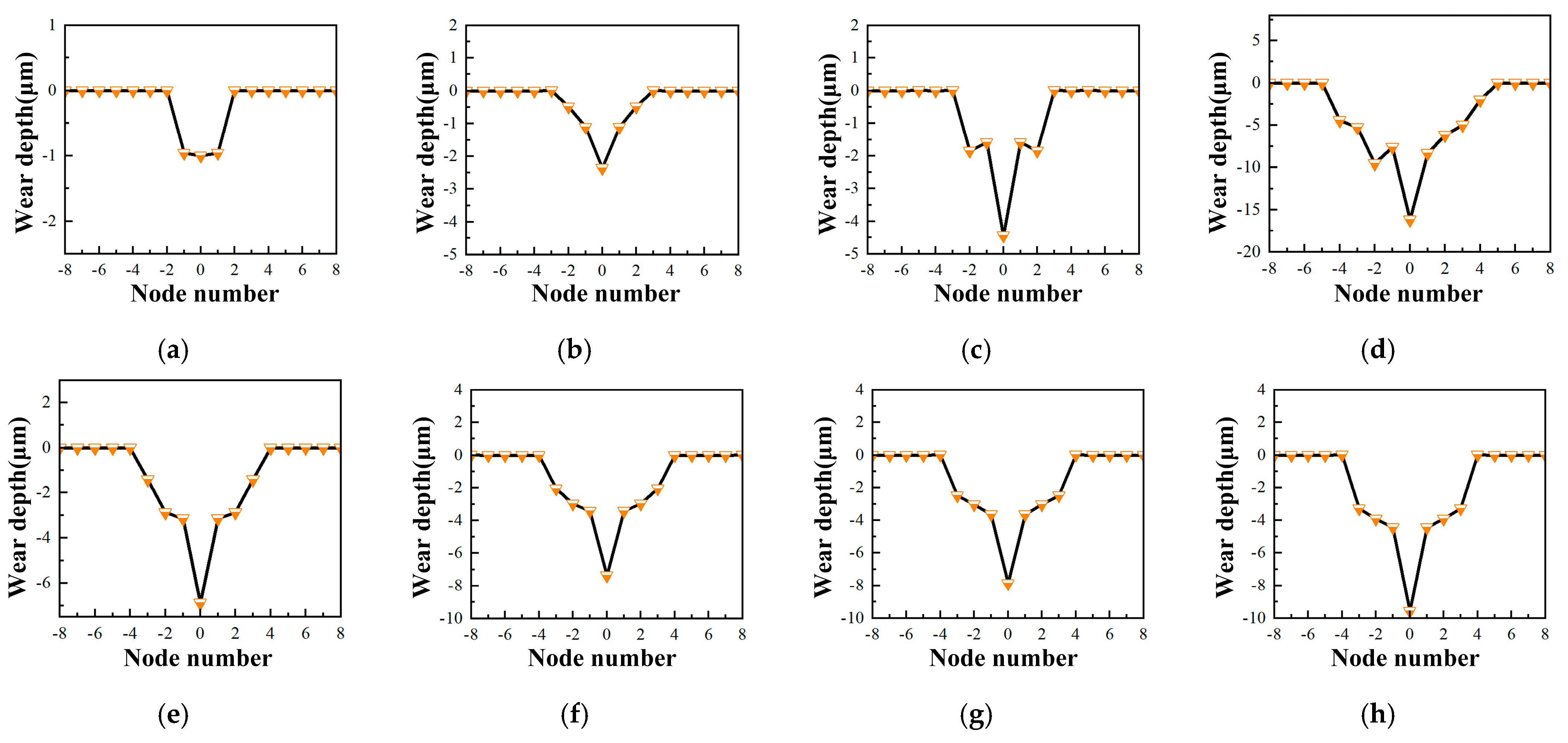

- The friction experiment on the hardened layer has found that the COF with different experimental parameters all show the variation law of continuously decreasing from the cut-in area to the cut-out area. In addition, although the wear profiles at different locations tend to be the same as the given experimental parameters, the test results of the wear depth, width and volume wear amount still reflect the influence of the hardness homogeneity on the overall wear resistance of the hardened layer.

- (3)

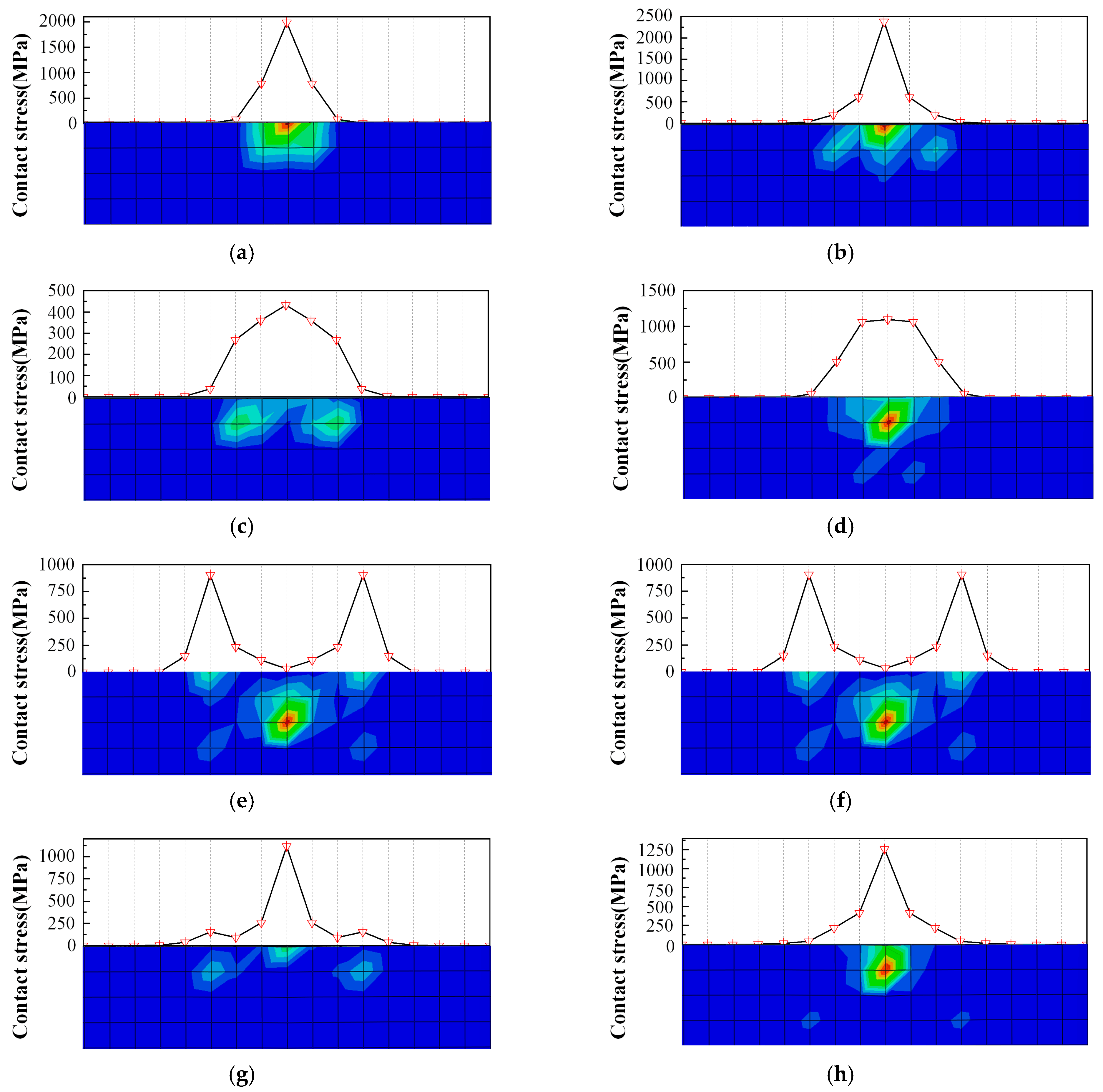

- A simulation study is carried out on the wear process of the hardened layer. The results show that the wear processes at different locations of the hardened layer are all affected by stress concentration, thereby causing the maximum value of the contact stress to move cyclically between the middle and the edge of wear area. It leads to a continuous increase in the wear depth and width as the contact stress and its distribution change. Eventually, the wear profile also varies accordingly. Meanwhile, by comparing the simulated values of the wear depth with different experimental parameters with the experimental values, the error is between 3.6% and 11.3%. It proves the effectiveness of the theoretical research on the simulation of the wear process of the hardened layer considering the influence of hardness homogeneity and the prediction of its depth.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, Z.C.; Zhu, L.D.; Zhang, G.X.; Ni, C.B.; Lin, B. Review of ultrasonic vibration-assisted machining in advanced materials. Int. J. Mach. Tool. Manuf. 2020, 156, 103594. [Google Scholar] [CrossRef]

- Liu, M.H.; Zhang, K.; Xiu, S.C. Mechanism investigation of hardening layer hardness uniformity based on grind-hardening process. Int. J. Adv. Manuf. Technol. 2017, 88, 3185–3194. [Google Scholar] [CrossRef]

- Nguyen, T.; Zhang, L.C.; Sun, D.L.; Wu, Q. Characterizing the Mechanical Properties of the Hardened Layer Induced by Grinding-Hardening. Mach. Sci. Technol. 2014, 18, 277–298. [Google Scholar] [CrossRef]

- Liu, S.Y.; Yang, G.; Zheng, J.Q.; Liu, X.H. Numerical and experimental studies on grind-hardening cylindrical surface. Int. J. Adv. Manuf. Technol. 2015, 76, 487–499. [Google Scholar]

- Wang, Y.S.; Xiu, S.C.; Dong, L.; Sun, C. Study on strengthened layer of workpiece in prestress dry grinding. Int. J. Adv. Manuf. Technol. 2017, 90, 1225–1233. [Google Scholar]

- Brockhoff, T. Grind-hardening: A comprehensive view. CIRP Ann. Manuf. Technol. 1999, 48, 255–260. [Google Scholar] [CrossRef]

- Zarudi, I.; Zhang, L.C. Mechanical property improvement of quenchable steel by grinding. J. Mater. Sci. 2002, 37, 3935–3943. [Google Scholar] [CrossRef]

- Alonso, U.; Ortega, N.; Sanchez, J.A.; Pombo, I.; Plaza, S.; Izquierdo, B. In-process prediction of the hardened layer in cylindrical traverse grind-hardening. Int. J. Adv. Manuf. Technol. 2014, 71, 101–108. [Google Scholar] [CrossRef]

- Sölter, J.; Eckebrecht, J.; Kolkwitz, B.; Heinzel, C. Analysis of the distortion and compensation potential in grind-hardening of linear guides. Materialwiss. Werkstofftech. 2016, 47, 726–734. [Google Scholar] [CrossRef]

- Fazli Shahri, H.R.; Akbari, A.A.; Mahdavinejad, R.; Solati, A. Surface hardness improvement in surface grinding process using combined Taguchi method and regression analysis. J. Adv. Mech. Des. Syst. Manuf. 2018, 12, 1–14. [Google Scholar] [CrossRef]

- Shi, X.L.; Zhang, X.M.; Xiu, S.C. A research on the mechanism and model of surface micro-damage in grinding hardening. Adv. Mech. Eng. 2021, 13, 1–14. [Google Scholar] [CrossRef]

- Shi, X.L.; Xiu, S.C.; Liu, X. Experiment study on the corrosion resistance of the surface metamorphic layer of grinding. Sci. Rep. 2021, 11, 23926. [Google Scholar] [CrossRef]

- Foeckerer, T.; Zaeh, M.F.; Zhang, O.B. A three-dimensional analytical model to predict the thermo-metallurgical effects within the surface layer during grinding and grind-hardening. Int. J. Heat Mass Transf. 2013, 56, 223–237. [Google Scholar] [CrossRef]

- Nguyen, T.; Liu, M.; Zhang, L.C.; Wu, Q.; Sun, D.L. An Investigation of the Grinding-Hardening Induced by Traverse Cylindrical Grinding. J. Manuf. Sci. Eng.-Trans. ASME 2014, 136, 051008. [Google Scholar] [CrossRef]

- Zhang, Y.; Ge, P.Q.; Be, W.B. Plane grind-hardening distortion analysis and the effect to grind-hardening layer. Int. J. Adv. Manuf. Technol. 2015, 78, 431–438. [Google Scholar] [CrossRef]

- Xiu, S.C.; Sun, C.; Duan, J.C.; Lan, D.X.; Li, Q.L. Study on the surface topography in consideration of the dynamic grinding hardening process. Int. J. Adv. Manuf. Technol. 2019, 100, 209–233. [Google Scholar] [CrossRef]

- Gao, S.X.; Liu, J.D.; Huang, S.W.; Lin, R.C. Effects of Heat Generated during Grind Hardening on Hardness and Microstructure of Alloy Metal: Optimal Process to Improve Efficiency. Sens. Mater. 2020, 32, 3383–3397. [Google Scholar] [CrossRef]

- Lerra, F.; Ascari, A.; Fortunato, A. Hardness Penetration Depth Prediction in the Grind-Hardening Process through a Combined FEM model. Procedia CIRP 2022, 108, 194–198. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, M.H.; Yin, M.A.; Yan, Y.T. Modeling of the Evolution of the Microstructure and the Hardness Penetration Depth for a Hypoeutectoid Steel Processed by Grind-Hardening. Metals 2020, 10, 1182. [Google Scholar] [CrossRef]

- Reichelt, M.; Cappella, B. Large scale multi-parameter analysis of wear of self-mated 100Cr6 steel-A study of the validity of Archard’s law. Tribol. Int. 2021, 159, 106945. [Google Scholar] [CrossRef]

- Zheng, M.L.; Wang, B.; Zhang, W.; Cui, Y.Z.; Zhang, L.; Zhao, S.H. Analysis and prediction of surface wear resistance of ball-end milling topography. Surf. Topogr. Metrol. Prop. 2020, 8, 025032. [Google Scholar] [CrossRef]

- Feyzi, M.; Fallahnezhad, K.; Taylor, M.; Hashemi, R. A review on the finite element simulation of fretting wear and corrosion in the taper junction of hip replacement implants. Comput. Biol. Med. 2021, 130, 104196. [Google Scholar] [CrossRef]

- Lu, C.; Jin, J.B.; Mo, J.L.; Wang, J.Y. Accumulated wear degradation prediction of railway friction block considering the evolution of contact status. Wear 2022, 494–495, 204251. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

|---|---|---|---|---|---|---|---|---|

| 0.45 | 0.25 | 0.56 | 0.02 | 0.01 | 0.02 | 0.01 | 0.02 | 0.01 |

| No. | Grinding Parameters | Friction Condition | |||||

|---|---|---|---|---|---|---|---|

| Grinding Depth ap (mm) | Feed Speed vw (m/s) | Location | Load FN (N) | Frequency f (Hz) | Sliding Distance (mm) | Time t (min) | |

| 1 | 0.10 | 0.020 | A—3 mm B—15 mm C—32 mm | 50 | 3.0 | 10 | 15 |

| 2 | 0.15 | ||||||

| 3 | 0.20 | ||||||

| 4 | 0.25 | ||||||

| 5 | 0.30 | ||||||

| No. | Location A | Location B | Location C | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Simulated/μm | Experimental/μm | Error | Simulated/μm | Experimental/μm | Error | Simulated/μm | Experimental/μm | Error | |

| 1 | 22.49 | 24.28 | 7.3% | 9.93 | 10.86 | 8.6% | 8.43 | 9.03 | 6.6% |

| 2 | 21.58 | 22.76 | 5.5% | 7.67 | 8.50 | 9.8% | 6.31 | 7.01 | 10.0% |

| 3 | 9.04 | 9.67 | 6.5% | 7.41 | 8.36 | 11.3% | 5.12 | 5.31 | 3.6% |

| 4 | 8.84 | 9.65 | 8.4% | 7.34 | 8.02 | 8.4% | 4.17 | 4.42 | 5.7% |

| 5 | 6.39 | 6.85 | 6.7% | 6.15 | 6.67 | 7.8% | 3.98 | 4.17 | 4.6% |

| No. | K × 10−8 | ||

|---|---|---|---|

| Location A | Location B | Location C | |

| 1 | 9.639 | 0.832 | 0.815 |

| 2 | 9.142 | 0.800 | 0.526 |

| 3 | 0.741 | 0.679 | 0.491 |

| 4 | 0.680 | 0.630 | 0.487 |

| 5 | 0.676 | 0.526 | 0.472 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Liu, M.; Zhang, Y. The Influence Mechanism of the Hardness Homogeneity of the Grind-Hardening Layer on Its Wear Resistance. Coatings 2025, 15, 1196. https://doi.org/10.3390/coatings15101196

Guo Y, Liu M, Zhang Y. The Influence Mechanism of the Hardness Homogeneity of the Grind-Hardening Layer on Its Wear Resistance. Coatings. 2025; 15(10):1196. https://doi.org/10.3390/coatings15101196

Chicago/Turabian StyleGuo, Yu, Minghe Liu, and Yiming Zhang. 2025. "The Influence Mechanism of the Hardness Homogeneity of the Grind-Hardening Layer on Its Wear Resistance" Coatings 15, no. 10: 1196. https://doi.org/10.3390/coatings15101196

APA StyleGuo, Y., Liu, M., & Zhang, Y. (2025). The Influence Mechanism of the Hardness Homogeneity of the Grind-Hardening Layer on Its Wear Resistance. Coatings, 15(10), 1196. https://doi.org/10.3390/coatings15101196