Research on Aging Characteristics and Interfacial Adhesion Performance of Polyurethane-Modified Asphalt

Abstract

1. Introduction

2. Materials and Test Methods

2.1. Materials and Preparation Process

2.2. Degradation Testing

2.3. Testing and Characterization

3. Molecular Dynamics Simulation

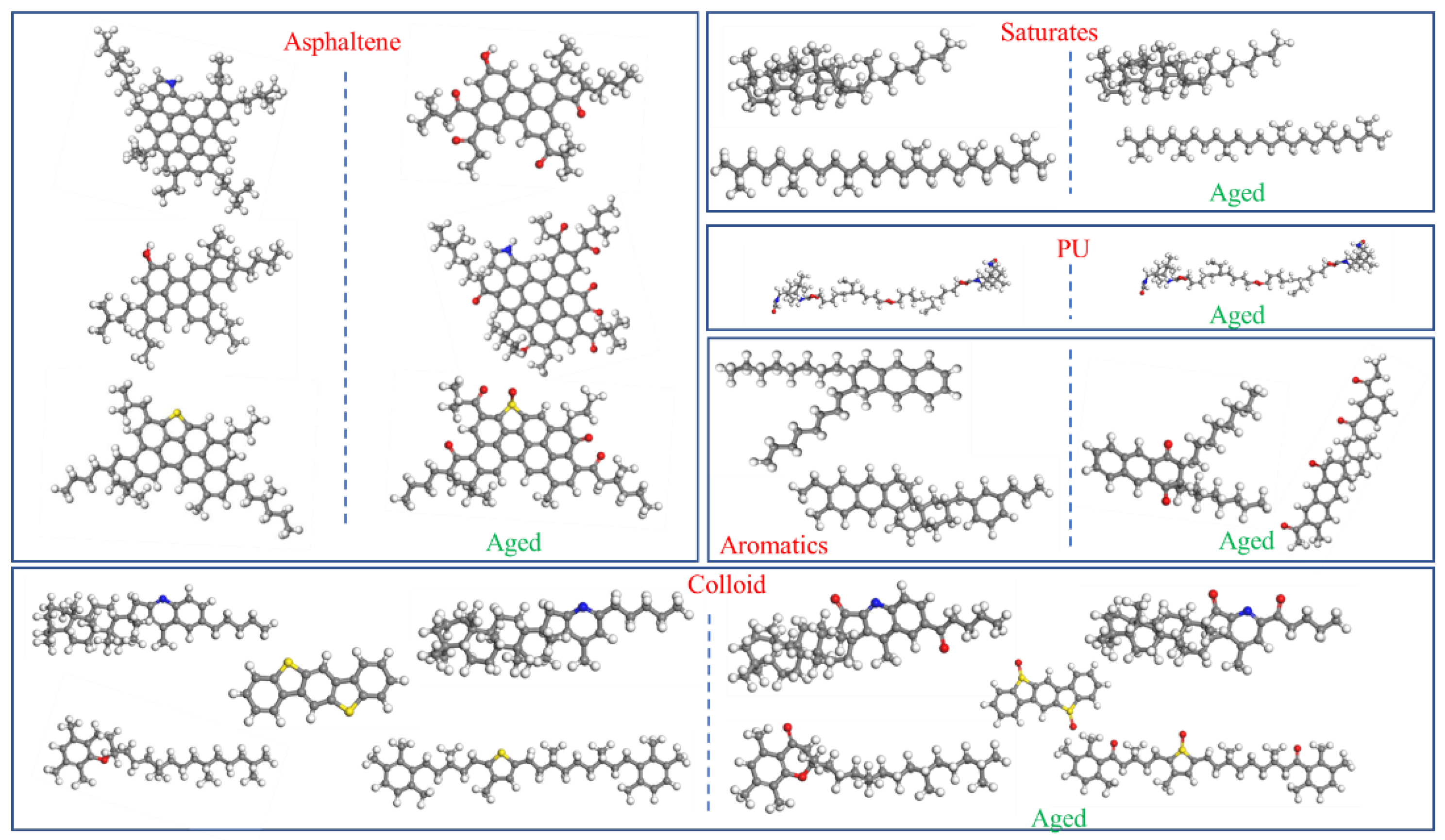

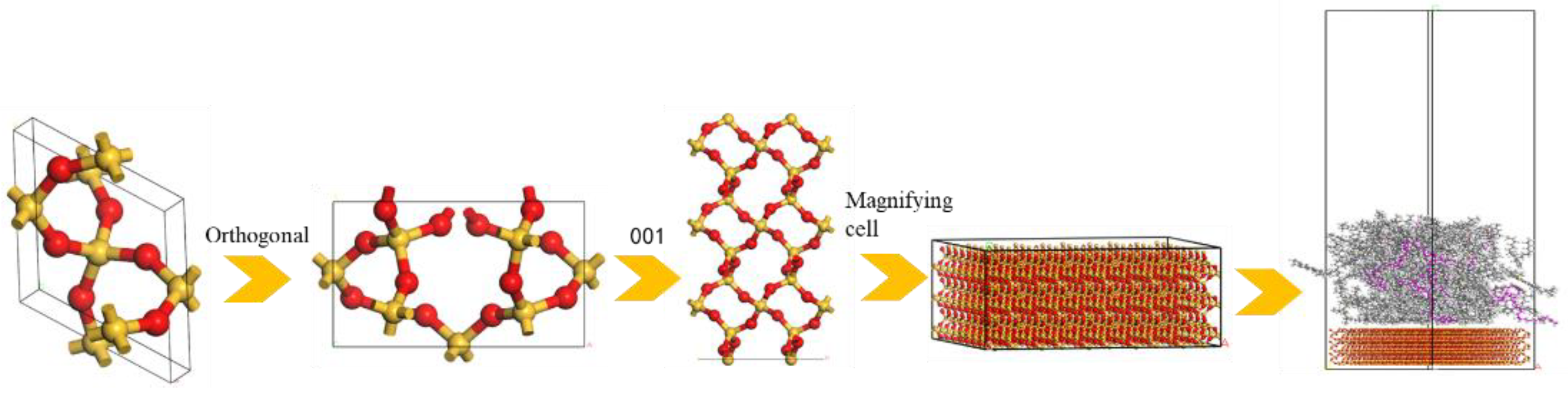

3.1. Molecular Model Construction

3.2. Analysis Method

3.2.1. Radial Distribution Function

3.2.2. Fractional Free Volume

3.2.3. Mechanical Property

3.2.4. Interface Adhesion Properties

4. Results and Discussions

4.1. Evaluation of Rheological Properties

4.1.1. Analysis of High Temperature Anti-Rutting Performance

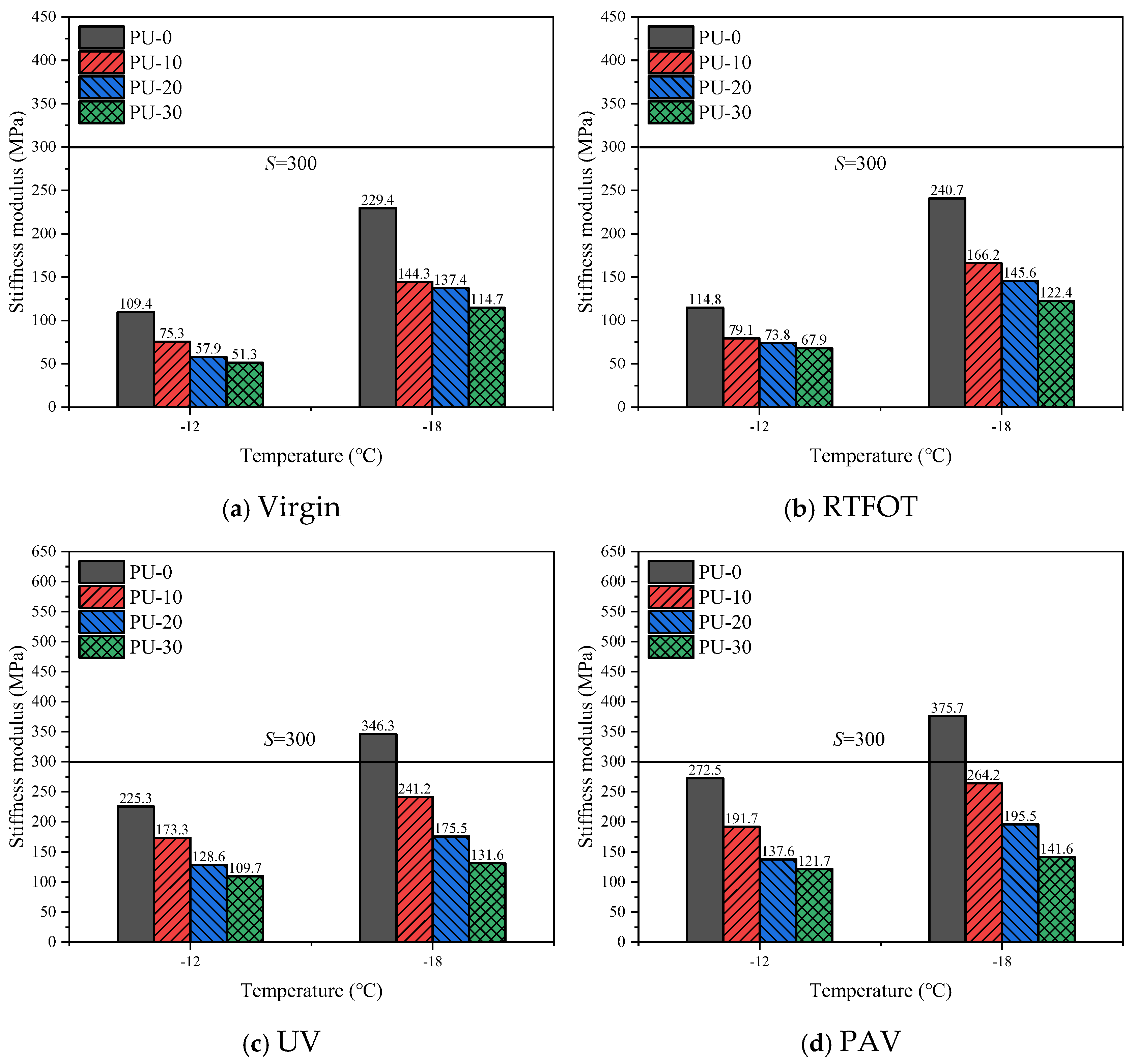

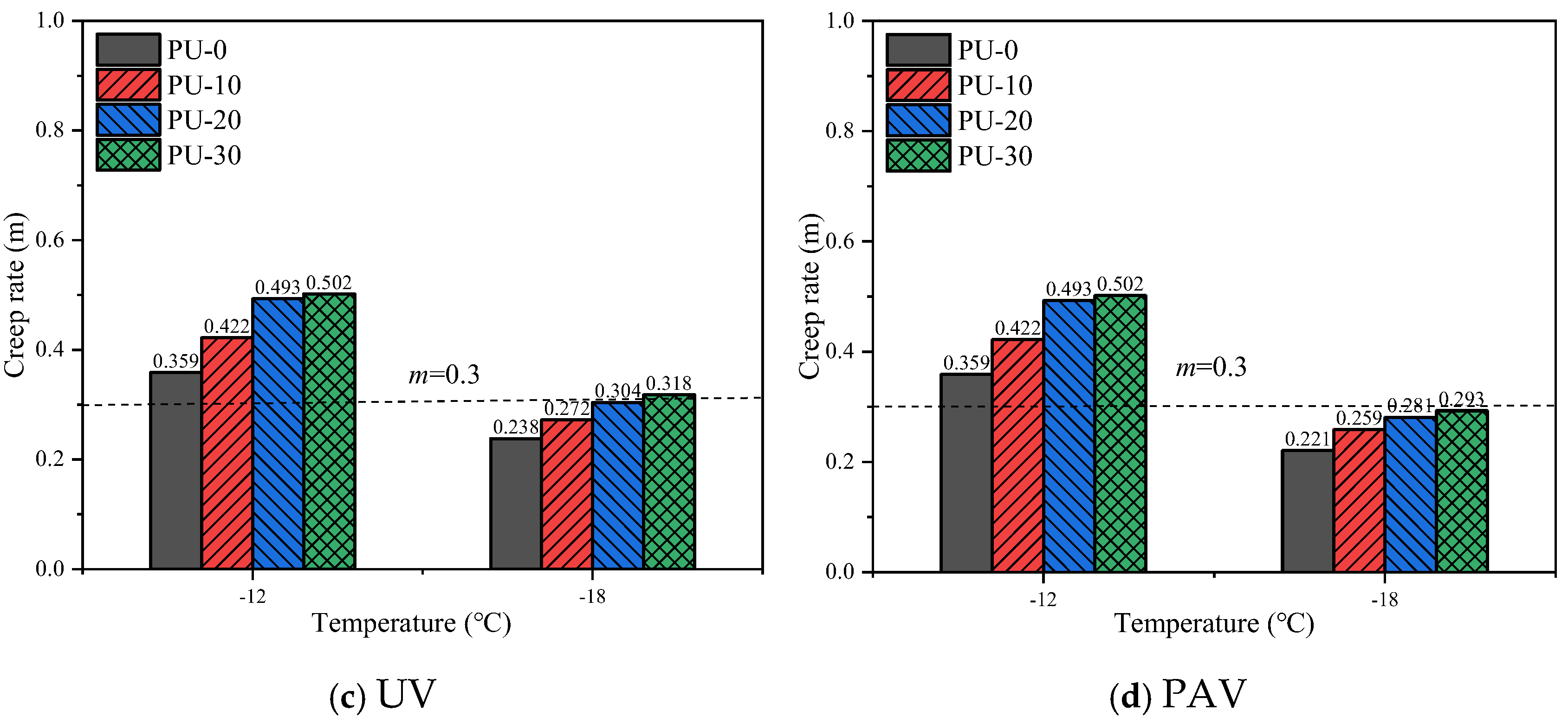

4.1.2. Analysis of Low Temperature Rheological Properties

4.2. Analysis of Molecular Dynamics Results

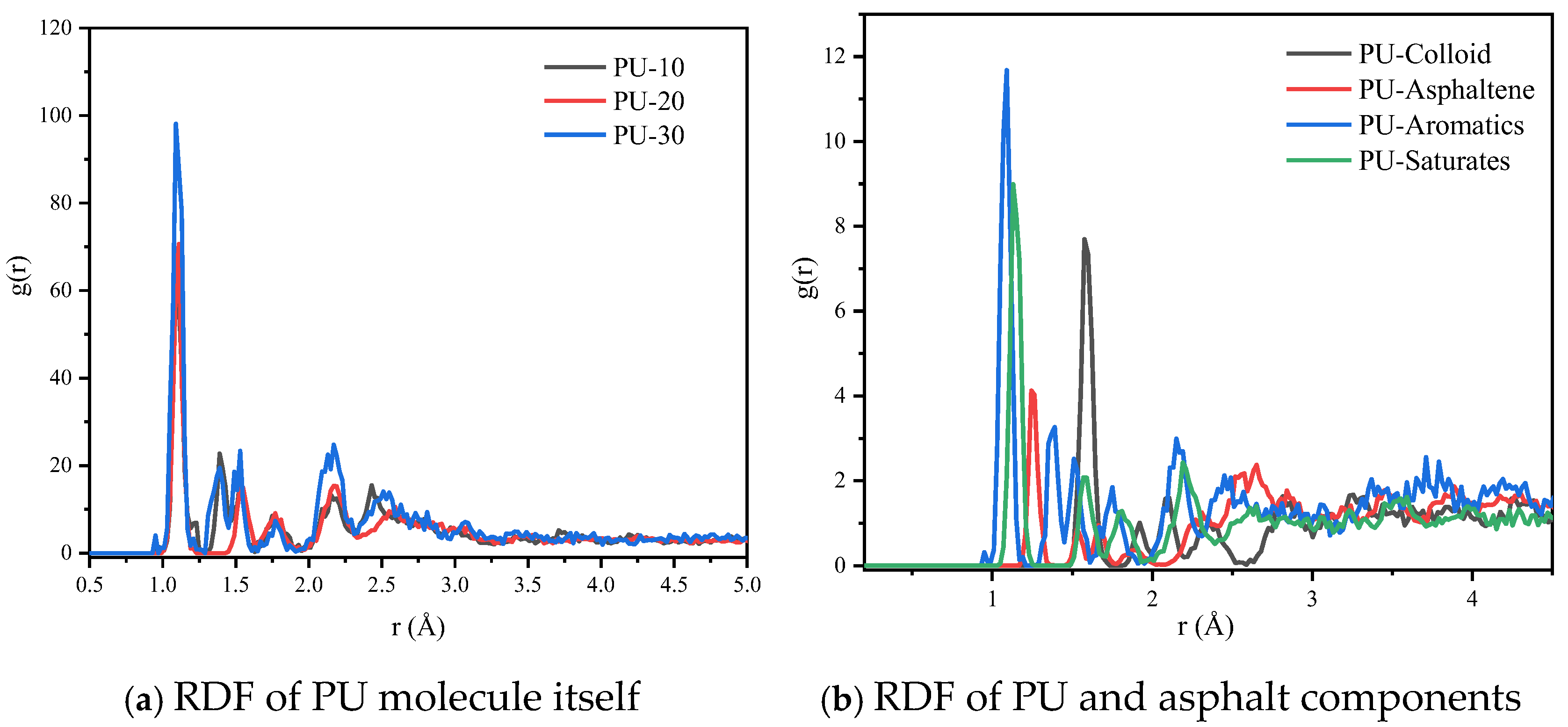

4.2.1. RDF Analysis

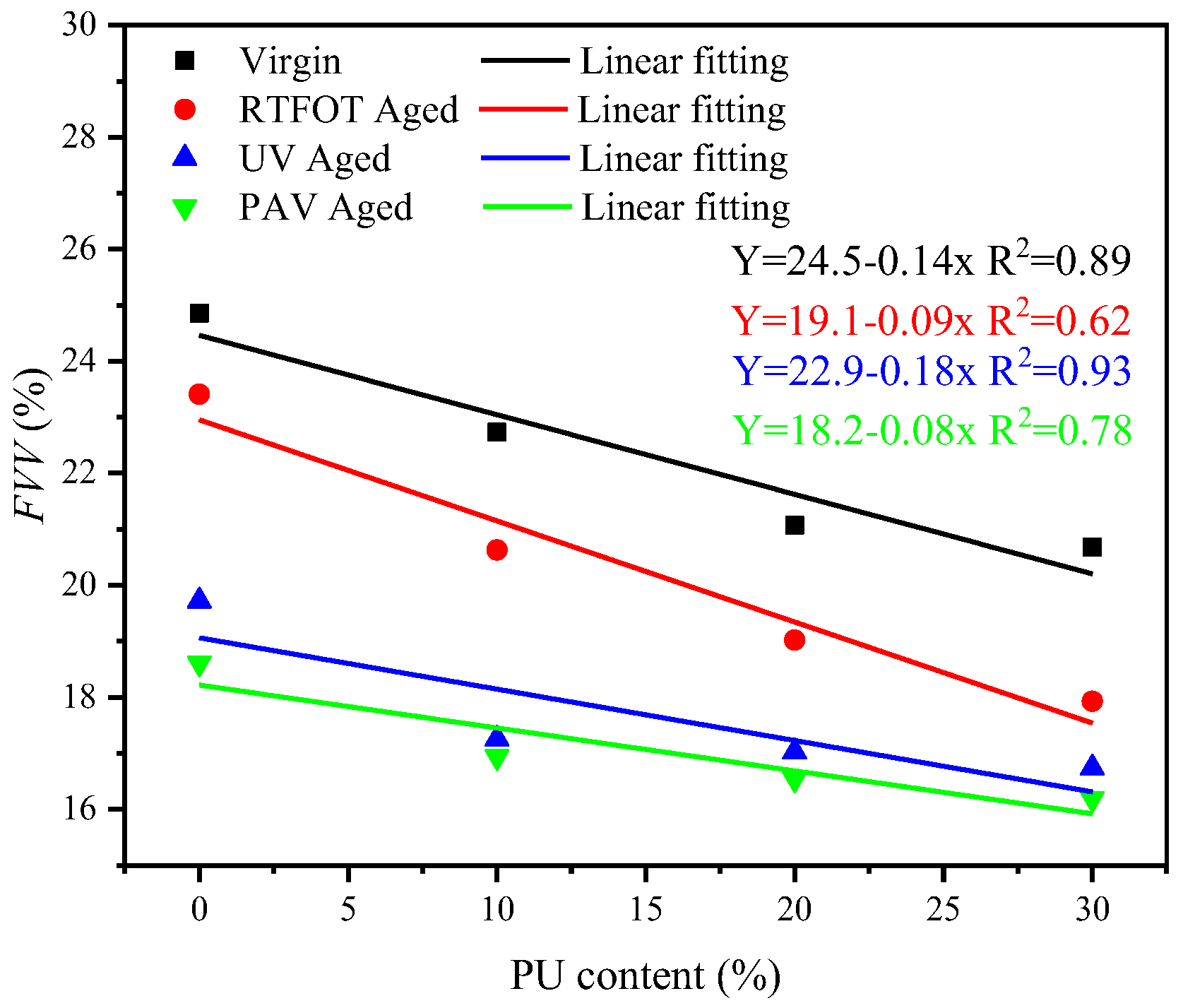

4.2.2. Fractional Free Volume

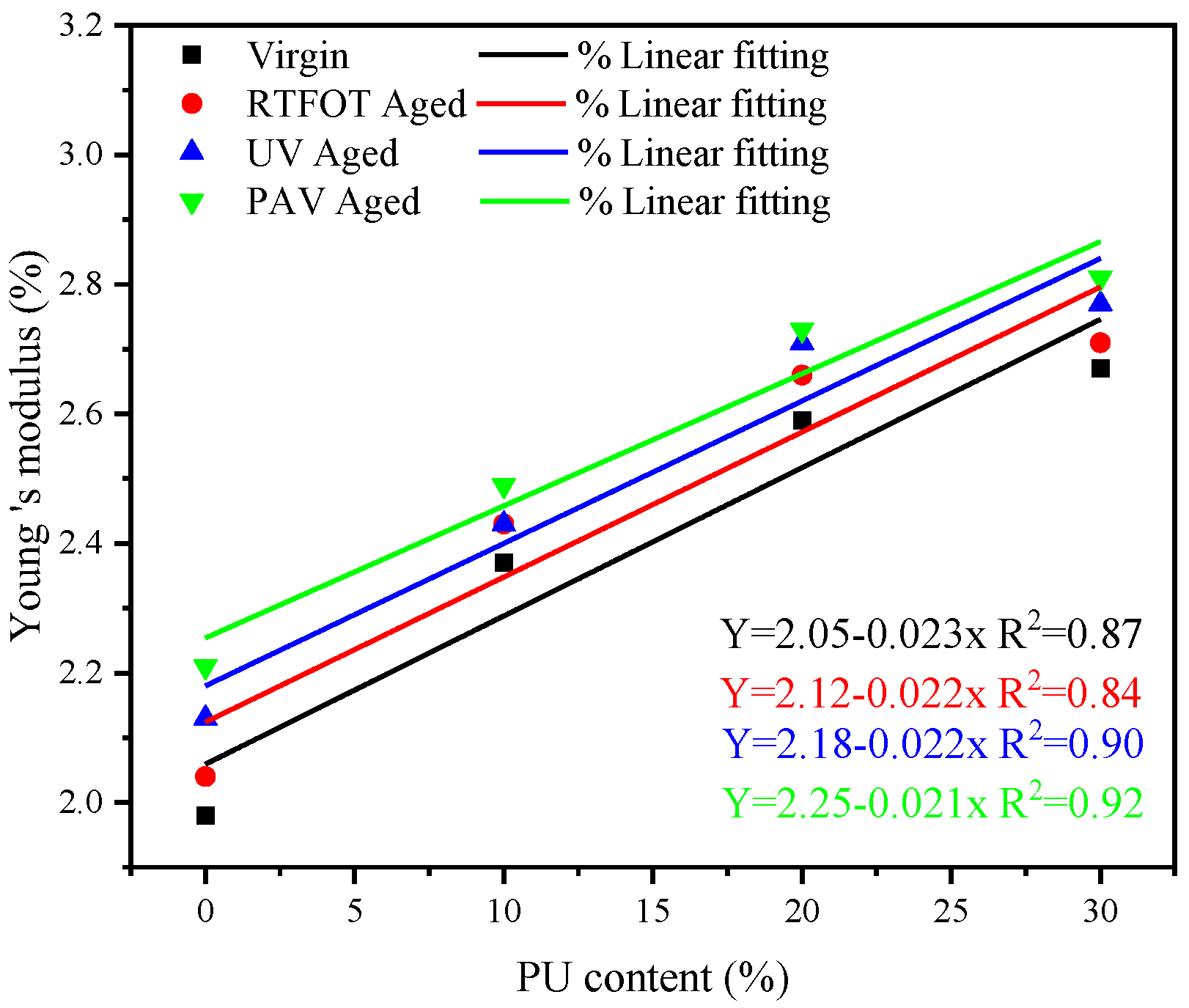

4.2.3. Mechanical Property

4.3. Interface Adhesion Properties

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PU | Polyurethane |

| JTG | Chinese Highway Engineering Standard (Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering) |

| RTFOT | Rolling Thin Film Oven Test |

| UV | Ultraviolet |

| PAV | Pressure Aging Vessel |

| MD | Molecular Dynamics |

| DSR | Dynamic Shear Rheometer |

| BBR | Bending Beam Rheometer |

| HTPB | Hydroxyl-terminated polybutadiene |

| IPDI | Isophorone diisocyanate |

| BDO | 1,4-Butanediol |

References

- Liu, F.; Hu, Z.; Wang, B.; Zhang, C.; Huang, L.; Wang, H.; Zhu, Y.; Lu, F. Molecular dynamics and experimental investigation on the mechanism and properties of nano-silica/graphene composite-modified asphalt. Constr. Build. Mater. 2025, 493, 143309. [Google Scholar] [CrossRef]

- Xiong, L.; Liu, K.; Kadhim, H.A.; Niu, D.; Gao, Y.; Liu, X. Comparative analysis of the fatigue characterisation of natural rock asphalt/SBS composite modified asphalt binders using time sweep test and linear amplitude sweep test. Constr. Build. Mater. 2025, 494, 143315. [Google Scholar] [CrossRef]

- Demchuk, Y.; Gunka, V.; Sidun, I.; Korchak, B.; Donchenko, M.; Drapak, I.; Poliuzhyn, I.; Pyshyev, S. Study of Road Bitumen Operational Properties Modified with Phenol–Cresol–Formaldehyde Resin. Resources 2025, 14, 91. [Google Scholar] [CrossRef]

- Guo, M.; Xie, X.; Gou, J.; Sun, Y.; Zhu, Y.; Du, X. Heterogeneous diffusion between recycled crumb rubber modified asphalt and virgin asphalt binders: Rheological methods and microstructure characterization. Constr. Build. Mater. 2025, 494, 143392. [Google Scholar] [CrossRef]

- Jin, X.; Li, D.; Gong, M.; Jiao, B.; Sun, B.; Yang, Y.; Yang, Y.; Zhang, J. Study on the intrinsic mechanism and adhesion performance mapping of block copolymer modified polyurethane prepolymer (M-PPU) modified asphalt. Constr. Build. Mater. 2025, 494, 143368. [Google Scholar] [CrossRef]

- Wu, W.; Huang, M.; Li, C.; Chen, B.; Li, Z. Effect of waste cooking oil on ethylene vinyl acetate modified asphalt based on multiscale study. Constr. Build. Mater. 2025, 492, 142689. [Google Scholar] [CrossRef]

- Ban, X.; Ji, J.; You, Z.; Fang, Y.; Zhang, Z.; Luo, Y.; Shi, E.; Li, J.; Liu, T. Synthesis of castor oil-based polyurethane (PU) containing different disulfide contents and self-healing properties of the PU modified asphalt. Constr. Build. Mater. 2025, 491, 142658. [Google Scholar] [CrossRef]

- Cao, Z.; Hao, Q.; Xu, S.; Han, X.; Yi, J.; Sun, G. Preparation and performance evaluation of bio–based polyurethane modified asphalt binders: Towards greener and more sustainable asphalt modifier. Constr. Build. Mater. 2025, 476, 141209. [Google Scholar] [CrossRef]

- Xia, W.; Xu, Z.; Xu, T. Self-healing behaviors and its effectiveness evaluations of fiber reinforced shape memory polyurethane/SBS modified asphalt mortar. Case Stud. Constr. Mater. 2023, 18, e01784. [Google Scholar] [CrossRef]

- Huang, G.; Yang, T.; He, Z.; Yu, L.; Xiao, H. Polyurethane as a modifier for road asphalt: A literature review. Constr. Build. Mater. 2022, 356, 129058. [Google Scholar] [CrossRef]

- Min, Z.; Chen, W.; Yang, H.; Qing, Y.; Chen, F.; Huang, W. Optimization of preparation process and pavement performance evaluation of polyurethane-modified epoxy asphalt mixtures. Constr. Build. Mater. 2025, 486, 141881. [Google Scholar] [CrossRef]

- Lu, J.; Xu, S.; Li, C.; Fu, C.; Gao, M.; Wang, Z.; Yang, F.; Zhou, G.; Li, R.; Ling, T. The latest research progress of polyurethane modified asphalt binder: Synthesis, characterization, and applications. Int. J. Adhes. Adhes. 2025, 140, 104035. [Google Scholar] [CrossRef]

- Motamedi, M.; Shafabakhsh, G.; Azadi, M. Evaluation of fatigue and rutting properties of asphalt binder and mastic modified by synthesized polyurethane. J. Traffic Transp. Eng. (Engl. Ed.) 2021, 8, 1036–1048. [Google Scholar] [CrossRef]

- Gao, J.; Guo, G.; Wang, H.; Xu, N.; Jin, D. Multiscale characterization of bio-based polyurethane modified asphalt: Macro-micro experiments and molecular dynamics simulations. Constr. Build. Mater. 2025, 491, 142699. [Google Scholar] [CrossRef]

- Zhang, M.; Xiong, K.; Zhang, J.; Li, Y.; He, Y.; Pei, J. Evaluation of the rheological properties and aging resistance of asphalt modified by MDI/TDI polyurethane. Constr. Build. Mater. 2024, 411, 134350. [Google Scholar] [CrossRef]

- Jin, X.; Guo, N.; You, Z.; Wang, L.; Wen, Y.; Tan, Y. Rheological properties and micro-characteristics of polyurethane composite modified asphalt. Constr. Build. Mater. 2020, 234, 117395. [Google Scholar] [CrossRef]

- Wang, H.; Tang, N.; Zhang, R. Preparation and property controllability of dynamically crosslinked polyurethane modified bitumen. Constr. Build. Mater. 2025, 491, 142700. [Google Scholar] [CrossRef]

- Long, K.; Huang, C.; Yang, Y.; Qu, C.; Huang, H.; Ai, C.; Yan, C. Investigation of the rheological properties and aging performance of rock asphalt/thermoplastic polyurethane composite modified asphalt. Constr. Build. Mater. 2025, 458, 139699. [Google Scholar] [CrossRef]

- Li, K.; Yan, X.; Wang, Y.; Zhang, Y.; Ai, T.; Yu, L.; You, Q.; Chen, Y. Experimental analysis and molecular dynamics simulation of anti-aging performance of weather-resistant polyurethane-modified asphalt. Constr. Build. Mater. 2025, 458, 139653. [Google Scholar] [CrossRef]

- Jin, X.; Li, D.; Fu, H.; Sun, B.; Yang, Y.; Guo, N.; Zhang, J. Research on fatigue self-healing of asphalts modified by thermoplastic polyurethane (TPU) with different soft segments. Constr. Build. Mater. 2024, 420, 135574. [Google Scholar] [CrossRef]

- Kong, L.; Wang, Z.; Su, S.; Yue, J.; Luo, W.; Zhou, S.; Ren, D.; Ai, C. Exploring the interplay between thermo-oxidative degradation and asphalt aging in thermoplastic polyurethane-modified asphalt: Mechanisms, properties, and performance evolution. Constr. Build. Mater. 2024, 412, 134694. [Google Scholar] [CrossRef]

- Wang, S.; Wei, K.; Yu, J.; Zhao, C.; Jiang, J. Polyurethane/aggregate interfacial adhesion characteristics and thin layer covering performance research. J. Clean. Prod. 2025, 519, 145980. [Google Scholar] [CrossRef]

- Shi, W.; Wei, K.; Guo, X.; Ni, T.; Tian, J. Study on the interfacial adhesion performance of polyurethane-modified asphalt based on molecular dynamics simulation. Appl. Surf. Sci. 2025, 685, 162041. [Google Scholar] [CrossRef]

- Cong, P.; Liu, C.; Han, Z.; Zhao, Y. A comprehensive review on polyurethane modified asphalt: Mechanism, characterization and prospect. J. Road Eng. 2023, 3, 315–335. [Google Scholar] [CrossRef]

- Yang, F.; Gong, H.; Cong, L.; Shi, J.; Guo, G.; Mei, Z. Investigating on polymerization process and interaction mechanism of thermosetting polyurethane modified asphalt. Constr. Build. Mater. 2022, 335, 127261. [Google Scholar] [CrossRef]

- Yu, R.; Wang, Q.; Wang, W.; Xiao, Y.; Wang, Z.; Zhou, X.; Zhang, X.; Zhu, X.; Fang, C. Polyurethane/graphene oxide nanocomposite and its modified asphalt binder: Preparation, properties and molecular dynamics simulation. Mater. Des. 2021, 209, 109994. [Google Scholar] [CrossRef]

- Huang, T.; Zhang, Z.; Wang, L.; Sun, J.; Wang, Z.; Liu, H.; Chen, L. Study on the compatibility between polyurethane and asphalt based on experiment and molecular dynamics simulation. Case Stud. Constr. Mater. 2022, 17, e01424. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, X.; Wang, Z.; Zhang, S.; Wang, Y.; Liu, H.; Kan, S.; Ji, J.; Shi, E. MDI-PTMG-based TPU modified asphalt: Preparation, rheological properties and molecular dynamics simulation. Fuel 2025, 379, 133007. [Google Scholar] [CrossRef]

- JTGE20-2011; Standard TestMethods of Bitumen and Bituminous Mixtures for Highway Engineering. Communication Press, Ministry of Transport of the People‘s Republic of China: Beijing, China, 2011.

- Li, H.; Ren, J.; Zuo, X.; Han, Y.; Sun, Y.; Zou, Z. Preparation and properties of hydroxy-terminated polybutadiene polyurethane-modified asphalt. Constr. Build. Mater. 2024, 453, 138580. [Google Scholar] [CrossRef]

- Wang, J.; Hong, B.; Wang, D.; Liu, W.; Tan, S.; Lin, J.; Li, T. Performance and modification mechanism investigation of polyurethane prepolymer system modified bitumen for 100 % reclaimed asphalt pavement (RAP) application. Constr. Build. Mater. 2025, 462, 139882. [Google Scholar] [CrossRef]

- Li, D.D.; Greenfield, M.L. Chemical compositions of improved model asphalt systems for molecular simulations. Fuel 2014, 115, 347–356. [Google Scholar] [CrossRef]

- Ge, J.; Yu, H.; Qian, G.; Dai, W.; Zhang, C.; Zhong, Y.; Zhu, X.; Zhou, H.; Nian, T. Evaluation on the diffusion-fusion properties and interfacial mechanical behavior of virgin and aged asphalt. J. Clean. Prod. 2024, 477, 143788. [Google Scholar] [CrossRef]

- Yu, H.; Ge, J.; Qian, G.; Zhang, C.; Dai, W.; Li, P. Evaluation on the rejuvenation and diffusion characteristics of waste cooking oil on aged SBS asphalt based on molecular dynamics method. J. Clean. Prod. 2023, 406, 136998. [Google Scholar] [CrossRef]

- Ge, J.; Yu, H.; Qian, G.; Dai, W.; Zhang, C.; Shi, C.; Zhou, H.; Nian, T.; Zhong, Y. Enhancement mechanism of aggregate surface roughness structure on interfacial properties of asphalt mixtures. Constr. Build. Mater. 2024, 449, 138388. [Google Scholar] [CrossRef]

- Yu, H.; Ge, J.; Qian, G.; Shi, C.; Zhang, C.; Dai, W.; Xie, T.; Nian, T. Evaluation of the interface adhesion mechanism between SBS asphalt and aggregates under UV aging through molecular dynamics. Constr. Build. Mater. 2023, 409, 133995. [Google Scholar] [CrossRef]

| Technology Index | Technical Requirement | Detect Method | Test Value |

|---|---|---|---|

| Needle penetration (30 °C)/(0.1 mm) | 60~80 | T0604 | 71 |

| Ductility (10 °C)/cm | ≥20 | T0605 | 79.4 |

| Softening point/°C | ≥46 | T0606 | 47.3 |

| Density (15 °C)/(g/cm3) | - | T0603 | 1.006 |

| Dynamic viscosity (60 °C)/(Pa·s) | 180~240 | T0620 | 213 |

| Type Asphalt | Mass Ratio | |||

|---|---|---|---|---|

| Asphaltene | Saturates | Aromatics | Colloid | |

| Virgin | 14.61% | 16.14% | 41.97% | 27.28% |

| RTFOT aged | 16.27% | 11.55% | 43.53% | 28.65% |

| UV aged | 23.69% | 10.59% | 34.38% | 31.34% |

| PAV aged | 24.99% | 11.54% | 30.54% | 32.93% |

| Component | Molecule | Virgin | RTFOT | UV | PAV | ||||

|---|---|---|---|---|---|---|---|---|---|

| Numbers | Ratio% | Numbers | Ratio% | Numbers | Ratio% | Numbers | Ratio% | ||

| Asphaltene | Asp-1 | 3 | 14.03 | 3 | 16.19 | 3 | 23.43 | 4 | 25.11 |

| Asp-2 | 2 | 2 | 4 | 6 | |||||

| Asp-3 | 3 | 4 | 5 | 5 | |||||

| Saturates | Hopane | 9 | 16.12 | 6 | 11.61 | 6 | 10.66 | 8 | 11.29 |

| Squalene | 5 | 5 | 5 | 4 | |||||

| Aromatic | PHPN | 18 | 42.17 | 18 | 43.85 | 15 | 34.18 | 14 | 30.72 |

| DOCHN | 21 | 22 | 19 | 18 | |||||

| Colloid | Colloid-1 | 3 | 27.68 | 4 | 28.36 | 5 | 31.73 | 5 | 32.87 |

| Colloid-2 | 18 | 16 | 16 | 19 | |||||

| Colloid-3 | 1 | 2 | 3 | 4 | |||||

| Colloid-4 | 2 | 3 | 4 | 4 | |||||

| Colloid-5 | 2 | 2 | 4 | 5 | |||||

| Modifier | PU | 0/2/4/6 | —— | 0/2/4/6 | —— | 0/2/4/6 | —— | 0/2/4/6 | —— |

| Type | FFV (%) | |||

|---|---|---|---|---|

| Virgin | RTFOT Aged | UV Aged | PAV Aged | |

| PU-0 | 24.86 | 23.41 | 19.72 | 18.61 |

| PU-10 | 22.73 | 20.63 | 17.26 | 16.94 |

| PU-20 | 21.07 | 19.02 | 17.03 | 16.54 |

| PU-30 | 20.68 | 17.93 | 16.74 | 16.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Li, J.; Chen, L.; Shi, C.; Ge, J. Research on Aging Characteristics and Interfacial Adhesion Performance of Polyurethane-Modified Asphalt. Coatings 2025, 15, 1194. https://doi.org/10.3390/coatings15101194

Wang M, Li J, Chen L, Shi C, Ge J. Research on Aging Characteristics and Interfacial Adhesion Performance of Polyurethane-Modified Asphalt. Coatings. 2025; 15(10):1194. https://doi.org/10.3390/coatings15101194

Chicago/Turabian StyleWang, Meng, Jixian Li, Lu Chen, Changyun Shi, and Jinguo Ge. 2025. "Research on Aging Characteristics and Interfacial Adhesion Performance of Polyurethane-Modified Asphalt" Coatings 15, no. 10: 1194. https://doi.org/10.3390/coatings15101194

APA StyleWang, M., Li, J., Chen, L., Shi, C., & Ge, J. (2025). Research on Aging Characteristics and Interfacial Adhesion Performance of Polyurethane-Modified Asphalt. Coatings, 15(10), 1194. https://doi.org/10.3390/coatings15101194